Development and Validation of a UFLC-DAD-ESI-MS Method for Analyzing Toxic Carbonyl Compounds in Thermally Oxidized Soybean Oil

Thermal oxidation of edible oils like soybean oil generates toxic carbonyl compounds (CCs) that pose significant health risks.

Development and Validation of a UFLC-DAD-ESI-MS Method for Analyzing Toxic Carbonyl Compounds in Thermally Oxidized Soybean Oil

Abstract

Thermal oxidation of edible oils like soybean oil generates toxic carbonyl compounds (CCs) that pose significant health risks. This article details the development, validation, and application of a novel UFLC-DAD-ESI-MS method for the precise determination of CCs, including acrolein, 4-hydroxy-2-nonenal (HNE), and 2,4-decadienal, in soybean oil during continuous heating at 180°C. The optimized method employs liquid-liquid extraction with acetonitrile and was rigorously validated for selectivity, precision, and accuracy, demonstrating high sensitivity with detection limits of 0.03–0.1 μg mLâ»Â¹. Application to heated oil samples identified and quantified key toxic aldehydes, with HNE, 2,4-decadienal, and 2,4-heptadienal presenting the highest concentrations. This reliable and accessible methodology provides a crucial tool for researchers and food scientists monitoring oil quality and assessing dietary exposure to harmful degradation products.

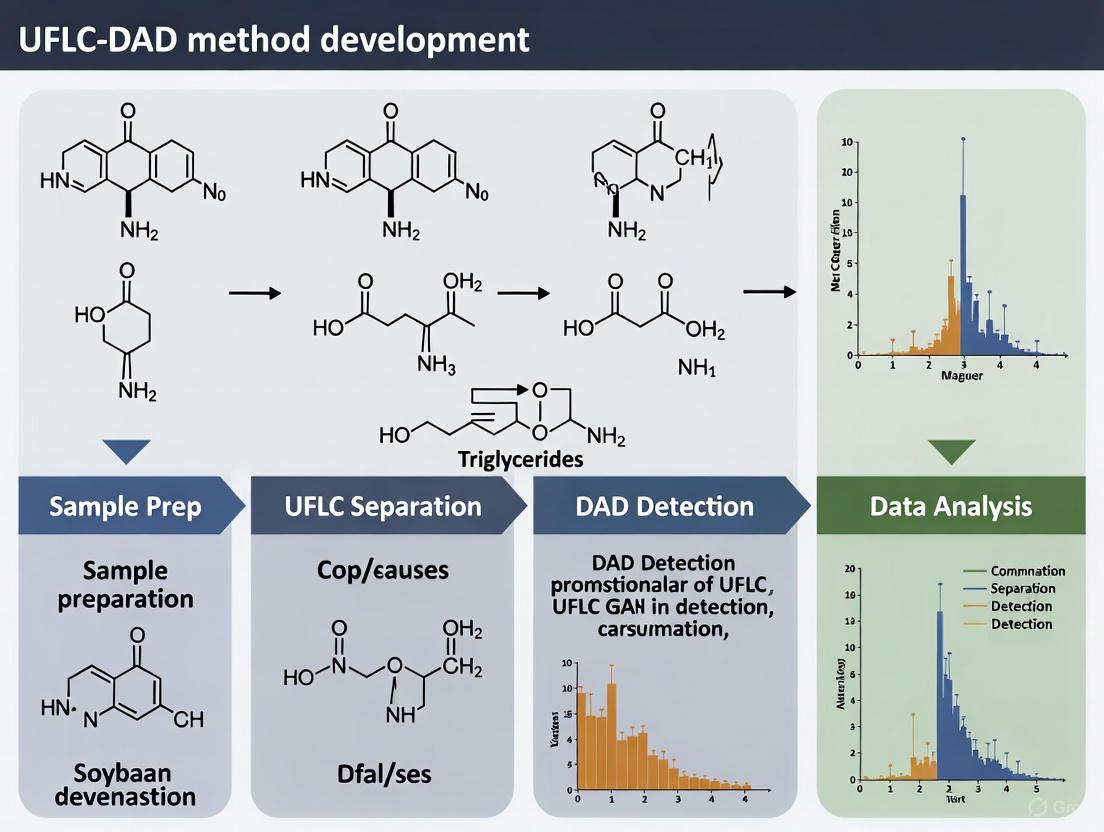

The Critical Need for Analyzing Carbonyl Compounds in Thermally Stressed Soybean Oil

Thermal oxidation of cooking oils is a major concern in food science and public health. When edible oils, particularly those rich in polyunsaturated fatty acids (PUFAs) like soybean oil, are subjected to high-temperature processes such as frying, they undergo complex chemical transformations that generate a variety of harmful compounds, including aldehydes [1] [2]. These aldehydes, especially the α,β-unsaturated aldehydes, are highly reactive and have been associated with numerous disease pathologies due to their ability to damage essential biomolecules like DNA and proteins [1]. The development of robust analytical methods, particularly Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD), for identifying and quantifying these toxic compounds is therefore crucial for risk assessment and the establishment of food safety guidelines. This application note details the relationship between thermally induced oil degradation, aldehyde formation, and associated health risks, with a specific focus on UFLC-DAD method development for soybean oil analysis.

Aldehyde Formation in Thermally Treated Oils

Chemical Pathways of Oil Degradation

During thermal stress, such as deep-frying at temperatures of 180°C or higher, triacylglycerides in edible oils undergo three primary degradation pathways: hydrolysis, oxidation, and polymerization [1]. Oxidation is the most significant route for aldehyde generation. It begins with the formation of lipid hydroperoxides (primary oxidation products) from unsaturated fatty acids. These hydroperoxides are unstable and readily decompose into a wide range of secondary lipid oxidation products (LOPs), notably aldehydes, ketones, and alcohols [2]. The type and quantity of aldehydes produced depend on several factors, including the oil's fatty acid profile, temperature, heating duration, surface area exposure, and the presence of oxygen or pro-oxidant metals [2] [3].

Oils with high PUFA content, such as conventional soybean oil, are particularly vulnerable to oxidation. For instance, linoleic acid (C18:2) and linolenic acid (C18:3) are susceptible due to the presence of multiple double bonds, which act as sites for oxygen attack [4] [1]. The degradation of linolenic acid hydroperoxides can lead to the formation of 4-hydroxy-2-hexenal (HHE), while linoleic acid hydroperoxides yield 4-hydroxy-2-nonenal (HNE) and 2,4-decadienal [2].

Key Toxic Aldehydes and Their Quantification

Advanced analytical techniques have identified numerous harmful aldehydes in thermally oxidized oils. Table 1 summarizes the most concerning aldehydes detected in heated soybean oil, their maximum reported concentrations, and their established toxicological effects.

Table 1: Key Harmful Aldehydes Identified in Thermally Oxidized Soybean Oil

| Aldehyde Compound | Type | Reported Concentration in Heated Oil | Major Health Concerns |

|---|---|---|---|

| 4-Hydroxy-2-Nonenal (HNE) | α,β-unsaturated hydroxyalkenal | Quantified in various heating studies [2] | Genotoxicity, inhibition of DNA synthesis, protein adduct formation, associated with cancer, atherosclerosis, Alzheimer's [2] |

| 4-Hydroxy-2-Hexenal (HHE) | α,β-unsaturated hydroxyalkenal | Quantified in various heating studies [2] | Cytotoxic, genotoxic, reacts with DNA and proteins [2] |

| Acrolein | α,β-unsaturated aldehyde | Detected in soybean oil heated at 180°C [2] | Severe irritant, linked to atherosclerosis, carcinogenesis, Alzheimer's, inhibits tumor suppressor p53 [2] |

| 2,4-Decadienal | α,β-unsaturated aldehyde | Detected in thermally oxidized oils [2] | Associated with development of lung adenocarcinoma and gastrointestinal cancers [2] |

| Saturated Aldehydes | Alkanals (e.g., Hexanal) | Significant increase after 60 min heating at 190°C [1] | Contribute to oxidative stress and cellular damage [1] |

Recent studies using high-field (800 MHz) NMR spectroscopy have further revealed the generation of particularly harmful α,β-unsaturated aldehydes—such as 4-hydroperoxy-(E)-2-alkenals, 4-hydroxy-(E)-2-alkenals, and 4,5-epoxy-(E)-2-alkenals—in various edible oils under both thermal and light exposure conditions [1]. These compounds are exceptionally reactive and are established mutagens and genotoxins, with associations to cancer, cardiovascular diseases, and neurological disorders like Alzheimer's and Parkinson's disease [1].

UFLC-DAD Methodology for Aldehyde Analysis

Sample Preparation and Derivatization

The accurate quantification of carbonyl compounds (CCs) in the complex lipid matrix requires efficient extraction and selective derivatization. The following protocol, adapted from Bastos et al. (2017), has been optimized for soybean oil [2].

- Reagents: 2,4-Dinitrophenylhydrazine (2,4-DNPH), hydrochloric acid, acetonitrile (HPLC grade), tetrahydrofuran (HPLC grade).

- DNPH Solution Preparation: Dissolve 2,4-DNPH in acetonitrile with a small percentage of hydrochloric acid as a catalyst.

- Derivatization Procedure:

- Weigh approximately 0.1 g of oil sample into a glass vial.

- Add 1 mL of tetrahydrofuran and vortex until the oil is completely dissolved.

- Add 1 mL of the prepared DNPH solution, vortex, and let the reaction proceed for 30 minutes at room temperature.

- The carbonyl compounds react with 2,4-DNPH to form stable hydrazone derivatives, which are highly chromophoric, enabling sensitive UV detection.

UFLC-DAD Analytical Conditions

The separation and quantification of DNPH-derivatized aldehydes are achieved using the following UFLC-DAD parameters [2].

- Chromatograph: Ultra-Fast Liquid Chromatography system.

