Advanced UFLC-DAD Method Optimization: From Foundational Principles to Robust Validation for Pharmaceutical and Biomedical Analysis

This comprehensive article explores the systematic optimization and validation of Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) methods for pharmaceutical and biomedical applications.

Advanced UFLC-DAD Method Optimization: From Foundational Principles to Robust Validation for Pharmaceutical and Biomedical Analysis

Abstract

This comprehensive article explores the systematic optimization and validation of Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) methods for pharmaceutical and biomedical applications. Tailored for researchers, scientists, and drug development professionals, it covers foundational principles, advanced methodological approaches, practical troubleshooting strategies, and rigorous validation protocols. By integrating chemometric experimental design, modern column technologies, and green chemistry principles, we demonstrate how to develop high-throughput UFLC-DAD methods that deliver superior resolution, reduced analysis times, and enhanced sensitivity while ensuring regulatory compliance. The content addresses critical challenges in analyzing complex matrices including plant extracts, pharmaceutical formulations, and biological samples, providing practical solutions for quality control and research applications.

UFLC-DAD Fundamentals: Principles, Advantages, and Instrumentation for Modern Laboratories

Ultra-Fast Liquid Chromatography (UFLC) represents a significant advancement in liquid chromatography technology, designed to achieve rapid separations without compromising resolution, sensitivity, or accuracy. This technique utilizes reduced particle sizes in stationary phases (often sub-2-micron) and operates at higher pressures compared to conventional High-Performance Liquid Chromatography (HPLC). The core principle involves enhancing chromatographic efficiency by optimizing the relationship between linear velocity, plate height, and back pressure, as described by the Van Deemter equation. The miniaturization of stationary phase particles increases the number of theoretical plates per unit column length, thereby allowing for shorter columns and faster flow rates while maintaining separation quality. UFLC systems are particularly valuable in high-throughput environments such as pharmaceutical development, clinical research, and food safety testing, where analyzing large sample batches efficiently is paramount. When coupled with detectors like Diode Array Detection (DAD) or Mass Spectrometry (MS), UFLC provides a powerful analytical platform for quantifying complex mixtures in diverse matrices [1] [2] [3].

Theoretical Foundations of Speed and Efficiency

The speed and efficiency gains in UFLC are underpinned by fundamental chromatographic principles. The Van Deemter equation illustrates the relationship between linear velocity (flow rate) and plate height (HETP - Height Equivalent to a Theoretical Plate). With smaller stationary phase particles, the optimum linear velocity shifts to higher values, and the minimum plate height decreases. This allows UFLC to operate at faster flow rates without significant loss of efficiency, enabling rapid separations.

The key parameters governing UFLC performance include:

- Reduced Plate Height (h): h = H/dp where H is the plate height and dp is the particle diameter. Smaller particles provide lower reduced plate heights, enhancing efficiency.

- Kinetic Performance: The dependence of separation impedance on particle size and system pressure. UFLC systems utilize elevated pressures (often >400 bar) to overcome the increased backpressure associated with smaller particles.

- Resolution Equation: Rs = (√N/4) × (α-1/α) × (k2/k2+1) where N is the number of theoretical plates, α is the selectivity factor, and k is the retention factor. UFLC maintains or improves resolution through increased efficiency (N) despite shorter analysis times.

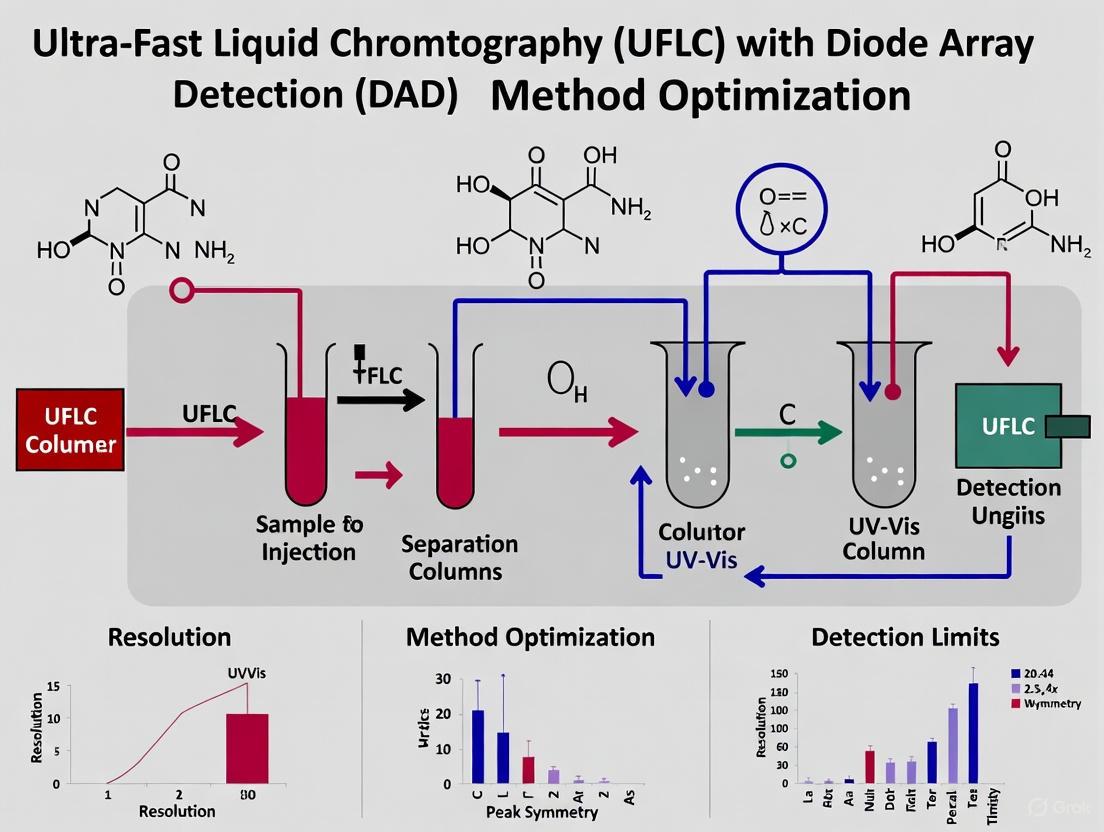

The following diagram illustrates the core principles and performance advantages of UFLC systems:

Figure 1: UFLC Performance Advantage Pathway. This diagram illustrates how core technical principles translate into practical performance benefits in Ultra-Fast Liquid Chromatography systems.

Key Methodological Advances in UFLC

Stationary Phase Innovations

UFLC methodologies leverage advanced stationary phases with optimized surface chemistry and particle morphology. The predominant use of sub-2-micron particles in C18 columns provides significantly increased surface area for analyte-stationary phase interactions, which directly enhances separation efficiency. Core-shell or fused-core particles, consisting of a solid core and porous outer layer, offer improved efficiency with lower backpressure compared to fully porous sub-2-micron particles. These particles are engineered with precise pore size distributions (typically 80-120 Ã…) to facilitate optimal analyte access and mass transfer. The chemical stability of these phases across extended pH ranges (1-12) enables method development flexibility, while specialized endcapping processes reduce secondary interactions with residual silanols, improving peak symmetry for basic compounds commonly encountered in pharmaceutical applications [1] [3].

Mobile Phase Delivery Systems

UFLC instruments incorporate advanced pumping systems capable of maintaining precise mobile phase composition at high pressures (up to 1000 bar or greater). These systems feature low-dispersion tubing and minimized delay volumes to reduce extracolumn band broadening, which is critical when using shorter columns with smaller particle sizes. Binary or quaternary high-pressure mixing systems ensure accurate gradient formation with minimal dwell volume, enabling rapid solvent switching for fast separations. The incorporation of pulse dampeners and active pump head compensation maintains flow rate accuracy below 0.1% RSD, essential for reproducible retention times in high-throughput analyses. These precision engineering features allow researchers to implement steep gradient elution programs (e.g., 5-95% organic modifier in 1-5 minutes) without compromising chromatographic performance, significantly reducing analysis times compared to conventional HPLC [2] [3].

Detection System Technologies

Modern UFLC systems integrate advanced detection technologies that maintain data acquisition rates compatible with narrow peak widths (often <1 second). Diode Array Detectors (DAD) in UFLC configurations feature reduced flow cell volumes (typically <1 μL) and high sampling rates (up to 100 Hz) to accurately capture fast-eluting peaks without sacrificing spectral resolution. The extended light path technology in some DAD cells enhances sensitivity despite the reduced volume. For mass spectrometric detection, UFLC-MS/MS systems employ low-dead-volume interfaces and rapid polarity switching capabilities (e.g., <20 ms) to maximize information content from transient chromatographic peaks. These detection advancements enable comprehensive spectral characterization even for rapidly eluting analytes, providing both quantitative data and confirmatory spectral matching within single, high-speed analyses [1] [2].

Application Protocols

Protocol 1: Quantitative Analysis of Tocopherols and Tocotrienols in Diverse Food Matrices

This protocol details a validated method for the selective quantification of tocopherol (T) and tocotrienol (T3) vitamers in plant oils, algae, fish oils, milk, and animal tissues using C18-UFLC with photodiode array (DAD) and fluorescence detection (FLD) [1].

Sample Preparation Methods

- For oils: Weigh 100 mg of oil sample precisely into a 10 mL volumetric flask. Dissolve and dilute to volume with n-hexane. Filter through a 0.45 μm PTFE syringe filter prior to injection. No saponification is required for tocopherol and tocotrienol quantification in oil matrices.

