UV-Vis vs. UFLC-DAD: A Strategic Guide for Selecting the Right Analytical Technique in Drug Development

This guide provides a comprehensive framework for researchers, scientists, and drug development professionals to strategically select between UV-Vis spectroscopy and UFLC-DAD for their analytical needs.

UV-Vis vs. UFLC-DAD: A Strategic Guide for Selecting the Right Analytical Technique in Drug Development

Abstract

This guide provides a comprehensive framework for researchers, scientists, and drug development professionals to strategically select between UV-Vis spectroscopy and UFLC-DAD for their analytical needs. It covers the fundamental principles of each technique, explores their specific applications in method development and analysis of pharmaceuticals and natural products, and addresses common troubleshooting scenarios. A detailed comparison of validation parameters, cost, speed, and environmental impact is presented to empower informed, method-specific decision-making that ensures data quality, regulatory compliance, and efficiency from preclinical research to quality control.

Understanding the Core Principles: How UV-Vis and UFLC-DAD Work

Ultraviolet-Visible (UV-Vis) spectroscopy is a cornerstone analytical technique that measures the absorption of light in the ultraviolet and visible regions of the electromagnetic spectrum [1] [2]. This technique operates on the principle that when molecules are exposed to light of specific wavelengths, they undergo electronic transitions, absorbing energy to promote electrons from ground states to higher energy states [2]. The UV region typically spans wavelengths from 190 to 400 nm, while the visible region covers 400 to 800 nm [2]. Shorter wavelengths in the UV region possess higher energy and frequency, while longer wavelengths in the visible region have lower energy and frequency [2].

UV-Vis spectroscopy serves as a cost-effective, simple, versatile, and non-destructive technique that allows samples to be reused for further analysis [2]. Its properties depend directly on sample composition and concentration, enabling researchers to identify components, assess purity, and perform quantitative analysis [2]. The technique finds application across diverse sample types including monolithic solids, liquids, glasses, powders, and thin films [2], making it indispensable in modern analytical laboratories, particularly in pharmaceutical research and drug development contexts.

Fundamental Principles of the Beer-Lambert Law

Theoretical Foundation

The Beer-Lambert Law (also referred to as Beer's Law) establishes a fundamental relationship between the attenuation of light passing through a substance and the properties of that substance [3] [4]. This law provides the theoretical foundation for quantitative analysis in UV-Vis spectroscopy, enabling researchers to determine concentrations of analytes in solution [3]. The law states that the absorbance of light by a solution is directly proportional to the concentration of the absorbing species and the path length through which the light travels [4].

The mathematical formulation of the Beer-Lambert Law is expressed as:

A = εlc

Where:

- A represents absorbance (a dimensionless quantity) [4]

- ε is the molar absorptivity or molar absorption coefficient (with units of L·molâ»Â¹Â·cmâ»Â¹) [4]

- l is the optical path length through the sample (typically in cm) [4]

- c is the concentration of the solution (in mol·Lâ»Â¹) [4]

The molar absorption coefficient (ε) is a substance-specific property that measures how strongly a chemical species absorbs light at a particular wavelength [3]. This value is constant for a given substance under specific conditions and represents the probability of electronic transitions occurring when light interacts with the molecules [4].

Transmittance and Absorbance Relationship

The Beer-Lambert Law establishes a logarithmic relationship between transmittance and absorbance [3]. Transmittance (T) is defined as the ratio of the transmitted light intensity (I) to the incident light intensity (Iâ‚€) [3]:

T = I/Iâ‚€

Absorbance (A) relates to transmittance through the following equations [3] [4]:

A = -logâ‚â‚€(T) = -logâ‚â‚€(I/Iâ‚€) = logâ‚â‚€(Iâ‚€/I)

This relationship means that absorbance increases logarithmically as transmittance decreases. The following table illustrates this inverse logarithmic relationship with common absorbance and transmittance pairings:

Table 1: Absorbance and Transmittance Values

| Absorbance (A) | Transmittance (T) |

|---|---|

| 0 | 100% |

| 1 | 10% |

| 2 | 1% |

| 3 | 0.1% |

| 4 | 0.01% |

| 5 | 0.001% |

An absorbance value of 0 corresponds to 100% transmittance (no absorption), while an absorbance of 1 indicates 10% transmittance (90% absorption) [3]. This relationship becomes particularly important when considering the dynamic range of UV-Vis instruments, as most spectrophotometers provide reliable quantitation at absorbance values below 1, where sufficient light reaches the detector for accurate measurement [1].

Instrumentation and Components

UV-Vis spectrophotometers consist of several key components that work in concert to measure light absorption by samples. Understanding these components is essential for proper method development and instrument selection in analytical research.

Core Instrument Components

Table 2: Main Components of a UV-Vis Spectrophotometer

| Component | Function | Common Types |

|---|---|---|

| Light Source | Emits light across a wide range of wavelengths | Deuterium lamp (UV), Tungsten/Halogen lamp (Visible), Xenon lamp (both UV-Vis) [1] [2] |

| Wavelength Selector | Selects specific wavelengths for sample examination | Monochromators (using diffraction gratings), Absorption filters, Interference filters, Bandpass filters [1] |

| Sample Container | Holds the sample during analysis | Cuvettes (typically with 1 cm path length); quartz for UV, glass or plastic for visible range [1] [2] |

| Detector | Converts light into an electronic signal | Photomultiplier tubes (PMT), Photodiodes, Charge-coupled devices (CCD) [1] |

The configuration of these components varies between different instrument designs. Single-beam instruments pass all radiation through the sample in one beam and determine color by comparing light source intensities before and after sample insertion [2]. Double-beam instruments split the radiation into two beams: one passing through the sample and another through a reference, allowing for more accurate measurements by compensating for lamp brightness fluctuations [1] [2]. Array-based systems utilize diode array detectors that can simultaneously capture entire spectra, enabling rapid data acquisition [1].

Figure 1: UV-Vis Spectrometer Workflow

Instrument Selection Considerations

When selecting UV-Vis instrumentation for research applications, several factors must be considered. Benchtop spectrophotometers dominate the market (55.67% share in 2024) due to their superior photometric accuracy and robust qualification kits, making them ideal for regulated environments like pharmaceutical quality control [5]. However, portable/hand-held devices are experiencing rapid growth (7.46% CAGR) driven by point-of-care diagnostics and on-site testing needs [5].

Technologically, dual-beam optics held 41.45% revenue share in 2024, valued for baseline stability during long analytical runs, while diode-array configurations are growing at 7.76% CAGR due to their ability to capture entire spectra in milliseconds, supporting peak-purity checks and forced-degradation profiling [5]. The choice between these technologies should be guided by application requirements, with dual-beam systems offering stability for prolonged studies and diode-array systems providing speed for dynamic reaction monitoring.

Practical Applications in Pharmaceutical Research

UV-Vis spectroscopy serves critical functions throughout drug development pipelines, from initial discovery through quality control of final products.

Quantitative Analysis and Calibration

The primary application of UV-Vis spectroscopy in pharmaceutical research involves quantitative analysis through calibration curves [3] [6]. This process involves measuring the absorbance of a series of standard solutions with known concentrations and plotting absorbance versus concentration to create a linear calibration curve [3] [6]. The concentration of unknown samples can then be determined by measuring their absorbance and referring to the calibration curve [3].

For accurate quantification, the following experimental protocol is recommended:

Preparation of Standard Solutions: Create at least three, but ideally five, standard solutions with concentrations spanning the expected range of the unknown samples [6]. Solutions should be prepared using digital pipettes and volumetric flasks rather than graduated cylinders and beakers to ensure accuracy [6].

Blank Measurement: Use a blank reference containing only the solvent to zero the instrument at the beginning of analysis [1] [6].

Absorbance Measurement: Measure absorbance at the wavelength of maximum absorption (λmax) for each standard solution [3] [6].

Calibration Curve: Plot absorbance versus concentration and determine the line of best fit [3] [6]. The correlation coefficient (R²) should be 0.9 or better for acceptable calibration [6].

Sample Analysis: Measure absorbance of unknown samples and determine concentration using the calibration curve equation [3].

This methodology enables precise quantification of active pharmaceutical ingredients, impurities, and degradation products throughout the drug development process.

