How to List Chromatography Skills on Your Resume: A Complete Guide for Scientists

This guide provides researchers, scientists, and drug development professionals with a comprehensive framework for effectively showcasing chromatography skills on a resume.

How to List Chromatography Skills on Your Resume: A Complete Guide for Scientists

Abstract

This guide provides researchers, scientists, and drug development professionals with a comprehensive framework for effectively showcasing chromatography skills on a resume. It covers everything from listing fundamental techniques and instrumentation to detailing advanced method development, troubleshooting expertise, and validation experience. The article offers actionable strategies to communicate technical proficiency, demonstrate impact with quantifiable achievements, and optimize resumes for both Applicant Tracking Systems and hiring managers in the competitive life sciences industry.

Mastering the Fundamentals: Essential Chromatography Techniques and Concepts

Core Chromatography Techniques Every Scientist Should List

Chromatography stands as a cornerstone analytical technique central to advancements in pharmaceutical development, biomedical research, and quality control. For scientists and researchers, a nuanced understanding and demonstrated proficiency in core chromatography methods are invaluable assets, often forming a critical section on a technical resume. This guide details four essential chromatography techniques—High-Performance Liquid Chromatography, Size Exclusion Chromatography, Ion-Exchange Chromatography, and Affinity Chromatography—providing the foundational knowledge, experimental protocols, and data presentation formats needed to effectively communicate your expertise.

High-Performance Liquid Chromatography (HPLC)

Principle: HPLC separates compounds in a liquid sample by exploiting the differential affinities of its components for a stationary phase (column) and a mobile phase (solvent) pumped through the system at high pressure. Analytes are retained based on properties like polarity, and the retention time is used for identification and quantification [1] [2].

A typical reversed-phase HPLC method for analyzing small molecules involves:

- Mobile Phase Preparation: Prepare a mixture of water and acetonitrile, often with a pH modifier like acetic acid. Filter under vacuum and degas to remove particulates and gases.

- Standard and Sample Preparation: Dissolve reference standards and the unknown sample in the mobile phase or a compatible solvent. Serial dilution may be required to achieve the desired concentration range.

- System Setup: Equilibrate the column with the mobile phase at a set flow rate (e.g., 0.5 to 2.0 mL/min). Set pressure limits (e.g., min: 250 psi, max: 4000 psi) and detector parameters.

- Injection and Analysis: Inject a precise volume (e.g., 100 µL) of the sample. Data collection begins at injection and continues until all peaks of interest have eluted.

- Data Analysis: Identify analytes by comparing retention times to standards. Quantify by integrating peak areas and comparing to a calibration curve.

Key Technical Specifications

| Parameter | Typical Specification | Application Note |

|---|---|---|

| Stationary Phase | C18 (Octadecyl silane), C8, Silica | C18 is most common for reversed-phase analysis of small molecules [3]. |

| Flow Rate | 1-2 mL/min (HPLC); 0.2-0.7 mL/min (UHPLC) | UHPLC uses smaller particles and higher pressures [2]. |

| Detection | UV-Vis, PDA, Mass Spectrometry (LC-MS) | UV detection at 254 nm is common for many pharmaceuticals [1]. |

| Separation Mode | Isocratic or Gradient | Gradient elution uses a changing solvent composition for superior separation of complex mixtures [2]. |

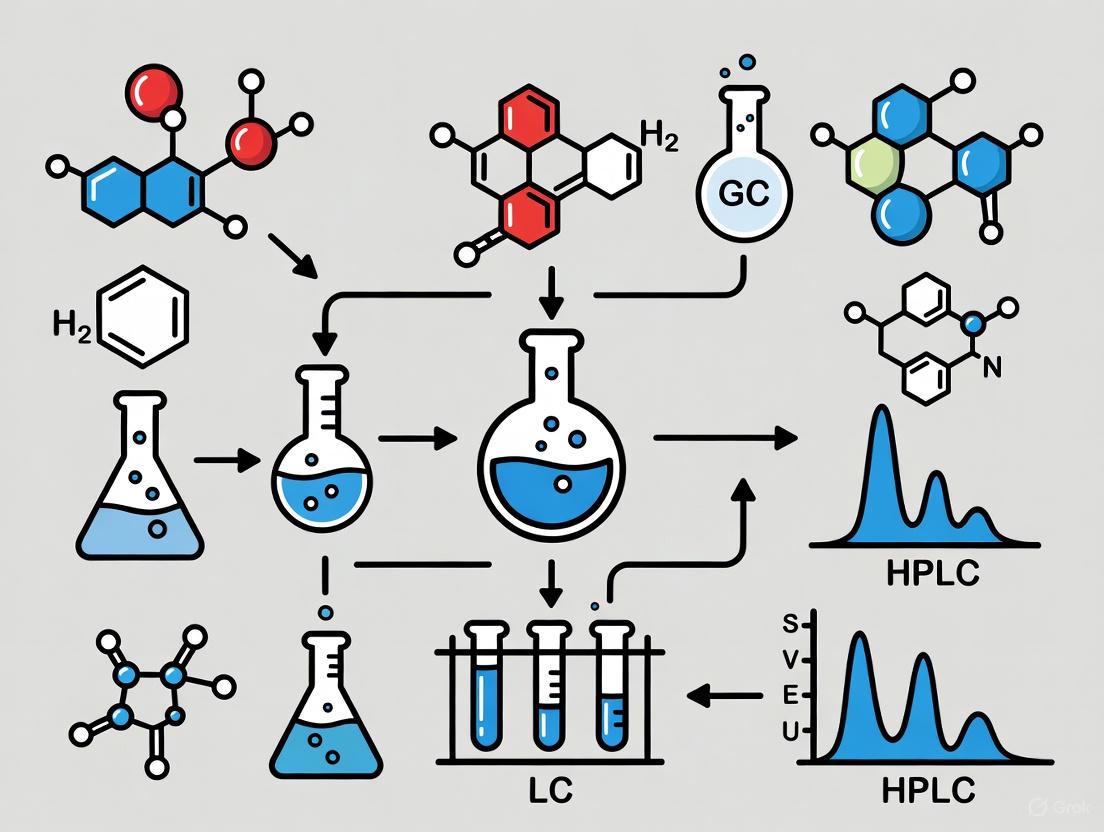

Figure 1: A simplified workflow for a standard HPLC analysis.

Size Exclusion Chromatography (SEC)

Principle: Also known as gel filtration, SEC separates molecules in a solution based on their size (hydrodynamic volume) in an aqueous buffer [4].

- Column Selection: Choose a column packed with porous beads (e.g., dextran, agarose) with a pore size range suitable for the target molecules.

- Equilibration: Equilibrate the column with at least 5 column volumes of an appropriate buffer (e.g., phosphate-buffered saline).

- Sample Preparation & Load: If necessary, clarify the sample by centrifugation or filtration. Load a small volume (typically 1-2% of the column volume) to ensure good resolution.

- Elution and Fraction Collection: Isocratically elute the sample with the same buffer used for equilibration. Larger molecules elute first, followed by smaller ones. Fractions can be collected for further analysis.

- Analysis: Analyze the elution profile (chromatogram). The retention volume can be compared to a standard curve of known molecular weights to estimate the size of unknown analytes.

Key Technical Specifications

| Parameter | Typical Specification | Application Note |

|---|---|---|

| Stationary Phase | Dextran (Sephadex), Agarose (Sepharose) | Beads are characterized by their fractionation range [4]. |

| Mobile Phase | Aqueous buffer (e.g., PBS) | Buffer must maintain protein stability and prevent aggregation [4]. |

| Detection | UV-Vis, Refractive Index (RI), Light Scattering | Multi-angle light scattering (MALS) provides absolute molecular weight [4]. |

| Key Application | Protein oligomerization analysis, Polymer MW distribution | Ideal for separating monomers from aggregates in proteins [4]. |

Figure 2: The separation mechanism of Size Exclusion Chromatography.

Ion-Exchange Chromatography (IEC)

Principle: IEC separates ions and polar molecules based on their affinity for charged functional groups attached to a stationary phase. Separation depends on the strength of electrostatic interaction [5] [6].

- Column and Buffer Selection: Choose a cation exchanger (negative charge, e.g., sulfonate) for bases or an anion exchanger (positive charge, e.g., quaternary ammonium) for acids. Select a starting buffer with a pH that ensures the analyte and stationary phase have opposite charges.

- Equilibration: Wash the column with 5-10 column volumes of starting buffer until the effluent pH and conductivity are stable.

- Sample Application and Wash: Prepare the sample in the starting buffer or a lower ionic strength buffer. Load the sample and then wash with the starting buffer to remove unbound components.