- Column: C18 reversed-phase column (e.g., 150 mm × 4.6 mm, 2.7 µm particle size).

- Mobile Phase:

- A: 0.1% Aqueous Formic Acid

- B: Acetonitrile

- Gradient Program:

Time (min) % A % B 0 70 30 15 10 90 18 10 90 18.1 70 30 23 70 30 - Flow Rate: 0.8 mL/min

- Injection Volume: 10 µL

- DAD Detection: 370 nm (characteristic absorption maximum for DNPH-hydrazones).

Method Validation

The developed method must be validated according to ICH guidelines to ensure reliability.

- Linearity: Demonstrate a linear calibration curve for each aldehyde of interest (e.g., acrolein, HNE, HHE) with a correlation of determination (R²) ≥ 0.999 over a concentration range of 0.025–10 µg/mL [5].

- Precision: Intra-day and inter-day precision should yield a relative standard deviation (% RSD) of ≤ 10% [5].

- Accuracy: Determine via recovery studies, with recovery rates ideally between 90–110%.

- Sensitivity: The lower limit of detection (LLOD) and quantification (LLOQ) for such methods can be as low as 0.008 µg/mL and 0.025 µg/mL, respectively [5].

Pathological Mechanisms of Aldehydes

The health risks of consuming thermally oxidized oils are primarily mediated by the reactivity of aldehydes. The following diagram illustrates the key pathogenic pathways triggered by these compounds.

The diagram above shows how aldehydes like HNE and acrolein act as reactive electrophilic species that readily form covalent adducts with nucleophilic sites in proteins, DNA, and other biomolecules [2] [3]. This molecular damage disrupts critical cellular functions:

- HNE can form adducts with DNA bases, inhibiting DNA synthesis and recombination, leading to mutations and potentially cancer. It can also modify proteins, disrupting enzyme activity and cell signaling [2].

- Acrolein is known to inhibit the tumor suppressor protein p53, which is a key mechanism in its contribution to carcinogenesis [2].

- Chronic consumption of oxidized oils has been shown in animal studies to negatively impact lipid profiles (increasing LDL and total cholesterol), promote atherosclerosis, induce oxidative stress, and impair vascular relaxation, which can lead to hypertension [3].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Reagents and Materials for Aldehyde Analysis in Oils

| Item | Function/Application | Brief Explanation |

|---|---|---|

| 2,4-Dinitrophenylhydrazine (2,4-DNPH) | Derivatization Reagent | Selectively reacts with carbonyl groups of aldehydes and ketones to form stable, chromophoric hydrazones, enabling UV detection [2] [6]. |

| UFLC-DAD System | Analytical Separation & Detection | Provides high-resolution separation of complex aldehyde-hydrazone mixtures with sensitive and selective ultraviolet detection [2] [7]. |

| C18 Reversed-Phase Column | Chromatographic Separation | The stationary phase for resolving derivatized aldehydes based on their hydrophobicity [2]. |

| Acetonitrile (HPLC Grade) | Mobile Phase / Extraction Solvent | Used as an organic modifier in the mobile phase and for extracting polar carbonyl compounds from the non-polar oil matrix [2]. |

| Soybean Oil Reference Materials | Matrix-matched Calibration | Essential for preparing calibration standards and validating method accuracy in the appropriate lipid background [4] [2]. |

| Deuterated Chloroform (CDCl₃) | NMR Solvent | Used for sample preparation in high-field NMR spectroscopy for non-targeted screening of oil degradation products, including aldehydes [1]. |

| 4-Phenoxybenzoic acid | 4-Phenoxybenzoic Acid | High Purity | RUO | 4-Phenoxybenzoic acid is a key biphenyl ether building block for medicinal chemistry and material science research. For Research Use Only. Not for human use. |

| Promethazine Sulfoxide-d6 | Promethazine Sulfoxide-d6|Isotopic Labeled Standard |

The link between the consumption of thermally oxidized oils and the pathogenesis of severe chronic diseases is strongly supported by the formation and action of reactive aldehydes. The application of robust and sensitive analytical methods, such as the UFLC-DAD protocol detailed herein, is fundamental for quantifying these toxic compounds in food matrices like soybean oil. This enables a clearer understanding of exposure risks and provides the scientific foundation for public health guidelines aimed at mitigating these risks. Researchers are encouraged to employ these methodologies to further investigate the specific mechanisms of aldehyde toxicity and to develop effective strategies, such as the use of antioxidants or breeding oilseed crops with improved thermal stability, to enhance the safety of thermally processed foods.

Soybean oil is an ideal model matrix for analytical method development due to its complex polyunsaturated fatty acid (PUFA) profile and global significance in the food supply. As the second most produced vegetable oil worldwide, its widespread use in food processing and cooking makes it a relevant substrate for studying lipid oxidation and developing advanced analytical techniques [4]. The high PUFA content, particularly linoleic acid (approximately 55%) and linolenic acid (approximately 8%), creates a labile system prone to oxidation, yielding diverse degradation products that challenge analytical separation and detection methods [8] [4]. This application note details the utilization of UFLC-DAD-based methodologies for analyzing both native fatty acids and oxidation-derived carbonyl compounds in soybean oil, providing researchers with validated protocols for assessing oil quality and stability.

Soybean Oil Composition and Analytical Challenges

Fatty Acid Profile

The characteristic fatty acid profile of soybean oil, dominated by PUFAs, establishes its utility as a model matrix for testing analytical methods under challenging conditions. [8] summarizes the typical composition of conventional soybean oil as 61% polyunsaturated fat, 24% monounsaturated fat, and 15% saturated fat. [4] provides a more detailed breakdown, specifying approximately 11% palmitic acid (16:0), 4% stearic acid (18:0), 25% oleic acid (18:1), 55% linoleic acid (18:2), and 8% linolenic acid (18:3). This composition varies significantly among cultivars, with [9] identifying eleven fatty acids in 18 Korean soybean cultivars, including myristic (C14:0), palmitoleic (C16:1, ω7), arachidic (C20:0), gondoic (C20:1, ω9), behenic (C22:0), and lignoceric (C24:0) acids in addition to the major components.

Table 1: Fatty Acid Composition of Conventional and High-Oleic Soybean Oil

| Fatty Acid | Conventional Soybean Oil (%) | High-Oleic Soybean Oil (%) | Category |

|---|---|---|---|

| Palmitic (C16:0) | 11 | < 6 | Saturated |

| Stearic (C18:0) | 4 | 3 - 5 | Saturated |

| Oleic (C18:1) | 25 | Up to 85 | Monounsaturated |

| Linoleic (C18:2) | 55 | < 3.5 | Polyunsaturated |

| Linolenic (C18:3) | 8 | < 1.2 | Polyunsaturated |

Genotypic Variation in Soybean Oils

The inherent diversity in soybean genotypes provides a natural library of matrices with varying fatty acid compositions. [9] applied principal component analysis (PCA) to the fatty acid profiles of 18 soybean cultivars, revealing that oleic and linoleic acids show an inverse association (r = -0.94, p<0.05), while stearic acid positively correlated with arachidic acid (r = 0.72, p<0.05). This chemometric approach effectively segregated soybean cultivars based on fatty acid composition, demonstrating the utility of statistical tools for classifying complex lipid matrices. Biotechnology has further expanded this variation, with [4] documenting the development of high-oleic soybean varieties containing up to 85% oleic acid, high-linolenic acid types for enhanced nutritional properties, and low-palmitic acid cultivars for reduced saturated fat content.

Analytical Methodologies

UFLC-DAD-ESI-MS Method for Carbonyl Compound Analysis

Sample Preparation and Extraction

The analysis of carbonyl compounds (CCs) in soybean oil requires careful sample preparation to isolate these degradation products from the complex lipid matrix. [2] developed an optimized liquid-liquid extraction protocol using acetonitrile as the extraction solvent, which demonstrated superior efficiency for CC recovery compared to methanol. The procedure is as follows:

- Weigh 0.5 g of soybean oil sample into a glass centrifuge tube.

- Add 1.0 mL of acetonitrile and vortex vigorously for 1 minute.

- Centrifuge at 3000 × g for 5 minutes to separate phases.

- Collect the lower acetonitrile layer using a glass syringe.

- Filter through a 0.20 μm Durapore HV membrane prior to UFLC analysis.

For derivatization of carbonyl compounds, the method employs 2,4-dinitrophenylhydrazine (2,4-DNPH) as the derivatizing agent, which reacts with aldehydes and ketones to form stable hydrazone derivatives that enhance chromatographic separation and detection sensitivity.

Instrumental Parameters

The UFLC-DAD-ESI-MS analysis is performed with the following parameters, optimized for separation of carbonyl-DNPH derivatives [2]:

- Column: C18 reversed-phase column (100 × 2.1 mm, 2.6 μm particle size)

- Mobile Phase A: 0.1% acetic acid in water with 5% solvent B

- Mobile Phase B: Acetonitrile/methanol/acetic acid (80/15/0.1, v/v/v)

- Gradient Program:

- 0.0-1.0 min: 20% B (isocratic)

- 1.0-1.5 min: 20-66% B (linear gradient)

- 1.5-8.0 min: 66% B (isocratic)

- 8.0-11.0 min: 66-100% B (linear gradient)

- 11.0-14.0 min: 100% B (isocratic)

- 14.0-14.5 min: 100-20% B (linear gradient)

- 14.5-15.0 min: 20% B (equilibration)

- Total Run Time: 15 minutes

- Column Temperature: 40°C

- Injection Volume: 10 μL

- DAD Detection: 360 nm (for DNPH derivatives)

- ESI-MS Source: Negative ion mode with ion spray voltage -4500 V

Method Validation

The UFLC-DAD method for carbonyl compound analysis was rigorously validated [2], demonstrating:

- High sensitivity with limits of detection for toxic aldehydes (acrolein, 4-hydroxy-2-nonenal) in the low nanomolar range

- Excellent precision with intra-day variability ≤15% for most analytes

- Good accuracy confirmed by comparison with GC-FID and LC-MS reference methods

- Linear response across clinically relevant concentration ranges

LC-MS Method for Fatty Acid Profiling

For comprehensive fatty acid profiling without derivatization, [10] developed a rapid LC-MS method that enables quantification of 41 saturated and unsaturated fatty acids with a 15-minute run time. The method employs a C8 reversed-phase column (100 × 2.1 mm, 2.6 μm core-shell particles) with a back pressure lower than 300 bar. Mobile phase consists of solvent A (0.1% acetic acid with 5% solvent B) and solvent B (ACN/MeOH/HAc, 80/15/0.1, v/v/v) with a gradient elution. Detection is performed using negative electrospray ionization in pseudo-selected reaction monitoring mode, yielding limits of detection of 5-100 nM.

