UV-Vis vs. UFLC-DAD: A Strategic Guide to Speed, Sensitivity, and Application in Pharmaceutical Analysis

This article provides a comprehensive comparison of UV-Vis spectroscopy and UFLC-DAD for pharmaceutical analysis, directly addressing the critical factor of analysis time.

UV-Vis vs. UFLC-DAD: A Strategic Guide to Speed, Sensitivity, and Application in Pharmaceutical Analysis

Abstract

This article provides a comprehensive comparison of UV-Vis spectroscopy and UFLC-DAD for pharmaceutical analysis, directly addressing the critical factor of analysis time. Tailored for researchers and drug development professionals, it explores the foundational principles of each technique, presents methodological workflows for API quantification, and offers troubleshooting guidance for common pitfalls. By synthesizing validation data and real-world case studies, this guide delivers actionable insights for selecting the optimal analytical method to balance speed, cost, regulatory compliance, and analytical performance in both quality control and research settings.

UV-Vis and UFLC-DAD Demystified: Core Principles and Instrumentation

In the realm of analytical chemistry, spectrophotometry and chromatography represent two foundational methodologies with distinct operational principles for substance identification and quantification. For researchers and drug development professionals, selecting the appropriate technique is crucial for method validation, quality control, and research outcomes. This guide provides an objective comparison framed within a broader thesis on analysis time, focusing particularly on UV-Vis spectroscopy and Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD).

Spectrophotometry, specifically UV-Vis spectroscopy, is an analytical technique that measures the amount of discrete wavelengths of ultraviolet or visible light absorbed by or transmitted through a sample in comparison to a reference or blank sample [1]. The fundamental principle operates on the Beer-Lambert Law, which states that absorbance (A) is proportional to the concentration (c) of the analyte, the path length (l) of the sample, and the molar absorptivity (ε) [1]. This relationship is expressed as A = εlc, providing the quantitative foundation for the technique [2].

In contrast, chromatographic separation encompasses a family of techniques primarily used for separating the components of a complex mixture before detection [3]. All chromatographic methods function on the principle of differential distribution of analytes between a stationary phase and a mobile phase [4]. Components in a mixture interact differently with these phases, causing them to elute at different times (retention times), thus achieving physical separation [3]. Ultra-Fast Liquid Chromatography (UFLC) represents an advanced form of liquid chromatography that results in shorter analysis time, increased peak capacity, and lower consumption of samples and solvents compared to conventional HPLC [5].

When these techniques are combined as UFLC-DAD, the system leverages the separation power of chromatography with the detection capabilities of spectroscopy, creating a powerful hybrid analytical tool [5]. The following sections provide detailed operational mechanisms, performance comparisons, and experimental considerations to guide technique selection.

Operational Mechanisms and Instrumentation

How UV-Vis Spectrophotometry Works

A UV-Vis spectrophotometer consists of several key components that work in sequence to measure light absorption [1]. The process begins with a light source that emits across a wide wavelength range, typically utilizing a deuterium lamp for UV light and a tungsten or halogen lamp for visible light [1] [6]. The light then passes through a wavelength selector (monochromator, filters, or diffraction gratings) that isolates specific wavelengths for sample examination [1]. This selected light passes through the sample compartment, where a reference measurement is first taken with a blank solvent, followed by the sample measurement [1]. The transmitted light then reaches a detector (photodiode, photomultiplier tube, or charge-coupled device) that converts light intensity into an electrical signal [1]. Finally, the signal is processed and output to a computer or display, typically presented as an absorption spectrum - a graph of absorbance versus wavelength [1].

The critical identifying parameter in UV-Vis spectroscopy is λmax (maximum absorbance wavelength), which represents the characteristic wavelength where a compound exhibits peak absorption [6]. This value provides information about the electronic structure of molecules and serves as a qualitative fingerprint, though it lacks specificity for completely unknown compounds in complex mixtures [3] [7].

How Chromatographic Separation Works

Chromatographic separation operates on fundamentally different principles from spectroscopy. The process begins with sample introduction, where the mixture is injected into the mobile phase stream [2]. In UFLC, this is typically done via an autosampler with precise injection volumes [8]. The sample is carried by the mobile phase (liquid solvent) through a column containing the stationary phase [2]. This phase can consist of silica particles with various surface chemistries that interact differently with analyte components [4].

Separation occurs due to differential partitioning between the mobile and stationary phases [3]. Molecules with stronger affinity for the stationary phase move more slowly through the column, while those with weaker affinity travel faster [2]. This differential migration results in physical separation of mixture components as they progress through the column [3] [4]. The separated components then elute from the column at characteristic retention times and pass through a detector (such as a DAD) [6]. The detector generates a signal proportional to each component's concentration, producing a chromatogram - a plot of detector response versus time [6].

In UFLC-DAD systems, the diode array detector captures full UV-Vis spectra of each eluting peak, providing both retention time and spectral information for enhanced compound identification [5] [6]. The "ultra-fast" aspect is achieved through columns with smaller particle sizes (<2μm) and systems capable of operating at higher pressures, which significantly reduces analysis time while maintaining resolution [5].

Performance Comparison: UV-Vis vs. UFLC-DAD

Quantitative Technical Comparison

The following table summarizes key performance parameters for UV-Vis spectrophotometry and UFLC-DAD based on experimental data and technical specifications:

| Performance Parameter | UV-Vis Spectrophotometry | UFLC-DAD |

|---|---|---|

| Analysis Time | Typically 1-5 minutes [2] | Approximately 8.5 minutes per sample [5] |

| Sample Throughput | High (minimal preparation) | Moderate (requires separation time) |

| Multi-Component Analysis | Limited, measures total absorbance | Excellent, separates individual components |

| Sensitivity | Moderate (depends on molar absorptivity) | High (detection limits ~0.57-3.23 g% for active components) [5] |

| Specificity/Selectivity | Low, identifies chromophores only | High, combines retention time and spectral data |

| Linear Range | ~0.1-2.0 AU (subject to Beer-Lambert deviation) | Wide linear dynamic range [5] |

| Precision | Good (±1-2% RSD) | Excellent (<0.2% RSD) [6] |

| Instrument Cost | Low to moderate | High (equipment and maintenance) |

| Operational Complexity | Low (minimal training required) | High (requires technical expertise) |

| Sample Volume Requirements | Larger amounts typically needed [5] | Minimal (μL volumes) |

| Environmental Impact | Lower solvent consumption [5] | Higher solvent consumption [5] |

Analysis Time and Efficiency Considerations

Within the context of our thesis on analysis time comparison, UV-Vis spectroscopy demonstrates significant advantages for single-analyte quantification in relatively pure solutions. The technique's speed stems from minimal sample preparation requirements and instantaneous measurement once the instrument is calibrated [2]. Experimental protocols for pharmaceutical analysis (e.g., metoprolol tartrate quantification) demonstrate that UV-Vis can provide results in minutes compared to >8 minutes for UFLC-DAD analysis [5].

However, this time advantage must be balanced against the technique's limitations. UV-Vis suffers from overlapping absorption bands when multiple chromophores are present, making quantitative analysis of individual components in complex mixtures challenging [5]. This limitation becomes particularly significant in pharmaceutical analysis where excipients, impurities, or related compounds may interfere with the target analyte's absorption [5].

UFLC-DAD addresses these limitations through physical separation prior to detection, but at the cost of increased analysis time. The separation process, while dramatically improved in UFLC systems, still requires approximately 5-15 minutes per sample depending on the method [5]. Nevertheless, for complex samples, the total analysis time may be comparable or even favorable for UFLC-DAD when considering that UV-Vis would require additional sample preparation, cleanup, or derivatization steps to achieve accurate results in complex matrices [5].

Experimental Protocols and Methodologies

Detailed UV-Vis Spectrophotometry Protocol

The following experimental protocol for determining active pharmaceutical ingredients (e.g., metoprolol tartrate) via UV-Vis spectrophotometry has been validated in pharmaceutical research [5]:

Instrumentation and Materials:

- UV-Vis spectrophotometer with quartz cuvettes (1 cm pathlength)

- Analytical balance

- Volumetric flasks

- Micropipettes

- Ultrapure water

- Reference standard of target analyte

- Sample tablets or formulations

Sample Preparation Protocol:

- Standard Solution Preparation: Accurately weigh approximately 25.0 mg of reference standard into a 25 mL volumetric flask. Dissolve in purified water and place in an ultrasonic bath for 30 minutes for complete dissolution [5].

- Calibration Curve: Prepare a series of dilutions from the stock solution to create standards covering the expected concentration range (e.g., 5-50 μg/mL).

- Sample Extraction: Weigh and powder tablets. Transfer an amount equivalent to one tablet into a 250 mL round-bottomed flask with 150 mL of purified water [5].

