Optimized Extraction and UFLC-DAD Analysis of Carbonyl Compounds: A Comprehensive Guide from Method Development to Validation

This article provides a systematic guide for the extraction and UFLC-DAD analysis of carbonyl compounds, critical analytes in food, environmental, and biomedical research.

Optimized Extraction and UFLC-DAD Analysis of Carbonyl Compounds: A Comprehensive Guide from Method Development to Validation

Abstract

This article provides a systematic guide for the extraction and UFLC-DAD analysis of carbonyl compounds, critical analytes in food, environmental, and biomedical research. It covers foundational principles of carbonyl compound chemistry and the role of derivatization, details a step-by-step optimized extraction procedure, addresses common troubleshooting and optimization challenges, and presents rigorous method validation protocols. By synthesizing recent methodological advances and comparative detection studies, this resource equips researchers and drug development professionals with the knowledge to implement robust, sensitive, and accurate analytical methods for quantifying these biologically significant compounds.

Understanding Carbonyl Compounds and the UFLC-DAD Analysis Framework

The Significance of Carbonyl Compounds in Food Safety and Human Health

Carbonyl compounds, including aldehydes and ketones, are a class of reactive molecules that significantly impact food quality, safety, and human health. They are generated during food processing, cooking, and storage, primarily through lipid peroxidation and the Maillard reaction [1] [2]. Their presence in food is a major concern as many exhibit cytotoxic, mutagenic, and carcinogenic properties [3]. The International Agency for Research on Cancer (IARC) classifies several carbonyls, such as formaldehyde and acetaldehyde, as known human carcinogens (Group 1) [4] [3]. Understanding their formation, analysis, and health effects is crucial for risk assessment and ensuring food safety. This document, framed within research on Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD), provides detailed application notes and protocols for analyzing these critical compounds.

Health Impacts of Carbonyl Compounds in Food

Carbonyl compounds pose health risks through dietary exposure and by forming other hazardous substances in food.

Table 1: Carcinogenicity Classifications of Selected Carbonyl Compounds

| Compound | IARC Classification Group | Carcinogenicity Description |

|---|---|---|

| Formaldehyde | Group 1 | Carcinogenic to humans [3] |

| Acetaldehyde | Group 1 | Carcinogenic to humans [3] |

| Acrolein | Group 2A | Probably carcinogenic to humans [5] |

| Crotonaldehyde | Group 2B | Possibly carcinogenic to humans [5] |

Direct Toxicity and Carcinogenicity

Reactive carbonyls are highly electrophilic and can readily modify DNA and proteins, leading to impaired cellular function [3]. Formaldehyde is a well-known sensory irritant linked to allergies and negative respiratory outcomes, while acetaldehyde can irritate the skin, eyes, and nose [4]. The health risk is particularly elevated for individuals with a genetic variant of the enzyme aldehyde dehydrogenase 2 (ALDH2*2), which has a significantly reduced capacity to metabolize reactive aldehydes [3].

Role as Precursors to Processing Contaminants

Carbonyl compounds are key intermediates in the formation of various toxicants during food processing. Reactive carbonyl species (RCS) can induce the formation of heterocyclic amines, advanced glycation end products (AGEs), acrylamide, and polycyclic aromatic hydrocarbons (PAHs) [2]. For instance, cooking processes like frying and grilling generate large quantities of carbonyls and other harmful products from the thermal degradation of oils and foods [6].

Analytical Methodologies: Extraction and Derivatization

Accurate analysis of carbonyl compounds requires robust extraction and derivatization techniques due to their reactivity and volatility.

Derivatization with DNPH

The most common strategy involves derivatizing carbonyl compounds with 2,4-dinitrophenylhydrazine (DNPH) to form stable 2,4-dinitrophenylhydrazone derivatives. These derivatives are ideal for chromatographic analysis as they enhance detection sensitivity and selectivity [4] [5]. The reaction is widely used in standardized methods for assessing indoor and occupational air quality [4].

Modern Microextraction Techniques

Recent advancements focus on microextraction techniques that minimize solvent use and can be coupled with derivatization.

- Gas-Diffusion Microextraction (GDME): This technique is highly effective for selective extraction of volatile carbonyls from solid and liquid samples. It uses a hydrophobic membrane to separate the sample from an acceptor solution, often containing DNPH, allowing for simultaneous extraction and derivatization [7] [5]. It has been successfully applied to analyze wood-based panels and food products [7].

- Fan-Assisted Extraction: A novel approach based on the full evaporation technique, where a fan inside a closed flask enhances the mass transport of volatiles from the sample to a DNPH-containing acceptor solution. This method has demonstrated high efficiency and minimal matrix effect in complex samples like brewed coffee [8].

- Dispersive Liquid-Liquid Microextraction (DLLME): This method involves dispersing tiny droplets of an extraction solvent in an aqueous sample solution, providing a high surface area for rapid extraction of target analytes [5].

Table 2: Comparison of Microextraction Techniques for Carbonyl Compounds

| Technique | Principle | Key Advantages | Example Application |

|---|---|---|---|

| GDME | Diffusion through a gas phase aided by a membrane | Selective for volatiles, combines extraction/derivatization, low solvent use [7] | Volatile carbonyls in dry-process fibreboard [7] |

| Fan-Assisted Extraction | Convective mass transport in a closed headspace | Rapid (e.g., 10 min), simple setup, minimal matrix effect [8] | Volatile carbonyls in brewed coffee [8] |

| DLLME | Cloudy dispersion of extractant solvent in sample | Fast, high enrichment, low cost [5] | Analysis of various food matrices [5] |

Detailed Experimental Protocols

Protocol 1: GDME for Carbonyl Compounds in Solid Food Samples (e.g., Roasted Coffee)

This protocol is adapted from methods used for roasted coffee beans and fibreboard [8] [7].

Workflow Overview:

Materials and Reagents:

- Samples: Roasted coffee beans, ground to a fine powder.

- Chemicals: DNPH, acetonitrile (HPLC grade), hydrochloric acid, ultrapure water.

- Equipment: GDME apparatus (100 mL flask with PTFE septum and integrated electric fan), PTFE reservoir, heated water bath, HPLC vials, Ultra-Fast Liquid Chromatography system with DAD detector.

- Acceptor Solution: 500 µL of DNPH solution (0.15% w/v) in acetonitrile acidified with HCl [7].

Procedure:

- Sample Preparation: Precisely weigh 0.5 g of ground coffee into the bottom of the clean, dry GDME flask.

- GDME Setup: Place the PTFE reservoir inside the flask. Pipette 500 µL of the acceptor DNPH solution into the cavity of the PTFE reservoir. Ensure no solution spills.

- Extraction/Derivatization: Close the flask tightly with its lid. Place the flask in a water bath set to 45°C. Activate the electric fan and extract for 35 minutes [7].

- Sample Collection: After extraction, carefully open the flask and quantitatively transfer the acceptor solution from the PTFE reservoir to an HPLC vial using a micro-syringe.

- UFLC-DAD Analysis: Inject the sample into the UFLC-DAD system. A suggested C18 column (e.g., 150 mm x 3 mm, 3 µm) with a gradient elution of water/acetonitrile can be used. The DAD should be set to 360 nm for detecting DNPH derivatives [7] [4].

Protocol 2: Fan-Assisted Extraction for Liquid Food Samples (e.g., Brewed Coffee)

This protocol leverages the full evaporation technique for highly efficient analysis of liquid samples [8].

Workflow Overview:

Materials and Reagents:

- Samples: Brewed coffee, filtered.

- Acceptor Solution: 4.0 mmol Lâ»Â¹ DNPH and 1.00 × 10â»âµ mol Lâ»Â¹ 2-nonanone (internal standard) in a 1:1 (v/v) mixture of acetonitrile and 40 mM HCl [8].

- Equipment: Fan-assisted extraction system (as described in [8]), precision micropipettes, HPLC vials.

Procedure:

- Sample Transfer: Pipette 5 µL of the filtered brewed coffee sample directly into the bottom of the extraction flask.

- System Setup: Place a PTFE cylinder inside the flask and add the acceptor solution to its cavity. Close the flask with the fan-equipped lid.

- Extraction: Place the flask in a water bath at 50°C for 10 minutes with the fan operating [8].

- Analysis: After extraction, retrieve the acceptor solution and analyze directly via UFLC-DAD using the chromatographic conditions mentioned in Protocol 1. The use of an internal standard (2-nonanone) corrects for potential instrumental variability.