Specific Pharmaceutical Applications

Table 3: Pharmaceutical Applications of UV-Vis Spectroscopy

| Application Area | Specific Use | Methodological Considerations |

|---|---|---|

| Drug Discovery | Chemical identification and quantification of novel compounds [2] | Overlapping absorbance peaks can be resolved using mathematical derivatives [2] |

| Quality Control | Quantification of impurities in drug ingredients [2] | Requires validation per regulatory guidelines (ICH, USP) [5] |

| Dissolution Testing | Monitoring drug release from solid oral dosage forms [2] | Often employs flow-through cells with continuous monitoring |

| Biologics Characterization | Protein concentration analysis (e.g., antibodies up to 300 mg/mL) [5] | Variable-pathlength instruments enable direct measurement without dilution [5] |

| Nucleic Acid Analysis | Purity assessment of DNA/RNA samples [2] | 260/280 nm ratio (1.8 for pure DNA, 2.0 for pure RNA) indicates protein contamination [2] |

The pharmaceutical and biotechnology industry constitutes the largest end-user segment of the UV-Vis spectroscopy market, accounting for 48.54% of market share in 2024 [5]. This dominance reflects the technique's indispensable role in modern drug development and quality assurance.

Advanced Methodologies and Complementary Techniques

Experimental Protocol for Method Validation

For regulatory compliance in pharmaceutical applications, UV-Vis methods require rigorous validation. The following protocol outlines key steps:

Linearity and Range: Establish linear relationship between absorbance and concentration across the working range using a minimum of five concentration levels [6]. The correlation coefficient should be ≥0.99 [6].

Accuracy: Determine recovery by spiking placebo with known amounts of analyte (80%, 100%, 120% of target concentration) and calculate percentage recovery [5].

Precision:

- Repeatability: Analyze six sample preparations at 100% concentration and calculate %RSD

- Intermediate precision: Perform analysis on different days, with different analysts, or different instruments [5]

Detection Limit (LOD) and Quantitation Limit (LOQ):

- LOD = 3.3σ/S (where σ is standard deviation of response, S is slope of calibration curve)

- LOQ = 10σ/S [5]

Robustness: Deliberately vary method parameters (wavelength ±2 nm, different instrument manufacturers) and evaluate impact on results [5].

Complementary Technique Integration

UV-Vis spectroscopy is frequently combined with other analytical techniques to provide comprehensive sample characterization:

UV-Vis with NMR: Simultaneous UV-Vis and Nuclear Magnetic Resonance spectroscopy provides insight into both electronic properties and hydrogen geometry of reaction products, particularly useful for studying acid-base chemistry of hydrogen-bonded complexes [7].

UV-Vis with ATR: Combining UV-Vis with Attenuated Total Reflection infrared spectroscopy enables monitoring of oxidation reactions at catalytic interfaces, with ATR identifying dissolved reaction products and UV-Vis tracking catalyst changes [7].

UV-Vis with Raman Spectroscopy: This combination allows researchers to simultaneously track reaction species formation/extinction (UV-Vis) while monitoring atomic-scale structural changes (Raman), providing comprehensive insight into complex reactions [7].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 4: Essential Research Reagents and Materials for UV-Vis Spectroscopy

| Item | Function | Application Notes |

|---|---|---|

| Quartz Cuvettes | Sample holder with high UV transparency | Essential for UV measurements below 300 nm; compatible with organic solvents [1] |

| Reference Standards | Certified reference materials for method validation | Required for instrument qualification (wavelength, photometric accuracy, stray-light verification) [5] |

| HPLC-Grade Solvents | High-purity solvents for sample preparation | Minimize UV absorption background; common choices include water, methanol, acetonitrile [6] |

| Buffer Salts | Maintain pH-dependent chromophore stability | Phosphate, acetate, and borate buffers at appropriate concentrations [6] |

| Protein Assay Dyes | Specific binding dyes for biomolecule quantification | Bradford, BCA, or Lowry reagents for protein concentration determination [5] |

| Nucleic Acid Standards | Calibration standards for DNA/RNA quantification | Calf thymus DNA or synthetic oligonucleotides for nucleic acid quantification [2] |

| Pterokaurane R | Pterokaurane R, MF:C20H34O3, MW:322.5 g/mol | Chemical Reagent |

| Tenacissimoside J | Tenacissimoside J, MF:C37H58O13, MW:710.8 g/mol | Chemical Reagent |

Limitations and Practical Considerations

Methodological Limitations

Despite its widespread utility, UV-Vis spectroscopy presents several important limitations that researchers must consider when selecting analytical techniques:

Concentration and Path Length Constraints: For accurate quantification using the Beer-Lambert Law, absorbance values should ideally be maintained below 1, as higher values result in insufficient light reaching the detector, compromising measurement reliability [1]. This limitation can be addressed by either diluting the sample or using cuvettes with shorter path lengths [1].

Sample Compatibility: UV-Vis spectroscopy works optimally with liquids and solutions [6]. Suspensions of solid particles in liquid can scatter light more than absorb it, resulting in skewed data [6]. While some instruments can analyze solid samples using diffraction apparatus, this is not common [6].

Spectral Overlap: Mixtures of chromophores with overlapping absorption bands can complicate quantification without mathematical processing or separation techniques [2].

Chemical and Optical Deviations: The Beer-Lambert Law represents an approximation that does not always account for electromagnetic effects arising from the wave nature of light [8]. These effects can cause band shifts and intensity changes based on optical conditions rather than chemical interactions [8].

Comparison with UFLC-DAD

When deciding between UV-Vis spectroscopy and Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) for research applications, consider that UFLC-DAD incorporates UV-Vis detection but adds separation capabilities that address several limitations of stand-alone UV-Vis:

Separation Power: UFLC-DAD separates mixture components before detection, resolving spectral overlap issues encountered in direct UV-Vis analysis [2].

Analysis Time: While UFLC-DAD provides superior separation, it requires longer analysis times compared to direct UV-Vis measurements [5].

Equipment Complexity and Cost: Stand-alone UV-Vis instruments are generally more cost-effective, simpler to operate, and require less maintenance than UFLC-DAD systems [5].

The selection between these techniques should be guided by specific application requirements, with UV-Vis offering rapid, cost-effective analysis for pure compounds or simple mixtures, and UFLC-DAD providing comprehensive characterization for complex mixtures.

UV-Vis spectroscopy, grounded in the fundamental principles of the Beer-Lambert Law, remains an indispensable analytical technique in pharmaceutical research and drug development. Its simplicity, cost-effectiveness, and versatility make it particularly valuable for quantitative analysis, purity assessment, and reaction monitoring throughout the drug development pipeline. While the technique has limitations regarding sample compatibility and spectral overlap, its integration with complementary methodologies and proper method validation establishes it as a reliable workhorse in analytical laboratories. When selecting between UV-Vis and more sophisticated techniques like UFLC-DAD, researchers must balance analysis requirements, time constraints, and resource availability to optimize their analytical approach for specific research objectives.

Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) represents a significant advancement in analytical separation science, combining high-resolution chromatographic separation with full-spectrum ultraviolet-visible detection. This powerful technique has become indispensable in modern laboratories for the analysis of complex mixtures, particularly in pharmaceutical development, food safety, and environmental monitoring. UFLC systems operate at significantly higher pressures than conventional HPLC, utilizing columns packed with smaller particles (typically below 2.2 µm) to achieve superior separation efficiency, reduced analysis time, and lower solvent consumption [9]. When coupled with a Diode Array Detector (DAD), this technique provides not only quantitative data but also spectral information for each separated component, enabling compound identification and purity assessment [10].

The fundamental advantage of UFLC-DAD lies in its ability to provide comprehensive chemical fingerprinting of samples through simultaneous acquisition of chromatographic and spectral data. Unlike conventional UV detectors that measure at a single wavelength, the DAD measures the entire UV-Vis spectrum (typically 190-900 nm) in real-time as compounds elute from the chromatography column [11] [12]. This dual capability makes UFLC-DAD particularly valuable for method development and for analyzing complex samples where compounds may co-elute or where unknown impurities must be identified. The technology has proven essential in environments requiring rapid, reliable, and information-rich analysis, from quality control laboratories to research institutions developing new therapeutic agents [13].

Fundamental Principles of Separation

Core Chromatographic Mechanisms

The separation power of UFLC stems from the differential interaction of sample components with two distinct phases: the stationary phase (contained within the column) and the mobile phase (pumped through the system under high pressure). Separation occurs as analytes are carried by the mobile phase over the stationary phase, with components that have stronger attraction to the stationary phase eluting slower than those with less attraction [11]. The efficiency of UFLC separation significantly surpasses conventional HPLC due to the use of columns packed with smaller particles (often sub-2µm), which provide greater surface area for interactions and enhanced theoretical plate counts [9]. This fundamental improvement allows for faster flow rates and dramatically reduced analysis times while maintaining or even improving resolution.

