UV-Vis Spectrophotometry in Dissolution Testing: A Modern Guide for Robust and Sustainable Pharmaceutical Analysis

This article provides a comprehensive resource for researchers and drug development professionals on the application of UV-Vis spectrophotometry in dissolution testing.

UV-Vis Spectrophotometry in Dissolution Testing: A Modern Guide for Robust and Sustainable Pharmaceutical Analysis

Abstract

This article provides a comprehensive resource for researchers and drug development professionals on the application of UV-Vis spectrophotometry in dissolution testing. It explores the foundational principles and regulatory framework governing dissolution testing for solid oral dosage forms, detailing the selection of apparatus and media. The content delves into advanced methodological applications, including chemometric techniques for analyzing complex drug mixtures, and addresses common troubleshooting and optimization challenges. Furthermore, it outlines the critical process of method validation against international standards and provides a comparative analysis with HPLC, highlighting the cost-effectiveness, speed, and growing sustainability advantages of modern UV-Vis methods in a quality control environment.

UV-Vis Spectrophotometry Fundamentals and Regulatory Framework for Dissolution Testing

Dissolution testing is an essential analytical procedure in the pharmaceutical sciences, defined as the process in which a substance forms a solution. Specifically, dissolution testing measures the extent and rate of solution formation from a dosage form, such as a tablet, capsule, or ointment, with the terms "dissolution" and "drug release" often used interchangeably [1]. This testing methodology serves as a critical bridge between the physical formulation of a drug product and its biological performance, providing vital insights into drug release characteristics that directly influence bioavailability and therapeutic effectiveness [1] [2].

The integration of UV-Vis spectrophotometry into dissolution testing protocols represents a significant advancement for researchers and drug development professionals seeking robust, efficient analytical techniques. This application note delineates the core principles of dissolution testing, emphasizing its tripartite role in formulation development, quality control (QC), and predicting in-vivo performance, while establishing its relevance within a broader research context focused on UV-Vis spectrophotometric methodologies.

The Fundamental Purposes of Dissolution Testing

Role in Formulation Development

During drug development, dissolution testing functions as a formulation optimization tool that guides scientists in selecting the most appropriate excipients, manufacturing processes, and dosage form designs. It provides critical data on how formulation variables affect the drug release rate, enabling researchers to identify optimal product characteristics prior to clinical evaluation [2] [3]. For poorly soluble Active Pharmaceutical Ingredients (APIs), which represent an increasing proportion of development pipelines, dissolution testing helps classify compounds according to the Developability Classification System (DCS), thereby informing formulation strategy [2]. By employing biorelevant dissolution methods that utilize media such as fasted simulated gastric fluid (FaSSGF) and fasted simulated intestinal fluid (FaSSIF), scientists can predict how a formulation will behave within the human body and ensure only the most promising candidates advance to clinical trials [2].

Function in Quality Control and Assurance

In a commercial manufacturing environment, dissolution testing transitions to a vital quality control tool that ensures batch-to-batch consistency, stability, and overall product quality [1] [2] [3]. The United States Pharmacopeia (USP) and other regulatory bodies mandate dissolution testing as part of the final release investigation for solid oral dosage forms [1] [2]. When employed for QC purposes, the dissolution method must demonstrate adequate discriminatory power to distinguish between acceptable and unacceptable batches, particularly those with meaningful variations in critical manufacturing variables [4]. Establishing and adhering to appropriate dissolution specifications – such as the requirement for immediate-release products to release at least 80% of the drug within a specified time frame (often 45 minutes) – forms the foundation of this quality assurance process [3].

Predicting In-Vivo Performance

Perhaps the most sophisticated application of dissolution testing lies in its ability to predict in-vivo performance and establish in-vitro-in-vivo correlations (IVIVC). For drugs where dissolution represents the rate-limiting step in absorption (particularly Biopharmaceutics Classification System (BCS) Class II and IV compounds and modified-release formulations), dissolution testing can serve as a reliable predictor of bioavailability [5] [6] [3]. Through careful method development that incorporates physiologically relevant conditions, researchers can create biopredictive dissolution methods that correlate with pharmacokinetic data from clinical trials [2]. This application is particularly valuable for generic drug development, where demonstrating similar dissolution profiles to the reference product using discriminatory, biorelevant methods can establish bioequivalence and potentially support biowaiver requests for highly soluble and highly permeable (BCS Class I) drugs [5] [3].

Table 1: Key Applications of Dissolution Testing in the Drug Development Lifecycle

| Development Stage | Primary Purpose | Typical Methods | Key Outcomes |

|---|---|---|---|

| Early Formulation Development | Formulation optimization, API characterization | Biorelevant media (FaSSGF, FaSSIF), USP Apparatus 1 & 2 | DCS classification, optimal formulation selection |

| Clinical Development | In-vivo performance prediction, IVIVC development | Biopredictive media, pharmacokinetic correlation | Bioavailability prediction, formulation refinement |

| Commercial Manufacturing | Quality control, batch release | Compendial methods (USP/FDA), validated QC methods | Batch consistency, stability assessment, specification compliance |

| Post-Approval Changes | Equivalence demonstration | Comparative dissolution profiling | SUPAC compliance, manufacturing change validation |

Experimental Protocols for Dissolution Testing

Standardized Apparatus and Conditions

Dissolution testing employs rigorously standardized apparatus to ensure reproducible and meaningful results. The United States Pharmacopeia describes seven different dissolution apparatuses, with Apparatus I (basket) and Apparatus II (paddle) being most common for solid oral dosage forms [1] [4]. The test conditions are carefully controlled to simulate physiological environments, with dissolution media maintained at 37±0.5°C to correspond to human body temperature [4]. Agitation speeds are standardized according to apparatus type, typically ranging from 50-100 rpm for baskets and 25-75 rpm for paddles, with appropriate speeds determined during method development to ensure discriminatory power without excessive agitation that could cause foaming or lack of discrimination [4].

Dissolution Media Selection

The selection of appropriate dissolution media is paramount to developing a physiologically relevant and discriminatory dissolution method. Key considerations include:

- pH: For weak acids, dissolution rate increases with pH, while for weak bases, dissolution rate increases with decreasing pH. The selected pH should maintain sink conditions and minimize the need for surfactants when possible [4].

- Sink Conditions: Defined as the volume of fluid needed to fully dissolve three times the targeted amount of drug substance in the dosage form, sink conditions ensure the dissolution profile shape is influenced primarily by formulation rather than drug solubility [4].

- Surfactants: When sink conditions cannot be achieved through pH adjustment alone, surfactants such as sodium lauryl sulfate (SLS) may be added to improve solubility, with appropriate selection based on drug substance characteristics (e.g., avoiding anionic surfactants with cationic drugs) [4].

- Buffer Capacity: The selected buffer must maintain constant pH throughout the dissolution test, particularly for ionizable drug substances whose dissolution may alter local pH [4].

Table 2: Dissolution Media Selection Guidelines Based on Drug Properties

| Drug Substance Characteristic | Recommended Media | Additional Considerations |

|---|---|---|

| Highly Soluble (BCS I/III) | Aqueous buffers (pH 1.2, 4.5, 6.8) | Volume: 500-1000 mL; Prioritize physiologically relevant pH |

| Weak Acid | Higher pH buffers (≥pKa) | pH selection should enhance solubility while maintaining physiological relevance |

| Weak Base | Lower pH buffers (≤pKa) | Acidic media (pH 1.2-3.0) typically provide optimal dissolution |

| Poorly Soluble (BCS II/IV) | Surfactant-containing media | Surfactant type and concentration must be justified; non-ionic surfactants often preferred |

| Ionizable | Adequate buffer capacity | Ensure buffer capacity sufficient to prevent pH shift during dissolution |

| Fed/Fasted State Evaluation | Biorelevant media (FaSSIF/FeSSIF) | Requires justification for inclusion in regulatory submissions |

UV-Vis Spectrophotometric Analysis in Dissolution Testing

UV-Vis spectrophotometry provides a rapid, cost-effective analytical finish for dissolution testing, particularly suitable for compounds with distinct chromophores and minimal interference from formulation excipients. The experimental protocol encompasses:

Instrument Calibration and Validation:

- Perform wavelength calibration using appropriate standards (e.g., holmium oxide filter)

- Verify photometric accuracy using potassium dichromate solutions

- Establish linearity across the expected concentration range (typically 0.001-0.1 absorbance units)

- Determine precision through replicate measurements of standard solutions

Sample Analysis Protocol:

- Withdraw dissolution samples at predetermined time points (e.g., 5, 10, 15, 30, 45, 60 minutes for immediate-release products)

- Filter samples immediately using compatible membranes (e.g., 0.45μm PVDF or nylon)

- Dilute samples if necessary to remain within the linear range of the calibration curve

- Measure absorbance at the predetermined λmax for the API

- Calculate concentration using the established calibration curve

- Apply appropriate correction for sample volume removal and media replacement

Case Study: Andrographolide Dispersible Tablets A recent study demonstrated the successful application of UV-Vis spectrophotometry for dissolution testing of andrographolide dispersible tablets. The optimized protocol utilized:

- Apparatus: USP Apparatus II (paddle) at 75 rpm

- Media: 900 mL citrate buffer (pH 3.1)

- Temperature: 37±0.5°C

- Detection: Complexation with Cu(II) and Alizarin Red S reagents at mole ratio 6:1:1.8

- Analysis: UV-Vis detection at 518 nm after 15-minute complexation time The method demonstrated appropriate validation parameters including specificity, linearity, precision, and accuracy, establishing UV-Vis spectrophotometry as a viable alternative to HPLC for this compound [7].