The Scientist's Toolkit: Key Research Reagents and Materials

Table 3: Essential Reagents and Materials for Carbonyl Compound Analysis

| Item | Function/Description | Application Note |

|---|---|---|

| 2,4-Dinitrophenylhydrazine (DNPH) | Derivatizing agent; reacts with carbonyls to form stable hydrazones detectable by UV and MS [4] [5]. | Purity should be >98%. Acidified solutions are used as acceptor phases in microextraction. |

| DNPH-coated Sorbent Cartridges | Standardized air sampling; derivatizes and traps airborne carbonyls for LC analysis [4]. | Used for ambient or indoor air monitoring in accordance with ISO methods [4]. |

| Acetonitrile (HPLC Grade) | Organic solvent for preparing DNPH solutions, mobile phase in UFLC, and sample dilution. | Ensures low UV background and compatibility with MS detection. |

| C18 Reversed-Phase Column | Stationary phase for chromatographic separation of DNPH-carbonyl derivatives. | A common choice is 150-250 mm length, 3-5 µm particle size, e.g., Acclaim Carbonyl C18 [4]. |

| Stable Isotope-coded DNPH (d₀-/d₃-) | Internal standards for non-targeted carbonylomics; enables accurate quantification and reduces false positives in HRMS [9]. | Critical for advanced research on complex samples like thermally oxidized cooking oils [9]. |

| PTFE Membranes & Septa | Used in GDME and closed-system extraction; provides inert, hydrophobic barriers for gas diffusion and system sealing [7]. | Prevents liquid mixing while allowing volatile carbonyls to pass through. |

| Methyl 3-oxodecanoate | Methyl 3-oxodecanoate|CAS 22348-96-5 | |

| PEG 20 cetostearyl ether | PEG 20 cetostearyl ether, CAS:9004-95-9, MF:C56H114O21, MW:1123.5 g/mol | Chemical Reagent |

Carbonyl compounds represent a critical intersection between food chemistry and public health. Their significance in food safety stems from their inherent toxicity and their role as precursors to a wide range of processing contaminants. The accurate monitoring of these compounds relies on sophisticated analytical methodologies. The protocols and techniques outlined here—particularly those coupling efficient microextraction like GDME and fan-assisted extraction with sensitive UFLC-DAD analysis—provide researchers with powerful tools for surveillance and risk assessment. Future directions will involve the adoption of non-targeted "carbonylomics" approaches using high-resolution mass spectrometry and stable isotope coding to uncover the full spectrum of reactive carbonyl species in our food, ultimately leading to improved safety controls and public health outcomes [9].

Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) represents a significant advancement in analytical separation science, offering enhanced speed, resolution, and detection capabilities compared to conventional High-Performance Liquid Chromatography (HPLC). This sophisticated analytical technique couples the high-separation efficiency of liquid chromatography using columns packed with fine particles (typically sub-2μm fully porous or sub-3μm core-shell particles) with the versatile detection capabilities of a photodiode array detector [10]. The synergy between these components enables researchers to achieve rapid separations without compromising data quality, making UFLC-DAD particularly valuable in applications requiring high-throughput analysis, such as pharmaceutical development, food safety monitoring, and environmental analysis [10] [11].

The fundamental working principle of UFLC-DAD involves two complementary processes: chromatographic separation followed by spectroscopic detection. During the separation phase, analytes are carried by a high-pressure mobile phase through a specialized column containing the stationary phase. Separation occurs based on differential partitioning of compounds between the mobile and stationary phases, with stronger affinity for the stationary phase resulting in longer retention times [11]. The diode array detector then monitors the eluent across a spectrum of wavelengths (typically 190-800 nm), generating three-dimensional data (retention time, absorbance, and wavelength) that provides both qualitative and quantitative information about the separated compounds [11]. This comprehensive detection approach allows for peak purity assessment and spectral library matching, making it indispensable for method development and compound identification in complex matrices.

Core Principles and Technical Foundations

Enhanced Separation Power of UFLC

The separation power of UFLC systems stems from several key technological improvements over conventional HPLC. The most significant advancement involves the use of columns packed with smaller particles (1.7-5 μm) in conjunction with high-pressure pumping systems capable of operating at pressures up to 130 MPa (19,000 PSI) [10] [11]. According to the van Deemter equation, which describes the relationship between linear velocity and plate height, smaller particles provide enhanced efficiency across a wider range of flow rates, resulting in sharper peaks and improved resolution [10]. This relationship allows UFLC systems to maintain separation efficiency while significantly reducing analysis time, enabling 90-120 runs per 8-hour day compared to only 16-24 runs with conventional HPLC [11].

The separation mechanism primarily relies on differential partitioning of analytes between the stationary and mobile phases. In reversed-phase chromatography (the most common mode for UFLC-DAD), the stationary phase is typically non-polar (e.g., C18-bonded silica), while the mobile phase is a polar solvent mixture (e.g., water and acetonitrile or methanol) [11]. Compounds interact with the stationary phase through hydrophobic interactions, with more non-polar compounds exhibiting stronger retention. The introduction of sub-2-micron particles in UFLC columns dramatically increases the surface area for interactions while reducing diffusion paths, resulting in superior separation efficiency [10]. This enhanced efficiency is particularly beneficial when analyzing complex samples containing numerous compounds with similar chemical properties, such as carbonyl derivatives in oxidized oils or pharmaceutical impurities in drug development [12] [13].

Detection Specificity of Diode Array Technology

The diode array detector provides critical detection specificity through its ability to acquire full UV-Vis spectra for each eluting compound during the separation process. Unlike single-wavelength UV detectors that monitor absorbance at a fixed wavelength, DAD systems employ an array of photodiodes (typically 512-1024 elements) to simultaneously measure absorbance across a broad wavelength range [11]. This capability enables the collection of complete spectral profiles for each analyte as it elutes from the column, generating three-dimensional data (retention time, absorbance, and wavelength) that provides a comprehensive chemical fingerprint for compound identification and characterization.

The specificity of DAD detection derives from several key features. Spectral comparison allows analysts to confirm compound identity by matching unknown spectra with reference standards, while peak purity assessment determines whether a chromatographic peak represents a single compound or co-eluting substances by comparing spectra across different regions of the peak [11]. Additionally, the optimal detection wavelength for each analyte can be selected post-acquisition by reviewing the full spectral data, which is particularly valuable during method development. For carbonyl compounds derivatized with DNPH, detection is typically performed at 360 nm, where these derivatives exhibit strong absorption [14] [15]. This multi-wavelength capability makes DAD especially suitable for method development and for analyzing samples with unknown composition, as it provides rich spectroscopic data to support compound identification beyond retention time matching alone.

The analysis of carbonyl compounds (CCs) represents a particularly relevant application of UFLC-DAD technology, especially in food chemistry and environmental science. Carbonyl compounds, including aldehydes and ketones, are generated during the thermal degradation of lipids and are important markers for assessing oil quality and safety [12] [13]. Among these compounds, α,β-unsaturated aldehydes such as 4-hydroxy-2-nonenal (HNE), 4-hydroxy-2-hexenal (HHE), and acrolein have received significant attention due to their biological reactivity and potential toxicity [13]. These compounds can form adducts with biomacromolecules including proteins and DNA, potentially leading to cellular dysfunction and mutagenic effects [13].

The combination of UFLC separation with DAD detection is exceptionally well-suited for carbonyl compound analysis following derivatization with 2,4-dinitrophenylhydrazine (DNPH). This derivatization reaction converts carbonyl compounds into stable hydrazone derivatives that exhibit strong UV absorption and are readily separated by reversed-phase chromatography [13] [14]. The UFLC component provides rapid separation of multiple carbonyl derivatives with similar structures, while the DAD enables specific detection at wavelengths where these derivatives absorb strongly (typically 360 nm) while simultaneously monitoring for potential interferences [14]. This approach has been successfully applied to quantify carbonyl compounds in various matrices, including thermally stressed edible oils, environmental air samples, and biological fluids [12] [13] [14].

Table 1: Key Carbonyl Compounds Analyzed by UFLC-DAD in Thermal Oxidation Studies

| Carbonyl Compound | Abbreviation | Mean Concentration in Heated Soybean Oil (μg/g) | Toxicological Significance |

|---|---|---|---|

| 4-Hydroxy-2-nonenal | HNE | 36.9 | DNA adduct formation, protein modification [12] [13] |

| 2,4-Decadienal | - | 34.8 | Associated with lung and gastrointestinal adenocarcinomas [13] |

| 2,4-Heptadienal | - | 22.6 | Secondary lipid oxidation product [12] |

| 4-Hydroxy-2-hexenal | HHE | Quantified (specific value not reported) | Cytotoxic and genotoxic effects [13] |

| Acrolein | - | Quantified (specific value not reported) | Eye/respiratory irritant, implicated in atherosclerosis and Alzheimer's disease [12] [13] |

Experimental Protocols: Extraction and Analysis of Carbonyl Compounds in Soybean Oil

Sample Preparation and Derivatization

The accurate quantification of carbonyl compounds in complex matrices like edible oils requires careful sample preparation to extract target analytes while minimizing interference from the lipid matrix. For soybean oil analysis, the optimized protocol begins with weighing approximately 1 g of oil sample into a glass vial. The extraction is performed using 1.5 mL of acetonitrile as the extraction solvent, which provides excellent extraction efficiency for carbonyl-DNPH derivatives while maintaining immiscibility with the oil matrix [12] [13]. The mixture is subjected to manual stirring for 3 minutes to ensure thorough contact between the extraction solvent and the oil sample, followed by 30 minutes of sonication to enhance extraction efficiency [12]. The sample is then centrifuged to separate the phases, and the acetonitrile layer containing the extracted carbonyl-DNPH derivatives is carefully collected for analysis.

For carbonyl compound determination, derivatization with 2,4-dinitrophenylhydrazine (DNPH) is typically performed prior to extraction. The derivatization process involves adding an appropriate volume of DNPH solution to the oil sample or standard, allowing the reaction to proceed at room temperature for a specified time [13] [14]. DNPH reacts with carbonyl functional groups to form stable hydrazone derivatives that exhibit strong UV absorption and are more amenable to reversed-phase chromatographic separation than the parent compounds [13]. The derivatives show enhanced detection sensitivity at 360 nm, allowing for quantification at trace levels. For quality control, method validation should include assessment of extraction efficiency using fortified samples, with reported average recoveries ranging from 70.7% to 85.0% at the lowest concentration level and detection limits between 0.03 and 0.1 μg/mL for various carbonyl compounds [12].