Two primary separation modes dominate UFLC applications: reverse-phase and normal-phase chromatography. Reverse-phase chromatography, which employs a non-polar stationary phase and a polar mobile phase, is the most common configuration and is particularly effective for separating analytes with moderate to low polarity [11]. The interaction mechanisms vary based on the chemistry employed, with reverse-phase separations exploiting hydrophobicity differences, while ion-exchange chromatography separates compounds based on charge characteristics, making it particularly useful for analyzing protein content or charged molecules [11]. The choice of separation mechanism depends entirely on the chemical properties of the target analytes and the matrix complexity.

Optimization Parameters

Several critical parameters must be optimized to achieve effective separation in UFLC. The mobile phase composition represents perhaps the most significant variable, with careful adjustment of organic solvent ratios (typically acetonitrile or methanol) and buffer conditions dramatically impacting retention times and selectivity [9]. Temperature control column chemistry selection (C8, C18, phenyl, etc.), and flow rate precision all contribute to the final separation efficiency. The enhanced pressure capabilities of UFLC systems (often exceeding 1000 bar) enable the use of smaller particle columns that would be impractical in conventional HPLC systems, directly contributing to the "ultra-fast" performance characteristic of this technology [9].

Table 1: Key Separation Parameters in UFLC Systems

| Parameter | Typical Range | Impact on Separation | Optimization Consideration |

|---|---|---|---|

| Particle Size | 1.7-2.2 µm | Smaller particles increase efficiency but require higher pressure | Balance between resolution and system capabilities |

| Column Temperature | 20-60°C | Higher temperatures reduce viscosity and may improve resolution | Temperature stability is critical for reproducibility |

| Flow Rate | 0.2-1.0 mL/min | Higher flows reduce analysis time but may compromise resolution | Optimize for speed versus resolution requirements |

| Mobile Phase pH | 2.0-8.0 | Affects ionization state of analytes and thus retention | Stability of analytes and column must be considered |

| Gradient Profile | Varies | Determines elution strength over time | Optimize for peak capacity and separation of critical pairs |

Diode Array Detection Fundamentals

Optical Design and Operating Principles

The Diode Array Detector represents a sophisticated evolution in UV-Vis detection for liquid chromatography. Unlike variable wavelength detectors that use a monochromator to select a specific wavelength before the flow cell, DAD employs a fundamentally different approach: polychromatic light passes through the flow cell, and after transmission, the light is dispersed onto an array of photodiodes [12]. This reversed optical design allows simultaneous measurement across the entire wavelength range, typically 190-900 nm, capturing the complete spectrum of each eluting compound every few milliseconds [12]. The heart of the DAD system consists of a deuterium lamp for UV light generation, often augmented with a tungsten lamp for visible range detection, a flow cell with precisely defined pathlength (typically 10 mm), and a diode array comprising hundreds of individual detection elements (typically 512 or 1024 diodes) [12].

The detection process follows the Beer-Lambert law, which states that absorbance (A) is proportional to the product of molar absorptivity (ε), pathlength (b), and analyte concentration (c): A = εbc [12]. This fundamental relationship enables both qualitative identification through spectral matching and quantitative analysis through peak area integration at specific wavelengths. Modern DAD systems maintain exceptionally low noise levels (typically <±1 × 10â»âµ AU), enabling highly sensitive detection while providing linear response across a wide concentration range, which is essential for accurate quantification in pharmaceutical applications where precision requirements are stringent [12].

Comparative Advantage Over Conventional UV Detection

The DAD provides several critical advantages over single wavelength UV detectors. While conventional UV detectors measure at only one or a few predefined wavelengths, DAD simultaneously captures the entire spectral signature of each eluting peak [10]. This capability enables post-run data analysis at any wavelength, facilitating method development and optimization without reinjection of samples. More importantly, the continuous spectral data allows for peak purity assessment by comparing spectra across different regions of a chromatographic peak, identifying potential co-elution that would remain undetected with single-wavelength monitoring [10] [12]. This purity assessment capability is particularly valuable in pharmaceutical analysis where regulatory requirements demand demonstration of method specificity [12].

Another significant advantage is the ability to select the optimal wavelength for quantification after data acquisition, which is particularly beneficial when analyzing complex samples with unknown components. The spectral data also aids in compound identification through library matching, as the UV-Vis spectrum provides characteristic information about chromophores present in the molecule [10]. For natural product analysis, such as distinguishing between different cannabinoids, DAD has proven invaluable in differentiating compounds with similar retention times but distinct spectral profiles, such as neutral cannabinoids (THC, CBD) versus their acidic forms (THCA, CBDA) [10].

Table 2: Comparison of Detection Technologies for Liquid Chromatography

| Detector Type | Key Principle | Advantages | Limitations | Ideal Applications |

|---|---|---|---|---|

| Diode Array (DAD) | Simultaneous multi-wavelength detection | Spectral information, peak purity assessment, post-acquisition wavelength selection | Higher cost than single wavelength UV | Method development, impurity profiling, natural products |

| Variable Wavelength UV | Single wavelength detection via monochromator | Cost-effective, robust, excellent linearity | Limited spectral information | Routine QC of known compounds |

| Fluorescence | Measures light emission from excited molecules | Extremely high sensitivity and selectivity | Limited to native or derivatized fluorescent compounds | Trace analysis, environmental monitoring |

| Mass Spectrometry | Mass-to-charge ratio measurement | Structural identification, high sensitivity | High cost, complexity | Metabolomics, unknown identification |

| Charged Aerosol | Universal detection via charged particle measurement | Uniform response, no chromophore needed | Less sensitive for volatile compounds | Sugars, lipids, polymers |

System Components and Configuration

Essential Hardware Components

A complete UFLC-DAD system comprises several integrated components that must operate in precise coordination to achieve optimal performance. The pumping system represents a critical component, capable of delivering highly stable, pulse-free mobile phase flows at pressures up to 1200 bar or higher, with sophisticated gradient formation capabilities for precise mixing of multiple solvents [9]. The autosampler provides accurate and reproducible sample introduction while minimizing carryover between injections. The column oven maintains stable temperature conditions crucial for retention time reproducibility, especially important in pharmaceutical applications where method robustness is rigorously validated [12].

The chromatography column itself serves as the heart of the separation system, with UFLC-specific columns featuring reduced internal diameters (often 2.1 mm) and stationary phases with particle sizes typically between 1.7-2.2 µm [9]. These columns provide enhanced efficiency but require specialized hardware to handle the resulting high backpressures. The DAD module represents the detection component, with modern systems featuring low-dispersion flow cells (typically 0.5-1 µL for UHPLC systems) to preserve the separation efficiency achieved on column [12]. Advanced DAD systems may incorporate innovative technologies such as LightPipe flow cells that enhance sensitivity through extended pathlength, or novel software functions like i-PDeA (intelligent Peak Deconvolution and Analysis) that mathematically resolve co-eluting peaks based on their spectral differences [10] [13].

Research Reagent Solutions

Successful implementation of UFLC-DAD methodology requires careful selection of consumables and reagents that meet the specific requirements of ultra-fast separations.

Table 3: Essential Research Reagents and Materials for UFLC-DAD

| Item | Function | Technical Specifications | Application Notes |

|---|---|---|---|

| UFLC Column | Stationary phase for compound separation | Sub-2µm particles, 2.1 mm ID, pressure-rated to >1000 bar | Select chemistry (C18, HILIC, etc.) based on analyte polarity |

| Mobile Phase Solvents | Carrier for analytes through the system | HPLC-grade with low UV cutoff, filtered and degassed | Acetonitrile preferred for low UV background, methanol as alternative |

| Buffer Salts | Mobile phase modifiers for pH control | High purity (>99.9%), volatile buffers preferred for MS compatibility | Ammonium formate/acetate for MS; phosphate for UV detection |

| Reference Standards | Compound identification and quantification | Certified reference materials with documented purity | Essential for method validation and accurate quantification |

| Sample Filters | Removal of particulate matter | 0.2 µm PTFE or nylon membrane, low analyte binding | Critical for protecting UFLC columns from particulates |

Advanced Detection Capabilities

Spectral Analysis and Peak Purity Assessment

The multi-wavelength detection capability of DAD enables sophisticated data analysis that extends far beyond simple quantification. Peak purity assessment represents one of the most valuable applications of DAD data, particularly in pharmaceutical analysis where regulatory requirements demand demonstration of method specificity [12]. This assessment involves comparing UV spectra acquired at different points across a chromatographic peak (typically upslope, apex, and downslope) to detect potential co-elution. Software algorithms calculate a purity index or purity angle based on spectral similarity, with significant differences indicating the presence of multiple compounds [12]. This capability is crucial for stability-indicating methods where the active pharmaceutical ingredient must be resolved from degradation products, and in natural product analysis where complex mixtures often contain structurally similar compounds.