- For milk samples: Transfer 2 mL of milk to a screw-cap test tube. Add 2 mL of ethanol and 1 mL of 50% potassium hydroxide solution. Saponify at 80°C for 20 minutes with occasional shaking. Cool under running water, add 2 mL of ethanol, and extract with 3 × 5 mL of n-hexane. Combine hexane layers and evaporate under nitrogen. Reconstitute residue in 1 mL of methanol for UFLC analysis.

- For biological tissues: Homogenize 1 g of tissue with 5 mL of phosphate buffer (pH 7.4). Add 3 mL of ethanol and vortex mix. Extract with 3 × 5 mL of n-hexane. Combine organic layers and evaporate under nitrogen stream. Reconstitute in 1 mL of methanol for analysis.

- For separation of β- and γ-tocol forms: To the dried extract, add 100 μL of pyridine and 100 μL of trifluoroacetic anhydride. Heat at 60°C for 10 minutes. Evaporate under nitrogen and reconstitute in mobile phase for UFLC analysis.

Chromatographic Conditions

- Column: C18 column (150 × 4.6 mm, 2.7 μm particle size)

- Mobile Phase: Gradient of methanol:water (95:5, v/v) (A) and methylene chloride (B)

- Gradient Program: 0-5 min: 0% B; 5-10 min: 0-30% B; 10-15 min: 30-50% B; 15-20 min: 50% B; 20-25 min: 50-0% B

- Flow Rate: 1.2 mL/min

- Temperature: 25°C

- Injection Volume: 10 μL

- Detection: DAD at 278 nm and 205 nm; FLD with excitation at 290 nm and emission at 330 nm

- Run Time: 25 minutes

Method Validation Parameters

Table 1: Method validation data for tocopherol and tocotrienol analysis using C18-UFLC-DAD-FLD

| Analyte | LOD (ng/mL) | LOQ (ng/mL) | Linearity Range (ng/mL) | Precision (% RSD) | Accuracy (%) |

|---|---|---|---|---|---|

| α-Tocopherol | 4.2 | 12.8 | 20-5000 | 1.2-3.5 | 95.8-102.3 |

| α-Tocotrienol | 3.8 | 11.5 | 20-5000 | 1.5-3.8 | 96.2-101.7 |

| β-Tocopherol | 5.1 | 15.4 | 20-5000 | 2.1-4.2 | 94.7-103.2 |

| γ-Tocopherol | 4.9 | 14.8 | 20-5000 | 1.8-4.0 | 95.3-102.8 |

| δ-Tocopherol | 6.3 | 19.1 | 20-5000 | 2.3-4.7 | 93.8-104.1 |

| Cholesterol | 8.5 | 25.7 | 50-10000 | 2.8-5.2 | 92.5-105.3 |

Protocol 2: Determination of Dialkyl Phosphate Metabolites in Human Urine

This protocol describes a validated UFLC-MS/MS method for quantifying six dialkyl phosphate (DAP) metabolites as biomarkers of organophosphate pesticide exposure in human urine [3].

Sample Preparation: Liquid-Liquid Extraction

- Transfer 200 μL of urine sample to a 2 mL Eppendorf tube.

- Add 100 μL of internal standard solution and 800 μL of cold ethyl acetate.

- Vortex mix vigorously for 1 minute.

- Place the mixture on ice for 10 minutes to facilitate phase separation.

- Centrifuge at 10,000 rpm for 10 minutes at 4°C.

- Transfer the organic (upper) layer to a 10 mL glass tube.

- Repeat the extraction twice with fresh ethyl acetate and combine organic layers.

- Evaporate the combined organic extracts to dryness under a gentle nitrogen stream.

- Reconstitute the residue in 500 μL of acetonitrile.

- Transfer to an autosampler vial for UFLC-MS/MS analysis.

Chromatographic Conditions

- Column: C18 column (100 × 2.1 mm, 2.5 μm particle size)

- Mobile Phase: (A) 0.1% formic acid in water; (B) 0.1% formic acid in acetonitrile

- Gradient Program: 0-2 min: 5% B; 2-8 min: 5-95% B; 8-10 min: 95% B; 10-11 min: 95-5% B; 11-15 min: 5% B

- Flow Rate: 0.4 mL/min

- Temperature: 40°C

- Injection Volume: 5 μL

- Run Time: 15 minutes

Mass Spectrometric Parameters

- Ionization Mode: Electrospray ionization (ESI) in negative mode

- Ion Spray Voltage: -4500 V

- Source Temperature: 500°C

- Nebulizer Gas: 50 psi

- Heater Gas: 50 psi

- Curtain Gas: 25 psi

- Detection: Multiple Reaction Monitoring (MRM)

Table 2: MRM transitions and method performance for DAP metabolites

| Metabolite | Precursor Ion > Product Ion | Retention Time (min) | LOD (ng/mL) | LOQ (ng/mL) | Recovery (%) | Precision (% RSD) |

|---|---|---|---|---|---|---|

| DMP | 125.0 > 95.0 | 4.2 | 0.021 | 0.061 | 95.2 | 2.4 |

| DMTP | 141.0 > 126.9 | 5.8 | 0.035 | 0.105 | 93.8 | 3.7 |

| DMDTP | 157.0 > 142.9 | 6.5 | 0.070 | 0.211 | 96.5 | 5.5 |

| DEP | 153.0 > 125.0 | 5.1 | 0.025 | 0.075 | 98.3 | 2.9 |

| DETP | 169.0 > 141.0 | 6.2 | 0.045 | 0.135 | 94.7 | 4.2 |

| DEDTP | 185.0 > 157.0 | 7.1 | 0.055 | 0.168 | 97.1 | 4.8 |

Protocol 3: Pharmacokinetic Study of Fukeqianjin Formula in Rat Plasma

This protocol outlines a UFLC-MS/MS method for simultaneous quantification of 19 bioactive components in rat plasma for pharmacokinetic studies following oral administration of Fukeqianjin formula, a traditional Chinese medicine [2].

Sample Preparation and Chromatography

- Plasma Pretreatment: Thaw frozen plasma samples on ice. Aliquot 100 μL of plasma into a 1.5 mL microcentrifuge tube. Add 10 μL of internal standard solution (bavachin, 1 μg/mL in methanol) and 300 μL of acetonitrile for protein precipitation. Vortex mix for 3 minutes. Centrifuge at 13,000 rpm for 15 minutes at 4°C. Transfer the supernatant to a new tube and evaporate to dryness under nitrogen. Reconstitute the residue in 100 μL of mobile phase for UFLC-MS/MS analysis.

- Chromatographic Conditions: Utilize a C18 column (100 × 2.1 mm, 2.6 μm) maintained at 40°C. The mobile phase consists of 0.1% formic acid in water (A) and 0.1% formic acid in acetonitrile (B) with a gradient elution: 0-2 min: 5-20% B; 2-10 min: 20-60% B; 10-15 min: 60-95% B; 15-18 min: 95% B; 18-20 min: 95-5% B. The flow rate is 0.4 mL/min with a total run time of 20 minutes.

- Mass Spectrometric Conditions: Employ electrospray ionization in positive and negative switching mode with multiple reaction monitoring. Optimize compound-dependent parameters including declustering potential, collision energy, and collision cell exit potential for each analyte.

The following workflow diagram illustrates the complete experimental procedure for UFLC-based bioanalysis in pharmacokinetic studies:

Figure 2: UFLC Bioanalysis Workflow. This diagram outlines the comprehensive procedure for sample preparation, analysis, and data processing in UFLC-based bioanalytical applications.

Essential Research Reagent Solutions

Table 3: Key reagents and materials for UFLC method development and analysis

| Reagent/Material | Function/Application | Specification Notes |

|---|---|---|

| C18 Chromatographic Columns | Stationary phase for reverse-phase separation | Sub-2-micron or core-shell particles (1.7-2.7 μm); 80-120 Å pore size; 50-150 mm length |

| Methanol (LC-MS Grade) | Mobile phase component | Low UV absorbance; minimal evaporative residue; HPLC-grade with purity ≥99.9% |

| Acetonitrile (LC-MS Grade) | Mobile phase component | Low UV absorbance; minimal amine contaminants; suitable for MS detection |

| Formic Acid (LC-MS Grade) | Mobile phase modifier | Enhances ionization in MS; improves peak symmetry; typically used at 0.05-0.1% |

| Trifluoroacetic Anhydride | Derivatization reagent | Enhances separation of structurally similar compounds (e.g., β- and γ-tocols) |

| Ethyl Acetate (HPLC Grade) | Extraction solvent | Low UV cutoff; minimal interference peaks; high purity for sample preparation |

| Water (LC-MS Grade) | Mobile phase component | 18.2 MΩ·cm resistivity; filtered through 0.22 μm membrane |

| Reference Standards | Quantitative calibration | Certified purity ≥95%; proper storage at -20°C; prepare fresh stock solutions |

Comparative Performance Data

Table 4: Comparison of UFLC analytical performance across different applications

| Application Area | Analysis Time (Conventional HPLC) | Analysis Time (UFLC) | Speed Enhancement | Resolution Improvement | Reference |

|---|---|---|---|---|---|

| Tocopherol Analysis | 45-60 minutes | 25 minutes | 1.8-2.4× faster | Baseline separation of 8 vitamers | [1] |

| DAP Metabolites | 25-30 minutes | 15 minutes | 1.7-2.0× faster | Resolution >1.5 for all analytes | [3] |

| Herbal Medicine Components | 40-50 minutes | 20 minutes | 2.0-2.5× faster | Simultaneous detection of 19 compounds | [2] |

| Pharmaceutical Compounds | 30-40 minutes | 10-15 minutes | 2.7-4.0× faster | Improved peak symmetry | Not Shown |

Ultra-Fast Liquid Chromatography represents a paradigm shift in separation science, offering substantial improvements in analytical throughput without compromising data quality. The core principles of UFLC—including reduced particle size technology, high-pressure capability, low-dispersion fluidics, and rapid detection systems—collectively enable significant reductions in analysis time while maintaining or enhancing chromatographic performance. The application protocols presented demonstrate the versatility of UFLC-DAD and UFLC-MS/MS platforms across diverse fields including food chemistry, environmental monitoring, and pharmaceutical research. As analytical demands continue to evolve toward higher throughput and greater sensitivity, UFLC methodologies provide researchers with powerful tools to address challenging separation problems efficiently. The continued refinement of stationary phase chemistry, instrument design, and detection technology promises to further extend the capabilities and applications of ultra-fast chromatography in analytical science.