- Extraction Process: Heat in a water bath for 30 minutes, cool, transfer quantitatively to a 250 mL volumetric flask, dilute to volume with purified water, and mix [5].

- Filtration: After suspended solids settle, filter the solution through filter paper, discarding the first 50 mL of filtrate [5].

- Dilution: Transfer 5 mL of the filtrate to a 25 mL volumetric flask and dilute to volume with purified water [5].

Measurement and Quantification:

- Blank Measurement: Fill quartz cuvette with solvent (purified water) and record baseline spectrum.

- Standard Measurements: Measure absorbance of standard solutions at λmax (223 nm for metoprolol).

- Sample Measurement: Measure absorbance of prepared sample solutions at the same wavelength.

- Quantification: Calculate sample concentration using the calibration curve based on Beer-Lambert Law.

Method Validation Parameters:

- Specificity: Verify λmax consistency and check for interference peaks.

- Linearity: Typically R² > 0.998 over working range.

- Accuracy: 98-102% recovery for pharmaceutical applications.

- Precision: RSD < 2% for repeatability.

Detailed UFLC-DAD Analysis Protocol

The following protocol outlines the determination of active components (e.g., metoprolol tartrate) using UFLC-DAD, validated for pharmaceutical applications [5]:

Instrumentation and Materials:

- UFLC system with DAD detector

- C18 reversed-phase column (e.g., 150 mm × 4.6 mm, 2.7 μm particle size)

- Analytical balance

- Volumetric flasks

- Syringe filters (0.45 μm)

- Mobile phase solvents (HPLC grade)

- Reference standards

- Sample tablets or formulations

Chromatographic Conditions:

- Mobile Phase: Optimized binary gradient (e.g., acetonitrile-phosphate buffer)

- Flow Rate: 1.0-1.5 mL/min

- Column Temperature: 25-40°C

- Injection Volume: 5-20 μL

- Detection: DAD monitoring at 223 nm with full spectral scanning (200-400 nm)

- Run Time: 8.5 minutes (optimized for speed in UFLC) [5]

Sample Preparation Protocol:

- Standard Solutions: Prepare stock solutions of reference standards (metoprolol tartrate) in appropriate solvent [5].

- Calibration Standards: Prepare serial dilutions covering the expected concentration range.

- Sample Extraction: Weigh and powder tablets. Extract equivalent of one tablet with 150 mL purified water in a 250 mL round-bottomed flask [5].

- Heating and Filtration: Heat in water bath for 30 minutes, cool, transfer to 250 mL volumetric flask, dilute to volume, mix, and filter, discarding the first 50 mL [5].

- Filtration: Filter samples through 0.45 μm syringe filters before injection.

System Operation and Data Analysis:

- System Equilibration: Condition column with initial mobile phase composition until stable baseline achieved.

- Standard Injection: Inject calibration standards to establish retention times and calibration curves.

- Sample Analysis: Inject prepared samples using autosampler.

- Peak Identification: Identify analytes by comparing retention times and UV spectra with standards.

- Peak Purity Assessment: Use DAD spectral comparison to verify peak homogeneity [6].

Method Validation Parameters [5]:

- Specificity: Resolution >1.5 between analyte and potential impurities.

- Linearity: R² > 0.999 over specified range.

- Accuracy: 98-102% recovery.

- Precision: RSD < 1% for retention time and peak area.

- Detection Limit: Typically 0.05-0.10% of target concentration.

Essential Research Reagent Solutions

The following table details key reagents, materials, and instrumentation essential for implementing both analytical techniques in pharmaceutical and research settings:

| Category | Specific Items | Function/Purpose | Technique |

|---|---|---|---|

| Solvents & Chemicals | HPLC-grade water, acetonitrile, methanol | Mobile phase preparation, sample dilution | Both |

| Phosphate buffers, trifluoroacetic acid | Mobile phase modifiers, pH control | Primarily UFLC | |

| Folin-Ciocalteu reagent | Total phenolic content assay | UV-Vis | |

| Reference Standards | Metoprolol tartrate, gallic acid, ellagic acid | Method calibration, quantification | Both |

| USP/EP reference standards | Regulatory compliance, method validation | Both | |

| Consumables | Quartz cuvettes (1 cm pathlength) | Sample holder for UV-Vis measurements | UV-Vis |

| Syringe filters (0.45 μm, 0.22 μm) | Sample clarification, particulate removal | Primarily UFLC | |

| HPLC vials, caps, septa | Sample containment during analysis | UFLC | |

| Chromatography Supplies | C18 reversed-phase columns | Stationary phase for compound separation | UFLC |

| Guard columns | Column protection, longevity extension | UFLC | |

| Syringes (25-100 μL) | Sample injection | UFLC | |

| Instrumentation | UV-Vis spectrophotometer | Absorbance measurements, quantification | UV-Vis |

| UFLC system with DAD | Separation and detection with spectral confirmation | UFLC | |

| Analytical balance | Precise weighing of standards and samples | Both | |

| Ultrasonic bath | Solvent degassing, standard dissolution | Both |

Application Scenarios and Technique Selection

Ideal Use Cases for UV-Vis Spectrophotometry

UV-Vis spectrophotometry excels in specific application scenarios where speed, cost-effectiveness, and simplicity are prioritized. Routine quality control of raw materials and finished products in pharmaceutical manufacturing represents an ideal application, particularly for single-component analysis [2]. The technique provides excellent performance for total content determination of compounds with strong chromophores, such as the quantification of metoprolol tartrate in tablets, where it demonstrated comparable accuracy to UFLC-DAD with significantly faster analysis times [5].

Environmental monitoring represents another strong application, where rapid screening of water samples for specific contaminants (nitrates, heavy metals) can be efficiently performed [1]. The technique's simplicity enables operation by technicians with minimal training, making it suitable for high-throughput environments where numerous samples must be processed daily [2]. Teaching laboratories frequently employ UV-Vis due to its straightforward principles, lower instrumentation costs, and minimal maintenance requirements compared to chromatographic systems [1].

Ideal Use Cases for UFLC-DAD

UFLC-DAD is indispensable in applications requiring specificity in complex matrices. Pharmaceutical impurity profiling represents a prime application where the technique can separate, detect, and quantify multiple components simultaneously, including active ingredients, degradation products, and synthetic impurities [6]. The combination of retention time and spectral data from the DAD detector provides two dimensions of confirmation for compound identity, essential for regulatory submissions and method validation [6].

Natural products analysis, such as the characterization of phenolic compounds in plant extracts, benefits tremendously from UFLC-DAD's separation power [9]. Research on Libidibia ferrea fruits demonstrated the technique's ability to quantify multiple markers (gallic acid, ellagic acid) simultaneously while providing spectral confirmation of compound identity [9]. Metabolomic studies and bioanalytical applications similarly leverage the technique's resolution capabilities for complex biological samples [10].

Stability-indicating methods represent another critical application where UFLC-DAD excels. The ability to monitor degradation products while confirming peak purity through spectral comparisons makes it the gold standard for pharmaceutical stability testing [6]. When methods require compliance with ICH guidelines, particularly for detection of impurities at the 0.05-0.10% level, UFLC-DAD provides the necessary sensitivity, specificity, and precision [6].

Hybrid Approaches and Complementary Techniques

Increasingly, analytical workflows incorporate both techniques in complementary roles. A common approach uses UV-Vis for rapid screening followed by UFLC-DAD for confirmatory analysis. This hybrid methodology balances the need for high-throughput with regulatory requirements for specificity [5]. Research on wine aging demonstrated how UV-Vis could provide rapid phenolic content estimates while UFLC-DAD delivered specific compound quantification [10].

The combination of UFLC with mass spectrometry (UFLC-MS) represents a further advancement, particularly for identification of unknown compounds or analysis of compounds lacking chromophores [3]. While MS detection provides superior sensitivity and structural information, UV detection (particularly DAD) remains preferred for quantitative analysis in regulated environments due to its superior precision and wider linear dynamic range [3] [6].

For comprehensive analysis, the integration of multiple detection techniques (DAD, CAD, MS) with chromatographic separation provides the most complete analytical picture, addressing the limitations of any single detection technology [8].

In the realm of analytical chemistry, the evolution from simple UV-Vis spectrophotometry to sophisticated Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) represents a significant technological advancement. While UV-Vis provides a rapid, economical means for analyzing samples with ultraviolet or visible light absorption characteristics, UFLC-DAD combines high-resolution separation with comprehensive spectral detection capabilities. Within pharmaceutical development and research settings, the choice between these techniques involves careful consideration of analysis time, data quality, cost, and application requirements. This guide provides an objective comparison of their performance characteristics, supported by experimental data, to inform selection decisions for specific analytical challenges.