Advanced spectral analysis also enables optimal wavelength selection for quantification, as analysts can review full spectra to identify wavelengths that maximize sensitivity for target analytes while minimizing interference from other sample components [10]. The ability to extract chromatograms at multiple wavelengths from a single injection provides additional method development flexibility and can help resolve partially separated peaks when their absorbance maxima differ sufficiently. In research applications, this spectral information can provide preliminary structural insights, particularly when analyzing compounds with characteristic chromophores, such as distinguishing between different classes of flavonoids or identifying compounds with specific substituent patterns based on their spectral characteristics [14].

Peak Deconvolution of Co-eluting Compounds

Perhaps the most advanced application of DAD data is mathematical deconvolution of co-eluting peaks, a capability that addresses one of the most common challenges in chromatographic analysis. Advanced algorithms, such as the i-PDeA function described in Shimadzu systems, utilize both chromatographic profile and spectral differences to virtually separate overlapping peaks [10]. This approach relies on the fundamental principle that each compound has a unique UV-Vis spectrum, which serves as a chemical signature. When peaks partially co-elute, their combined signal contains both temporal information (retention behavior) and spectral information (absorbance characteristics), which sophisticated software can disentangle through multivariate analysis techniques [10].

This deconvolution capability proves particularly valuable when complete chromatographic resolution is difficult to achieve due to structural similarity of compounds or when analysis time constraints prevent method optimization for baseline separation. The technology has demonstrated practical utility in analyzing natural products, such as distinguishing between structurally similar cannabinoids that exhibit distinct spectral profiles despite similar retention times [10]. Unlike traditional integration methods that estimate partially resolved peaks through Gaussian fitting, spectral deconvolution relies on scientifically sound principles of spectral uniqueness, providing more accurate quantification of individual components in complex mixtures without requiring additional separation cycles [10].

Experimental Design and Methodologies

Method Development Protocol

Developing a robust UFLC-DAD method requires systematic optimization of multiple parameters to achieve the desired separation while maintaining compatibility with detection requirements. The process typically begins with column selection based on analyte properties, with C18 columns serving as the default choice for most reverse-phase applications. Mobile phase composition represents the next critical parameter, with initial scouting gradients employed to determine the appropriate solvent strength and selectivity [9]. The use of experimental design (Design of Experiments, DoE) approaches has demonstrated significant advantages over traditional one-factor-at-a-time optimization, enabling more efficient identification of optimal conditions and understanding of factor interactions [9].

A representative method development protocol for pharmaceutical analysis might include these systematic steps: (1) column screening using a generic gradient; (2) optimization of organic modifier percentage using a central composite design; (3) evaluation of buffer pH and concentration; (4) temperature optimization; and (5) final gradient fine-tuning. Throughout this process, DAD detection provides valuable feedback through spectral analysis, helping identify optimal monitoring wavelengths and flag potential co-elution issues [9]. The dramatically reduced analysis times of UFLC compared to conventional HPLC facilitate more rapid method optimization iterations, with run times often reduced 3-5 fold while maintaining or improving resolution [9].

Representative Experimental Applications

UFLC-DAD has been successfully applied across diverse research areas, with several studies demonstrating its capabilities in challenging analytical scenarios. In pharmaceutical development, a validated UFLC-DAD method was developed for simultaneous quantification of anticancer guanylhydrazones (LQM10, LQM14, LQM17) [9]. The method employed a methanol-water (60:40 v/v) mobile phase adjusted to pH 3.5 with acetic acid at ambient temperature, with detection at 290 nm. The UFLC approach demonstrated significant advantages over conventional HPLC, with four times less solvent consumption and 20 times smaller injection volume while maintaining excellent precision (intra-day RSD <2%) and accuracy (98.7-101.5%) [9].

In natural product research, UFLC-DAD-TOF/MS was employed to identify β-amyloid fibrillation inhibitors from Scutellaria baicalensis, demonstrating the technique's power in bioactivity-guided fractionation [15] [16]. The method identified thirteen major chemical components, with significant reduction in peak areas for baicalein and baicalin after incubation with Aβ (1-42) peptide, indicating binding and potential inhibitory activity [16]. This application highlights how DAD spectral data combined with mass detection enables rapid identification of bioactive compounds in complex matrices, significantly accelerating natural product drug discovery.

Another advanced application involves anthocyanin analysis in food matrices, where UFLC-DAD provides superior resolution of structurally similar pigments compared to conventional HPLC [14]. The enhanced speed and resolution of UFLC enables rapid profiling of these unstable compounds, while DAD detection facilitates preliminary identification based on characteristic UV-Vis spectra and monitoring of degradation processes. These diverse applications demonstrate the versatility of UFLC-DAD across different compound classes and analytical challenges.

Table 4: Validation Parameters for a Representative UFLC-DAD Method (Guanylhydrazones Analysis)

| Validation Parameter | LQM10 | LQM14 | LQM17 | Acceptance Criteria |

|---|---|---|---|---|

| Linearity (r²) | 0.9994 | 0.9997 | 0.9997 | r² ≥ 0.999 |

| Accuracy (% Recovery) | 99.3-101.6% | 98.7-101.5% | 99.5-100.5% | 98-102% |

| Precision Intra-day (RSD%) | 0.53% | 0.84% | 1.27% | ≤2% |

| Precision Inter-day (RSD%) | 1.12% | 1.05% | 1.89% | ≤3% |

| Specificity (Similarity Index) | 999 | 999 | 1000 | ≥950 |

| Robustness (Flow Variation RSD%) | 2.07% | 2.34% | 2.54% | ≤3% |

Operational Workflow and Data Analysis

Systematic Analytical Procedure

A standardized operational workflow ensures consistent and reliable UFLC-DAD performance. The process begins with mobile phase preparation using high-purity solvents and buffers, followed by thorough degassing to prevent bubble formation in the high-pressure system and DAD flow cell [12]. System equilibration follows, typically requiring 10-15 column volumes until stable baseline is achieved, with monitoring of backpressure and baseline noise as key indicators of system readiness. Sample preparation must be appropriate for UFLC sensitivity, typically involving dissolution in mobile phase or weaker solvent, filtration through 0.2 µm membranes, and consideration of injection volume (typically 1-5 µL for UFLC) to maintain separation efficiency [9].

The analytical sequence should include appropriate system suitability tests as defined by regulatory guidelines, typically evaluating parameters such as plate count, tailing factor, resolution between critical pairs, and repeatability of retention time and peak area [12]. During data acquisition, DAD parameters must be optimized including spectral acquisition range (typically 200-400 nm for most small molecules), spectral bandwidth (typically 1-4 nm for balance of sensitivity and specificity), and acquisition rate (typically 10-40 Hz depending on peak widths) [12]. Post-acquisition, data processing includes integration parameter optimization, wavelength selection for quantification, and spectral analysis for peak purity assessment or compound identification.

Data Interpretation and Troubleshooting

Effective interpretation of UFLC-DAD data extends beyond simple peak integration to comprehensive assessment of chromatographic and spectral information. Retention time stability provides insights into system performance, with shifts potentially indicating column degradation, mobile phase composition errors, or temperature fluctuations. Peak shape evaluation (tailing, fronting, broadening) can reveal secondary interactions, column overload, or extra-column volume issues. The DAD spectral data enables additional troubleshooting capabilities; for example, changing spectral profiles across a peak may indicate co-elution, while unexpected spectral features might suggest degradation during analysis or contamination [10] [12].

Advanced data analysis includes multi-wavelength processing to maximize sensitivity for trace components, three-dimensional plotting (time-wavelength-absorbance) for comprehensive sample visualization, and spectral library searching for compound identification. For complex separations, the peak deconvolution algorithms available in modern DAD software can mathematically resolve overlapping peaks, provided their spectral features differ sufficiently [10]. When method issues arise, systematic troubleshooting should address both the chromatographic separation (retention, resolution, peak shape) and detection aspects (sensitivity, baseline noise, spectral anomalies), recognizing that these elements are interconnected in a properly optimized UFLC-DAD method.

Application in Broader Analytical Context

UFLC-DAD occupies a strategic position in the hierarchy of analytical techniques, particularly in the context of pharmaceutical analysis and quality control. The technology bridges the gap between conventional HPLC and more sophisticated LC-MS systems, providing more information than single-wavelength UV detection without the complexity and cost of mass spectrometry [13]. This positioning makes UFLC-DAD ideal for routine analysis where reliability, precision, and information content must be balanced against operational costs and technical requirements. In regulated environments, the peak purity assessment capability of DAD provides critical data for method validation specifically addressing specificity requirements [12].