Table 2: Key Research Reagent Solutions for Soybean Oil Analysis

| Reagent/Material | Function/Application | Specifications |

|---|---|---|

| 2,4-Dinitrophenylhydrazine (2,4-DNPH) | Derivatization of carbonyl compounds for UV detection | Analytical grade, fresh solution prepared in acetonitrile |

| Acetonitrile (HPLC grade) | Extraction solvent for carbonyl compounds; mobile phase component | Low UV absorbance, high purity |

| Methanol (HPLC grade) | Mobile phase component; sample dilution | Low UV absorbance, high purity |

| Acetic acid (HPLC grade) | Mobile phase modifier for improved separation | High purity, 0.1% in mobile phase |

| C18 or C8 reversed-phase column | Stationary phase for chromatographic separation | 100-150 mm length, 2.1 mm ID, 2.6 μm particle size |

| Fatty acid standards | Quantification and identification of fatty acids | Individual and mixed standards at high purity |

| Carbonyl compound standards | Quantification of oxidation products | Acrolein, 4-HNE, 2,4-decadienal, others |

Applications in Stability Assessment and Quality Control

Monitoring Thermal Degradation

The developed UFLC-DAD method enables precise monitoring of soybean oil degradation during thermal processing. [2] applied this methodology to soybean oil heated continuously at 180°C for different time intervals, demonstrating a time-dependent increase in toxic carbonyl compounds, including acrolein, 4-hydroxy-2-nonenal (HNE), and 2,4-decadienal. These compounds form through thermal oxidation of PUFAs and have been associated with various health risks, including carcinogenicity and disruption of cellular functions. The method's sensitivity allows detection of these harmful compounds before organoleptic changes become apparent, providing an early warning system for oil quality degradation.

Nutritional Quality Assessment

Beyond detecting degradation products, UFLC-DAD and LC-MS methods facilitate comprehensive nutritional profiling of soybean oil. The ability to quantify essential fatty acids, including the omega-6 linoleic acid and omega-3 α-linolenic acid, supports nutritional labeling and claims. [8] notes that the U.S. Food and Drug Administration has issued a qualified health claim stating that daily consumption of about 1½ tablespoons (20.5 grams) of soybean oil may reduce the risk of coronary heart disease when replacing saturated fat. Accurate analytical methods are essential for verifying compliance with such health claims and for monitoring the fatty acid profile of novel soybean varieties developed through biotechnology [4].

Experimental Workflows

The following workflow diagrams illustrate the key experimental procedures for soybean oil analysis:

Carbonyl Compound Analysis Workflow

Fatty Acid Profiling Workflow

Soybean oil, with its high PUFA content and global dietary prevalence, serves as an excellent model matrix for developing and validating UFLC-DAD analytical methods. The protocols detailed in this application note enable comprehensive characterization of both native fatty acids and oxidation-derived carbonyl compounds, supporting quality control, stability assessment, and nutritional profiling. The robustness of these methods allows for application across diverse soybean genotypes, including novel varieties with modified fatty acid profiles developed through biotechnological approaches. As dietary lipids continue to play a critical role in human health and disease prevention, these analytical methods provide researchers and industry professionals with essential tools for ensuring oil quality and verifying health-related claims.

The thermal degradation of edible oils, particularly those rich in polyunsaturated fatty acids like soybean oil, leads to the formation of various carbonyl compounds (CCs). Among these, acrolein, 4-Hydroxy-2-nonenal (4-HNE), and 2,4-Decadienal are recognized as particularly significant due to their high reactivity and documented biological effects. The development of robust analytical methods, such as the UFLC-DAD-ESI-MS technique, is crucial for accurately identifying and quantifying these compounds to assess oil quality and understand their health implications. The analysis of soybean oil is of specific interest given its widespread use in food preparation and its high content of polyunsaturated fatty acids, which are prone to oxidation upon heating [11] [2].

These aldehydes are not merely markers of oil degradation; they are biologically active. Acrolein is a potent irritant and has been linked to several diseases, including atherosclerosis and carcinogenesis. It is also known to inhibit the tumor suppressor protein p53, which may contribute to lung cancer development [2]. 4-HNE is a major product of lipid peroxidation and can form adducts with DNA, potentially leading to mutations. It can also react with proteins, disrupting cellular functions [2]. 2,4-Decadienal has been associated with the development of adenocarcinomas in the lungs and the digestive tract upon exposure to cooking oil fumes or consumption of fried foods [2]. Understanding the formation and concentration of these compounds is therefore essential for ensuring food safety and quality.

Quantitative Profiling in Thermally Stressed Soybean Oil

The following table summarizes the typical concentrations of key carbonyl compounds identified in soybean oil heated continuously at 180°C, as quantified using a validated UFLC-DAD-ESI-MS method [11].

Table 1: Concentrations of Key Carbonyl Compounds in Soybean Oil Heated at 180°C

| Carbonyl Compound | Chemical Classification | Mean Concentration (μg/g of oil) |

|---|---|---|

| 4-Hydroxy-2-nonenal (4-HNE) | α,β-unsaturated hydroxyalkenal | 36.9 |

| 2,4-Decadienal | α,β-unsaturated aldehyde | 34.8 |

| 2,4-Heptadienal | α,β-unsaturated aldehyde | 22.6 |

| 4-Hydroxy-2-hexenal (HHE) | α,β-unsaturated hydroxyalkenal | Quantified* |

| Acrolein | Unsaturated aldehyde | Quantified* |

| 2-Heptenal | α,β-unsaturated aldehyde | Quantified* |

| 2-Octenal | α,β-unsaturated aldehyde | Quantified* |

| 4,5-Epoxy-2-decadal | Epoxy aldehyde | Quantified* |

| 2-Decenal | α,β-unsaturated aldehyde | Quantified* |

| 2-Undecenal | α,β-unsaturated aldehyde | Quantified* |

Note: The method quantified these additional compounds, with acrolein being highlighted for its toxicity, though their specific mean concentrations are not listed in the summary. The limits of quantification for all compounds were 0.2 μg/mL [11].

The data shows that 4-HNE and 2,4-Decadienal are among the most abundant aldehydes formed under these thermal conditions. The presence of these compounds in such significant quantities underscores the extent of lipid peroxidation occurring during the heating process.

Experimental Protocol: UFLC-DAD-ESI-MS Analysis

This section details a validated protocol for the extraction and analysis of carbonyl compounds, including acrolein, 4-HNE, and 2,4-Decadienal, from soybean oil samples [11].

Reagents and Materials

- Soybean Oil Samples: Fresh and heated under controlled conditions.

- Derivatization Reagent: 2,4-Dinitrophenylhydrazine (2,4-DNPH). This reagent is widely used for its fast reaction with carbonyl compounds at room temperature and the high stability of the resulting hydrazone derivatives [2].

- Extraction Solvent: Acetonitrile (ACN), analytical grade.

- Standards: Pure analytical standards of target carbonyl compounds (e.g., acrolein, 4-HNE, 2,4-Decadienal) for calibration.

Sample Preparation and Extraction Workflow

The sample preparation process involves liquid-liquid extraction to isolate carbonyl compounds from the oil matrix.

Instrumental Analysis: UFLC-DAD-ESI-MS Parameters

- Chromatography: Ultra-Fast Liquid Chromatography (UFLC) with a suitable reverse-phase column (e.g., C18).

- Detection:

- Diode Array Detector (DAD): Typically used for initial detection and quantification.

- Electrospray Ionization Mass Spectrometry (ESI-MS): Used for definitive identification and confirmation of compounds based on their mass spectra.

- Method Validation: The described method was validated for selectivity, precision, and accuracy. Average recoveries for spiked soybean oil samples at the lowest concentration level (0.2 μg/mL) ranged from 70.7% to 85.0%. The method demonstrated high sensitivity, with a limit of detection (LOD) of 0.03-0.1 μg/mL and a limit of quantification (LOQ) of 0.2 μg/mL for all compounds [11].

The Scientist's Toolkit: Essential Research Reagents

Table 2: Key Reagents and Materials for Carbonyl Compound Analysis

| Item | Function/Application |

|---|---|

| 2,4-Dinitrophenylhydrazine (2,4-DNPH) | Derivatizing agent for carbonyl compounds; forms stable hydrazones for chromatographic analysis. |

| Acetonitrile (HPLC Grade) | Extraction solvent for isolating carbonyl compounds from the oil matrix. |

| Carbonyl Compound Standards (Acrolein, 4-HNE, 2,4-Decadienal) | Used for calibration curves, method validation, and peak identification. |

| UFLC-DAD-ESI-MS System | Core analytical platform for separation (chromatography), detection (UV-Vis), and confirmation (mass spectrometry). |

| Sonicator | Laboratory device used to enhance the extraction efficiency of carbonyls into the solvent. |

| Muraglitazar glucuronide | Muraglitazar glucuronide, CAS:875430-26-5, MF:C35H36N2O13, MW:692.7 g/mol |

| Seco Rapamycin ethyl ester | Seco Rapamycin ethyl ester, MF:C53H83NO13, MW:942.2 g/mol |

Health Implications and Biological Pathways

The carbonyl compounds formed in heated oils pose health risks due to their high reactivity and ability to disrupt cellular functions.

