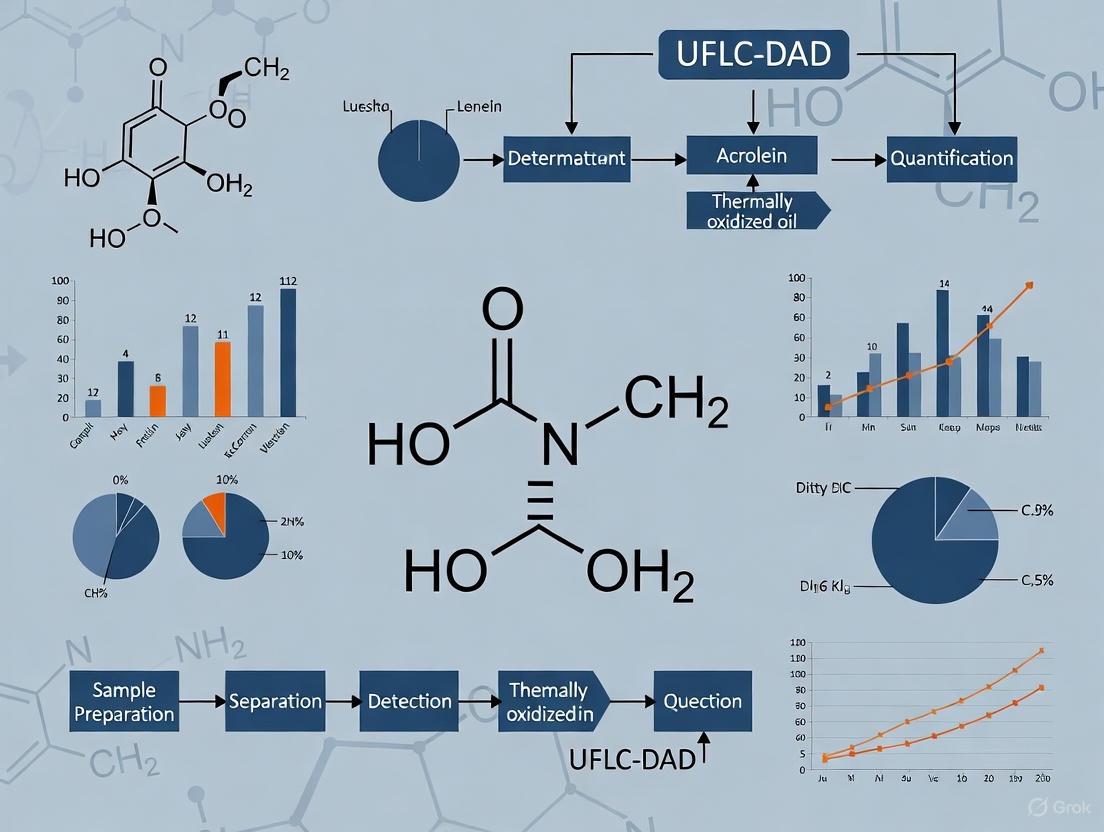

Determining Acrolein in Thermally Oxidized Oil Using UFLC-DAD: A Comprehensive Methodological Guide for Food and Biomedical Research

This article provides a detailed exploration of the Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) methodology for the precise determination of acrolein in thermally oxidized edible oils.

Determining Acrolein in Thermally Oxidized Oil Using UFLC-DAD: A Comprehensive Methodological Guide for Food and Biomedical Research

Abstract

This article provides a detailed exploration of the Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) methodology for the precise determination of acrolein in thermally oxidized edible oils. Aimed at researchers, scientists, and drug development professionals, the content covers the foundational toxicology of acrolein, a step-by-step analytical protocol involving derivatization with 2,4-dinitrophenylhydrazine (DNPH), critical troubleshooting for method optimization, and rigorous validation parameters. It further contextualizes the UFLC-DAD approach by comparing it with emerging techniques like SFC-MS/MS and PTR-MS. The synthesis of this information is crucial for advancing food safety analysis, understanding dietary exposure to toxic aldehydes, and supporting related biomedical research on chronic diseases.

Acrolein in Thermally Processed Oils: Toxicology, Formation Pathways, and Public Health Imperatives

Here is the article based on your instructions and the search results.

The Toxicological Profile of Acrolein: Carcinogenicity and Links to Chronic Disease

Abstract Acrolein (2-propenal) is a highly reactive α,β-unsaturated aldehyde identified as a high-priority toxicant by regulatory agencies. As a ubiquitous environmental pollutant, dietary contaminant, and product of endogenous lipid peroxidation, acrolein exposure is linked to numerous chronic diseases, including cancer, cardiovascular disease, and neurodegenerative disorders. This application note details the toxicological profile of acrolein, with a focus on its carcinogenic potential and mechanisms of action. Furthermore, it provides validated protocols for the determination of acrolein and other carbonyl compounds in thermally oxidized soybean oil using UFLC-DAD-ESI-MS, providing critical methodologies for exposure assessment in food safety and toxicological research.

1. Introduction Acrolein is a significant health concern due to its pervasive presence in the environment, food, and endogenously in biological systems. It is formed through the incomplete combustion of organic materials (e.g., tobacco smoke, petroleum fuels), the thermal degradation of lipids during high-temperature cooking, and the cellular peroxidation of polyunsaturated fatty acids (PUFAs) [1] [2]. Its high electrophilicity allows it to form stable adducts with DNA, proteins, and glutathione, disrupting cellular functions and initiating pathogenic processes [1]. This note consolidates evidence of acrolein's carcinogenicity and its role in chronic diseases, and provides a detailed analytical protocol for its detection in heated oils, a major dietary source.

2. Quantitative Data on Acrolein Exposure and Toxicity The following tables summarize key quantitative data on acrolein formation in food and its established health effects.

Table 1: Concentration of Selected Carbonyl Compounds in Soybean Oil Heated at 180°C [3] [4]

| Carbonyl Compound | Mean Concentration (μg/g of oil) | Toxicological Significance |

|---|---|---|

| 4-Hydroxy-2-nonenal (HNE) | 36.9 | Mutagenic, forms DNA & protein adducts [4] |

| 2,4-Decadienal | 34.8 | Associated with lung & stomach adenocarcinoma [4] |

| 2,4-Heptadienal | 22.6 | Product of lipid peroxidation |

| Acrolein | Detected (specific conc. range not provided) | Irritant, inhibits tumor suppressor p53, linked to multiple diseases [4] |

Table 2: Key Mechanisms of Acrolein Toxicity and Associated Health Outcomes [1] [2]

| Mechanism of Toxicity | Molecular Interaction | Linked Health Outcomes |

|---|---|---|

| DNA Adduction | Forms exocyclic adducts with guanine residues (e.g., γ-OH-Acrolein-dG), leading to mutations [2]. | Carcinogenesis, inhibited DNA synthesis and recombination [4] |

| Protein Adduction | Michael addition with cysteine, histidine, and lysine residues, altering protein function [1]. | Inactivation of tumor suppressor p53, myofilament dysfunction, enzyme inhibition [1] [4] |

| Oxidative Stress | Depletes glutathione, generates reactive oxygen species (ROS) [1]. | Atherosclerosis, Alzheimer’s disease, diabetes, inflammation [1] [2] |

| Endothelial Dysruption | Impairs tight junction proteins, induces inflammation and foam cell formation [2]. | Cardiovascular disease, atherosclerosis [2] |

| Dyslipidemia | Increases plasma cholesterol, triglycerides, and VLDL in animal studies [2]. | Increased risk of cardiovascular disease [2] |

3. Molecular Mechanisms of Carcinogenicity and Chronic Disease Acrolein's toxicity stems from its role as a strong electrophile, enabling covalent modifications of biomacromolecules.

3.1 Signaling Pathways in Disease Pathogenesis The diagram below illustrates the key molecular pathways through which acrolein exposure contributes to chronic diseases like cancer and atherosclerosis.

Diagram 1: Key signaling pathways of acrolein toxicity. Acrolein induces DNA and protein adducts and oxidative stress, leading to cellular consequences that drive major chronic diseases. GSH: Glutathione; ROS: Reactive Oxygen Species; ER: Endoplasmic Reticulum.

4. Experimental Protocol: Determination of Carbonyl Compounds in Thermally Oxidized Soybean Oil by UFLC-DAD-ESI-MS This protocol is adapted from validated methods for analyzing carbonyl compounds (CCs) in the liquid phase of heated oils [3] [4].

4.1 The Scientist's Toolkit: Research Reagent Solutions Table 3: Essential Materials and Reagents for Acrolein Analysis

| Item | Function / Specification | Brief Explanation |

|---|---|---|

| Soybean Oil | Analytical matrix | High PUFA content makes it representative for lipid oxidation studies [4]. |

| 2,4-Dinitrophenylhydrazine (2,4-DNPH) | Derivatization reagent | Reacts with carbonyl functional groups to form stable hydrazones for UV and MS detection [4]. |

| Acetonitrile (HPLC Grade) | Extraction solvent | Effectively extracts carbonyl-DNPH derivatives from the oil matrix with low interference [3] [4]. |

| Carbonyl Standard Mixture | Analytical standards | Includes acrolein, 4-HNE, 2,4-decadienal, etc., for calibration and quantification [3]. |

| UFLC-DAD-ESI-MS System | Analytical instrumentation | UFLC provides fast separations, DAD detects DNPH derivatives (~360 nm), and ESI-MS confirms compound identity [3]. |

4.2 Sample Preparation and Extraction Workflow The following diagram outlines the sample preparation and analysis workflow.

Diagram 2: Experimental workflow for the extraction and analysis of carbonyl compounds from heated oil.

4.3 Detailed Methodology

- Heating Procedure: Continuously heat soybean oil samples at 180°C in a laboratory heating apparatus for different time intervals (e.g., 0, 30, 60 minutes) in the presence of atmospheric oxygen to simulate thermal oxidation [4].