The role of UFLC-DAD continues to evolve with technological advancements. As computational power increases, more sophisticated data analysis algorithms enable extraction of additional information from DAD spectral data, including preliminary structural predictions and enhanced peak deconvolution capabilities [10]. The combination of UFLC-DAD with other detection techniques, particularly mass spectrometry, creates powerful hyphenated systems that leverage the strengths of each technology [15] [16]. In such configurations, UFLC provides high-resolution separation, DAD offers universal detection with spectral information, and MS delivers molecular weight and structural information. This comprehensive approach has proven particularly valuable in complex sample analysis, such as natural product characterization or impurity profiling in pharmaceuticals, where complete chemical understanding requires multiple information dimensions [14] [16].

For researchers selecting analytical techniques, UFLC-DAD represents the optimal choice when dealing with known chromophoric compounds requiring precise quantification with additional confidence in peak identity and purity. For completely unknown identification or compounds without chromophores, mass spectrometry or universal detectors represent better alternatives [13]. However, for the vast majority of pharmaceutical and natural product applications, UFLC-DAD provides an unparalleled balance of performance, information content, and practical utility, establishing it as a cornerstone technology in modern analytical laboratories.

Comparative Strengths and Inherent Limitations of Each Technique

Ultraviolet-Visible (UV-Vis) spectroscopy and Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) represent two cornerstone analytical techniques in modern laboratories. While both methods leverage the principle of light absorption by molecules, they offer distinct capabilities and are suited to different analytical challenges. UV-Vis spectroscopy provides a rapid, straightforward means of quantifying analytes in solution, whereas UFLC-DAD combines high-resolution separation with comprehensive spectral characterization. Within the context of pharmaceutical research, food science, environmental monitoring, and cosmetic quality control, understanding the comparative strengths and limitations of these techniques is paramount for selecting the appropriate method for specific analytical needs. This guide provides an in-depth technical comparison to inform researchers, scientists, and drug development professionals in their methodological decision-making [12] [1] [17].

Fundamental Principles and Instrumentation

UV-Vis Spectroscopy: Core Principles

UV-Vis spectroscopy is an analytical technique that measures the amount of discrete wavelengths of ultraviolet or visible light absorbed by a sample in comparison to a reference or blank. The fundamental principle is based on the excitation of electrons to higher energy states when molecules absorb light with energy corresponding to the energy difference between molecular orbitals. The absorbance (A) of light is quantitatively described by the Beer-Lambert law: A = ε * c * L, where ε is the molar absorptivity (a compound-specific constant), c is the concentration, and L is the path length of light through the sample. The resulting absorption spectrum, a plot of absorbance versus wavelength, provides a characteristic fingerprint for many compounds, with the wavelength of maximum absorption (λmax) being particularly useful for identification and quantification [1].

The instrumentation for UV-Vis spectroscopy typically consists of several key components as visualized in Figure 1:

Figure 1. Schematic of a UV-Vis Spectrophotometer. The light source emits broad-spectrum light, which is filtered to specific wavelengths. This monochromatic light passes through the sample, and the detector measures the intensity before and after the sample to calculate absorbance.

A light source (often a deuterium lamp for UV and a tungsten/halogen lamp for visible regions) emits broad-spectrum light. A wavelength selection system, such as a monochromator (containing a diffraction grating with 300-2000 grooves per mm) or filters, isolates specific wavelengths. The sample is contained in a cuvette (typically quartz for UV, with a standard pathlength of 1 cm), and a detector (e.g., photomultiplier tube, photodiode, or CCD) converts the transmitted light intensity into an electrical signal for data processing. The key measurement is the ratio of the intensity of light after passing through the sample (I) to the initial intensity (Iâ‚€), known as transmittance, from which absorbance is calculated as A = -log(I/Iâ‚€) [1].

UFLC-DAD: Core Principles

UFLC-DAD is a hybrid technique that couples the high-resolution separation power of liquid chromatography with the spectroscopic capabilities of a diode array detector. The chromatography component separates a complex mixture into its individual constituents based on their differential partitioning between a stationary phase (column packing material) and a mobile phase (liquid solvent pumped at high pressure). UFLC, a derivative of HPLC, utilizes columns packed with smaller particles (<2 μm) and operates at higher pressures, resulting in enhanced speed, resolution, and sensitivity compared to conventional HPLC [18] [19].

The role of the DAD is critical. Unlike a single-wavelength UV detector, the DAD captures the complete UV-Vis spectrum (e.g., 190-600 nm) of each analyte as it elutes from the chromatography column. This is achieved by passing the light through the flow cell (with volumes of 0.5–1 µL for UHPLC) and then dispersing it onto an array of hundreds of photodiodes (e.g., 512 or 1024). This allows for simultaneous multi-wavelength detection and the collection of full spectral data for each point in the chromatogram [12] [10].

A schematic of the UFLC-DAD system is shown in Figure 2:

Figure 2. Schematic of a UFLC-DAD System. A high-pressure pump delivers the mobile phase, which mixes the solvents and carries the injected sample through the separation column. The separated components then pass through the DAD flow cell, where full UV-Vis spectra are continuously acquired.

Comparative Strengths and Limitations

The choice between UV-Vis spectroscopy and UFLC-DAD is dictated by the analytical problem, sample complexity, and required information. Their core strengths and inherent limitations are compared in Table 1 and detailed in the following sections.

Table 1: Comparative Analysis of UV-Vis Spectroscopy and UFLC-DAD

| Feature | UV-Vis Spectroscopy | UFLC-DAD |

|---|---|---|

| Principle | Measures light absorption by a solution [1] | Combines chromatographic separation with full-spectrum UV-Vis detection [12] [10] |

| Analytical Information | Total analyte content, concentration, reaction monitoring [1] | Individual quantification, identification, and purity assessment of multiple components [12] [10] |

| Sample Complexity | Low to moderate (solutions with few absorbing species) [1] | High (complex mixtures like plant extracts, pharmaceuticals, biofluids) [18] [19] |

| Speed of Analysis | Very fast (seconds to minutes) [17] | Moderate to fast (minutes to tens of minutes) [18] |

| Sensitivity | Good (e.g., LOD for Bakuchiol: ~µg/mL range via calibration) [17] | Excellent (e.g., LOD for posaconazole: ~1 µg/mL; phenolic compounds: ng range) [18] [19] |

| Selectivity | Low, unless analytes have distinct, non-overlapping spectra [1] | Very High, via two orthogonal dimensions: retention time and spectrum [12] [10] |

| Peak Purity/Purity Assessment | Not possible | Yes, via spectral comparison across a peak [10] |

| Quantitation without Standard | Possible via Beer-Lambert law with known ε [1] | Requires standards for identification and calibration [12] |

| Method Development & Cost | Simple, fast, and low cost [1] [13] | Complex, time-consuming, and higher cost (instrumentation & solvents) [13] |

Strengths of UV-Vis Spectroscopy

- Simplicity and Ease of Use: UV-Vis spectrophotometers are straightforward to operate, requiring minimal training. Method development is typically rapid, involving primarily the selection of an appropriate wavelength and solvent [1] [13].

- Speed and High Throughput: Analysis time is very short, often taking only seconds to minutes per sample, making it ideal for kinetic studies and high-throughput quantitative analysis [17].

- Cost-Effectiveness: Both the initial capital investment and operational costs are low compared to chromatographic systems. It requires no expensive consumables like chromatography columns [13] [20].

- Non-Destructive Nature: The sample is generally recoverable after analysis, as the technique typically does not alter or consume the analyte [1].

- Quantitative Accuracy: For a single, well-defined analyte in a clean solution, UV-Vis provides highly precise and accurate quantification with a wide linear dynamic range, crucial for applications like pharmaceutical quality control where precision of <0.2% RSD is required [12].

Limitations of UV-Vis Spectroscopy

- Lack of Selectivity: The primary limitation is its inability to resolve mixtures. The measured absorbance is the sum of contributions from all light-absorbing species in the solution, leading to potential inaccuracies in complex matrices [1].

- Requirement for Chromophores: The analyte must contain a chromophore (a functional group that absorbs UV or visible light). Compounds like sugars, alcohols, and many polymers cannot be detected directly [13] [20].

- Matrix Interference: The technique is highly susceptible to interference from colored or turbid samples, which can scatter light and cause significant measurement errors. This often necessitates extensive sample preparation [1] [17].

Strengths of UFLC-DAD

- High Selectivity and Resolution: The combination of chromatographic separation and spectral identification provides two orthogonal dimensions of selectivity. Co-eluting compounds can often be resolved and quantified if their spectra are distinct, using advanced software features like peak deconvolution (e.g., Shimadzu's i-PDeA) [10] [19].

- Comprehensive Information: DAD provides both quantitative data (peak area) and qualitative information (retention time and UV-Vis spectrum) for each separated component in a single run. This is invaluable for identifying unknown peaks and confirming the identity of target analytes [12] [10].