UV-Vis spectrophotometry operates on the Beer-Lambert law principle, measuring the absorption of light by analytes in solution at specific wavelengths. The technique has evolved considerably, with modern instruments featuring touchscreen interfaces, pre-programmed methods, and smaller footprints to maximize laboratory efficiency while maintaining analytical precision [11]. Its fundamental strength lies in direct quantification of compounds without requiring separation, making it ideal for routine analysis where sample matrices are simple and target compounds are known.

In contrast, UFLC-DAD represents an advanced hyphenated technique that couples the high-resolution separation power of liquid chromatography with the detection capabilities of a diode array detector. The DAD component significantly enhances detection by capturing the complete UV-Vis spectrum across a wavelength range (typically 190-900 nm) for each eluting compound, rather than monitoring at a single fixed wavelength like conventional UV detectors [12] [13]. This comprehensive spectral capture enables peak purity assessment, method development optimization, and impurity profiling that would be impossible with single-wavelength detection.

Technical Instrumentation Breakdown

UV-Vis Spectrophotometry Components and Evolution

Modern UV-Vis systems have undergone significant refinement to address contemporary laboratory needs. Key advancements include:

Optical System Enhancements: Improved optical stability through robust components with fewer moving parts, reducing instrumental drift and extending operational lifespan. Thermal regulation, enhanced detectors, and solid-state light sources contribute to measurement consistency with less frequent calibration requirements [11].

User Interface Modernization: Intuitive touchscreen interfaces with guided workflows and real-time visual feedback minimize training requirements and reduce user error, making the technology accessible to multidisciplinary teams without specialized spectrophotometry expertise [11].

Footprint and Connectivity: Compact benchtop designs address space constraints while maintaining full performance capabilities. Integrated SD card slots and PC connectivity options facilitate secure data handling and integration with digital laboratory ecosystems for electronic record-keeping [11].

The Techcomp UV2500 exemplifies these advancements, engineered specifically for high-speed operation while maintaining precision, making it suitable for laboratories processing high sample volumes where throughput is prioritized [11].

UFLC-DAD System Architecture

UFLC-DAD systems integrate several sophisticated components that work in concert to deliver high-resolution separations with comprehensive detection:

Pumping Systems: Modern UFLC pumps like the Chromaster PLUS 5110/5160 series offer high-pressure capabilities (40-60 MPa) supporting both traditional HPLC and UHPLC applications. Advanced liquid delivery systems employ high-speed feedback control and high-frequency proportioning valves to achieve gradient precision and retention time reproducibility [12].

Autosampler Technology: Advanced autosamplers (e.g., Chromaster PLUS 5260/5280) incorporate high-precision syringe mechanisms and redesigned fluid paths to achieve exceptional injection volume reproducibility while minimizing sample carryover through optimized connection geometry and injection port structures [12].

Column Oven Configuration: Thermostatted compartments maintain stable separation temperatures with preheating capabilities and extended temperature ranges (typically from 15°C below ambient to 85°C). Spacious interior designs accommodate multiple columns including those with guard column setups [12].

Diode Array Detection: The DAD represents the most significant analytical advancement over conventional detection. Unlike single-wavelength UV detectors that capture data at one fixed wavelength, DADs simultaneously monitor the complete spectral profile of eluting compounds [13]. Key features include:

- Broad wavelength range (190-900 nm) for extensive compound coverage

- High spectral resolution enabled by 1024-element diode arrays

- Simultaneous multi-wavelength monitoring without requiring multiple injections

- Peak purity assessment through spectral comparison across the peak profile

- Post-acquisition method optimization by extracting data at different wavelengths [12] [13]

The Chromaster PLUS 5430 DAD exemplifies these capabilities with noise levels comparable to single-wavelength detectors (≤0.5×10â»âµ AU) and minimal drift (≤0.4×10â»Â³ AU/hr), enabling high-sensitivity detection while providing comprehensive spectral information [12].

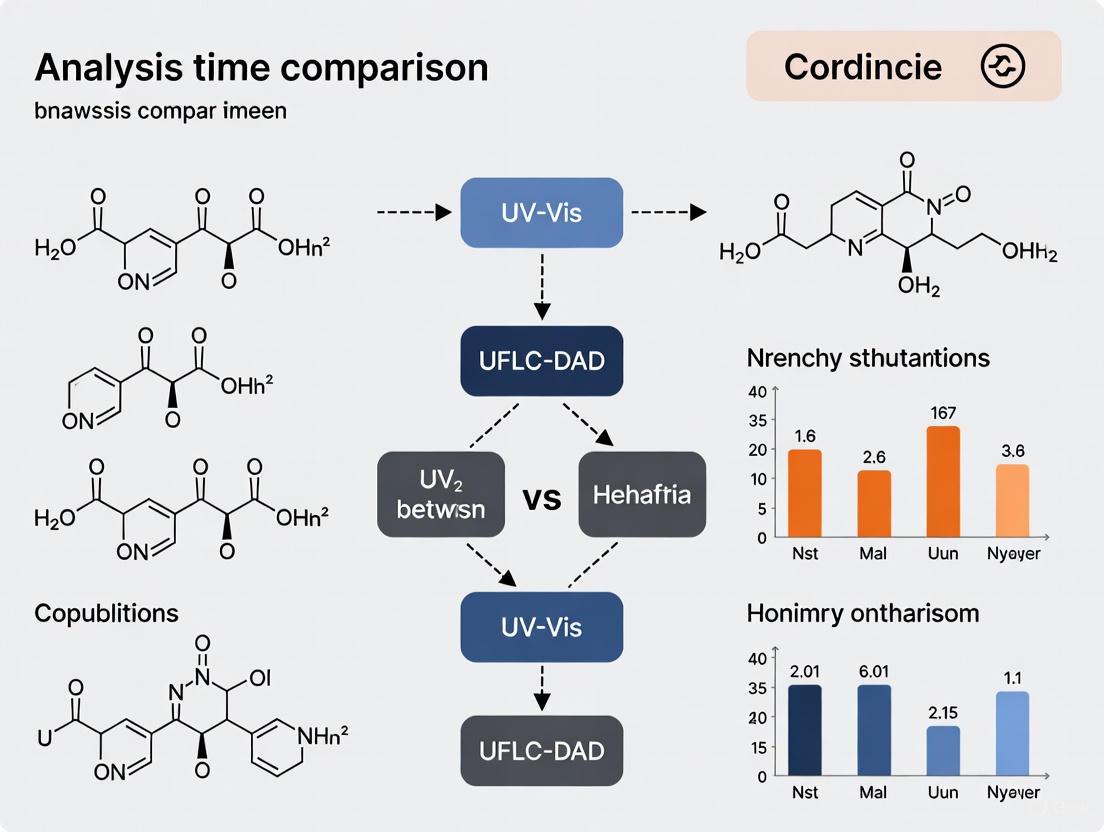

Figure 1: Instrumentation workflow comparison between UV-Vis spectrophotometry and UFLC-DAD systems

Performance Comparison and Experimental Data

Analysis Time and Throughput

Analysis time represents a critical differentiator between these techniques, with significant implications for laboratory workflow and operational costs.

Table 1: Analysis Time and Throughput Comparison

| Parameter | UV-Vis Spectrophotometry | UFLC-DAD |

|---|---|---|

| Typical Sample Analysis Time | Immediate (seconds to minutes) | 10-30 minutes per sample |

| Sample Preparation Requirements | Minimal to moderate | Extensive (filtration, dilution, derivatization) |

| Method Development Time | Hours to days | Days to weeks |

| Multi-Component Analysis Capability | Limited without separation | Excellent for complex mixtures |

| Automation Potential | Moderate (autosamplers available) | High (advanced autosamplers) |

| Daily Sample Throughput | Dozens to hundreds [11] | Limited by chromatographic run times |

UV-Vis offers substantial time advantages for direct quantitative analysis of single components in simple matrices. Modern UV-Vis instruments like the Techcomp UV2500 are specifically "engineered for high-speed operation, delivering quick, stable readings without compromising precision — ideal for labs processing dozens or hundreds of samples per day" [11]. This throughput advantage makes UV-Vis particularly valuable for quality control environments where rapid assessment of known compounds is required.

UFLC-DAD requires significantly longer analysis times per sample due to the chromatographic separation process. However, this time investment yields substantial informational benefits for complex mixtures. As demonstrated in the validation study of metoprolol tartrate analysis, UFLC-DAD provided "advantages in terms of speed and simplicity" compared to more complex analytical methods, though it remains slower than direct UV-Vis analysis [5]. The technique's true throughput must be evaluated in the context of information gained per unit time rather than simply samples processed.

Sensitivity and Detection Capabilities

Detection sensitivity and specificity vary considerably between these techniques, influencing their application domains.

