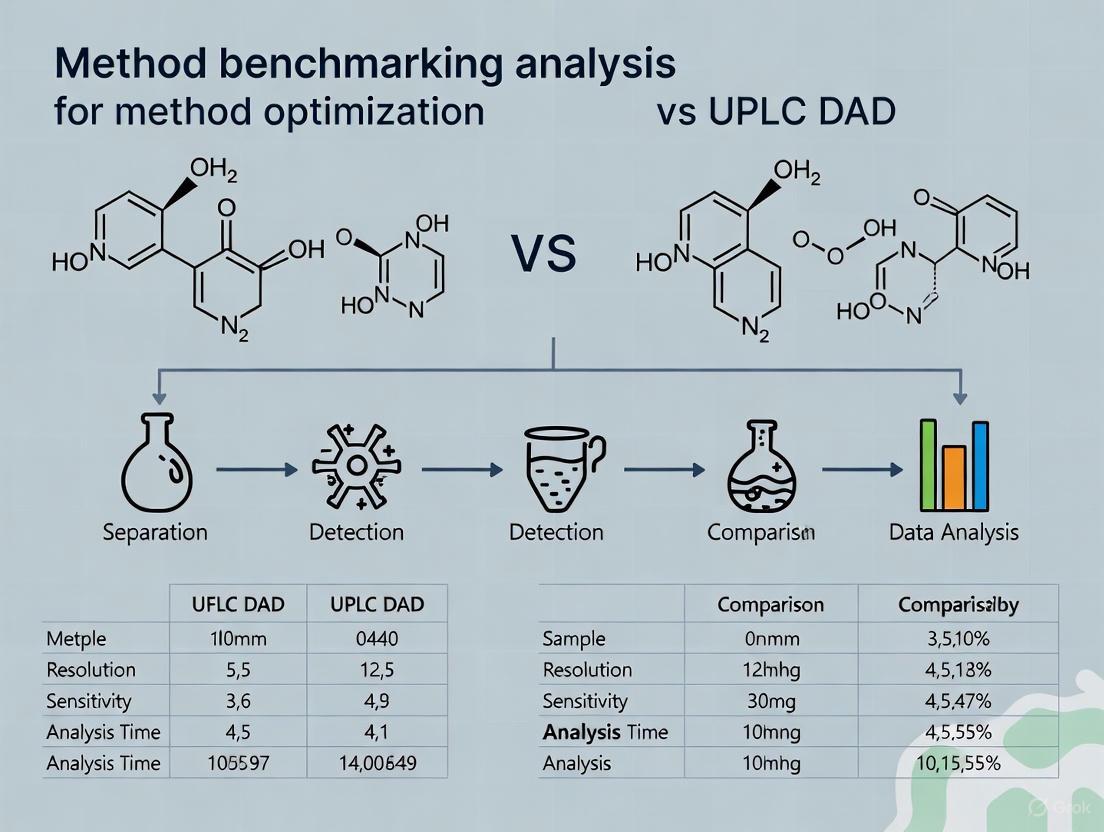

Benchmarking UFLC-DAD vs. UPLC-DAD: A Strategic Guide for Method Optimization in Pharmaceutical and Biomedical Analysis

This article provides a comprehensive comparative analysis of Ultra-Fast Liquid Chromatography (UFLC) and Ultra-Performance Liquid Chromatography (UPLC), both coupled with Diode Array Detection (DAD), to guide researchers and drug development...

Benchmarking UFLC-DAD vs. UPLC-DAD: A Strategic Guide for Method Optimization in Pharmaceutical and Biomedical Analysis

Abstract

This article provides a comprehensive comparative analysis of Ultra-Fast Liquid Chromatography (UFLC) and Ultra-Performance Liquid Chromatography (UPLC), both coupled with Diode Array Detection (DAD), to guide researchers and drug development professionals in analytical method optimization. We explore the foundational principles separating these techniques, including particle technology and system pressure. The piece delves into practical method development and transfer strategies, highlights common troubleshooting and optimization practices for complex biological matrices, and establishes a rigorous framework for method validation and comparative performance assessment. By synthesizing key operational, economic, and performance criteria, this guide aims to empower scientists in selecting and optimizing the most appropriate platform for their specific quality control and research applications.

UFLC-DAD vs. UPLC-DAD: Unpacking Core Technologies and Separation Mechanisms

UFLC DAD vs. UPLC DAD: A technical comparison grounded in separations science and contemporary application data.

The advancement of High-Performance Liquid Chromatography (HPLC) into Ultra-Performance Liquid Chromatography (UPLC) and similarly named platforms represents a paradigm shift in analytical separations. While the terms UPLC (a Waters Corporation trademark) and the more generic Ultra-Fast Liquid Chromatography (UFLC) or Ultra-High-Performance Liquid Chromatography (UHPLC) are often used interchangeably, they are rooted in a common technological principle: the use of sub-2-micron particle columns to achieve superior performance. This guide objectively compares these platforms, focusing on the critical roles of particle size, operating pressure, and instrument design in benchmarking UFLC-DAD against UPLC-DAD for method optimization research. The Diode Array Detector (DAD) is a constant, widely valued for its reliability, cost-effectiveness, and ability to provide spectral data for compound identification [1].

Core Technological Differences

The performance leap from traditional HPLC is primarily driven by fundamental changes in column packing chemistry and the high-pressure systems required to support it.

Particle Size and the van Deemter Equation

The separation efficiency in liquid chromatography is theoretically described by the van Deemter equation, which relates plate height (H) to linear velocity (v): H = A + B/v + Cv [2] [3]. The A-term (Eddy diffusion) and C-term (Mass transfer) are significantly reduced by using smaller, more uniform particles. While HPLC traditionally uses 3-5 µm particles, UPLC and UFLC utilize particles typically below 2.1 µm [2] [3]. This reduction minimizes the paths a molecule can take and the time for analytes to diffuse in and out of the porous stationary phase, leading to narrower peaks, higher resolution, and the ability to operate at faster flow rates without losing efficiency [1] [2].

System Pressure and Instrument Design

To achieve practical flow rates through columns tightly packed with sub-2-micron particles, instrument systems must operate at significantly higher pressures.

- UPLC Systems are specifically engineered to handle pressures up to 15,000 psi (1034 bar) [2] [3]. This involves specialized pumps, injection systems, and detector flow cells designed for low dispersion under ultra-high pressure.

- UFLC/UHPLC Systems also operate at high pressures, often in a similar range (e.g., up to 1300 bar or 18,850 psi for some modern systems) [4]. The term can be more generalized, encompassing systems from various manufacturers that are designed to leverage sub-2-micron columns [2].

Table 1: Core Technical Specifications of HPLC, UFLC/UHPLC, and UPLC Platforms

| Feature | Traditional HPLC | UFLC/UHPLC | UPLC |

|---|---|---|---|

| Typical Particle Size | 3–5 µm [2] [3] | 1.7–2.5 µm [2] | ~1.7 µm (sub-2 µm) [2] |

| Operating Pressure | ~6000 psi (400 bar) [3] | Up to 1300 bar (18,850 psi) [4] | Up to 15,000 psi (1034 bar) [2] [3] |

| System Design Philosophy | Generalized, flexible hardware [2] | Generalized term for high-pressure systems; vendor-agnostic [2] | Proprietary, optimized system for sub-2µm particles [2] |

Performance Benchmarking and Experimental Data

The theoretical advantages of smaller particles and higher pressures translate into measurable performance gains in speed, sensitivity, and resolution.

Analysis Speed and Throughput

A primary benefit is the dramatic reduction in analysis time. A study developing a UPLC-DAD method for 38 polyphenols in applewood achieved separation in under 21 minutes, a significant improvement over the 60-100 minutes required by the original HPLC method [1]. Similarly, a method for caffeine and potassium sorbate in energy drinks was completed in just 4.0 minutes using UPLC-PDA [5]. This high-throughput capability is essential for laboratories processing large numbers of samples.

Sensitivity and Resolution

The use of smaller particles leads to sharper, more concentrated peaks, which directly improves detection limits. In the applewood polyphenol study, the validated UPLC-DAD method demonstrated excellent limits of detection (LOD) between 0.0074 – 0.1179 mg Lâ»Â¹ [1]. The narrow peaks also contribute to higher resolution, allowing for the separation of complex mixtures with similar structures, such as the 38 polyphenols, which included flavonoids, non-flavonoids, and phenolic acids [1].

Table 2: Comparative Performance Data from Application Studies

| Application | Platform | Analytes | Key Performance Metrics |

|---|---|---|---|

| Polyphenols in Applewood [1] | UPLC-DAD | 38 compounds | Runtime: < 21 minLOD: 0.0074 – 0.1179 mg Lâ»Â¹Linearity (R²): > 0.999 |

| Alkaloids in Menispermi Rhizoma [6] | UPLC-DAD-MS | 9 alkaloids | Runtime: Not specified (gradient elution)Linearity (R²): ≥ 0.9991Precision (RSD): ≤ 3.32% |

| Caffeine & Potassium Sorbate in Energy Drinks [5] | UPLC-PDA | 2 compounds | Runtime: 4.0 minLOD: 0.18 µg/mL (Caffeine), 0.20 µg/mL (PS)Linearity (R²): 0.9996 & 0.9994 |

| Cranberry Triterpenoids [7] | UPLC-DAD | Multiple compounds | LOD: 0.27–1.86 µg/mLSpecificity: Successful identification in complex matrix |

Experimental Protocols for Method Development and Validation

Robust method development and validation are critical for generating reliable data. The following workflow, based on cited studies, outlines a systematic approach.