Advanced Applications and Correlation with In-Vivo Performance

In-Vitro In-Vivo Correlations (IVIVC)

The development of meaningful IVIVC represents the pinnacle of dissolution method sophistication, creating a predictive relationship between in-vitro dissolution and in-vivo bioavailability. For BCS Class II and IV drugs and modified-release formulations where dissolution is the rate-limiting step in absorption, dissolution tests are expected to ensure adequate in-vivo product performance [6]. A novel approach to IVIVC development involves estimating in-vivo dissolution profiles through deconvolution using a "synthetic solution method" that incorporates human permeability predictions derived from preclinical models (e.g., Caco-2 cells) [6]. This methodology is particularly valuable when administration of an oral solution is not feasible, allowing researchers to estimate in-vivo dissolution profiles during early development phases and refine dissolution methods to better reflect physiological conditions [6].

Regulatory Applications and Biowaivers

Dissolution testing plays a pivotal role in regulatory decision-making, particularly for generic drug products. The FDA's Biopharmaceutics Classification System (BCS) guidance permits biowaivers for BCS Class I drug products (high solubility, high permeability) that demonstrate rapid dissolution (no less than 85% dissolution within 30 minutes using USP Apparatus 1 at 100 rpm or Apparatus 2 at 50 rpm in 900 mL volume) [5]. For generic products, comparative dissolution testing using at least 12 dosage units each of test and reference products is required across multiple pH conditions (typically pH 1.2, 4.5, and 6.8 buffers) to demonstrate similarity throughout the gastrointestinal transit range [5]. Additionally, dissolution testing provides the scientific foundation for Scale-Up and Post-Approval Changes (SUPAC), where significant alterations to formulation, manufacturing process, or equipment require demonstration of equivalent dissolution profiles to the approved product [5] [3].

The Scientist's Toolkit: Essential Materials and Reagents

Successful dissolution testing requires carefully selected apparatus, reagents, and analytical tools. The following table outlines essential components of a comprehensive dissolution testing laboratory with emphasis on UV-Vis spectrophotometric analysis.

Table 3: Essential Research Reagent Solutions and Materials for Dissolution Testing

| Item | Function/Application | Key Considerations |

|---|---|---|

| USP Apparatus 1 (Basket) | Dissolution testing of tablets, capsules | Standard for floating products; mesh size critical |

| USP Apparatus 2 (Paddle) | Dissolution testing of tablets, capsules | Most common apparatus; sinkers may be needed for floating products |

| UV-Vis Spectrophotometer | Quantitative analysis of drug concentration | Requires appropriate flow cells for automation; validation essential |

| Dissolution Media Buffers | Simulate gastrointestinal environments | pH 1.2 (gastric), 4.5 (jejunal), 6.8 (intestinal); buffer capacity critical |

| Surfactants (SLS, Polysorbates) | Enhance solubility of hydrophobic drugs | Concentration optimization required; potential for foaming |

| Deaeration System | Remove dissolved gases that interfere with dissolution | Vacuum filtration with heating standard; not for surfactant-containing media |

| Membrane Filters (0.45μm) | Clarify samples for spectrophotometric analysis | Compatibility with API (non-adsorbing); minimal extractables |

| Reference Standards | Calibration curve generation | Certified purity; appropriate storage conditions |

| Sinkers | Immerse floating dosage forms | Standardized mesh size and configuration; can affect dissolution rate |

| Amine-PEG-CH2COOH (MW 3400) | Amine-PEG-CH2COOH (MW 3400), CAS:10366-71-9, MF:C4H9NO3, MW:119.12 g/mol | Chemical Reagent |

| MAPTAM | MAPTAM, CAS:147504-94-7, MF:C36H44N2O18, MW:792.7 g/mol | Chemical Reagent |

Workflow and Decision Pathways

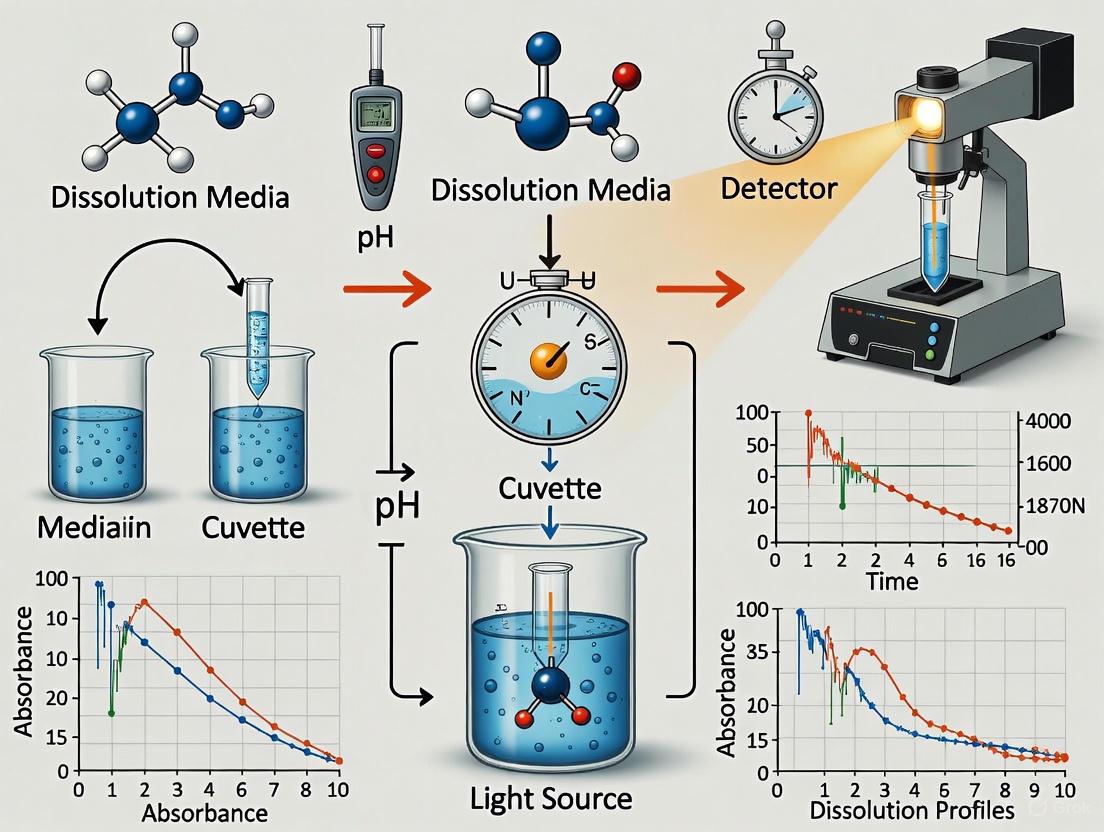

The dissolution testing workflow encompasses method development, validation, and application across the product lifecycle. The following diagram illustrates the integrated relationship between dissolution testing and UV-Vis spectrophotometric analysis:

Dissolution Testing Workflow with UV-Vis Analysis

For regulatory compliance, particularly in generic drug development, a systematic approach to dissolution method selection is required:

Dissolution Method Selection Pathway for Generic Drugs

Dissolution testing serves as an indispensable tool throughout the pharmaceutical development lifecycle, providing critical insights that inform formulation optimization, ensure product quality, and predict biological performance. The integration of UV-Vis spectrophotometric methods enhances the efficiency and accessibility of dissolution analysis while maintaining scientific rigor when appropriately validated. As pharmaceutical scientists face increasing challenges with poorly soluble compounds and complex dosage forms, the continuing evolution of dissolution apparatus, media, and analytical techniques will be essential to maintaining the relevance and predictive power of this fundamental pharmaceutical test. By adhering to standardized methodologies while incorporating advances in biorelevant testing and in-vitro-in-vivo correlation, researchers can fully leverage dissolution testing to develop safe, effective, and reliable pharmaceutical products.

In pharmaceutical development, dissolution testing serves as a critical quality control tool, providing essential data on drug release from solid oral dosage forms. UV-Vis spectrophotometry has formed a natural bond with dissolution testing due to its simplicity, specificity, and cost-effectiveness for quantifying active pharmaceutical ingredient (API) release [8]. This application note examines the current regulatory framework governing dissolution methodology, with specific focus on the application of UV-Vis spectrophotometry within the context of FDA guidance documents and USP standards.