Table 2: Sensitivity and Detection Capabilities Comparison

| Parameter | UV-Vis Spectrophotometry | UFLC-DAD |

|---|---|---|

| Detection Limit | Moderate (typically μg/mL) | High (typically ng/mL) |

| Selectivity in Mixtures | Poor without separation | Excellent due to chromatographic separation |

| Spectral Information | Single or dual wavelengths | Full spectrum (190-900 nm) |

| Peak Purity Assessment | Not available | Comprehensive via spectral comparison |

| Linear Dynamic Range | 2-3 orders of magnitude | 4-5 orders of magnitude [5] |

| Matrix Effect Susceptibility | High | Reduced due to separation |

UF-Vis exhibits limitations in complex matrices due to overlapping absorption bands. As noted in pharmaceutical validation studies, "a serious predicament is observed while dealing with the overlapping bands of the analytes and interferences, making quantitative data analysis complex" [5]. This constraint necessitates extensive method validation to ensure specificity when analyzing samples with multiple absorbing components.

UFLC-DAD delivers enhanced detection capabilities through the combination of physical separation and spectral verification. The DAD component enables detection of co-eluting peaks that might be missed with single-wavelength detection. As highlighted in detector comparisons, "What appears as a clean, singular peak with UV detection might reveal shoulder peaks or co-elutions when analyzed by DAD. Quantitation may vary between the two detectors. And in some cases, impurities completely invisible to UV detection suddenly appear in the DAD chromatogram" [13]. This capability is particularly valuable for impurity profiling and method development where complete resolution of all components is challenging.

Analytical Performance and Validation Data

Direct comparative studies provide objective performance data for these techniques under controlled conditions.

Table 3: Experimental Validation Data for Metoprolol Tartrate Analysis [5]

| Validation Parameter | UV-Vis Spectrophotometry | UFLC-DAD |

|---|---|---|

| Linear Range | 1-14 μg/mL | 0.1-100 μg/mL |

| Detection Limit | 0.27 μg/mL | 0.025 μg/mL |

| Quantitation Limit | 0.83 μg/mL | 0.083 μg/mL |

| Precision (RSD) | <2% | <1% |

| Accuracy (% Recovery) | 98.5-101.2% | 99.2-101.5% |

| Specificity | Limited in complex matrices | High (separation + spectral verification) |

In a study comparing the quantification of active pharmaceutical ingredients, UFLC-DAD demonstrated broader linear dynamic range and lower detection limits compared to UV-Vis spectrophotometry [5]. The research concluded that "UFLC analysis is more selective and sensitive in analyzing organic compounds and quantifying isolated substances" [5]. This performance advantage comes with increased operational complexity and cost, necessitating careful consideration of actual analytical requirements.

The specificity advantage of UFLC-DAD was clearly demonstrated in wine aging research, where the technique successfully identified and quantified specific phenolic compounds (catechin, caffeic acid, caftaric acid, gallic acid, protocatechuic acid, and p-coumaric acid) and correlated their concentrations with wine age [10]. Such precise compound-specific analysis would be challenging with direct UV-Vis measurement due to extensive spectral overlap in complex natural product matrices.

Experimental Protocols and Methodologies

UV-Vis Analysis of Metoprolol Tartrate in Pharmaceuticals

Based on validated methodology for pharmaceutical analysis [5]:

- Instrumentation: Modern UV-Vis spectrophotometer with 1 cm pathlength quartz cuvettes and temperature control capability

- Wavelength Selection: Fixed wavelength detection at λ~max~ = 223 nm for metoprolol tartrate

- Sample Preparation:

- Extract active component from commercial tablets using ultrapure water

- Protect solutions from light to prevent photodegradation

- Dilute samples to fall within validated linear range (1-14 μg/mL)

- Method Validation:

- Establish calibration curve with minimum of 5 concentration levels

- Determine precision through repeated measurements (n=6)

- Assess accuracy through standard addition and recovery studies

- Verify specificity against potential interferents from excipients

- Analysis Conditions:

- Room temperature measurement

- Blank correction with ultrapure water

- Triple measurements per sample for statistical reliability

UFLC-DAD Method for Compound Separation and Identification

Based on comprehensive analysis of natural products [14] and pharmaceutical applications [5]:

- Instrumentation: UFLC system with DAD detector, C18 reversed-phase column (100 × 2.1 mm, 1.8 μm particle size)

- Mobile Phase: Binary gradient system with solvent A (0.1% formic acid in water) and solvent B (0.1% formic acid in acetonitrile)

- Gradient Program:

- 0-2 min: 5% B (isocratic)

- 2-20 min: 5-95% B (linear gradient)

- 20-25 min: 95% B (isocratic)

- 25-26 min: 95-5% B (re-equilibration)

- 26-30 min: 5% B (column re-equilibration)

- Detection Parameters:

- Full spectral acquisition: 190-900 nm

- Spectral resolution: 1.2 nm

- Extraction wavelengths: 223 nm, 254 nm, 280 nm based on analyte characteristics

- Peak purity assessment: Spectral comparison across peak width (5 points)

- Identification Approach:

- Retention time matching with reference standards

- UV spectral library comparison

- Mass spectrometric confirmation when available [14]

Figure 2: Comparative analytical workflows for UV-Vis and UFLC-DAD methodologies

Essential Research Reagent Solutions

Table 4: Key Reagents and Materials for Analytical Methods

| Reagent/Material | Function/Purpose | UV-Vis Application | UFLC-DAD Application |

|---|---|---|---|

| High-Purity Solvents (HPLC-grade water, acetonitrile, methanol) | Sample dissolution, mobile phase preparation | Required for sample preparation | Critical for mobile phase and sample preparation |

| Buffer Salts (ammonium formate, phosphate buffers) | pH control, ion pairing | Limited use | Essential for reproducible separation |

| Reference Standards | Method calibration, compound identification | Required for quantitative analysis | Essential for retention time and spectral matching |

| Cuvettes/Flow Cells | Sample containment for detection | Quartz cuvettes (1 cm pathlength) | Specialized HPLC flow cells (nano-volume) |

| Syringe Filters (0.22 μm, 0.45 μm) | Sample clarification | Recommended for particulate removal | Essential to protect chromatography column |

| Chromatography Columns | Compound separation | Not applicable | Critical component (C18, C8, phenyl, etc.) |

The choice between UV-Vis spectrophotometry and UFLC-DAD systems involves balancing analysis time, information needs, and resource constraints. UV-Vis provides rapid, cost-effective quantification for single-analyte determination in simple matrices, with modern instruments offering improved usability and connectivity [11]. UFLC-DAD delivers comprehensive separation and detection capabilities essential for complex samples, with the DAD component enabling peak purity assessment and method robustness evaluation [13].

For routine quality control environments where analysis time and operational costs are primary concerns, UV-Vis spectrophotometry offers compelling advantages, particularly when analyzing samples with minimal matrix interference. For method development, impurity profiling, and complex mixture analysis, UFLC-DAD provides indispensable capabilities that justify its longer analysis times and higher operational costs. The technique's ability to detect co-elutions and provide spectral confirmation makes it particularly valuable for regulatory submissions where method robustness must be thoroughly demonstrated [13].

Future developments will likely further bridge these technologies, with UV-Vis systems incorporating more advanced detection capabilities and UFLC systems achieving faster separation times while maintaining resolution. Understanding the fundamental capabilities and limitations of each technique enables researchers to make informed selections based on their specific analytical requirements, balancing the competing demands of analysis time, data quality, and operational efficiency.

The selection of an appropriate analytical technique is a critical decision in pharmaceutical development and research. Two methodologies frequently employed for the quantification of organic compounds are Ultraviolet-Visible spectroscopy (UV-Vis) and Ultra-Fast Liquid Chromatography with Diode-Array Detection (UFLC-DAD). These techniques operate on fundamentally different principles, leading to distinct performance profiles regarding their inherent selectivity and operational speed. This guide provides a theoretical and experimental comparison of these two approaches, contextualized within research focused on analysis time. Understanding their complementary strengths and limitations enables scientists to make informed decisions, selecting the optimal method for specific application requirements in drug development.

Theoretical Foundations and Performance Parameters

The core differences between UV-Vis and UFLC-DAD stem from their operational principles. UV-Vis is a non-separative technique that measures the absorption of ultraviolet or visible light by a sample, providing a composite spectrum of all chromophoric compounds present [6]. Its selectivity is inherently limited to compounds with different absorption spectra, which can be challenging to deconvolute in mixtures. In contrast, UFLC-DAD is a hyphenated technique that combines a physical separation module (chromatography) with a spectral detection module (DAD). The chromatography column separates compounds based on their differential interaction with the stationary and mobile phases, after which the DAD identifies and quantifies them based on their UV-Vis spectra [5] [15]. This two-stage process is the source of both its superior selectivity and longer analysis time.