- Elution: Retained analytes are eluted using a gradient of increasing ionic strength (e.g., with NaCl). Alternatively, a pH gradient can be used to neutralize the charge on the analyte or the stationary phase.

- Regeneration and Storage: Wash the column with a high-concentration salt solution (e.g., 1-2 M NaCl) to remove strongly bound species, then re-equilibrate in starting buffer or a storage buffer.

Key Technical Specifications

| Parameter | Typical Specification | Application Note |

|---|---|---|

| Stationary Phase | Strong Cation Exchanger (SO₃â»), Weak Anion Exchanger (NH₃âº) | Strong exchangers maintain charge over a wide pH range [5]. |

| Elution Method | Linear or step gradient of salt (NaCl, KCl) | Ionic strength gradient is the most common elution method [6]. |

| Detection | Conductivity, UV-Vis, Mass Spectrometry | Suppressor technology is used with conductivity detection to enhance sensitivity [6]. |

| Selectivity Order | For cations: Al³⺠> Ba²⺠> Pb²⺠> ... > Na⺠> H⺠> Li⺠[5] | Selectivity depends on ion charge and surface activity [6]. |

Affinity Chromatography

Principle: This technique purifies a biomolecule based on a highly specific biological interaction, such as between an antigen and antibody, an enzyme and a substrate, or a receptor and a ligand [7].

- Ligand Immobilization: Covalently couple a biospecific ligand (e.g., an antibody, glutathione, or metal ion) to a solid support like beaded agarose.

- Equilibration: Wash the affinity support with a binding buffer at physiological pH and ionic strength (e.g., PBS).

- Sample Application: Incubate the crude sample (e.g., cell lysate) with the affinity support to allow the target molecule to bind.

- Washing: Wash extensively with binding buffer to remove nonspecifically bound contaminants.

- Elution: Release the purified target molecule using an elution buffer. Conditions can be specific (e.g., a competitive ligand like glutathione for GST-tagged proteins) or nonspecific (e.g., low pH glycine buffer, high salt, or chaotropic agents).

Key Technical Specifications

| Parameter | Typical Specification | Application Note |

|---|---|---|

| Solid Support | Cross-linked beaded Agarose (CL-4B, CL-6B) | Agarose offers high porosity and low non-specific binding [7]. |

| Common Elution Buffers | 0.1 M Glycine•HCl (pH 2.5-3.0), 3.5 M MgCl₂ | Low pH is common but may denature some proteins; fractions should be neutralized immediately [7]. |

| Detection | UV-Vis at 280 nm | A single purification step can achieve >1000-fold purification [7]. |

| Key Application | Purification of His-tagged proteins, Antibodies (Immunoaffinity) | The most powerful technique for specific, high-purity isolations [7]. |

Figure 3: The core steps of an Affinity Chromatography purification.

Essential Research Reagents & Materials

A proficient scientist not only understands the techniques but also the key reagents and materials that ensure success.

| Item | Function & Technical Detail |

|---|---|

| C18 HPLC Column | The workhorse for reversed-phase separation of small molecules and peptides [3]. |

| SEC Beads (Agarose) | Porous matrix for separating biomolecules by size; choice of pore size is critical [4]. |

| Ion-Exchange Resin | Functionalized polymer (e.g., with sulfonate groups) for separating charged molecules [5]. |

| Immobilized Ligand | Biospecific agent (e.g., Protein A for antibodies) covalently attached to a solid support [7]. |

| SPE Cartridges | Used for sample clean-up and concentration prior to analysis; available in various chemistries (C18, Ion-Exchange) [3]. |

| Syringe Filters (0.22µm) | Critical for removing particulate matter from samples to prevent column clogging [3]. |

| HPLC-Grade Solvents | High-purity solvents (acetonitrile, methanol) to ensure low UV background and consistent results [1]. |

Mastering these four core chromatography techniques—HPLC, SEC, IEC, and Affinity Chromatography—equips a scientist with a versatile and powerful analytical toolkit. Effectively listing these skills on a resume requires more than just naming the techniques; it demands the ability to articulate a deep understanding of their principles, hands-on experience with their protocols, and insight into the critical reagents that drive successful separations. This comprehensive understanding demonstrates true technical prowess and is highly valued in research and drug development environments.

Proficiency in chromatography and mass spectrometry is a cornerstone of modern analytical science, particularly in pharmaceutical research and drug development. This technical guide details the essential instrumentation skills—from foundational High-Performance Liquid Chromatography (HPLC) and Gas Chromatography (GC) to advanced hyphenated systems like Liquid Chromatography-Mass Spectrometry (LC-MS)—that professionals must highlight to demonstrate competency. For scientists crafting their resumes, clearly articulating hands-on experience with these technologies is critical. The field is rapidly evolving, with current trends emphasizing high-throughput analysis, miniaturized systems, and the integration of artificial intelligence (AI) for data processing and instrument optimization [8]. Framing your skills within this context of innovation shows a forward-thinking and adaptable approach to potential employers.

Instrument proficiency extends beyond mere operation; it encompasses method development, validation, troubleshooting, and data interpretation. This guide provides a structured framework to help you list these competencies effectively, ensuring you communicate both the depth and breadth of your technical expertise.

Foundational Chromatography Methods

High-Performance Liquid Chromatography (HPLC) and Ultra-HPLC (UHPLC)

HPLC is a fundamental technique for separating, identifying, and quantifying compounds in a liquid mixture. It is particularly vital for analyzing thermally labile, non-volatile, or high-molecular-weight substances. The core principle involves forcing a pressurized liquid solvent (mobile phase) containing the sample mixture through a column packed with a solid adsorbent material (stationary phase). Components interact differently with the stationary phase, leading to separation.

- Key Applications: Analysis of pharmaceuticals, peptides, proteins, nucleic acids, and most small molecules in complex biological matrices.

- Skill Highlights for Resumes:

- Method Development and Validation: Expertise in selecting appropriate columns (C18, C8, phenyl, etc.), optimizing mobile phase composition (e.g., water/acetonitrile gradients with modifiers like formic acid), and validating methods as per ICH or other regulatory guidelines [9].

- UHPLC Operation: Experience with Ultrahigh-Performance Liquid Chromatography (UHPLC), which utilizes smaller particle sizes (<2 µm) and higher pressures to achieve faster separations with superior resolution and sensitivity [10] [9].

- Troubleshooting: Ability to diagnose and resolve issues related to pressure fluctuations, peak shape deterioration, and retention time shifts.

Gas Chromatography (GC) and GC-Mass Spectrometry (GC-MS)

GC is the technique of choice for separating volatile, thermally stable compounds. The sample is vaporized and injected onto a column, where it is carried by an inert gas mobile phase. Separation occurs based on the compound's volatility and interaction with the stationary phase coating the column walls.

- Key Applications: Analysis of fatty acids, steroids, environmental contaminants, residual solvents, and metabolites in urine for drug testing [11] [9].

- Skill Highlights for Resumes:

- Sample Preparation and Derivatization: Proficiency in techniques like solid-phase extraction (SPE) and chemical derivatization to increase analyte volatility and detectability for GC analysis [11].

- GC-MS Operation: Demonstrated experience coupling GC with mass spectrometry (GC-MS) for unambiguous identification and quantification. This includes operating and maintaining electron impact (EI) or chemical ionization (CI) sources [11].

- Data Interpretation: Skill in interpreting complex mass spectra and using library databases for compound identification.

Table 1: Comparison of Core Chromatography Techniques

| Feature | HPLC/UHPLC | GC |

|---|---|---|

| Sample Suitability | Non-volatile, thermally labile, ionic, high molecular weight | Volatile, thermally stable |

| Mobile Phase | Liquid (solvents) | Inert gas (e.g., He, Nâ‚‚) |

| Common Detectors | UV-Vis, Photodiode Array (PDA), Mass Spectrometry (MS) | Flame Ionization (FID), Mass Spectrometry (MS) |

| Typical Applications | Drug quantification, protein analysis, metabolomics | Fatty acid analysis, environmental monitoring, forensics |

| Key Skill to Highlight | Method development, gradient optimization, LC-MS/MS | Sample derivatization, inlet maintenance, GC-MS |

Advanced and Hyphenated Systems

Liquid Chromatography-Mass Spectrometry (LC-MS) and LC-Tandem MS (LC-MS/MS)

The coupling of liquid chromatography with mass spectrometry represents a powerful advancement, combining superior separation power with highly sensitive and specific detection. Electrospray Ionization (ESI) and Atmospheric Pressure Chemical Ionization (APCI) are the most common interfaces, gently ionizing analytes as they elute from the LC column for mass analysis [12].