- Derivatization and Extraction:

- Weigh approximately 100 mg of heated oil into a glass vial.

- Add 1.5 mL of acetonitrile as the extraction solvent [3].

- Add the appropriate volume of 2,4-DNPH solution for derivatization.

- Manually stir the mixture for 3 minutes to ensure efficient contact.

- Sonicate the mixture for 30 minutes to complete the extraction of derivatized carbonyls [3].

- Clean-up: Centrifuge the mixture to separate phases and collect the clear acetonitrile (upper) layer. Filter the extract through a 0.20 μm membrane (e.g., Durapore HV) prior to injection [4].

- UFLC-DAD-ESI-MS Analysis:

- Chromatography: Utilize an Ultra-Fast Liquid Chromatography (UFLC) system with a C18 reverse-phase column. A gradient elution using water and acetonitrile is recommended for optimal separation of hydrazone derivatives.

- Detection: Monitor the effluent with a Diode Array Detector (DAD) at 360 nm for quantification. The identity of compounds, especially acrolein and hydroxyalkenals, must be confirmed using Electrospray Ionization Mass Spectrometry (ESI-MS) in negative or positive ion mode [3] [4].

4.4 Method Validation Highlights The described method has been validated, demonstrating [3]:

- Recovery: Average recoveries at the lowest concentration level ranged from 70.7% to 85.0%.

- Sensitivity: Detection limits (LOD) between 0.03 and 0.1 μg·mLâ»Â¹, and a quantification limit (LOQ) of 0.2 μg·mLâ»Â¹ for all target carbonyl compounds.

- Precision: The method shows good selectivity and precision.

5. Discussion and Conclusion The data confirms that acrolein is a potent toxicant generated during the thermal oxidation of dietary oils. Its ability to form adducts with DNA and key regulatory proteins like p53 provides a mechanistic basis for its carcinogenic potential [1] [4]. Furthermore, its role in inducing oxidative stress and inflammation underpins its contribution to cardiovascular and neurodegenerative diseases [1] [2]. The analytical protocol provided offers a robust, sensitive, and validated method for monitoring acrolein and other toxic carbonyl compounds in oil matrices. This is critical for advancing research on lipid oxidation, assessing human exposure risks from fried foods, and developing strategies to mitigate the formation of these harmful compounds. Future research should focus on the efficacy of natural antioxidants in suppressing acrolein formation and the development of scavenging molecules to counteract its toxicity in biological systems [1] [5].

Within the context of determining acrolein in thermally oxidized oil using UFLC-DAD, understanding its precursor pathways is fundamental. Acrolein, a highly reactive and toxic aldehyde, primarily forms in heated oils through two major routes: the thermal decomposition of glycerol and the oxidative degradation of fatty acids [4] [3]. This Application Note provides a detailed comparative analysis of these distinct formation pathways. We summarize key quantitative data and present standardized protocols for simulating these degradation processes in a laboratory setting, specifically tailored for subsequent analysis via UFLC-DAD-ESI-MS. The focus is on enabling researchers to accurately track acrolein formation from its origins, thereby supporting the development of mitigation strategies in food science and toxicology.

Comparative Pathway Analysis

The thermal degradation of glycerol and the oxidation of fatty acids represent distinct chemical processes that converge on the production of harmful carbonyl compounds, including acrolein.

Thermal Degradation of Glycerol

Glycerol (C3H8O3) decomposition is a pyrolytic process initiated by high temperatures. The primary pathway for acrolein formation involves a single dehydration step, where glycerol loses two water molecules to form acrolein directly [6]. This reaction is predominant in the vapor phase at temperatures exceeding the boiling point of glycerol. In the film boiling regime at atmospheric pressure, glycerol decomposition initiates with radical species and yields a gaseous fuel mixture containing hydrogen (H2), carbon monoxide (CO), methane (CH4), ethylene (C2H4), and ethane (C2H6) [6]. The operational domain for this decomposition lies between glycerol's minimum film boiling temperature and an upper limit dictated by the materials used. Studies show that up to 95% of the gases produced from glycerol decomposition are themselves viable fuels, indicating a high conversion efficiency under optimized conditions [6]. Beyond acrolein, the degradation of glycerol-plasticized Poly(vinyl alcohol) films involves complex overlapping mechanisms, where deconvolution of differential thermogravimetry (DTG) curves reveals distinct peaks for glycerol, PVA/glycerol complexes, and PVA itself [7] [8]. The apparent activation energy (Ea) for the degradation of these plasticized films shows a reduced dependence on conversion compared to pure PVA in air, indicating that glycerol significantly alters the oxidative degradation pathways [8].

Fatty Acid Oxidation

In contrast, fatty acid oxidation is a complex, multi-stage radical chain reaction involving oxygen. The process begins with the formation of lipid hydroperoxides as primary oxidation products, which are subsequently decomposed into a wide array of secondary oxidation products, including aldehydes, ketones, and carboxylic acids [9]. Aldehydes are the most abundant among these secondary products [4]. The specific profile of carbonyl compounds depends on the precursor fatty acids; for instance, linoleic acid and linolenic acid in soybean oil are major precursors for acrolein and other toxic aldehydes like 4-hydroxy-2-nonenal (HNE) and 2,4-decadienal [4] [3]. The concentration of these aldehydes increases significantly with heating time. In soybean oil heated continuously at 180°C, 4-hydroxy-2-nonenal, 2,4-decadienal, and 2,4-heptadienal reach the highest mean concentrations of 36.9, 34.8, and 22.6 μg.gâ»Â¹ of oil, respectively [3]. These compounds are of significant concern due to their documented toxicity, including associations with inflammation, mutagenesis, and various diseases [4] [10].

Table 1: Key Carbonyl Compounds from Fatty Acid Oxidation in Heated Soybean Oil (180°C)

| Carbonyl Compound | Average Concentration (μg.gâ»Â¹ oil) | Primary Precursor Fatty Acid | Toxicity and Health Concerns |

|---|---|---|---|

| 4-Hydroxy-2-nonenal (HNE) | 36.9 | Omega-6 PUFA (e.g., Linoleic) | DNA adduct formation, protein modification, mutagenesis [4] |

| 2,4-Decadienal | 34.8 | Omega-6 PUFA (e.g., Linoleic) | Associated with lung and stomach adenocarcinoma [4] |

| 2,4-Heptadienal | 22.6 | Omega-3 PUFA (e.g., Linolenic) | -- |

| Acrolein | Detected (exact concentration varies) | Glycerol, Glycerides, PUFA | Eye/skin irritant, carcinogenesis, atherosclerosis [4] |

Table 2: Comparative Overview: Glycerol Degradation vs. Fatty Acid Oxidation

| Characteristic | Thermal Glycerol Degradation | Fatty Acid Oxidation |

|---|---|---|

| Primary Process | Pyrolysis/Dehydration [6] | Radical-mediated Auto-oxidation [9] |

| Key Initiating Factor | High Temperature (> 280°C) [6] | Molecular Oxygen, Pro-oxidants |

| Main Initial Product | Acrolein (from direct dehydration) [6] | Lipid Hydroperoxides (LOOH) [9] |

| Typical Environment | Vapor phase (film boiling) [6] | Liquid (bulk oil) or at oil-air interface [9] |

| Product Spectrum | Narrower (Acrolein, synthesis gases) [6] | Broader (Various aldehydes, ketones, acids) [3] |

| Key Analytical Technique | Gas analysis, TGA/DTG [6] [7] | UFLC-DAD-ESI-MS for carbonyls [4] [3] |

Experimental Protocols

Protocol 1: Simulating Glycerol Thermal Degradation via Film Boiling

This protocol outlines a method to decompose glycerol and analyze its volatile products, based on a film boiling heat transfer setup [6].

3.1.1 Reagents and Equipment

- Glycerol (≥99.0% purity)

- Horizontal heating tube (material suitable for high temperatures, e.g., certain metal alloys)

- High-temperature furnace or heating system

- Thermocouples for temperature monitoring

- Gas-tight syringe

- Gas Chromatography (GC) system with Flame Ionization Detector (FID) and/or Mass Spectrometer (MS)

3.1.2 Procedure

- Setup: Place the horizontal heating tube inside a container filled with saturated liquid glycerol. Ensure thermocouples are correctly positioned to monitor the temperature of the tube and the glycerol pool.

- Initiating Film Boiling: Gradually increase the power to the heating tube until the critical heat flux (CHF) is surpassed and a stable vapor film is established around the tube. The operational temperature for decomposition is between glycerol's minimum film boiling temperature and the maximum safe operating temperature of the tube material.

- Collection: As glycerol decomposes within the vapor film, gaseous products percolate as bubbles through the liquid pool. Collect the evolved gases using a gas-tight syringe from the headspace above the liquid pool.

- Analysis: Inject the collected gas sample into the GC system. Identify and quantify the decomposition products (e.g., H2, CO, CH4, C2H4, C2H6, and potentially acrolein if condensed) by comparing retention times and mass spectra with authentic standards.

Protocol 2: Inducing Fatty Acid Oxidation and Carbonyl Analysis in Oils

This protocol details a method for thermally oxidizing edible oil and quantifying the resulting carbonyl compounds (CCs) via UFLC-DAD-ESI-MS, adapted from established methodologies [4] [3].

3.2.1 Reagents and Equipment

- Edible oil sample (e.g., Soybean oil)

- Acetonitrile (HPLC grade)

- 2,4-Dinitrophenylhydrazine (2,4-DNPH) derivatization reagent

- UFLC system coupled to DAD and ESI-MS

- Thermostatic oil bath or heating block (± 1°C accuracy)

- Glass reaction vessels

- Centrifuge

- Solvent Evaporator

3.2.2 Procedure

- Heating/Thermal Oxidation:

- Dispense 10 mL of oil into a clean, dry glass vessel.

- Place the vessel in a thermostatic oil bath pre-heated to 180°C.