The landscape of dissolution testing is evolving beyond traditional USP Apparatus 1 and 2 methods toward more informative, mechanistic approaches. Advanced spectroscopic imaging techniques now enable researchers to observe dynamic dissolution processes with high spatial and temporal resolution [9]. Among these technologies, UV dissolution imaging has emerged as a powerful tool for visualizing API behavior at the solid-liquid interface while simultaneously obtaining concentration measurements [9] [8]. Understanding the regulatory expectations for method validation and application is paramount for successfully implementing these technologies in drug development.

Current FDA Regulatory Framework and Recent Guidance Documents

The FDA's guidance documents represent the Agency's current thinking on regulatory issues, though they do not establish legally enforceable responsibilities unless they cite specific statutory requirements [10]. The table below summarizes recent FDA guidance documents relevant to pharmaceutical development and analytical method validation:

Table 1: Selected Recently Issued FDA Guidance Documents (2024-2025)

| Topic Area | Guidance Title | Status | Issue Date | Relevance to Dissolution Testing |

|---|---|---|---|---|

| Pharmaceutical Quality | Alternative Tools: Assessing Drug Manufacturing Facilities Identified in Pending Applications | Final | 09/12/2025 | Facility assessment for drug applications |

| Pharmaceutical Quality | Control of Nitrosamine Impurities in Human Drugs | Final | 09/05/2024 | Impurity control in drug products |

| Biopharmaceutics | M13A Bioequivalence for Immediate-Release Solid Oral Dosage Forms | Final | 10/30/2024 | Bioequivalence standards |

| Clinical Pharmacology | Drug Interaction Information in Human Prescription Drug and Biological Product Labeling | Draft | 10/21/2024 | Drug interaction labeling |

| Real World Evidence | Real-World Data: Assessing Electronic Health Records and Medical Claims Data | Final | 07/25/2024 | Use of real-world data |

While these documents provide broad regulatory context, specific analytical method validation for UV-Vis spectrophotometry in dissolution testing falls under the umbrella of ICH guidelines and USP chapters, which establish standardized approaches for method development and validation.

UV-Vis Spectrophotometry in Dissolution Testing: Method Development and Validation

Fundamental Principles and Applications

UV-Vis spectrophotometry operates on the principle that most pharmaceutically active compounds absorb light in the ultraviolet or visible range (190-800 nm) [9]. The absorption occurs when an electron is promoted to a higher energy state by the energy of an incident photon, with the extent of light absorption following the Beer-Lambert law, which establishes a linear relationship between concentration and absorbance at a specific wavelength [9]. This fundamental principle enables quantitative determination of API concentration in dissolution media.

Traditional dissolution testing methodologies have relied on offline UV measurements of withdrawn aliquots, but technological advancements now enable continuous monitoring through fiber-optic UV systems and advanced UV imaging techniques [8]. UV dissolution imaging, sometimes referred to as UV/Vis imaging or surface dissolution imaging, has emerged as a valuable approach for determining intrinsic dissolution rates (IDRs) and understanding API release mechanisms [9].

Method Validation Parameters and Acceptance Criteria

UV-Vis spectrophotometric methods for dissolution testing must be validated according to ICH guidelines to ensure reliability and reproducibility. The following experimental protocol outlines the key validation parameters and procedures:

Table 2: Method Validation Protocol for UV-Vis Spectrophotometric Analysis of APIs in Dissolution Testing

| Validation Parameter | Experimental Procedure | Acceptance Criteria | Example Results (Terbinafine HCl [11]) |

|---|---|---|---|

| Linearity & Range | Prepare standard solutions at 5-30 μg/ml in dissolution medium; measure absorbance at λmax | Correlation coefficient (r²) ≥ 0.999 | r² = 0.999; Range: 5-30 μg/ml |

| Accuracy | Spike pre-analyzed samples with standard at 80%, 100%, 120% levels; calculate recovery | Recovery: 98-102% | Recovery range: 98.54-99.98% |

| Precision (Repeatability) | Analyze six replicates of 20 μg/ml concentration; calculate %RSD | %RSD ≤ 2% | %RSD < 2% |

| Intermediate Precision | Analyze 10, 15, 20 μg/ml solutions on different days by different analysts | %RSD ≤ 2% | %RSD < 2% |

| Specificity | Compare absorbance spectra of pure API vs. formulation in dissolution medium | No interference from excipients | Demonstrated specificity |

| LOD/LOQ | Calculate using LOD = 3.3×N/B and LOQ = 10×N/B, where N=noise, B=slope | LOD: 0.42 μg, LOQ: 1.30 μg | LOD: 0.42 μg, LOQ: 1.30 μg |

The validation protocol for terbinafine hydrochloride analysis demonstrates compliance with ICH guidelines, establishing a robust framework for UV-Vis method validation in dissolution testing [11]. Similar approaches have been successfully applied to other APIs, including oxytetracycline, where methods demonstrated absolute and relative bias within a tolerable interval of [-2%, +2%] with repeatability RSD values lower than 2% [12].

Advanced Applications: UV Dissolution Imaging in Pharmaceutical Development

UV dissolution imaging represents a significant advancement over traditional dissolution testing by providing visualization of the dissolution process at the solid-liquid interface while simultaneously quantifying API concentration [9]. The technology utilizes a flow cell system where a compacted API sample or dosage form portion is mounted and exposed to flowing dissolution medium. A selected wavelength of UV light is directed through the flow cell, and a CMOS array detector captures images of the concentration gradients near the solid-liquid interface [8].

Diagram 1: UV dissolution imaging workflow

Research Applications and Case Studies

UV dissolution imaging has enabled significant advances in multiple areas of pharmaceutical development:

Form Selection and API Characterization: UV imaging allows direct visualization and quantification of dissolution behavior for different solid forms (polymorphs, hydrates, salts) under various hydrodynamic conditions. This capability is particularly valuable for understanding form transformations during dissolution and their impact on dissolution rates [9] [8].

Drug-Excipient Compatibility: The technology enables real-time assessment of excipient effects on API dissolution, including polymer barrier formation, surfactant effects, and disintegration behavior. This application provides crucial insights during formulation development, especially for controlled-release systems [9].

Whole Dosage Form Imaging: With the introduction of larger area imaging systems, UV dissolution imaging can now be applied to entire tablets and capsules. This advancement bridges the gap between intrinsic dissolution studies and conventional dissolution testing of final dosage forms [9].

Case Study: Co-processed API Screening During development of a potent BCS Class II drug, researchers employed UV surface dissolution imaging to screen co-processed API formulations. Samples were prepared by compacting 3-5 mg of co-processed slurry into a sample cup, with dissolution testing in 0.1 N HCl. UV imaging enabled comparison of drug release from formulations with three different carriers (MCC/HPC blend, Neusilin US2, and calcium silicate), providing crucial data for carrier selection based on release profiles and mechanism understanding [8].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Essential Materials and Reagents for UV-Vis Dissolution Method Development and Validation

| Item Category | Specific Examples | Function/Application | Quality/Regulatory Standards |

|---|---|---|---|

| Reference Standards | USP/EP API Reference Standards; Oxytetracycline RS [12] | Method calibration and qualification | Certified purity with documentation |

| Dissolution Media | 0.1N HCl; pH 4.5-7.4 buffer solutions; biorelevant media | Simulating physiological conditions | Prepared per USP specifications |

| Chemical Reagents | Hydrochloric acid; sodium hydroxide; buffer salts | Media preparation and pH adjustment | Analytical grade or higher |

| Quality Control Samples | System suitability samples; validated reference formulations | Method performance verification | Well-characterized and stable |

| UV-Vis Calibration Standards | Holmium oxide; potassium dichromate filter sets | Instrument wavelength verification | Traceable to national standards |

| N-Methyl lactam | N-Methyl lactam, CAS:116212-46-5, MF:C8H8N2O, MW:148.16 g/mol | Chemical Reagent | Bench Chemicals |

| Piazthiole | Piazthiole, CAS:273-13-2, MF:C6H4N2S, MW:136.18 g/mol | Chemical Reagent | Bench Chemicals |

The successful application of UV-Vis spectrophotometry in dissolution testing requires careful navigation of regulatory expectations while leveraging technological advancements. FDA guidance documents establish the current regulatory thinking, while USP standards and ICH guidelines provide the methodological framework for validation and implementation. The emergence of UV dissolution imaging represents a significant innovation that bridges traditional quality control testing with mechanistic understanding of dissolution processes.

As pharmaceutical development continues to evolve toward more predictive and mechanistic approaches, UV-Vis spectrophotometry and its advanced applications will play an increasingly important role in ensuring drug product quality and performance. By integrating regulatory compliance with scientific innovation, researchers can maximize the value of dissolution testing throughout the drug development lifecycle.

Within pharmaceutical development, in vitro dissolution testing is a critical quality control tool that provides vital data on the performance of solid oral dosage forms (OSDs) [13]. The test determines the rate and extent of active pharmaceutical ingredient (API) release from its dosage form, which directly influences bioavailability and therapeutic effectiveness [14]. For researchers employing UV-Vis spectrophotometric methods, selecting the appropriate dissolution apparatus is paramount for generating reliable, reproducible data that can predict in vivo performance. The U.S. Pharmacopeia (USP) describes several dissolution apparatuses, with USP Apparatus 1 (Basket) and USP Apparatus 2 (Paddle) being the most prevalent for OSD testing [15] [4]. This application note provides a detailed comparative analysis of these two apparatuses, supported by structured protocols and data, specifically framed within research utilizing UV-Vis spectrophotometry as the analytical finish.