Acrolein's high toxicity manifests as severe irritation to the eyes, skin, and respiratory tract. Its primary metabolic pathway involves the alkylation of glutathione, depleting this key cellular antioxidant [12]. It is a significant contributor to the non-cancer health risks associated with cigarette smoke and has been linked to the suppression of tumor suppressor proteins [12] [2].

4-HNE is a key mediator of oxidative stress. Its biological effects are dose-dependent. At low concentrations (0.1-5 μM), it can participate in beneficial cell signaling, promoting proliferation and antioxidant defense. At higher concentrations (10-20 μM), it becomes cytotoxic, inducing apoptosis (programmed cell death) and necrosis [13] [14]. It can form protein adducts via Michael addition reactions and Schiff base formation, disrupting cellular functions. It has been implicated in the pathology of Alzheimer's disease, atherosclerosis, and cancer [13] [2]. The body has specific detoxification enzymes, such as glutathione S-transferases (GSTs) like hGSTA4-4 and aldose reductase, to manage intracellular 4-HNE levels [13].

The following diagram illustrates the dual role and metabolic fate of 4-HNE within the cell:

2,4-Decadienal has been studied for its potential carcinogenic effects. Research indicates it can induce cell proliferation and cytokine production in human bronchial epithelial cells, likely through the generation of reactive oxygen species [15] [2]. This mechanism may contribute to its association with lung and digestive tract adenocarcinomas observed in epidemiological studies [2].

Limitations of Existing Analytical Methods for Carbonyl Profiling in Oils

Carbonyl compounds, including toxic species like acrolein and 4-hydroxy-2-nonenal, are critical markers of oil degradation during thermal processing. Their accurate profiling is essential for assessing oil quality and safety. This application note systematically outlines the principal limitations of existing chromatographic methods for carbonyl determination in oils, with particular focus on challenges encountered in UFLC-DAD method development for soybean oil analysis. We present validated experimental protocols to overcome these limitations, alongside innovative workflow visualization and essential reagent solutions to support method development for researchers and analytical scientists.

Carbonyl compounds (CCs) generated during thermal oxidation of edible oils serve as crucial indicators of oil quality and safety. In soybean oil, which is rich in polyunsaturated fatty acids (PUFAs), heating promotes oxidation reactions that yield numerous aldehydes and ketones, many of which exhibit toxicological concerns [2] [16]. Accurate quantification of these compounds is paramount for nutritional and safety assessments.

The development of Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) methods addresses the need for robust analytical techniques to monitor oil degradation. However, existing methodologies face significant challenges including complex sample matrices, diverse chemical properties of carbonyl compounds, and sensitivity limitations [2] [17] [18]. This document delineates these limitations within the context of soybean oil analysis and provides optimized protocols to enhance analytical performance.

Critical Limitations in Carbonyl Compound Analysis

Sample Preparation and Extraction Challenges

Sample preparation represents a primary bottleneck in carbonyl analysis. Traditional methods often require separate extraction and derivatization steps, leading to prolonged sample processing, potential analyte loss, and compromised reproducibility [19].

Table 1: Limitations of Conventional Sample Preparation Methods

| Method | Key Limitations | Impact on Analysis |

|---|---|---|

| Liquid-Liquid Extraction | Emulsion formation, high solvent consumption, requires large sample volumes [2] | Reduced recovery of polar aldehydes, poor reproducibility |

| Solid-Phase Extraction | Cartridge clogging, requires optimization of sorbents, additional equipment [19] | Inconsistent derivatization efficiency, matrix interference |

| Separate Derivatization | Multiple processing steps, increased manual handling [19] | Analyte degradation, time-consuming protocols |

| Ultrasonic-Assisted Extraction | Potential thermal degradation, requires precise parameter control [2] | Variable extraction yields for different carbonyl classes |

Analytical Separation and Detection Constraints

Chromatographic analysis of carbonyl compounds encounters obstacles related to compound diversity, detection specificity, and ionization efficiency.

Table 2: Analytical Limitations in Separation and Detection

| Analytical Challenge | Technical Limitation | Consequence |

|---|---|---|

| Diverse Compound Polarity | Wide range of carbonyl polarities complicates single-method separation [17] | Co-elution, inadequate resolution of critical isomers |

| Poor Ionization Efficiency | Neutral carbonyl groups exhibit poor ESI response without derivatization [18] | Reduced sensitivity, higher limits of detection |

| Matrix Interference | Co-extracted triglycerides and other oil components [2] [17] | Signal suppression, inaccurate quantification |

| Isomer Differentiation | Limited resolution of isomeric aldehydes (e.g., E/Z isomers) [17] | Incomplete profiling, underestimated complexity |

Sensitivity and Quantitation Hurdles

Achieving reliable quantification of toxic carbonyls at low concentrations remains challenging due to methodological constraints and compound instability.

- Detection Limits: Under optimized UFLC-DAD-ESI-MS conditions, quantification limits for key aldehydes (acrolein, HNE, HHE) typically range from 0.03 to 0.1 μg·mLâ»Â¹, which may be insufficient for monitoring early-stage oxidation [2] [11].

- Matrix Effects: Co-eluting components from the oil matrix can significantly suppress or enhance ionization efficiency in mass spectrometry, compromising quantification accuracy without appropriate internal standards [2] [18].

- Compound Instability: Reactive aldehydes like 4-hydroxy-2-nonenal (HNE) and 4-hydroxy-2-hexenal (HHE) are susceptible to degradation during sample storage and analysis, leading to underestimation of true concentrations [2] [16].

Experimental Protocols

Protocol 1: Miniaturized Kapok Fiber-Supported Liquid-Phase Extraction/In-Situ Derivatization (mini-KF-SLE-ISD)

This integrated protocol simultaneously addresses extraction and derivatization challenges, significantly streamlining sample preparation [19].

Principle: Natural kapok fiber serves as a support matrix within a pipette tip, enabling simultaneous extraction of carbonyl compounds from oil and their derivatization with DNPH directly on the fiber surface.

Reagents and Materials:

- Soybean oil samples (heated and unheated controls)

- HPLC-grade acetonitrile, methanol, ethanol

- 2,4-dinitrophenylhydrazine (DNPH) derivatization reagent (1 mg·mLâ»Â¹ in acetonitrile)

- Phosphoric acid (0.1% v/v in water)

- Standard aldehyde solutions (trans-2-hexenal, trans-2-heptenal, trans-2-octenal, etc.)

- Deionized water (Milli-Q system)

- Kapok fiber (natural, untreated)

- 1 mL pipette tips

- Disposable pipette

Procedure:

- Kapok Fiber Preparation: Place approximately 5 mg of kapok fiber into a 1 mL pipette tip, gently tamping to create a uniform extraction bed.

- Sample Loading: Draw 0.5 g of soybean oil sample into the pipette tip containing kapok fiber. Allow the oil to saturate the fiber completely.

- Extraction/Derivatization: Prepare a solution containing DNPH (1 mg·mLâ»Â¹) in acetonitrile with 0.1% phosphoric acid. Draw 500 μL of this solution through the oil-saturated kapok fiber bed slowly (approximately 1 drop per second).

- Elution: Collect the eluate containing derivatized carbonyl compounds in a clean microcentrifuge tube.

- Analysis: Inject 5-10 μL of eluate directly into the UFLC-DAD-ESI-MS system for analysis.

Optimization Notes:

- Derivatization Efficiency: The acidic environment (0.1% phosphoric acid) catalyzes the hydrazone formation reaction between aldehydes and DNPH.

- Extraction Time: The entire process requires approximately 3-5 minutes per sample, significantly faster than conventional separate procedures.

- Compatibility: This method is compatible with various vegetable oils beyond soybean oil, including palm, sunflower, and olive oils.

Protocol 2: UFLC-DAD-ESI-MS Analysis of Carbonyl-DNPH Derivatives

This protocol details the chromatographic separation and detection of carbonyl-DNPH derivatives extracted from soybean oil, optimized for maximum sensitivity and resolution [2].

Chromatographic Conditions:

- Column: C18 reverse-phase column (150 mm × 2.1 mm, 1.7 μm particle size)

- Mobile Phase A: Water with 0.1% formic acid

- Mobile Phase B: Acetonitrile with 0.1% formic acid

- Gradient Program: 0 min (60% B), 0-5 min (60-75% B), 5-10 min (75-85% B), 10-15 min (85-95% B), 15-18 min (95% B), 18-20 min (95-60% B)

- Flow Rate: 0.3 mL·minâ»Â¹

- Column Temperature: 35°C

- Injection Volume: 5 μL

Detection Parameters:

- DAD Detection: 360 nm (characteristic absorbance for DNPH derivatives)

- ESI-MS Source Parameters: Positive ion mode, capillary voltage: 3.5 kV, cone voltage: 30 V, source temperature: 120°C, desolvation temperature: 350°C

- Selected Ion Monitoring (SIM): Target precursor ions for specific carbonyl-DNPH derivatives (e.g., acrolein-DNPH m/z 235, HNE-DNPH m/z 336, 2,4-decadienal-DNPH m/z 363)

Validation Parameters:

- Linearity: Prepare calibration standards in the range of 0.1-10 μg·mLâ»Â¹ for each carbonyl compound of interest.

- Precision: Inject six replicate samples at low, medium, and high concentrations within the calibration range; calculate %RSD for retention times and peak areas.

- Recovery: Spike soybean oil samples with known concentrations of aldehyde standards prior to extraction; calculate recovery percentages (target: 70-120%).