UFLC-DAD Analytical Conditions

The chromatographic separation of carbonyl-DNPH derivatives employs specific conditions optimized for resolution and speed. A typical UFLC system is configured with a reversed-phase C18 column (e.g., 2.1 × 100 mm, 1.7-2.1 μm particle size) maintained at a constant temperature (typically 35-40°C) [12] [16]. The mobile phase consists of a binary gradient combining aqueous solvent (water or aqueous buffer) and organic modifier (acetonitrile or methanol). A representative gradient program for carbonyl separation might begin with 40-50% organic phase, increasing to 90-95% over 5-10 minutes, followed by re-equilibration [12] [13]. The flow rate is typically set between 0.2-0.5 mL/min to maintain optimal separation efficiency while operating within system pressure limits [12].

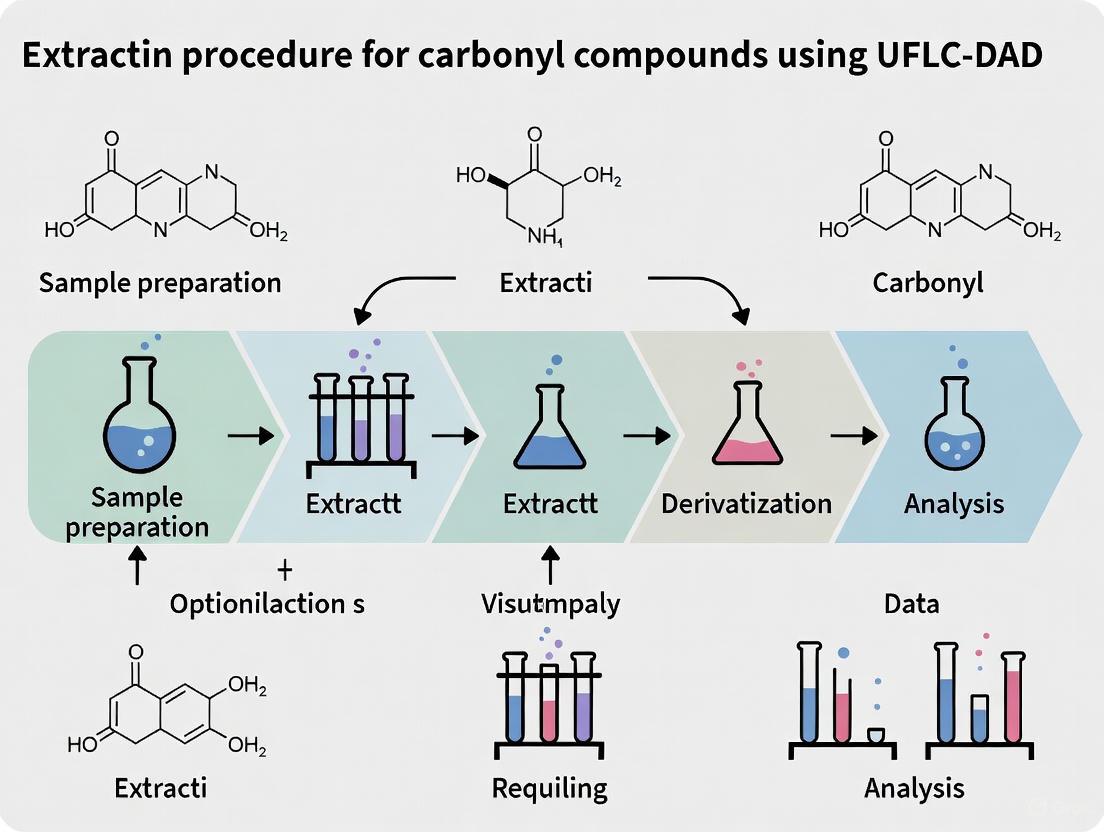

Detection is performed using a diode array detector with the primary monitoring wavelength set at 360 nm for DNPH derivatives, while simultaneously acquiring full spectra (e.g., 190-600 nm) for peak purity assessment and confirmatory identification [14] [17]. The injection volume is typically between 1-10 μL, depending on analyte concentration and detection sensitivity requirements [12] [16]. Under these conditions, target carbonyl compounds including 4-hydroxy-2-nonenal, 2,4-decadienal, 2,4-heptadienal, 4-hydroxy-2-hexenal, and acrolein are successfully separated and quantified in heated soybean oil samples [12]. The complete workflow for carbonyl compound analysis using UFLC-DAD is illustrated in Figure 1.

Figure 1: Workflow for UFLC-DAD Analysis of Carbonyl Compounds in Soybean Oil

Method Validation Parameters

For reliable quantification, the UFLC-DAD method for carbonyl compounds must undergo comprehensive validation to establish key performance characteristics. Linearity is typically demonstrated across concentration ranges relevant to the application (e.g., 0.2-10.0 μg/mL for carbonyl compounds in soybean oil), with correlation coefficients (R²) exceeding 0.995 [12]. Precision is evaluated through both intra-day repeatability (expressed as relative standard deviation, RSD%) and inter-day repeatability, with acceptable values typically below 10% and 16%, respectively [14] [15]. Accuracy is established through recovery studies using spiked samples, with reported average recoveries for carbonyl compounds ranging from 70.7% to 85.0% at the lowest concentration level [12]. The limit of detection (LOD) and limit of quantification (LOQ) for carbonyl compounds in UFLC-DAD analyses have been reported at 0.03-0.1 μg/mL and 0.2 μg/mL, respectively, demonstrating the method's sensitivity for detecting these compounds at trace levels [12].

Table 2: UFLC-DAD Method Validation for Carbonyl Compound Analysis

| Validation Parameter | Experimental Results | Acceptance Criteria |

|---|---|---|

| Linearity | R² = 0.9934-0.999 [12] [17] | R² ≥ 0.990 |

| Precision (Intra-day) | RSD% = 0.7-10 [14] [15] | RSD% ≤ 10 |

| Precision (Inter-day) | RSD% = 5-16 [14] [15] | RSD% ≤ 15 |

| Accuracy (Recovery) | 70.7-105.3% [12] [16] | 70-120% |

| Limit of Detection (LOD) | 0.03-0.1 μg/mL [12] | - |

| Limit of Quantification (LOQ) | 0.2 μg/mL [12] | - |

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful implementation of UFLC-DAD methods for carbonyl compound analysis requires specific reagents and materials optimized for this application. The following table summarizes key components of the research toolkit for this analytical approach.

Table 3: Essential Research Reagent Solutions for Carbonyl Compound Analysis by UFLC-DAD

| Reagent/Material | Specification | Function in Analysis |

|---|---|---|

| 2,4-Dinitrophenylhydrazine (DNPH) | Analytical grade, derivatization reagent [13] [14] | Reacts with carbonyl compounds to form UV-absorbing hydrazone derivatives with enhanced chromatographic properties |

| Acetonitrile | HPLC or UFLC grade, low UV cutoff [12] [13] | Primary extraction solvent and mobile phase component; provides excellent extraction efficiency for carbonyl-DNPH derivatives |

| C18 Chromatographic Column | Sub-2μm particles, 100-150 mm length, 2.1 mm i.d. [12] [16] | Stationary phase for reversed-phase separation of carbonyl-DNPH derivatives; provides high efficiency and resolution |

| Carbonyl-DNPH Standard Solutions | Certified reference materials [14] | Method calibration, quality control, and compound identification through retention time and spectral matching |

| Water | Ultrapure (18.2 MΩ·cm), filtered through 0.20 μm membrane [13] | Mobile phase component; minimizes background interference and system contamination |

| 2-Methylcitric acid trisodium | 2-Methylcitric acid trisodium, MF:C7H7Na3O7, MW:272.10 g/mol | Chemical Reagent |

| Methyl acetylacetate-d3 | Methyl acetylacetate-d3, MF:C5H8O3, MW:119.13 g/mol | Chemical Reagent |

Comparative Analysis: UFLC-DAD Versus Alternative Techniques

When selecting an analytical method for carbonyl compound analysis, understanding the relative advantages and limitations of UFLC-DAD compared to alternative techniques is essential for making informed methodological decisions. UFLC-DAD offers several distinct advantages including universal detection for chromophoric compounds, compatibility with gradient elution, comprehensive spectral information for peak identification and purity assessment, and relatively low operational costs compared to MS-based detection [11]. The technique is particularly well-suited for routine analysis of known carbonyl compounds in quality control laboratories where capital and operational expenses are significant considerations.

However, UFLC-DAD also presents certain limitations that researchers must consider. The technique offers lower sensitivity compared to mass spectrometric detection, with one study reporting successful quantification of only 32% of environmental samples using DAD versus 98% with MS/MS detection [14] [15]. Additionally, DAD provides reduced specificity in complex matrices where co-elution may occur, as it cannot distinguish between compounds with similar spectra but different masses [14]. The dependency on chromophores limits application to compounds with UV-absorbing properties or those that can be derivatized to introduce chromophores [11]. For applications requiring ultimate sensitivity, specificity for trace-level analysis, or identification of unknown compounds, UFLC-MS/MS may be preferable despite higher instrument costs and operational complexity [14] [15]. Similarly, emerging techniques such as supercritical fluid chromatography (SFC) coupled with MS detection offer promising alternatives for carbonyl analysis, with recent studies demonstrating advantages including low solvent consumption and excellent sensitivity for α,β-unsaturated aldehydes in edible oils [18].