USP Apparatus 1 and 2 share several core components and operating principles but differ fundamentally in how the dosage form is presented to the dissolution medium. Both systems consist of a set of vessels maintained at 37 ± 0.5 °C to simulate physiological conditions, a metallic drive shaft, and a motor for controlled agitation [15]. The selection between them is a decisive step in method development, as an inappropriate choice can lead to poor discrimination, high variability, and data that does not reflect the product's true performance.

The following table summarizes the fundamental characteristics and recommended applications of each apparatus.

Table 1: Key Characteristics of USP Apparatus 1 and 2

| Feature | USP Apparatus 1 (Basket) | USP Apparatus 2 (Paddle) |

|---|---|---|

| Agitation Mechanism | Rotating cylindrical basket (mesh) | Rotating single-piece paddle |

| Typical Rotation Speed | 50 - 100 rpm [4] | 25 - 75 rpm [4] |

| Ideal Dosage Form Applications | Capsules, floating tablets, chewables, extended-release formulations, encapsulated beads [15] | Immediate-release tablets, suspensions, powder-filled capsules, tablets made by direct compression [15] |

| Key Advantages | Prevents floating dosage forms; contains the sample, minimizing particle escape [15] | Simulates GI hydrodynamics; avoids potential clogging of basket mesh; versatile for many forms [15] |

| Common Challenges | Potential for clogged mesh from gelling excipients; "cone" formation of insoluble excipients below basket [15] [16] | Risk of "coning" (mounding of insoluble excipients under paddle); requires sinkers for floating dosage forms [15] [16] |

The Scientist's Toolkit: Essential Materials for Dissolution Testing

The following table details key reagents and materials essential for conducting dissolution studies, particularly when coupled with UV-Vis spectrophotometric analysis.

Table 2: Essential Research Reagents and Materials for Dissolution Testing

| Item | Function & Importance |

|---|---|

| Dissolution Medium (e.g., 0.1 N HCl, buffers) | Simulates gastrointestinal fluid to provide biologically relevant release data. Composition is critical for maintaining sink conditions [4] [16]. |

| Surfactants (e.g., SLS) | Enhances solubility of poorly soluble drugs in the medium to achieve sink conditions and discriminate formulation changes [4] [17]. |

| Enzymes (e.g., Pepsin) | Added to dissolution medium to digest cross-linked gelatin in capsules that may form during stability studies, ensuring proper drug release [18] [17]. |

| Deaerated Medium | Removal of dissolved air prevents bubble formation on dosage form or apparatus, which can alter hydrodynamic conditions and cause variability [4] [16]. |

| UV-Vis Spectrophotometer | Provides a simple, cost-effective, and replicable analytical finish for quantifying API concentration in dissolution samples [19]. |

| Performance Verification Tablets (e.g., Prednisone) | Certified reference standards used to mechanically and chemically calibrate the dissolution apparatus, ensuring compliance with USP specifications [16] [18]. |

| Qualitative Filter Paper (pore size ~11 µm) | Used in filter compatibility studies to remove undissolved particles from sampled aliquots, preventing ongoing dissolution and analytical interference [19]. |

| Levamlodipine besylate | Levamlodipine besylate, CAS:150566-71-5, MF:C26H31ClN2O8S, MW:567.1 g/mol |

| 1,2-DLPC | Dilaurylphosphatidylcholine (DLPC) |

Integration with UV-Vis Spectrophotometric Analysis

UV-Vis spectrophotometry serves as a widely used analytical technique for quantifying drug release in dissolution testing due to its simplicity, cost-effectiveness, and replicability [19]. The bosutinib case study demonstrates a complete validation using UV-Vis, where the API showed a specified maximum absorbance at 266 nm using a quartz cell and 0.1 N HCl as the dissolution medium and blank [19]. This direct analysis simplifies method development compared to more complex techniques like HPLC.

The workflow for a combined dissolution and UV-Vis method involves several key stages, from apparatus selection to data analysis, as illustrated below.

Detailed Experimental Protocols

Protocol: Apparatus Selection and Mechanical Calibration

Objective: To select the appropriate dissolution apparatus and verify its mechanical and chemical performance prior to analysis.

Apparatus Selection Decision Tree:

- Use USP Apparatus 1 (Basket) if: Testing capsules, dosage forms that tend to float, or modified-release products where physical containment is beneficial [15] [20].

- Use USP Apparatus 2 (Paddle) if: Testing immediate-release tablets, suspensions, or products that may produce fine powders. This apparatus is generally preferred for its simplicity and wider usage for standard tablets [15] [4].

- Sinker Usage: For capsules or tablets that float in Apparatus 2, a few turns of inert, helical wire sinker may be used to hold the dosage form at the bottom of the vessel. The type of sinker must be justified and documented [16].

Mechanical Calibration:

Performance Verification Test (PVT):

- Use USP-certified prednisone or salicylic acid calibrator tablets.

- Execute the PVT according to USP procedures, ensuring the results for geometric mean and %CV fall within the specified acceptance ranges [18] [17].

- All vessels and individual stirring elements (shafts, baskets, paddles) should be uniquely identified and their positions documented for all dissolution runs to facilitate investigation of aberrant results [17].

Protocol: Developing a Validated Dissolution Method with UV-Vis Analysis

Objective: To establish and validate a discriminative dissolution method for an immediate-release tablet using USP Apparatus 2 and UV-Vis spectrophotometry, based on the bosutinib model [19].

Table 3: Exemplary Dissolution Test Conditions and Validation Parameters (Bosutinib Model)

| Parameter | Established Conditions | Validation Results & Acceptance Criteria |

|---|---|---|

| Apparatus | USP Apparatus 2 (Paddle) | - |

| Medium | 900 mL of 0.1 N HCl, deaerated | - |

| Speed | 50 rpm | - |

| Temperature | 37 ± 0.5 °C | - |

| Sampling Times | 10, 15, 20, 30, 45 minutes | - |

| Analytical Method | UV-Vis Spectrophotometry | - |

| Wavelength (λ_max) | 266 nm | - |

| Linearity & Range | 2.8 - 8.3 µg/mL | R² = 0.999 [19] |

| Accuracy (Recovery) | - | Mean = 100.0%; %RSD = 0.8% [19] |

| Repeatability (Precision) | - | Average = 96.2%; %RSD = 1.6% [19] |

| Intermediate Precision | - | Analyst 1: 96.2%, Analyst 2: 91.91%; %RSD = 2.8% [19] |

Dissolution Medium Preparation: Prepare 0.1 N HCl. Deaerate by heating to approximately 41°C, filtering through a 0.45-µm membrane filter under vacuum, with vigorous stirring for a short period, or by sonication [4] [16].

Standard Solution Preparation: Accurately weigh the drug substance working standard. Dissolve and dilute with the dissolution medium to obtain a stock solution. Further dilute to the target concentration within the linear range (e.g., 5.5 µg/mL for bosutinib). Filter a portion through filter paper (pore size ~11 µm) if necessary [19].

Dissolution Test Procedure:

- Place 900 mL of deaerated 0.1 N HCl into each vessel and allow temperature to equilibrate to 37 ± 0.5 °C.

- Carefully drop one tablet into each vessel, ensuring it settles at the base. Immediately start the paddles at 50 rpm and the timer.

- At specified time intervals (e.g., 10, 15, 20, 30, 45 min), withdraw a predetermined volume (e.g., 5-10 mL) from each vessel from a zone midway between the vessel wall and the shaft, not less than 1 cm below the medium surface.

- Immediately replace the withdrawn volume with fresh, pre-warmed medium to maintain a constant volume.

- Filter the samples through a compatible filter (e.g., Whatman qualitative filter paper, ~11 µm).

UV-Vis Spectrophotometric Analysis:

- Use the dissolution medium as the blank.

- Measure the absorbance of the standard and filtered test samples at the λ_max of the API (e.g., 266 nm).

Calculate the percentage of drug dissolved at each time point using the formula below, where Au and As are the absorbances of the test sample and standard solution, respectively; C_s is the concentration of the standard; D is the dilution factor; and L is the label claim of the dosage form.

% Dissolved = (A_u / A_s) * C_s * D * (Media Volume / 1000) * (100 / L)

Method Validation: The dissolution method, including the analytical finish, must be validated as per ICH guidelines [19] [18]. Key parameters are summarized in Table 3.

Data Interpretation and Regulatory Considerations

Interpreting Dissolution Profiles

The percentage of drug dissolved at each time point is plotted to generate a dissolution profile curve. For the bosutinib example, the mean dissolution was 96.20% at 45 minutes, well above the typical tolerance (Q) value of 70% [19]. Key metrics for interpretation include:

- Q Value: The minimum amount of drug dissolved at a specified time, expressed as a percentage of the label claim. It is a key quality control specification for batch release [13].