Diode Array Detection (DAD), also frequently termed Photodiode Array (PDA) detection, represents a significant technological advancement over conventional single-wavelength ultraviolet (UV) detectors in liquid chromatography. Unlike variable-wavelength UV detectors that measure absorbance at a single predetermined wavelength at a time, DAD detectors simultaneously capture absorbance data across a broad spectrum of wavelengths [4] [5]. This capability provides researchers with three-dimensional data (time, absorbance, and wavelength), enabling more confident peak identification, purity assessment, and method development, which is particularly valuable in Ultra-Fast Liquid Chromatography (UFLC) where analysis times are short and peak widths are narrow [4].

The fundamental operational principle involves passing polychromatic (white) light from a deuterium lamp through the chromatographic flow cell. After the light exits the cell, it is dispersed by a diffraction grating onto an array of typically 512 or 1024 individual photodiodes [4] [6]. Each diode corresponds to a specific wavelength, allowing the detector to record full UV spectra for every point in the chromatogram. This "reverse optics" configuration, where the light is dispersed after the flow cell, is the key differentiator from variable-wavelength detectors and enables the simultaneous multi-wavelength monitoring [5].

DAD Performance and Comparative Advantages

The primary advantage of DAD is the rich spectral information it provides for each analyte. Table 1 summarizes a direct performance comparison between DAD and single-wavelength UV detection in the quantitative analysis of synthetic cathinones, illustrating their complementary strengths [7].

Table 1: Comparison of UV and DAD Detection for Synthetic Cathinone Analysis

| Performance Parameter | Single Wavelength UV Detection | Diode Array Detection (DAD) |

|---|---|---|

| Linearity Correlation | Higher correlation coefficients | Broader linearity ranges |

| Limit of Detection | Higher | Lower |

| Repeatability | Compatible | Compatible |

| Selectivity for Co-eluting Compounds | Limited; requires full peak resolution | High; can resolve using extracted ion chromatograms (for MS) or spectral deconvolution |

| Qualitative Information | Retention time only | Retention time plus full UV spectrum for peak identity and purity assessment |

Beyond the quantitative parameters, DAD offers unparalleled qualitative capabilities. It allows for the comparison of UV spectra from a sample peak with a reference standard, providing a second dimension of identification beyond mere retention time matching [5]. This is crucial in complex matrices, such as cosmetic formulations, where it can confirm the identity of sunscreen filters like avobenzone and octyl methoxycinnamate amidst other ingredients like glucans and plant extracts [8]. Furthermore, by comparing spectra across different points of a chromatographic peak (apex vs. upslope vs. downslope), analysts can assess peak purity, a critical attribute for confirming method specificity and the absence of co-eluting impurities [6].

Experimental Protocols for DAD Method Optimization

Optimizing a UFLC-DAD method requires careful consideration of both chromatographic and detector parameters to balance sensitivity, resolution, and data quality.

Protocol 1: Optimizing DAD Settings for Enhanced Sensitivity and Specificity

This protocol is adapted from best practices for configuring detector parameters to achieve optimal signal-to-noise ratio and reliable qualitative data [6].

Materials:

- HPLC system equipped with a DAD detector (e.g., Agilent, Shimadzu, Waters)

- Analytical column suitable for the application (e.g., C18, Phenyl)

- Standard solutions of target analytes in appropriate solvent

- Mobile phase components (HPLC grade)

Procedure:

- Preliminary Spectral Acquisition: Inject a standard of the target analyte and collect a full spectrum (e.g., 200-400 nm). Examine the resulting spectrum to identify the wavelength of maximum absorption (λ_max).

- Set Acquisition Wavelength and Bandwidth:

- The acquisition wavelength is typically set at the λ_max of the analyte.

- The bandwidth is set according to the width of the spectral feature at 50% of the maximum absorbance. A narrower bandwidth (e.g., 4-8 nm) preserves spectral detail for qualitative analysis, while a wider bandwidth (e.g., 10-20 nm) can improve signal-to-noise for quantitative work [6].

- Set Reference Wavelength and Bandwidth:

- To minimize baseline drift during gradient elution, a reference wavelength is used. Determine the first wavelength on the spectrum where the absorbance falls below 1 mAU. Set the reference wavelength 60-100 nm higher than this point to ensure it is in a region where the analyte does not absorb.

- The reference bandwidth is typically set wide (e.g., 100 nm) to further reduce noise and drift effects [6].

- Optimize Spectral Resolution and Slit Width:

- The spectral bandwidth or resolution setting controls the number of diodes averaged to produce a single data point. For peak purity and identification, use a narrower setting (e.g., 1-2 nm). For maximum sensitivity, use a wider setting.

- The slit width physically controls the amount of light reaching the diodes. A width of 4 nm or 8 nm often provides a good compromise between sensitivity and spectral resolution.

- Adjust Data Acquisition Rate:

- To accurately model fast-eluting UFLC peaks, ensure the acquisition rate is sufficiently high to capture at least 20-25 data points across the narrowest peak of interest. This may require rates of 10-20 Hz or higher depending on the chromatographic system [6].

Protocol 2: Simultaneous Quantitation of Sunscreen Filters in a Complex Cosmetic Matrix

This detailed protocol demonstrates a practical application of DAD for analyzing multiple compounds in a challenging formulation, highlighting the value of spectral information for confirming identity in the presence of interferents [8].

Materials:

- Reagents: Acetonitrile (HPLC grade), Methanol (HPLC grade), Ammonium formate (analytical grade), Water (HPLC grade).

- Standards: 4-methylbenzylidene camphor (4-MBC, 99.8%), Octyl methoxycinnamate (OMC, 99.9%), Avobenzone (AVO, 99.6%).

- Equipment: UFLC system with DAD, Fortis Phenyl analytical column (150.0 × 2.1 mm, 5 μm).

- Sample: Moisturizing sunscreen cream.

Chromatographic Procedure:

- Chromatographic Conditions:

- Column: Fortis Phenyl (150.0 × 2.1 mm, 5 μm)

- Mobile Phase: Acetonitrile / 45 mM Ammonium Formate aqueous solution (57:43, v/v)

- Flow Rate: 0.4 mL/min

- Elution Mode: Isocratic

- Injection Volume: 5 μL

- DAD Acquisition: Collect data from 200-400 nm. Monitor quantitation at 225 nm for 4-MBC and AVO, and 275 nm for OMC.

- Sample Preparation:

- Accurately weigh approximately 0.5 g of the sunscreen cream.

- Transfer to a volumetric flask and add about 20 mL of methanol.

- Sonicate for 15 minutes to ensure complete extraction and dissolution.

- Dilute to volume with methanol and mix thoroughly.

- Further dilute the solution serially with the mobile phase to bring the analyte concentrations within the linear range of the method.

- Filter through a 0.45 μm nylon or PVDF syringe filter before injection.

- System Suitability and Quantitation:

- Inject system suitability standards to ensure resolution between critical pairs (e.g., OMC and AVO) is greater than 1.5 and that the relative standard deviation (RSD%) of peak areas and retention times is ≤ 2.0%.

- Construct a five-point calibration curve for each analyte.

- Inject the prepared sample and identify the analytes based on both retention time and spectral match against the reference standards.

- Calculate the concentration of each sunscreen filter in the cream using the peak area and the respective calibration curve.

The following workflow diagram illustrates the complete DAD-based analytical method:

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful implementation of UFLC-DAD methods relies on the appropriate selection of reagents and materials. Table 2 lists key solutions and their functions based on the cited protocols.