Carbonyl compounds, such as aldehydes and ketones, are ubiquitous pollutants and significant oxygenated volatile organic compounds (OVOCs) that play essential roles as precursors and intermediates in photochemical reactions [19]. Accurate measurement of these compounds is critical for atmospheric chemistry studies, occupational health, and drug development. However, their inherent properties—high reactivity, volatility, and polarity—present substantial analytical challenges for direct chromatographic analysis and detection [19]. Derivatization, the chemical modification of compounds to form derivatives with more favorable properties, emerges as an indispensable strategy to overcome these limitations.

This application note details why derivatization is crucial for enhancing detection and chromatography of carbonyl compounds, with specific protocols and data framed within Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) research. The widely adopted derivatization agent 2,4-dinitrophenylhydrazine (DNPH) serves as our primary model, forming stable hydrazone derivatives that significantly improve chromatographic separation, detection sensitivity, and compound stability [20] [14] [21].

The Critical Role of Derivatization

Fundamental Analytical Challenges of Carbonyl Compounds

Carbonyl compounds exhibit a wide range of concentration variability, high reactivity, and instability, with typically short atmospheric lifetimes, placing stringent demands on sampling and analytical techniques [19]. Their high polarity leads to poor retention on reverse-phase chromatographic columns, resulting in co-elution with other polar matrix components and inadequate separation. Furthermore, their volatility causes significant losses during sample concentration steps, while the lack of strong chromophores or fluorophores in many carbonyl compounds renders them virtually invisible to conventional UV-Vis or fluorescence detectors [19] [14]. Without chemical derivatization, accurate quantification of carbonyl compounds at trace levels in complex matrices remains challenging.

How Derivatization Addresses These Challenges

Derivatization with DNPH specifically targets the carbonyl functional group (C=O), forming stable 2,4-dinitrophenylhydrazone derivatives that transform the analytical properties of the original compounds [14]. This reaction significantly increases the molecular weight and hydrophobicity of the derivatives, enhancing their retention on reverse-phase C18 columns and enabling effective separation from interfering matrix components [21]. The introduction of the strong chromophoric 2,4-dinitrophenyl group creates derivatives with high molar absorptivity at around 360 nm, making them highly amenable to UV-DAD detection [14] [22]. Additionally, the hydrazone derivatives exhibit superior stability compared to the parent carbonyl compounds, preventing degradation during sample storage and analysis, which is crucial for obtaining accurate quantitative results [19].

Experimental Protocols: DNPH Derivatization for UFLC-DAD

Reagents and Materials

- Derivatization Reagent: 2,4-Dinitrophenylhydrazine (DNPH), purified by recrystallization [14].

- Sampling Cartridges: Commercially available DNPH-coated silica cartridges (e.g., 270 mg DNPH-coated silica). Dual-bed cartridges containing 130 mg of 1,2-bis(2-pyridyl) ethylene (BPE)-coated silica for ozone scrubbing are recommended for air sampling to prevent ozone interference [14] [4].

- Solvents: Acetonitrile (ACN), HPLC grade. Water, LC-MS grade [14].

- Acid Catalyst: Phosphoric acid or hydrochloric acid for acidifying the derivatization solution to promote the reaction [14].

- Standard Solutions: Carbonyl-DNPH derivative standard mixture (e.g., containing Formaldehyde-DNPH, Acetaldehyde-DNPH, Propionaldehyde-DNPH, etc.) for calibration and identification [14].

Derivatization Procedures

Air Sampling and On-Cartridge Derivatization

This protocol is optimized for workplace and environmental air monitoring [14] [4].

- Cartridge Preparation: Ensure DNPH-coated cartridges are stored in the dark at +4°C before use. Condition if specified by the manufacturer.

- Air Sampling: Connect the cartridge to a calibrated portable sampling pump. The recommended flow rate is 0.14 L/min, with sampling times ranging from 51 to 406 minutes, ensuring the collected carbonyl compounds consume less than 30% of the available DNPH to maintain derivatization efficiency.

- Ozone Removal: When using dual-bed cartridges, the BPE layer effectively scrubs ozone before it can interfere with the DNPH derivatization reaction.

- Post-Sampling Handling: Seal cartridges immediately after sampling and store in the dark at +4°C. Analysis should be performed within two weeks of sampling.

- Extraction of Derivatives: Elute the hydrazone derivatives from the cartridge with 2-3 mL of acetonitrile into a 5 mL volumetric flask. Make up to volume with acetonitrile.

- Filtration: Filter the solution through a 0.22 μm PTFE syringe filter prior to UFLC-DAD analysis.

Liquid-Phase Derivatization for Liquid Samples

For samples in solution (e.g., biological fluids, extracts).

- Reagent Preparation: Dissolve DNPH in acetonitrile acidified with 2-4% phosphoric or hydrochloric acid.

- Derivatization Reaction: Mix the sample solution with the DNPH reagent. A typical molar ratio of DNPH to carbonyl compounds should exceed 10:1 to ensure complete reaction.

- Reaction Conditions: Allow the reaction to proceed for 30-60 minutes at room temperature (25°C) in the dark.

- Dilution and Filtration: Dilute the reaction mixture with the mobile phase to achieve the desired concentration and filter through a 0.22 μm PTFE membrane before injection.

UFLC-DAD Analysis Conditions

The following conditions are adapted from recent methodologies developed for carbonyl-DNPH analysis [14] [21] [22].

- Column: Acclaim Carbonyl C18 RSLC (150 × 3.0 mm, 3 μm) or equivalent C18 column suitable for carbonyl separations.

- Mobile Phase: Isocratic or gradient elution using water (A) and acetonitrile (B).

- Flow Rate: 0.4 - 0.6 mL/min.

- Column Temperature: 30 - 40°C.

- Injection Volume: 10 - 20 μL.

- DAD Detection: 360 nm (primary quantification wavelength); scan from 200-500 nm for peak purity assessment.

The experimental workflow for the analysis of carbonyl compounds via derivatization is summarized below.

Comparative Performance Data

Analytical Performance of DNPH-Derivatization with Different Detection Systems

Table 1: Comparison of LC-UV/DAD and LC-MS/MS methods for determining 12 carbonyl compounds after DNPH derivatization [14].

| Parameter | LC-UV/DAD Method | LC-MS/MS Method |

|---|---|---|

| Linear Range | Not specified | Not specified |

| Linearity (R²) | 0.996 – 0.999 | 0.996 – 0.999 |

| Intra-day Repeatability (RSD%) | 0.7 – 10 | 0.7 – 10 |

| Inter-day Repeatability (RSD%) | 5 – 16 | 5 – 16 |

| Sensitivity (Quantifiable Samples) | 32% of samples | 98% of samples |

| Agreement for Formaldehyde/Acetaldehyde | Good (0.1 – 30% deviation) | Good (0.1 – 30% deviation) |

| Key Advantage | Cost-effective, widely available | High sensitivity and selectivity |

Performance of a Novel Transportable HPLC-UV for Carbonyl Hydrazones

Table 2: Performance characteristics of a transportable HPLC-UV system for the analysis of 13 carbonyl-DNPH derivatives [21] [22].

| Performance Metric | UV Detector | LED Detector |

|---|---|---|

| Limit of Detection (LOD) Range | 0.12 – 0.38 mg Lâ»Â¹ | 0.45 – 1.04 mg Lâ»Â¹ |

| LOD for Formaldehyde-DNPH | < 1 mg Lâ»Â¹ | > 1 mg Lâ»Â¹ |

| Precision (RSD) | < 11.5% | < 14.1% |

| Analysis Time | < 20 minutes (for 11 out of 13 hydrazones) | < 20 minutes |

| Separation Efficiency | Full separation of 11 hydrazones; co-elution of BO-DNPH and BA-DNPH | Same as UV |

| Key Strength | Better sensitivity and precision | Potentially higher robustness |

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key reagents and materials for DNPH derivatization and UFLC-DAD analysis of carbonyl compounds.

| Item | Function / Purpose | Example / Specification |

|---|---|---|

| DNPH-Coated Silica Cartridges | Sampling and simultaneous derivatization of airborne carbonyls. | 270 mg DNPH-coated silica; dual-bed with BPE for ozone removal [14] [4]. |

| DNPH Reagent | Derivatizing agent for carbonyl group, forming hydrazones. | Purified DNPH in acidified acetonitrile [14]. |

| Carbonyl-DNPH Standard Mix | Calibration, identification, and quantification of target analytes. | Certified reference material containing 12+ carbonyl-DNPH derivatives (e.g., Formaldehyde-DNPH to Decanal-DNPH) [14]. |

| Acetonitrile (HPLC Grade) | Mobile phase component; solvent for standard preparation and cartridge elution. | Low UV cutoff, high purity [14] [21]. |

| C18 Analytical Column | Chromatographic separation of hydrazone derivatives. | Reverse-phase, 3-5 µm particle size, 150-250 mm length (e.g., Acclaim Carbonyl C18) [14] [22]. |

| PTFE Syringe Filters | Clarification of final sample solutions before injection. | 0.22 µm pore size, 13 mm diameter [14]. |

| E3 Ligase Ligand-linker Conjugate 54 | E3 Ligase Ligand-linker Conjugate 54, MF:C28H37N5O6, MW:539.6 g/mol | Chemical Reagent |

| 2-Allyl-3-methylpyrazine-d3 | 2-Allyl-3-methylpyrazine-d3, MF:C8H10N2, MW:137.20 g/mol | Chemical Reagent |

Derivatization with DNPH is not merely an optional sample preparation step but a fundamental cornerstone for the reliable analysis of carbonyl compounds by UFLC-DAD. It directly addresses the core analytical challenges posed by these molecules by converting them into derivatives with superior chromatographic behavior, enhanced detection properties, and improved stability. The protocols and data presented herein provide a robust framework for researchers to implement this crucial technique, enabling accurate and sensitive quantification of carbonyl compounds in complex matrices for environmental monitoring, occupational health assessment, and pharmaceutical research.