- Similarity Factor (f2): A statistical tool for comparing two dissolution profiles. An f2 value between 50 and 100 suggests similarity, which is critical for demonstrating bioequivalence or assessing product changes [13].

Critical Regulatory Aspects

Adherence to regulatory guidance from the FDA and USP is non-negotiable [4]. The developed method must demonstrate:

- Discriminatory Power: The ability to detect changes in critical manufacturing variables (e.g., ±10-20% change in excipient ranges). Altered batches should have an f2 value of <50 compared to the clinical batch [4].

- Robustness: The method's reliability should be proven when deliberate small changes are made to parameters like wavelength (±2 nm) [19].

- Stability-Indicating Property: For gelatin capsules, if cross-linking is observed during stability studies, the dissolution test should be performed with the addition of an appropriate enzyme (e.g., pepsin) to the medium [18] [17].

In the development of a UV-Vis spectrophotometric method for dissolution testing, the design of the dissolution medium is a critical determinant of the method's predictive power and reliability. The medium must not only facilitate the accurate quantification of drug release but also serve as a meaningful surrogate for the physiological environment the drug product will encounter in vivo. This application note details the strategic formulation of the dissolution medium, focusing on the interplay of three pivotal factors: pH, sink conditions, and buffer capacity. A scientifically robust medium ensures that the dissolution test is a discriminatory tool, capable of detecting critical changes in formulation and manufacturing processes, thereby supporting quality control and biopharmaceutical assessments [21] [5].

Critical Factor 1: pH of the Dissolution Medium

Physiological and Chemical Rationale

The pH of the dissolution medium is paramount as it directly influences the drug's solubility and dissolution rate, particularly for ionizable compounds. The gastrointestinal (GI) tract exhibits a dynamic pH range, from highly acidic in the fasted stomach (pH ~1.2–3.0) to near-neutral in the small intestine (pH > 6.0) [22]. A dissolution method intended to be predictive of in vivo performance must account for this variability. For instance, a recent study on diclofenac sodium (an acidic drug, pKa 4.0) demonstrated that small differences in acidic pH conditions (e.g., between pH 1.2 and 2.0) can cause significant variations in dissolution profiles and the supersaturation behavior of drug products, despite the pH being well below the API's pKa [22]. This finding challenges the assumption that a single, highly acidic pH condition is sufficient for dissolution testing of acidic drug salts and underscores the need for a more nuanced approach.

Strategic Selection of pH

The selection of pH should be guided by the drug's pKa and its Biopharmaceutics Classification System (BCS) category. A multimedia approach is often necessary to fully characterize the drug product.

- For BCS Class II Weak Acids: Testing in neutral to alkaline media (e.g., pH 6.8 phosphate buffer) is often most discriminatory, as it promotes ionization and dissolution, helping to differentiate between formulations based on their dissolution rates [21].

- For BCS Class II Weak Bases: Testing in acidic media (e.g., 0.1N HCl, pH 1.2) is critical to ensure adequate solubility and to identify potential dissolution-rate limited absorption.

- For Enteric-Coated (Delayed-Release) Products: A sequential pH method is mandatory. This involves exposing the product to an acidic medium (e.g., pH 1.2 for 2 hours) to demonstrate acid resistance, followed by transfer to a neutral buffer (e.g., pH 6.8) to assess drug release in simulated intestinal conditions [5].

Table 1: Recommended pH Conditions for Dissolution Testing Based on Drug Properties

| Drug Substance Property | Recommended Dissolution Media (pH) | Scientific Rationale |

|---|---|---|

| Weak Acid (pKa 3-5) | pH 1.2, pH 4.5, pH 6.8 | To assess dissolution across the physiological range; small differences in acidic pH can be critical for salt forms [22]. |

| Weak Base (pKa 6-8) | pH 1.2, pH 4.5, pH 6.8 | To ensure solubility in gastric conditions and assess precipitation risk upon entry into the intestine. |

| Immediate-Release (BCS II) | pH 6.8 Phosphate Buffer | Often provides the most discriminatory power for poorly soluble drugs [21]. |

| Delayed-Release | pH 1.2 (2 hrs) → pH 6.8 | To confirm gastric resistance and subsequent release in the intestine [5]. |

Critical Factor 2: Sink Conditions

Definition and Importance

Sink condition is a fundamental principle in dissolution testing, defined as the ability of the dissolution medium to dissolve at least three times the amount of drug present in the dosage form [23]. Maintaining sink conditions is vital for ensuring robustness and biological relevance. In vivo, the continuous absorption of a drug across the intestinal membrane prevents the dissolved drug from accumulating and saturating the GI fluids. In an in vitro test, a lack of sink conditions leads to an artificially reduced dissolution rate as the concentration in the vessel approaches saturation (Cs), violating the (Cs - Ct) term in the Noyes-Whitney equation [23]. This can mask true differences between formulations and reduce the method's ability to predict in vivo performance, especially for controlled-release formulations of poorly soluble drugs [24].

Achieving and Maintaining Sink Conditions

When the saturation solubility of the drug in a simple aqueous medium is insufficient, several strategies can be employed to achieve sink conditions, each with its own considerations:

- pH Adjustment: For ionizable compounds, setting the pH to ensure the drug is in its ionized form is the most physiologically relevant method to enhance solubility.

- Addition of Surfactants: Surfactants like sodium lauryl sulfate (SLS) can solubilize poorly soluble drugs via micelle formation. While effective, the type and concentration must be justified, as they can sometimes over-solubilize and lose discriminatory power [23] [5].

- Increased Volume: The use of larger volume vessels (e.g., 2-liter) is a direct way to increase the capacity of the medium, though it may deviate from physiological volumes [23].

- Use of Biorelevant Media: Incorporating surfactants and bile salts at concentrations mimicking human intestinal fluids can create sink conditions while maintaining physiological relevance.

Table 2: Strategies to Achieve Sink Conditions for Poorly Soluble Drugs

| Strategy | Typical Implementation | Advantages | Limitations / Considerations |

|---|---|---|---|

| pH Adjustment | Use of buffers at a pH where the drug is ionized. | Physiologically relevant; simple. | Only applicable to ionizable compounds. |

| Surfactants | Addition of SLS, Tween, CTAB, or Triton X. | Highly effective for many hydrophobic drugs. | Can be overly aggressive; may reduce method discrimination; requires validation. |

| Increased Volume | Using a 2-liter vessel instead of the standard 1-liter. | Simple and direct increase in solvent capacity. | Not physiologically representative. |

| Biorelevant Media | Use of media containing bile salts and phospholipids. | Enhances predictability for in vivo performance (IVIVC). | Can be complex and costly to prepare. |

Critical Factor 3: Buffer Capacity

Role in Dissolution Testing

Buffer capacity, defined as the resistance of a solution to pH change upon addition of an acid or base, is a critical yet often overlooked parameter. A dissolution medium with sufficient buffer capacity maintains a stable pH throughout the test, which is essential for obtaining consistent and reproducible dissolution profiles. This is particularly important for APIs or excipients that are inherently acidic or basic, as they can locally alter the pH at the solid-liquid interface (the diffusion layer), thereby affecting the dissolution rate. A medium with low buffer capacity can experience significant pH shifts, leading to unpredictable dissolution behavior that does not reflect the drug's performance in vivo.

Designing Media with Robust Buffer Capacity

The buffer capacity (β) of a medium is determined by the concentration and pKa of the buffering species. For a monoprotic acid, the approximate buffer capacity is given by β = 2.3 * C * (Ka [H+] / (Ka + [H+])^2), where C is the total buffer concentration. To ensure robustness:

- Use Adequate Buffer Molarity: Higher concentrations of the buffering species provide greater resistance to pH change. A common practice is to use buffer concentrations between 0.05 M and 0.1 M.

- Match Buffer pKa to Target pH: The most effective buffering occurs when the pKa of the buffer is within ±1 unit of the desired medium pH.

- Consider Ionic Strength: The ionic strength of the medium, which can vary with food intake (e.g., higher in the fed state), can influence drug solubility and polymer behavior. As demonstrated in a 2023 study, changes in ionic strength (from 0.2 M to 0.4 M) can significantly alter the dissolution efficiency of formulations, particularly those containing hydrophilic polymers like HPC [25]. Therefore, controlling ionic strength is part of designing a medium with consistent performance.

Integrated Experimental Protocols

Protocol: Development of a Discriminatory Dissolution Method for an Immediate-Release Tablet

Objective: To develop and validate a discriminatory dissolution method for a BCS Class II drug (weak base) tablet using UV-Vis spectrophotometry.

Materials:

- Apparatus: USP Apparatus II (Paddle), UV-Vis spectrophotometer with flow-through cells or fiber optic probes.

- Reagents: Hydrochloric acid, potassium dihydrogen phosphate, sodium hydroxide, surfactants (e.g., SLS).

- Chemicals: The following reagents are essential for this protocol [21]:

- Hydrochloric Acid (HCl): Used to prepare 0.1N HCl and simulate gastric pH.

- Potassium Dihydrogen Phosphate (KHâ‚‚POâ‚„): The primary buffering agent for pH 6.8 phosphate buffer.