- LC-MS/MS (Tandem Mass Spectrometry): This is the gold standard for quantitative bioanalysis in clinical and pharmaceutical settings. A triple quadrupole mass spectrometer is typically used, where the first quadrupole selects a precursor ion, the second (collision cell) fragments it, and the third analyzes the resulting product ions [12]. This Multiple Reaction Monitoring (MRM) mode provides exceptional specificity and sensitivity in complex samples like plasma or serum [9].

- Skill Highlights for Resumes:

- API Ionization Expertise: Deep understanding of optimizing ESI and APCI source parameters (e.g., nebulizer gas, vaporizer temperature, spray voltage) to maximize ionization efficiency and minimize ion suppression [13] [12].

- Quantitative LC-MS/MS Assay Development: Proven track record in developing, validating, and troubleshooting robust MRM assays for small molecules, peptides, and proteins [13].

- High-Throughput and Automated Methods: Experience with turbulent flow chromatography and other online sample preparation techniques to automate and increase analytical throughput [9].

Emerging Trends and Specialized Techniques

Staying current with technological trends is a valuable skill in itself. On your resume, mention familiarity with:

- Automation and AI: Using AI for instrument calibration, process optimization, and data analysis [8].

- Microfluidic and Chip-Based Systems: Employing micropillar array columns and chip-based designs for enhanced reproducibility and scalability, especially in proteomics [8].

- Complex Separation Challenges: Experience with specialized methods for "sticky" compounds like PFAS, mRNA, and nucleotide therapeutics [8].

- Sustainability Initiatives: Implementing methods with reduced solvent consumption and lower energy usage [8].

Experimental Protocols and Methodologies

Detailed Protocol: Development and Validation of a Quantitative LC-MS/MS Assay

This protocol outlines the key steps in developing a bioanalytical method for quantifying a small molecule drug in plasma, a common task in drug development [13] [9].

1. Sample Preparation:

- Protein Precipitation: Mix plasma sample (100 µL) with an internal standard solution and 300 µL of cold acetonitrile. Vortex and centrifuge to pellet proteins. Transfer the supernatant for analysis.

- Solid-Phase Extraction (SPE): Load sample onto an SPE cartridge, wash with aqueous solvent, and elute analytes with an organic solvent. Evaporate and reconstitute in mobile phase.

- Automated Online Extraction (e.g., Turbulent Flow Chromatography): Dilute sample and inject directly into a system that automatically performs online extraction and transfer to the analytical column, significantly increasing throughput [9].

2. LC-MS/MS Method Development:

- Chromatography Optimization:

- Column: Select a suitable column (e.g., C18, 2.1 x 50 mm, 1.7-1.8 µm particle size).

- Mobile Phase: Test different buffers (e.g., formic acid in water) and organic modifiers (acetonitrile vs. methanol) with gradient elution to achieve optimal separation and peak shape.

- Flow Rate: Optimize for resolution and speed (typical for UHPLC: 0.3-0.6 mL/min).

- Mass Spectrometry Optimization:

- Ionization: Determine whether ESI or APCI is more effective for the analyte.

- MRM Transitions: Using direct infusion, identify the precursor ion and the 2-3 most intense product ions for each analyte and internal standard. Optimize collision energy for each transition [12].

3. Method Validation: Following regulatory guidance (e.g., FDA), validate the assay for:

- Selectivity/Specificity: Demonstrate no interference from blank matrix.

- Accuracy and Precision: Assess using quality control samples at multiple concentrations.

- Linearity: Establish the calibration curve range.

- Matrix Effects: Evaluate ion suppression/enhancement using post-column infusion experiments [13].

Workflow Diagram: LC-MS/MS Quantitative Analysis

The following diagram visualizes the integrated workflow of a quantitative LC-MS/MS analysis, from sample to result.

The Scientist's Toolkit: Essential Research Reagents and Materials

A proficient scientist is not only skilled in instrument operation but also in selecting the appropriate consumables and reagents that are critical for a successful analysis.

Table 2: Key Research Reagent Solutions for Chromatography

| Item | Function & Importance |

|---|---|

| LC Columns (C18, C8, HILIC, etc.) | The heart of the separation. Choice of stationary phase chemistry, particle size (e.g., 1.7-5 µm), and dimensions directly impact resolution, speed, and sensitivity. |

| GC Columns (e.g., 5% Phenyl Polysiloxane) | Capillary columns with different stationary phases and film thicknesses are selected based on the polarity and volatility of the target analytes. |

| Mass Spectrometry Reference Materials | Certified Reference Materials (CRMs) are essential for instrument calibration, method validation, and ensuring data accuracy. Certificates should follow ISO Guides 31-35 [14]. |

| High-Purity Solvents & Mobile Phase Additives | LC-MS grade solvents and additives (e.g., formic acid, ammonium acetate) are critical to prevent ion suppression, background noise, and instrument contamination. |

| Solid-Phase Extraction (SPE) Cartridges | Used for sample clean-up and pre-concentration of analytes. Available in various chemistries (e.g., reverse phase, ion exchange) to selectively retain target compounds. |

| Derivatization Reagents (for GC) | Chemicals like MSTFA (N-Methyl-N-(trimethylsilyl)trifluoroacetamide) are used to modify analytes, making them more volatile and thermally stable for GC analysis [11]. |

| Stable Isotope-Labeled Internal Standards | Compounds like ¹³C or ²H-labeled analogs of the analyte are added to samples to correct for variability in sample preparation and ionization efficiency in quantitative MS [12]. |

| Einecs 306-377-0 | Einecs 306-377-0, CAS:97158-47-9, MF:C32H38ClN3O8, MW:628.1 g/mol |

| Einecs 287-139-2 | Einecs 287-139-2, CAS:85409-69-4, MF:C43H89N3O10, MW:808.2 g/mol |

Mastering the instrumentation from basic HPLC/GC to advanced LC-MS/MS systems is a multi-faceted endeavor. To effectively list these skills on a resume, move beyond simply naming instruments. Detail your specific achievements and technical capabilities, such as: "Developed and validated a high-throughput UHPLC-MS/MS method for quantifying immunosuppressants in whole blood, implementing turbulent flow chromatography to reduce sample preparation time by 70%," or "Became the lab expert in troubleshooting APCI source contamination for a GC-MS steroid panel." By framing your proficiencies within the context of concrete projects, results, and an awareness of current trends, you present yourself as a highly capable and strategic scientist poised to contribute significantly to any research and development team.

In the field of chromatography, expertise extends beyond instrument operation to encompass three fundamental supporting skills: sample preparation, calibration, and adherence to Standard Operating Procedures (SOPs). These skills form the critical foundation for generating reliable, reproducible, and defensible data in drug development and research. Within the context of resume development for chromatography professionals, highlighting competencies in these areas demonstrates a comprehensive understanding of the analytical workflow and a commitment to data integrity. Mastery of these skills is what distinguishes a competent scientist who merely operates instruments from one who ensures data quality and regulatory compliance [15] [16] [17].

This guide provides an in-depth technical overview of these essential supporting skills, detailing methodologies, best practices, and their direct impact on analytical outcomes. For researchers and scientists, effectively communicating this expertise on a resume is crucial for showcasing technical proficiency and attention to detail.

Sample Preparation: The Critical First Step

Sample preparation is the most pivotal step in the chromatographic workflow, as it directly influences the need for subsequent troubleshooting. As emphasized by experts at CHROMtalks 2025, effective sample preparation can preemptively eliminate a significant portion of potential analytical issues [15]. Proper techniques ensure that the sample introduced into the chromatographic system is clean, stable, and in a form suitable for accurate separation and detection.

Core Principles and Methodologies

The primary goal of sample preparation is to isolate target analytes from a complex sample matrix while minimizing interferences. This process can involve multiple techniques, each selected based on the sample properties and analytical requirements. Key objectives include:

- Removing potentially interfering substances to enhance signal-to-noise ratio

- Preconcentrating analytes to improve detection limits

- Converting analytes into a suitable form for chromatographic analysis

- Ensizing sample stability during storage and analysis

Essential Sample Preparation Techniques

The following table summarizes common sample preparation techniques used in chromatographic analysis, particularly in pharmaceutical and bioanalytical applications:

Table: Common Sample Preparation Techniques for Chromatography

| Technique | Principle | Primary Applications | Key Considerations |

|---|---|---|---|

| Liquid-Liquid Extraction (LLE) | Partitioning of analytes between two immiscible liquids based on solubility | Extraction of drugs from biological fluids; sample clean-up | Requires optimization of solvent polarity; may require large solvent volumes |

| Solid-Phase Extraction (SPE) | Selective adsorption and desorption of analytes using functionalized sorbents | Concentration and purification of analytes from complex matrices; desalting | Offers high selectivity and recovery; multiple sorbent chemistries available (C18, ion-exchange, mixed-mode) |

| Protein Precipitation | Denaturation and removal of proteins using organic solvents, acids, or salts | Rapid clean-up of biological samples (plasma, serum) | Simple and fast; may not remove all interferences effectively |

| Derivatization | Chemical modification of analytes to enhance detection or chromatographic behavior | Improving volatility for GC; enhancing detectability for UV/FL | Can improve sensitivity and selectivity; adds complexity to sample preparation |

Recent trends focus on developing greener microextraction techniques that minimize solvent usage while maintaining high extraction efficiency, as highlighted in current chromatography forums [15]. These include techniques such as solid-phase microextraction (SPME) and liquid-phase microextraction (LPME).