The analysis of carbonyl compounds is a critical component in environmental, food, and biological research due to their widespread occurrence and significant health implications. Carbonyl compounds, characterized by the presence of an acyl group (R-C=O), including aldehydes and ketones, are prevalent in various samples from airborne particulate matter to biological fluids [20] [23]. Accurate quantification of these compounds is essential as they serve as potential biomarkers for numerous diseases, including diabetes, cardiovascular diseases, neurodegenerative disorders, and cancer [23] [24]. However, the direct analysis of carbonyl compounds using reversed-phase liquid chromatography with diode-array detection (RPLC-DAD) or mass spectrometry (MS) presents substantial challenges due to their poor ionization efficiency, high polarity resulting in inadequate chromatographic retention, and low abundance in complex matrices [24].

To overcome these analytical obstacles, chemical derivatization has emerged as a powerful strategy prior to Ultra-Fast Liquid Chromatography with DAD (UFLC-DAD) analysis. Derivatization enhances detection sensitivity by introducing chromophores or fluorophores that improve UV-Vis absorption characteristics, facilitates better chromatographic separation by reducing polarity, and enables the analysis of thermally unstable compounds that are unsuitable for gas chromatography [24] [25]. Among various derivatizing agents, 2,4-dinitrophenylhydrazine (DNPH) has been historically predominant, but several alternatives have been developed to address specific analytical needs and overcome limitations associated with DNPH [26] [25]. This article provides a comprehensive overview of DNPH and its alternatives, focusing on their application within the context of UFLC-DAD analysis for carbonyl compounds, with detailed protocols for implementation in research settings.

Established Derivatization Agents: Properties and Applications

DNPH (2,4-Dinitrophenylhydrazine)

DNPH remains the most widely used derivatizing agent for carbonyl compounds, with approximately 50% occurrence in published methods according to a literature survey [25]. Its popularity stems from its ability to form stable hydrazone derivatives with both aldehydes and ketones, characterized by strong UV absorption around 360 nm, making it ideal for DAD detection [25] [14]. The DNPH derivatization process involves a nucleophilic addition reaction where the hydrazine group attacks the carbonyl carbon, forming a hydrazone linkage with the elimination of water. The resulting dinitrophenylhydrazone derivatives exhibit enhanced chromophoric properties and improved chromatographic behavior on reversed-phase columns [25].

Despite its widespread use, DNPH methodology faces several challenges. The derivatization kinetics can be slow, particularly for ketones, requiring sufficient time to reach equilibrium [25]. Additionally, the reaction is sensitive to environmental factors such as relative humidity, sampling time, and the presence of interferents like ozone and NO₂, which often necessitates the use of ozone denuders or KI filters during sampling [25]. A recent comparative study highlighted another limitation: while DNPH-based methods showed acceptable linearity (0.996 < R² < 0.999) and repeatability (RSD 0.7-10% intra-day), they demonstrated significantly lower sensitivity compared to MS detection, with only 32% of samples correctly quantifiable by DAD versus 98% by MS/MS [14].

Emerging Alternative Derivatization Agents

While DNPH remains prevalent, several alternative derivatization agents have been developed to address specific analytical needs. The following table summarizes the key characteristics of DNPH and its principal alternatives:

Table 1: Comparison of Derivatization Agents for Carbonyl Compounds

| Derivatization Agent | Abbreviation | Reaction Time | Key Advantages | Detection Methods | Typical Applications |

|---|---|---|---|---|---|

| 2,4-Dinitrophenylhydrazine | DNPH | Slow (up to 24h for some ketones) | Well-established, stable derivatives, strong UV absorption | HPLC-UV/DAD (360 nm) | Air sampling, workplace monitoring [25] [14] |

| O-tert-butylhydroxylamine | TBOX | Fast (shortened reaction time) | Lower MW derivatives, aqueous reactions, faster kinetics | GC/MS, LC-MS | Dicarbonyls, multi-functional compounds [26] |

| 4-Hydrazinobenzoic acid | HBA | Moderate | High water solubility, stable, applicable to HPLC-UV and CE-DAD | HPLC-UV, CE-DAD, LC-MS | Food and beverage analysis, biological fluids [27] |

| Pentalfluorobenzylhydroxylamine | PFBHA | Moderate (faster than DNPH) | Improved volatility for GC, electron-capture properties | GC-ECD, GC-MS | Atmospheric samples, mechanism studies [26] |

| Dansylhydrazine | DNSH | Moderate | Fluorescent detection, high sensitivity | HPLC-FL, LC-MS | Trace analysis, metabolomics [24] |

TBOX represents a significant advancement for analyzing multi-carbonyl compounds, as it generates lower molecular weight oximes compared to DNPH hydrazones, facilitating better separation and detection of complex carbonyl mixtures [26]. This advantage was demonstrated in studies investigating limonene ozonolysis products, where TBOX enabled the detection of 3-acetyl-6-oxoheptanal (3A6O), highlighting the benefit of a smaller molecular weight derivatization agent for multi-carbonyl compounds [26]. HBA has recently gained attention as a derivatizing agent due to its "stability, relatively high solubility in water and other solvents, high selectivity and sensibility, reduced impurities, [and] simple preparation steps" [27]. Its applicability to different separation techniques, including HPLC-UV and CE-DAD, makes it particularly versatile for various analytical scenarios.

Experimental Protocols for Carbonyl Derivatization

Standard DNPH Derivatization Protocol for Liquid Samples

This protocol describes the derivatization of carbonyl compounds in liquid matrices (e.g., water, biological fluids, extracts) using DNPH prior to UFLC-DAD analysis.

Table 2: Reagent Solutions for DNPH Derivatization

| Reagent/Solution | Composition/Preparation | Storage Conditions | Stability |

|---|---|---|---|

| DNPH Derivatization Solution | 2.5 mg/mL DNPH in acetonitrile acidified with 0.1-1% phosphoric acid | Amber vial at 4°C | 1 month |

| Carbonyl-Free Water | Deionized water purified via solid-phase extraction to remove carbonyl impurities | Room temperature | 1 week |

| Calibration Standards | Serial dilutions of target carbonyl-DNPH derivatives in ACN | Amber vial at -20°C | 6 months |

| Mobile Phase A | Water with 0.1% acetic acid or ammonium formate buffer | Room temperature | 1 week |

| Mobile Phase B | Acetonitrile with 0.1% acetic acid or ammonium formate buffer | Room temperature | 1 week |

Procedure:

- Sample Preparation: For liquid samples, filter through a 0.45 μm membrane to remove particulates. For solid samples, perform extraction using carbonyl-free water or acetonitrile via sonication or mechanical shaking.

- Derivatization: Combine 1.0 mL of sample with 1.0 mL of DNPH derivatization solution in a sealed amber vial.

- Reaction Incubation: Heat at 40°C for 60 minutes with occasional vortexing. For ketones or stubborn aldehydes, extend reaction time up to 24 hours at room temperature.

- Quenching and Dilution: Add 2.0 mL of carbonate buffer (pH 8.0) to quench the reaction and adjust to final volume with acetonitrile.

- Chromatographic Analysis: Inject 10-20 μL onto UFLC system with C18 column (e.g., Acclaim Carbonyl C18, 150 × 3 mm, 3 μm) using gradient elution with mobile phases A (water with 0.1% acetic acid) and B (acetonitrile with 0.1% acetic acid). Optimized gradient: 40-95% B over 15 minutes, flow rate 0.4 mL/min.

- Detection: Monitor at 360 nm with DAD. Identify compounds by retention time matching with certified standards and quantify using external calibration curves.

Quality Control:

- Include method blanks (carbonyl-free water processed identically to samples) to monitor contamination.

- Prepare and analyze laboratory control samples with each batch to assess precision and accuracy.

- Check derivatization efficiency by analyzing unreacted DNPH at 360 nm to ensure consumption does not exceed 30% of available reagent [14].

Air Sampling Protocol with DNPH-Coated Cartridges

This protocol describes the active sampling of airborne carbonyl compounds using DNPH-coated cartridges for subsequent UFLC-DAD analysis, particularly relevant for workplace monitoring [14].

Procedure:

- Cartridge Preparation: Use commercial dual-bed sampling cartridges containing 130 mg 2-BPE coated silica (for ozone scrubbing) followed by 270 mg DNPH-coated silica.

- Sampling Setup: Connect cartridge to portable sampling pump (e.g., SKC AirChek TOUCH) with appropriate tubing. Calibrate pump flow rate using a primary flowmeter (e.g., DryCal DC-lite) before and after sampling.

- Air Sampling: Draw air through cartridge at 0.14 L/min for predetermined time (typically 4-8 hours for workplace monitoring). Ensure sampled volume does not consume more than 30% of DNPH coating.