Table 2: Key Research Reagent Solutions for UFLC-DAD Analysis

| Reagent / Material | Function / Role | Example from Protocol |

|---|---|---|

| Phenyl-Bonded Analytical Column | Provides alternative selectivity to C18 phases; improves resolution of structurally similar compounds (e.g., OMC and AVO). | Fortis Phenyl (150.0 × 2.1 mm, 5 μm) [8] |

| Ammonium Formate Buffer | A volatile buffer additive used to control mobile phase pH and ionic strength, improving peak shape and reproducibility. | 45 mM aqueous solution in mobile phase [8] |

| HPLC-Grade Acetonitrile & Methanol | Primary organic modifiers for reversed-phase mobile phases; methanol is also used for sample extraction. | Used in mobile phase and sample prep [8] |

| Certified Reference Standards | High-purity compounds used for positive identification (via spectral matching) and accurate quantitation (calibration curves). | ≥ 99.6% pure 4-MBC, OMC, AVO [8] |

| Syringe Filters (0.45 μm) | Essential for removing particulate matter from samples to protect the UFLC column and detector flow cell. | Nylon or PVDF membrane [8] |

| 5-Isobutylpyrimidin-2-amine | 5-Isobutylpyrimidin-2-amine|RUO | High-purity 5-Isobutylpyrimidin-2-amine for research. Study its potential as a β-glucuronidase inhibitor. For Research Use Only. Not for human or veterinary use. |

| ChamaejasmeninC | ChamaejasmeninC, MF:C33H28O10, MW:584.6 g/mol | Chemical Reagent |

Visualization of DAD Operation and Configuration

To fully leverage DAD technology, understanding its internal operation and the impact of key settings is crucial. The following diagram illustrates the detector's "reverse optics" design and the logical flow for optimizing its parameters.

Chromatography remains a foundational technique in analytical laboratories, with Liquid Chromatography (LC) technologies evolving significantly to meet modern demands for speed, resolution, and sensitivity. Among these, High-Performance Liquid Chromatography (HPLC), Ultra-Fast Liquid Chromatography (UFLC), and Ultra-High-Performance Liquid Chromatography (UHPLC) represent key milestones in this technological evolution [9]. Understanding their comparative advantages is essential for selecting the optimal technique for specific analytical scenarios in pharmaceutical research, quality control, and method development.

This application note provides a structured comparison of HPLC, UFLC, and UHPLC technologies, focusing on their operational principles, performance characteristics, and suitability for different laboratory applications. The content is framed within broader research on UFLC-DAD method optimization, providing practical guidance for researchers and drug development professionals seeking to implement or transition between these chromatographic techniques.

Technical Comparison of Chromatographic Systems

The evolution from HPLC to UFLC and UHPLC represents significant advancements in pressure capability, particle technology, and system design [10] [9]. The following table summarizes the key technical parameters that differentiate these systems:

Table 1: Technical Specifications of HPLC, UFLC, and UHPLC Systems

| Parameter | HPLC | UFLC | UHPLC |

|---|---|---|---|

| Particle Size | 3-5 μm [11] [9] | 2-3 μm [11] | <2 μm (typically 1.7-1.8 μm) [10] [11] [9] |

| Operating Pressure | ~400 bar (≈4000-6000 psi) [10] [11] | 5000-6000 psi [11] | Up to 1200-1500 bar (≈15,000-17,400 psi) [10] [9] |

| Typical Flow Rate | ~1 mL/min [11] | ~2 mL/min [11] | ~0.6 mL/min [11] |

| Analysis Speed | Moderate [10] | Fast [11] | Very Fast [10] [9] |

| Resolution | Good [10] | Good to High | Excellent [10] [9] |

| Sensitivity | Moderate | Moderate to High | High [9] |

| Solvent Consumption | Higher | Moderate | Lower (up to 80% reduction with microbore columns) [12] |

| System Cost | Lower initial investment [10] [11] | Moderate | Higher initial investment [10] [11] |

UFLC, a proprietary technology from Shimadzu, occupies an intermediate position between traditional HPLC and UHPLC, offering faster analysis times than HPLC while operating at lower pressures than UHPLC systems [11]. The term "UPLC" is a Waters Corporation trademark often used interchangeably with UHPLC in industrial contexts [10].

Analytical Performance and Application Scenarios

Each chromatographic technique offers distinct advantages tailored to specific laboratory requirements and operational constraints.

Separation Efficiency and Resolution

The reduction in particle size from HPLC to UHPLC directly impacts separation efficiency through increased surface area for interactions between the mobile and stationary phases [10] [9]. UHPLC's sub-2-μm particles produce significantly narrower peaks and sharper separations, resulting in improved resolution and sensitivity, particularly for detecting low-concentration analytes or complex mixtures [9]. A properly designed UHPLC system can provide up to 28-33% greater peak capacity compared to modified HPLC systems attempting to operate at ultra-high pressures [12].

Application-Specific Recommendations

Table 2: Recommended Applications for Each Chromatographic Technique

| Application Scenario | Recommended Technique | Rationale |

|---|---|---|

| Routine QC Testing | HPLC [11] | Reliability, cost-effectiveness, established methods |

| High-Throughput Environments | UFLC [11] | Faster analysis while maintaining performance |

| Method Development & Complex Separations | UHPLC [11] [9] | Superior resolution for challenging analyses |

| Sample-Limited Studies | UHPLC [9] | Enhanced sensitivity with minimal sample volumes |

| Budgets with Limited Capital | HPLC [10] [11] | Lower initial investment and operating costs |

| Regulated Environments | HPLC or Application-Specific System [13] [10] | Validated methods, regulatory compliance |

Solvent Consumption and Environmental Impact

UHPLC systems offer significant reductions in solvent consumption - up to 80% compared to conventional HPLC when using microbore columns (2.1-mm I.D.) instead of analytical-scale columns (4.6-mm I.D.) [12]. This aligns with growing emphasis on "green chromatography" principles aiming to minimize environmental impact through reduced solvent usage and waste generation [14].

System Selection Workflow

The following diagram illustrates the decision-making process for selecting the appropriate chromatographic technique based on analytical requirements and operational constraints:

Experimental Protocol: UHPLC-DAD Method for Polyphenol Quantification

The following protocol adapts a validated method for the simultaneous quantification of 38 polyphenols in applewood extracts, demonstrating UHPLC capabilities in handling complex natural product matrices [15].

Materials and Reagents

Table 3: Essential Research Reagent Solutions

| Item | Specification | Function/Application |

|---|---|---|

| UHPLC System | Binary pump, DAD detector, thermostatted autosampler and column compartment | Separation and detection |

| Analytical Column | Reversed-phase C18 (100 × 2.1 mm, 1.8-1.9 μm) | Stationary phase for compound separation |

| Mobile Phase A | 0.1% formic acid in water | Aqueous component for gradient elution |

| Mobile Phase B | 0.1% formic acid in acetonitrile | Organic component for gradient elution |

| Polyphenol Standards | Reference standards (≥95% purity) | Calibration and identification |

| Internal Standard | Daidzein (Extrasynthese) | Quality control and normalization |

| Solvents | LC-MS grade water, acetonitrile, methanol | Mobile phase and sample preparation |

Sample Preparation Protocol

- Extraction: Weigh 100 mg of homogenized applewood powder and add to 10 mL of methanol-water (80:20, v/v) extraction solvent.

- Sonication: Sonicate the mixture for 30 minutes at 40°C in an ultrasonic bath.

- Centrifugation: Centrifuge at 10,000 × g for 10 minutes at 4°C.

- Filtration: Transfer supernatant and filter through a 0.22-μm PTFE membrane filter.

- Internal Standard Addition: Add daidzein internal standard (final concentration: 5 μg/mL) to the filtered extract.

- Storage: Store prepared samples at 4°C until analysis (within 24 hours).

UHPLC-DAD Instrumental Parameters

The following workflow outlines the key steps in method execution and optimization:

Method Validation Parameters

The optimized method demonstrates excellent chromatographic performance with the following validated parameters:

- Analysis Time: 21 minutes for 38 polyphenols [15]

- Linearity: R² > 0.99 for all analytes across calibration range

- Precision: Intra-day and inter-day precision < 5% RSD

- Detection Limits: Sub-μg/mL levels for most compounds

The selection between HPLC, UFLC, and UHPLC technologies involves careful consideration of analytical requirements, throughput needs, and operational constraints. HPLC remains the workhorse for routine quality control applications where reliability and cost-effectiveness are paramount. UFLC provides an intermediate solution for laboratories seeking faster analysis times without transitioning to full UHPLC capabilities. UHPLC offers superior resolution, sensitivity, and speed for method development, complex separations, and sample-limited studies.

The experimental protocol demonstrates that modern UHPLC-DAD methods can simultaneously quantify numerous analytes in complex matrices with significantly reduced analysis times compared to conventional HPLC, while maintaining robust performance characteristics suitable for research and regulatory applications.

Ultra-Fast Liquid Chromatography coupled with a Diode Array Detector (UFLC-DAD) represents a significant advancement in liquid chromatography, offering improved speed, resolution, and sensitivity over conventional HPLC. This technique is indispensable in modern analytical laboratories, particularly in pharmaceutical development where it accelerates method optimization and analytical workflows. The performance of a UFLC-DAD system hinges on the optimal integration and configuration of three core components: columns that provide the necessary chromatographic separation, pumps that deliver stable mobile phase flow at elevated pressures, and detectors that enable sensitive, multi-wavelength detection. This application note details the specifications, configuration, and operational protocols for these critical subsystems within the context of method optimization research, providing scientists with structured quantitative data and validated experimental procedures to enhance their analytical capabilities.

Core Instrumentation Components

The performance of a UFLC-DAD system is determined by the synergistic operation of its core components. Understanding their technical specifications and how they interact is fundamental to method optimization.

Columns

The column is the heart of the chromatographic separation. UFLC utilizes advanced stationary phases packed with smaller particles to achieve superior efficiency.

- Particle Technology: Fully porous sub-2 µm particles are the state-of-the-art for UFLC, providing high peak capacity and resolution [16]. As an alternative, core-shell particles (e.g., 1.5 µm) feature a solid core and a porous shell, which can provide similar efficiency to sub-2 µm fully porous particles but with a lower pressure drop [16].