- Heat the oil for a defined period (e.g., 0, 30, 60, 90, 120 min) under continuous stirring to ensure homogeneous heating and contact with atmospheric oxygen.

- After the set time, immediately remove the oil sample and cool it in an ice-water bath to halt further oxidation.

Carbonyl Compound Extraction and Derivatization:

- Weigh approximately 1 g of the heated oil into a centrifuge tube.

- Add 1.5 mL of acetonitrile as the extraction solvent.

- Manually stir the mixture vigorously for 3 minutes, followed by 30 minutes of sonication.

- Centrifuge the mixture at 4000 rpm for 10 minutes to separate the layers.

- Carefully collect the upper (acetonitrile) layer, which contains the extracted carbonyl compounds.

- React the extract with 2,4-DNPH to form stable hydrazone derivatives for analysis.

UFLC-DAD-ESI-MS Analysis:

- Chromatography: Inject the derivatized sample into the UFLC system. Use a suitable C18 column and a mobile phase gradient of water and acetonitrile.

- Detection: Monitor the effluent with a DAD detector, typically at a wavelength of 360 nm, characteristic of DNPH derivatives.

- Identification and Quantification: Use the ESI-MS in negative ion mode to confirm the identity of carbonyl-DNPH derivatives based on their mass-to-charge (m/z) ratios. Quantify concentrations using external calibration curves of authentic standards for acrolein-DNPH, HNE-DNPH, etc. The method has a reported quantification limit of 0.2 μg.mLâ»Â¹ for all target compounds [3].

Pathway Visualization

The following diagram illustrates the parallel formation pathways of acrolein from glycerol and fatty acids, culminating in the analytical workflow for its determination.

Diagram 1: Comparative formation pathways of acrolein from glycerol and fatty acids during heating, leading to the analytical workflow for its determination via UFLC-DAD-ESI-MS.

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Reagents and Materials for Thermal Degradation and Oxidation Studies

| Item | Function/Application |

|---|---|

| Glycerol (≥99.0%) | High-purity substrate for studying thermal decomposition pathways and acrolein formation [7]. |

| Polyunsaturated Oils (e.g., Soybean) | Model system for studying fatty acid oxidation due to high linoleic/linolenic acid content [4] [3]. |

| 2,4-Dinitrophenylhydrazine (2,4-DNPH) | Derivatization reagent for carbonyl compounds; forms stable hydrazones for sensitive LC-UV/MS detection [4] [3]. |

| Acetonitrile (HPLC Grade) | Extraction solvent for carbonyl compounds from the oil matrix; also used as mobile phase in UFLC [4] [3]. |

| Stable Isotope-Labeled Fatty Acids (e.g., ¹³C-Palmitate) | Tracers for precise quantification of fatty acid oxidation fluxes and pathway analysis using LC-MS [11]. |

| UFLC-DAD-ESI-MS System | Core analytical platform for separating, identifying, and quantifying carbonyl-DNPH derivatives with high sensitivity and selectivity [4] [3]. |

| Thermogravimetric Analyzer (TGA/DTG) | Instrument for studying thermal stability and decomposition kinetics of materials like glycerol-PVA blends [7] [8]. |

| Trielaidin | Trielaidin | High Purity | For Research Use |

| Spinetoram J | Spinetoram J | High-Purity Insecticide | For RUO |

Acrolein (2-propenal) is a highly reactive, toxic α,β-unsaturated aldehyde recognized as a significant food processing contaminant. It forms during the thermal decomposition of lipids, particularly during the heating of oils and fats, and is also generated from glycerol by microbial activity in certain fermented beverages [12] [13]. As a prevalent carbonyl compound (CC) in thermally oxidized edible oils, acrolein poses substantial challenges to food safety and public health. Within the broader research on determining carbonyl compounds in thermally oxidized oil using UFLC-DAD, understanding acrolein's prevalence, formation pathways, and robust detection methods is paramount for researchers and drug development professionals assessing dietary exposure risks. This application note consolidates analytical methodologies and empirical data on acrolein in food matrices, providing detailed protocols for its determination and contextualizing its health implications.

Health Significance and Formation Pathways

Acrolein exposure is a health concern due to its corrosive, toxic, and hazardous effects. It is classified as a Group 3 carcinogen by the International Agency for Research on Cancer (IARC) [13]. Its toxicity primarily stems from the ability to form protein and DNA adducts, leading to irritant effects, decreased respiratory function, and cardiovascular diseases [13]. In the context of food, it is notorious for imparting a bitter, undesirable taste to cider, severely compromising product quality [12].

The formation of acrolein in foods occurs through several pathways:

- Thermal Degradation of Lipids: During heating processes like frying, acrolein is produced from the decomposition of glycerol and triacylglycerols [13]. The presence of glycerol and triacetin in e-cigarettes and tobacco products also leads to acrolein formation upon heating [13].

- Microbial Activity: In fermented beverages like cider, specific Lactobacillus bacteria produce acrolein from glycerol via the intermediate 3-hydroxy-propionaldehyde [12].

- Combustion and Thermal Processes: Beyond food, it is emitted from wood decomposition, fuel combustion, incense burning, and candle emissions, contributing to overall environmental exposure [13].

Table 1: Key Hazard Information for Acrolein

| Property/Endpoint | Description |

|---|---|

| IARC Classification | Group 3 (Not classifiable as to its carcinogenicity to humans) [13] |

| Primary Toxicological Concern | Formation of protein and DNA adducts; irritant [13] |

| Sensory Impact in Food | Bitter taste, spoils cider quality [12] |

| Main Dietary Formation | Thermal decomposition of lipids during frying/cooking [13] |

Furthermore, acrolein is not merely an end-product of degradation; it actively participates in further reactions. It has been shown to dose-dependently increase the formation of the heterocyclic aromatic amine PhIP (2-amino-1-methyl-6-phenylimidazo[4,5-b]pyridine) in model systems and roasted fish patties. It facilitates Strecker degradation of phenylalanine, reacts with key precursors (phenylalanine and creatinine), and forms adducts with PhIP itself [14]. This underscores its role in generating other hazardous compounds in processed foods.

Quantitative Data on Carbonyl Compounds in Heated Oil

Comprehensive profiling of carbonyl compounds formed during the thermal oxidation of oils is crucial for risk assessment. A validated UFLC-DAD-ESI-MS method applied to soybean oil continuously heated at 180°C identified and quantified several toxic aldehydes.

Table 2: Carbonyl Compounds Identified in Soybean Oil Heated at 180°C [4] [3]

| Carbonyl Compound | Mean Concentration (μg.gâ»Â¹ of oil) | Toxicological Significance |

|---|---|---|

| 4-Hydroxy-2-nonenal (HNE) | 36.9 | Reacts with DNA bases and proteins, can cause mutations [4] |

| 2,4-Decadienal | 34.8 | Associated with lung and stomach adenocarcinomas [4] |

| 2,4-Heptadienal | 22.6 | - |

| Acrolein | Quantified (Specific concentration not listed) | Irritant, linked to chronic diseases, inhibits tumor suppressor p53 [4] [13] |

| 4-Hydroxy-2-hexenal (HHE) | Quantified | Toxic α,β-unsaturated hydroxyaldehyde [4] |

| 2-Heptenal | Quantified | - |

| 2-Octenal | Quantified | - |

| 4,5-Epoxy-2-decenal | Quantified | - |

| 2-Decenal | Quantified | - |

| 2-Undecenal | Quantified | - |

The data confirms that acrolein is a significant component of the carbonyl compound profile in thermally stressed soybean oil, a common frying medium. Its presence, alongside other toxic aldehydes like HNE and 2,4-decadienal, highlights the complex mixture of hazardous compounds generated during food processing operations like frying.

Analytical Methodologies for Acrolein Determination

UFLC-DAD-ESI-MS for Carbonyl Compounds in Oils

The determination of acrolein and other carbonyl compounds in the liquid phase of oils requires extraction and derivatization due to their reactivity and low concentrations.

Experimental Protocol: Extraction and Analysis of CCs from Oils [4] [3]

Sample Preparation: Subject oil samples (e.g., soybean oil) to continuous heating at a controlled temperature (e.g., 180°C) for varying time intervals (0 to 12 hours) in the presence of atmospheric oxygen to simulate thermal oxidation.

Derivatization: React the carbonyl compounds in the oil matrix with 2,4-dinitrophenylhydrazine (2,4-DNPH). This reagent simultaneously reacts with aldehydes and ketones at room temperature, forming stable hydrazone derivatives ideal for chromatographic analysis.

Liquid-Liquid Extraction:

- Transfer a measured quantity of heated oil to a vial.

- Add 1.5 mL of acetonitrile as the extraction solvent. Acetonitrile demonstrated superior extraction capacity for carbonyl-DNPH derivatives compared to methanol in empirical tests [4].

- Manually stir the mixture for 3 minutes.

- Sonicate the sample for 30 minutes to enhance extraction efficiency.

- Centrifuge the mixture to separate the acetonitrile (upper) layer containing the derivatized carbonyl compounds from the oil phase.

UFLC-DAD-ESI-MS Analysis:

- Chromatography: Inject the extracted hydrazones into an Ultra-Fast Liquid Chromatography (UFLC) system. Use a suitable C18 reversed-phase column and a gradient elution with mobile phases such as water and acetonitrile.

- Detection: Analyze the eluent using a Diode Array Detector (DAD), typically monitoring at 360 nm for DNPH derivatives. Subsequently, confirm the identity of acrolein-DNPH and other carbonyl-DNPH adducts using Electrospray Ionization Mass Spectrometry (ESI-MS) in negative ion mode.

Method Validation: The protocol demonstrates good selectivity, precision, sensitivity, and accuracy. Key validation parameters include:

- Linearity: Concentration range of 0.2 to 10.0 μg.mLâ»Â¹.

- Recovery: Ranged from 70.7% to 85.0% at the lowest concentration level.