Detailed Methodological Steps

- Sample Preparation: For plant materials like applewood or cranberries, this typically involves drying, grinding, and extraction using solvents like methanol or ethanol, often assisted by techniques like ultrasound or accelerated solvent extraction (ASE) [1] [7] [8].

- Chromatographic Conditions:

- Column: Reversed-phase C18 columns with sub-2µm particles are standard (e.g., Waters Acquity BEH C18, 100 mm × 2.1 mm, 1.7 µm) [1] [5].

- Mobile Phase: Typically a binary gradient of water (often acidified with 0.1% formic acid) and an organic solvent like acetonitrile or methanol [1] [7] [6].

- Detection: DAD detection is set at specific wavelengths optimal for the target analytes (e.g., 284 nm for caffeine, 205 nm for triterpenoids) [7] [5].

- Chemometric Optimization: As demonstrated in the energy drink study, a factorial design can efficiently optimize critical parameters like column temperature, mobile phase composition, and flow rate to achieve the best resolution in the shortest time [5].

- Method Validation: Adherence to International Council for Harmonisation (ICH) guidelines is standard practice. This includes assessment of [1] [7] [5]:

- Linearity: Demonstrated by a high coefficient of determination (R² > 0.999).

- Precision: Intra-day and inter-day precision reported as %RSD (typically < 5%).

- Accuracy: Via recovery studies (typically 95-105%).

- Sensitivity: Determination of LOD and LOQ.

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful implementation of UFLC/UPLC-DAD methods relies on a set of core materials and reagents.

Table 3: Essential Reagents and Materials for UPLC-DAD Method Development

| Item | Function / Description | Example from Literature |

|---|---|---|

| Sub-2µm UPLC Column | The core component enabling high-resolution, high-speed separations. | Waters Acquity BEH C18 (1.7 µm) [5]; ACE C18 (1.7 µm) [7] |

| HPLC-Grade Solvents | High-purity water, acetonitrile, and methanol form the mobile phase, critical for low baseline noise and consistent performance. | Used in all cited studies for mobile phase preparation [1] [7] [5]. |

| Acid / Buffer Additives | Modifiers like formic acid or ammonium acetate buffer control pH and improve peak shape by suppressing analyte ionization. | 0.1% Formic acid [1] [7] [6]; 5 mM Ammonium Acetate [6] |

| Reference Standards | High-purity chemical standards are essential for peak identification, method development, and calibration. | Extrasynthese (Lyon, France) [1]; Commercial suppliers for caffeine, triterpenoids [7] [5]. |

| Chemometric Software | Software for Design of Experiments (DoE) to efficiently optimize multiple method parameters simultaneously. | Used for RSM with Central Composite Design [5]. |

| Littorine | Littorine, MF:C17H23NO3, MW:289.4 g/mol | Chemical Reagent |

| Barbatic acid | Barbatic acid, CAS:17636-16-7, MF:C19H20O7, MW:360.4 g/mol | Chemical Reagent |

The benchmarking of UFLC/UHPLC and UPLC platforms against traditional HPLC reveals a clear and consistent outcome: the strategic reduction of stationary phase particle size, supported by robust high-pressure instrument design, delivers unparalleled gains in analytical speed, sensitivity, and resolution. For researchers in drug development and analytical science, the choice between a specific UPLC system and a generic UFLC/UHPLC system may come down to specific vendor capabilities, existing laboratory infrastructure, and required operating pressure. However, the fundamental conclusion is that migrating to a sub-2-micron particle-based DAD platform is a definitive step for method optimization, enabling higher throughput and more precise quantification in complex matrices, from natural products to formulated pharmaceuticals.

Diode Array Detection (DAD), also referred to as Photo Diode Array (PDA), represents a significant advancement in chromatographic detection technology. As a detection system primarily coupled with High-Performance Liquid Chromatography (HPLC) and Ultra-High-Performance Liquid Chromatography (UHPLC), DAD has revolutionized compound analysis by simultaneously detecting multiple wavelengths across the ultraviolet and visible (UV-VIS) spectrum, typically ranging from 190 to 900 nm [9]. Unlike single-wavelength detectors that capture data at one fixed wavelength, DAD employs an array of diodes, each sensitive to specific wavelengths, enabling comprehensive spectral acquisition for each data point in the chromatogram [9]. This capability provides a three-dimensional data output (retention time, absorbance, and wavelength) that delivers detailed information about sample composition, making it particularly valuable for analyzing complex mixtures in pharmaceutical, environmental, and food science applications [9] [10].

The fundamental operation of a DAD system involves two light sources (typically deuterium and tungsten lamps) emitting a broad spectrum of UV and visible light directed through a flow cell containing the sample [9]. As various analytes in the sample absorb light at distinct wavelengths based on their chemical properties, the transmitted light is separated into its component wavelengths by a diffraction grating before striking the diode array [9]. Each diode then measures the light intensity at its specific wavelength, collectively generating a complete absorption spectrum for each analyte as it elutes from the chromatography column [9]. This accumulated spectral data enables both identification and quantification of diverse components within a sample, providing significant advantages for compound verification and purity assessment.

Operational Principles of DAD Technology

Fundamental Detection Mechanism

The operational principle of Diode Array Detection relies on the Beer-Lambert law, which states that the absorbance of light by a compound is directly proportional to its concentration in the solution. When coupled with HPLC or UHPLC systems, the DAD detector monitors the column effluent as it passes through a flow cell, typically with a path length of 1-10 mm. The key differentiator of DAD technology is its ability to capture the entire UV-VIS spectrum simultaneously for each time point during the chromatographic run, rather than being limited to pre-selected wavelengths [9]. This simultaneous multi-wavelength detection is achieved through an array of hundreds of individual photodiodes arranged in a linear pattern, with each diode dedicated to detecting a specific, narrow band of wavelengths [9] [10].

The optical system of a DAD consists of several critical components: the light source (typically a deuterium lamp for UV and tungsten lamp for visible regions), a lens system to focus the light through the flow cell, a diffraction grating to disperse the transmitted light into its constituent wavelengths, and the diode array itself to detect the intensity at each wavelength [9]. This configuration allows for continuous spectral acquisition throughout the chromatographic separation, typically generating comprehensive 3D data plots of absorbance versus wavelength versus retention time. The resulting data structure provides a complete spectral profile for every compound eluting from the column, regardless of whether those compounds were anticipated in the sample, making DAD exceptionally valuable for method development, impurity profiling, and unknown compound identification [9] [11].

Critical Acquisition Parameters and Their Optimization

Several acquisition parameters significantly impact the performance and data quality of DAD detection, requiring careful optimization based on analytical needs:

Data Acquisition Rate: Expressed in Hertz (Hz), this parameter determines how many data points are collected per second across the wavelength range. Higher acquisition rates (e.g., 80 Hz) yield more data points, resulting in sharper peak definition and improved resolution for fast-eluting compounds, particularly in UHPLC applications where peak widths can be very narrow. However, higher rates also increase baseline noise and generate larger data files [12].

Spectral Bandwidth: This parameter defines the range of wavelengths detected on either side of the target wavelength. For example, a bandwidth setting of 4 nm at 250 nm would detect wavelengths from 248 to 252 nm and average the results. Narrow bandwidth increases selectivity by focusing on unique wavelength ranges for target analytes, while broader bandwidth can reduce noise and potentially improve sensitivity for certain applications [12].

Wavelength Step Setting: This determines the interval between measured wavelengths when acquiring full spectra. Smaller step settings (e.g., 1 nm) produce smoother spectral curves with higher resolution, which is particularly valuable for peak purity assessment and spectral library matching. Larger steps reduce data file size but may miss critical spectral features [12].

Reference Wavelength: Proper selection of a reference wavelength helps compensate for fluctuations in lamp intensity and background absorbance changes during gradient elution. The isoabsorbance plot feature in modern DAD software assists in selecting optimal reference wavelengths to minimize baseline drift and improve quantification accuracy [12].