- Column Hardware: To mitigate the effects of viscous heating at high pressures, the standard column internal diameter has shifted from 4.6 mm to 2.1 mm [16]. This narrower bore format facilitates better heat dissipation, minimizing radial temperature gradients that can degrade chromatographic efficiency.

Pumps

The pump must generate a stable, reproducible, and pulse-free flow of mobile phase against the high backpressure created by columns packed with fine particles.

- Pressure Rating: Modern UFLC systems typically operate at pressures up to 1500 bar, a significant increase over the 400-bar limit of traditional HPLC [16].

- System Volume: To maintain the efficiency gained from the column, the pump and overall system must have a minimized extra-column volume [16]. This prevents peak broadening before and after the column.

- Gradient Performance: The pump must be capable of forming highly accurate and precise binary or quaternary gradients at low flow rates and small volumes, which is critical for fast and efficient separations of complex mixtures.

Detector Configurations

The Diode Array Detector (DAD) is a key component for method development and peak identification.

- Detection Principle: A DAD captures the full UV-Vis spectrum of an analyte as it elutes from the column. This is achieved by passing light through the flow cell onto a photodiode array, allowing simultaneous detection at multiple wavelengths [15].

- Configuration for UFLC: To preserve the narrow peaks produced by UFLC, the DAD must feature a low-volume flow cell (often in the microliter range) and high data acquisition rates [15]. This configuration prevents peak broadening within the detector and ensures accurate representation of fast eluting peaks.

- Advantages over Single Wavelength: The ability to collect spectral data across a range (e.g., 190-600 nm) enables peak purity assessment and library matching, which is invaluable for identifying compounds and confirming method specificity [17].

Table 1: Quantitative Performance Data of UFLC-DAD in Pharmaceutical Analysis

| Application Context | Analyte | Column Type & Dimensions | Mobile Phase & Flow Rate | Run Time | Detection Wavelength | Key Performance Metric |

|---|---|---|---|---|---|---|

| Anti-arthritis Agent [18] | Jatropha isabellei Fraction (Jatrophone) | C-18 | Not Specified | Not Specified | DAD Scan | Jatrophone content: ~90 µg/mg of fraction |

| Vitamin K2 in Plasma [17] | Menaquinone-4 (MK-4) | C-18 | Isopropyl Alcohol:ACN (50:50 v/v), 1 mL/min | 10 min | 269 nm | Linear Range: 0.374-6 µg/mL (R²=0.9934) |

| Polyphenol Analysis [15] | 38 Polyphenols in Applewood | Not Specified (UPLC) | Optimized Gradient, High Flow | < 21 min | Multiple DAD Wavelengths | Simultaneous quantification of 38 compounds |

Experimental Protocol: UFLC-DAD Method for Quantifying Bioactive Compounds

This protocol outlines the development and validation of a UFLC-DAD method for the quantification of a bioactive diterpene (e.g., jatrophone) in a plant extract, based on validated research methodologies [18] [17].

Research Reagent Solutions

Table 2: Essential Materials and Reagents

| Item Name | Function / Description | Example / Specification |

|---|---|---|

| Reference Standard | Provides a pure substance for peak identification and calibration. | Jatrophone (or target analyte), high purity (e.g., >95%) [18]. |

| Internal Standard (IS) | Accounts for sample preparation and injection variability. | A compound not in the sample, with similar chemical properties (e.g., Daidzein for polyphenols) [15]. |

| Chromatographic Solvents | Form the mobile phase for elution and separation. | HPLC-grade Acetonitrile, Methanol, Water; Acid/Base modifiers (e.g., Formic Acid, Ammonium Acetate). |

| Sample Preparation Solvents | Used for extraction, dilution, and protein precipitation. | Ethanol, Methanol, Dichloromethane, Dimethyl Sulfoxide (DMSO) [18] [17]. |

| Stationary Phase Column | The medium where chromatographic separation occurs. | C-18 column (e.g., 150 x 4.6 mm, 2.6 µm core-shell or sub-2 µm fully porous particles). |

Sample Preparation

- Standard Solutions: Accurately weigh the reference standard and dissolve in an appropriate solvent (e.g., ethanol) to prepare a primary stock solution (e.g., 1 mg/mL). Prepare working standards by serial dilution [17].

- Internal Standard Solution: Prepare a stock solution of the IS similarly and spike it into all calibration standards and samples at a fixed concentration.

- Plant Extract Preparation: Follow the cited literature for authenticity [18]:

- Dry plant material (e.g., J. isabellei underground parts) at room temperature and powder.

- Macerate the powder with 70% (v/v) ethanol (plant-to-solvent ratio 1:3 w/v) for 10 days.

- Filter and evaporate the ethanol under reduced pressure.

- Partition the resulting dispersion with dichloromethane to obtain a dichloromethane fraction (DFJi). Evaporate to dryness and note the yield (e.g., 3.7%).

- Reconstitution: Prior to injection, reconstitute the dried DFJi in the initial mobile phase or a compatible solvent. For in vivo studies, protein precipitation (e.g., with cold acetonitrile) is a common cleanup step for biological fluids like plasma [17].

- Filtration: Pass all samples through a 0.22 µm syringe filter to remove particulate matter.

Instrumental Configuration and Analysis

- System Setup:

- Pump: Configure for a binary or quaternary gradient. Set the pressure limit to the maximum of your system (e.g., 1500 bar).

- Autosampler: Set the injection volume (typically 1-10 µL) and maintain the sample tray at a controlled temperature (e.g., 4-10°C).

- Column Oven: Set temperature to a constant value (e.g., 25-40°C) to ensure retention time stability.

- DAD: Set the spectral acquisition range (e.g., 200-400 nm). Select a specific wavelength for quantification based on the analyte's maximum absorption and set a bandwidth (e.g., 269 nm for MK-4, with a reference wavelength to minimize baseline noise) [17].

- Chromatographic Conditions (Example based on literature [18] [17]):

- Mobile Phase: (A) Water with 0.1% Formic Acid, (B) Acetonitrile with 0.1% Formic Acid.

- Gradient Program:

Time (min) % A % B Flow Rate (mL/min) 0 90 10 0.8 10 10 90 0.8 12 10 90 0.8 12.1 90 10 0.8 15 90 10 0.8 - Column: C-18 (100 x 2.1 mm, 1.8 µm).

- Detection: DAD, 254 nm (for jatrophone-like compounds), with spectrum collection from 190-600 nm.

- Sequence Execution: Run the sequence in the following order: blank solvent, system suitability standard, calibration standards, quality control samples, and finally, the unknown test samples.

Data Analysis and Method Validation

- Peak Integration and Calibration: Integrate the analyte and IS peaks. Plot the peak area ratio (Analyte/IS) against the nominal concentration of the calibration standards. Perform linear regression to obtain the calibration curve. The method should demonstrate a correlation coefficient (R²) of >0.995 [17].

- Validation Parameters:

- Accuracy & Precision: Assess using quality control (QC) samples at low, medium, and high concentrations. Accuracy (expressed as % bias) should be within ±15%, and precision (% RSD) should be <15% [17].

- Specificity: Verify that the analyte peak is pure and free from interference from the blank matrix at its specific retention time, using DAD spectral data for peak purity assessment [15].

- Stability: Conduct short-term and long-term stability studies of the analyte in the solution and matrix under various storage conditions.

UFLC-DAD Method Optimization Workflow

The following workflow diagrams the logical process for developing and optimizing a UFLC-DAD method, from initial setup to final validation.

Ultra-Fast Liquid Chromatography with Diode-Array Detection (UFLC-DAD) represents a significant advancement in analytical technology, offering improved separation efficiency, reduced analysis time, and comprehensive spectral data collection for pharmaceutical applications. This technique combines the high-resolution capabilities of ultra-fast chromatography with the versatile detection power of diode-array technology, making it particularly valuable for method development in drug research and quality control. The DAD component enables simultaneous multi-wavelength detection and peak purity assessment by capturing full UV-Vis spectra during analysis, providing a critical layer of data integrity when analyzing complex pharmaceutical matrices where interfering components may co-elute with target analytes [19].

The pharmaceutical industry increasingly adopts UFLC-DAD to address challenges in analytical method development, including the need for faster results, improved resolution of complex mixtures, and comprehensive compound characterization. This technique has proven particularly valuable for analyzing active pharmaceutical ingredients (APIs), their impurities, degradation products, and complex natural product formulations where multiple compounds require identification and quantification within a single analytical run [20]. The environmental benefits of reduced solvent consumption compared to conventional HPLC further align UFLC-DAD with modern green analytical chemistry principles [20].

Technical Advantages of UFLC-DAD

Comparative Analysis of UFLC-DAD Versus Other Techniques

Table 1: Comparison of UFLC-DAD with Other Chromatographic Techniques

| Parameter | UFLC-DAD | Conventional HPLC-DAD | HPLC-MS |

|---|---|---|---|

| Typical Analysis Time | 5-15 minutes | 20-60 minutes | 15-45 minutes |

| Solvent Consumption | ~40-60% reduction vs. HPLC | High | Moderate to High |

| Detection Capabilities | Full UV-Vis spectra, peak purity | Full UV-Vis spectra | Mass, structural information |

| Resolution | High (with sub-2μm particles) | Moderate to High | High |

| Operational Costs | Moderate | Moderate | High |

| Method Transferability | Excellent to UPLC | Good | Instrument-dependent |

| Matrix Effect Interference | Low to Moderate [19] | Moderate | High [19] |

| Linear Range | Typically >10² [20] | Typically >10² | Varies widely |

The core advantage of UFLC-DAD lies in its ability to provide rapid separations without compromising data quality. Operating at higher pressures (typically up to 15,000 psi) with smaller particle columns (often sub-2μm) significantly enhances separation efficiency according to van Deemter principles, which describe the relationship between flow rate and plate height [20]. This enables faster analysis times while maintaining or improving resolution—a critical factor in high-throughput pharmaceutical laboratories where analytical efficiency directly impacts research and development timelines.