- Limit of Detection (LOD): 0.03 to 0.1 μg.mLâ»Â¹.

- Limit of Quantification (LOQ): 0.2 μg.mLâ»Â¹ for all target compounds [3].

Complementary Analytical Techniques

1H NMR for Acrolein in Cider [12] For a rapid and direct quantitative determination of acrolein in aqueous-based beverages like cider, 1H NMR offers a derivatization-free approach.

- Sample Preparation: Degas the cider sample by stirring under vacuum. Mix 600 μL of degassed cider with 100 μL of a TSP-BTC-D₂O solution (containing 1,3,5-benzenetricarboxylic acid, BTC, as an internal standard and TSP for referencing).

- Analysis: Record the 1H NMR spectrum at 500 MHz. The aldehydic proton of acrolein produces a distinct doublet at 9.49 ppm.

- Quantification: Use the peak area ratio of the acrolein signal (9.49 ppm) to the internal standard BTC (signals between 8.4-8.8 ppm) for concentration calculation. This method correlates excellently with GC methods (Pearson coefficient 0.9994) [12].

TD-GC/MS for Acrolein in Air [13] Monitoring acrolein in the vapor phase during frying is also important for exposure assessment.

- Sampling: Draw ambient or chamber air (4-6 L volume) through a sampling tube packed with graphitized carbon black (Carbograph 5TD).

- Analysis: Perform thermal desorption (TD) of the sampling tube directly into a Gas Chromatograph/Mass Spectrometer (GC/MS).

- Performance: This robust method requires no derivatization, achieves a low LOD of 0.08–0.1 μg mâ»Â³, and shows no breakthrough or analyte loss during storage [13].

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents and Materials for Acrolein and Carbonyl Compound Analysis

| Reagent/Material | Function and Application |

|---|---|

| 2,4-Dinitrophenylhydrazine (2,4-DNPH) | Derivatizing agent for aldehydes and ketones to form stable hydrazones for UV and MS detection in LC analysis [4] |

| Acetonitrile (HPLC Grade) | Extraction solvent for carbonyl-DNPH derivatives from oil matrices; component of mobile phase in UFLC [4] |

| Deuterium Oxide (Dâ‚‚O) | Lock solvent for field frequency stabilization in quantitative 1H NMR analysis [12] |

| 1,3,5-Benzenetricarboxylic Acid (BTC) | Internal standard for quantification in 1H NMR, providing a reference peak in the phenolic region [12] |

| TSP (3-(trimethylsilyl)-2,2,3,3-d4-propionic acid sodium salt) | Chemical shift reference (0.00 ppm) in 1H NMR spectroscopy [12] |

| Carbograph 5TD Sorbent Tubes | Solid adsorber for collecting gaseous acrolein from air in TD-GC/MS analysis [13] |

| Soybean Oil | Model matrix for studying carbonyl compound formation during thermal oxidation due to high polyunsaturated fatty acid content [4] |

| (R)-Leucic acid | (R)-Leucic acid, CAS:10303-64-7, MF:C6H12O3, MW:132.16 g/mol |

| Seliforant | Seliforant|H4 Receptor Antagonist|SENS-111 |

Visualized Workflows and Pathways

Lipid Oxidation & Acrolein Formation Pathway

Figure 1: Formation pathway of acrolein and other carbonyls from lipid thermal oxidation.

Acrolein Analysis Workflow in Oils

Figure 2: Experimental workflow for determining acrolein and carbonyl compounds in oils.

Acrolein (prop-2-enal) is a highly toxic α,β-unsaturated aldehyde identified as a priority toxic air contaminant by regulatory bodies worldwide due to its significant health risks [15]. As a pervasive toxicant generated during thermal processing of edible oils, acrolein presents substantial challenges for accurate quantification and regulatory control [16]. This application note examines the current regulatory thresholds, tolerable intake values, and advanced analytical methodologies for determining acrolein in thermally oxidized oils, with specific focus on UFLC-DAD-ESI-MS applications within food safety research.

The International Agency for Research on Cancer and the U.S. Environmental Protection Agency have classified acrolein as a priority toxic chemical, with dietary intake representing one of the primary exposure routes for humans [17] [16]. Ensuring precise acrolein quantification is paramount for researchers and regulatory professionals working in food safety, drug development, and toxicological risk assessment.

Regulatory Framework and Toxicity Profile

Established Exposure Limits

Various international agencies have established exposure limits for acrolein based on its acute and chronic toxicity profiles. [18]

Table 1: Occupational and Environmental Exposure Limits for Acrolein

| Agency/Standard | Exposure Limit | Type | Basis |

|---|---|---|---|

| NIOSH REL | 0.1 ppm (0.25 mg/m³) TWA; 0.3 ppm (0.8 mg/m³) STEL | Recommended | Worker protection |

| OSHA PEL | 0.1 ppm (0.25 mg/m³) TWA | Permissible | Regulatory compliance |

| ACGIH TLV | 0.1 ppm (0.23 mg/m³) TWA; 0.3 ppm (0.67 mg/m³) STEL | Threshold | Worker health |

| AIHA ERPG-1 | 0.1 ppm (60-minute) | Emergency | Mild irritation effects |

| AIHA ERPG-2 | 0.5 ppm (60-minute) | Emergency | Irreversible effects |

| AIHA ERPG-3 | 3 ppm (60-minute) | Emergency | Life-threatening effects |

| Revised IDLH | 2 ppm | Immediate Danger | Human inhalation toxicity data |

Dietary Intake Guidelines and Health Implications

The World Health Organization has established a tolerable daily acrolein intake level of 7.5 μg/kg body weight/day [16]. Dietary exposure can be significant, with certain alcoholic beverages potentially contributing over 1 mg of acrolein daily – far exceeding the WHO guideline for an average adult [16]. Acrolein's toxicity stems from its highly electrophilic structure, enabling it to readily bind nucleophilic biomacromolecules including proteins and nucleic acids, resulting in oxidative stress, endoplasmic reticulum stress, mitochondrial dysfunction, inflammation, and abnormal immune responses [16].

Epidemiological and clinical evidence has associated acrolein exposure with several chronic diseases:

- Cardiovascular disease [16]

- Alzheimer's disease [16] [4]

- Diabetes mellitus [19]

- Various cancers through DNA damage mechanisms [16] [4]

- Chronic obstructive pulmonary disease (COPD) [16]

Analytical Challenges in Acrolein Determination

Complexity of Food Matrices

The accurate quantification of acrolein in thermally oxidized oils presents significant analytical challenges due to the compound's reactivity, volatility, and complex food matrix effects. Heated rapeseed oil can contain acrolein levels up to 150 mg/kg, while foods fried in the same oil (e.g., potato chips) may contain only 23 μg/kg – demonstrating substantial matrix-dependent partitioning [16]. This nearly 3700-fold concentration difference between frying oils and fried foods complicates exposure assessments and necessitates precise matrix-specific methodologies [16].

Formation Pathways and Precursor Complexity

Acrolein generation in edible oils occurs through multiple pathways that vary based on fatty acid composition and processing conditions, further complicating analytical predictability:

Diagram 1: Acrolein formation pathways in oils

Recent research has demonstrated that singlet oxygen oxidation products of linoleic acid (LA) and linolenic acid (LnA) serve as significant acrolein sources, with specific hydroperoxide isomers (10- and 15-HpOTE) generating twice the acrolein yield compared to other isomers [17]. This pathway is particularly relevant in oils subjected to photo-irradiation during storage, with studies showing increased acrolein formation in rice bran oil (high in LA) under these conditions [17].

Advanced Analytical Methodologies

UFLC-DAD-ESI-MS Protocol for Carbonyl Compounds

Bastos et al. (2017) developed a validated method for determining carbonyl compounds, including acrolein, in soybean oil during continuous heating [4]. This protocol offers high sensitivity and specificity for acrolein quantification in complex oil matrices.

Sample Preparation and Extraction

- Weighing: Accurately weigh 1.0 g of heated oil sample into a 15 mL centrifuge tube [4]

- Derivatization: Add 1.0 mL of 2,4-dinitrophenylhydrazine (2,4-DNPH) derivatizing solution (0.2 mg/mL in acetonitrile) [4]

- Extraction: Add 1.5 mL of acetonitrile as extraction solvent, manually stir for 3 minutes, then sonicate for 30 minutes [4]

- Centrifugation: Centrifuge at 3000 × g for 10 minutes to separate phases

- Collection: Collect the clear acetonitrile layer (lower phase) for analysis

- Filtration: Pass through a 0.20 μm Durapore HV membrane prior to injection [4]

Table 2: Method Validation Parameters for Acrolein Determination in Soybean Oil

| Validation Parameter | Result | Conditions |

|---|---|---|

| Average Recovery | 70.7-85.0% | At lowest concentration level (0.2 μg/mL) |

| Detection Limit | 0.03-0.1 μg/mL | Signal-to-noise ratio of 3:1 |

| Quantification Limit | 0.2 μg/mL | For all carbonyl compounds |

| Precision (RSD) | <15% | Intra-day and inter-day variability |

| Extraction Solvent | Acetonitrile | Superior to methanol for carbonyl extraction |

| Linearity | R² > 0.995 | 0.2-10.0 μg/mL concentration range |

Instrumental Parameters

- System: Ultra-Fast Liquid Chromatography with DAD and ESI-MS detection [4]

- Column: C18 reverse phase (150 × 4.6 mm, 5 μm particle size) [4]

- Mobile Phase: Gradient of (A) water and (B) acetonitrile [4]

- Flow Rate: 1.0 mL/min with column temperature maintained at 30°C [4]

- Injection Volume: 20 μL [4]

- DAD Detection: 360 nm for 2,4-DNPH derivatives [4]

- MS Detection: ESI positive mode, full scan 50-500 m/z, acrolein-DNPH m/z 211 [4]

Complementary Analytical Approaches

Proton Transfer Reaction-Mass Spectrometry (PTR-MS)

PTR-MS enables rapid detection of acrolein precursors by monitoring m/z 57 fragment intensity, demonstrating 70-fold signal increases in oxidized hempseed oil [19]. This approach requires minimal sample preparation and offers real-time monitoring capabilities for early oxidation detection [19].