- Limit of Detection (LOD) and Quantification (LOQ): Determine based on signal-to-noise ratios of 3:1 and 10:1, respectively.

Workflow Visualization

Figure 1: Carbonyl Analysis Method Comparison. The diagram contrasts traditional multi-step methods with integrated approaches that combine extraction and derivatization, highlighting potential points of analyte loss in conventional workflows.

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagent Solutions for Carbonyl Analysis in Oils

| Reagent/Material | Function | Application Notes |

|---|---|---|

| 2,4-Dinitrophenylhydrazine (DNPH) | Derivatization reagent forming stable hydrazone derivatives with carbonyl compounds [2] [19] | Enhances UV detection and MS ionization; use concentration of 1 mg·mLâ»Â¹ in acetonitrile |

| Kapok Fiber | Natural support for liquid-phase extraction [19] | Provides high surface area for efficient extraction/derivatization; requires no pretreatment |

| Acetonitrile (HPLC grade) | Extraction solvent and mobile phase component [2] [11] | Optimal for carbonyl extraction from oil matrices; minimal emulsion formation |

| Formic Acid | Mobile phase additive [2] | Improves chromatographic peak shape and ESI ionization efficiency (0.1% concentration) |

| Carbonyl Standards | Quantification reference materials [2] [16] | Essential: acrolein, HNE, HHE, 2,4-decadienal; prepare fresh solutions due to reactivity |

| Phosphoric Acid | Derivatization catalyst [19] | Acidic environment (0.1%) accelerates hydrazone formation in integrated methods |

| GLP-1R modulator L7-028 | GLP-1R modulator L7-028, MF:C24H28N2O3, MW:392.5 g/mol | Chemical Reagent |

| Luteolin-4'-O-glucoside | Luteolin-4'-O-glucoside, MF:C21H20O11, MW:448.4 g/mol | Chemical Reagent |

Comprehensive carbonyl profiling in thermally processed soybean oil remains analytically challenging due to limitations in sample preparation, separation efficiency, and detection sensitivity. The integrated mini-KF-SLE-ISD protocol presented herein significantly streamlines sample preparation by combining extraction and derivatization into a single step, reducing analysis time and potential analyte losses. When coupled with optimized UFLC-DAD-ESI-MS conditions, this approach enables reliable quantification of toxic carbonyl compounds at concentrations relevant to food safety assessment. Further advancements in stationary phase chemistry and derivatization reagents continue to address these limitations, promising enhanced analytical performance for quality control and research applications in edible oil analysis.

Within the realm of food chemistry and safety, the thermal oxidation of edible oils presents a significant analytical challenge. Soybean oil, rich in polyunsaturated fatty acids (PUFAs), is highly susceptible to degradation during thermal processes like frying, generating a variety of carbonyl compounds (CCs) [2]. Among these secondary lipid oxidation products, α,β-unsaturated aldehydes such as acrolein, 4-hydroxy-2-nonenal (HNE), and 2,4-decadienal are of particular concern due to their documented cytotoxicity and association with chronic diseases, including atherosclerosis, carcinogenesis, and Alzheimer's disease [2]. Accurate risk assessment and quality control therefore necessitate precise monitoring of these harmful compounds in heated oils.

However, a critical analytical gap exists. Traditional methods for assessing oil degradation, such as anisidine value or thiobarbituric acid reactive substances (TBARS), lack the specificity to identify and quantify individual toxic aldehydes [17]. While chromatographic techniques have been applied, many suffer from extended analysis times, inadequate sensitivity for trace-level toxicants, or an inability to simultaneously resolve the wide spectrum of carbonyl compounds with varying polarities generated during thermal stress [17]. This application note delineates the development and validation of a tailored Ultra-Fast Liquid Chromatography with Diode Array and Electrospray Ionization Mass Spectrometric detection (UFLC-DAD-ESI-MS) method designed to bridge this gap, enabling the sensitive, multi-compound assessment of carbonyl compounds in thermally oxidized soybean oil.

The Analytical Challenge and Limitations of Existing Methods

The thermal degradation of soybean oil is a complex process resulting in a myriad of oxidation products. The table below summarizes key toxic carbonyl compounds and their reported biological effects, highlighting the necessity for a targeted analytical approach.

Table 1: Key Carbonyl Compounds of Concern in Thermally Oxidized Soybean Oil

| Carbonyl Compound | Toxicological Significance |

|---|---|

| Acrolein | Irritant; linked to atherosclerosis, carcinogenesis, and Alzheimer's disease; inhibits tumor suppressor p53 [2]. |

| 4-Hydroxy-2-nonenal (HNE) | Forms DNA and protein adducts leading to mutations and disrupted cellular functions; cytotoxic [2]. |

| 2,4-Decadienal | Associated with the development of adenocarcinoma in lungs and gut [2]. |

| 4-Hydroxy-2-hexenal (HHE) | A toxic α,β-unsaturated hydroxyaldehyde similar in reactivity to HNE [2]. |

Existing methods for monitoring oil oxidation are insufficient for this task:

- Conventional Indices: Global indices like peroxide value (primary oxidation) and anisidine value (secondary oxidation) provide no information on the specific profile of toxic aldehydes [17].

- Chromatographic Methods: While GC-MS and HPLC methods exist, they often feature long analysis times (>40 min), have high detection limits, or involve complex sample preparation that is not optimized for a broad range of CCs [17]. The co-occurrence of water-soluble and fat-soluble components in oxidized oil matrices further complicates analysis [20].

Developed UFLC-DAD-ESI-MS Method and Protocol

The following section details the experimental protocol for the sensitive and simultaneous determination of carbonyl compounds in soybean oil.

Research Reagent Solutions

The following reagents and instruments are essential for the successful implementation of this method.

Table 2: Essential Research Reagents and Equipment

| Item | Function/Description |

|---|---|

| 2,4-Dinitrophenylhydrazine (DNPH) | Derivatization reagent; reacts with carbonyl functional groups to form stable hydrazones suitable for UV and MS detection [2]. |

| Acetonitrile (HPLC/MS Grade) | Serves as the extraction solvent and mobile phase component; provides optimal extraction efficiency for carbonyl-DNPH derivatives from the oil matrix [11] [2]. |

| Carbonyl Compound Standards | Certified reference materials for quantification (e.g., acrolein, HNE, 2,4-decadienal) [2]. |

| UFLC-DAD-ESI-MS System | Analytical instrument for separation and detection. A system comprising a Shimadzu UFLC with a DAD and ESI-MS/MS is suitable [21]. |

| Reverse-Phase C18 Column | Stationary phase for chromatographic separation of derivatized carbonyl compounds. |

Detailed Experimental Workflow

The entire analytical procedure, from sample preparation to data analysis, is outlined in the workflow below.

Figure 1: Experimental workflow for the analysis of carbonyl compounds in soybean oil.

Sample Preparation, Derivatization, and Extraction

- Heating Protocol: Subject soybean oil samples to continuous heating at 180 °C in the presence of atmospheric oxygen for different time intervals (e.g., 0, 2, 4, 6, 8 hours) to induce thermal oxidation [2].

- Derivatization: Accurately weigh a portion of the heated oil (e.g., 1.0 g) into a vial. Add a solution of DNPH in an appropriate solvent to derivative the carbonyl compounds into their corresponding 2,4-dinitrophenylhydrazones. This step enhances stability and detection sensitivity [2] [17].

- Extraction: Extract the derivatized carbonyl compounds using 1.5 mL of acetonitrile. Employ manual stirring for 3 minutes, followed by 30 minutes of sonication to maximize recovery [11]. Centrifuge the mixture and collect the clear acetonitrile (upper) layer for analysis.

Instrumental Analysis: UFLC-DAD-ESI-MS

- Chromatographic Separation:

- System: UFLC system (e.g., Shimadzu Prominence) [21].

- Column: Reversed-phase C18 column (e.g., 2.1 mm x 150 mm, 1.7-1.8 µm particle size).

- Mobile Phase: Gradient elution with water (A) and acetonitrile (B), both containing 0.1% formic acid.

- Gradient Program: Initiate at 20% B, increase to 95% B over 12 minutes, hold for 2 minutes, then re-equilibrate.

- Flow Rate: 0.2 mL/min.

- Column Oven: 35 °C.

- Injection Volume: 5 µL.

- Detection:

- DAD: Monitor at 360 nm for specific detection of DNPH derivatives [2].

- ESI-MS/MS: Operate in negative ion mode for hydroxyalkenals and positive ion mode for other aldehydes. Use Multiple Reaction Monitoring (MRM) for high sensitivity and selectivity. The MS parameters should be optimized for each compound.

Method Validation

The developed method was rigorously validated according to standard guidelines to ensure reliability, as summarized in the table below.

Table 3: Method Validation Parameters and Performance

| Validation Parameter | Result |

|---|---|

| Linear Range | 0.2 - 10.0 μg mLâ»Â¹ for all compounds [11] |

| Limit of Detection (LOD) | 0.03 - 0.1 μg mLâ»Â¹ [11] |

| Limit of Quantification (LOQ) | 0.2 μg mLâ»Â¹ for all compounds [11] |

| Recovery (at LOQ) | 70.7% - 85.0% [11] |

| Precision (RSD) | < 4.00% (Intra- and inter-day) [20] |

Application Results: Profiling Carbonyls in Heated Soybean Oil

The application of this method to soybean oil heated at 180°C successfully identified and quantified ten key carbonyl compounds. The data below demonstrates the method's effectiveness in profiling the dynamic changes in the carbonyl profile.