Table 1: Theoretical Comparison of UV-Vis and UFLC-DAD Techniques

| Performance Parameter | UV-Vis Spectroscopy | UFLC-DAD |

|---|---|---|

| Fundamental Principle | Measurement of electronic excitation of chromophores | Separation followed by spectral identification |

| Inherent Selectivity | Low to Moderate; relies on spectral differences | Very High; combines retention time and spectral data |

| Typical Analysis Speed | Very Fast (seconds to minutes) | Slower (minutes to tens of minutes) |

| Sample Throughput | Very High | Moderate |

| Multi-analyte Resolution | Poor without chemometrics; measures total response | Excellent; physically separates individual analytes |

| Peak Purity Assessment | Not applicable | Yes, via spectral comparison across the peak [15] |

| Key Limitation | Limited ability to analyze complex mixtures | Longer analysis time and higher operational complexity |

Experimental Data and Quantitative Comparison

Validation studies and application reports provide concrete data on the practical performance of these techniques. In one comparative study, researchers developed methods for quantifying Metoprolol Tartrate (MET) in commercial tablets. The UV-Vis method was noted for its simplicity, precision, and low cost but showed limitations in dealing with higher concentrations and overlapping spectral bands [5]. The UFLC-DAD method, while more complex, demonstrated superior selectivity and sensitivity for the same application [5].

Another study on wine age prediction highlights the speed advantage of spectroscopy. Synchronous Fluorescence (SF) spectroscopy, a vibrational spectroscopy technique similar in speed to UV-Vis, allowed for rapid prediction of wine age with high accuracy (RMSEP of 0.8 years). The study concluded that the spectroscopic method "significantly reduces analytical time, cost, and environmental damage compared to chemical and chromatographic methods" [10]. The following diagram illustrates the typical workflow for each technique, highlighting the key steps that contribute to the difference in overall analysis time.

Diagram 1: A comparison of experimental workflows. The UFLC-DAD process involves more preparatory and separation steps, contributing to its longer total analysis time.

Table 2: Summary of Experimental Performance from Case Studies

| Study Context | UV-Vis Performance | UFLC-DAD Performance | Reference |

|---|---|---|---|

| Metoprolol Quantification | Simple, fast, and cost-effective; limitations with overlapping bands and higher concentrations. | Selective and sensitive; successfully quantified MET in 50 mg and 100 mg tablets. | [5] |

| Wine Age Prediction | SF spectroscopy predicted age with RMSEP of 0.8 years; method praised for speed and low cost. | HPLC-DAD used as a reference to correlate specific compounds (e.g., gallic acid) with age. | [10] |

| Active Component Analysis | Greenness assessment favored the spectrophotometric method due to lower solvent consumption. | Provided superior separation power but required more solvents and energy. | [5] |

Essential Research Reagent Solutions

The execution of these analytical methods requires specific materials and reagents. The following table details key components and their functions in UFLC-DAD and UV-Vis protocols.

Table 3: Key Reagents and Materials for Analytical Protocols

| Reagent / Material | Function in Analysis | Example in Protocol |

|---|---|---|

| Chromatography Column | Stationary phase for separating analytes based on chemical affinity. | C18 reversed-phase column (e.g., 2.1 x 50 mm, 1.3 μm) [16]. |

| HPLC-Grade Solvents | Mobile phase to carry samples through the column; purity is critical. | Acetonitrile and methanol as organic modifiers; buffer solutions like potassium dihydrogen phosphate [16]. |

| Analytical Standards | High-purity reference compounds for method calibration and quantification. | Metoprolol Tartrate (≥98%) or Posaconazole (≥98%) used to prepare calibration curves [5] [16]. |

| UV-Transparent Solvents | Dissolve samples without interfering in the spectral window of interest. | Ultrapure water, methanol, or acetonitrile for preparing sample solutions in UV-Vis [5]. |

UV-Vis spectroscopy and UFLC-DAD serve distinct yet complementary roles in the analytical toolkit. UV-Vis's primary strength is its exceptional speed, offering results in seconds to minutes with minimal sample preparation, making it ideal for rapid quantification, high-throughput screening, and applications where the analyte is known and the matrix is simple. Its principal limitation is lower inherent selectivity, which restricts its utility in complex mixtures. Conversely, UFLC-DAD's defining strength is its high selectivity, achieved by combining chromatographic separation with spectral verification. This makes it indispensable for analyzing complex formulations, confirming peak purity, and quantifying multiple analytes simultaneously. This capability, however, comes at the cost of longer analysis time, greater operational complexity, and higher resource consumption. The choice between these techniques is a direct trade-off between selectivity and speed, guided by the specific analytical question, sample complexity, and required throughput.

In the field of analytical chemistry, the selection of an appropriate technique is critical for the success of drug development and quality control. This guide provides an objective comparison between Ultraviolet-Visible (UV-Vis) spectroscopy and Ultra-Fast Liquid Chromatography with Diode-Array Detection (UFLC-DAD), two widely used techniques for quantifying active pharmaceutical ingredients (APIs). The comparison is framed around three key performance metrics: analysis time, sensitivity (Limit of Detection and Quantification), and specificity. Understanding the distinct capabilities of each method enables researchers and scientists to make informed decisions tailored to their specific project needs, whether for rapid, high-throughput analysis or for resolving complex mixtures with high confidence.

The table below provides a high-level comparison of the core performance characteristics of UV-Vis and UFLC-DAD to guide initial technique selection.

| Performance Metric | UV-Vis Spectroscopy | UFLC-DAD |

|---|---|---|

| Typical Analysis Time | Fast (minutes) | Longer (tens of minutes) |

| Sensitivity (LOD/LOQ) | Lower sensitivity; limited by sample matrix and path length [5] [1]. | Higher sensitivity; nanogram or picogram levels possible [5]. |

| Specificity | Lower; susceptible to spectral overlap from interferents [5] [17]. | Higher; separation step isolates analyte from interferents [5]. |

| Best Used For | Rapid quantification of a single, well-defined analyte in a simple matrix; cost-effective and green analysis [5]. | Quantification in complex mixtures; confirmatory analysis; methods requiring high specificity and sensitivity [5]. |

In-Depth Metric Comparison and Experimental Data

Analysis Time

UV-Vis Spectroscopy: The workflow is inherently simple, often requiring minimal sample preparation (e.g., dissolution and filtration). Data acquisition is rapid, with a single absorbance measurement taking seconds to minutes [5]. The primary time investment is often in the preparation of calibration standards. This makes UV-Vis ideal for high-throughput environments where speed is essential.

UFLC-DAD: The analysis time is dominated by the chromatographic separation step. A typical run can range from 10 to 30 minutes, depending on the method complexity [5]. While the UFLC separation itself is faster than conventional HPLC, the overall process—including column equilibration and a potentially more extensive sample preparation (e.g., extraction, purification)—makes it a more time-consuming technique overall.

Sensitivity (LOD and LOQ)

Sensitivity defines the lowest amount of an analyte that can be reliably detected (LOD) or quantified (LOQ). The underlying principles differ significantly between the two techniques.

- Limit of Detection (LOD) is the lowest concentration of an analyte that can be reliably distinguished from the background noise [18] [19].

- Limit of Quantification (LOQ) is the lowest concentration that can be measured with acceptable accuracy and precision [18] [19].

Experimental Context from Metoprolol Study A study quantifying metoprolol tartrate (MET) demonstrated this sensitivity gap. The optimized UFLC-DAD method achieved a significantly lower LOD of 0.025 μg/mL compared to the UV-Vis method. Similarly, the LOQ for UFLC-DAD was 0.083 μg/mL, underscoring its superior capability for measuring trace-level analytes [5]. UV-Vis spectroscopy's sensitivity is fundamentally limited by the Beer-Lambert law and its requirement for a relatively high sample concentration in a clear solution [5] [1].

Specificity

Specificity refers to the ability of a method to accurately measure the analyte in the presence of other components, such as impurities, degradants, or the sample matrix.

UV-Vis Spectroscopy: Specificity is a key limitation. The technique measures the total absorbance at a specific wavelength, which can lead to co-measurement of other UV-absorbing substances [5]. This makes it susceptible to interference from complex sample matrices and is generally not suitable for analyzing mixtures without prior separation [17].

UFLC-DAD: Offers high specificity due to its two-dimensional identification process. First, the chromatographic column separates components based on their chemical properties. Second, the DAD detector provides a full UV spectrum for each separated peak, allowing for peak purity assessment and confirmation of analyte identity [5]. This dual verification is the gold standard for ensuring specificity in quantitative analysis.

Detailed Experimental Protocols

To illustrate how these performance metrics are evaluated in practice, here are the core experimental methodologies from a comparative study on metoprolol tartrate (MET) [5].

Protocol 1: UV-Vis Spectrophotometric Method

- Sample Preparation: MET was extracted from commercial tablets using ultrapure water. The solution was filtered and protected from light [5].

- Instrumentation & Measurement: Absorbance was measured using a spectrophotometer at the wavelength of maximum absorption (λmax) for MET, 223 nm. A blank solvent was used for background correction [5].