GC-EI-MS for Pathway Elucidation

GC-EI-MS provides critical data on acrolein generation pathways from specific fatty acid hydroperoxides, with studies showing significantly different acrolein yields from various HpOTE isomers [17].

Research Reagent Solutions

Table 3: Essential Research Reagents for Acrolein Analysis

| Reagent/Material | Function | Application Notes |

|---|---|---|

| 2,4-Dinitrophenylhydrazine (2,4-DNPH) | Derivatization of carbonyl compounds | Forms stable hydrazones with acrolein; 0.2 mg/mL in acetonitrile [4] |

| Acetonitrile (HPLC grade) | Extraction solvent | Superior extraction efficiency for carbonyl-DNPH derivatives; immiscible with oil [4] |

| Methanol (HPLC grade) | Alternative solvent | Used in extraction optimization; demonstrated lower efficiency than acetonitrile [4] |

| AIBN (2,2'-azobis(2-methylpropionitrile)) | Radical initiator | Induces autoxidation at 60°C to simulate storage conditions; 20 mM concentration [19] |

| Rose Bengal | Photosensitizer | Generates singlet oxygen for photo-oxidation studies [17] |

| Deuterated acrolein standards | Internal standards | Improves quantification accuracy in mass spectrometric methods |

| C18 Reverse Phase Column | Chromatographic separation | 150 × 4.6 mm, 5 μm particle size for UFLC separation [4] |

| Fatty acid hydroperoxide standards | Reference standards | Essential for identifying acrolein precursors (HpODE, HpOTE) [17] |

Experimental Workflow for Comprehensive Analysis

Diagram 2: Analytical workflow for acrolein determination

The accurate determination of acrolein in thermally oxidized oils requires sophisticated analytical approaches that address the significant challenges posed by its chemical reactivity, complex formation pathways, and low regulatory thresholds. The UFLC-DAD-ESI-MS protocol detailed herein provides researchers with a validated methodology capable of achieving the sensitivity and specificity necessary for compliance with current regulatory standards. As research continues to elucidate the complex relationship between fatty acid composition, processing conditions, and acrolein formation, analytical methods must evolve to address the emerging challenges in this critical field of food safety research.

Future methodological developments should focus on improved precursor detection, real-time monitoring capabilities, and enhanced sensitivity to meet increasingly stringent regulatory requirements for this toxicologically significant compound.

{1. Introduction}

Within the context of determining acrolein in thermally oxidized oils using UFLC-DAD, understanding its origin is paramount. Lipid peroxidation of polyunsaturated fatty acids (PUFAs) is a primary source of this highly toxic carbonyl compound. Among common fatty acids, linolenic acid (LnA; C18:3, n-3) has been identified as a major precursor for acrolein formation during the heating of edible oils [20]. Acrolein (CAS No. 107-02-8) is a volatile, highly toxic aldehyde listed as a significant air pollutant and dietary hazard due to its strong electrophilic character, which allows it to react readily with proteins and DNA, contributing to various chronic diseases [20] [19]. This application note details the mechanistic pathways and provides validated protocols for studying acrolein generation from LnA in thermally stressed oils.

{2. Mechanistic Pathways of Acrolein Formation from Linolenic Acid}

Acrolein is generated from LnA through the decomposition of its fatty acid hydroperoxide (FAOOH) isomers, a process initiated by two distinct oxidation mechanisms [20].

- Radical Oxidation: Traditional pathways involve radical oxidation, where free radicals abstract hydrogen from LnA, leading to hydroperoxide isomers like 9-, 12-, 13-, and 16-HpOTE (hydroperoxy octadecatrienoic acid).

- Singlet Oxygen (¹O₂) Oxidation: Recent research confirms a significant pathway via type II photo-oxidation, which generates specific ¹O₂-derived HpOTE isomers, notably 10- and 15-HpOTE [20]. Studies show that the amount of acrolein derived from these ¹O₂-specific isomers can be twice that from other HpOTE isomers [20].

Subsequent thermal degradation of these HpOTE isomers, particularly through β-scission reactions at the hydroperoxyl group, leads to the formation of acrolein [20]. The position of the hydroperoxyl group on the fatty acid chain is a critical factor determining the yield of acrolein.

Diagram 1: Pathways of acrolein formation from linolenic acid during oil heating.

{3. Quantitative Data on Carbonyl Compounds in Heated Oil}

The following table summarizes quantitative data on key carbonyl compounds, including acrolein, identified in soybean oil heated continuously at 180°C, as determined by UFLC-DAD-ESI-MS [3] [4].

Table 1: Carbonyl Compounds Identified in Thermally Oxidized Soybean Oil (180°C) [3]

| Carbonyl Compound | Category | Mean Concentration (μg/g of oil) |

|---|---|---|

| 4-Hydroxy-2-nonenal (HNE) | α,β-Unsaturated hydroxyaldehyde | 36.9 |

| 2,4-Decadienal | α,β-Unsaturated aldehyde | 34.8 |

| 2,4-Heptadienal | α,β-Unsaturated aldehyde | 22.6 |

| 4-Hydroxy-2-hexenal (HHE) | α,β-Unsaturated hydroxyaldehyde | Not Specified |

| Acrolein | α,β-Unsaturated aldehyde | Detected, concentration not specified |

| 2-Heptenal | α,β-Unsaturated aldehyde | Not Specified |

| 2-Octenal | α,β-Unsaturated aldehyde | Not Specified |

| 4,5-Epoxy-2-decadal | Epoxy aldehyde | Not Specified |

| 2-Decenal | α,β-Unsaturated aldehyde | Not Specified |

| 2-Undecenal | α,β-Unsaturated aldehyde | Not Specified |

{4. Analytical Methodologies for Detection and Quantification}

Various chromatographic techniques are employed for the analysis of acrolein and other reactive carbonyl species (RCS) in oils. The choice of method involves trade-offs between sensitivity, speed, and complexity.

Table 2: Comparison of Analytical Methods for Acrolein and Carbonyl Compounds

| Method | Key Features | Sample Preparation | Limitations / Notes |

|---|---|---|---|

| UFLC-DAD-ESI-MS [3] [4] | High selectivity and sensitivity for multiple carbonyls; LOD: 0.03-0.1 μg/mL. | Liquid-liquid extraction with acetonitrile, derivatization with 2,4-DNPH. | Well-validated for soybean oil; requires derivatization. |

| SFC-ESI-QqQ-MS/MS [21] | Fast separation of low-polarity derivatives; minimal solvent use; excellent LOD/LOQ. | Derivatization with 2,4-DNPH, one-step solvent extraction. | Emerging technique; high efficiency for trace analysis. |

| GC-MS [20] | Suitable for volatile analysis; powerful for identifying decomposition products. | Can be complex and time-consuming; may require extensive pre-treatment. | High detection limits; potential matrix interference [21]. |

| PTR-MS [19] | Rapid, direct analysis of volatiles; minimal sample prep. | Headspace analysis of samples. | Used for precursor monitoring (e.g., m/z 57 fragment); less specific for compound identification. |

{5. Detailed Experimental Protocol: UFLC-DAD-ESI-MS Analysis}

This protocol is adapted from validated methods for determining carbonyl compounds in the liquid phase of soybean oil [3] [4].

5.1. Reagents and Materials

- Samples: Soybean oil (or other edible oil of interest).

- Derivatization Reagent: 2,4-Dinitrophenylhydrazine (2,4-DNPH) solution.

- Extraction Solvent: Acetonitrile (HPLC grade).

- Standards: Carbonyl compound standards (e.g., acrolein, HNE, HHE) for calibration.

5.2. Sample Preparation and Extraction

- Heating Procedure: Heat oil samples (e.g., 10 g) at 180°C in a laboratory heating apparatus for different time intervals (0–60 minutes) to simulate thermal oxidation [4].

- Derivatization: React an aliquot of the heated oil with a 2,4-DNPH solution to form stable hydrazone derivatives of the carbonyl compounds.

- Liquid-Liquid Extraction:

- Add 1.5 mL of acetonitrile per gram of oil as the extraction solvent [3].

- Manually stir the mixture for 3 minutes.

- Sonicate the mixture for 30 minutes.

- Centrifuge to separate the layers and collect the acetonitrile (upper) layer containing the derivatized carbonyl compounds.

- Filtration: Filter the extract through a 0.20 μm membrane before injection into the UFLC system [4].

5.3. UFLC-DAD-ESI-MS Instrumental Parameters The analytical workflow, from sample preparation to data analysis, is summarized in the following diagram.

Diagram 2: Experimental workflow for acrolein analysis in oil using UFLC-DAD-ESI-MS.

- Chromatography:

- Detection:

5.4. Method Validation The described method has been validated with the following performance characteristics [3]:

- Recovery: 70.7% to 85.0% at the lowest spiked concentration level.

- Linearity: Calibration curves from 0.2 to 10.0 μg·mLâ»Â¹.

- Limit of Detection (LOD): 0.03 to 0.1 μg·mLâ»Â¹.

- Limit of Quantification (LOQ): 0.2 μg·mLâ»Â¹ for all target compounds.