The following diagram illustrates the fundamental operational workflow and key optimization parameters in a DAD system:

Figure 1: DAD Operational Workflow and Key Parameters

Comparative Performance: DAD Versus Alternative Detection Techniques

Technical Comparison of Detection Methods

The selection of an appropriate detection technique for liquid chromatography depends on multiple factors, including the nature of target analytes, matrix complexity, sensitivity requirements, and available instrumentation. DAD occupies a unique position among detection options, balancing versatility, information content, and accessibility. The following table provides a systematic comparison of DAD against other common detection techniques:

Table 1: Performance Comparison of HPLC/UHPLC Detection Techniques

| Detection Technique | Detection Principle | Key Advantages | Key Limitations | Ideal Applications |

|---|---|---|---|---|

| Diode Array Detection (DAD) | Simultaneous multi-wavelength UV-VIS absorption | Full spectral information for peak purity; No compound derivatization needed; Good for method development [9] [11] | Limited to UV-absorbing compounds; Lower sensitivity vs. specialized detectors [11] | Pharmaceutical QC; Natural products; Impurity profiling [13] [7] |

| Single Wavelength UV | Single wavelength UV absorption | Simplicity; Lower cost; Reduced data complexity | No spectral information; Limited peak purity assessment; May miss optimal wavelengths | Routine analysis of known compounds; Methods with established parameters |

| Mass Spectrometry (MS) | Mass-to-charge ratio measurement | High sensitivity and specificity; Structural information; Universal detection possible | High cost; Matrix effects; Complex operation and maintenance [11] | Metabolomics; Trace analysis; Structural elucidation [1] |

| Charged Aerosol Detection (CAD) | Universal detection of non-volatiles | Universal response; No chromophores needed; Good for lipids and carbohydrates | Narrow linear range; No spectral information; Affected by mobile phase [11] | Excipient analysis; Carbohydrates; Lipids without chromophores |

| Fluorescence Detection (FLD) | Emission after light excitation | Very high sensitivity for native fluorophores; Excellent selectivity | Limited to native or derivatized fluorophores; Method development more complex [11] | Natural fluorophores; Derivatized amino acids; Polycyclic aromatic hydrocarbons |

| Coulometric Detection (CD) | Electrochemical oxidation/reduction | Excellent for antioxidants; High sensitivity for electroactive compounds; Can quantify unidentified antioxidants [11] | Limited to electroactive compounds; Electrode maintenance required; More specialized application [11] | Antioxidant analysis; Catecholamines; Pharmaceutical oxidation studies |

Practical Performance in Complex Matrices

The comparative performance of detection techniques becomes particularly evident when analyzing complex matrices. In a comprehensive study comparing DAD and CAD for phenolic compound analysis in apple extracts, DAD demonstrated superior selectivity and sensitivity, with limits of detection ranging from 0.0074 to 0.1179 mg/L for polyphenols in applewood extracts [1] [11]. The CAD response was notably affected by co-eluting substances during rapid-screening analyses, highlighting a key advantage of DAD's spectral discrimination capabilities [11]. Similarly, when analyzing posaconazole in pharmaceutical formulations, HPLC-DAD achieved excellent linearity (r² > 0.999) with a detection limit of 0.82 μg/mL, demonstrating sufficient sensitivity for quality control applications [13].

For compounds with strong UV chromophores, DAD often provides the optimal balance of information content and practical performance. In the analysis of 38 polyphenols in applewood, UHPLC-DAD achieved complete separation and quantification in just 21 minutes, with precision (CV%) below 5% and accuracy ranging between 95.0% and 104%, performance characteristics suitable for routine analytical laboratories [1]. This demonstrates that for many applications requiring compound identification and purity assessment, DAD provides sufficient sensitivity without the operational complexity and cost associated with MS detection [1] [11].

Benchmarking DAD Performance: Experimental Data and Validation

Experimental Protocols for Method Validation

Comprehensive validation of DAD-based methods follows established guidelines such as those from the International Council for Harmonisation (ICH), evaluating critical parameters including specificity, linearity, precision, accuracy, and detection limits [13] [7] [14]. The following experimental protocols represent standardized approaches for validating DAD methods in pharmaceutical and natural product applications:

Protocol 1: Pharmaceutical Compound Analysis (e.g., Posaconazole)

- Chromatographic System: HPLC-DAD system with Zorbax SB-C18 column (4.6 × 250 mm, 5 μm)

- Mobile Phase: Gradient elution with acetonitrile:15 mM potassium dihydrogen orthophosphate (30:70 to 80:20 linear over 7 minutes)

- Flow Rate: 1.5 mL/min

- Detection Wavelength: 262 nm (with full spectral acquisition from 200-400 nm)

- Column Temperature: 25°C

- Injection Volume: 20-50 μL

- Validation Parameters: Linearity (5-50 μg/mL), precision (CV% < 3%), accuracy (bias < 3%), LOD/LOQ determination [13]

Protocol 2: Natural Product Analysis (e.g., Cranberry Phenolics)

- Chromatographic System: UPLC-DAD with ACQUITY UPLC BEH C18 column (2.1 × 50 mm, 1.7 μm)

- Mobile Phase: Gradient elution with 0.1% formic acid in water (A) and 100% methanol (B)

- Gradient Program: 0 min (8% A), 8 min (3% A), 9 min (2% A), 29.5 min (2% A), 30 min (8% A)

- Flow Rate: 0.2 mL/min

- Column Temperature: 25°C

- Detection: Multiple wavelengths with full spectral acquisition (190-400 nm)

- Validation Parameters: Specificity, linearity (R² > 0.999), precision (%RSD < 2%), LOD/LOQ, recovery (80-110%) [7] [14]

Protocol 3: High-Throughput Polyphenol Analysis

- Chromatographic System: UHPLC-DAD with reversed-phase column

- Mobile Phase: Optimized gradient for rapid separation

- Analysis Time: 21 minutes for 38 polyphenols

- Validation: Linear range with R² > 0.999 for all compounds, LOD: 0.0074-0.1179 mg/L, LOQ: 0.0225-0.3572 mg/L, precision: CV < 5% [1]

Quantitative Performance Benchmarks

The performance of DAD detection in validated methods demonstrates its capability for precise and accurate quantification across various applications. The following table summarizes key validation parameters from recent studies employing DAD technology:

Table 2: DAD Method Validation Parameters from Experimental Studies

| Application/Study | Linearity (R²) | Precision (%RSD) | LOD/LOQ | Accuracy (% Recovery) | Analysis Time |

|---|---|---|---|---|---|

| Posaconazole HPLC-DAD [13] | > 0.999 | < 3% | 0.82/2.73 μg/mL | < 3% error | 11 minutes |

| Cranberry Triterpenoids UPLC-DAD [7] | > 0.999 | < 2% | 0.27-1.86/0.90-6.18 μg/mL | 80-110% | 30 minutes |

| Applewood Polyphenols UHPLC-DAD [1] | > 0.999 | < 5% | 0.0074-0.1179/0.0225-0.3572 mg/L | 95-104% | 21 minutes |

| Cranberry Phenolics UPLC-DAD [14] | > 0.999 | < 2% | 0.38-1.01/0.54-3.06 μg/mL | 80-110% | Not specified |

These validation data demonstrate that properly optimized DAD methods consistently achieve excellent linearity, typically with correlation coefficients exceeding 0.999, with precision below 5% RSD across diverse applications [13] [7] [1]. The sensitivity, as indicated by LOD/LOQ values, is sufficient for most pharmaceutical quality control and natural product analysis applications, though it may not reach the levels achievable with more specialized detection techniques like MS for trace analysis.

Essential Research Toolkit for DAD Method Development

Critical Instrumentation and Consumables

Successful implementation of DAD-based analytical methods requires specific instrumentation components and consumables. The following table outlines essential items for establishing reliable DAD analysis in research and quality control settings:

Table 3: Essential Research Toolkit for DAD Method Development and Operation

| Component | Specification/Recommendation | Function/Purpose |

|---|---|---|

| DAD Detector | UV-VIS range (190-900 nm); 512 diode array or higher; 1-10 Hz acquisition rate capability | Simultaneous multi-wavelength detection; Spectral acquisition for peak purity [9] |

| Light Sources | Deuterium (D2) lamp (UV); Tungsten (W) lamp (Visible) | Broad-spectrum emission for UV and visible detection ranges [9] |

| Flow Cells | Micro-volume flow cells (e.g., 1-10 μL volume); Extended pathlength options for sensitivity | Sample detection cell; Pathlength selection balances sensitivity and band broadening [9] |

| Chromatography Columns | C18 stationary phases; Sub-2μm particles for UHPLC; Various dimensions (e.g., 2.1 × 50-100 mm) | Compound separation; Column selection impacts resolution and analysis time [13] [7] |

| Mobile Phase Components | HPLC-grade solvents; Buffer salts (e.g., potassium dihydrogen phosphate); Acid modifiers (e.g., formic acid) | Carrier medium for chromatographic separation; Mobile phase optimization critical for peak shape [13] [7] |

| Reference Standards | Certified reference materials; Internal standards (e.g., itraconazole) [13] | Compound identification and quantification; Method validation and quality control |

| Cytogenin | 8-hydroxy-3-(hydroxymethyl)-6-methoxyisochromen-1-one | High-purity 8-hydroxy-3-(hydroxymethyl)-6-methoxyisochromen-1-one for research applications. This product is for Research Use Only (RUO) and is not intended for diagnostic or therapeutic use. |

| 13-Hydroxylupanine | 13-Hydroxylupanine, MF:C15H24N2O2, MW:264.36 g/mol | Chemical Reagent |

Method Optimization Tools

Beyond core instrumentation, several tools and approaches facilitate optimal DAD method development:

- Spectral Library Software: Enables comparison of unknown spectra with reference databases for compound identification [11]

- Peak Purity Algorithms: Mathematical processing of spectral data across a peak to detect co-elution [11]

- Isoabsorbance Plot Tools: Assist in selecting optimal wavelengths and reference wavelengths for specific methods [12]

- System Suitability Protocols: Standardized tests to verify DAD performance before analytical runs [11]

The following diagram illustrates the logical workflow for DAD method development and optimization, highlighting critical decision points:

Figure 2: DAD Method Development and Optimization Workflow

Advantages and Applications in Pharmaceutical Analysis

Key Advantages for Compound Identification and Purity Assessment

DAD technology provides several distinct advantages for compound identification and purity assessment in pharmaceutical and natural product analysis:

Peak Purity Assessment: By comparing spectra across a chromatographic peak, DAD enables detection of co-eluting impurities that might be missed by single-wavelength detection. Spectral homogeneity throughout the peak confirms purity, while spectral variations indicate potential co-elution [11]. This capability is particularly valuable for pharmaceutical quality control where impurity profiling is critical [13].