The DAD detection component provides distinct advantages over single-wavelength UV detectors by capturing the complete absorbance spectrum for each eluting peak. This capability facilitates peak purity assessment through spectral comparison across the peak profile, which is particularly valuable for stability-indicating methods where analyte degradation must be identified [19]. Furthermore, the ability to retrospectively extract chromatograms at different wavelengths without reinjecting samples provides exceptional flexibility during method development and troubleshooting [21].

When to Select UFLC-DAD: Key Application Scenarios

UFLC-DAD is particularly well-suited for several specific scenarios in pharmaceutical analysis:

- Stability Studies and Forced Degradation: The technique efficiently separates and identifies degradation products while confirming peak purity of the main active ingredient through spectral analysis [19].

- Quality Control of Natural Health Products: For complex botanical extracts containing multiple active compounds (e.g., flavonoids, phenolic compounds), UFLC-DAD provides both qualitative spectral confirmation and quantitative data in a single analysis [20].

- Method Development Phases: The rapid analysis times enable faster screening of chromatographic conditions, significantly shortening method development cycles.

- Routine Analysis of Formulations with UV-Active Components: When analyzing vitamins [22], preservatives, or other compounds with characteristic UV spectra in dosage forms.

- Laboratories Seeking MS-Complementary Techniques: For facilities where mass spectrometry is unavailable or as a complementary technique to provide UV spectral data for compound identification.

Figure 1: Decision Pathway for Selecting UFLC-DAD in Pharmaceutical Analysis

Detailed Experimental Protocols

Method Development and Optimization Protocol

Objective: To develop and validate a stability-indicating UFLC-DAD method for simultaneous quantification of multiple active pharmaceutical ingredients and their degradation products.

Materials and Reagents:

- UFLC System: Shimadzu Nevera or equivalent with DAD detector

- Analytical Column: ACQUITY UPLC BEH C18 (2.1 × 50 mm, 1.7 µm) or equivalent [20]

- Mobile Phase: HPLC-grade solvents (acetonitrile, methanol) and high-purity water

- Buffer Salts: Ammonium formate, ammonium acetate, or phosphate buffers

- Reference Standards: Certified reference materials of target analytes

- Samples: Pharmaceutical formulations (tablets, capsules, gummies) or biological fluids

Procedure:

Sample Preparation:

- For pharmaceutical gummies/solid dosage forms: Weigh accurately (~1.0 g) and homogenize. Extract using appropriate solvent (e.g., methanol, buffer) via sonication for 15-30 minutes with occasional shaking [22].

- Centrifuge at 10,000 × g for 10 minutes and filter through 0.22 µm membrane filter.

- For biological fluids: Apply appropriate sample clean-up such as Solid Phase Extraction (SPE) using C18 cartridges [22].

Initial Chromatographic Screening:

System Optimization:

- Mobile Phase Optimization: Evaluate different pH values (typically 2.5-4.0 for acidic compounds, 6.5-7.5 for basic compounds) and buffer concentrations (10-50 mM).

- Gradient Optimization: Adjust gradient steepness and shape to achieve resolution (R_s > 2.0) between critical pairs.

- Column Screening: Test different stationary phases (C18, C8, phenyl, polar-embedded) if separation is inadequate.

Detection Optimization:

- Determine optimal wavelengths for each analyte from acquired spectra.

- Set primary quantification wavelength and secondary wavelengths for confirmation.

- Establish bandwidth (typically 4-8 nm) and data acquisition rate (≥10 Hz).

Table 2: Method Validation Parameters Based on ICH Guidelines

| Validation Parameter | Acceptance Criteria | Protocol |

|---|---|---|

| Linearity | R² > 0.999 [22] | Analyze 5-8 concentrations in triplicate |

| Accuracy | Mean recovery 100 ± 3% [22] | Spike known amounts to placebo at 3 levels |

| Precision | %RSD < 2% [20] | Repeat analysis 6 times on same day and different days |

| LOD | Signal-to-noise ≥ 3 | Serial dilution until S/N = 3 |

| LOQ | Signal-to-noise ≥ 10 | Serial dilution until S/N = 10 |

| Specificity | No interference from placebo | Compare placebo, standard, and sample chromatograms |

| Robustness | %RSD < 2% for deliberate changes | Intentional small changes in flow, temperature, pH |

Analysis of B-Complex Vitamins in Pharmaceutical Gummies

Objective: To simultaneously determine vitamins B1 (thiamine), B2 (riboflavin), and B6 (pyridoxine) in pharmaceutical gummies using UFLC-DAD with pre-column derivatization for B1 [22].

Specific Materials:

- Derivatization Reagent: Potassium ferricyanide in alkaline medium for thiamine oxidation to thiochrome [22]

- Extraction Solvent: NaHâ‚‚POâ‚„ buffer (pH 4.95) - methanol (70:30, v/v) [22]

- SPE Cartridges: C18 for sample clean-up if needed [22]

Chromatographic Conditions:

- Column: Aqua C18 (250 mm × 4.6 mm, 5 µm) or equivalent [22]

- Mobile Phase: Isocratic elution with NaHâ‚‚POâ‚„ buffer (pH 4.95):methanol (70:30, v/v) [22]

- Flow Rate: 0.9 mL/min [22]

- Temperature: 40°C [22]

- Detection: DAD with quantification at 254 nm (B1), 268 nm (B2), and 290 nm (B6) [22]

- Injection Volume: 10 µL

Procedure:

- Pre-column Derivatization of B1: To 1.0 mL of standard or sample extract, add 0.5 mL of potassium ferricyanide solution (1% w/v) in 15% NaOH. Mix thoroughly and allow to react for 1-2 minutes before injection [22].

- Extraction: Homogenize 1.0 g of gummy sample in 10 mL of extraction solvent. Sonicate for 30 minutes, then centrifuge at 10,000 × g for 10 minutes. Filter supernatant through 0.45 µm membrane.

- Analysis: Inject derivatized samples and analyze using the chromatographic conditions above.

- Quantification: Use external standard method with calibration curves ranging from 1-100 µg/mL for each vitamin.

Figure 2: UFLC-DAD Method Development Workflow

Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for UFLC-DAD Pharmaceutical Analysis

| Reagent/Material | Function | Application Notes |

|---|---|---|

| C18 Analytical Columns (1.7-5 µm) | Stationary phase for reverse-phase separation | Sub-2µm particles for UFLC; 3-5µm for method development [20] |

| Ammonium Formate/Acetate | Mobile phase buffer | Volatile for potential MS transfer; use 10-50 mM concentration |

| Phosphate Buffers | Mobile phase for non-MS methods | Better buffer capacity; [22] uses NaHâ‚‚POâ‚„ buffer pH 4.95 |

| Acetonitrile (HPLC grade) | Organic mobile phase modifier | Preferred for UV transparency and low viscosity |

| Methanol (HPLC grade) | Alternative organic modifier | Different selectivity vs. acetonitrile |

| Trifluoroacetic Acid | Ion-pairing reagent for basic compounds | Use at 0.05-0.1% for improved peak shape |

| SPE Cartridges (C18) | Sample clean-up | Essential for biological fluids or complex matrices [22] |

| Derivatization Reagents | Enhance detection of non-UV active compounds | Pre-column oxidation for vitamin B1 analysis [22] |

Applications in Pharmaceutical Analysis

Case Studies and Implementations

Analysis of Phenolic Compounds in Natural Health Products: A validated UPLC-DAD method for phenolic compounds in American cranberry fruit demonstrates the application of this technique for quality control of natural health products. The method achieved excellent separation of myricetin-3-galactoside, quercetin-3-galactoside, chlorogenic acid, and related compounds in less than 10 minutes. Validation according to ICH guidelines confirmed linearity (R² > 0.999), precision (%RSD < 2%), LOD (0.38–1.01 µg/mL), LOQ (0.54–3.06 µg/mL), and recovery (80–110%) [20]. This application highlights the utility of UFLC-DAD for comprehensive profiling of complex botanical matrices in dietary supplements.

In Vitro Digestion Studies: UFLC-DAD has been applied to investigate the release profile of vitamins from pharmaceutical gummies under simulated gastrointestinal conditions. A three-phase in vitro digestion protocol assessed whether co-administration with water, orange juice, or milk affected vitamin release. The results showed no significant differences with slight superiority in release of B2 and B6 with water, while B1 release was better with orange juice [22]. Such studies demonstrate how UFLC-DAD facilitates pharmaceutical formulation development and biopharmaceutical assessment.