- Sample Extraction: Elute hydrazone derivatives from cartridge with 5 mL acetonitrile into amber volumetric flask.

- Analysis: Inject 10 μL onto UFLC-DAD system using conditions described in Section 3.1.

- Quantification: Calculate airborne concentrations using the formula: Concentration (μg/m³) = (Mass on cartridge [μg] × 1000) / (Sampling rate [L/min] × Time [min])

TBOX Derivatization Protocol for Dicarbonyl Compounds

This protocol describes the use of O-tert-butylhydroxylamine hydrochloride (TBOX) as an alternative derivatization agent, particularly advantageous for dicarbonyl compounds and situations requiring faster reaction times [26].

Procedure:

- Reagent Preparation: Prepare fresh 10 mM TBOX solution in carbonyl-free water.

- Derivatization: Mix 1.0 mL aqueous sample with 1.0 mL TBOX solution in sealed headspace vial.

- Reaction: Incubate at room temperature for 30 minutes (significantly faster than DNPH).

- Analysis: Inject directly onto UFLC system. For GC-MS analysis, extract oxime derivatives with dichloromethane before injection.

- Chromatographic Conditions: Use similar UFLC conditions as for DNPH but optimize gradient for more hydrophilic TBOX-oxime derivatives.

Analytical Workflow and Strategic Implementation

The overall process for carbonyl compound analysis via derivatization and UFLC-DAD follows a systematic workflow:

Carbonyl Analysis Workflow

The Scientist's Toolkit: Essential Research Reagent Solutions

Successful implementation of carbonyl derivatization methods requires careful selection and preparation of research reagents. The following table details essential solutions and materials:

Table 3: Research Reagent Solutions for Carbonyl Derivatization

| Category | Specific Items | Function/Purpose | Considerations for UFLC-DAD |

|---|---|---|---|

| Derivatization Reagents | DNPH, TBOX, HBA, PFBHA | React with carbonyl groups to form detectable derivatives | Select based on target analytes: DNPH for general use, TBOX for dicarbonyls, HBA for hydrophilic aldehydes |

| Chromatographic Columns | Acclaim Carbonyl C18 (150 × 3 mm, 3 µm) | Separation of carbonyl derivatives | Specialized columns enhance resolution of hydrazones/oximes |

| Sampling Media | DNPH-coated silica cartridges with BPE ozone scrubber | Air sampling for workplace monitoring | BPE coating eliminates ozone interference [14] |

| Solvents & Mobile Phases | LC-MS grade acetonitrile, water, acetic acid, ammonium formate | Sample preparation and chromatographic separation | High-purity solvents reduce background interference |

| Calibration Standards | Certified carbonyl-DNPH derivative mixtures | Quantification and method calibration | Commercial standards ensure accuracy for regulated compounds |

| 5-Pentyldihydrofuran-2(3H)-one-d4 | 5-Pentyldihydrofuran-2(3H)-one-d4 | 5-Pentyldihydrofuran-2(3H)-one-d4, a deuterated stable isotope for research. Applications in MS, metabolism, and flavor analysis. For Research Use Only. Not for human use. | Bench Chemicals |

| 3-Dehydroxy Chlorthalidone-D4 | 3-Dehydroxy Chlorthalidone-D4, MF:C14H11ClN2O3S, MW:326.8 g/mol | Chemical Reagent | Bench Chemicals |

The selection of an appropriate derivatizing agent for carbonyl analysis in UFLC-DAD research requires careful consideration of analytical goals, sample matrix, and target compounds. While DNPH remains a robust, well-characterized option for general carbonyl analysis, alternatives like TBOX, HBA, and others offer distinct advantages for specific applications, including faster reaction kinetics, improved sensitivity for dicarbonyls, and enhanced compatibility with various separation techniques. The protocols provided herein offer detailed methodologies for implementing these derivatization strategies in research settings, with particular attention to quality control measures essential for generating reliable data. As analytical demands evolve toward lower detection limits and more complex sample matrices, the continued development and refinement of derivatization agents will remain crucial for advancing carbonyl compound research in environmental, biological, and pharmaceutical contexts.

The accurate analysis of carbonyl compounds is a critical procedure in various scientific fields, including food chemistry, environmental monitoring, and pharmaceutical development. These compounds, such as aldehydes and ketones, are often reactive and present at low concentrations in complex matrices, necessitating robust and sensitive analytical methods. Ultra-Fast Liquid Chromatography (UFLC) coupled with diode-array detection (DAD) and mass spectrometry (MS) has emerged as a powerful technique for the separation, identification, and quantification of these analytes. The core of a successful UFLC-DAD-MS method lies in the careful selection and optimization of the chromatographic system—specifically the solvents, columns, and mobile phase compositions. These components must be compatible with each other, with the detection systems, and with the target carbonyl compounds to ensure optimal extraction, separation, and detection. This application note, framed within a broader thesis on extraction procedures for carbonyl compounds, provides detailed protocols and system compatibility guidelines for researchers, scientists, and drug development professionals engaged in UFLC-DAD research.

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table details key reagents and materials essential for the analysis of carbonyl compounds via UFLC-DAD-MS.

Table 1: Essential Research Reagent Solutions and Materials for Carbonyl Analysis

| Item | Function/Description | Application Note |

|---|---|---|

| Acetonitrile (HPLC Grade) | A common mobile phase component for reversed-phase chromatography; offers low viscosity and high UV transparency [28]. | Preferred for MS detection due to low background noise; excellent for separating basic compounds [28]. |

| Methanol (HPLC Grade) | A polar organic solvent used in mobile phases; strong hydrogen bonding properties enhance separation of polar compounds [28]. | Often used as an extraction solvent; compatible with mass spectrometry [28]. |

| Water (HPLC Grade) | The polar component in reversed-phase mobile phases. | Must be high-purity to minimize baseline noise and interference; often used with buffers for pH control. |

| 2,4-Dinitrophenylhydrazine (DNPH) | A derivatizing agent that reacts with carbonyl compounds to form stable hydrazone derivatives [29] [30]. | Derivatization enhances UV detection sensitivity and improves chromatographic performance of volatile carbonyls [30]. |

| C18 Reversed-Phase Column | A non-polar stationary phase for separating a wide range of organic compounds. | The workhorse column for many carbonyl applications; sub-2 µm particles are used for UHPLC for higher efficiency [29]. |

| Formic Acid / Ammonium Acetate | Mobile phase additives for pH control and buffering. | Volatile buffers are mandatory for LC-MS compatibility to prevent source contamination and ion suppression [28]. |

| Carbonyl Standard Mixtures | Authentic reference materials for method development, calibration, and quantification. | Essential for validating method accuracy, precision, and for identifying compounds in samples [12] [30]. |

| N-Nitroso-N-methyl-N-dodecylamine-d5 | N-Nitroso-N-methyl-N-dodecylamine-d5, MF:C13H28N2O, MW:233.40 g/mol | Chemical Reagent |

| Tetrabromobisphenol A-D6 | Tetrabromobisphenol A-D6, MF:C15H12Br4O2, MW:549.9 g/mol | Chemical Reagent |

System Configuration and Optimization

Mobile Phase Solvent Selection and Pairing

The choice of mobile phase solvents is paramount as it directly influences analyte retention, separation selectivity, and detection compatibility. For reversed-phase chromatography of carbonyl compounds, the primary solvents are water and a water-miscible organic modifier.

- Acetonitrile vs. Methanol: Acetonitrile often is the preferred organic modifier for UFLC-MS applications due to its lower viscosity (reducing system backpressure), higher elution strength in reversed-phase systems, and superior UV transparency at low wavelengths [28]. Methanol, with its stronger hydrogen-bonding properties, can offer different selectivity for polar compounds and is often more cost-effective, but its higher viscosity can result in increased column backpressure [28].

- pH Control and Buffering: For ionizable compounds, mobile phase pH is a critical parameter. The pH should be set at least 1.5 units away from the pKa of the analytes to maintain a consistent ionization state, which ensures reproducible retention times and sharp peak shapes [28]. For MS detection, only volatile buffers such as ammonium formate or ammonium acetate (typically 5-20 mM) should be used. Non-volatile buffers like phosphate can suppress ionization and contaminate the MS source [28].

- Degassing: Mobile phases must be degassed to remove dissolved gases, which can cause baseline noise, pump cavitation, and inconsistent retention times. Helium sparging, vacuum filtration, or using the instrument's built-in degasser are effective methods [28].

Column Selection and Thermodynamics

The analytical column is the heart of the chromatographic separation. For carbonyl compound analysis, a reversed-phase C18 column is most commonly employed.

- Particle Size: Columns packed with sub-2 µm particles are the standard for UHPLC/UFLC systems. They provide higher efficiency, improved resolution, and faster separations under higher operating pressures compared to traditional 3-5 µm particles [29].

- Column Chemistry: While C18 columns are versatile, other stationary phases (e.g., C8, phenyl) can be explored to alter selectivity if C18 does not provide sufficient resolution for critical analyte pairs.

- Temperature Control: Maintaining a stable and optimized column temperature is crucial. Increasing the column temperature can reduce mobile phase viscosity, leading to lower backpressure and faster analysis. A 10°C increase typically reduces retention times by 20-30% and can improve peak shape [28]. Most methods are operated between 30°C and 40°C.

The following diagram illustrates the logical workflow for developing and optimizing a UFLC method for carbonyl analysis.