Method Development and Optimization: The full spectral data acquired during method development helps identify optimal detection wavelengths for each compound in a mixture, maximizing sensitivity while minimizing interference [12]. The ability to retrospectively extract chromatograms at different wavelengths from a single injection significantly reduces method development time [9] [10].

Compound Identification Confirmation: The UV-VIS spectrum serves as a compound-specific fingerprint, allowing tentative identification by comparison with reference spectra [11]. While not as definitive as mass spectrometric identification, spectral matching provides valuable supporting evidence for compound identity, especially when combined with retention time matching [11] [14].

Unknown Compound Characterization: In samples containing unexpected components, the archived spectral data enables preliminary characterization of unknown compounds based on their UV spectral characteristics, which can guide subsequent analysis by complementary techniques [9] [11].

Pharmaceutical and Natural Product Applications

The application of DAD spans numerous fields where compound identification and purity assessment are paramount:

Pharmaceutical Quality Control: DAD is widely employed for assay and impurity testing of active pharmaceutical ingredients and finished dosage forms. For example, the quantification of posaconazole in bulk powder and suspension formulations demonstrated the effectiveness of HPLC-DAD for pharmaceutical quality control [13]. The technology successfully monitored content uniformity and detected potential degradants, fulfilling regulatory requirements for pharmaceutical analysis [13].

Natural Product Standardization: DAD methods enable comprehensive profiling of complex botanical extracts, such as the simultaneous quantification of multiple triterpenoids in cranberry fruit [7] and phenolic compounds in American cranberry cultivars [14]. These applications highlight DAD's ability to characterize complex natural matrices for standardization of herbal medicines and dietary supplements.

Food and Agricultural Analysis: The rapid quantification of 38 polyphenols in applewood extracts using UHPLC-DAD demonstrates the technique's applicability to food and agricultural samples [1]. The method provided the necessary sensitivity, selectivity, and throughput for routine analysis of agricultural byproducts for valorization purposes.

Method Transfer and Harmonization: The wealth of spectral information provided by DAD facilitates method transfer between laboratories and instrumentation platforms by enabling more comprehensive system suitability assessment and troubleshooting compared to single-wavelength detection [11] [12].

Diode Array Detection represents a versatile and powerful detection technology that occupies a crucial niche in modern chromatographic analysis, particularly for applications requiring compound identification and purity assessment. While mass spectrometry offers superior sensitivity and definitive structural information, DAD provides an optimal balance of performance, accessibility, and information content for many pharmaceutical, natural product, and quality control applications [1] [11]. The ability to acquire full UV-VIS spectra throughout the chromatographic run enables comprehensive peak purity assessment, method optimization, and preliminary compound identification that significantly surpasses the capabilities of single-wavelength detection [9] [11].

The experimental data from validated methods demonstrate that DAD consistently delivers excellent linearity (typically R² > 0.999), precision (often < 3% RSD), and sufficient sensitivity for most routine applications [13] [7] [1]. When properly optimized with respect to critical parameters including acquisition rate, bandwidth, and wavelength selection, DAD methods achieve robust performance suitable for regulatory compliance in pharmaceutical quality control [13] [12]. As chromatographic techniques continue to evolve toward faster separations with UHPLC and UPLC systems, the comprehensive spectral data provided by DAD will remain invaluable for method development, transfer, and troubleshooting across the pharmaceutical and natural product industries.

Fundamental Principles of Resolution and Efficiency in Fast Liquid Chromatography

The evolution of liquid chromatography has been fundamentally driven by the pursuit of higher resolution and efficiency. This guide objectively benchmarks Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) against Ultra-Performance Liquid Chromatography with Diode Array Detection (UPLC-DAD), two pivotal technologies enabling rapid, high-resolution separations. By examining core principles, performance metrics, and practical applications—particularly in pharmaceutical and natural products research—this analysis provides a structured framework for scientists to optimize analytical methods. Data presented herein demonstrate that UPLC systems, leveraging sub-2µm particles and higher pressure capabilities, typically achieve superior resolution and reduced analysis times compared to UFLC. However, UFLC remains a robust, cost-effective solution for many routine applications. The comparative data and methodologies summarized will aid researchers in making informed, context-appropriate selections for their method development workflows.

The fundamental principles of resolution (Rs) and efficiency (N) form the cornerstone of all chromatographic separations. Resolution, defining the ability to distinguish between two adjacent peaks, is mathematically expressed as Rs = 2[(tR2 - tR1) / (wb1 + wb2)], where tR is retention time and wb is peak width. Efficiency, measured by the number of theoretical plates (N = 16 (tR/wt)^2, where w_t is the peak width at base), quantifies the column's ability to produce sharp, narrow peaks. The driving force behind Fast Liquid Chromatography has been the enhancement of these parameters to achieve faster analyses without sacrificing, and often improving, separation quality.

The Van Deemter equation (H = A + B/u + C*u, where H is plate height and u is linear velocity) explains the theoretical basis for these advances by describing the relationship between flow rate and efficiency. The development of smaller, uniform stationary phase particles reduces the A (eddy diffusion) and C (mass transfer) terms, allowing for high efficiency even at increased flow rates. This principle enabled the transition from High-Performance Liquid Chromatography (HPLC) to more advanced platforms like UFLC and UPLC. UPLC operates at significantly higher pressures (often exceeding 1000 bar) using columns packed with sub-2µm particles, whereas UFLC typically utilizes particles in the 2-3µm range at moderate pressures (400-600 bar), representing an intermediate step between conventional HPLC and UPLC in the evolution of chromatographic speed and performance [1] [15]. This guide systematically benchmarks UFLC-DAD against UPLC-DAD to provide a clear, data-driven comparison for method optimization research.

Core Technology Comparison: UFLC-DAD vs. UPLC-DAD

The performance differential between UFLC and UPLC stems from their distinct engineering and material specifications. Understanding these core technological differences is essential for predicting system behavior and selecting the appropriate platform for a given application.

Table 1: Core System Specifications and Performance Characteristics

| Feature/Specification | UFLC-DAD | UPLC-DAD |

|---|---|---|

| Typical Operating Pressure | 400 - 600 bar | 600 - 1300+ bar [4] |

| Stationary Phase Particle Size | 2 - 3 µm | Often sub-2 µm (e.g., 1.7 µm, 1.8 µm) [1] [7] |

| System Dispersion (Extra-column Volume) | Moderate | Minimized |

| Analysis Speed | Faster than HPLC | Very high; typically 3x faster than HPLC |

| Solvent Consumption | Reduced vs. HPLC | Significantly reduced [1] |

| Detector Acquisition Rate | Standard for fast LC | High-speed capable (compatible with narrow peaks) |

| Method Transfer | Easier transfer from HPLC | Requires re-validation and often re-development from HPLC methods |

UPLC's use of smaller particles provides a larger surface area for interaction, directly enhancing chromatographic efficiency (theoretical plates, N). The increased pressure capability is necessary to overcome the high backpressure generated by these tightly packed beds. Furthermore, UPLC systems are designed with minimized extra-column volume (in tubing, connectors, and detector flow cells) to prevent peak broadening, which is critical when dealing with the very narrow peaks produced by efficient columns [15]. UFLC systems improve upon traditional HPLC in these areas but do not reach the extremes of UPLC design, positioning them as a high-performance yet more accessible technology.

Quantitative Performance Benchmarking

Direct application-based comparisons reveal the practical impact of these technological differences. The following data, compiled from validation studies, quantifies the performance of each system in real-world scenarios.