Impact on Chromatographic Performance

Proper sample preparation directly influences critical chromatographic parameters:

- Chromatographic Peak Shape: Inadequate cleaning can lead to matrix components binding to the column, causing peak tailing or broadening

- System Pressure: Particulate matter or precipitated matrix components can clog frits and tubing, increasing backpressure

- Detection Sensitivity: Co-extracted matrix components can quench or enhance detector response, affecting quantification accuracy

- Column Lifetime: Accumulation of matrix components on the column reduces column efficiency and longevity

As emphasized by Steven Lehotay at CHROMtalks 2025, "Better sample preparation reduces the need for troubleshooting in the first place" [15]. Investing time in optimizing sample preparation protocols yields significant returns in data quality and instrument reliability.

Calibration: Ensuring Analytical Accuracy

Calibration establishes the relationship between instrument response and analyte concentration, providing the foundation for quantitative analysis. A robust calibration strategy ensures that results are accurate, precise, and traceable to recognized standards.

Calibration Fundamentals and Procedures

Calibration in chromatography involves comparing the responses of unknown samples to those of standards with known concentrations. The calibration process follows a defined workflow to ensure accuracy and traceability:

Diagram: Instrument Calibration Workflow. This flowchart outlines the systematic approach to calibrating chromatographic instruments, emphasizing decision points and documentation requirements [16].

Calibration Methods in Chromatography

Chromatographic quantification employs several calibration approaches, each with specific applications and considerations:

Table: Chromatography Calibration Methods and Applications

| Calibration Method | Principle | When to Use | Advantages | Limitations |

|---|---|---|---|---|

| External Standard | Comparison of sample response to external calibration standards | Simple sample matrices; high method robustness | Simple implementation; minimal sample preparation | Vulnerable to injection volume variations; matrix effects |

| Internal Standard | Response normalized to a added compound with similar properties | Complex matrices; variable injection volumes; sample loss expected | Compensates for injection volume variability and sample loss | Requires finding suitable IS that doesn't co-elute with analytes |

| Standard Addition | Standards added directly to the sample matrix | Complex matrices with significant suppression/enhancement effects | Compensates for matrix effects effectively | Time-consuming; requires more sample; multiple injections needed |

Implementing and Maintaining Calibration

According to standard operating procedures, calibration must be performed using certified standards traceable to national or international standards [16]. Key implementation considerations include:

- Frequency: Critical instruments typically require calibration every six months, while non-critical instruments may be calibrated annually [16]

- Range: Calibration must cover the instrument's entire operational range, including minimum, maximum, and typical working concentrations

- Documentation: Each calibration event must be recorded with details of standards used, traceability information, instrument identification, and results

- Action on Failure: If an instrument fails calibration, it must be immediately removed from service, labeled "UNDER MAINTENANCE," and the failure investigated per incident reporting procedures [16]

Calibration in Chromatography Data Systems

Modern Chromatography Data Systems (CDS) automate much of the calibration process, offering:

- Automated Calculation of calibration curves using various regression models (linear, quadratic, weighted)

- Retention Time Windows for automated peak identification based on calibrated standards

- System Suitability Testing (SST) integration to ensure the analytical system is performing appropriately before sample analysis

- Audit Trail functionality that automatically records all calibration activities for regulatory compliance [17]

The CDS generates a Result Table that displays calibrated results with columns for retention time, response, calculated amount, amount percentage, and peak type, providing a comprehensive view of the analytical results [18].

Standard Operating Procedures (SOPs): Framework for Quality

SOPs provide the standardized framework that ensures consistency, compliance, and quality in all chromatographic operations. They document the approved methods and practices for instrumentation, analysis, and data handling.

SOPs in Regulated Chromatography Environments

In regulated environments such as pharmaceutical development, SOPs govern all aspects of chromatographic analysis. As outlined in chromatography SOPs, these documents detail:

- Responsibilities of analysts, project leaders, and quality assurance personnel [19]

- Specific instructions for operating liquid and gas chromatography systems

- Calibration requirements and schedules

- Documentation practices and data integrity measures

- Guidelines for manual integration and reprocessing of chromatograms

These procedures ensure compliance with established standards and regulatory requirements such as Good Manufacturing Practice (GMP) and Good Laboratory Practice (GLP) [17].

Core Components of Chromatography SOPs

A comprehensive chromatography SOP typically includes the following components based on standardized templates:

Table: Essential Components of a Chromatography SOP

| SOP Section | Content Description | Purpose |

|---|---|---|

| Objective | Clear statement of the SOP's purpose | Define the scope and goals of the procedure |

| Scope | Applicability to instruments, departments, and analyses | Delineate where and when the procedure applies |

| Responsibility | Roles and responsibilities for execution | Assign accountability for specific tasks |

| Accountability | Oversight and approval authority | Define quality oversight and management responsibility |

| Procedure | Step-by-step instructions for operations | Provide detailed, reproducible methods |

| Abbreviations | Definitions of acronyms and technical terms | Ensure consistent interpretation of terminology |

| References | Related documents, regulations, and standards | Provide context and connection to broader quality system |

Integration and Data Management Procedures

SOPs provide critical guidance on data handling practices, particularly for integration and review processes:

- Manual Integration: Specific circumstances under which manual integration is permitted must be defined, with clear scientific justification required for any reprocessing [19]

- Review Procedures: SOPs define the review process for chromatographic data, including verification of integration, calibration, and system suitability

- Audit Trail Review: In regulated environments, SOPs mandate regular review of electronic audit trails to detect unauthorized changes to data [17]

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful execution of chromatography methods requires specific reagents and materials that ensure analytical reliability. The following table details essential items in the chromatographer's toolkit:

Table: Essential Research Reagent Solutions for Chromatography

| Item Category | Specific Examples | Function/Purpose | Technical Considerations |

|---|---|---|---|

| Reference Standards | Certified reference materials (CRMs), USP standards | Calibration and method validation; establishing accuracy and traceability | Must be traceable to national/international standards; require proper storage and handling |

| Internal Standards | Stable isotope-labeled analogs, structural analogs | Normalization of analytical response; compensation for variability | Should mimic analyte behavior but be chromatographically resolvable |

| Sample Preparation Sorbents | C18, ion-exchange, mixed-mode, polymeric sorbents | Selective extraction and clean-up of samples | Selection depends on analyte properties (polarity, pKa, molecular weight) |

| Mobile Phase Additives | Mass spectrometry: Formic acid, ammonium acetate; LC-MS grade solvents | Modifying separation selectivity and detection sensitivity | Must be HPLC or LC-MS grade; can significantly impact ionization efficiency in MS |

| System Suitability Solutions | Resolution mixtures, efficiency test mixtures, tailing factor solutions | Verifying chromatographic system performance before sample analysis | Should test critical parameters relevant to the analytical method |

| Einecs 286-938-3 | Einecs 286-938-3, CAS:85393-37-9, MF:C43H51ClN3O10P, MW:836.3 g/mol | Chemical Reagent | Bench Chemicals |

| Pyrenolide C | Pyrenolide C | Pyrenolide C is a 10-membered keto-lactone fungal metabolite with growth-inhibitory and morphogenic activity. For Research Use Only. Not for human use. | Bench Chemicals |

Demonstrating Expertise on Professional Resumes

Effectively communicating these supporting skills on a resume requires strategic presentation that highlights both technical competence and their impact on analytical outcomes.