Troubleshooting Common Challenges

Matrix Effects and Interference: Complex pharmaceutical matrices (e.g., herbal extracts, protein-containing formulations) may cause interference. Solutions include:

- Improved Sample Clean-up: Implement SPE with appropriate sorbents [22]

- Optimized Extraction: Use of sonication, varying solvent composition, and pH adjustment

- Chromatographic Resolution: Adjust gradient profile or change stationary phase chemistry

Peak Tailing and Poor Efficiency:

- For basic compounds: Use low-pH mobile phases with phosphate buffers or add alkyl sulfonates as ion-pair reagents

- For acidic compounds: Use higher pH (if column stability allows) or add triethylamine as modifier

- Ensure adequate column temperature control (typically 30-45°C)

Retention Time Drift:

- Maintain consistent mobile phase preparation and column temperature

- Equilibrate column thoroughly after gradient runs

- Check for column degradation or contamination

The implementation of UFLC-DAD in pharmaceutical analysis continues to expand as researchers recognize its advantages in method development speed, resolution capability, and comprehensive detection. When properly validated according to regulatory guidelines, UFLC-DAD methods provide robust solutions for quality control, stability testing, and formulation development across diverse pharmaceutical applications.

Systematic Method Development: Practical Strategies for Pharmaceutical and Natural Product Analysis

Experimental Design and Chemometric Approaches for Efficient Method Optimization

In the field of pharmaceutical analysis, Ultra-Fast Liquid Chromatography (UFLC) coupled with Diode Array Detection (DAD) represents a powerful analytical technique for the separation and quantification of complex mixtures. The optimization of UFLC-DAD methods has evolved significantly from traditional one-variable-at-a-time (OVAT) approaches to more sophisticated chemometric methods based on Design of Experiments (DOE). OVAT approaches are inherently inefficient, requiring numerous experimental runs while failing to detect critical interactions between method parameters [23]. In contrast, chemometric approaches enable systematic investigation of multiple factors and their interactions simultaneously, leading to more robust and optimized methods with fewer experiments.

The application of DOE in chromatographic method development falls under the Quality by Design (QbD) framework, which aims to ensure predefined product quality through deliberate design rather than empirical testing. Regulatory agencies, including the US FDA, strongly encourage QbD principles as they provide a deeper understanding of method performance characteristics and establish a design space where operational adjustments do not adversely affect results [23]. This structured approach to method development is particularly crucial for chiral separations and pharmaceutical analysis where method robustness directly impacts drug safety and efficacy.

Chemometric Experimental Designs

Fundamental DOE Concepts and Terminology

Chemometric approaches rely on several key statistical concepts. Factors or independent variables are the method parameters being investigated (e.g., mobile phase composition, pH, flow rate). Responses or dependent variables are the measured outcomes (e.g., retention time, resolution, peak asymmetry). Experimental design refers to the strategic arrangement of factor combinations to be tested, while response surface methodology (RSM) encompasses the mathematical and statistical techniques for modeling and analyzing problems where responses are influenced by multiple factors.

Selection of Experimental Designs

Different experimental designs serve distinct purposes in method optimization:

- Screening Designs: Plackett-Burman or fractional factorial designs identify the most influential factors from a large set of potential variables with minimal experimental runs.

- Optimization Designs: Full factorial, Central Composite Design (CCD), and Box-Behnken Design (BBD) characterize factor effects and interactions while modeling response surfaces.

- Robustness Testing Designs: Fractional factorial designs verify method resilience to small, intentional parameter variations.

The Box-Behnken Design (BBD) has proven particularly valuable for chromatographic method optimization due to its efficiency and practical advantages. As a spherical, rotatable design with fewer required runs compared to CCD, BBD does not include experimental points at the extreme vertices where factor combinations might produce unsatisfactory results [23]. This prevents potentially damaging conditions to instrumentation or columns while still effectively modeling quadratic response surfaces.

Case Study: Application of Box-Behnken Design for Chiral Separation of Alogliptin Enantiomers

Experimental Setup and Chromatographic Conditions

A practical application of BBD for UFLC-DAD method development comes from the enantioselective separation of alogliptin, an antidiabetic drug [23]. The study aimed to develop and validate a stereoselective method for determining alogliptin enantiomers in formulations and rat plasma.

Chromatographic System:

- Instrument: Shimadzu Prominence Modular UFLC system with DAD detector [23]

- Column: Phenomenex Lux Cellulose-2 chiral column (250 mm × 4.6 mm, 5 μm) [23]

- Detection: 230 nm [23]

- Internal Standard: Pioglitazone [23]

- Temperature: 25°C [23]

- Injection Volume: 20 μL [23]

Box-Behnken Design Implementation

The optimization employed a three-factor, three-level BBD to identify optimal conditions for the separation of R- and S-alogliptin enantiomers. The factors and levels were selected based on preliminary experiments:

Table 1: Independent Variables and Their Levels for Box-Behnken Design

| Variable | Low (-1) | Medium (0) | High (+1) |

|---|---|---|---|

| Methanol (%) | 40 | 55 | 70 |

| pH of Buffer | 3.0 | 3.5 | 4.0 |

| Flow Rate (mL/min) | 0.8 | 1.0 | 1.2 |

The experimental design required 17 randomized runs to minimize the effects of uncontrolled variables. Critical responses measured included retention time of the R-isomer and resolution between R and S enantiomers.

Table 2: Partial Box-Behnken Design Matrix and Experimental Results

| Run | Methanol (%) | pH | Flow Rate (mL/min) | R-Isomer Retention Time (min) | Resolution (R & S) |

|---|---|---|---|---|---|

| 1 | 40 | 3.0 | 1.0 | 7.263 | 1.588 |

| 2 | 70 | 3.5 | 1.2 | 6.647 | 0.904 |

| ... | ... | ... | ... | ... | ... |

Optimization and Data Analysis

The experimental data were analyzed using Design-Expert software (Stat-Ease Inc., Minneapolis, USA) to generate mathematical models describing the relationship between factors and responses. Multiple regression analysis produced quadratic polynomial equations for each response variable. The general form of the model was:

Y = β₀ + βâ‚Xâ‚ + β₂Xâ‚‚ + β₃X₃ + βâ‚â‚‚Xâ‚Xâ‚‚ + βâ‚₃Xâ‚X₃ + β₂₃Xâ‚‚X₃ + βâ‚â‚X₲ + β₂₂X₂² + β₃₃X₃²

Where Y is the predicted response, β₀ is the intercept, βâ‚-β₃ are linear coefficients, βâ‚â‚‚-β₂₃ are interaction coefficients, and βâ‚â‚-β₃₃ are quadratic coefficients.

Derringer's desirability function was employed for multi-criteria optimization, simultaneously maximizing resolution while maintaining acceptable retention times. The function converts each response into an individual desirability value (d) ranging from 0 (undesirable) to 1 (fully desirable), then combines them into an overall desirability index (D) calculated as the geometric mean of individual values.

Optimized Method and Validation

The optimized chromatographic conditions achieved complete separation of both ALO enantiomers and the internal standard pioglitazone within 8 minutes, with a resolution of 0.77 minutes between R and S enantiomers and resolution greater than 2.0 between each enantiomer and pioglitazone [23]. The method demonstrated ≥95% recovery and was successfully validated according to ICH guidelines, showing linearity from 10-70 ng mLâ»Â¹ for both enantiomers in rat plasma with a limit of quantification of 1.2 ng mLâ»Â¹ [23].

The validated method was applied to a comparative pharmacokinetic study in rats following administration of a single oral dose of 25 mg alogliptin racemate tablets, demonstrating its practical utility for enantioselective pharmacokinetic studies [23].

Advanced UFLC Instrumentation and Column Technologies

Modern UFLC Systems

Recent advancements in UFLC instrumentation have enhanced the capabilities for rapid method development and analysis:

- Shimadzu i-Series HPLC/UHPLC: Compact, integrated systems capable of handling pressures up to 70 MPa (10,152 psi) with eco-friendly design reducing energy consumption [13].

- Agilent Infinity III LC Series: Includes models with pressure capabilities from 600 bar to 1300 bar, featuring level sensing monitors, sample ID readers, and laboratory advisor software for maintenance [13].

- Waters Alliance iS Bio HPLC System: Specifically designed for biopharmaceutical QC laboratories, handling pressures up to 12,000 psi with bio-inert design and MaxPeak HPS technology [13].

Innovative Column Technologies

Column technology continues to evolve, supporting faster and more efficient separations:

- Advanced Materials Technology Halo Inert: Features passivated hardware creating a metal-free barrier, particularly advantageous for phosphorylated compounds and metal-sensitive analytes [24].

- Fortis Technologies Evosphere C18/AR: Utilizes monodisperse fully porous particles for higher efficiency, suitable for oligonucleotide separation without ion-pairing reagents [24].

- Restek Raptor and Force Series: Superficially porous particle columns with inert hardware, providing fast analysis times and improved response for metal-sensitive compounds [24].

Integrated UFLC-DAD Method Optimization Workflow

The following diagram illustrates the comprehensive workflow for chemometric optimization of UFLC-DAD methods:

Research Reagent Solutions and Essential Materials

Table 3: Key Research Reagents and Materials for UFLC-DAD Method Development

| Category | Specific Examples | Function and Application |

|---|---|---|

| Chromatography Columns | Phenomenex Lux Cellulose-2 [23], Halo Inert [24], Evosphere C18/AR [24] | Stationary phases providing separation mechanisms; chiral selectors for enantiomers, reversed-phase for small molecules |

| Mobile Phase Modifiers | Formic acid [23], Ammonium acetate, Trifluoroacetic acid | Adjust pH and improve ionization; enhance peak shape and resolution in reversed-phase chromatography |

| Mass Spectrometry Compatible Reagents | Low ionic strength volatile buffers (formic acid) [24] | Compatible with ESI-MS detection; enable direct coupling of UFLC to mass spectrometry |

| Sample Preparation Materials | C-18 Solid Phase Extraction cartridges [23], Protein precipitation reagents | Extract and concentrate analytes; remove matrix interferences from biological samples |

| Reference Standards | Racemic mixtures, Pure enantiomers [23], Internal standards (e.g., Pioglitazone) [23] | Method development and validation; quantitative calibration and quality control |

Detailed Experimental Protocol for Chemometric UFLC-DAD Optimization

Preliminary Method Scoping

- Column Selection: Based on analyte properties (polarity, chirality, molecular weight), select appropriate stationary phase. For chiral separations, use dedicated chiral columns like cellulose- or amylose-based phases [23].