Table 2: Application Performance Metrics from Validation Studies

| Application / Metric | UPLC-DAD Method Performance | UFLC/HPLC-DAD Method Performance |

|---|---|---|

| Polyphenols in Applewood [1] | 38 compounds in 21 min; R² > 0.999; LOD: 0.0074–0.1179 mg/L | Similar HPLC method required 60 min for only 22 compounds |

| Triterpenoids in Cranberry [7] | Analysis time: 30 min; R² > 0.999; LOD: 0.27–1.86 µg/mL; Recovery: 80–110% | Not directly available; conventional HPLC for similar compounds often exceeds 60 min |

| Phenolic Compounds in G. littoralis [16] | (HPLC) 16 compounds; R² > 0.999; Precision RSD < 3% | |

| Sweeteners/Preservatives in Beverages [17] | (HPLC) 7 compounds in < 9 min; R² ≥ 0.9995; Recovery: 94.1–99.2% | |

| Vitamins B1, B2, B6 [18] | (HPLC with FLD) R² > 0.999; Accuracy (% Mean Recovery): 100 ± 3% |

A key benchmark study [1] directly demonstrates UPLC's advantage: a method separating 38 polyphenols in just 21 minutes, whereas a conventional HPLC approach required 60 minutes to separate only 22 compounds. This represents a significant increase in throughput and informational density per unit time. Both UPLC-DAD and well-optimized UFLC/HPLC-DAD methods consistently demonstrate excellent linearity (R² > 0.999) and precision (RSD often < 3-5%) when properly validated according to International Council for Harmonisation (ICH) guidelines [1] [17] [7]. The limits of detection (LOD) for UPLC-DAD are exceptionally low, as seen in the polyphenol application (as low as 0.0074 mg/L), making it suitable for trace analysis [1].

Experimental Protocols for Method Comparison

To generate comparable data like that in Section 3, standardized experimental protocols are essential. The following workflow outlines a systematic approach for benchmarking UFLC-DAD and UPLC-DAD performance using the same sample set.

Figure 1: Experimental workflow for the systematic comparison of UFLC-DAD and UPLC-DAD method performance.

Sample and Standard Preparation

- Standard Solution: Prepare a mixture of analytes covering a range of polarities. For instance, a polyphenol standard mix could include chlorogenic acid, caffeic acid, rutin, quercetin, and phloridzin [1] [16]. Prepare serial dilutions in the initial mobile phase or a compatible solvent (e.g., methanol) for calibration curves (e.g., 5–100 mg/L).

- Real Sample Extraction: For plant material (e.g., applewood, cranberry), lyophilize and grind the sample into a fine powder. Accurately weigh ~100 mg, and extract with 1 mL of a solvent like 80% methanol using ultrasonication for 90 minutes at room temperature. Centrifuge (e.g., 3500 rpm for 20 min) and filter the supernatant through a 0.22 µm membrane filter prior to injection [1] [16] [7].

Instrumental Configuration and Method Parameters

UFLC-DAD System:

- Column: Kinetex C18 (150 mm × 4.6 mm, 2.6 µm) [or similar core-shell column].

- Mobile Phase: (Example) (A) 0.1% Formic acid in water, (B) Acetonitrile.

- Gradient: Optimized for the column, e.g., 5% B to 95% B over 20-30 minutes.

- Flow Rate: 1.0 - 1.5 mL/min.

- Temperature: 30 - 40 °C.

- Injection Volume: 1 - 5 µL.

- DAD Wavelength: As per analyte, e.g., 280 nm for polyphenols [1] [16].

UPLC-DAD System:

- Column: ACE C18 (100 mm × 2.1 mm, 1.7 µm) [7] or equivalent.

- Mobile Phase: (Example) (A) 0.1% Formic acid in water, (B) Methanol [7].

- Gradient: Scaled and optimized from the UFLC method, e.g., 8% B to 98% B over 10-15 minutes.

- Flow Rate: 0.2 - 0.6 mL/min (adjusted for backpressure and separation).

- Temperature: 25 - 40 °C [7].

- Injection Volume: 1 - 2 µL.

- DAD Wavelength: As per analyte; may require faster data acquisition rates.

Key Experiments and Validation Parameters

Once the systems are configured, the following performance parameters should be evaluated and compared between the two platforms:

- System Suitability Test: Before data collection, inject a standard mixture to ensure the system meets acceptance criteria for retention time stability (%RSD < 1%), peak asymmetry (As, 0.8-1.2), and resolution (R, ≥ 1.5 between critical pair) [17].

- Linearity and Sensitivity: Analyze the standard calibration curves. Calculate the coefficient of determination (R²) and the Limits of Detection (LOD) and Quantification (LOQ) for each analyte on both systems [1] [17] [7].

- Precision and Accuracy: Perform intra-day (repeatability) and inter-day (intermediate precision) analysis of QC samples at low, medium, and high concentrations. Calculate %RSD for precision. Assess accuracy via a spike-recovery experiment in a real sample matrix, with ideal recovery ranging from 95–105% [1] [17].

- Peak Capacity and Analysis Time: For the same sample, directly compare the total run time and the number of peaks resolved (or the peak capacity) to quantify the gain in throughput and resolution.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Reagents and Materials for UFLC-DAD/UPLC-DAD Method Development

| Item | Function & Specification | Example Use Case |

|---|---|---|

| UHPLC/Grade Solvents | High-purity mobile phase components to prevent baseline noise and system damage. | Acetonitrile, Methanol, Water (HPLC grade); Additives like Formic Acid (≥98%) [17] [16]. |

| Analytical Reference Standards | High-purity compounds for peak identification and calibration. | Chlorogenic acid (≥95%), Caffeic acid (≥98%), Ursolic acid, etc. [1] [16] [7]. |

| Reversed-Phase UHPLC Column | The stationary phase for separation; sub-2µm for UPLC, 2-3µm for UFLC. | ACE C18 (100x2.1mm, 1.7µm) [7] or similar for UPLC; Kinetex C18 (150x4.6mm, 2.6µm) for UFLC. |

| Internal Standard | Compound added to correct for procedural losses and instrument variability. | Daidzein was used in polyphenol analysis [1]. |

| Syringe Filters | For clarification of sample solutions prior to injection to protect the column. | 0.22 µm (or 0.45 µm) pore size, PVDF or Nylon membrane [17] [16]. |

| Vial Inserts | For low-volume samples, minimizing solvent evaporation and improving autosampler precision. | Useful for 2.1 mm inner diameter UPLC columns with low injection volumes. |

| Clovamide | Clovamide, CAS:53755-03-6, MF:C18H17NO7, MW:359.3 g/mol | Chemical Reagent |

| Arvenin I | Arvenin I, CAS:65247-27-0, MF:C38H56O13, MW:720.8 g/mol | Chemical Reagent |

Strategic Application and Selection Guidelines

The choice between UFLC-DAD and UPLC-DAD is not merely technical but also strategic, depending on project goals, infrastructure, and regulatory constraints.

Select UPLC-DAD for cutting-edge research and complex samples where maximum resolution, speed, and sensitivity are paramount. Its superior performance is critical for analyzing complex matrices with hundreds of constituents (e.g., plant metabolomics [15]) or for high-throughput environments like pharmaceutical quality control, where a validated UPLC-DAD method separated 7 additives in under 9 minutes [17]. The significantly reduced solvent consumption also aligns with Green Analytical Chemistry principles [1].

Opt for UFLC-DAD for method development and regulated environments. UFLC serves as an excellent platform for initial method scouting due to its wider compatibility with HPLC methods and lower operational pressure. In many regulated pharmaceutical quality control (QC) laboratories, established HPLC/UFLC methods are preferred as changes require extensive re-validation [4]. UFLC provides a robust balance of improved performance over HPLC and easier method transfer, making it a cost-effective and practical choice for many routine analyses.

The trend in analytical chemistry is toward the integration of advanced metabolite profiling with targeted isolation [15]. In this context, UPLC-DAD-MS systems are increasingly becoming the gold standard. The high-resolution separation achieved by UPLC directly enhances MS detection by reducing ion suppression and providing cleaner spectra for compound identification. Therefore, for laboratories planning to incorporate mass spectrometry in the future, investing in UPLC technology provides a more forward-compatible and versatile platform.

The pursuit of optimal performance in liquid chromatography is fundamentally governed by the kinetic parameters that control band broadening and separation efficiency. At the heart of this understanding lies the Van Deemter equation, a foundational mathematical model that describes the relationship between linear velocity and chromatographic efficiency, expressed as height equivalent to a theoretical plate (HETP). This equation provides the theoretical framework for comparing different chromatographic platforms, particularly Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) and Ultra-Performance Liquid Chromatography with Diode Array Detection (UPLC-DAD) [19] [20].

The Van Deemter equation is expressed as: HETP = A + B/u + C·u, where A represents eddy diffusion, B represents longitudinal diffusion, and C represents the resistance to mass transfer between phases [19]. The A-term is primarily related to the particle size of the packing material and how well the chromatographic bed is packed. The B-term relates to the diffusion of the analyte in the bulk mobile phase and decreases with increasing mobile phase velocity. The C-term is related to both the linear velocity and the square of the particle size, describing the interaction of analyte molecules with the internal surface of the stationary phase [20].

Modern chromatography has evolved toward systems utilizing progressively smaller particles, with UPLC systems employing sub-2µm particles compared to the larger particles (typically 3-5µm) used in conventional UFLC systems. This reduction in particle size directly impacts all terms of the Van Deemter equation, leading to flatter curves with lower minimum HETP values and higher optimal linear velocities, thereby enabling faster separations without sacrificing efficiency [20].