- Peak Purity Assessment: By comparing spectra from the upslope, apex, and downslope of a chromatographic peak, DAD can assess peak homogeneity. This is a critical tool in pharmaceutical analysis for detecting co-eluting impurities [12] [10].

- Enhanced Sensitivity: UFLC systems, with their smaller particle sizes, produce sharper peaks, leading to lower limits of detection. For example, an LOD of 0.82 µg/mL was reported for posaconazole using HPLC-DAD [18].

- Universal Data Collection: The DAD collects data across all wavelengths simultaneously, allowing the user to retrospectively reprocess data and quantify compounds at different wavelengths without reinjecting the sample [12].

Limitations of UFLC-DAD

- Complexity and Cost: The instrumentation is significantly more complex and expensive to purchase, operate, and maintain. It also requires a continuous supply of high-purity solvents and columns [13].

- Longer Analysis Times: A typical chromatographic run takes several minutes to over an hour, which limits sample throughput compared to UV-Vis [18].

- Requirement for Method Development: Developing a robust chromatographic method that adequately separates all components of interest can be a time-consuming process requiring expert knowledge [13].

- Indirect Quantification: Unlike UV-Vis, quantification in chromatography is almost always relative, depending on comparison to a calibrated standard. It cannot directly use the Beer-Lambert law for absolute quantitation without a standard [12].

Experimental Protocols and Applications

Protocol: Quantification of an Active Ingredient in Cosmetics by UV-Vis

A study quantifying bakuchiol in cosmetic serums demonstrates a typical UV-Vis protocol [17].

- Objective: To determine the concentration of bakuchiol in commercial cosmetic serums.

- Sample Preparation: For oil-based serums, a weighed amount of the product was dissolved directly in ethanol. For oil-in-water emulsions, complete dissolution was not always achievable, leading to potential quantification issues [17].

- Instrumentation: UV-Vis spectrophotometer with quartz cuvettes (1 cm pathlength).

- Methodology:

- A standard solution of pure bakuchiol was prepared in ethanol.

- The UV-Vis spectrum (e.g., 200-400 nm) of the standard was acquired, identifying λmax at 262 nm.

- A calibration curve was constructed by measuring the absorbance at 262 nm for a series of standard solutions of known concentration.

- The sample solutions were measured at the same wavelength, and the concentration was determined by interpolating the absorbance value against the calibration curve.

- Key Reagents and Materials:

- Ethanol (HPLC grade): Serves as the solvent for dissolving standards and samples.

- Bakuchiol standard: High-purity reference material for creating the calibration curve.

- Quartz cuvettes: Required for accurate UV transmission, as plastic and glass absorb UV light.

Protocol: Analysis of Phenolic Compounds in Apple Juice by UFLC-DAD

A study comparing UHPLC-UV and UHPLC-MS/MS for phenolic compounds in apple juice provides a robust UFLC-DAD protocol [19].

- Objective: To separate, identify, and quantify multiple phenolic compounds in a complex apple juice matrix.

- Sample Preparation: Raw apple juice was mixed with an equal volume of methanol containing 1% acetic acid to improve compound stability during analysis and precipitate proteins. The mixture was then centrifuged and filtered before injection [19].

- Chromatographic Conditions:

- Column: Kinetex-C18 (2.1 x 50 mm, 1.3 µm).

- Mobile Phase: A gradient elution composed of acetonitrile and an aqueous buffer (e.g., 15 mM potassium dihydrogen orthophosphate).

- Flow Rate: 0.4 mL/min.

- Column Temperature: 40 °C.

- Injection Volume: 5 µL.

- DAD Conditions: Full spectra were collected from 190-400 nm. For quantification of specific phenolics like catechin, chlorogenic acid, and phloridzin, their respective λmax values were used.

- Key Reagents and Materials:

- UHPLC column with sub-2µm particles: Essential for high-resolution separation under high pressure.

- MS-grade acetonitrile and water: High-purity solvents to prevent baseline noise and column damage.

- Acetic acid: Added to the mobile phase or sample to suppress ionization of acidic analytes and improve peak shape.

- Phenolic compound standards: A suite of standards is necessary for identifying peaks and constructing calibration curves.

Application Case Studies

- Pharmaceutical Quality Control: A study developed and validated both HPLC-DAD and UHPLC-UV methods for quantitating the antifungal drug posaconazole in a suspension. The UHPLC-UV method offered superior speed (3 min vs. 11 min run time) and reduced solvent consumption, demonstrating the advantage of UFLC for routine quality control where high throughput is desired. Both methods showed excellent linearity (r² > 0.999) and precision (CV% < 3%), meeting ICH guidelines [18].

- Food and Beverage Analysis: UV-Vis and synchronous fluorescence spectroscopy were compared with HPLC-DAD for predicting the age of sweet wines. While spectroscopic methods coupled with chemometrics offered a faster, cheaper alternative, HPLC-DAD was critical for identifying and quantifying specific phenolic compounds (e.g., catechin, gallic acid, caftaric acid) whose changing concentrations correlated with wine aging. This highlights the role of UFLC-DAD in providing definitive compound-specific data to validate simpler, high-throughput methods [21].

- Analysis of Complex Plant Matrices: The comparison of UHPLC-UV and UHPLC-MS/MS for phenolic compounds in apple juice revealed that UV detection is highly effective for major compounds. However, challenges like co-elution can lead to overestimation of certain compounds, a limitation that can be mitigated by the superior resolution of UFLC and the peak purity assessment capability of the DAD [19].

Technique Selection Guide

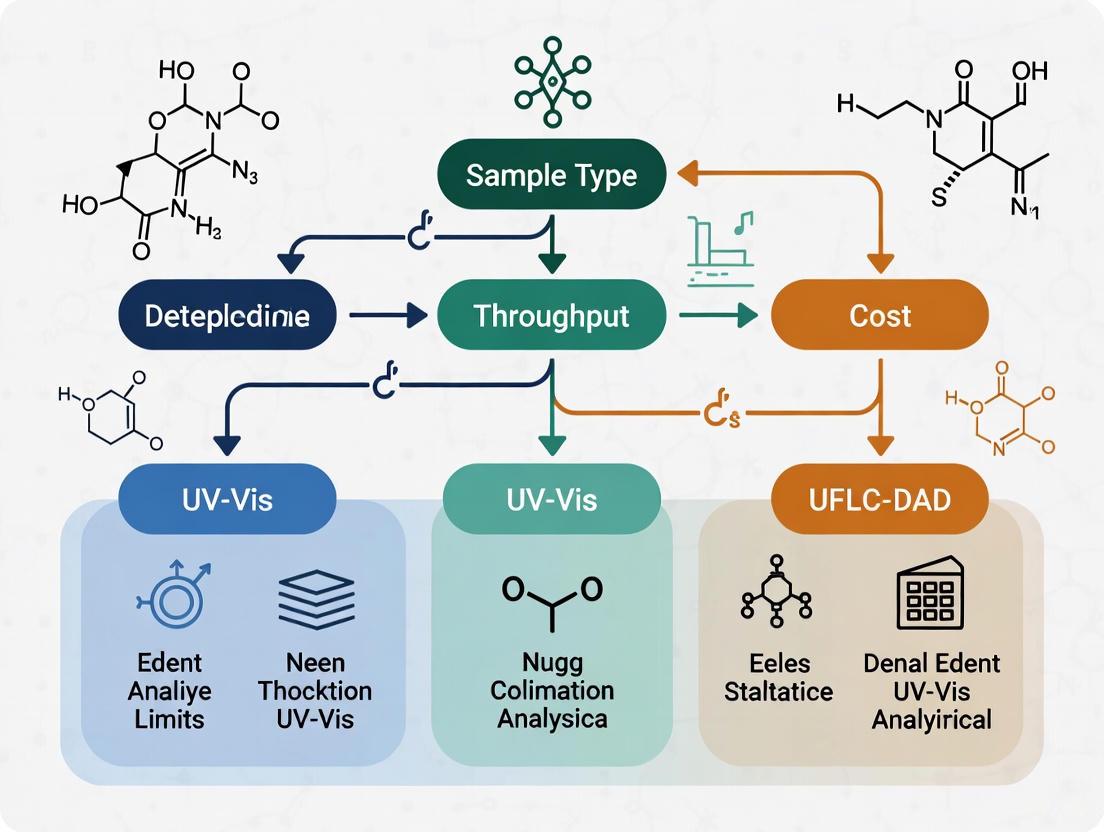

The decision-making process for selecting between UV-Vis and UFLC-DAD is summarized in Figure 3.