- Sodium Hydroxide (NaOH): Used to adjust the pH of the phosphate buffer to 6.8.

- Sodium Lauryl Sulfate (SLS): A surfactant used to achieve sink conditions for poorly soluble drugs.

Procedure:

- Solubility Profiling:

- Determine the saturation solubility of the API in a range of media: 0.1N HCl (pH ~1.2), acetate buffer (pH 4.5), and phosphate buffer (pH 6.8). Shake an excess of API in each medium for 24 hours at 37°C, filter, and analyze the concentration using UV-Vis [21].

- Sink Condition Assessment:

- Calculate the required volume for sink condition (3x the dose solubility). If the standard 900 mL volume does not provide sink, consider strategies from Table 2, such as adding a justified concentration of SLS.

- Preliminary Method Scouting:

- Perform dissolution tests on the reference listed drug (RLD) using 900 mL of each medium from step 1. Use Apparatus II at 50 and 75 rpm. Withdraw samples at 5, 10, 15, 30, 45, and 60 minutes, filter, and analyze by UV-Vis.

- Buffer Capacity and Ionic Strength Confirmation:

- For the selected medium, confirm its buffer capacity by adding a small volume of 1N HCl or NaOH to the medium at 37°C and measuring the pH change. A robust medium should not shift by more than ±0.05 pH units.

- If relevant, investigate the impact of ionic strength by comparing dissolution profiles in media with 0.2 M and 0.4 M added NaCl [25].

- Method Discrimination:

- Challenge the selected method with tablets containing the API of different particle sizes or with minor formulation changes. A discriminatory method should be able to detect these differences in the dissolution profiles [21].

- Validation:

- Validate the final method for specificity, accuracy, precision, and linearity according to ICH and FDA guidelines [21].

Protocol: pH-Shift Dissolution Test for an Acidic Drug Salt

Objective: To simulate the dynamic gastric-to-intestinal transition and assess the dissolution and supersaturation behavior of an acidic drug salt (e.g., Diclofenac Sodium) [22].

Materials:

- Apparatus: USP Apparatus II (Paddle), pH meter, and probe.

- Reagents: HCl, NaOH, phosphate buffer.

Procedure:

- Gastric Phase: Initiate the dissolution test in 500 mL of a low-pH medium (e.g., pH 1.6 or 2.0, precisely adjusted with HCl) for 30-45 minutes. The specific pH should be selected based on preliminary data showing its discriminatory power [22].

- Intestinal Phase: Rapidly add a pre-warmed, concentrated solution of phosphate buffer (e.g., 400 mL of 0.2 M Naâ‚‚HPOâ‚„) to the vessel to shift the pH to 6.8. The total volume is now 900 mL.

- Monitoring: Continue the test for a further 45-90 minutes, sampling frequently. Use UV-Vis spectrophotometry to monitor the concentration, paying close attention to any supersaturation and precipitation events upon pH shift.

- Data Analysis: Compare the dissolution profiles of test and reference products. The use of a more biorelevant pH-shift method can reveal differences in performance that are not apparent in single-pH tests [22].

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for Dissolution Medium Design

| Reagent / Solution | Function in Dissolution Testing |

|---|---|

| 0.1 N Hydrochloric Acid (HCl) | Simulates the acidic environment of the fasted stomach; critical for testing weak bases and enteric-coated products. |

| Phosphate Buffer (pH 6.8) | Simulates the intestinal environment; a widely used medium for immediate-release products and for demonstrating sink conditions. |

| Acetate Buffer (pH 4.5) | Represents the pH of the fed stomach or the proximal small intestine; useful for intermediate pH testing. |

| Surfactants (e.g., SLS) | Added to dissolution media to achieve sink conditions for poorly soluble drugs by increasing solubility via micellization. |

| Sodium Chloride (NaCl) | Used to adjust the ionic strength of the dissolution medium, simulating the variable ionic environment of the GI tract. |

| 3,5-Dinitro-p-toluic acid | 3,5-Dinitro-p-toluic acid, CAS:16533-71-4, MF:C8H6N2O6, MW:226.14 g/mol |

| 1-(2,3-Dichlorphenyl)piperazine | 1-(2,3-Dichlorphenyl)piperazine, CAS:41202-77-1, MF:C10H12Cl2N2, MW:231.12 g/mol |

Workflow and Decision Pathways

The following diagram illustrates the integrated decision-making process for designing a dissolution medium, incorporating the critical factors of pH, sink conditions, and buffer capacity.

Dissolution Medium Design Workflow

The systematic design of the dissolution medium, grounded in a deep understanding of pH, sink conditions, and buffer capacity, is fundamental to the success of any UV-Vis spectrophotometric dissolution method. By treating the medium not as a mere solvent but as a dynamic, physiologically-relevant environment, researchers can develop highly discriminatory and predictive tests. This approach ensures that dissolution data is reliable for formulation development, quality control, and the establishment of meaningful in vitro-in vivo correlations, ultimately contributing to the delivery of safe and effective drug products to the market.

In vitro dissolution testing is a critical quality control tool and a pivotal predictor of the in vivo performance of solid oral dosage forms [26] [16]. For poorly water-soluble drugs, which constitute a significant proportion of new drug candidates, the development of a discriminatory and biologically relevant dissolution method presents a substantial scientific challenge [27]. The composition of the dissolution medium is a primary factor influencing the test's ability to accurately reflect the drug product's behavior, moving beyond simple quality control to become a surrogate for bioavailability [26] [28]. This document outlines a structured, evidence-based approach to justify dissolution media composition, framed within the context of a UV-Vis spectrophotometric dissolution testing research program. The principles and protocols herein are designed to equip scientists with the methodologies needed to develop robust, fit-for-purpose dissolution tests.

Scientific Rationale for Media Selection

The fundamental goal of dissolution media development is to balance sink conditions with physiological relevance and discriminatory power. Sink condition, where the volume of medium is at least three times that required to form a saturated solution of the drug substance, ensures that dissolution results reflect the properties of the dosage form itself rather than being limited by saturation solubility [16]. However, the pursuit of sink conditions must be tempered by the need for the test to discriminate between formulations with meaningful differences in performance.

Poorly water-soluble drugs are often classified as either 'brick-dust' molecules, whose solubility is limited by high crystal lattice energy, or 'grease-ball' molecules, whose solubility is limited by high lipophilicity [27]. This distinction is crucial for media selection, as 'grease-ball' molecules often benefit from surfactant-containing media that mimic the solubilizing capacity of intestinal fluids, while 'brick-dust' molecules may require pH adjustment or solid-state modification.

The following diagram illustrates the logical decision pathway for justifying dissolution media composition.

Quantitative Foundations for Media Design

Surfactant Selection and Concentration

The choice and concentration of surfactant are critical for modulating the dissolution rate and achieving sink conditions. The table below summarizes effective surfactant types and concentrations documented for various poorly soluble drugs.

Table 1: Surfactant-Mediated Dissolution of Poorly Soluble Drugs

| Drug | Drug Class | Surfactant | Concentration (% w/v) | Key Finding | Source |

|---|---|---|---|---|---|

| Olmesartan medoxomil | Antihypertensive (BCS Class IV) | Sodium Lauryl Sulfate (SLS) | 0.5% | Provided adequate sink condition and discriminating profiles at pH 6.8. | [26] |

| Posaconazole, Ritonavir, Griseofulvin | Antifungal, Antiretroviral, Antifungal | Polysorbate 80 (PS80) | Not Specified | Significantly increased dissolution compared to buffer; dissolution was successfully predicted with a film model. | [29] |

| Bicalutamide | Antiandrogen (BCS Class II) | Sodium Lauryl Sulfate (SLS) | 1% | Used in single-phase dissolution test to maintain sink conditions. | [28] |

| Ketamine HCl | Anesthetic/Antidepressant | Sodium Lauryl Sulfate (SLS) | 1% | Most effective surfactant for enhancing solubility in acidic pH (pH 3.5). | [30] |

pH and Solubility Optimization

For ionizable drugs, pH is a powerful lever for controlling solubility. The following table provides examples of pH optimization for solubility enhancement.

Table 2: pH-Dependent Solubility Optimization for Ionizable Drugs

| Drug | pKa | Optimal pH for Solubility | Justification | Source |

|---|---|---|---|---|

| Olmesartan medoxomil | 4.3 | pH 6.8 (with 0.5% SLS) | The drug has low solubility in the pH 4.0-6.0 range; a higher pH with a surfactant was chosen. | [26] |

| Ketamine HCl | 7.5 | pH 3.5 | As a weak base, its protonated form is favored in acidic conditions, leading to higher solubility. | [30] |

Experimental Protocols for Media Justification

Protocol 1: Determination of Sink Conditions

This foundational protocol is used to determine the saturation solubility of a drug in a candidate medium, which is essential for justifying the medium volume and composition [26] [30].

Research Reagent Solutions:

- Test Article: Drug substance (e.g., Olmesartan medoxomil reference standard).

- Media: A range of physiologically relevant buffers (e.g., 0.1 M HCl, pH 4.5 acetate buffer, pH 6.8 phosphate buffer, pH 7.5 phosphate buffer).