- Calibration: A series of standard solutions with known concentrations of MET reference standard were prepared. A calibration curve of absorbance versus concentration was constructed to establish linearity and for subsequent quantification [5].

- Validation Parameters: The method was validated for specificity, linearity, accuracy, precision, LOD, and LOQ [5].

Protocol 2: UFLC-DAD Method

- Sample Preparation: A similar extraction procedure was used for the UFLC-DAD analysis. The sample may require additional filtration to prevent column damage [5].

- Chromatographic Conditions:

- Column: A reversed-phase C18 column.

- Mobile Phase: A mixture of methanol and water.

- Flow Rate: 1.0 mL/min.

- Detection: DAD acquisition set at 223 nm for MET, with spectral scanning for peak identification [5].

- Method Validation: The method was validated for parameters including specificity/selectivity, linearity, accuracy, precision, LOD, and LOQ [5].

Analytical Workflow Comparison

This diagram visualizes the fundamental procedural differences between UV-Vis and UFLC-DAD, highlighting the source of their differences in analysis time and specificity.

The Scientist's Toolkit: Essential Research Reagents and Materials

The table below lists key materials and reagents required to perform the analyses described in the experimental protocols.

| Item | Function/Brief Explanation |

|---|---|

| Reference Standard | A pure, well-characterized sample of the analyte (e.g., MET); essential for method calibration and validation [5]. |

| Ultrapure Water (UPW) | Solvent for preparing standard and sample solutions; minimizes background interference [5]. |

| HPLC-Grade Solvents | High-purity methanol, acetonitrile, and water; used as the mobile phase in UFLC-DAD to ensure reproducible separation and low background noise [5]. |

| Chromatographic Column | Typically a reversed-phase C18 column; the heart of the UFLC system where chemical separation occurs [5]. |

| Cuvettes / Vials | Quartz cuvettes for UV-Vis (transparent to UV light) and certified vials for UFLC-DAD autosamplers [1]. |

| Syringe Filters | Used to filter sample solutions before injection into the UFLC-DAD system to remove particulates and protect the column [5]. |

| Buffer Salts | Used to prepare buffered solutions that control pH, which can be critical for analyte stability and separation efficiency [17]. |

| (1R,3S)-Compound E | (1R,3S)-Compound E, MF:C27H24F2N4O3, MW:490.5 g/mol |

| QST4 | 1-(3-Chlorophenyl)-3-(quinolin-8-ylsulfonylamino)thiourea |

The choice between UV-Vis and UFLC-DAD is not a matter of one technique being universally superior, but rather of selecting the right tool for the specific analytical challenge. UV-Vis spectroscopy offers compelling advantages in speed, cost, and operational simplicity, making it an excellent choice for the quantitative analysis of a single component in a simple matrix where high sensitivity is not required. Conversely, UFLC-DAD is the definitive technique for applications demanding high specificity, superior sensitivity, and the accurate quantification of analytes in complex mixtures. By understanding the inherent trade-offs between analysis time, sensitivity, and specificity outlined in this guide, researchers can strategically deploy these techniques to enhance the efficiency and reliability of their work in drug development.

From Theory to Practice: Method Development for API Quantification

Streamlined UV-Vis Workflow for Routine Quality Control of Single-Component Formulations

In the pharmaceutical industry, quality control (QC) laboratories face increasing pressure to deliver accurate results faster while managing costs and ensuring regulatory compliance. For routine analysis of single-component formulations, the choice of analytical technique directly impacts throughput, operational expense, and environmental footprint. While chromatographic methods like Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) offer high selectivity, they often introduce complexity that may be unnecessary for straightforward QC applications.

Ultraviolet-Visible (UV-Vis) spectroscopy presents a compelling alternative for many routine QC applications, offering simplicity, speed, and cost-effectiveness [20]. This guide objectively compares UV-Vis and UFLC-DAD approaches for quantifying active pharmaceutical ingredients (APIs) in single-component formulations, providing experimental data to support technique selection based on analytical needs and operational constraints.

Technical Comparison: UV-Vis vs. UFLC-DAD

Fundamental Principles and Instrumentation

UV-Vis Spectroscopy measures the absorption of ultraviolet or visible light by molecules as they undergo electronic transitions [21]. When samples are irradiated with light, they selectively absorb incident light at specific wavelengths, with the wavelength of highest absorbance (λmax) typically used for quantitative analysis based on the Beer-Lambert law [21]. Modern UV-Vis systems feature intuitive interfaces, pre-programmed methods, and simplified workflows that enable non-experts to produce reliable results quickly [22].

UFLC-DAD represents an advanced form of high-performance liquid chromatography that utilizes columns packed with smaller particles (<2μm) and operates at higher pressures compared to conventional HPLC [16]. This configuration enables enhanced speed, resolution, and sensitivity, with the diode array detector providing spectral information for peak purity assessment [16]. The technique offers superior separation power for complex mixtures but requires more sophisticated instrumentation and operational expertise.

Direct Performance Comparison

Recent studies provide quantitative comparisons between spectroscopic and chromatographic methods for pharmaceutical analysis. The following table summarizes key performance metrics from validation studies:

Table 1: Comparative Method Validation Parameters for Metoprolol Tartrate Analysis

| Validation Parameter | UV-Vis Spectrophotometry | UFLC-DAD |

|---|---|---|

| Linear Range | 5-50 μg/mL | 5-50 μg/mL |

| Correlation Coefficient (r²) | >0.999 | >0.999 |

| Precision (CV%) | <2% | <2% |

| Accuracy (% Error) | <3% | <3% |

| Limit of Detection | 0.82 μg/mL | 1.04 μg/mL |

| Limit of Quantification | 2.73 μg/mL | 3.16 μg/mL |

| Analysis Time | Minutes | 11 minutes |

| Sample Consumption | Higher | Lower |

| Solvent Consumption | Lower | Higher |

Source: Adapted from Perić et al. [5] and Al-Majed et al. [16]

A separate study comparing analytical techniques for bakuchiol quantification in cosmetic products further validated that UV-Vis methods can produce results comparable to HPLC, with the added advantage of significantly shorter analysis time [23].

Experimental Section: Methodologies for Comparison

UV-Vis Spectrophotometric Protocol for Metoprolol Tartrate

Instrumentation and Conditions:

- Spectrophotometer with 1 cm matched quartz cells

- Analytical wavelength: 223 nm

- Spectrum mode: 200-400 nm for identification

- Quantitative mode: fixed wavelength at λmax

Sample Preparation:

- Standard stock solution prepared by dissolving reference standard in ultrapure water

- Working standards prepared by serial dilution to cover concentration range of 5-50 μg/mL

- Tablet samples extracted using appropriate solvent followed by filtration and dilution

- All solutions protected from light and stored in dark conditions [5]

Quantification Procedure:

- Measure absorbance of standard solutions at λmax

- Construct calibration curve (absorbance vs. concentration)

- Measure absorbance of prepared sample solutions

- Calculate concentration using regression equation from calibration curve

- Perform system suitability tests with quality control samples [5]

UFLC-DAD Chromatographic Protocol for Metoprolol Tartrate

Instrumentation and Conditions:

- UFLC system with DAD detector

- Column: C18 reversed-phase (e.g., Zorbax SB-C18, 4.6 × 250 mm, 5 μm)

- Mobile phase: Optimized gradient of acetonitrile and 15 mM potassium dihydrogen orthophosphate

- Flow rate: 1.5 mL/min

- Injection volume: 20-50 μL

- Detection wavelength: 223 nm

- Column temperature: 25°C [5]

Sample Preparation:

- Standard and sample preparation similar to UV-Vis method

- Additional step: filtration through 0.45 μm membrane filter

- Use of internal standard where necessary to improve precision

Quantification Procedure:

- Inject standard solutions to establish retention time and calibration curve

- Inject quality control samples to verify system performance

- Inject prepared sample solutions

- Quantify based on peak area compared to calibration standards

- Verify peak purity using DAD spectral information [5]

Workflow Efficiency Analysis

Time and Resource Utilization

The most significant differences between UV-Vis and UFLC-DAD emerge in workflow efficiency and resource requirements. The following visualization illustrates the comparative workflows:

Figure 1: Comparative Workflow Analysis: UV-Vis vs. UFLC-DAD

Operational Considerations for QC Laboratories

Table 2: Operational and Economic Factors in Technique Selection

| Factor | UV-Vis Spectroscopy | UFLC-DAD |

|---|---|---|

| Instrument Cost | Lower initial investment and maintenance | Significantly higher acquisition and upkeep |

| Operator Skill | Minimal training required | Extensive technical expertise needed |

| Sample Throughput | High (minutes per sample) | Moderate (10-20 minutes per sample) |

| Method Development | Straightforward | Complex, time-consuming |

| Solvent Consumption | Minimal (ml per sample) | Substantial (ml per minute) |

| Regulatory Compliance | Meets pharmacopeia standards with proper validation [24] | Meets pharmacopeia standards with proper validation |

| Environmental Impact | Lower (AGREE score: 0.81) [5] | Higher (AGREE score: 0.65) [5] |