Strategic Presentation of Supporting Skills

When listing chromatography skills on a resume, incorporate these supporting skills in multiple sections:

- Technical Skills Section: Create a dedicated subsection for "Sample Preparation," "Instrument Calibration," and "SOP Development/Compliance"

- Experience Descriptions: Use action verbs to describe achievements: "Implemented improved sample preparation protocol that reduced matrix effects by 30%," "Developed and validated calibration procedures for 15+ HPLC systems," "Authored SOPs for chromatographic data review that reduced compliance observations by 50%" [20]

- Quantifiable Achievements: Include metrics wherever possible: "Reduced sample preparation time by 25% through implementation of solid-phase extraction," "Maintained 100% on-time calibration schedule for department instruments" [20]

Aligning with Industry Expectations

Employers in pharmaceutical and research settings specifically seek candidates with demonstrated competencies in these supporting areas. Highlighting experience with regulatory compliance (GMP/GLP), method validation, and quality systems demonstrates a comprehensive understanding of the analytical environment beyond basic instrument operation [17].

Emphasize familiarity with Chromatography Data Systems (CDS) and their role in calibration maintenance, electronic record keeping, and audit trail functionality, as these are critical components of modern regulated laboratories [17].

Sample preparation, calibration, and SOP adherence represent the essential supporting framework that ensures the generation of reliable, defensible chromatographic data in drug development and research. Mastery of these skills distinguishes competent analytical scientists and represents a critical differentiator in professional advancement.

For chromatography professionals, effectively documenting these competencies on resumes and in professional development records is essential for career growth. By highlighting specific technical abilities, quantifiable achievements, and understanding of quality systems, scientists can position themselves as valuable contributors to any analytical organization.

How to Structure Your Skills Section for Maximum Clarity and Impact

For researchers, scientists, and drug development professionals, a resume is not merely a list of past jobs; it is a document arguing your capability to conduct rigorous, reproducible science. The skills section, therefore, becomes a critical catalog of your technical arsenal. Framed within the broader thesis of effectively listing chromatography skills, this guide provides a detailed methodology for structuring your skills to achieve maximum clarity and professional impact, ensuring your resume accurately reflects your scientific expertise.

The Strategic Foundation of Your Skills Section

Before structuring the content, one must understand the strategic goals a skills section must accomplish. It must be immediately scannable, rich with relevant keywords for both human readers and Applicant Tracking Systems (ATS), and provide concrete evidence of your proficiency [20] [21].

A successful skills section is not a random collection of techniques. It is a curated and organized presentation built on three pillars:

- Categorization: Grouping related skills allows a hiring manager to quickly assess your overall capabilities. A disorganized list forces them to hunt for relevant information.

- Quantification: Whenever possible, move beyond simply naming a skill. Use numbers, percentages, or outcomes to demonstrate the impact and level of your expertise [22].

- Relevance: Tailor your skills list for every application, prioritizing those mentioned in the job description. This demonstrates attention to detail and a genuine interest in the specific role [20] [23].

A Methodical Framework for Organizing Skills

Implementing the following structured approach will transform your skills section from a simple list into a compelling narrative of your technical qualifications.

Step 1: Create Thematic Skill Clusters

Organize your skills into logical, clearly labeled categories. This is the most effective way to guide the reader's eye and present a coherent picture of your abilities. The following table outlines recommended categories for a chromatography-focused resume.

| Category | Description & Purpose | Example Skills |

|---|---|---|

| Chromatographic Techniques [21] [23] | Showcases core hands-on experience with separation methods. | Gas Chromatography (GC), High-Performance Liquid Chromatography (HPLC), Liquid Chromatography-Mass Spectrometry (LC-MS), Ion Chromatography |

| Supporting Analytical Techniques [20] | Demonstrates a well-rounded analytical skill set beyond chromatography. | Mass Spectrometry (MS), Spectroscopy (UV-Vis, IR, NMR), Titrimetric Analysis, Calorimetry |

| Data Analysis & Software [21] [23] | Highlights computational proficiency and ability to interpret data. | Chromeleon, Empower, LabSolutions, MATLAB, Python, Statistical Analysis, Data Interpretation |

| Method Development & Validation [21] | Proves advanced ability to create, optimize, and qualify methods. | Method Development, Analytical Method Validation, Transfer of Methods, QC/QA, SOP Development |

| Laboratory & Compliance [21] [23] | Establishes foundational knowledge of lab safety and industry regulations. | Good Laboratory Practice (GLP), Good Manufacturing Practice (GMP), FDA/EPA Regulations, Laboratory Safety, HPLC Instrument Maintenance & Troubleshooting |

This categorical organization makes your skill set instantly digestible. A hiring manager can immediately see that you are not just a technician who operates an HPLC, but a scientist who develops methods, analyzes data with specific software, and operates within a regulated quality framework.

Step 2: Quantify Proficiency and Achievements

For each skill, especially your key techniques, strive to add a layer of quantification. This turns a passive statement of knowledge into an active demonstration of accomplishment. The methodology is to integrate these metrics directly into your bullet points, either in the skills section itself or, more powerfully, within the experience section of your resume.

The table below provides a protocol for translating common laboratory activities into quantified achievements.

| Skill/Activity | Experimental Protocol & Metrics | Quantified Resume Achievement |

|---|---|---|

| Method Development | Develop a new HPLC-UV method for a novel compound. Protocol: Optimize mobile phase composition, column temperature, and flow rate. Metrics: Achieve a resolution >1.5 and a run time under 10 minutes. | "Developed an HPLC-UV method that achieved baseline resolution (Rs>2.0) for a novel API, reducing analysis time by 30%." |

| Method Validation | Validate an analytical procedure per ICH guidelines. Protocol: Determine accuracy, precision, linearity, LOD, and LOQ. Metrics: Demonstrate precision with %RSD <2.0%. | "Validated a GC-MS method for trace impurity analysis, demonstrating high precision (intra-day %RSD <1.5%) in accordance with ICH guidelines." |

| Instrument Management | Perform routine calibration and maintenance on an HPLC system. Protocol: Execute performance qualification (PQ) tests, replace seals, and purge pumps. Metrics: Reduce instrument downtime. | "Managed a fleet of 3 HPLC systems, performing preventative maintenance that reduced unplanned downtime by 25%." |

| Sample Analysis | Conduct high-throughput analysis of stability samples. Protocol: Prepare and analyze 100+ samples per week using a validated UPLC method. Metrics: Maintain a high on-time result delivery rate. | "Analyzed 150+ chemical samples monthly using GC-FID, improving data reporting accuracy by 25%." |

This evidence-based approach is what separates a competent applicant from a standout candidate [22]. It provides tangible proof of your impact in a previous role.

Step 3: Tailor and Contextualize with Keywords

Finally, the content must be dynamically tailored for each job application. Analyze the job description to identify the specific techniques (e.g., GC-MS vs. LC-MS), instruments (e.g., "Agilent GC systems"), and regulatory standards (e.g., "GMP environment") the employer prioritizes [21]. Ensure these keywords are prominently featured in your skills clusters.

Furthermore, context is king. While the skills section is a centralized list, the most powerful way to demonstrate a skill is to describe its application in your "Work Experience" section. For example, a bullet point like "Utilized HPLC" is weak. Instead, write: "Applied HPLC for the purification of reaction mixtures, achieving >95% purity for all final compounds" [20]. This directly links the skill to a valuable scientific outcome.

Essential Research Reagent Solutions for the Chromatographer

A professional's expertise is also defined by their familiarity with essential laboratory materials and instruments. The following table details key components of the chromatographer's toolkit.

| Item | Function in Research & Analysis |

|---|---|

| HPLC/UPLC System | High-/Ultra-Performance Liquid Chromatography instrument for separating, identifying, and quantifying compounds in a liquid mixture [23]. |

| GC-MS | Gas Chromatography-Mass Spectrometry system for separating volatile compounds (GC) and then identifying them based on their mass-to-charge ratio (MS) [21]. |

| C18 Reverse-Phase Column | A widely used stationary phase for HPLC that separates molecules based on their hydrophobicity [23]. |

| Mass Spectrometer Detector | A detector that provides structural and molecular weight information for analyte identification and quantification, often coupled with a chromatograph [21] [24]. |

| Chromeleon/Empower Software | Chromatography Data System (CDS) software for instrument control, data acquisition, and result processing [21]. |

| LIMS (Laboratory Information Management System) | A software-based system for tracking samples, managing associated data, and streamlining laboratory workflows [21]. |

| Standard Reference Materials (SRMs) | Certified materials with known purity and composition used for instrument calibration, method validation, and quality control [23]. |

Workflow for Structuring an Impactful Skills Section

The process of building your skills section can be visualized as a logical workflow that moves from raw data to a tailored, professional presentation. The following diagram maps this process.

By adopting this structured, methodological approach—categorizing for clarity, quantifying for impact, and tailoring for relevance—you will craft a skills section that is not merely a list, but a powerful and convincing argument for your candidacy. It will demonstrate to any hiring manager in drug development or research that you are a precise, results-oriented, and highly skilled scientific professional.