- Detection Wavelength: Using DAD, perform wavelength scanning of analytes to determine optimal detection wavelength with maximum absorbance and minimal interference [23].

- Mobile Phase Screening: Test different organic modifiers (methanol, acetonitrile), buffers (phosphate, acetate), and pH ranges to identify promising regions for optimization.

Experimental Design Implementation

- Factor Selection: Identify 3-4 critical factors most likely to influence separation based on preliminary experiments.

- Design Setup: Using statistical software (e.g., Design-Expert, Minitab), create a Box-Behnken Design with appropriate factor levels.

- Randomization: Generate randomized run order to minimize systematic bias.

- Experimental Execution: Perform chromatographic runs according to the design matrix, measuring all predefined responses (retention times, resolution, peak asymmetry, etc.).

Data Analysis and Optimization

- Model Fitting: Input response data into statistical software to generate quadratic models.

- Model Validation: Check model adequacy using ANOVA, lack-of-fit tests, and residual analysis.

- Response Surface Analysis: Create contour and 3D surface plots to visualize factor-response relationships.

- Multi-response Optimization: Apply desirability functions to identify conditions satisfying all method criteria simultaneously.

Method Validation

- Specificity: Verify separation from potential impurities and matrix components.

- Linearity: Prepare calibration standards across the working range (e.g., 10-70 ng mLâ»Â¹) and establish correlation coefficient and linearity [23].

- Accuracy and Precision: Perform recovery studies and repeatability/intermediate precision testing.

- Sensitivity: Determine Limit of Detection (LOD) and Limit of Quantification (LOQ) [23].

- Robustness: Deliberately vary critical parameters (e.g., temperature ±2°C, flow rate ±0.1 mL/min) to demonstrate method resilience.

Advanced Applications and Recent Technological Developments

Recent innovations continue to expand UFLC-DAD applications in pharmaceutical analysis:

- LC-MS Integration: Modern UFLC systems seamlessly couple with mass spectrometers including triple quadrupole (QQQ), quadrupole time-of-flight (Q-TOF), and Orbitrap systems for enhanced sensitivity and compound identification [25].

- High-Throughput Screening: Systems like the Knauer Azura HTQC UHPLC configure for quality control applications with short cycle times and high sample capacity [13].

- Automated Method Development: Thermo Fisher Vanquish Neo systems with tandem direct injection workflows perform column loading, washing, and equilibration offline to increase throughput [13].

- Bioinert Configurations: Systems with MaxPeak HPS technology or MP35N, gold, and ceramic flow paths enable analysis of metal-sensitive compounds while resisting high-salt mobile phases under extreme pH [13].

The diagram below illustrates the relationship between different chemometric approaches in the context of method development lifecycle:

The integration of chemometric approaches, particularly Box-Behnken Design, with UFLC-DAD methodology represents a powerful framework for efficient chromatographic method optimization. This systematic approach enables researchers to develop robust, validated methods with fewer experiments while gaining comprehensive understanding of factor interactions and method robustness. The case study of alogliptin enantiomer separation demonstrates the practical application of these principles, resulting in a method suitable for pharmacokinetic studies with excellent resolution, sensitivity, and efficiency.

As UFLC instrumentation and column technologies continue to advance, complemented by increasingly sophisticated chemometric tools, the paradigm of method development is shifting from empirical trial-and-error to systematic, knowledge-based approaches that align with regulatory expectations for pharmaceutical analysis.

In Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) method development, mobile phase optimization represents the most powerful tool for controlling retention, selectivity, and peak symmetry. The strategic selection of mobile phase composition, pH, and buffer systems directly determines the success of chromatographic separations, particularly for ionizable analytes which constitute approximately 80% of pharmaceutical compounds [26]. Within the context of UFLC-DAD optimization research, this application note provides detailed protocols and evidence-based strategies for developing robust, transferable methods that deliver high resolution while maintaining detection compatibility.

The fundamental principles of reversed-phase chromatography govern the interaction between analytes, stationary phase, and mobile phase components. In this environment, hydrophobic interactions primarily drive retention, while ionic modifications selectively modulate separation characteristics [26]. Modern trends emphasize simpler mobile phase systems with MS-compatible additives, elimination of filtration requirements, and binary solvents with linear gradients to enhance method robustness [26]. This guide translates these principles into practical protocols for researchers engaged in method development for drug substances and related compounds.

Mobile Phase Composition Fundamentals

Organic Modifier Selection

The choice of organic solvent ("Mobile Phase B") significantly impacts elution strength, viscosity, and selectivity. The three historical solvents—acetonitrile, methanol, and tetrahydrofuran—offer distinct selectivity properties based on their proton acceptor/donor capabilities and dipole interactions [26].

Table 1: Comparison of Common Organic Modifiers in Reversed-Phase UFLC

| Organic Solvent | Eluotropic Strength | Viscosity (cP) | UV Cutoff (nm) | Selectivity Characteristics |

|---|---|---|---|---|

| Acetonitrile | Medium | 0.37 | 190 | Aprotic, proton acceptor, π-π interactions |

| Methanol | Weakest | 0.55 | 210 | Protic, proton donor/acceptor |

| Tetrahydrofuran | Strongest | 0.51 | 220 | Strong solubilizing power, safety concerns |

For UFLC-DAD applications, acetonitrile is generally preferred due to its lower viscosity (reducing system backpressure), strong eluting power, and excellent UV transparency down to 190 nm [26]. Methanol provides alternative selectivity for challenging separations but generates higher backpressure, particularly in water mixtures (50:50 methanol:water viscosity = 1.62 cP) [26]. Tetrahydrofuran is rarely used due to peroxide formation and toxicity concerns, though methyl tert-butyl ether can serve as a safer alternative for specific applications [26].

Aqueous Phase Modifiers and Additives

The aqueous phase ("Mobile Phase A") typically consists of water with pH modifiers, buffers, or salts to control ionization and retention of analytes. For neutral molecules, purified water may suffice, but ionizable compounds require precise pH control [26]. The addition of small concentrations of modifiers (typically 0.05-0.1%) such as trifluoroacetic acid, formic acid, or acetic acid provides ionization control and improves peak symmetry [26].

A common practice includes using identical additive concentrations in both mobile phases A and B to minimize baseline shifts during gradient elution, particularly at low UV wavelengths [26]. With modern pump systems and online mixers, adding water to organic mobile phase B (e.g., 95% acetonitrile in water) to equalize viscosity provides minimal benefit and reduces solvent strength [26].

pH and Buffer Selection Strategies

pH Control for Ionizable Compounds

Mobile phase pH dramatically affects retention of ionizable analytes by controlling their ionization state. Ionized forms exhibit significantly lower retention than non-ionized forms in reversed-phase systems [26]. Figure 1 illustrates the generalized retention behavior of acids and bases across the pH range.

For method robustness, the mobile phase pH should be maintained at least 1.5-2 pH units away from the analyte pKa, where small variations in pH cause minimal retention time shifts [27]. When developing methods for multiple ionizable compounds with different pKa values, pH optimization becomes critical for achieving adequate separation [27].

Buffer Selection Criteria

Buffers prevent pH fluctuations during separation, ensuring retention time reproducibility. Effective buffer selection requires consideration of multiple factors summarized in Table 2.

Table 2: Buffer Selection Guide for UFLC-DAD Applications

| Buffer/Additive | pKa | Effective pH Range | UV Cutoff (nm) | MS Compatibility | Typical Concentration |

|---|---|---|---|---|---|

| Trifluoroacetic Acid | 2.1 | 1.5-2.7 | 220 | Limited (ion pairing) | 0.05-0.1% |

| Formic Acid | 3.8 | 2.8-4.8 | 240 | Excellent | 0.05-0.1% |

| Acetic Acid | 4.8 | 3.8-5.8 | 240 | Excellent | 0.05-0.1% |

| Ammonium Acetate | 4.8, 9.2 | 3.8-5.8, 8.2-10.2 | 230 | Excellent | 5-50 mM |

| Ammonium Formate | 3.8 | 2.8-4.8 | 230 | Excellent | 5-50 mM |

| Phosphate | 2.1, 7.2, 12.3 | 1.1-3.1, 6.2-8.2, 11.3-13.3 | 200 | Non-volatile | 5-50 mM |

| Ammonium Citrate | 3.1, 4.8, 6.4 | 2.1-4.1, 3.8-5.8, 5.4-7.4 | 230 | Good | 5-50 mM |

Buffer capacity is maximized when operating within ±1 pH unit of the buffer pKa [28]. For UFLC-DAD applications, the detection wavelength must exceed the buffer UV cutoff to maintain adequate sensitivity. Phosphate buffers provide excellent UV transparency but are non-volatile and incompatible with MS detection [26]. For LC-MS applications, volatile buffers such as ammonium acetate, ammonium formate, or formic acid are essential [28].

Buffer Concentration and Preparation