Advanced Strategies for Optimizing UV-Vis Sensitivity in Low Concentration Sample Analysis

This article provides a comprehensive guide for researchers and drug development professionals on enhancing the sensitivity of UV-Vis spectroscopy for analyzing low-concentration samples.

Advanced Strategies for Optimizing UV-Vis Sensitivity in Low Concentration Sample Analysis

Abstract

This article provides a comprehensive guide for researchers and drug development professionals on enhancing the sensitivity of UV-Vis spectroscopy for analyzing low-concentration samples. It covers foundational principles of band shape analysis and instrumental selection, advanced methodological approaches including derivative spectroscopy and curve fitting, practical troubleshooting for sample preparation and interference minimization, and rigorous validation protocols against established standards. By integrating theoretical insights with practical applications from recent scientific literature, this resource aims to equip scientists with the knowledge to achieve reliable, precise, and sensitive quantification in pharmaceutical and biological matrices, ultimately supporting robust analytical outcomes in research and quality control.

Mastering Core Principles: The Science Behind UV-Vis Sensitivity and Low Concentration Detection

Understanding the Beer-Lambert Law and its Limitations at Low Concentrations

The Beer-Lambert Law is a fundamental principle in absorption spectroscopy, forming the basis for quantitative analysis of substances in solution. It states that the absorbance of light by a sample is directly proportional to the concentration of the absorbing species and the path length the light travels through [1]. While this relationship provides a powerful tool for concentration determination, researchers working with low-concentration samples often encounter significant deviations from ideal behavior. This technical guide explores the limitations of the Beer-Lambert Law at low concentrations and provides practical troubleshooting methodologies to enhance measurement accuracy and reliability in sensitive analytical applications.

Core Principles and Fundamental Limitations

The Beer-Lambert Law: Foundation and Formulation

The Beer-Lambert Law establishes a linear relationship between absorbance and concentration, expressed mathematically as A = εcl, where A is absorbance, ε is the molar absorptivity (in L·mol⁻¹·cm⁻¹), c is the concentration (in mol·L⁻¹), and l is the path length (in cm) [1]. Absorbance itself is defined as A = log₁₀(I₀/I), where I₀ is the incident light intensity and I is the transmitted light intensity [2].

At its core, the law assumes that the absorbing species act independently, the light is monochromatic, the sample is homogeneous, and no chemical interactions occur that would alter the absorption characteristics [3]. While these conditions are often approximately met in ideal systems, they frequently break down in real-world analytical scenarios, particularly when working with low-concentration samples or complex matrices.

Key Limitations at Low Concentrations

| Limitation | Underlying Cause | Impact on Low Concentration Measurements |

|---|---|---|

| Deviations from Linearity | Instrumental noise, stray light, chemical interactions | Reduced accuracy in quantification; non-linear calibration curves [4] |

| Interference Effects | Multiple reflections in cuvette; light scattering | Fluctuations in measured absorbance due to wave interference [3] |

| Molecular Environment Effects | Solvent-solute interactions; proximity of other molecules | Changes in molar absorptivity (ε) at different concentrations [3] |

| Sample Heterogeneity | Micro-inhomogeneities in sample matrix | Non-representative absorption measurements [3] |

| Instrumental Limitations | Detector sensitivity; source stability; spectral bandwidth | Poor signal-to-noise ratio at low absorbance values [5] |

Troubleshooting Guides

Guide 1: Addressing Non-Linearity in Calibration Curves

Problem: Calibration curve shows significant deviation from linearity at low concentrations, making accurate quantification difficult.

Solution Steps:

- Implement a Blank Correction Strategy: Use an appropriate reference solution that matches the sample matrix to account for solvent and cuvette contributions [3].

- Limit Absorbance Range: Keep measured absorbance values preferably between 0.1 and 1.0 AU to operate within the instrument's optimal detection range [5].

- Apply Higher-Order fitting: For concentrations where linearity fails, consider using a quadratic fit (y = Ax - Bx²) to better model the behavior at low concentrations [4].

- Validate with Standard Additions: Use the method of standard additions to account for matrix effects that may cause non-linearity.

Verification: Prepare independent validation standards at concentrations spanning your range of interest. The predicted concentrations should fall within ±5% of the actual values for acceptable method performance.

Guide 2: Minimizing Interference and Scattering Effects

Problem: Interference patterns or scattering effects distort absorption spectra, particularly problematic for thin films or turbid samples.

Solution Steps:

- Use Matched Cuvettes: Ensure reference and sample cuvettes have identical optical properties to minimize interference from light reflections [3].

- Employ Integrating Spheres: For highly scattering samples, use instrumentation with integrating spheres to capture both transmitted and scattered light.

- Apply Dual-Wavelength Methods: For samples with background interference, use two wavelengths—one at the analyte peak and another as reference—to compensate for turbidity [6].

- Optimize Path Length: Use shorter path length cuvettes (e.g., 1 mm instead of 10 mm) for concentrated samples to avoid exceeding the linear range of detection [5].