Application Protocol: Analysis of Carbonyl Compounds in Oils

This protocol is adapted from validated methods for analyzing carbonyl compounds in heated soybean oil and virgin olive oil, detailing the steps from derivatization to quantification [12] [30].

Experimental Workflow

The end-to-end process for sample preparation and analysis is outlined below.

Materials and Reagents

- Samples: Soybean oil, olive oil, or other oil matrices.

- Standard Solutions: Carbonyl compound standards (e.g., hexanal, 2,4-decadienal, 4-hydroxy-2-nonenal, acrolein) and an internal standard (e.g., cyclopentanal) [12] [30].

- Derivatization Reagent: 2,4-Dinitrophenylhydrazine (DNPH) solution.

- Extraction Solvent: HPLC-grade acetonitrile [12].

- Equipment: UFLC system coupled with DAD and ESI-MS, analytical balance, sonicator, centrifuge, vortex mixer, syringe filters (0.22 µm).

Detailed Step-by-Step Procedure

Derivatization (Optional but Recommended):

- For volatile or low-UV-absorbing carbonyls, derivatize the oil sample or standard solution with DNPH to form stable, strongly UV-absorbing hydrazone derivatives [30]. Incubate at room temperature for a specified time (e.g., 60 minutes).

Sample Preparation and Extraction:

- Weigh approximately 1.0 g of oil sample into a glass vial.

- Add 1.5 mL of acetonitrile as the extraction solvent [12].

- Manually stir the mixture vigorously for 3 minutes to ensure thorough mixing and extraction [12].

- Sonicate the mixture for 30 minutes to enhance extraction efficiency [12].

- Centrifuge the sample at high speed (e.g., 10,000 rpm for 10 minutes) to separate phases.

- Filter the supernatant (acetonitrile layer) through a 0.22 µm syringe filter into a clean UFLC vial.

UFLC-DAD-MS Analysis:

- Chromatographic System: UFLC system equipped with a quaternary pump, autosampler, and column oven.

- Column: Reversed-phase C18 column (e.g., 2.1 x 100 mm, 1.9 µm) [29].

- Mobile Phase: Acetonitrile/Water gradient. Example: Start at 5% acetonitrile, ramp to 95% over 13 minutes [29]. For better separation of certain carbonyls, a small percentage of tetrahydrofuran (1-5%) can be added to disrupt π-π interactions [28].

- Flow Rate: 0.8 mL/min [29].

- Column Temperature: 35°C [12].

- Injection Volume: 5-50 µL.

- Detection:

Data Analysis:

- Identify carbonyl compounds by comparing retention times and MS spectra with those of authentic standards.

- Quantify using an external calibration curve or internal standard method.

Method Validation and Performance Data

Robust method validation is required to ensure the reliability of the analytical procedure. The following table summarizes typical validation parameters obtained for carbonyl compound analysis based on the cited literature.

Table 2: Method Validation Data for Carbonyl Compound Analysis by UFLC-DAD-MS

| Validation Parameter | Result / Value | Experimental Details |

|---|---|---|

| Linear Range | 0.2 - 10.0 µg/mL [12] | Calibration curves for spiked soybean oil samples. |

| Correlation Coefficient (R²) | > 0.999 [29] [30] | For carbonyl-DNPH derivatives. |

| Limit of Detection (LOD) | 0.03 - 0.1 µg/mL [12] | In soybean oil. Varies by specific carbonyl compound. |

| Limit of Quantification (LOQ) | 0.2 µg/mL [12] | In soybean oil. |

| Recovery (%) | 70.7% - 115.3% [12] [30] | At the lowest spiked concentration (0.2 µg/mL), recoveries were 70.7-85.0% [12]. |

| Reproducibility (RSD%) | < 7.6% [30] | For retention time and peak area. |

The compatibility of solvents, columns, and mobile phases forms the foundation of a reliable and sensitive UFLC-DAD-MS method for carbonyl compound analysis. This application note has detailed a validated protocol for extracting and analyzing carbonyls in complex oil matrices, demonstrating excellent performance in terms of linearity, sensitivity, and accuracy. The principles of method development and optimization discussed herein—including solvent selection, derivatization, and system configuration—are broadly applicable and can be adapted for the analysis of carbonyl compounds in other complex samples within the scope of pharmaceutical, food, and environmental research. Adherence to these guidelines and rigorous validation will ensure the generation of high-quality, reproducible data essential for advanced scientific research and drug development.

A Step-by-Step Protocol for Carbonyl Compound Extraction and UFLC-DAD Analysis

Within the framework of analytical research utilizing UFLC-DAD, the sample preparation stage is a critical determinant of data quality and reliability. For the analysis of carbonyl compounds—a class of molecules pivotal in food science, environmental monitoring, and pharmaceutical degradation studies—liquid-liquid extraction (LLE) remains a fundamental pre-concentration and clean-up technique. The efficiency of LLE is predominantly governed by the selective partitioning of target analytes between two immiscible phases, a process controlled by precise solvent selection and rigorous optimization of operational parameters. This protocol details a validated method for the extraction of carbonyl compounds from complex matrices, specifically optimized for subsequent identification and quantification via UFLC-DAD-ESI-MS, as employed in thermal oxidation studies of soybean oil [12]. The following sections provide a systematic guide covering theoretical principles, a detailed experimental workflow, and a comprehensive toolkit for researchers.

Theoretical Foundations and Key Parameters

The success of LLE hinges on understanding the physicochemical properties of the target analytes and how they interact with the extraction solvent. The primary goal is to maximize the distribution ratio (D), which is the ratio of the total concentration of a solute in the organic phase to its total concentration in the aqueous phase at equilibrium [31]. For ionizable compounds, the partition coefficient (Log P) and the dissociation constant (pKa) are indispensable for method development.

- Analyte pH Manipulation: The pH of the aqueous sample phase must be controlled to ensure target carbonyl compounds are in their neutral, uncharged form, thereby maximizing their partitioning into the organic solvent. For instance, adjusting the sample solution pH to at least 9.55 ensures a LogD of 1.18 for a model analyte, favoring a 10:1 partition into the organic phase [32].

- Solvent Polarity: The choice of organic solvent should align with the polarity of the target analytes. A solvent with a matching polarity index will yield optimal recovery. For example, dichloromethane (Polarity Index: 3.1) is often suitable for mid-polarity carbonyls like 2-heptenal or 2-octenal [12] [32].

- Back-Extraction for Selectivity: To improve analytical specificity, a back-extraction can be performed. After the initial extraction, the organic phase (containing the neutral target analytes and other neutral interferents) is shaken with a fresh aqueous phase whose pH is adjusted to ionize the target carbonyls. This drives them back into the aqueous phase, leaving many interferents behind in the organic solvent [32].

- Use of Salts: The recovery of hydrophilic analytes can be enhanced by saturating the aqueous phase with salts like sodium sulfate. This "salting-out" effect reduces the solubility of the analytes in the aqueous phase, driving them into the organic extract [32].

Table 1: Optimization Parameters for LLE of Carbonyl Compounds

| Parameter | Objective | Strategic Action | Key Consideration |

|---|---|---|---|

| Sample pH | Maximize neutral species | Adjust aqueous phase pH to ≥2 units above pKa for basic compounds. | For many aldehydes, basic conditions (pH ~9-10) are effective [32]. |

| Extraction Solvent | Maximize partition coefficient (K) | Match solvent polarity to analyte hydrophobicity (LogP) [32]. | Solvents like acetonitrile have been successfully used for carbonyl extraction from oil [12]. |

| Phase Volume Ratio | Maximize analyte mass transfer | Optimize the ratio of organic to aqueous volume; typical is 1:1 to 1:10. | A smaller volume of organic solvent preconcentrates the analyte but can reduce recovery. |

| Salt Addition | Reduce aqueous solubility | Saturate aqueous phase with salts (e.g., NaCl, Naâ‚‚SOâ‚„). | Effective for polar carbonyls; can emulsion formation in some matrices. |

| Number of Extraction Steps | Achieve quantitative recovery | Perform multiple (2-3) sequential extractions with fresh solvent. | The greatest gain is from the first extraction; subsequent steps yield diminishing returns. |

Experimental Protocol: LLE of Carbonyls from Oily Matrices

This protocol is adapted from a validated method for extracting carbonyl compounds from thermally oxidized soybean oil, with recoveries ranging from 70.7% to 85.0% and quantification limits of 0.2 μg mLâ»Â¹ for target analytes [12].

Research Reagent Solutions and Materials

Table 2: Essential Materials and Reagents for LLE

| Item | Specification / Example | Primary Function |

|---|---|---|

| Organic Solvent | Acetonitrile (HPLC grade) | Extraction solvent for mid-to-high polarity carbonyl compounds. |

| Sample Matrix | Soybean oil (heated to 180°C) | Source of target carbonyl analytes (e.g., 4-hydroxy-2-nonenal, 2,4-decadienal) [12]. |

| Derivatization Agent | O-(2,3,4,5,6)-(Pentafluorobenzyl)hydroxylamine (PFBHA) or 2,4-Dinitrophenylhydrazine (DNPH) | Forms stable derivatives with carbonyl groups for improved chromatographic separation and MS detection [33] [8]. |

| Acid/Base for pH Control | Hydrochloric Acid (HCl) or Sodium Hydroxide (NaOH) solutions | Adjusts sample pH to optimize analyte partitioning. |

| Salting-Out Agent | Anhydrous Sodium Sulfate (Naâ‚‚SOâ‚„) | Reduces water content in the organic extract and can aid partitioning. |

| Centrifuge Tubes | Glass, 10-15 mL with PTFE-lined caps | Vessel for LLE, resistant to organic solvents. |

| Ultrasonic Bath | -- | Applies energy to facilitate mass transfer and disrupt the matrix. |

| Centrifuge | -- | Ensures complete and rapid phase separation post-extraction. |

Step-by-Step Procedure

- Sample Preparation: Weigh 1.0 g of the oil sample (e.g., soybean oil heated to 180°C) into a 15 mL glass centrifuge tube.