Incorporating Industry Keywords to Pass Applicant Tracking Systems (ATS)

In the contemporary job market, particularly for technical roles in research and drug development, an Applicant Tracking System (ATS) functions as the first and most critical gatekeeper. By 2025, these systems have evolved into an integrated orchestration layer for recruitment, with sophisticated AI that does far more than simple keyword matching. They leverage predictive analytics and machine learning models trained on thousands of successful placements to forecast a candidate's potential success and fit for a specific role [25]. For scientists and researchers, this means a resume is no longer reviewed primarily by a human but is first screened, parsed, and scored by an algorithm. Analysis confirms that 87% of resumes with standard formatting successfully pass initial ATS screening, whereas 73% of creatively formatted resumes (those containing graphics, tables, or multiple columns) are rejected before human review [25]. The strategic inclusion of industry-specific keywords, particularly for a specialized skill set like chromatography, is therefore not an option but a necessity for a successful job search.

Foundational ATS Principles for Scientific Resumes

To effectively communicate with an ATS, a resume must satisfy two distinct filters: the machine and the human recruiter.

- Filter 1: Machine Compatibility: The path to passing the initial automated screening requires strict structural standardization. Utilizing universally recognized section headings (e.g., "Professional Experience," "Education," "Technical Skills") ensures information is correctly categorized and scored by the ATS parser [25]. A clean, single-column layout is essential, as complex formatting with columns, tables, or graphics significantly increases parsing errors. While PDFs are common, the

.docxformat often offers the best compatibility across all major ATS platforms [25]. - Filter 2: Human Engagement: Once the application passes the machine filter, its quality is measured by its impact on the human reviewer. A resume must tell a coherent career story, maintain clear and professional language, and—most importantly—include compelling, quantified achievement statements. Vague bullet points are flagged as low-value by AI analysis, whereas quantified statements instantly communicate the scope and impact of your contributions [26] [25].

The following diagram illustrates the dual-filter process every modern application must navigate.

Chromatography Skills: The ATS Keyword Lexicon

For researchers and drug development professionals, chromatography techniques represent a core competency. An ATS is programmed to scan for these specific technical terms. The following table catalogs the most sought-after chromatography skills and keywords based on recent job postings for analytical chemists, scientists, and laboratory analysts [21] [27] [28].

Table 1: Essential Chromatography Techniques and Associated Keywords for ATS Optimization

| Technique Category | Core Techniques & Acronyms | Associated Methods & Skills | Relevant Software & Tools |

|---|---|---|---|

| Liquid Chromatography | High-Performance Liquid Chromatography (HPLC), Liquid Chromatography-Mass Spectrometry (LC-MS, LC-MS/MS) | Method Development, Analytical Method Validation, Method Transfer, Purification, System Suitability Testing | Empower Software, LabSolutions, ChemStation, OpenLab [21] [28] |

| Gas Chromatography | Gas Chromatography (GC), Gas Chromatography-Mass Spectrometry (GC-MS), GC-FID | Method Development, Method Validation, Qualitative and Quantitative Analysis, Headspace Analysis | ChemStation, LabSolutions [21] |

| General Chromatography | Chromatography, Ion Chromatography, Thin-Layer Chromatography (TLC) | Method Development, Method Validation, Data Analysis, Troubleshooting | N/A |

| Supporting Skills | Good Laboratory Practice (GLP), Good Manufacturing Practice (GMP), Standard Operating Procedure (SOP), ICH Guidelines | Quality Control (QC), Quality Assurance (QA), Compliance, Regulatory Standards, Data Integrity | LIMS (Laboratory Information Management System), Electronic Lab Notebook (ELN) [21] [27] [29] |

Experimental Protocol: A Methodology for Keyword Integration

Merely listing skills in a dedicated section is insufficient. The following protocol provides a detailed methodology for integrating chromatography keywords throughout your resume to maximize ATS compatibility and human readability.

Extract & Analyze (Job Description Deconstruction)

- Objective: Identify the precise terminology used by the employer.

- Procedure: Systematically review the target job description. Highlight all technical skills, instruments, methodologies, and compliance standards mentioned (e.g., "HPLC method development," "GC-MS validation," "GMP environment"). Prioritize these keywords for integration [26].

Distribute & Contextualize (Strategic Keyword Placement)

- Objective: Demonstrate competency by proving keyword usage in a professional context.

- Procedure: Weave the prioritized keywords naturally into the bullet points of your "Professional Experience" section. Avoid "keyword stuffing," which can trigger ATS red flags. Instead, integrate them into descriptions of your responsibilities and, crucially, your achievements [25].

Quantify & Amplify (Achievement Articulation)

- Objective: Transform generic task descriptions into impactful, data-driven statements that both ATS and human recruiters value.

- Procedure: For every chromatography-related task, attach a quantifiable result. Use the Q-M-T (Quantity-Metric-Timeframe) framework:

Table 2: Transformation of Generic Statements into ATS-Optimized, Quantified Achievements

| Generic Statement (Low ATS Score) | ATS-Optimized & Quantified Achievement (High ATS Score) |

|---|---|

| "Responsible for HPLC analysis." | "Developed and validated a novel HPLC method for API, increasing sample throughput by 25% and reducing analysis time by 30%." |

| "Used GC-MS in the lab." | "Utilized GC-MS for complex quantitative analysis, improving the accuracy of results by 15% and supporting root-cause investigations for OOS (Out-of-Specification) results." |

| "Involved in method validation." | "Led the analytical method validation for a new drug product in accordance with ICH guidelines, resulting in a successful FDA submission with zero major deficiencies." |

| "Followed GMP and GLP." | "Maintained strict adherence to GMP/GLP protocols, resulting in a 100% compliance rate during internal and regulatory audits over a 3-year period." |

The Scientist's Toolkit: Essential Resume Reagents

Beyond the specific techniques, an effective scientific resume is constructed from several key components, or "research reagents," that are essential for a successful reaction—in this case, securing an interview.

Table 3: Key "Research Reagent Solutions" for Resume Construction

| Item | Function in the Resume "Experiment" |

|---|---|

| Action Verbs | To initiate a proactive and impactful description of experience. Examples: Spearheaded, Developed, Implemented, Optimized, Validated [30]. |

| Quantitative Data | To act as a catalyst, providing measurable evidence of impact and scope. Examples: percentages, timeframes, volumes, financial figures [26] [25]. |

| Industry Keywords | To serve as the specific substrate, ensuring recognition and a high match score within the ATS. Examples: HPLC, GMP, Method Validation [21] [27] [28]. |

| Compliance Standards | To function as a buffer, establishing a foundation of quality, safety, and regulatory knowledge. Examples: GLP, GMP, ICH Guidelines, OSHA, FDA Regulations [21] [29]. |

| Technical Software | To act as the specialized equipment, demonstrating proficiency with industry-standard data systems and instruments. Examples: Empower, LIMS, ChemStation, Microsoft Office Suite [21] [28]. |

| Benfluorex, (S)- | Benfluorex, (S)-, CAS:1333167-90-0, MF:C19H20F3NO2, MW:351.4 g/mol |

| Rucaparib metabolite M309 | Rucaparib Metabolite M309 |

In the highly competitive fields of research and drug development, passing the ATS is the first critical step in the hiring process. For professionals with chromatography skills, this requires a strategic, systematic approach to resume construction. By understanding the dual-filter system of machine and human review, mastering the ATS lexicon of chromatography keywords, and following an experimental protocol for integrating and quantifying these skills, candidates can significantly increase their chances of success. A resume must be more than a list of duties; it must be a data-rich document that proves competency to an algorithm and tells a compelling story of impact to a human recruiter.

From Theory to Practice: Demonstrating Real-World Chromatography Application

In the competitive fields of research and drug development, technical expertise in chromatography is not enough; professionals must convincingly communicate the value and impact of their work. While many scientists list chromatography as a skill on their resumes, few effectively quantify their achievements to stand out to hiring managers and recruiters. This guide provides a comprehensive framework for using performance metrics, data integrity measures, and quantitative outcomes to transform technical chromatography skills into compelling, evidence-based professional achievements. By adopting the methodologies and metrics used to evaluate chromatographic performance in regulated environments, you can present your skills within a context of quality, precision, and tangible impact that resonates with pharmaceutical and biotechnology employers.

Core Chromatography Performance Metrics: Measurement and Significance

Chromatography system performance is quantitatively assessed using specific metrics that evaluate separation efficiency, peak characteristics, and overall method robustness. Understanding and applying these metrics is fundamental to both analytical work and professional communication.