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential Materials for UV-Vis Pharmaceutical QC

| Material/Reagent | Specification | Function in Analysis |

|---|---|---|

| Reference Standard | USP/EP grade certified purity | Primary standard for calibration |

| Ultrapure Water | 18.2 MΩ·cm resistivity | Solvent for aqueous preparations |

| Spectrophotometric Cells | Matched quartz, 1 cm pathlength | Sample holder for measurement |

| Volumetric Flasks | Class A, appropriate volumes | Precise solution preparation |

| Syringe Filters | 0.45 μm pore size, compatible with solvent | Sample clarification |

| Mobile Phase Components | HPLC grade solvents and buffers | Required for UFLC-DAD analysis only |

| Quality Control Samples | Independent source with known concentration | Method performance verification |

| PTC258 | PTC258, MF:C16H18ClN3S2, MW:351.9 g/mol | Chemical Reagent |

| Tri-GalNAc(OAc)3-Perfluorophenyl | Tri-GalNAc(OAc)3-Perfluorophenyl, MF:C99H151F5N10O44, MW:2280.3 g/mol | Chemical Reagent |

Application Note: Successful Implementation for Metoprolol Tartrate QC

A recent comparative study demonstrated the practical implementation of both techniques for quality control of metoprolol tartrate in commercial tablets [5]. The research validated a simple UV-Vis method at 223 nm that successfully quantified the API in 50 mg strength tablets with precision (CV% <2%) and accuracy (% error <3%) meeting ICH validation criteria.

The study concluded that for this single-component formulation, UV-Vis spectroscopy provided adequate specificity and accuracy while offering substantial advantages in cost, analysis time, and environmental impact [5]. The greenness assessment using the Analytical GREEnness (AGREE) metric scored the UV-Vis method at 0.81 compared to 0.65 for the UFLC-DAD method, confirming its superior environmental profile [5].

Regulatory and Compliance Considerations

Both UV-Vis and chromatographic methods can satisfy regulatory requirements when properly validated. Regulatory bodies including FDA, EMA, and ICH recognize spectroscopic methods as validated analytical tools when developed, validated, and documented according to established guidelines [20].

For pharmaceutical QC applications, UV-Vis systems must comply with pharmacopeia standards (USP <857>, Ph. Eur. 2.2.5, JP <2.24>) and electronic record requirements (21 CFR Part 11) when implemented in regulated environments [24]. Modern UV-Vis instruments are specifically designed to support these compliance needs through enhanced security software, audit trails, and data integrity features [24].

UV-Vis spectroscopy offers a compelling solution for routine quality control of single-component formulations, providing significant advantages in speed, cost, and operational simplicity when method specificity is sufficient. The technique enables laboratories to maintain data quality while improving efficiency and reducing environmental impact.

UFLC-DAD remains indispensable for complex matrices, impurity profiling, and cases requiring high selectivity. However, for many routine QC applications involving single-component formulations, UV-Vis spectrophotometry represents a rational choice that balances analytical performance with practical operational needs.

The evolving landscape of UV-Vis instrumentation continues to enhance its value proposition, with modern systems offering improved connectivity, intuitive interfaces, and compliance features that further streamline implementation in regulated environments [22]. By carefully considering analytical requirements and validation data, QC managers can make evidence-based decisions that optimize laboratory efficiency without compromising data quality.

In the field of pharmaceutical analysis, the choice of analytical technique significantly impacts the reliability, efficiency, and cost-effectiveness of quality control and research processes. Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) and UV-Vis spectrophotometry represent two powerful yet fundamentally different approaches for compound quantification. This guide provides an objective comparison of their performance, with a specific focus on developing robust UFLC-DAD methods through strategic column selection, mobile phase optimization, and gradient design. Framed within broader research comparing analysis times and capabilities, this information assists researchers and drug development professionals in selecting and optimizing appropriate methodologies for their specific applications, from routine quality control to complex multi-component analysis.

Fundamental Principles and Technical Comparisons

UV-Vis Spectrophotometry operates on the principle of measuring the absorption of ultraviolet or visible light by a sample at specific wavelengths. It provides a simple, rapid, and economical means of quantification for compounds containing chromophores. The technique is popular due to procedural simplicity, wide instrument availability, precision, and accuracy [5]. However, its limitations become apparent in complex mixtures, as it lacks inherent separation capabilities, leading to potential overlapping signals from multiple analytes and excipients [5].

UFLC-DAD (Ultra-Fast Liquid Chromatography with Diode Array Detection) combines high-efficiency chromatographic separation with full-spectrum ultraviolet detection. UFLC systems operate at higher pressures than conventional HPLC, utilizing columns packed with smaller particles (often sub-2µm) to achieve faster separations and increased peak capacity [5]. The key differentiator is the DAD detector, which captures the entire UV-Vis spectrum for each point in the chromatogram, unlike a single-wavelength UV detector that captures data at a fixed wavelength [13]. This allows for retrospective data analysis and peak purity assessment without reinjection.

Direct Performance Comparison

The table below summarizes a direct performance comparison between the two techniques, drawing from experimental data across multiple studies.

Table 1: Performance Comparison between UV-Vis Spectrophotometry and UFLC-DAD

| Parameter | UV-Vis Spectrophotometry | UFLC-DAD |

|---|---|---|

| Analysis Time | Short (minutes) | Longer, but faster than conventional HPLC [5] |

| Sample Throughput | High | Moderate to High |

| Selectivity/Specificity | Low; susceptible to interference in mixtures [5] | High; physical separation of analytes [5] |

| Sensitivity | Good | Excellent; lower LOD and LOQ [5] |

| Multi-Component Analysis | Limited without prior separation | Excellent |

| Peak Purity Assessment | Not possible | Yes, via spectral comparison [13] |

| Structural Information | Limited | Yes, via UV spectrum library matching |

| Data Robustness | Single wavelength data | Full spectral data for verification [13] |

| Solvent Consumption | Low | Lower than HPLC, but higher than UV [5] |

| Instrument Cost & Complexity | Low | High |

Analysis Time and Greenness Considerations

A core aspect of the thesis context is the comparison of analysis time. While UV-Vis is inherently faster for a single measurement, UFLC-DAD provides comprehensive data in a single run. A study quantifying metoprolol tartrate (MET) demonstrated that while the UFLC-DAD optimization itself is a multi-step process, it results in a method that is "more selective and sensitive" [5]. The same study also compared the greenness of the two applied methods using the Analytical GREEnness (AGREE) metric, concluding that the UV spectrophotometric approach was more environmentally friendly, adding a significant practical consideration for sustainable method development [5].

UFLC-DAD Method Development: A Strategic Framework

Developing a robust UFLC-DAD method requires a systematic approach to optimize critical parameters that influence separation, sensitivity, and speed.

Column Selection and Optimization

The column is the heart of the chromatographic separation. For UFLC, columns packed with sub-2µm particles are standard to withstand high backpressures and provide high efficiency.

- Stationary Phase Chemistry: The C18 (ODS) column is the most widely used reverse-phase column due to its versatility and well-understood properties. It is considered "relatively inexpensive, easily available and commonly used," making methods easily accessible for routine analysis [25]. For specific separations, such as distinguishing between β- and γ- forms of tocopherols and tocotrienols, specialized columns like solid-core pentafluorophenyl, C30 silica, or perfluorinated phenyl phases may be necessary [25].

- Column Dimensions: Shorter columns (e.g., 50-100 mm) provide faster analysis, while longer columns (e.g., 150 mm) offer higher peak capacity for complex mixtures. Reduced internal diameter (e.g., 2.1 mm) enhances sensitivity by reducing dilution but may increase backpressure.

Table 2: Experimental Column and Mobile Phase Conditions from Cited Studies

| Analyte | Column Type | Mobile Phase Composition | Elution Mode | Detection | Citation |

|---|---|---|---|---|---|

| Metoprolol Tartrate | Not specified | Acetonitrile and phosphate buffer (15:85, v/v) | Isocratic | DAD (λ=223 nm) | [5] |

| Tocopherols & Tocotrienols | Conventional C18 | Acetonitrile, methanol, water (gradient) | Gradient | FLD (Ex/Em: 290/327 nm), DAD | [25] |

| Bakuchiol | Endcapped C18 | Acetonitrile with 1% formic acid | Isocratic | DAD (λ=260 nm) | [23] |

| Cranberry Phenolics | ACQUITY UPLC BEH C18 (2.1x50 mm, 1.7 µm) | 0.1% formic acid (A) and acetonitrile (B) | Gradient | DAD (λ=370, 350, 320, 280 nm) | [26] |

Mobile Phase and Gradient Optimization

The mobile phase composition and elution profile are critical for achieving resolution and controlling analysis time.