Table 4: Carbonyl Compounds Identified and Quantified in Soybean Oil After Heating at 180°C

| Identified Carbonyl Compound | Mean Concentration (μg gâ»Â¹ of oil) |

|---|---|

| 4-Hydroxy-2-nonenal (HNE) | 36.9 |

| 2,4-Decadienal | 34.8 |

| 2,4-Heptadienal | 22.6 |

| 4-Hydroxy-2-hexenal (HHE) | Identified |

| Acrolein | Identified |

| 2-Heptenal | Identified |

| 2-Octenal | Identified |

| 4,5-Epoxy-2-decenal | Identified |

| 2-Decenal | Identified |

| 2-Undecenal | Identified |

The results confirm that HNE, 2,4-decadienal, and 2,4-heptadienal are the dominant carbonyl compounds formed after prolonged heating, underscoring the importance of monitoring these specific toxicants [11]. The method provides a powerful tool for studying the kinetics of their formation under various processing conditions.

The UFLC-DAD-ESI-MS method detailed herein effectively bridges a critical analytical gap in food safety research. It provides a validated, robust, and practical solution for the simultaneous qualification and quantification of a broad spectrum of toxic carbonyl compounds in thermally oxidized soybean oil. The protocol offers significant advantages in speed, sensitivity, and specificity over traditional methods, enabling researchers to better understand the formation of harmful compounds during thermal processing and to conduct more accurate risk assessments for the benefit of public health.

A Step-by-Step Protocol: UFLC-DAD-ESI-MS Method Development and Real-World Application

{carbonyl compounds in heated soybean oil, focusing on the optimization of an extraction method using UFLC-DAD-ESI-MS for analysis.

Thermal oxidation of edible oils during processes like frying generates various carbonyl compounds (CCs), which are secondary oxidation products [2]. Among these, aldehydes such as acrolein, 4-hydroxy-2-nonenal (HNE), and 2,4-decadienal are particularly concerning due to their potential toxicological effects, including associations with mutagenicity, carcinogenesis, and other diseases [2]. Monitoring these degradation products is therefore critical for ensuring food safety and quality.

This application note details a validated protocol for the extraction, identification, and quantification of key carbonyl compounds in soybean oil subjected to continuous heating. The method centers on the optimization of three critical parameters: solvent selection, manual stirring, and sonication time, ensuring high sensitivity and accuracy for routine analysis in food chemistry and safety laboratories.

Optimized Extraction and Analysis Workflow

The following diagram illustrates the comprehensive workflow for the sample preparation and analysis of carbonyl compounds in soybean oil.

Critical Optimization Parameters

The method's effectiveness hinges on the systematic optimization of the extraction procedure. The key parameters investigated and their optimal conditions are summarized below.

Optimization Pathway

The logical sequence for optimizing the main parameters is shown in the following pathway.

Table 1: Optimized extraction parameters for carbonyl compounds from soybean oil.

| Parameter | Optimized Condition | Experimental Justification |

|---|---|---|

| Extraction Solvent | 1.5 mL Acetonitrile | Demonstrated superior extraction capacity compared to methanol, as determined by the sum of chromatographic peak areas [2]. |

| Manual Stirring | 3 minutes | Sufficient for initial homogenization and partitioning of carbonyl compounds into the acetonitrile phase [2] [11]. |

| Sonication Time | 30 minutes | Provided optimal extraction yield for the target analytes from the oil matrix into the solvent [2] [11]. |

Detailed Experimental Protocol

Reagents and Solutions

Table 2: Key research reagents and solutions for the protocol.

| Item | Function / Role in the Protocol |

|---|---|

| Soybean Oil | Sample matrix for analysis of thermal degradation products [2]. |

| Acetonitrile (HPLC Grade) | Optimal solvent for liquid-liquid extraction of carbonyl compounds from the oil matrix [2] [11]. |

| 2,4-Dinitrophenylhydrazine (2,4-DNPH) | Derivatization reagent; reacts with carbonyl functional groups to form stable hydrazones suitable for UV and MS detection [2]. |

| Carbonyl Compound Standards | Used for method validation, calibration, and quantification (e.g., acrolein, 4-HNE, 2,4-decadienal) [2] [11]. |

Sample Preparation and Derivatization

- Heating Procedure: Subject soybean oil samples to continuous heating at 180 °C in the presence of atmospheric oxygen for defined time intervals (e.g., 0 to 8 hours) to induce thermal oxidation [2].

- Liquid-Liquid Extraction: Accurately weigh approximately 1.0 g of heated oil. Add 1.5 mL of acetonitrile [2] [11].

- Mixing and Sonication:

- Perform manual stirring for 3 minutes to ensure thorough initial contact between the oil and solvent.

- Subsequently, place the mixture in an ultrasonic bath and sonicate for 30 minutes to complete the extraction.

- Derivatization: The extracted carbonyl compounds are derivatized with 2,4-Dinitrophenylhydrazine (2,4-DNPH) to form hydrazone derivatives, which enhances their stability and detectability in chromatographic analysis [2].

Instrumental Analysis: UFLC-DAD-ESI-MS

- Chromatography:

- System: Ultra-Fast Liquid Chromatography (UFLC).

- Detection: Diode Array Detector (DAD) and Electrospray Ionization Mass Spectrometry (ESI-MS).

- The DAD is used for initial detection and quantification, while the ESI-MS provides confirmatory identification based on molecular mass and fragmentation patterns [2].

- Method Validation:

- The method was rigorously validated. The average recoveries for spiked samples at the lowest concentration level (0.2 μg·mLâ»Â¹) ranged from 70.7% to 85.0%.

- The method demonstrates high sensitivity, with detection limits (LOD) between 0.03 and 0.1 μg·mLâ»Â¹ and a quantification limit (LOQ) of 0.2 μg·mLâ»Â¹ for all target compounds [2] [11].

Application Data: Carbonyl Compounds in Heated Soybean Oil

When the optimized method was applied to soybean oil heated at 180°C, ten key carbonyl compounds were identified and quantified.

Table 3: Carbonyl compounds identified and their concentrations in heated soybean oil.

| Carbonyl Compound | Average Concentration (μg·gâ»Â¹ of oil) |

|---|---|

| 4-Hydroxy-2-nonenal (HNE) | 36.9 |

| 2,4-Decadienal | 34.8 |

| 2,4-Heptadienal | 22.6 |

| 4-Hydroxy-2-hexenal (HHE) | Data Provided in [11] |

| Acrolein | Data Provided in [11] |

| 2-Heptenal | Data Provided in [11] |

| 2-Octenal | Data Provided in [11] |

| 4,5-Epoxy-2-decenal | Data Provided in [11] |

| 2-Decenal | Data Provided in [11] |

| 2-Undecenal | Data Provided in [11] |

The data confirms that 4-Hydroxy-2-nonenal, 2,4-decadienal, and 2,4-heptadienal are among the most abundant carbonyl compounds formed during the thermal stressing of soybean oil, highlighting their significance as key markers of oil degradation [2] [11].

Within the framework of developing UFLC-DAD methods for analyzing soybean oil, the accurate quantification of carbonyl compounds (CCs), particularly toxic aldehydes, is paramount. During thermal processes such as frying, soybean oil undergoes oxidation, generating various carbonyl-containing secondary products including acrolein, 4-hydroxy-2-nonenal (HNE), and 2,4-decadienal [2]. These compounds are not only associated with off-flavors but also pose significant health risks, such as being linked to mutagenicity and the development of adenocarcinoma [2]. Derivatization using 2,4-dinitrophenylhydrazine (2,4-DNPH) is a cornerstone technique for analyzing these reactive and volatile carbonyls. This reagent forms stable hydrazone derivatives, facilitating their sensitive and selective analysis via UFLC-DAD-ESI-MS, thus providing a robust approach for monitoring oil degradation and ensuring consumer safety [2] [22].

Research Reagent Solutions

The following table details the essential reagents and materials required for the derivatization and analysis of carbonyl compounds in edible oils.

Table 1: Key Research Reagents and Materials for Carbonyl Derivatization

| Reagent/Material | Function/Application | Specific Example from Protocol |

|---|---|---|

| 2,4-Dinitrophenylhydrazine (DNPH) | Derivatization reagent; reacts with carbonyl functional groups (aldehydes, ketones) to form stable, chromophoric hydrazones suitable for UV and MS detection [2] [22]. | Prepared as a solution in acetonitrile with added perchloric acid [22]. |

| Acetonitrile | Solvent; used for preparing DNPH solution and for liquid-liquid extraction of carbonyl-DNPH derivatives from the oil matrix [2]. | Served as the extraction solvent for hydrazones from the liquid phase of soybean oil [2]. |

| Perchloric Acid | Catalyst; added to the DNPH solution to acidify the medium, thereby catalyzing the hydrazone formation reaction [22]. | Added at a concentration of 200 µL of 70% perchloric acid per 100 mL of DNPH solution [22]. |

| Carbonyl Standard Solutions | Calibration and quantification; used to create calibration curves for accurate quantification of target carbonyls in unknown samples [22]. | Formulated solutions of formaldehyde, acetaldehyde, acrolein, etc., used for generating calibration curves [22]. |

| Isotopically Labeled Carbonyl-DNPH Analogues | Internal Standards; added to correct for variability in sample preparation and instrument response, improving analytical accuracy and precision [22]. | Formaldehyde-d2-DNPH, acetaldehyde-d4-DNPH, etc., spiked into samples before analysis [22]. |

| Pyridine in Acetonitrile | Extraction solution; neutralizes the reaction mixture post-derivatization and aids in the extraction of derivatives from solid matrices [22]. | Used as a 2% (v/v) solution in acetonitrile for extracting derivatized carbonyls from treated Cambridge filter pads [22]. |

Experimental Protocol

The following diagram illustrates the comprehensive workflow for the derivatization and analysis of carbonyl compounds in soybean oil.

Detailed Methodology

3.2.1 Sample Preparation and Derivatization

- Heating Protocol: Subject soybean oil samples to continuous heating at 180 °C in the presence of atmospheric oxygen for varying time intervals (e.g., 0, 30, 60 minutes) to simulate thermal degradation [2].