Key Column Performance Metrics

Chromatography column qualification relies primarily on two calculated parameters that assess packing uniformity and operational efficiency [31]:

Height Equivalent to a Theoretical Plate (HETP): HETP quantifies separation efficiency by correlating theoretical plate height to peak sharpness, with lower values indicating higher column efficiency [31]. HETP is calculated using the relationship:

N = 5.54 × (tᵣ/w₀.₅)² where N is the column plate number, tᵣ is retention time, and w₀.₅ is peak width at half height [31].

HETP = L/N where L is the column length [31].

Asymmetry Factor (Aâ‚›): This metric assesses flow uniformity through a column by measuring peak tailing or fronting [31]. It is determined using the relationship:

Aâ‚› = b/a where a and b are the peak half-widths at 10% of the peak height on the leading and tailing edges, respectively [31].

An optimally packed column typically demonstrates HETP values less than twice the particle diameter and asymmetry factors between 0.8 and 1.8, indicating uniform resin distribution and minimal flow irregularities [31].

Comprehensive LC-MS/MS System Metrics

For liquid chromatography-tandem mass spectrometry systems, performance monitoring expands to include 46 distinct metrics covering chromatographic performance, electrospray source stability, MS1 and MS2 signals, dynamic sampling of ions for MS/MS, and peptide identification [32]. Key metrics from this framework include:

- Chromatographic Peak Width at Half-Height: Median values and interquartile distances (measured in seconds) where sharper peaks and tighter distributions indicate better chromatographic resolution [32].

- Interquartile Retention Time Period: The time period over which 50% of peptides were identified, with longer times indicating better chromatographic separation [32].

- MS1 Signal Stability: Counts of significant signal fluctuations (>10x) between adjacent scans, which flag electrospray ionization instability [32].

These metrics typically display variations less than 10% and can reveal even subtle differences in performance of system components, making them ideal for quantifying improvements in method development and optimization work [32].

Separation Metrics Beyond Resolution

While resolution (Râ‚›) remains a widely accepted metric for separation quality between two peaks, it has limitations including lack of additivity and underestimation of actual peak capacity [33]. Alternative metrics provide more comprehensive assessment:

Peak Capacity (n): Approximates "the maximum number of peaks to be separated on a given column" [33]. For Gaussian peaks, this can be calculated as:

n = ¼ ∫(t₠to t₂) dt/σ where t₠and t₂ are boundaries of the separation space and σ is standard deviation [33].

Separation Measure (S): A proposed unified metric that represents the number of σ-wide subintervals between arbitrary time points t₠and t₂, providing a flexible, additive measure of separation power regardless of peak symmetry [33].

Experimental Protocols: Methodologies for Metric Generation

Column Qualification Protocol

Chromatography column qualification follows a standardized methodology to ensure accurate assessment of packing quality and performance [31]:

- Column Packing: Pack columns according to vendor-recommended procedures to achieve uniform resin distribution.

- System Equilibration: Equilibrate the column with an appropriate buffer until stable baseline is achieved.

- Tracer Injection: Inject a non-binding tracer (e.g., acetone or sodium chloride) to evaluate column performance without binding interactions.

- Data Collection: Record retention time, peak width at half height, and peak asymmetry parameters.

- Metric Calculation: Compute HETP and asymmetry factor using the equations in Section 2.1.

- Acceptance Criteria: Compare calculated values to established thresholds (HETP < 2× particle diameter; asymmetry factor 0.8-1.8).

This methodology ensures robust qualification that can be directly referenced in professional contexts as evidence of technical competency [31].

Data Integrity Assessment Protocol

Regulated laboratories implement systematic data integrity metrics to monitor analytical processes [34]:

- Automated Metric Generation: Implement systems that automatically generate metrics to avoid error-prone manual collection.

- Key Performance Indicators: Focus on critical metrics including invalidated out-of-specification (OOS) rate, data acquisition anomalies, and audit trail reviews.

- Regular Review Cycles: Establish scheduled management reviews of data integrity metrics with defined escalation paths.

- Corrective Actions: Implement CAPAs (Corrective and Preventive Actions) when metrics indicate potential integrity concerns.

The FDA's quality metrics guidance specifically identifies invalidated out-of-specification rate (IOOSR) as a key laboratory metric, defined as the number of OOS test results for lot release and long-term stability testing invalidated divided by the total number of OOS results [34].

LC-MS/MS Performance Monitoring Protocol

Implement comprehensive system performance assessment using the 46-metric framework [32]:

- System Suitability Testing: Perform replicate LC-MS/MS analyses of standard samples under identical conditions.

- Data Processing: Use specialized software to extract metrics directly from raw data files.

- Trend Analysis: Monitor metrics across multiple runs to identify performance drift or suboptimal operation.

- Component-Specific Optimization: Use metric patterns to identify specific system components requiring adjustment (LC system, MS instrument, or software settings).

This protocol enables quantitative assessment of technical improvements and troubleshooting effectiveness [32].

Quantitative Achievement Framework: From Metrics to Resume Statements

Translating technical metrics into professional achievements requires a structured approach that connects specific actions, quantitative outcomes, and business impact.

Table 1: Chromatography Performance Metrics and Professional Achievement Examples

| Metric Category | Specific Metric | Baseline Performance | Improved Performance | Resume Achievement Statement |

|---|---|---|---|---|

| Column Efficiency | HETP | 12 μm (pre-optimization) | 8 μm (post-optimization) | "Reduced HETP by 33% through optimized packing protocols, enhancing separation efficiency for protein purification" |

| Peak Characteristics | Asymmetry Factor | 1.9 (tailing) | 1.1 (symmetric) | "Normalized peak asymmetry from 1.9 to 1.1 by modifying mobile phase composition, reducing tailing and improving quantification accuracy" |

| Method Speed | Analysis Time | 22 minutes | 15 minutes | "Accelerated analytical throughput by 32% through gradient optimization while maintaining resolution >2.0" |

| Data Quality | Invalidated OOS Rate | 5.2% | 1.8% | "Slashed invalidated OOS rate by 65% via enhanced system suitability testing, reducing investigation costs by $45K annually" |

| System Utilization | Peak Capacity | 180 | 240 | "Increased peak capacity by 33% through column chemistry selection, enabling characterization of more complex mixtures" |

Achievement Formulation Methodology

Effective resume statements follow a consistent structure that demonstrates impact:

- Action Verb: Begin with a strong, action-oriented verb (Developed, Optimized, Reduced, Implemented).

- Technical Action: Describe the specific technical intervention or improvement.

- Quantitative Outcome: Include the measurable result with specific metrics.

- Business/Research Impact: Connect the technical outcome to broader organizational goals.

Example: "Implemented a new High-Performance Liquid Chromatography (HPLC) technique, resulting in a 30% overall reduction in sample analysis time while maintaining data quality for regulatory submissions" [21].

Visualization Framework: Chromatography Metric Relationships

Effective communication of technical achievements benefits from clear visual representations of relationships between chromatography concepts and metrics.

Diagram 1: Chromatography Metrics Hierarchy

Diagram 2: Metric-Driven Achievement Workflow

The Scientist's Toolkit: Essential Research Reagent Solutions

Chromatography achievements depend on proper selection and application of specialized materials and software. The table below details key resources referenced in the search results.

Table 2: Essential Chromatography Materials and Software Solutions

| Item Category | Specific Tool/Reagent | Function in Chromatography | Application Context |

|---|---|---|---|

| Qualification Tracers | Acetone / Sodium Chloride | Non-binding tracers for column performance evaluation without binding interactions | Column qualification protocols [31] |

| Data Analysis Software | OpenLab CDS | Provides peak assessment, purity analysis, and visualization tools for chromatographic data interpretation | Routine data analysis in regulated environments [35] |

| Separation Media | HPLC Columns (Various chemistries) | Stationary phases that separate compounds based on chemical properties | Method development and optimization |

| Mass Spectrometry Software | Spectral Libraries (e.g., NIST) | Reference databases for compound identification by mass spectrum matching | LC-MS/MS compound confirmation [35] |

| Regulatory Compliance Tools | Electronic Audit Trail Systems | Automated tracking of data modifications and system access | Data integrity assurance in GMP/GLP environments [34] |

| Einecs 286-867-8 | Einecs 286-867-8, CAS:85392-10-5, MF:C15H24N8S4, MW:444.7 g/mol | Chemical Reagent | Bench Chemicals |

| Estradiol-3b-glucoside | Estradiol-3b-glucoside|High Purity|For Research | Estradiol-3b-glucoside, a key estrogen metabolite. This product is for research use only (RUO) and is not intended for diagnostic or personal use. | Bench Chemicals |

Implementation Strategy: Integrating Metrics into Professional Documentation

Successfully showcasing chromatography achievements requires strategic presentation throughout professional materials.