- Mobile Phase Selection: Acetonitrile is a common organic modifier due to its low viscosity and high UV transparency. Methanol is an alternative. The addition of buffers (e.g., phosphate) or modifiers (e.g., formic acid) helps control ionization and improve peak shape. For instance, 1% formic acid was used to aid in the separation of bakuchiol [23], while 0.1% formic acid was used for cranberry phenolic compounds [26].

- Isocratic vs. Gradient Elution: Isocratic elution (constant mobile phase composition) is simple and suitable for simple mixtures, as seen in the analysis of MET [5] and bakuchiol [23]. Gradient elution (changing the composition over time) is essential for complex samples with a wide range of analyte polarities, such as the tocopherol/tocotrienol profile in diverse foods [25] or multiple phenolic compounds in cranberries [26]. A well-designed gradient ensures all components elute in a minimal time with sufficient resolution.

The following diagram illustrates the logical workflow for developing and optimizing a UFLC-DAD method, from initial setup to final validation.

Experimental Protocols and Validation

Exemplary UFLC-DAD Protocol: Quantification of Phenolic Compounds

A validated UPLC-DAD method for phenolic compounds in cranberry fruit provides a transferable protocol for UFLC-DAD [26].

- Sample Preparation: Dried fruit samples were homogenized and extracted with ethanol using an ultrasonic bath. The extract was centrifuged, filtered, and diluted before injection.

- Chromatographic Conditions:

- Column: ACQUITY UPLC BEH C18 (2.1 × 50 mm, 1.7 µm).

- Mobile Phase: 0.1% formic acid in water (A) and acetonitrile (B).

- Gradient: 0-5 min (5%-20% B), 5-7 min (20%-25% B), 7-9 min (25%-50% B), 9-10 min (50%-100% B), 10-11.5 min (100% B), 11.5-12 min (100%-5% B).

- Flow Rate: 0.4 mL/min.

- Temperature: 30°C.

- Injection Volume: 1 µL.

- DAD Detection: Multiple wavelengths (370, 350, 320, 280 nm) with spectral scanning from 200-500 nm.

- Method Validation: The method was validated per ICH guidelines, demonstrating:

- Linearity: R² > 0.999 for all analytes.

- Precision: %RSD for intra- and inter-day precision < 2%.

- Accuracy: Recovery rates between 80-110%.

- Sensitivity: LOD and LOQ in the ranges of 0.38–1.01 µg/mL and 0.54–3.06 µg/mL, respectively [26].

Exemplary UV-Vis Protocol: Quantification of Terbinafine Hydrochloride

A simple UV-Vis method for terbinafine hydrochloride illustrates the standard validation approach for spectrophotometry [27].

- Sample Preparation: A standard stock solution (100 µg/mL) was prepared in distilled water. Appropriate dilutions (5-30 µg/mL) were made for the calibration curve.

- Instrumental Conditions:

- Wavelength: 283 nm (λmax determined by scanning from 200-400 nm).

- Solvent: Distilled water.

- Method Validation:

- Linearity: Concentration range of 5–30 µg/mL with a correlation coefficient of 0.999.

- Accuracy: Recovery at 80%, 100%, and 120% levels was 98.54–99.98%.

- Precision: Intra-day and inter-day %RSD values were less than 2% [27].

Essential Research Reagent Solutions

The table below details key reagents and materials commonly used in developing and applying UFLC-DAD and UV-Vis methods, based on the cited experimental works.

Table 3: Key Research Reagents and Materials for Analytical Method Development

| Reagent/Material | Function/Application | Example from Literature |

|---|---|---|

| Acetonitrile (HPLC Grade) | Organic mobile phase component for reverse-phase chromatography. | Used as the organic modifier in mobile phases for MET, bakuchiol, and cranberry phenolic analysis [5] [23] [26]. |

| Formic Acid (ACS Grade) | Mobile phase additive to suppress analyte ionization and improve peak shape. | Added at 1% to mobile phase for bakuchiol separation [23] and at 0.1% for cranberry phenolics [26]. |

| Phosphate Buffer | Aqueous mobile phase component to control pH and ensure reproducibility. | Used in a 85:15 ratio with acetonitrile for the isocratic elution of MET [5]. |

| Ultrapure Water | Solvent for standard/sample preparation and aqueous mobile phase component. | Used as solvent for terbinafine HCl analysis and mobile phase component [27] [5]. |

| C18 Reverse-Phase Column | The stationary phase for separating non-polar to medium-polarity analytes. | The most common column type used across multiple studies [5] [25] [26]. |

| Standard Reference Compounds | For method development, calibration, and validation (identification, linearity, accuracy). | High-purity MET, terbinafine HCl, and bakuchiol were used as standards [5] [27] [23]. |

The choice between UFLC-DAD and UV-Vis spectrophotometry is not a matter of superiority, but of appropriate application. UV-Vis stands out for its remarkable simplicity, speed, low cost, and greenness, making it ideal for routine quantification of single components in relatively simple matrices. In contrast, UFLC-DAD is an indispensable tool for method development and complex analyses, offering unparalleled selectivity, sensitivity, and the ability to deconvolute multi-component samples with confidence in peak identity and purity. The ongoing development of more efficient columns and the trend towards miniaturization and automation continue to enhance the speed and reduce the environmental footprint of UFLC-DAD, solidifying its critical role in modern pharmaceutical and biomedical research.

Quality control in pharmaceutical manufacturing necessitates rigorous testing to ensure the safety, efficacy, and consistency of solid dosage forms such as tablets and capsules. Achieving uniformity in these formulations and ensuring homogeneity of active pharmaceutical ingredients (APIs) within each dosage unit present significant analytical challenges. Traditionally, quality control has relied on established analytical methodologies, with high-performance liquid chromatography (HPLC) coupled with mass spectrometry (MS) or diode array detection (DAD) being one of the most important methods in this field [28]. However, HPLC analysis often demands remarkable quantities of time and solvents, making it costly and not environmentally sustainable [28].

In 2004, the American Food and Drug Administration (FDA) introduced the concept of Process Analytical Technology (PAT), encouraging the development of innovative, non-destructive, and efficient analytical methodologies to monitor critical process parameters throughout manufacturing [28]. For pharmaceutical quality control, solid-phase spectrophotometric techniques like UV-Vis Diffuse Reflectance Spectroscopy (UV-Vis DRS) have gained attention as they offer rapid, non-destructive, and cost-effective facilities to directly analyze solid pharmaceutical formulations [28]. Direct analysis of solid samples fulfills some requirements of green chemistry because no solvent is needed, making these spectrophotometric methods particularly attractive for modern pharmaceutical analysis [28].

Fundamental Principles of UV-Vis Diffuse Reflectance Spectroscopy

Technical Basis of DRS

Diffuse reflectance spectroscopy is a spectroscopic technique where the diffuse reflection of radiation in the ultraviolet to visible range (190-800 nm) of a sample is measured [29]. This technique is used to characterize samples in solid (thin film) or liquid form. For granular or powder samples, or thin films with high surface roughness, the reflection is not specular, and the transmitted intensity becomes too low to measure absorption effectively [29]. In these cases, DRS becomes particularly valuable.

When photons enter a material, some are reflected from grain surfaces, some pass through the grain, and some are absorbed. Those photons that are reflected from grain surfaces or refracted through a particle are said to be scattered. Scattered photons may encounter another grains or be scattered away from the surface where they can be detected and measured [29]. The variety of absorption processes and their wavelength dependence provide information about the chemistry of the material from the reflected light.

Instrumentation and Measurement Approaches

Typically, diffuse reflectance is measured by two primary methods. The most common approach uses an integrating sphere mated with a spectrophotometer, allowing the measurement of both transmitted and reflected scatter [29]. The second method employs biconical geometry, where a mirror focuses a beam of light at a small point on a sample and the scattered reflected light is collected by a parabolic or similar curved mirror that directs the beam to a detector [29].

The advantage of biconical accessories is that they allow spectra to be obtained from far smaller samples than required with an integrating sphere. However, biconical devices do not collect scatter at all angles, so anisotropic materials are not measured as accurately. For this reason, biconical devices are generally considered qualitative, while integrating sphere systems provide both qualitative and quantitative capabilities [29].

Experimental Comparison: UV-Vis DRS vs. Chromatographic Methods

Methodology for Direct Solid Dosage Form Analysis

A recent study demonstrated the application of UV-Vis DRS for quantifying active pharmaceutical ingredients (APIs) in solid drug mixtures using multivariate data processing [28]. The research focused on determining the percentages of acetylsalicylic acid, caffeine, and paracetamol in a commercial solid pharmaceutical formulation (Neo Nisidine tablets) using rapid, non-destructive analytical protocols.