{6. The Scientist's Toolkit: Key Research Reagent Solutions}

Table 3: Essential Reagents and Materials for Acrolein Analysis

| Item | Function / Application | Specific Example / Note |

|---|---|---|

| 2,4-Dinitrophenylhydrazine (2,4-DNPH) | Derivatizing agent for carbonyl compounds; forms stable hydrazones for UV and MS detection. | Most widely used reagent for this purpose; reacts with aldehydes and ketones at room temperature [4]. |

| Acetonitrile (HPLC Grade) | Extraction solvent for carbonyl compounds from the oil matrix. | Demonstrated superior extraction capacity compared to methanol for carbonyls in soybean oil [3] [4]. |

| Linolenic Acid (LnA) Standards | Model compound for studying acrolein generation pathways and precursor role. | Used in controlled thermal degradation studies to establish yield and mechanisms [20]. |

| Fatty Acid Hydroperoxide (FAOOH) Isomers | Key intermediate standards for studying decomposition pathways. | Purified HpOTE isomers (e.g., 9-, 12-, 10-, 15-HpOTE) are used to trace acrolein formation [20]. |

| Carbonyl Compound Standards | Calibration and identification of target analytes (e.g., acrolein, HNE, HHE). | Essential for quantitative analysis; available as pure compounds or pre-derivatized DNPH-hydrazones [21]. |

{7. Conclusion}

Linolenic acid is a critically important precursor in the formation of acrolein during the thermal oxidation of edible oils. The pathways involve both radical and singlet oxygen-mediated peroxidation, leading to specific hydroperoxide intermediates whose decomposition yields acrolein. The UFLC-DAD-ESI-MS protocol, supported by robust extraction and derivatization with 2,4-DNPH, provides a validated and reliable method for the simultaneous detection and quantification of acrolein and other toxic carbonyl compounds. This integrated understanding and methodology are crucial for accurately assessing oil quality and safety, as well as for evaluating health risks associated with dietary exposure to acrolein.

A Step-by-Step UFLC-DAD Protocol for Acrolein Quantification in Oil Matrices

The accurate determination of reactive carbonyl compounds, particularly acrolein, in thermally oxidized oils presents a significant analytical challenge due to their high reactivity, volatility, and low concentrations within complex lipid matrices. Derivatization using 2,4-dinitrophenylhydrazine (DNPH) has emerged as a fundamental sample preparation technique to overcome these limitations, significantly enhancing both selectivity and sensitivity in chromatographic analyses. This protocol details the application of DNPH derivatization within the context of determining acrolein in soybean oil under thermal oxidation conditions, utilizing UFLC-DAD for separation and detection.

The core chemical principle involves the formation of stable hydrazone derivatives via nucleophilic addition-elimination between the carbonyl group of aldehydes/ketones and the hydrazine group of DNPH. This reaction converts small, volatile, and poorly detectable carbonyl compounds into stable, chromophoric derivatives with excellent spectroscopic properties for UV detection. The resulting DNPH-hydrazones provide enhanced chromatographic behavior, reduced volatility, and heightened detectability, making them ideal for accurate quantification in challenging matrices like thermally stressed edible oils [4] [22].

Experimental Principles and Workflow

The DNPH Derivatization Mechanism

The reaction of DNPH with a carbonyl compound (e.g., acrolein) is a classic acid-catalyzed nucleophilic addition-elimination, resulting in the formation of a 2,4-dinitrophenylhydrazone derivative with water as a byproduct. This transformation is crucial for analytical success for several reasons:

- Enhanced UV Detectability: The introduction of the strongly electron-withdrawing dinitrophenyl group creates a derivative with a high molar absorptivity in the UV region (typically around 360 nm), enabling highly sensitive detection with a DAD detector [4].

- Improved Chromatographic Performance: The derivatization increases the molecular weight and modulates the polarity of the analyte, leading to better retention and separation on reversed-phase LC columns compared to the underivatized, highly volatile parent carbonyl [21] [23].

- Increased Analyte Stability: The hydrazone derivatives are significantly more stable than the parent carbonyl compounds, which are prone to degradation and polymerization, thus ensuring analytical integrity throughout the analysis [22].

Comprehensive Workflow for Oil Analysis

The complete analytical procedure, from sample preparation to data analysis, can be visualized as a streamlined workflow. The following diagram outlines the key stages in determining acrolein in thermally oxidized oil using DNPH derivatization and UFLC-DAD analysis.

Research Reagent Solutions and Essential Materials

A successful analysis requires specific, high-purity reagents and materials. The following table catalogues the essential components of the "Researcher's Toolkit" for this method.

Table 1: Essential Reagents and Materials for DNPH Derivatization and UFLC-DAD Analysis

| Item | Function/Description | Technical Notes |

|---|---|---|

| 2,4-Dinitrophenylhydrazine (DNPH) | Derivatizing reagent. Forms stable, chromophoric hydrazones with carbonyl compounds. | Typically used in an acidified solution (e.g., with phosphoric acid) to catalyze the reaction [4] [23]. |

| Acetonitrile (HPLC Grade) | Primary solvent for preparing DNPH reagent, standards, and as the LC mobile phase. | Low UV cutoff and high purity are critical to minimize background interference [4]. |

| Acrolein Standard | Primary standard for calibration curve construction. | Due to high volatility and toxicity, prepare stock solutions in acetonitrile with care in a fume hood [24]. |

| Soybean Oil | Sample matrix. High in polyunsaturated fatty acids (PUFAs), making it prone to thermal oxidation and acrolein formation [4]. | |

| UFLC System | Ultra-Fast Liquid Chromatography system for high-resolution separation of derivatives. | Provides rapid and efficient separation of complex mixtures [4]. |

| DAD Detector | Diode Array Detection for monitoring eluent. | Enables specific detection of DNPH-derivatized carbonyls at ~360 nm [4]. |

Detailed Experimental Protocols

Protocol 1: Thermal Oxidation of Soybean Oil and Carbonyl Extraction

This protocol simulates the degradation that occurs during high-temperature cooking.

Materials:

- Refined soybean oil

- Heating appliance (e.g., oil bath or hot plate)

- Thermometer

- Acetonitrile (HPLC grade)

Procedure:

- Thermal Oxidation: Place 100 mL of soybean oil in a suitable container (e.g., a beaker). Heat the oil to 180 °C and maintain this temperature for up to 6 hours under continuous stirring. Withdraw aliquots (e.g., 1 mL) at predetermined time intervals (e.g., 0, 1, 2, 4, 6 hours) for analysis [4].

- Carbonyl Extraction: Accurately weigh 0.1 g of the heated oil sample into a microcentrifuge tube. Add 1.0 mL of acetonitrile. Vortex the mixture vigorously for 2 minutes to facilitate the transfer of carbonyl compounds from the oil to the acetonitrile phase. Centrifuge at 10,000 rpm for 5 minutes to achieve complete phase separation. Collect the clear acetonitrile (upper) layer for the subsequent derivatization step [4] [23].

Protocol 2: DNPH Derivatization of Acrolein

This is the core reaction that enables sensitive detection.

Materials:

- DNPH derivatizing solution (e.g., 1 mM DNPH in acidified acetonitrile)

- Acrolein standard solutions

- Thermostatic water bath or block

Procedure:

- Reagent Preparation: Prepare a 1 mM DNPH derivatization solution by dissolving the appropriate mass of DNPH in acetonitrile containing 0.1% (v/v) phosphoric acid [23].

- Derivatization Reaction: To 500 µL of the extracted sample (in acetonitrile) or acrolein standard, add 500 µL of the DNPH derivatization solution. Vortex to mix thoroughly.

- Incubation: Allow the reaction mixture to stand at room temperature (20-25 °C) for 30 minutes to ensure complete derivatization [24]. The solution will typically develop a yellow color due to the formation of the hydrazones.

- Pre-Injection Preparation: After the reaction is complete, the derivatized sample can be filtered (0.22 µm PVDF syringe filter) directly into a UFLC vial for analysis.

Protocol 3: UFLC-DAD Analysis of Acrolein-DNPH Hydrazone

This protocol covers the separation and quantification of the derivative.

Exemplary UFLC-DAD Conditions [4]:

- Column: C18 reversed-phase column (e.g., 150 mm x 4.6 mm, 2.7 µm)

- Mobile Phase: A: Water / B: Acetonitrile

- Gradient Program:

- 0 min: 40% B

- 10 min: 95% B

- 12 min: 95% B

- 12.1 min: 40% B

- 15 min: 40% B (re-equilibration)

- Flow Rate: 0.8 mL/min

- Injection Volume: 10 µL

- DAD Detection: 360 nm (characteristic for DNPH derivatives)

Quantification:

- Construct a calibration curve by analyzing a series of acrolein standards of known concentration (e.g., 0.05 - 5 µM) that have undergone the same derivatization procedure.

- Plot the peak area of the acrolein-DNPH hydrazone against the concentration.

- Identify the acrolein peak in the sample chromatogram based on the retention time of the standard.

- Quantify the acrolein concentration in the original oil sample by comparing the sample peak area to the calibration curve, applying the appropriate dilution factors.

Performance Data and Analytical Figures of Merit

The effectiveness of the DNPH derivatization approach is demonstrated by its superior analytical performance. The following table summarizes key validation parameters as reported in the literature for the determination of acrolein and related carbonyls in oil matrices.

Table 2: Quantitative Performance Metrics of DNPH-Based Methods for Carbonyl Analysis in Oils

| Analyte | Reported LOD/LOQ | Linear Range | Recovery (%) | Precision (RSD%) | Key Methodological Note | Citation |

|---|---|---|---|---|---|---|

| Acrolein | - | - | - | - | Extracted with acetonitrile from soybean oil. | [4] |

| General Aldehydes | LOD: 0.14-1.73 µg/kg (in food) | - | 82.12–119.30 | 0.52–12.11 | Validated LC-MS/MS method after DNPH derivatization. | [25] |

| MDA & α,β-Unsaturated Aldehydes | LOD: 0.003-0.03 µg/kg (SFC-MS/MS) | - | 82.4–118.2 | 1.2–13.8 (Intra-day); 2.5–14.9 (Inter-day) | DNPH derivatization with one-step solvent extraction. | [21] |

| Carbonyl Compounds | - | - | - | - | Miniaturized Kapok Fiber-Supported Liquid-Phase Extraction coupled with in-situ derivatization. | [23] |

Troubleshooting and Technical Notes

- Low Derivatization Yield: Ensure the DNPH solution is fresh and properly acidified. The reaction is acid-catalyzed; insufficient acid will slow the reaction kinetics. Confirm the reaction time and temperature are adequate.