Resume Integration Techniques

- Skills Section: List specific technical capabilities with associated metrics (e.g., "HPLC Method Development: Reduced analysis time 30% while maintaining resolution >2.0") [21].

- Experience Section: Begin bullet points with action verbs followed by quantitative outcomes (e.g., "Optimized GC-MS method, increasing sample throughput by 40% and reducing detection limits by 50% for target analytes") [23].

- Project Highlights: Include specific metrics in project descriptions to demonstrate technical scope and achievement scale.

Interview Discussion Framework

When discussing chromatography achievements in interviews, apply the STAR (Situation, Task, Action, Result) framework with emphasis on the quantitative Result component:

- Situation: Briefly describe the technical challenge or opportunity.

- Task: State the specific objective or goal.

- Action: Explain the technical interventions implemented.

- Result: Present the quantitative outcomes using specific metrics and connect to broader impact.

Professional Development Planning

- Metric Tracking: Maintain detailed records of method performance improvements, system optimization results, and troubleshooting successes.

- Skill Certification: Pursue recognized certifications in chromatography methodologies and document the quantitative competencies demonstrated.

- Continuous Learning: Stay current with emerging metrics and monitoring approaches, such as the 46 LC-MS/MS performance metrics [32] and data integrity monitoring frameworks [34].

In competitive research and drug development environments, the ability to quantify and effectively communicate technical impact separates exceptional candidates from merely qualified ones. By systematically applying the metrics, methodologies, and communication frameworks presented in this guide, chromatography professionals can transform their technical expertise into compelling evidence of their ability to generate measurable results. The integration of performance metrics, data integrity measures, and quantitative outcomes into professional documentation creates a powerful narrative of competence, precision, and value that resonates with hiring managers and advances research careers.

This guide provides a structured methodology for researchers and drug development professionals to reframe technical chromatography skills as measurable, value-driven accomplishments on a resume. By moving beyond passive task listings to proactive achievement statements, scientists can significantly enhance the impact and visibility of their resumes with both Applicant Tracking Systems (ATS) and hiring managers. The framework integrates action verbs, quantitative metrics, and strategic keyword integration, all contextualized within the broader thesis of optimizing resume presentation for chromatography expertise.

The Imperative for an Action-Oriented Resume

In competitive fields like drug development, a resume must immediately communicate not just capability, but impact. Applicant Tracking Systems (ATS) are calibrated to scan for specific keywords and phrases related to technical skills like High-Performance Liquid Chromatography (HPLC) and Method Development [27] [21]. However, passing an ATS is only the first hurdle; the human reviewer seeks evidence of application and results. A passive list of duties fails to differentiate a candidate, whereas framing experiences as proactive accomplishments demonstrates critical thinking, problem-solving, and direct contribution to organizational goals. This strategic shift is essential for effectively showcasing chromatography research and its role in advancing pharmaceutical projects.

Strategic Framework for Chromatography Skill Articulation

The following section outlines a core methodology for translating technical responsibilities into compelling resume bullet points.

The Anatomy of an Accomplishment Statement

An effective accomplishment statement is built upon three pillars, which work together to create a powerful narrative of your experience:

- Action Verb: The initiator that frames your role as proactive and decisive.

- Quantifiable Metric: The evidence that provides scale, magnitude, and tangible proof of your success.

- Technical Keyword & Context: The specific skill and its application, ensuring ATS compatibility and technical relevance.

This structure transforms a passive task into a proactive achievement. The diagram below illustrates the logical workflow for constructing these statements, from identifying a core skill to articulating a quantified result.

Action Verb Lexicon for Chromatography Professionals

The choice of action verb sets the tone for the accomplishment. The table below categorizes powerful verbs aligned with common chromatography-related activities.

Table 1: Action Verbs for Chromatography Tasks

| Category | Action Verbs | Ideal For... |

|---|---|---|

| Method Development & Optimization | Developed, Engineered, Optimized, Pioneered, Redesigned | Creating new HPLC/LC-MS methods, improving existing protocols, enhancing separation techniques [27]. |

| Analysis & Problem-Solving | Analyzed, Investigated, Diagnosed, Resolved, Troubleshot | Identifying impurities, determining root causes of analytical issues, interpreting complex data [23]. |

| Leadership & Initiative | Spearheaded, Led, Managed, Initiated, Coordinated | Leading a project team, managing method validation studies, coordinating cross-functional testing [36]. |

| Efficiency & Impact | Streamlined, Accelerated, Reduced, Increased, Consolidated | Improving throughput, cutting analysis time, reducing costs or errors, increasing accuracy [27] [37]. |

| Implementation & Compliance | Implemented, Validated, Calibrated, Maintained, Ensured | Bringing new equipment online, executing validation protocols, adhering to GLP/GMP [21] [38]. |

Quantifying Chromatography Accomplishments

Metrics provide objective evidence of your contributions. The following table offers standard and advanced metrics relevant to chromatography work.

Table 2: Metrics for Quantifying Chromatography Impact

| Metric Category | Standard Metrics | Advanced/Strategic Metrics |

|---|---|---|

| Efficiency | - Sample throughput (e.g., "increased by 30%") [27]- Analysis time (e.g., "reduced by 35%") [21]- Turnaround time (e.g., "decreased by 20%") [37] | - Reduction in project timelines (e.g., "by 15%") [27]- Resource savings (e.g., "reduced reagent waste by 10%") [38] |

| Quality & Accuracy | - Data accuracy (e.g., "improved by 20%") [27]- Error rate (e.g., "reduced errors by 25%") [21]- Method robustness (e.g., "improved reproducibility by 15%") [37] | - Compliance (e.g., "reduced non-compliance issues by 80%") [21]- Detection limits (e.g., "lowered detection limit by 50%") [23] |

| Financial & Operational | - Cost savings (e.g., "10% cost improvement") [21]- Equipment utilization (e.g., "reduced downtime by 15%") [38] | - Project/value (e.g., "project valued at $2M") [36]- Team/Scope (e.g., "managed a team of 5 analysts") [21] |

Experimental Protocol for Resume Development

This section provides a detailed, step-by-step methodology for applying the action verb strategy to your resume.

Materials and Reagents

Table 3: Research Reagent Solutions for Resume Development

| Item | Function |

|---|---|

| Master Job Description | The target template; provides keywords, required skills, and context for tailoring application materials [38]. |

| Current Resume Draft | The initial sample containing raw data on experience, skills, and prior roles. |

| Industry-Appropriate Keywords | Critical reagents for ATS reaction; include techniques (HPLC, LC-MS, GC), regulations (GMP, GLP), and processes (Method Validation, Quality Control) [27] [21]. |

| Accomplishment Inventory | A self-compiled list of all projects, achievements, and solved problems from your career. |

Methodology

- Extraction and Analysis: Meticulously review your current resume and professional history. Identify all bullet points that are simple task listings (e.g., "Responsible for HPLC operation").

- Keyword Hybridization: Cross-reference the keywords from your inventory with those found in your target job descriptions. Prioritize the most relevant terms for inclusion [38].

- Synthesis of Accomplishments: For each task-based bullet point, apply the framework from Section 2.1. Select a powerful verb from Table 1 and integrate it with your technical keywords and a quantifiable metric from Table 2.

- Purification and Validation: Scrutinize each new accomplishment statement for clarity, impact, and truthfulness. Ensure metrics are accurate and not exaggerated. Remove any vague or weak language.

Data Analysis and Expected Results

The successful application of this protocol will transform your resume's content. The table below demonstrates the stark contrast between passive task listings and proactive accomplishment statements.

Table 4: Before-and-After Analysis of Resume Statements

| Category | Before: Passive Task Listing | After: Proactive Accomplishment Statement |

|---|---|---|

| Method Development | "Experience with HPLC method development." | "Developed and validated a novel HPLC method, reducing sample analysis time by 30% and improving throughput by 25%." [27] |

| Instrumentation | "Operated and maintained GC-MS systems." | "Troubleshot and resolved recurring GC-MS calibration issues, increasing data accuracy by 15% and reducing instrument downtime by 20%." [21] |

| Compliance & QA | "Followed GLP and GMP in the lab." | "Implemented a new SOP for Analytical Method Validation, ensuring 100% compliance with GLP/GMP and decreasing project timelines by 15%." [27] |

| Team Leadership | "Responsibilities included training junior staff." | "Mentored and trained a team of 5 junior analysts on LC-MS operation and data interpretation, elevating the team's overall compliance and productivity." [27] [36] |