- Surfactant Solutions: Stock solutions of surfactants like Sodium Lauryl Sulfate (SLS), Polysorbate 80, etc., for preparing media with varying concentrations (e.g., 0.5%, 1.0%, 1.5% SLS).

Procedure:

- Prepare 250 mL of each candidate dissolution medium in a volumetric flask. Deaerate the medium by heating, filtration, or applying vacuum [16].

- Pre-warm the media in a thermostatically controlled water bath at 37 ± 0.5°C.

- Add an excess of the drug substance (approximately 40 mg for a 40 mg tablet strength) to each vessel.

- Gently agitate the suspensions for a predetermined period (e.g., 1-2 hours).

- Withdraw aliquots (e.g., 10 mL) from each vessel and filter immediately using a suitable membrane (e.g., 0.45 µm nylon).

- Dilute the filtrate appropriately and analyze the drug concentration using a validated UV-Vis spectrophotometric method.

- Calculation: Calculate the saturation solubility (Cs) in µg/mL. A medium volume is considered to provide sink conditions if it is at least three times the volume required to form a saturated solution of the drug dose [16]. For a 40 mg tablet, this means the saturated concentration (Cs) should be greater than (40,000 µg / Medium Volume) * 3.

Protocol 2: Developing a Surfactant-Containing Medium

This protocol details the steps for incorporating surfactants to achieve sink conditions when aqueous buffers are insufficient [26] [29].

Procedure:

- Select Surfactant Candidates: Based on the drug's lipophilicity (log P) and literature, select non-ionic (e.g., Polysorbate 80), anionic (e.g., SLS), or endogenous (e.g., bile salts) surfactants.

- Prepare Media: Prepare dissolution media (e.g., pH 6.8 phosphate buffer) containing increasing concentrations of the selected surfactants (e.g., 0.1%, 0.5%, 1.0%).

- Determine Solubility: Follow Protocol 1 to determine the saturation solubility in each surfactant-containing medium.

- Profile Dissolution: Conduct a full dissolution profile (using USP Apparatus 2 at 50 rpm, 900 mL medium, 37°C) on the drug product using the media from the previous step [26].

- Assess Discrimination: Test the ability of each medium to discriminate between different formulation prototypes or products with known manufacturing differences.

- Select Optimal Concentration: Choose the lowest surfactant concentration that provides adequate sink conditions and maintains discriminatory power.

The UV-Vis Spectrophotometer in Dissolution Research

The UV-Vis spectrophotometer is a cornerstone instrument for rapid, cost-effective analysis in dissolution research. Its utility extends beyond quantitative analysis to include foundational physico-chemical characterization.

Research Reagent Solutions for UV-Vis Method:

- Blank Solution: The dissolution medium without the drug, for background subtraction.

- Standard Solutions: Known concentrations of the drug substance in the dissolution medium, for constructing a calibration curve.

- Cuvette: 1.0 cm quartz cells for UV range analysis.

Key Applications:

- Method Validation: As demonstrated with Ketamine HCl, UV-Vis methods must be validated for parameters including linearity (e.g., R² > 0.999 over a specified range), selectivity (confirming the blank medium does not interfere at the analytical wavelength), and precision [30].

- Diffusivity Studies: A modified UV-Vis method using a cuvette with a slit cover can be applied to investigate the diffusion coefficients of drugs, which is critical for understanding dissolution kinetics. Studies show this method can accurately measure diffusion coefficients with high reproducibility [31].

Advanced Systems and Correlation with In Vivo Performance

For drugs whose absorption is dissolution-rate limited, advanced dissolution models can provide a more predictive assessment of in vivo performance.

Biphasic Dissolution Systems: This system incorporates an organic phase (e.g., octanol) immiscible with the aqueous buffer. As the drug dissolves in the aqueous phase, it partitions into the organic phase, which acts as an absorptive sink. This setup simultaneously models dissolution and absorption, making it highly suitable for establishing an In Vitro-In Vivo Correlation (IVIVC) for BCS Class II drugs [28] [32]. A Level A IVIVC has been successfully established for Bicalutamide using this system [28].

Dissolution-Permeation Systems: These are more complex apparatuses that incorporate a cellular monolayer or artificial membrane to directly measure drug permeation in addition to dissolution, providing a direct link between in vitro testing and the in vivo absorption process [32].

Justifying dissolution media composition is a multi-faceted process that requires a systematic investigation of a drug's physicochemical properties. The journey begins with simple aqueous buffers and progresses to surfactant-modified and even advanced biphasic systems. A scientifically rigorous approach, grounded in the determination of sink conditions and supported by a discriminatory dissolution profile, is paramount. The UV-Vis spectrophotometer serves as an invaluable tool throughout this process, from initial solubility screening and method validation to specialized diffusion studies. By adhering to the structured protocols and decision-making frameworks outlined in this document, scientists can develop and justify dissolution media that not only ensure product quality but also meaningfully predict a drug's performance in vivo.

Advanced UV-Vis Method Development and Chemometric Applications for Complex Formulations

Ultraviolet-Visible (UV-Vis) spectrophotometry remains a cornerstone technique in pharmaceutical analysis, particularly for dissolution testing of solid oral dosage forms. Its simplicity, cost-effectiveness, and robustness make it an attractive choice for routine quality control and research settings where high-throughput analysis is required [33]. This Application Note provides a detailed protocol for developing, implementing, and validating a single-analyte UV-Vis spectrophotometric method tailored for dissolution testing research. The framework aligns with regulatory guidelines and emphasizes practical considerations for ensuring method reliability, accuracy, and compliance in drug development workflows [34].

Method Development Workflow

The development of a robust UV-Vis method requires a systematic approach to optimize analytical conditions and ensure selective quantification of the target analyte. The following workflow outlines the critical stages from initial setup to validation.

Diagram 1: Systematic workflow for developing and validating a single-analyte UV-Vis method for dissolution testing.

Critical Development Parameters

Wavelength Selection: Identify the wavelength of maximum absorbance (λmax) for the target analyte using a full spectrum scan (190-400 nm for UV, 400-800 nm for Vis). Ensure the selected wavelength provides sufficient absorbance intensity while avoiding interference from excipients, degradation products, or dissolution medium components [34] [35].

Specificity Verification: Demonstrate that the analytical procedure can accurately measure the analyte response in the presence of potential interferents. For dissolution testing, this includes filter compatibility, deaeration effects, and excipient interference [34].

Solution Stability: Evaluate standard and sample solution stability under analytical conditions (e.g., ambient temperature, refrigerated). Instabilities may arise from photodegradation, oxidation, or hydrolysis, particularly during extended dissolution runs [34].

Method Validation

Method validation provides documented evidence that the analytical procedure is suitable for its intended purpose. The International Council for Harmonisation (ICH) guidelines define key parameters for validation, with acceptance criteria dependent on the method's application [34].

Table 1: Validation Parameters and Acceptance Criteria for a UV-Vis Spectrophotometric Method

| Validation Parameter | Protocol Description | Acceptance Criteria |

|---|---|---|

| Specificity [34] | Compare analyte response in presence of potential interferents (excipients, filters, degradation products). | No interference ≥ ±2% from nominal analyte response. |

| Linearity [34] | Prepare and analyze standard solutions at 5-6 concentration levels across the working range. | Correlation coefficient (R²) ≥ 0.999 |

| Accuracy [34] | Spike known analyte quantities into dissolution medium (n=3 per level). Calculate % recovery. | Recovery: 98-102% |

| Precision(Repeatability) [34] | Analyze multiple preparations (n=6) of a single sample at 100% test concentration. | Relative Standard Deviation (RSD) ≤ 2.0% |

| Range [34] | Established from linearity, accuracy, and precision data. | Typically 80-120% of test concentration. |

| Robustness [34] | Deliberately vary method parameters (e.g., wavelength ±2 nm, dilution volume). | Method performance remains within specified limits. |

Essential Research Reagent Solutions

Successful implementation requires carefully selected reagents and materials that meet quality standards and ensure method consistency.

Table 2: Essential Materials and Reagents for UV-Vis Dissolution Analysis

| Item | Function/Purpose | Key Considerations |

|---|---|---|

| High-Purity Analytical Standards | Calibration and method validation. | Certified ≥95% purity; well-characterized storage stability [34]. |

| Biorelevant Dissolution Media | Simulate gastrointestinal conditions for predictive release profiles. | pH-buffered solutions (e.g., phosphate buffers); surfactants (SLS) for poorly soluble drugs [35]. |

| Spectrophotometric Grade Solvents | Prepare standards/samples and as mobile phase in HPLC-cross validation. | Low UV absorbance; appropriate for analyte stability and solubility [34]. |

| Chemical Reference Standards | System suitability and qualification of instrumentation. | Known absorbance characteristics for wavelength verification [34]. |

| Syringe Filters | Clarify dissolution samples prior to analysis. | Compatibility with analyte (non-binding) and dissolution medium; typically 0.45 µm pore size [35]. |

Detailed Experimental Protocols

Protocol: Wavelength Selection and Specificity Assessment

Objective: To determine the optimal analytical wavelength and confirm absence of interference.