Theoretical Framework: Van Deemter Equation and Kinetic Plots

Mathematical Foundation of the Van Deemter Equation

The Van Deemter equation provides a complete description of the band broadening processes occurring within a chromatographic column. The eddy diffusion (A-term) occurs as analyte molecules take different paths through the packed bed, with larger particles causing more variable path lengths and thus broader peaks. The longitudinal diffusion (B-term) becomes significant at lower flow rates where molecules have more time to diffuse axially. The mass transfer resistance (C-term) quantifies how quickly molecules can diffuse into and out of the porous stationary phase, with smaller particles dramatically reducing this term because molecules have shorter distances to travel [19] [20].

For small particles (below 2µm), the A-term becomes negligible in well-packed columns, and the C-term is significantly reduced. This transforms the shape of the Van Deemter curve, making it flatter and shifting the optimum to higher linear velocities. This fundamental difference explains the performance advantages of UPLC technology, allowing operation at faster flow rates without the typical efficiency loss observed with larger particles [20].

Kinetic Plot Theory and Application

While Van Deemter curves plot HETP against linear velocity, kinetic plots provide a more practical representation by plotting analysis time versus required efficiency. This transformation allows direct comparison of different chromatographic systems for achieving specific separation goals. Kinetic plots are derived from the Van Deemter equation through mathematical transformation, incorporating column permeability constraints that become particularly important when using smaller particles that generate higher backpressures [20].

The construction of kinetic plots involves calculating the minimum analysis time required to achieve a target plate count for each chromatographic system. When comparing UFLC and UPLC platforms, kinetic plots consistently demonstrate that UPLC systems can achieve the same efficiency in significantly shorter times, or higher efficiency in comparable times, within pressure limitations. This makes them particularly valuable for high-throughput laboratories where method throughput is critical [20].

Diagram 1: Theoretical Impact of Particle Size Reduction on Chromatographic Performance. This flowchart illustrates the causal relationship between reduced particle size in UPLC systems and the resulting improvements in separation kinetics through modification of Van Deemter parameters.

Experimental Comparison: UFLC-DAD vs. UPLC-DAD Performance

Methodologies for Experimental Comparison

Valid comparison of UFLC-DAD and UPLC-DAD systems requires carefully controlled experimental protocols that eliminate variables unrelated to the core technological differences. The following standardized methodology has been adopted from multiple studies comparing chromatographic performance [1] [7] [21]:

Column Selection and Mobile Phase Preparation: For UPLC-DAD analysis, columns packed with sub-2µm particles (e.g., 1.7-1.8µm) with dimensions of 100 × 2.1 mm should be used. For UFLC-DAD analysis, columns with 3-5µm particles with dimensions of 150 × 4.6 mm provide the appropriate comparison. The same mobile phase composition should be used for both systems, typically employing acidified water (0.1% formic acid) and methanol or acetonitrile in gradient elution mode [7]. The gradient profile should be scaled appropriately to maintain the same number of column volumes.

Instrumentation Parameters and Test Mixture: Both systems should employ DAD detection with identical detection wavelengths (typically 205-280 nm depending on analytes) and sampling rates. The test mixture should contain compounds with varying hydrophobicities and molecular weights to adequately assess separation performance across different retention domains. A suitable mixture includes pharmaceutical compounds like warfarin and its metabolites [22], or naturally occurring analytes like triterpenoids and phenolic compounds [7] [21]. Column temperature should be maintained constant at 25-30°C, and injection volumes should be scaled according to column dimensions to maintain comparable loading.

Data Collection and Processing: For Van Deemter curve construction, flow rates should be varied systematically from 0.1 mL/min to the pressure limit of each system (typically 1.5-2.0 mL/min for UPLC and 0.5-1.5 mL/min for UFLC). At least five replicate injections should be performed at each flow rate to ensure statistical significance. Data should be processed using chromatography data systems (CDS) that accurately measure retention time, peak width at half height, and peak asymmetry for each analyte [4].

Quantitative Performance Data

The following tables summarize experimental data comparing UFLC-DAD and UPLC-DAD systems across multiple performance parameters, compiled from published studies and manufacturer specifications [1] [4] [7]:

Table 1: System Parameter Comparison Between UFLC-DAD and UPLC-DAD Platforms

| Parameter | UFLC-DAD | UPLC-DAD | Performance Implication |

|---|---|---|---|

| Typical Particle Size | 3-5µm | 1.7-1.8µm | UPLC provides higher efficiency per unit length |

| Operating Pressure Range | 200-400 bar | 600-1300 bar | UPLC enables longer columns or faster flow rates |

| Optimal Linear Velocity | ~0.95 mm/s | ~2.5-3.0 mm/s | UPLC achieves optimum efficiency at higher speeds |

| Minimum HETP | 10-15µm | 5-8µm | UPLC provides 1.5-2x higher efficiency |

| Typical Analysis Time | 15-60 minutes | 3-21 minutes | UPLC reduces analysis time by 3-5x |

| Solvent Consumption per Run | 10-25 mL | 2-5 mL | UPLC reduces solvent use by 70-80% |

Table 2: Experimental Performance Data for Polyphenol Separation [1]

| Metric | UFLC-DAD Method | UPLC-DAD Method | Improvement Factor |

|---|---|---|---|

| Number of Compounds Separated | 22 compounds | 38 compounds | 1.7x more compounds |

| Analysis Time | 60 minutes | 21 minutes | 2.9x faster |

| Peak Capacity | 120 | 210 | 1.75x higher |

| Resolution (Critical Pair) | 1.2 | 1.8 | 50% improvement |

| LOD Range | 0.01-0.05 mg/L | 0.0074-0.1179 mg/L | Comparable to improved |

Table 3: Van Deemter Parameters for Different Particle Sizes [20]

| Particle Size | A-term (µm) | B-term (mm²/s) | C-term (ms) | Optimal Velocity (mm/s) | Minimum HETP (µm) |

|---|---|---|---|---|---|

| 10µm | 18.0 | 4.5 | 15 | 0.7 | 18.0 |

| 5µm | 10.0 | 4.5 | 8 | 0.95 | 10.0 |

| 1.7µm | 3.5 | 4.5 | 2.5 | 2.5-3.0 | 5.0-6.0 |

Application-Based Performance Validation

Recent studies demonstrate the practical implications of these theoretical differences in real-world applications. In pharmaceutical analysis, a study comparing the separation of warfarin and its metabolites showed that UPLC-DAD achieved baseline resolution in 4.5 minutes compared to 18 minutes required by UFLC-DAD, representing a 75% reduction in analysis time while maintaining equivalent resolution [22]. Similarly, in natural products analysis, a method for quantifying triterpenoids in cranberry samples achieved complete separation of 10 analytes in 30 minutes using UPLC-DAD, whereas conventional UFLC-DAD required over 60 minutes for comparable separation [7].

The implementation of automated method development with feedback-controlled optimization, as described by Aldine et al., further leverages the kinetic advantages of UPLC systems. By using AI-based algorithms to optimize gradient profiles and column temperatures, researchers achieved optimal separations of complex pharmaceutical mixtures in significantly fewer development iterations compared to manual approaches [22].

Diagram 2: Experimental Workflow for Chromatographic System Comparison. This workflow outlines the standardized methodology for comparative evaluation of UFLC-DAD and UPLC-DAD system performance through Van Deemter analysis and kinetic plot construction.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 4: Essential Research Reagents and Materials for Chromatographic Method Development

| Item | Function | Application Notes |

|---|---|---|

| Sub-2µm UPLC Columns | Stationary phase for high-resolution separations | Provides superior efficiency; requires high-pressure compatible systems [20] |

| 3-5µm UFLC Columns | Reference stationary phase for conventional separations | Standard particle size for baseline comparison [21] |

| HPLC-Grade Methanol/Acetonitrile | Mobile phase components | Ensure low UV absorbance and minimal impurities [7] [21] |

| Acidification Reagents (Formic/Phosphoric Acid) | Mobile phase modifiers | Improve peak shape and ionization in mass spectrometry [7] |

| Pharmaceutical Standards (Warfarin metabolites) | Test compounds for method validation | Well-characterized compounds with known retention behavior [22] |

| Polyphenol/Triterpenoid Mixtures | Natural product test mixtures | Complex mixtures for challenging separation evaluation [1] [7] |

| Column Oven/Temperature Controller | Temperature regulation | Essential for reproducible retention times and efficiency [22] |

| Automated Method Development Software | Optimization algorithms | Reduces development time through intelligent experimentation [22] |

| Euphorbetin | Euphorbetin Research Compound|For Research Use Only | Euphorbetin, a flavonoid from Euphorbia species. For Research Use Only (RUO). Not for diagnostic or therapeutic use. Explore its potential research applications. |

| Demethylmacrocin | Demethylmacrocin|Tylosin Intermediate|RUO | Demethylmacrocin is a key biosynthetic intermediate in tylosin production. This product is for research use only and not for human or veterinary use. |

The theoretical framework provided by Van Deemter curves and kinetic plots demonstrates clear performance advantages for UPLC-DAD systems over UFLC-DAD platforms, primarily through reduced particle size technology that minimizes all band-broadening terms in the fundamental resolution equation. Experimental data validates these theoretical predictions, showing typical improvements of 2-5x in analysis speed, 1.5-2x in efficiency, and 70-80% reduction in solvent consumption [1] [20].