- Liquid-Liquid Extraction: For each heated oil sample, perform a liquid-liquid extraction using a suitable solvent. Acetonitrile has been demonstrated to have superior extraction capacity for carbonyl compounds from the oil matrix compared to solvents like methanol [2].

- Derivatization Reaction: React the extracted carbonyl compounds with a solution of 2,4-DNPH. The reaction proceeds efficiently at room temperature, forming the corresponding 2,4-dinitrophenylhydrazone derivatives [2] [22]. The DNPH solution can be prepared by dissolving 1.5 g of DNPH and 200 µL of 70% perchloric acid in 100 mL of acetonitrile to catalyze the reaction [22].

3.2.2 UFLC-DAD-ESI-MS Analysis

- Chromatographic Separation: Inject the derivatized sample extracts into an UFLC system. Employ a reversed-phase C18 column. The mobile phase, typically a mixture of water and an organic modifier like methanol or acetonitrile, is delivered under gradient conditions to achieve optimal separation of the various hydrazone derivatives [2] [23] [24].

- Detection and Identification:

- DAD Detection: Monitor the eluent with a Diode Array Detector (DAD). The hydrazone derivatives exhibit strong absorption, allowing for sensitive detection and peak purity assessment [2] [23].

- ESI-MS Detection: Couple the system to an Electrospray Ionization Mass Spectrometer (ESI-MS) for definitive compound identification. Mass spectrometry provides molecular mass and fragmentation information to confirm the identity of each carbonyl-DNPH derivative [2] [22].

3.2.3 Method Validation

The developed method should be rigorously validated according to International Council for Harmonisation (ICH) guidelines to ensure reliability, with key parameters including [2] [23]:

- Linearity: Demonstrating a linear response over the intended concentration range with a correlation coefficient (r²) of ≥0.999 [23].

- Accuracy: Confirmed through recovery studies, with results ideally between 98-102% [23].

- Precision: Establishing both intra-day and inter-day precision (relative standard deviation, RSD) of less than 2-3% [23].

- Selectivity/Specificity: Ensuring that the method can unequivocally identify and quantify the analytes in the presence of other components in the sample matrix [2] [23].

Application Data & Results

Quantitative Analysis in Heated Soybean Oil

Application of the validated UFLC-DAD-ESI-MS method to soybean oil heated at 180°C allows for the tracking of specific, toxic carbonyl compounds. The method highlights the formation of compounds like acrolein and 4-Hydroxy-2-nonenal (HNE), which are of significant toxicological concern [2].

Table 2: Carbonyl Compounds of Toxicological Interest Detected in Heated Soybean Oil

| Carbonyl Compound | Toxicological Concern | Abundance Notes |

|---|---|---|

| Acrolein | Irritant; linked to atherosclerosis, carcinogenesis, and Alzheimer's disease; inhibits tumor suppressor p53 [2]. | Among the most abundant carbonyls detected [2]. |

| 4-Hydroxy-2-nonenal (HNE) | Can form DNA adducts leading to mutations; reacts with proteins to disrupt cellular functions [2]. | A key α,β-unsaturated hydroxyaldehyde of toxicological interest [2]. |

| 4-Hydroxy-2-hexenal (HHE) | An α,β-unsaturated hydroxyaldehyde with associated toxicity [2]. | Highlighted for its toxicity alongside HNE [2]. |

| 2,4-Decadienal | Associated with the development of adenocarcinoma in lungs and gut from exposure to oil smoke or consumption of fried foods [2]. | Found in heated vegetable oils [2]. |

Advantages of the 2,4-DNPH Strategy

- Comprehensive Trapping: 2,4-DNPH reacts simultaneously with a wide range of aldehydes and ketones [2].

- High Reactivity and Stability: The derivatization reaction is fast at room temperature, and the resulting hydrazone derivatives are highly stable, facilitating sample handling and analysis [2].

- Enhanced Detectability: The introduction of the strong chromophore from the DNPH group enables highly sensitive UV-Vis detection. Furthermore, the derivatives are amenable to analysis by mass spectrometry, providing structural confirmation [2] [22].

- Matrix Compatibility: The strategy, particularly when coupled with a liquid-liquid extraction step, is effective for complex matrices like edible oils, providing good selectivity and sensitivity [2].

This document details the application of Ultra-Fast Liquid Chromatography coupled with a Diode Array Detector and Electrospray Ionization Mass Spectrometry (UFLC-DAD-ESI-MS) for analyzing carbonyl compounds, specifically toxic aldehydes, in soybean oil under thermal stress. This protocol supports thesis research focused on method development for assessing oil quality and safety, providing a robust framework for identifying and quantifying key degradation products like 4-hydroxy-2-nonenal (HNE) and acrolein [2] [11].

Experimental Protocols

Sample Preparation: Carbonyl Compound Extraction from Soybean Oil

The following protocol is optimized for the extraction of carbonyl compounds from soybean oil samples [2].

- Principle: Carbonyl compounds are extracted from the oil matrix into an acetonitrile phase via liquid-liquid extraction, facilitated by derivatization with 2,4-dinitrophenylhydrazine (DNPH).

Materials:

- Soybean oil sample (heated or unheated)

- Acetonitrile (HPLC grade)

- Derivatization reagent: 2,4-Dinitrophenylhydrazine (DNPH) solution

- Centrifuge tubes

- Ultrasonic bath

- Centrifuge

- Syringe filters (0.20 μm or 0.45 μm, PTFE or equivalent)

Procedure:

- Weigh: Accurately weigh approximately 1.0 g of soybean oil into a suitable centrifuge tube.

- Extract and Derivatize: Add 1.5 mL of acetonitrile to the oil sample. Manually stir the mixture vigorously for 3 minutes to ensure thorough contact between the phases and to promote derivatization.

- Sonicate: Place the tube in an ultrasonic bath and sonicate for 30 minutes. This step enhances the extraction efficiency of the derivatized carbonyl compounds.

- Separate: Centrifuge the mixture to achieve complete phase separation.

- Collect and Filter: Carefully collect the lower, acetonitrile-rich layer. Filter the collected extract through a 0.20 μm or 0.45 μm syringe filter prior to UFLC-DAD-ESI-MS analysis.

Instrumental Analysis: UFLC-DAD-ESI-MS Conditions

The optimized instrumental parameters for the separation and detection of DNPH-derivatized carbonyl compounds are as follows [2] [11].

Chromatographic Conditions (UFLC):

- Column: Reversed-phase C18 column (e.g., LichroCART 125-4 with Lichrophore 100 RP-18e packing or equivalent).

- Mobile Phase: Binary gradient system.

- Eluent A: Aqueous component (e.g., water with 0.1% formic acid).

- Eluent B: Organic component (Acetonitrile).

- Gradient Program: Time (min) / % Eluent B (Initial); Time (min) / % Eluent B (Final). Specific gradient profile to be optimized based on the target analytes and column.

- Flow Rate: 0.5 - 1.0 mL/min.

- Injection Volume: 5 - 20 μL.

- Column Temperature: Ambient or controlled (e.g., 25-40°C).

Detection Conditions (DAD):

- Detection Wavelength: 320 nm [2]. This wavelength is optimal for monitoring the DNPH derivatives of carbonyl compounds.

Mass Spectrometric Conditions (ESI-MS):

- Ionization Mode: Electrospray Ionization (ESI), typically in negative ion mode for DNPH derivatives.

- Scan Range: m/z 100 - 500 (or adjusted for target analyte masses).

- Source Parameters:

- Drying Gas Flow: ~10-12 L/min.

- Nebulizer Pressure: ~35-40 psi.

- Drying Gas Temperature: ~300-350 °C.

- Capillary Voltage: ~3500-4000 V.

Data Presentation

Key Carbonyl Compounds Identified in Heated Soybean Oil

The following table summarizes the carbonyl compounds identified and quantified using the described UFLC-DAD-ESI-MS method in soybean oil heated continuously at 180°C [11].

Table 1: Carbonyl Compounds Detected in Thermally Stressed Soybean Oil.

| Compound Class | Compound Name | Mean Concentration (μg/g of oil) |

|---|---|---|

| Hydroxyalkenals | 4-Hydroxy-2-nonenal (HNE) | 36.9 |

| Alkadienals | 2,4-Decadienal | 34.8 |

| Alkadienals | 2,4-Heptadienal | 22.6 |

| Hydroxyalkenals | 4-Hydroxy-2-hexenal (HHE) | Detected |

| Aldehydes | Acrolein | Detected |

| Alkenals | 2-Heptenal | Detected |

| Alkenals | 2-Octenal | Detected |

| Epoxyaldehydes | 4,5-Epoxy-2-decenal | Detected |

| Alkenals | 2-Decenal | Detected |

| Alkenals | 2-Undecenal | Detected |

Method Validation Parameters

The developed method was validated to ensure reliability, with key performance metrics shown below [11].

Table 2: Validation Data for the UFLC-DAD-ESI-MS Method.

| Validation Parameter | Performance Result |

|---|---|

| Linear Range | 0.2 - 10.0 μg/mL |

| Limit of Detection (LOD) | 0.03 - 0.1 μg/mL |

| Limit of Quantification (LOQ) | 0.2 μg/mL for all compounds |

| Average Recovery (at LOQ) | 70.7% - 85.0% |

Workflow Visualization

The following diagram illustrates the complete experimental workflow for the analysis of carbonyl compounds in soybean oil, from sample preparation to data analysis.