Materials: UV-Vis spectrophotometer with scanning capability, quartz cuvettes (1 cm pathlength), analyte stock solution (e.g., 100 µg/mL in dissolution medium), filtered dissolution medium (blank), and placebo solution (dissolution medium with all excipients except API).

Procedure:

- Blank Scan: Place filtered dissolution medium in cuvette and scan from 400 nm to 200 nm. Save as baseline.

- Analyte Scan: Scan analyte stock solution (diluted to mid-range concentration) against air. Identify the wavelength of maximum absorbance (λmax).

- Placebo Interference: Scan placebo solution using the established baseline. The placebo spectrum should show no significant absorbance at the selected λmax.

- Specificity Confirmation: Measure absorbance of the placebo solution at the selected λmax. The absorbance should not exceed 2% of the absorbance of a standard solution at the target concentration.

Protocol: Construction of Calibration Curve

Objective: To establish a linear relationship between analyte concentration and absorbance.

Materials: Analytical balance, volumetric flasks, UV-Vis spectrophotometer, stock standard solution.

Procedure:

- Stock Solution: Accurately weigh and dissolve reference standard to prepare a primary stock solution (e.g., 1 mg/mL).

- Standard Dilutions: Precisely dilute stock solution with dissolution medium to prepare at least five standard solutions covering the range (e.g., 50%, 80%, 100%, 120%, 150% of target test concentration).

- Absorbance Measurement: Measure absorbance of each standard solution in triplicate against a medium blank.

- Linear Regression: Plot mean absorbance versus concentration. Calculate the regression equation (y = mx + c) and correlation coefficient (R²). The R² must be ≥ 0.999 [34].

Protocol: Dissolution Testing with UV-Vis Analysis

Objective: To determine the dissolution profile of a solid oral dosage form using a validated UV-Vis method.

Materials: USP Apparatus I (baskets) or II (paddles), dissolution bath maintained at 37.0°C ± 0.5°C, dissolution medium (e.g., 900 mL phosphate buffer pH 6.8), vacuum pump, syringe filters (0.45 µm), and UV-Vis spectrophotometer.

Procedure:

- Medium Preparation: Add deaerated dissolution medium to vessels and equilibrate to 37.0°C.

- Dosage Form Introduction: Place one dosage unit in each vessel and start the apparatus immediately at the specified rotation speed (e.g., 50 rpm for paddles).

- Sampling: At predetermined time intervals (e.g., 10, 15, 20, 30, 45, 60 min), withdraw aliquots (e.g., 5-10 mL) from each vessel without replacing the medium, ensuring a zone midway between vessel wall and paddle/basket.

- Sample Filtration: Immediately filter samples using 0.45 µm syringe filters, discarding the first 1 mL of filtrate.

- Absorbance Measurement: Dilute filtrate if necessary and measure absorbance at the validated λmax against a fresh dissolution medium blank.

- Calculation: Using the regression equation, calculate the concentration of drug dissolved at each time point and express it as a cumulative percentage of the label claim.

This Application Note provides a comprehensive framework for implementing and validating a robust single-analyte UV-Vis spectrophotometric method for dissolution testing. By adhering to the detailed protocols for method development and validation, researchers can generate reliable, high-quality data that supports formulation development and ensures product quality. The systematic approach outlined here, emphasizing specificity, linearity, and precision, aligns with regulatory expectations and provides a solid foundation for a thesis investigating UV-Vis applications in dissolution science.

In the pharmaceutical industry, dissolution testing serves as a critical quality control tool, ensuring that solid oral dosage forms release their active pharmaceutical ingredients (APIs) in a consistent and predictable manner. UV-Vis spectrophotometry has long been favored for dissolution testing due to its simplicity, cost-effectiveness, and speed [16]. However, a significant challenge arises when analyzing multi-component dosage forms, where the absorption spectra of active ingredients extensively overlap, preventing accurate quantification of individual components through conventional spectrophotometric methods [36].

This application note addresses this challenge by detailing the implementation of chemometric techniques—mathematical procedures for extracting chemical information from complex spectral data [37]. These techniques enable researchers to perform simultaneous quantification of multiple drugs in dissolution samples without prior separation, even when their spectra severely overlap. By integrating these methods into dissolution testing protocols, pharmaceutical scientists can maintain the efficiency of UV-Vis spectrophotometry while overcoming its primary limitation for combination products, thereby supporting robust pharmaceutical analysis and quality assurance processes [36] [38].

Key Chemometric Techniques and Applications

Chemometrics applies mathematical and statistical methods to chemical data to resolve complex analytical challenges. For dissolution testing of multi-component formulations, several techniques have demonstrated particular efficacy.

Derivative Spectroscopy

Derivative spectroscopy eliminates constant background interference and resolves overlapping spectral bands by converting normal zero-order absorption spectra into first or higher-order derivative spectra [36]. This transformation effectively removes baseline shifts and enhances minor spectral features, enabling quantification of individual components at wavelengths where the derivative spectrum of one analyte shows a distinct feature while the contributions from other components are zero [38].

In practice, the third derivative (D3) spectrophotometry has been successfully applied to resolve severely overlapping spectra of terbinafine HCl and ketoconazole in combined tablet formulations. For example, Terbinafine HCl was quantified at 214.7 nm and Ketoconazole at 208.6 nm using third-order derivatives, despite significant spectral overlap in their zero-order spectra [38].

Ratio-Based Methods

Ratio-based chemometric techniques involve mathematical manipulation of ratio spectra to isolate the contribution of individual analytes:

Ratio Difference Method: This approach involves dividing the absorption spectrum of a mixture by a standard spectrum of one component (divisor), then calculating the difference in amplitudes at two selected wavelengths in the ratio spectrum [36] [38]. This difference is proportional to the concentration of the analyte of interest, independent of the other components. For Terbinafine and Ketoconazole mixtures, the ratio difference was measured at 222.7 nm and 204.3 nm for Terbinafine, and at 209.8 nm and 233.2 nm for Ketoconazole [38].

First Derivative of Ratio Spectra (DD1): After obtaining ratio spectra, the first derivative is computed to further enhance spectral resolution [36]. This method was effectively implemented for Amlodipine besylate and Telmisartan combinations, with Amlodipine measured at 214.3 nm and Telmisartan at 211.5 nm in their derivative ratio spectra [36].

Advanced Resolution Techniques

For particularly challenging analytical scenarios, more sophisticated chemometric approaches have been developed:

Induced Dual Wavelength (IDW) Method: This technique selects two wavelengths where the ratio of absorbances for the interfering component is constant, allowing mathematical cancellation of its contribution while maintaining a linear response for the analyte of interest [38].

Dual Wavelength Resolution (DWR) Technique: DWR involves subtracting the computed spectrum of one component (based on its normalized absorptivity) from the total mixture spectrum to isolate the absorption profile of the second component, which can then be quantified using derivative spectroscopy [38].

Table 1: Performance Characteristics of Chemometric Methods for Drug Combinations

| Drug Combination | Technique | Linear Range (µg/mL) | LOD (µg/mL) | LOQ (µg/mL) | Reference |

|---|---|---|---|---|---|

| Amlodipine-Telmisartan | First Derivative | 0.1211-0.4304 (AMLB)0.0773-0.5640 (TEL) | 0.1211 (AMLB)0.0773 (TEL) | 0.4304 (AMLB)0.5640 (TEL) | [36] |

| Terbinafine-Ketoconazole | Third Derivative (D3) | 0.6-12.0 (TFH)1.0-10.0 (KTZ) | Not specified | Not specified | [38] |

| Terbinafine-Ketoconazole | Ratio Difference | 0.6-12.0 (TFH)1.0-10.0 (KTZ) | Not specified | Not specified | [38] |

Experimental Protocols

Sample Preparation for Dissolution Testing

The following protocol outlines the standard procedure for preparing dissolution samples of multi-component dosage forms for chemometric analysis:

Dissolution Media Preparation: Select appropriate dissolution media based on drug solubility and discriminatory capability. Common media include dilute hydrochloric acid, buffers in the physiological pH range (1.2-7.5), simulated gastric or intestinal fluids, water, or surfactants such as polysorbate 80 or sodium lauryl sulfate [16]. Maintain sink conditions (volume at least three times that required to form a saturated solution) to ensure accurate dissolution profiling [16].

Dissolution Test Execution: Place the dosage form in the dissolution vessel containing 500-1000 mL (typically 900 mL) of deaerated medium maintained at 37±0.5°C. Use USP Apparatus 1 (basket) at 100 rpm or Apparatus 2 (paddle) at 50-75 rpm, unless justified otherwise [16].

Sample Collection: Withdraw aliquots at predetermined time points (e.g., every 2 minutes for immediate-release formulations) from a zone midway between the top of the paddle/basket and the media surface, not less than 1 cm from the vessel wall [16].

Filtration: Immediately filter samples through a suitable membrane filter (e.g., 0.45 μm pore size) to remove undissolved drug particles and excipients that could cause turbidity or background interference [16].