- Solvent Addition: Add 1.5 mL of acetonitrile to the tube. This solvent has been validated for efficient extraction of carbonyls like acrolein and 4-hydroxy-2-nonenal from oil [12].

- Manual Mixing: Securely cap the tube and mix manually by vigorous shaking or inversion for 3 minutes to ensure intimate contact between the oil and solvent phases.

- Sonication: Place the tube in an ultrasonic bath and sonicate for 30 minutes. This step applies energy to further enhance the extraction efficiency.

- Phase Separation: Centrifuge the tube at 3000 RCF for 5 minutes to achieve clear phase separation. The upper organic (acetonitrile) layer, now containing the extracted carbonyl compounds, is separated from the lower oil layer.

- Concentration (Optional): If necessary, gently evaporate the organic extract under a stream of nitrogen and reconstitute in a smaller volume of a solvent compatible with the UFLC-DAD-MS mobile phase (e.g., acetonitrile) to pre-concentrate the analytes.

- Filtration: Pass the final extract through a 0.22 μm PTFE or nylon syringe filter into a UFLC vial to remove any particulate matter.

The extracted carbonyl compounds are now ready for instrumental analysis. For the UFLC-DAD-ESI-MS method, the identified carbonyls included 4-hydroxy-2-nonenal (36.9 μg gâ»Â¹), 2,4-decadienal (34.8 μg gâ»Â¹), and 2,4-heptadienal (22.6 μg gâ»Â¹) in heated soybean oil samples [12].

Workflow and Signaling Pathways

The following diagram illustrates the logical workflow and decision-making process for developing an optimized LLE protocol, from initial parameter selection to final analysis.

Optimized LLE Development Workflow

The meticulous optimization of liquid-liquid extraction, with a specific focus on solvent selection and efficiency parameters, is a cornerstone for achieving reliable and sensitive quantification of carbonyl compounds in UFLC-DAD research. By systematically applying the principles and protocols outlined herein—leveraging analyte physicochemical properties, strategic pH control, and appropriate solvent systems—researchers can significantly enhance method performance. This structured approach to LLE development ensures robust sample preparation, forming a solid foundation for accurate chromatographic analysis and meaningful data interpretation in complex analytical applications.

The accuracy and sensitivity of Ultra-Fast Liquid Chromatography with Diode-Array Detection (UFLC-DAD) analysis for carbonyl compounds are fundamentally dependent on the efficacy of the initial sample preparation. Extraction parameters, particularly sonication time and stirring, directly influence analyte recovery, reproducibility, and overall method performance. This application note delineates a validated protocol for establishing these critical parameters, providing researchers and drug development professionals with a robust framework for optimizing extraction procedures within UFLC-DAD research workflows. The methodology is contextualized within a broader thesis on developing standardized extraction protocols for carbonyl compounds, which are significant markers of lipid peroxidation in various biological, food, and environmental matrices [5].

Theoretical Background and Significance

Carbonyl compounds, including aldehydes and ketones, are secondary products of lipid peroxidation with significant implications in food quality, consumer health, and oxidative stress biomarkers [5]. Their precise quantification requires efficient extraction from complex matrices. Sonication and stirring are pivotal mechanical aids that enhance extraction efficiency. Sonication utilizes ultrasonic energy to induce cavitation, disrupting cell walls and facilitating the transfer of analytes into the solvent [12]. Stirring promotes constant contact between the sample and solvent, reducing the extraction time by minimizing the static layer around the sample particles and improving mass transfer [8]. Optimizing these parameters is essential for developing a method that is not only efficient but also reproducible and aligned with the principles of green analytical chemistry by potentially reducing solvent consumption [5].

Established Extraction Parameters from Literature

A review of validated methods reveals specific quantitative data for sonication and stirring. The following table summarizes key established parameters from a relevant study for the extraction of carbonyl compounds from an oil matrix.

Table 1: Optimized Extraction Parameters for Carbonyl Compounds from Soybean Oil in UFLC-DAD-ESI-MS Research [12]

| Parameter | Optimized Condition | Experimental Range Assessed | Key Findings |

|---|---|---|---|

| Extraction Solvent | Acetonitrile (1.5 mL) | Not Specified | Provided optimal selectivity and recovery for the target carbonyl compounds. |

| Stirring | Manual Stirring (3 min) | Not Specified | Initial homogenization and facilitated initial analyte-solvent contact. |

| Sonication Time | 30 minutes | Not Specified | Significant impact on extraction efficiency; 30 minutes provided maximum analyte recovery. |

| Overall Recovery | 70.7% to 85.0% (at lowest spike level) | --- | Demonstrates the method's accuracy under optimized stirring and sonication. |

| Quantification Limit | 0.2 µg mLâ»Â¹ for all compounds | --- | Achievable sensitivity with the implemented parameters. |

Detailed Experimental Protocol

This protocol is adapted from a validated method for extracting carbonyl compounds from soybean oil, providing a template for method development in other matrices [12].

Materials and Reagents

- Analytical Standards: Target carbonyl compounds (e.g., 4-hydroxy-2-nonenal, acrolein, 2,4-decadienal).

- Solvent: HPLC-grade acetonitrile.

- Sample: Homogenized sample matrix (e.g., oil, tissue, plant material).

- Equipment: Ultrasonic bath, vortex mixer or magnetic stirrer, calibrated micropipettes, volumetric flasks, UFLC-DAD system.

Step-by-Step Procedure

- Sample Preparation: Precisely weigh 1.0 g of the homogenized sample into a 10 mL glass centrifuge tube.

- Solvent Addition: Add 1.5 mL of HPLC-grade acetonitrile to the tube using a calibrated micropipette [12].

- Initial Stirring: Manually stir the mixture vigorously for 3 minutes to ensure complete homogenization and initial contact between the sample and solvent [12].

- Sonication: Place the tube in an ultrasonic bath and sonicate for 30 minutes at ambient temperature. Ensure the water level in the bath is consistent and the tube is securely positioned for maximum energy transfer.

- Phase Separation: Centrifuge the sample at 5000 rpm for 5 minutes to separate the organic layer from the solid residue.

- Collection: Carefully collect the supernatant acetonitrile layer (extract) using a micropipette.

- Analysis: Filter the extract through a 0.22 µm syringe filter into a vial for subsequent UFLC-DAD analysis.

Optimization Strategy

While the protocol above provides a starting point, method optimization for a new sample matrix is critical.

- Sonication Time: Conduct a univariate experiment by varying sonication time (e.g., 10, 20, 30, 40 minutes) while keeping other parameters constant. Plot the recovery of target analytes against time to identify the plateau region of maximum efficiency [12].

- Stirring Mode and Duration: Compare manual stirring vs. mechanical stirring (e.g., vortex, magnetic stirrer). Evaluate different durations to ensure efficient sample dispersion before sonication.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Reagent Solutions and Materials for Carbonyl Compound Extraction [12] [5]

| Item | Function/Application |

|---|---|

| Acetonitrile (HPLC Grade) | Primary extraction solvent for carbonyl compounds; offers a good balance of polarity and selectivity. |

| 2,4-Dinitrophenylhydrazine (DNPH) | Derivatizing agent for carbonyl compounds, forming stable hydrazone derivatives that enhance chromatographic separation and UV detection. |

| Ultrasonic Bath | Applies ultrasonic energy to disrupt the sample matrix and improve extraction yield. |

| Polytetrafluoroethylene (PTFE) Membranes | Used in microextraction techniques like Gas-Diffusion Microextraction (GDME) for selective isolation of volatile carbonyls from complex matrices. |

| Hydrophobic Membrane (for GDME) | Serves as a barrier in GDME, allowing the passage of volatile carbonyls from the sample to the acceptor solution while excluding non-volatile matrix interferences. |

| (9Z,11Z)-Octadecadienoyl-CoA | (9Z,11Z)-Octadecadienoyl-CoA, MF:C39H66N7O17P3S, MW:1030.0 g/mol |

| 3-Oxo-4(R),8-dimethyl-nonanoyl-CoA | 3-Oxo-4(R),8-dimethyl-nonanoyl-CoA, MF:C32H54N7O18P3S, MW:949.8 g/mol |

Workflow and Parameter Interrelationship

The following diagram illustrates the logical sequence of the extraction process and the critical role of the optimized parameters within the broader analytical workflow.

Concluding Remarks

The meticulous establishment of sonication time and stirring parameters is a cornerstone of a reliable extraction protocol for carbonyl compounds in UFLC-DAD research. The application of the specified conditions—30 minutes of sonication preceded by 3 minutes of manual stirring—has been empirically validated to yield high recovery rates and robust analytical performance. Adherence to this detailed protocol provides a solid foundation for researchers to achieve consistent, accurate, and reproducible results, thereby strengthening the validity of findings in drug development and related scientific fields.