For drug development professionals, these performance differences translate into tangible benefits throughout the method development and optimization workflow. The increased throughput of UPLC-DAD systems enables faster method scouting and more comprehensive method optimization within constrained development timelines. The improved efficiency provides better resolution of complex mixtures, potentially revealing critical impurities or degradation products that might co-elute in conventional UFLC-DAD analyses [22] [23].

Future developments in chromatographic technology continue to build upon these fundamental principles, with emerging trends including further reduction in particle size, improved column packing technology, and enhanced instrumentation that minimizes extra-column band broadening. The integration of artificial intelligence for method development, as exemplified by feedback-controlled optimization systems, represents the next frontier in leveraging these theoretical principles for practical analytical advantage in pharmaceutical research and quality control environments [22].

Strategic Method Development and Real-World Application Across Industries

The relentless pursuit of higher efficiency, faster analysis, and better resolution in analytical chemistry has driven the evolution from High-Performance Liquid Chromatography (HPLC) to more advanced techniques including Ultra-Fast Liquid Chromatography (UFLC) and Ultra-Performance Liquid Chromatography (UPLC). This transition represents more than incremental improvement; it constitutes a paradigm shift in separation science enabled by fundamental advances in particle chemistry, system pressure capabilities, and detector technology [24]. For researchers and drug development professionals, understanding the principles and practical considerations for method transfer between these platforms is crucial for maintaining competitiveness in fast-paced environments like pharmaceutical quality control and method development [2]. The ability to strategically convert existing HPLC methods to UFLC or UPLC platforms can dramatically enhance laboratory throughput, reduce solvent consumption, and improve overall analytical performance [25] [26]. This guide provides a comprehensive comparison of these technologies, supported by experimental data and practical protocols for successful method transfer.

Technical Fundamentals: Core Principles and Differences

The Van Deemter Foundation

The theoretical foundation for modern liquid chromatography advancements rests substantially on the Van Deemter equation, which describes the relationship between linear velocity and plate height (HETP). The equation is expressed as: H = A + B/v + Cv, where A represents eddy diffusion, B represents longitudinal diffusion, and C represents the mass transfer kinetic term [2] [27]. The revolutionary aspect of UPLC technology lies in its utilization of stationary phases with particles smaller than 2μm, which significantly reduces the A and C terms in the Van Deemter equation [27]. This reduction translates to flatter curves where higher linear velocities can be employed without sacrificing efficiency, meaning separations can be performed faster while maintaining resolution [28] [24].

Pressure and Particle Size Relationships

The relationship between particle size and required operating pressure follows the Kozeny-Carman equation, where pressure increases inversely with the square of particle size [28]. When particle size decreases from 5μm to 1.7μm, the pressure requirement increases approximately eight-fold if other parameters remain constant [29]. This fundamental relationship explains why UPLC systems must operate at significantly higher pressures (up to 1000 bar or 15,000 psi) compared to traditional HPLC systems (typically 400 bar) [25]. UFLC occupies a middle ground, utilizing optimized system components with conventional 3-5μm particles to achieve faster analysis than HPLC without requiring the extreme pressure capabilities of UPLC systems [25].

Comparative Analysis: HPLC vs. UFLC vs. UPLC

System Specifications and Performance Metrics

Table 1: Technical Specifications and Performance Comparison of HPLC, UFLC, and UPLC

| Parameter | HPLC | UFLC | UPLC |

|---|---|---|---|

| Full Name | High Performance Liquid Chromatography | Ultra Fast Liquid Chromatography | Ultra Performance Liquid Chromatography |

| Column Particle Size | 3–5 μm [25] | 3–5 μm [25] | ≤2 μm (typically 1.7 μm) [25] |

| Pressure Limit | Up to ~400 bar (6000 psi) [25] | Up to ~600 bar (8700 psi) [25] | Up to ~1000 bar (15,000 psi) [25] [2] |

| Speed of Analysis | Moderate (10–30 min typical run time) [25] | Faster than HPLC (5–15 min) [25] | Very fast (1–10 min) [25] |

| Resolution | Moderate [25] | Improved compared to HPLC [25] | High resolution due to smaller particle size [25] |

| Sensitivity | Moderate [25] | Slightly better than HPLC [25] | High sensitivity [25] |

| Instrument Cost | Lower [25] | Moderate [25] | Higher [25] |

| Column Cost | Lower [25] | Moderate [25] | Higher [25] |

| Solvent Consumption | Higher [26] [13] | Moderate reduction [25] | 4-5 times less than HPLC [26] [13] |

| Sample Throughput | Low to Moderate [25] | Moderate [25] | High [25] |

Experimental Case Studies and Performance Data

Pharmaceutical Compound Analysis

A direct comparison of HPLC and UPLC methods for analysis of the antifungal drug posaconazole demonstrated significant advantages for UPLC technology. The HPLC method utilized a Zorbax SB-C18 (4.6 × 250 mm, 5 μm) column with gradient elution over 7 minutes, resulting in a total run time of 11 minutes. In contrast, the UPLC method employed a Kinetex-C18 (2.1 × 50 mm, 1.3 μm) column with isocratic elution, achieving separation in just 3 minutes [13]. This represents a 73% reduction in analysis time while maintaining excellent linearity (r² > 0.999) for both methods. The UPLC method also demonstrated substantially reduced solvent consumption, contributing to lower operating costs and environmental impact [13].

Food Colorant Analysis

In the analysis of synthetic food colorants in commercial products, researchers developed complementary HPLC-DAD and UPLC-ESI-MS/MS methods. The HPLC approach successfully separated five colorants (Tartrazine, Sunset Yellow, Allura Red, Carmoisine, and Brilliant Blue) within 9 minutes using a C18 column (100 mm × 4.6 mm, 5-μm) with gradient elution [30]. The UPLC method achieved separation of the same compounds in just 3 minutes using MS/MS detection, representing a 67% reduction in analysis time [30]. This enhanced throughput is particularly valuable in quality control environments where large sample batches must be processed efficiently.

Guanylhydrazones Anticancer Agents

A systematic comparison of HPLC and UHPLC methods for analyzing guanylhydrazones with anticancer activity revealed that the UHPLC method provided superior economic and performance characteristics [26]. The UHPLC approach demonstrated four times less solvent consumption and used 20 times less injection volume while maintaining excellent precision, accuracy, and linearity [26]. Notably, the researchers employed experimental design (DoE) for UHPLC method development, which proved faster and more rational compared to the empirical approach used for HPLC method development [26].

Table 2: Experimental Method Comparison from Published Studies

| Study | Analytes | HPLC Conditions | UPLC/UHPLC Conditions | Improvement |

|---|---|---|---|---|

| Posaconazole Analysis [13] | Antifungal drug | Column: 4.6 × 250 mm, 5μmTime: 11 minFlow: 1.5 mL/min | Column: 2.1 × 50 mm, 1.3μmTime: 3 minFlow: 0.4 mL/min | 73% faster analysis, reduced solvent consumption |

| Food Colorants [30] | Five synthetic colorants | Column: 100 × 4.6 mm, 5μmTime: 9 minGradient elution | Time: 3 minMS/MS detection | 67% faster analysis, superior detection |

| Guanylhydrazones [26] | Anticancer compounds | Empirical method developmentHigher solvent consumption | DoE approach4x less solvent, 20x less injection volume | Economic and environmental benefits |

Method Transfer Protocols: Practical Implementation

Systematic Method Transfer Approach

Successful method transfer from HPLC to UPLC or UFLC requires a systematic approach that accounts for fundamental differences in system characteristics. The process begins with careful assessment of the original HPLC method's critical parameters, including resolution requirements, peak pair of interest, and current performance metrics [29]. The next step involves calculating scaling parameters to maintain equivalent separation performance while leveraging the advantages of smaller particle sizes [29]. Method transfer typically involves adjusting column dimensions, particle size, flow rate, and injection volume while maintaining the same stationary phase chemistry whenever possible [27].

Scaling Calculations and Parameter Adjustment

The fundamental relationship for method transfer between different chromatographic systems follows the principle of constant linear velocity when adjusting column dimensions. When transferring from HPLC to UPLC, the following calculations ensure consistent separation performance:

Flow Rate Adjustment:

Where F is flow rate, d_c is column diameter, and L is column length [29].

Gradient Time Adjustment:

Where t_G is gradient time and V is column volume [29].

Injection Volume Adjustment:

Where V_inj is injection volume [29].

A practical example demonstrates these calculations: transferring a method from a conventional HPLC column (150 mm × 4.6 mm, 5μm) to a UPLC column (50 mm × 2.1 mm, 1.7μm) while maintaining separation quality. The flow rate would be adjusted from 1.0 mL/min to approximately 0.21 mL/min, and the injection volume would be scaled down proportionally [29]. These calculations provide a starting point for method optimization, which typically requires additional fine-tuning to achieve optimal performance on the new platform.