Figure 3. Technique Selection Workflow. This diagram guides the user through key questions to determine the most appropriate analytical technique based on their sample and information requirements.

When to Choose UV-Vis Spectroscopy

- For routine quantitation of a known analyte in a relatively clean matrix, such as checking the concentration of an active pharmaceutical ingredient (API) in a standard solution [12] [17].

- When speed and cost are primary drivers, and the necessary selectivity can be achieved through simple sample preparation.

- For kinetic studies or monitoring reactions in real-time, where rapid, continuous measurements are required [1].

- When the analyte lacks a chromophore, consider that neither technique is suitable. Alternative detectors like Refractive Index (RI) or Charged Aerosol Detection (CAD) would be necessary [13] [20].

When to Choose UFLC-DAD

- For analyzing complex mixtures containing multiple, potentially unknown, components that require separation, such as plant extracts, environmental samples, or formulated products [18] [19].

- When confirmatory analysis is critical, and information beyond retention time (i.e., a UV spectrum) is needed to confidently identify a compound [10].

- For impurity profiling or peak purity assessment in pharmaceutical development to meet regulatory requirements [12] [10].

- During method development, where the ability to retrospectively reprocess data at different wavelengths can save significant time and resources.

UV-Vis spectroscopy and UFLC-DAD are powerful yet distinct tools in the analytical chemist's arsenal. UV-Vis stands out for its simplicity, speed, and cost-effectiveness for targeted quantitative analysis of pure substances or simple mixtures. In contrast, UFLC-DAD excels in resolving, identifying, and quantifying individual components within complex matrices, providing a depth of information that is unattainable with standalone spectroscopy. The choice between them is not a matter of one being universally superior but hinges on the specific analytical question, the nature of the sample, and the required level of certainty. By understanding their complementary strengths and inherent limitations, researchers and drug development professionals can make informed decisions, ensuring the selection of the most efficient and effective technique for their specific application.

Selecting a Technique Based on Analytical Target Profile (ATP)

In modern pharmaceutical research and quality control, the selection of an appropriate analytical technique is a critical decision that directly impacts the reliability, efficiency, and regulatory compliance of analytical data. This decision-making process must be guided by a structured Analytical Target Profile (ATP), which defines the required performance characteristics of an analytical procedure based on its intended purpose. An ATP explicitly outlines the quality attributes to be measured, the required accuracy and precision, and the appropriate measurement conditions. Within this framework, scientists must frequently choose between established techniques like Ultraviolet-Visible spectroscopy (UV-Vis) and more advanced separation-based methods like Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD).

This technical guide provides a structured approach for researchers, scientists, and drug development professionals to select between UV-Vis and UFLC-DAD based on a predefined ATP. We present core principles, direct performance comparisons, detailed experimental protocols, and decision-making workflows to guide this selection process, ensuring that the chosen technique aligns with both analytical requirements and operational constraints.

Core Principles and Instrumentation of UV-Vis and UFLC-DAD

UV-Visible Spectroscopy (UV-Vis)

UV-Vis spectroscopy is a classical analytical technique that measures the absorption of ultraviolet or visible light by a sample. The fundamental principle is governed by the Beer-Lambert Law, which states that absorbance is directly proportional to the concentration of the absorbing species, the path length of the measurement cell, and the compound-specific molar absorptivity [12]. A UV-Vis detector in a liquid system typically uses a deuterium (D2) lamp for the UV range (190–380 nm) and may be supplemented with a tungsten lamp for the visible range (380–950 nm) [22]. In a variable wavelength detector (VWD), light of a specific wavelength is selected using a monochromator before it passes through the flow cell [12].

Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD)

UFLC-DAD combines high-speed chromatographic separation with full-spectrum ultraviolet detection. UFLC utilizes columns packed with smaller particles (<2 µm) and operates at higher pressures compared to conventional HPLC, resulting in enhanced speed, resolution, and sensitivity [18]. The Diode Array Detector (DAD), also known as a Photodiode Array (PDA), represents a significant advancement over single-wavelength UV detection. Its optical system differs in that light from the source passes directly through the flow cell, and the transmitted light is then dispersed by a diffraction grating onto an array of photodiodes (e.g., 512 or 1024 elements). This allows for the simultaneous capture of the entire UV-Vis spectrum for each data point in the chromatogram [12] [22]. This capability for spectral confirmation is pivotal for peak identity verification and purity assessment [23].

Comparative Analysis: UV-Vis vs. UFLC-DAD

The choice between UV-Vis and UFLC-DAD is fundamentally dictated by the complexity of the sample and the specificity of information required by the ATP. The table below summarizes the core differentiating factors.

Table 1: Key Characteristics of UV-Vis and UFLC-DAD

| Characteristic | UV-Vis Spectroscopy | UFLC-DAD |

|---|---|---|

| Analytical Principle | Measures absorption of light by a sample without separation | Combines chromatographic separation with spectral detection |

| Information Output | Total absorbance at specified wavelength(s); concentration | Retention time, quantitative concentration, and full UV-Vis spectrum |

| Specificity | Low for mixtures; requires selective wavelength or sample purity | High; based on retention time and spectral match |

| Peak Purity Assessment | Not possible | Yes, by comparing spectra across a peak |

| Analysis Speed | Very fast (minutes) | Fast, but longer than UV-Vis (run time-dependent) |

| Sample Complexity | Suitable for pure solutions or simple mixtures | Ideal for complex mixtures (e.g., formulations, biological matrices) |

| Impurity Profiling | Limited; cannot resolve co-absorbing impurities | Excellent; can detect and identify co-eluting impurities [23] |

| Data Acquisition Rate | N/A (continuous measurement) | Adjustable (e.g., 0.31 to 80 Hz); higher rates improve peak definition [24] |

Quantitative Performance and Validation

The ATP must define required performance metrics such as linearity, accuracy, and limits of detection/quantitation (LOD/LOQ). A direct comparison study of Levofloxacin quantification demonstrates how technique selection impacts these parameters.

Table 2: Quantitative Performance Comparison for Levofloxacin Analysis [25]

| Parameter | HPLC-UV (Similar to UFLC-DAD) | UV-Vis |

|---|---|---|

| Linear Range | 0.05 – 300 µg/mL | 0.05 – 300 µg/mL |

| Regression Equation | y = 0.033x + 0.010 | y = 0.065x + 0.017 |

| Coefficient (R²) | 0.9991 | 0.9999 |

| Recovery (Low Conc.) | 96.37 ± 0.50% | 96.00 ± 2.00% |

| Recovery (Medium Conc.) | 110.96 ± 0.23% | 99.50 ± 0.00% |

| Recovery (High Conc.) | 104.79 ± 0.06% | 98.67 ± 0.06% |

While both methods showed a wide linear range and excellent R² values, the HPLC-UV method exhibited variable and less accurate recovery rates at medium and high concentrations in a complex scaffold matrix, whereas UV-Vis recovery was consistently close to 100%. This counter-intuitive result highlights that in specific contexts where the analyte is free from interference, UV-Vis can provide superior accuracy, while chromatographic methods may be affected by matrix interactions [25]. However, for impurity analysis in pharmaceuticals, the ICH Q3A guidelines implicitly assume UV detection for stability-indicating methods, requiring high precision (<0.2% RSD) and sensitivity for quantitation down to 0.05–0.10% [12].

Experimental Protocols and Workflows

Detailed Protocol for UFLC-DAD Analysis of a Pharmaceutical Formulation

The following protocol, adapted from the analysis of Posaconazole suspension, outlines a typical UFLC-DAD method for quantifying an Active Pharmaceutical Ingredient (API) in a formulation [18].

- Instrumentation: Agilent 1290 Infinity Binary Pump LC system coupled with a DAD and an autosampler. Data collection and analysis are performed using ChemStation software.

- Chromatographic Conditions:

- Column: Kinetex-C18 (2.1 × 50 mm, 1.3 µm).

- Mobile Phase: Acetonitrile and 15 mM potassium dihydrogen orthophosphate (45:55, v/v).

- Flow Rate: 0.4 mL/min.

- Injection Volume: 5 µL.

- Column Temperature: 40 °C.

- Run Time: 3 minutes.

- DAD Acquisition Settings:

- Detection Wavelength: 262 nm (for quantification).

- Spectral Acquisition: Full spectrum from 190–400 nm for peak identity and purity.

- Bandwidth: 4 nm (range of wavelengths averaged for the primary signal).

- Data Acquisition Rate: 20 Hz (to ensure sufficient data points across narrow UHPLC peaks).

- Sample Preparation:

- Accurately weigh an amount of the pharmaceutical suspension equivalent to about 4 mg of Posaconazole.

- Dilute to 10 mL with methanol and vortex mix (Solution S1).