- High Background Noise in Chromatogram: Use high-purity, LC-MS grade solvents to minimize UV-absorbing impurities. Check for degradation of the DNPH reagent, which can appear as multiple peaks in the chromatogram.

- Poor Chromatographic Peak Shape: This may indicate column overloading or matrix effects. Ensure the extraction and derivatization steps are efficient and consider diluting the sample extract prior to derivatization. Verify that the UFLC gradient is effectively separating the target analyte from interfering compounds.

Within the scope of research on the formation of toxic degradation products in thermally oxidized oils, the accurate quantification of acrolein and other carbonyl compounds (CCs) is of paramount importance. The sample preparation stage is a critical determinant of analytical success, as it directly influences the sensitivity, accuracy, and reproducibility of the subsequent ultrafast liquid chromatography-diode array detection (UFLC-DAD) analysis. This protocol details an optimized liquid-liquid extraction (LLE) method using acetonitrile, developed specifically for the isolation of CCs, including the highly reactive acrolein, 4-hydroxy-2-nonenal (HNE), and 2,4-decadienal, from soybean oil matrices [4]. The method is characterized by its simplicity, rapidity, and low solvent consumption, making it ideally suited for monitoring oil degradation during thermal stress studies [4].

Experimental Protocols

Key Reagents and Materials

- Edible Oil Samples: Refined soybean oil is used as a representative matrix due to its high polyunsaturated fatty acid content and widespread use [4].

- Extraction Solvent: Acetonitrile (ACN), HPLC grade [4] [23].

- Derivatization Reagent: 2,4-Dinitrophenylhydrazine (DNPH). This reagent reacts with carbonyl functional groups to form stable hydrazone derivatives, which are essential for sensitive chromatographic detection [4] [23] [21].

- Acid Catalyst: Phosphoric acid is often used to acidify the DNPH solution, facilitating the derivatization reaction [23].

- Carbonyl Compound Standards: Acrolein, 4-HNE, 2,4-decadienal, and others for method validation and quantification [4] [21].

Optimized Liquid-Liquid Extraction Procedure

The following steps describe the optimized LLE protocol for the preparation of soybean oil samples heated at 180°C for varying durations [4].

- Weighing: Precisely weigh 1.0 g of the heated soybean oil sample into a suitable extraction vessel, such as a glass vial or test tube.

- Solvent Addition: Add 1.5 mL of acetonitrile to the oil sample. This solvent volume has been optimized for maximum extraction efficiency of the target carbonyl compounds [4].

- Manual Mixing: Manually stir the mixture vigorously for 3 minutes to ensure thorough contact between the oil and the acetonitrile phase, promoting the transfer of carbonyl compounds into the solvent.

- Sonication: Subject the mixture to ultrasonic treatment for 30 minutes. This step enhances the extraction yield by disrupting the oil matrix and improving mass transfer.

- Phase Separation: Allow the mixture to stand until complete phase separation occurs. Due to its different density and polarity, acetonitrile will form a distinct upper layer separate from the oil.

- Collection: Carefully collect the upper acetonitrile layer (extract) using a micropipette or syringe.

- Derivatization (Optional On-Site): The acetonitrile extract can be directly derivatized with a DNPH solution for analysis. Alternatively, as demonstrated in advanced methodologies, a solution of DNPH in acetonitrile can be integrated into the extraction step itself, performing in-situ derivatization to streamline the workflow [23].

- Analysis: The resulting extract (or derivatized extract) is then suitable for injection into the UFLC-DAD or UFLC-DAD-ESI-MS system for separation and quantification [4].

Parameter Optimization and Rationale

The specified parameters were selected based on systematic optimization to maximize recovery.

- Solvent Selection: Acetonitrile was found to have superior extraction capability for carbonyl compounds compared to solvents like methanol, as determined by the sum of chromatographic peak areas of the target analytes [4].

- Solvent Volume: The use of 1.5 mL of acetonitrile per 1.0 g of oil provides an optimal balance between pre-concentration and high recovery rates [4].

- Extraction Time: The combined 3-minute manual stirring and 30-minute sonication protocol ensures efficient extraction without unnecessarily prolonging the sample preparation time [4].

The optimized method was rigorously validated using spiked soybean oil samples. The tables below summarize the key quantitative performance data and the concentrations of major carbonyl compounds detected in heated oil.

Table 1: Method Validation Parameters for Carbonyl Compounds in Soybean Oil

| Parameter | Value / Range | Details |

|---|---|---|

| Recovery (%) | 70.7 - 85.0% | Assessed at the lowest spiking concentration level (0.2 μg mLâ»Â¹) [4]. |

| Limit of Detection (LOD) | 0.03 - 0.1 μg mLâ»Â¹ | Compound-dependent [4]. |

| Limit of Quantification (LOQ) | 0.2 μg mLâ»Â¹ | Consistent for all target analytes [4]. |

| Calibration Range | 0.2 - 10.0 μg mLâ»Â¹ | Linear range used for validation [4]. |

Table 2: Concentrations of Key Carbonyl Compounds Identified in Soybean Oil Heated at 180°C

| Carbonyl Compound | Mean Concentration (μg gâ»Â¹ of oil) | Toxicity and Significance |

|---|---|---|

| 4-Hydroxy-2-nonenal (HNE) | 36.9 | Cytotoxic; can form adducts with DNA and proteins [4]. |

| 2,4-Decadienal | 34.8 | Associated with lung and stomach adenocarcinomas [4]. |

| 2,4-Heptadienal | 22.6 | A common secondary oxidation product [4]. |

| Acrolein | Detected | Highly toxic, irritant, and linked to chronic diseases [4] [20]. |

| 4-Hydroxy-2-hexenal (HHE) | Detected | Toxic oxidation product from n-3 polyunsaturated fatty acids [4]. |

Workflow Visualization

The following diagram illustrates the complete experimental workflow from sample preparation to analysis, as detailed in this protocol.

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for LLE of Acrolein

| Reagent / Material | Function | Application Note |

|---|---|---|

| Acetonitrile (HPLC Grade) | Extraction solvent | Optimized for high recovery of polar carbonyl compounds from the non-polar oil matrix. Low miscibility with oil prevents emulsion formation [4] [23]. |

| 2,4-Dinitrophenylhydrazine (DNPH) | Derivatizing agent | Selectively reacts with carbonyl groups (aldehydes/ketones) to form stable 2,4-dinitrophenylhydrazone derivatives. These derivatives enhance UV detection and ESI-MS response [4] [23] [21]. |

| Carbonyl Compound Standards | Calibration and Identification | Pure analytical standards (e.g., acrolein, HNE, 2,4-decadienal) are crucial for constructing calibration curves, determining recovery rates, and identifying peaks in chromatograms [4] [21]. |

| Acidified Solution | Reaction catalyst | An acidic environment (e.g., with phosphoric acid) is required to protonate the carbonyl oxygen, facilitating the nucleophilic addition reaction with DNPH [23]. |

| CS-2100 | CS-2100, MF:C25H23N3O4S, MW:461.5 g/mol | Chemical Reagent |

| Didemnin C | Didemnin C|Antitumor Peptide|CAS 77327-06-1 | Didemnin C is a marine-derived cyclic depsipeptide with potent antitumor properties and protein synthesis inhibition. For Research Use Only. Not for human use. |

Within the framework of research aimed at determining acrolein in thermally oxidized oils using Ultra-Fast Liquid Chromatography with a Diode Array Detector (UFLC-DAD), the optimization of the mobile phase is a critical determinant for achieving successful separation, identification, and quantification. Acrolein (2-propenal) is a toxic aldehydic compound generated from the thermal degradation of lipids, particularly polyunsaturated fatty acids (PUFAs) [20]. Its analysis in complex oil matrices presents significant challenges, including its high polarity and the co-elution of numerous other oxidation products. This application note provides detailed protocols and data for the chromatographic separation of acrolein, with a specific focus on mobile phase composition and elution profiles tailored for UFLC-DAD analysis in the context of edible oil research.

Literature Review: Mobile Phase Strategies for Aldehyde Analysis

The analysis of reactive aldehydes like acrolein in oily matrices often requires derivatization to enhance chromatographic performance and detection sensitivity. The selection of a mobile phase must be compatible with the derivatizing agent, the column chemistry, and the detection system.

2.1. Derivatization and UFLC-DAD-ESI-MS Analysis A validated method for carbonyl compounds in soybean oil employed 2,4-dinitrophenylhydrazine (DNPH) for derivatization. The corresponding mobile phase for UFLC-DAD-ESI-MS analysis was optimized to separate the resulting hydrazone derivatives [3]. The best separation was achieved using a gradient elution with a mobile phase consisting of:

- Mobile Phase A: Water with 0.1% (v/v) Formic Acid

- Mobile Phase B: Acetonitrile with 0.1% (v/v) Formic Acid The addition of acid improves peak shape by suppressing the ionization of residual silanol groups on the stationary phase and the analytes, leading to better resolution [3].

2.2. Advanced Techniques: SFC-MS/MS as a Comparative Method While not directly using UFLC, a novel method utilizing Supercritical Fluid Chromatography-tandem mass spectrometry (SFC-MS/MS) has been developed for aldehydes in oils. This method uses supercritical COâ‚‚ as the primary mobile phase, with acetonitrile as a modifier, following DNPH derivatization [21]. A key advantage noted is that the evaporation of the supercritical fluid before it enters the mass spectrometer minimizes organic solvent interference and improves ionization efficiency. This highlights the importance of mobile phase selection in desolvation and sensitivity, principles that translate to optimizing LC systems [21].