The Scientist's Toolkit

Table 3: Essential Reagents and Materials for UFLC-DAD-ESI-MS Analysis of Carbonyl Compounds in Oils.

| Item | Function/Application |

|---|---|

| 2,4-Dinitrophenylhydrazine (DNPH) | Derivatization reagent that reacts with carbonyl functional groups to form stable hydrazone derivatives, enabling UV detection and improving MS sensitivity [2]. |

| Acetonitrile (HPLC/MS Grade) | Primary solvent for extraction of derivatized carbonyls from the oil matrix and as the organic mobile phase component in UFLC [2] [11]. |

| Reversed-Phase C18 Column | The stationary phase for chromatographic separation of derivatized carbonyl compounds based on their hydrophobicity [2]. |

| Formic Acid | Mobile phase additive used to enhance ionization efficiency in the ESI source and improve chromatographic peak shape [2]. |

| Carbonyl Compound Standards (e.g., HNE, Acrolein, 2,4-Decadienal) | Required for method development, calibration, and positive identification of analytes in the sample [11]. |

| Syringe Filters (0.20-0.45 μm) | For final purification of the sample extract prior to injection into the UFLC system to prevent column and instrument clogging [2]. |

| Phenol-amido-C1-PEG3-N3 | Phenol-amido-C1-PEG3-N3, MF:C14H20N4O5, MW:324.33 g/mol |

| Propargyl-PEG2-urea-C3-triethoxysilane | Propargyl-PEG2-urea-C3-triethoxysilane, MF:C17H34N2O6Si, MW:390.5 g/mol |

Sample Preparation Workflow for Heated Soybean Oil Analysis

Within the broader context of UFLC-DAD method development for soybean oil analysis, sample preparation represents a critical foundational step that directly determines analytical accuracy and reliability. This application note details a optimized sample preparation workflow specifically designed for the analysis of carbonyl compounds in soybean oil subjected to thermal stress. The protocol supports subsequent analysis using UFLC-DAD-ESI-MS instrumentation, enabling precise quantification of thermal degradation markers that form during heating processes [11]. As soybean oil continues to dominate the edible oil market with projected growth to $59.85 billion by 2033, rigorous analytical methods for quality assessment become increasingly vital for both food safety and product development [25].

Sample Preparation Workflow

Oil Heating Conditions

Initiate the protocol by subjecting soybean oil samples to controlled thermal stress to simulate cooking and processing conditions:

- Heating temperature: 180°C

- Monitoring period: Continuous heating with time-course sampling

- Sample aliquots: Collect multiple samples at predetermined intervals for comprehensive degradation profiling

Carbonyl Compound Extraction

The optimized extraction procedure for carbonyl compounds from the heated oil matrix proceeds as follows:

- Sample weighing: Accurately weigh 1.0 g of heated soybean oil into a labeled extraction vessel

- Solvent addition: Add 1.5 mL of acetonitrile as the extraction solvent [11]

- Initial mixing: Employ manual stirring for precisely 3 minutes to ensure complete homogenization

- Sonication: Transfer the mixture to an ultrasonic bath for 30 minutes to enhance compound recovery

- Phase separation: Allow samples to stand briefly for clear phase separation

- Collection: Carefully collect the acetonitrile layer containing extracted carbonyl compounds for analysis

This optimized extraction protocol has demonstrated average recoveries of 70.7% to 85.0% for target analytes at the lowest concentration levels, with quantification limits of 0.2 μg·mLâ»Â¹ for all target carbonyl compounds [11].

UFLC-DAD-ESI-MS Analysis

Following sample preparation, analysis proceeds using UFLC-DAD-ESI-MS with these critical parameters:

- Separation: Ultra-Fast Liquid Chromatography with optimized gradient elution

- Detection: Diode Array Detection (DAD) for broad-spectrum detection

- Identification: Electrospray Ionization Mass Spectrometry (ESI-MS) for compound confirmation

- Quantification: External calibration with authentic standards for precise concentration determination

Table 1: Key Carbonyl Compounds Identified in Heated Soybean Oil and Their Concentrations

| Compound | Mean Concentration (μg·gâ»Â¹ oil) | Chemical Class |

|---|---|---|

| 4-Hydroxy-2-nonenal | 36.9 | Hydroxy alkenal |

| 2,4-Decadienal | 34.8 | Dienal |

| 2,4-Heptadienal | 22.6 | Dienal |

| 4-Hydroxy-2-hexenal | Detected | Hydroxy alkenal |

| Acrolein | Detected | Aldehyde |

| 2-Heptenal | Detected | Enonal |

| 2-Octenal | Detected | Enonal |

| 4,5-Epoxy-2-decadal | Detected | Epoxy aldehyde |

| 2-Decenal | Detected | Enonal |

| 2-Undecenal | Detected | Enonal |

Complementary Method for Total Oil Content Analysis

For comprehensive soybean oil characterization, a complementary protocol for total oil content measurement provides valuable contextual data [26]:

Sample Preparation

- Communition: Grind soybean seeds using a water-cooled mill for 10 seconds

- Moisture assessment: Determine moisture content using validated moisture analysis methods

- Replication: Perform triplicate measurements for statistical reliability

Accelerated Solvent Extraction

Utilize an Accelerated Solvent Extractor (ASE) with the following parameters:

- Extraction cell preparation: Load 1.0 g of powdered sample mixed with Ottawa sand

- Extraction solvent: Pharmaceutical grade hexane

- Temperature: 105°C oven temperature

- Pressure: 1000 psi extraction pressure

- Timing: 10 minutes static time with 2 cycles

- Post-processing: Evaporate hexane under nitrogen purge, followed by oven drying at 100°C for 70 minutes

Calculation

Determine total oil content using the standard equation:

C = 100 × Ow / (W × (1 - moisture))

Where:

- C = Total oil content (%)

- Ow = Mass of oil extracted from ground sample (g)

- W = Weight of ground sample (g)

- moisture = Moisture percentage of ground sample

Table 2: Major Fatty Acids in Soybean Oil and Their Typical Proportions

| Fatty Acid | Chemical Designation | Typical Percentage in Soybean Oil |

|---|---|---|

| Palmitic acid | C16:0 | ~10-12% |

| Stearic acid | C18:0 | ~3-5% |

| Oleic acid | C18:1 | ~18-25% |

| Linoleic acid | C18:2 | ~50-55% |

| Alpha-linolenic acid | C18:3 | ~5-9% |

Workflow Visualization

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential Research Reagents and Materials for Soybean Oil Analysis

| Item | Function/Application | Specifications/Notes |

|---|---|---|

| Acetonitrile (HPLC grade) | Extraction solvent for carbonyl compounds | Primary extraction medium; 1.5 mL per 1.0 g sample [11] |

| Accelerated Solvent Extractor (ASE) | Total oil extraction from soybean matrix | Conditions: 105°C, 1000 psi, 10 min static time [26] |

| Hexane (pharmaceutical grade) | Oil extraction solvent | Used in ASE; evaporated under nitrogen purge [26] |

| UFLC-DAD-ESI-MS System | Carbonyl compound separation and detection | Provides quantification and identification capabilities [11] |

| Reference standards | Carbonyl compound identification and quantification | Including 4-hydroxy-2-nonenal, 2,4-decadienal, acrolein, etc. [11] |

| Sodium methoxide solution | Transesterification for fatty acid analysis | 1 N solution for GC analysis of fatty acid profile [26] |

| Ottawa sand | Matrix for accelerated solvent extraction | Fills dead volume of extractor cell [26] |

| Glass fiber filters | Filtration during extraction | Catalog No. 600004-2129-DB [26] |

| N-(Biotin-PEG4)-N-bis(PEG4-Boc) | N-(Biotin-PEG4)-N-bis(PEG4-Boc), MF:C50H94N4O18S, MW:1071.4 g/mol | Chemical Reagent |

| 2-Methoxyfuranoguaia-9-ene-8-one | 2-Methoxyfuranoguaia-9-ene-8-one, MF:C16H20O3, MW:260.33 g/mol | Chemical Reagent |

Applications and Significance

The detailed sample preparation workflow described herein enables precise monitoring of thermal degradation products in soybean oil, with significant implications for:

- Food Quality and Safety: Quantification of potentially harmful carbonyl compounds like acrolein and 4-hydroxy-2-nonenal [11]

- Product Development: Optimization of processing conditions to minimize degradation

- Shelf-life Studies: Monitoring compound formation during storage and use

- Biofuel Research: Assessing oil quality for industrial applications [25]

The method's validation parameters confirm its reliability for research applications, with detection limits ranging from 0.03 to 0.1 μg·mLâ»Â¹, covering the relevant concentration range for thermal degradation markers [11].

This application note provides a comprehensive, validated sample preparation workflow for the analysis of carbonyl compounds in heated soybean oil. The protocol is optimized for compatibility with UFLC-DAD-ESI-MS analysis and delivers robust performance with excellent recovery rates and sensitivity. When implemented within a broader thesis focused on UFLC-DAD method development, this sample preparation workflow provides a solid foundation for investigating thermal degradation pathways in soybean oil and related products, contributing valuable analytical capabilities to the field of food science and lipid chemistry.

Thermal oxidation of edible oils generates carbonyl compounds (CCs) that degrade nutritional quality and raise food safety concerns due to their biological reactivity [2] [17]. This application study profiles carbonyl formation in soybean oil during continuous heating at 180°C, supporting a broader thesis on UFLC-DAD method development for analyzing oil oxidation products. Understanding the kinetics of harmful compounds like acrolein and 4-hydroxy-2-nonenal (HNE) is crucial for assessing oil quality and safety [2] [11].

The core analytical approach involves UFLC-DAD-ESI-MS, which enables precise separation, identification, and quantification of carbonyl compounds derived from thermally stressed soybean oil [2] [11].

Key Research Reagent Solutions

Table 1: Essential Research Reagents and Materials

| Reagent/Material | Function in Experimental Protocol |

|---|---|

| Soybean Oil | Test matrix for studying thermal oxidation; chosen for high PUFA content and widespread use [2] [11]. |

| Acetonitrile (HPLC/MS grade) | Primary solvent for liquid-liquid extraction of carbonyls from the oil matrix [2] [11]. |