- Further dilute 0.1 mL of S1 to 1 mL with methanol containing the internal standard (Itraconazole, 10 µg/mL).

- Centrifuge if necessary, and transfer the supernatant to an LC vial for analysis.

- Validation Parameters:

- Linearity: Prepare and analyze standard solutions across the concentration range of 5–50 µg/mL.

- Precision and Accuracy: Analyze replicate samples (n=3) at low, medium, and high concentrations within the linear range on the same day (intra-day) and on three different days (inter-day).

Detailed Protocol for UV-Vis Analysis of a Cosmetic Ingredient

This protocol, derived from the quantification of Bakuchiol in cosmetic serums, describes a direct UV-Vis method for a pure analyte in solution [17].

- Instrumentation: UV-Vis spectrophotometer (e.g., Shimadzu UV-2600) with 1 cm pathlength quartz cuvettes.

- Method Development and Conditions:

- Wavelength Selection: Dissolve the pure Bakuchiol standard in ethanol and scan from 200–400 nm to identify the maximum absorbance (λmax), found to be 262 nm.

- Bandwidth: Set to 1–2 nm for high spectral resolution.

- Sample Preparation:

- For oil-based serums (samples 1-4): Accurately weigh a small amount of the product and dissolve it directly in ethanol to a nominal concentration within the linear range.

- For water-containing emulsions (samples 5-6): Liquid-liquid extraction may be required. The sample is shaken with ethanol, and the organic layer is separated and diluted for analysis. Note: incomplete extraction can lead to quantification errors [17].

- Vortex mix and centrifuge if the solution is not clear.

- Calibration and Quantification:

- Prepare a stock solution of authentic Bakuchiol standard in ethanol.

- Create a series of standard solutions by serial dilution to cover a concentration range of, for example, 1–50 µg/mL.

- Measure the absorbance of each standard and the sample at 262 nm.

- Construct a calibration curve (Absorbance vs. Concentration) and determine the sample concentration using the linear regression equation.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for UV-Vis and UFLC-DAD Analysis

| Item | Function / Description | Example Use Case |

|---|---|---|

| Deuterium (D₂) Lamp | Provides stable, continuous light source in the UV range (190–400 nm). | Standard light source in both VWD and DAD detectors [12]. |

| Photodiode Array | Semiconductor device consisting of hundreds of individual diodes that simultaneously detect a range of wavelengths. | Enables full-spectrum acquisition in DAD for peak purity and identification [22]. |

| UHPLC Column | Column packed with sub-2µm particles for high-efficiency separations. | Kinetex-C18 (1.3 µm) for fast separation of Posaconazole [18]. |

| HPLC-Grade Solvents | High-purity solvents (ACN, MeOH, water) with low UV absorbance background. | Mobile phase preparation to minimize baseline noise and ghost peaks. |

| Buffer Salts | Provides controlled pH and ionic strength in the mobile phase. | 15 mM Potassium dihydrogen orthophosphate for Posaconazole analysis [18]. |

| Standard Reference Material | High-purity analyte of known identity and concentration. | Used for calibration curve construction and method validation [17]. |

| Codaphniphylline | Codaphniphylline, MF:C30H47NO3, MW:469.7 g/mol | Chemical Reagent |

| Hericenone J | Hericenone J, MF:C19H24O4, MW:316.4 g/mol | Chemical Reagent |

A Structured Workflow for Technique Selection Based on ATP

The following diagram illustrates a logical decision-making process for selecting between UV-Vis and UFLC-DAD, grounded in the specific requirements of the ATP.

Technique Selection Workflow

The selection between UV-Vis and UFLC-DAD is not a matter of one technique being universally superior to the other. Instead, it is a strategic decision that must be anchored in a well-defined Analytical Target Profile. UV-Vis spectroscopy offers a robust, rapid, and cost-effective solution for the quantitative analysis of pure substances or simple mixtures in routine quality control. In contrast, UFLC-DAD provides a powerful orthogonal approach that delivers high specificity, making it indispensable for method development, analysis of complex matrices, and whenever definitive peak identification or purity assessment is mandated.

By applying the structured comparison, detailed protocols, and the decision workflow outlined in this guide, scientists and drug development professionals can make informed, defensible choices that ensure analytical methods are fit-for-purpose, efficient, and compliant with regulatory standards.

Techniques in Action: Method Development and Real-World Applications

In the landscape of pharmaceutical analysis, the selection of an appropriate analytical technique is paramount for ensuring drug quality, stability, and efficacy. This guide is situated within a broader research thesis comparing Ultraviolet-Visible (UV-Vis) spectroscopy and Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD). While UFLC-DAD offers high separation power and specificity for complex mixtures, UV-Vis spectroscopy remains a vital, rapid, and economical tool for the quantitative analysis of active pharmaceutical ingredients (APIs) in bulk and formulated products, especially when dealing with pure compounds or simple matrices [26] [27]. Its utility extends to critical applications such as assay development, drug stability testing, and determining key parameters like the drug-to-antibody ratio (DAR) in antibody-drug conjugates [27] [28]. The robustness of a UV-Vis method, however, is fundamentally anchored in two core development stages: the judicious selection of a suitable solvent and the precise optimization of the analytical wavelength. This technical guide provides an in-depth examination of these critical steps, complete with detailed protocols and data presentation frameworks.

Core Principles of UV-Vis Spectroscopy

UV-Vis spectroscopy operates on the principle of measuring the absorption of ultraviolet or visible light by a molecule. When a molecule absorbs light of a specific energy, it undergoes an electronic transition from a ground state to an excited state. The wavelength at which maximum absorption occurs (λmax) is characteristic of the molecule's chemical structure, particularly the presence of chromophores, which are functional groups capable of absorbing light (e.g., C=C, C=O, aromatic rings). The intensity of the absorption at λmax, governed by the Beer-Lambert Law (A = ε * b * c), provides the basis for quantitative analysis, where A is the absorbance, ε is the molar absorptivity, b is the path length, and c is the concentration.

A key advantage of UV-Vis in a pharmaceutical context is its role in drug stability testing. Stressors like light, temperature, and pH can cause chemical degradation, altering the API's absorption profile. UV-Vis serves as a fast and reliable method to monitor these changes, providing critical data on potency and the formation of impurities early in the drug development process, thereby informing decisions about a drug's commercial viability [28].

Solvent Selection: A Critical First Step

The choice of solvent is a critical determinant in the success of a UV-Vis method, as it can significantly influence the absorption spectrum of the analyte.

Key Selection Criteria

- Solvent Transparency: The solvent must not absorb significantly in the spectral region where the analyte absorbs. This ensures that the measured absorbance is primarily from the analyte of interest. Standard solvents have specific "UV cut-off" wavelengths below which they exhibit strong absorption.

- Solubility and Stability: The solvent must completely dissolve the analyte without causing chemical degradation or interaction during the analysis. The analyte should be stable in the chosen solvent for the duration of the measurement and method development process.

- Polarity and Hydrogen Bonding: The solvent's polarity can cause shifts in the analyte's λmax. More polar solvents can stabilize excited states, often leading to a redshift (bathochromic shift) compared to spectra obtained in non-polar solvents. The potential for hydrogen bonding can also affect the absorption profile.

Common Solvents and Their Properties

The table below summarizes the key characteristics of solvents commonly used in UV-Vis method development.

Table 1: Properties of Common Solvents for UV-Vis Spectroscopy

| Solvent | UV Cut-off (nm) | Polarity | Common Applications & Notes |

|---|---|---|---|

| Water | ~190 nm | High | Ideal for water-soluble, ionizable compounds; compatible with biological APIs [26]. |

| Methanol | ~205 nm | High | Good for a wide range of polar organic compounds. |

| Ethanol | ~210 nm | High | Similar to methanol; often preferred for its lower toxicity. |

| n-Hexane | ~210 nm | Low | Suitable for non-polar analytes; minimal solvent shift. |

| Acetonitrile | ~190 nm | Medium-High | Excellent transparency; often used in HPLC and compatible with UV-Vis. |

| Chloroform | ~245 nm | Low | Used for non-polar compounds; higher cut-off limits useful range. |

| 1,4-Dioxane | ~215 nm | Low | Useful for a variety of organic compounds. |

Wavelength Optimization and Method Validation

Once a suitable solvent is selected, the next critical step is to identify the optimal analytical wavelength and rigorously validate the method to ensure it is fit for its intended purpose.

Experimental Workflow for Wavelength Optimization

The following diagram outlines the logical workflow for developing and optimizing a UV-Vis method, from solvent selection to final validation.

Detailed Experimental Protocol

The workflow can be executed using the following detailed procedures, which are aligned with ICH guidelines for method validation [26].