Table 1: Summary of Mobile Phase Compositions for Aldehyde Analysis in Oils

| Analysis Technique | Derivatization Agent | Mobile Phase Composition | Key Separation Findings | Source |

|---|---|---|---|---|

| UFLC-DAD-ESI-MS | 2,4-dinitrophenylhydrazine (DNPH) | A: Water with 0.1% Formic AcidB: Acetonitrile with 0.1% Formic AcidGradient Elution | Successfully separated 10 carbonyl compounds, including acrolein, 4-HNE, and 2,4-decadienal from heated soybean oil. | [3] |

| SFC-ESI-QqQ-MS/MS | 2,4-dinitrophenylhydrazine (DNPH) | Supercritical CO₂ with acetonitrile modifier | Minimized solvent consumption and improved trace analysis of α,β-unsaturated aldehydes due to enhanced desolvation. | [21] |

Experimental Protocols

Protocol A: Determination of Carbonyl Compounds in Oils via UFLC-DAD-ESI-MS

This protocol is adapted from the method developed for soybean oil [3].

I. Sample Preparation and Derivatization

- Weighing: Accurately weigh 0.1 g of the thermally oxidized oil sample into a glass vial.

- Extraction: Add 1.5 mL of acetonitrile as the extraction solvent.

- Mixing: Manually stir the mixture for 3 minutes to ensure thorough homogenization.

- Sonication: Sonicate the mixture for 30 minutes to complete the extraction.

- Derivatization: Add an appropriate volume of DNPH derivatization reagent to the extract.

- Filtration: Centrifuge and filter the final solution through a 0.22 μm PTFE syringe filter prior to injection.

II. Chromatographic Conditions

- Apparatus: Ultra-Fast Liquid Chromatography (UFLC) system coupled with DAD and ESI-MS.

- Column: C18 reversed-phase column (e.g., 150 mm x 4.6 mm, 2.7 μm).

- Mobile Phase: As detailed in Table 1.

- Elution Profile: Gradient elution. Initial conditions 60% A / 40% B, ramping to 10% A / 90% B over 15 minutes, followed by a hold and re-equilibration.

- Flow Rate: 0.8 mL/min.

- Injection Volume: 10 μL.

- Column Temperature: 40 °C.

- DAD Detection: Scan from 200-400 nm; specific quantification of DNPH derivatives at ~360 nm.

III. Method Validation The method should be validated for:

- Linearity: Using calibration standards (e.g., 0.2 to 10.0 μg/mL).

- Recovery: Average recoveries at the lowest concentration level should range from 70-85% [3].

- Sensitivity: Limit of Detection (LOD) and Limit of Quantification (LOQ). For this method, LODs ranged from 0.03 to 0.1 μg/mL, and the LOQ was 0.2 μg/mL for all compounds [3].

Protocol B: Sample Preparation for Aldehyde Extraction from Oil-Containing Foods

This protocol is based on a method for analyzing aldehydes in various food matrices [21].

- Homogenization: Pulverize the food sample (e.g., fried, baked) to a fine powder using a laboratory mill.

- Derivatization: React the sample with a DNPH solution to convert aldehydes to their stable hydrazone derivatives.

- Lipid Removal (if necessary): Perform a liquid-liquid extraction with a solvent like hexane to remove excess non-polar lipids.

- Extraction of Derivatives: Extract the polar DNPH-derivatized aldehydes using a suitable solvent (e.g., acetonitrile).

- Concentration: Gently evaporate the extract under a stream of nitrogen and reconstitute in an injection-compatible solvent (e.g., acetonitrile or the initial mobile phase).

- Filtration: Filter through a 0.22 μm membrane before chromatographic analysis.

The following workflow diagram illustrates the key stages of the sample preparation and analysis process.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents and Materials for Acrolein Analysis in Oils

| Reagent/Material | Function/Application | Specifications/Notes | |

|---|---|---|---|

| 2,4-Dinitrophenylhydrazine (DNPH) | Derivatizing agent for carbonyl compounds (aldehydes & ketones). Forms stable, chromophoric hydrazones amenable to UV-Vis detection. | Purity ≥95%. Prepare in acetonitrile acidified with a small percentage of phosphoric or hydrochloric acid. | [21] [3] |

| Acetonitrile (HPLC/MS Grade) | Primary solvent for extraction, derivatization, and mobile phase composition. | Low UV cutoff, high purity to minimize background interference. | [21] [3] |

| Formic Acid (LC-MS Grade) | Mobile phase additive. Modifies pH, improves peak shape by suppressing silanol effects, and enhances ionization in ESI-MS. | Typically used at 0.1% (v/v) concentration. | [3] |

| C18 Reversed-Phase Column | Stationary phase for chromatographic separation of DNPH-aldehyde derivatives. | Common dimensions: 150 mm x 4.6 mm, particle size 2.7-5 μm. | [3] |

| Acrolein-DNPH Standard | Certified reference material for method calibration and quantification. | Typically supplied as 100 μg/mL solution in acetonitrile. | [21] |

| PTFE Syringe Filters | Clarification of sample extracts prior to injection into the chromatograph. | 0.22 μm pore size, compatible with organic solvents. | [3] |

| Regrelor disodium | Regrelor Disodium | P2Y12 Antagonist Research Compound | Research-grade Regrelor disodium, a potent P2Y12 receptor antagonist. This product is for Research Use Only (RUO). Not for human or veterinary diagnosis or therapy. | |

| GL3 | GL3, MF:C48H64O27, MW:1073.0 g/mol | Chemical Reagent |

The accurate determination of acrolein in thermally oxidized oils via UFLC-DAD is highly dependent on a meticulously optimized mobile phase and sample preparation workflow. The use of a DNPH-derivatization step coupled with a reversed-phase C18 column and an acidified water-acetonitrile gradient elution provides a robust and validated methodology [3]. The composition of the mobile phase, specifically the inclusion of acidic modifiers, is crucial for achieving the resolution necessary to separate acrolein from other complex lipid oxidation products in the sample matrix. The protocols and data summarized in this application note serve as a foundational guide for researchers conducting precise and reliable assessments of this toxic compound in lipid-based systems.

Within the scope of a broader thesis focused on determining acrolein in thermally oxidized oils using UFLC-DAD, the selection of an appropriate detection wavelength and a thorough understanding of the analyte's spectral behavior are paramount. Acrolein (2-propenal) is a highly reactive α,β-unsaturated aldehyde and a known toxicant generated during the lipid peroxidation of polyunsaturated fatty acids (PUFAs) in edible oils under thermal stress [26] [27]. Its accurate monitoring is crucial for assessing food safety and quality. The established methodology for its analysis involves derivatization with 2,4-dinitrophenylhydrazine (DNPH) to form a stable hydrazone derivative, followed by separation using Ultra-Fast Liquid Chromatography (UFLC) and detection with a Diode Array Detector (DAD) [28] [29]. This application note provides a detailed protocol and critical insights for researchers, scientists, and drug development professionals working on the analysis of lipid oxidation products, with a specific focus on the DAD detection of the acrolein-DNPH derivative.

Theoretical Foundations: The Acrolein-DNPH Derivative

The derivatization of acrolein with DNPH is a cornerstone of this analytical method. The reaction proceeds via a nucleophilic addition mechanism, where the carbonyl group (C=O) of acrolein reacts with the amino group (NH2) of DNPH, leading to the formation of an acrolein-DNPH hydrazone. This derivative possesses a strong chromophore due to the conjugated 2,4-dinitrophenylhydrazone group, which absorbs intensely in the ultraviolet (UV) region, thereby enabling sensitive detection with a DAD [28].

A critical analytical challenge is the acid-catalyzed isomerization of the acrolein-DNPH hydrazone. The initially formed purified derivative exists predominantly as the E-isomer. However, in the presence of even trace amounts of acid during sample preparation or analysis, isomerization can occur, leading to a mixture of E- and Z-isomers [29]. For acrolein-DNPH, the equilibrium Z/E isomer ratio has been reported to be approximately 0.028 [29]. This isomerization is a significant potential source of analytical error, as the two isomers may have different retention times and spectral properties, potentially leading to peak splitting or inaccurate quantification if not properly managed.

Wavelength Selection and Spectral Analysis

Primary Wavelength Selection

The conjugated system in the DNPH-hydrazone moiety has a characteristic absorption maximum. For the quantitative analysis of acrolein-DNPH and other carbonyl-DNPH derivatives, a detection wavelength of 360 nm is standard and recommended [30] [29]. At this wavelength, the derivative exhibits strong absorption, ensuring high sensitivity for detection in complex matrices like oil extracts.

The Role of Diode Array Detection (DAD)

The use of a DAD is highly advantageous over a single-wavelength UV detector. It allows for the continuous collection of spectral data for each eluting peak throughout the analysis. This capability is crucial for:

- Peak Purity Assessment: Verifying that the acrolein-DNPH peak is pure and not co-eluting with other matrix interferents.

- Spectral Confirmation: Comparing the UV spectrum of the analyte peak in a sample with that of a true acrolein-DNPH standard confirms identity. The spectrum should show a characteristic broad absorption band with λ_max around 360 nm.

- Troubleshooting Isomerization: Monitoring for peak splitting or shoulders that may indicate the presence of E/Z isomers, which can be resolved by optimizing the mobile phase acidity.

Table 1: Key Spectral and Analytical Parameters for Acrolein-DNPH Analysis by UFLC-DAD

| Parameter | Specification / Value | Rationale / Implication |

|---|---|---|

| Recommended Detection Wavelength | 360 nm | Maximum absorbance for DNPH-hydrazones, ensuring high sensitivity [29]. |

| Typical Spectral Range | 300 - 400 nm | Allows for peak purity analysis and spectral confirmation. |

| Z/E Isomer Ratio (at equilibrium) | ~0.028 [29] | Indicates a lower propensity for Z-isomer formation compared to other aldehydes (e.g., Acetaldehyde: 0.309). |