Method Validation and System Suitability

After transferring a method to a new platform, verification against system suitability criteria is essential. This process typically includes assessment of precision, accuracy, linearity, specificity, and robustness [26] [13]. For quantitative analysis, baseline resolution (R > 1.5) between critical peak pairs should be maintained, though some method transfers intentionally sacrifice excess resolution for speed [29]. In the case of posaconazole analysis, both HPLC and UPLC methods demonstrated excellent precision (CV% < 3%) and accuracy (% error < 3%), confirming that the transfer process maintained data quality while improving efficiency [13].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Research Reagents and Materials for Chromatography Method Transfer

| Item | Function | Application Notes |

|---|---|---|

| Columns (HPLC) | Stationary phase for separation | Typically 3-5μm particles, 4.6mm diameter, 150-250mm length [25] |

| Columns (UFLC) | Stationary phase for separation | Uses similar particles to HPLC (3-5μm) with optimized hardware [25] |

| Columns (UPLC) | Stationary phase for separation | Sub-2μm particles (typically 1.7μm), 2.1mm diameter, shorter lengths [25] [27] |

| Mobile Phase Solvents | Carrier for analytes through system | HPLC-grade acetonitrile, methanol, water with modifiers [26] [30] |

| Buffer Salts | Mobile phase modifiers | Ammonium acetate, potassium dihydrogen phosphate for pH control [30] [13] |

| Standard Reference Materials | Method calibration and validation | High-purity analytical standards for quantification [30] [13] |

| pH Adjustment Reagents | Mobile phase optimization | Formic acid, acetic acid, ammonium hydroxide for pH control [26] [30] |

| ER-34122 | ER-34122|Dual COX/5-LO Inhibitor|CAS 179325-62-3 | |

| Torososide B | Torososide B, MF:C40H52O25, MW:932.8 g/mol | Chemical Reagent |

Application Scenarios and Selection Guidelines

Strategic Technology Selection

Choosing between HPLC, UFLC, and UPLC platforms depends on multiple factors including application requirements, throughput needs, and budget constraints. HPLC remains the most cost-effective option for routine analyses where maximum speed is not critical, offering well-established methods, lower instrument costs, and widespread availability [25]. UFLC provides an excellent middle ground, delivering faster analysis than conventional HPLC without the substantial investment required for UPLC infrastructure, making it ideal for laboratories seeking to enhance throughput while maintaining compatibility with existing methods [25]. UPLC delivers the highest performance in terms of speed, resolution, and sensitivity, making it the preferred choice for high-throughput environments, method development, and complex separations where maximum performance is required [25] [24].

Industry-Specific Applications

In pharmaceutical analysis, UPLC has demonstrated particular value for quality control applications where rapid analysis of active pharmaceutical ingredients and finished products is essential during processing and storage [24]. For food safety testing, the combination of UPLC with mass spectrometry provides the sensitivity and speed needed to monitor synthetic colorants and other additives in complex matrices [30]. In clinical diagnostics and forensic applications, UPLC-MS/MS systems enable processing of thousands of samples per day, providing the throughput necessary for large-scale studies and routine screening [2]. Environmental analysis also benefits from UPLC technology when monitoring trace contaminants in water samples, where enhanced sensitivity and reduced analysis time provide significant operational advantages.

The strategic transfer of methods from HPLC to UFLC or UPLC platforms offers significant advantages in analysis speed, solvent consumption, and overall efficiency. UPLC technology represents the current peak of performance with separations up to 10 times faster than conventional HPLC, while UFLC provides a practical middle ground with more modest system requirements [25]. Successful method transfer requires careful calculation of scaled parameters and systematic verification to ensure maintained performance [29]. As chromatographic technology continues to evolve, the principles outlined in this guide will remain essential for researchers and drug development professionals seeking to maximize laboratory productivity while ensuring data quality. The ongoing development of novel stationary phases and system components promises further enhancements in separation science, continuing the trajectory from HPLC to UFLC and UPLC technologies.

The pursuit of higher efficiency, faster analysis, and better resolution in liquid chromatography has driven the development of advanced stationary phase particles. Two dominant technologies have emerged: fully porous sub-2 µm particles and fused-core particles (also known as superficially porous or core-shell particles). This guide provides an objective comparison of these technologies within the context of benchmarking Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) against Ultra-Performance Liquid Chromatography with Diode Array Detection (UPLC-DAD) for method optimization research. Understanding the performance characteristics, advantages, and limitations of each particle type enables researchers, scientists, and drug development professionals to make informed decisions based on their specific analytical requirements, instrument capabilities, and application needs.

Fused-core particles feature a solid, non-porous core surrounded by a thin, porous silica shell, typically with overall diameters of 2.7-5 µm [31] [32]. This architecture creates a shorter diffusional path for analytes, significantly reducing band broadening and resistance to mass transfer. In contrast, sub-2 µm fully porous particles provide enhanced efficiency through their dramatically reduced overall size but require specialized instrumentation capable of withstanding the resulting high backpressures [32]. The selection between these technologies involves careful consideration of multiple factors including desired separation efficiency, analysis time, detection sensitivity, solvent consumption, and compatibility with existing instrumentation.

Technical Specifications and Performance Characteristics

Fundamental Particle Properties and Separation Mechanisms

The fundamental differences in particle architecture between sub-2 µm fully porous and fused-core technologies directly influence their separation mechanisms and performance characteristics. Sub-2 µm fully porous particles (typically 1.7-1.9 µm) provide a large surface area for analyte interaction due to their extensive porous network throughout the entire particle. This comprehensive porous structure facilitates high sample loading capacity but creates relatively long diffusion paths for analyte molecules, potentially limiting mass transfer kinetics, especially at higher flow rates [31]. The van Deemter curves for these particles show improved efficiency at higher linear velocities, making them particularly suitable for fast separations when coupled with appropriate high-pressure instrumentation.

Fused-core particles, typically with overall diameters of 2.7 µm (featuring a 1.7 µm solid core and 0.5 µm porous shell) or 5 µm, are engineered to minimize the limitations of diffusion while maintaining high efficiency [32]. The thin, porous outer layer (approximately 0.5 µm) creates a short, consistent diffusion path for analyte molecules, significantly reducing resistance to mass transfer (the C term in the van Deemter equation). This architectural advantage enables fused-core particles to maintain high efficiency across a wide range of flow rates while generating significantly lower backpressure (approximately 60% less) compared to sub-2 µm fully porous particles of equivalent efficiency [32]. The solid core also provides structural stability, allowing for dense, uniform packing that enhances the overall separation efficiency.

Comparative Performance Data Across Applications

Table 1: Performance Comparison of Sub-2 µm and Fused-Core Particles in Various Applications

| Application Area | Particle Type | Separation Efficiency | Analysis Time | Backpressure | Key Findings |

|---|---|---|---|---|---|

| Global DNA Methylation [31] | 1.7 µm Fused-Core C18 | 23,000 theoretical plates | < 1 minute | ~220 bar at 2 mL/min | Excellent resolution of 5mdC and 2dG with high sensitivity (LOD: 0.54-1.47 fmol) |

| Polyphenol Analysis [1] | Sub-2 µm C18 | High | 21 minutes for 38 compounds | Not specified | Successful separation of complex mixture; validated per ICH guidelines |

| Pharmaceutical Analysis [32] | 2.7 µm Fused-Core C18 | ~23,000 theoretical plates | 75% time savings vs. conventional HPLC | 60% lower than sub-2 µm | Near-identical efficiency to sub-2 µm with conventional HPLC compatibility |

| Flavonol Separation [33] | Sub-2 µm C18 | High resolution | < 2.7 minutes for 7 compounds | Not specified | Optimized using Box-Behnken design; excellent precision and linearity |

The performance data compiled in Table 1 demonstrates that both particle technologies can achieve excellent separation efficiency across diverse applications. Fused-core particles consistently provide analysis times comparable to sub-2 µm fully porous particles while offering the significant advantage of lower backpressure generation. For instance, in the analysis of global DNA methylation status, a 1.7 µm fused-core C18 column achieved baseline separation of 2′-deoxyguanosine and 5-methyl-2′-deoxycytidine in under one minute with detection limits of 0.54-1.47 fmol, demonstrating both exceptional speed and sensitivity [31]. The backpressure recorded during this analysis was approximately 220 bar at 2 mL/min, which is within the operating range of many conventional HPLC systems.

Similarly, applications utilizing sub-2 µm particles highlight their exceptional resolving power for complex mixtures. A method for simultaneous quantification of 38 polyphenols in applewood achieved complete separation in 21 minutes with excellent linearity (R² > 0.999), precision (RSD < 5%), and sensitivity (LOD: 0.0074-0.1179 mg Lâ»Â¹) [1]. The ability to separate such complex mixtures in reasonable timeframes demonstrates the power of sub-2 µm technology for challenging separations where maximum resolution is required.

Experimental Protocols and Method Implementation

Protocol for Method Development with Fused-Core Columns