Verification: Compare the absorption spectrum of your sample in different path length cuvettes. The spectra should maintain the same features when normalized for path length if interference effects are minimal.

Frequently Asked Questions (FAQs)

Q1: Why does the Beer-Lambert Law often fail at very low concentrations? The law assumes ideal conditions that break down at low concentrations due to several factors: instrumental noise becomes significant relative to the signal, molecular interactions with the solvent environment cause changes in molar absorptivity, and minor impurities or background absorption contribute proportionally more to the total signal [3] [4]. Additionally, the logarithmic relationship between transmittance and absorbance magnifies errors in intensity measurement at low concentrations.

Q2: What is the optimal absorbance range for accurate quantitative measurements? For most UV-Vis instruments, the optimal absorbance range for quantitative work is between 0.1 and 1.0 absorbance units [5]. Below 0.1 AU, the signal-to-noise ratio typically decreases, while above 1.0 AU, the transmitted light intensity is too low (less than 10% of incident light) for reliable detection, and deviations from linearity become more pronounced due to instrumental limitations.

Q3: How can I improve detection limits for low-concentration samples? Several strategies can enhance detection limits: (1) use cuvettes with longer path lengths to increase the effective absorption path; (2) employ derivative spectroscopy to resolve overlapping peaks and enhance sensitivity [7]; (3) utilize area under the curve (AUC) measurements across a wavelength range rather than single-point absorbance [7]; (4) ensure proper sample preparation to eliminate interfering substances; and (5) use high-sensitivity instrumentation with low-stray light and reduced noise characteristics.

Q4: What are the most common sources of error in UV-Vis measurements at low concentrations? The predominant error sources include: (1) instrumental noise from the detector and light source instability; (2) chemical effects such as association/dissociation equilibria or molecular interactions that alter absorptivity; (3) optical effects including light scattering, fluorescence, or refractive index changes; (4) positioning errors with cuvettes; and (5) dilution errors during sample preparation [3] [5]. Proper method validation and quality control measures help identify and minimize these error sources.

Experimental Protocols for Low Concentration Analysis

Protocol 1: Dual-Wavelength Method for Compensating Background Interference

Principle: This method uses two wavelengths to distinguish analyte signal from background interference, with one wavelength at the analyte's maximum absorption and another where the analyte shows minimal absorption but background interference is similar [6].

Procedure:

- Prepare a series of standard solutions spanning the expected concentration range.

- Scan the absorption spectrum of each standard to identify the optimal analytical wavelength (λanalyte) and reference wavelength (λreference).

- Measure absorbance of all standards and samples at both wavelengths.

- Calculate the corrected absorbance: Acorrected = Aanalyte - A_reference.

- Prepare a calibration curve using A_corrected versus concentration.

- For soil or complex matrices with organic matter interference, research indicates that the wavelength pair 235 nm/275 nm often provides better performance than the traditional 220 nm/275 nm combination for nitrate detection [6].

Validation: Analyze certified reference materials or spiked recovery samples. Percent recovery should fall between 95-105% for acceptable method accuracy.

Protocol 2: First-Order Derivative Spectroscopy for Enhanced Resolution

Principle: Derivative spectroscopy transforms normal absorption spectra into their first derivatives, which enhances the resolution of overlapping peaks and reduces the effect of baseline offsets [7].

Procedure:

- Record the zero-order absorption spectrum of both standards and samples with high wavelength resolution (e.g., 1 nm or less).

- Apply the first-derivative transformation using the spectrometer's software or mathematical processing.

- Identify the zero-crossing points or peak-to-peak measurements in the derivative spectrum that correspond to concentration.

- Construct a calibration curve using the derivative amplitude values versus concentration.

- For tafamidis meglumine analysis, this approach has demonstrated excellent precision with percent recovery ranging from 98.8% to 101.3% [7].

Applications: Particularly useful for analyzing drugs in biological fluids or complex formulations where excipients or metabolites cause spectral interference.

Critical Reagents and Materials

Research Reagent Solutions for Low Concentration UV-Vis Analysis

| Reagent/Material | Function | Critical Specifications |

|---|---|---|

| High-Purity Solvents | Dissolve analytes without introducing UV-absorbing impurities | UV-cutoff below measurement wavelength; e.g., HPLC-grade methanol for ~200 nm cutoff [7] |

| Reference Standards | Calibration curve establishment | Certified purity >98%; appropriate stability for reliable quantification |

| Matched Quartz Cuvettes | Contain samples for measurement | Precise path length (typically 1 cm); transparent in UV-Vis range; strain-free [5] |

| Buffer Systems | Maintain constant pH environment | Non-absorbing in spectral region of interest; appropriate ionic strength |

| Chemical Derivatization Agents | Enhance absorption characteristics for poor chromophores | Selective for target analyte; yield stable, highly absorbing products |

Method Optimization Workflow

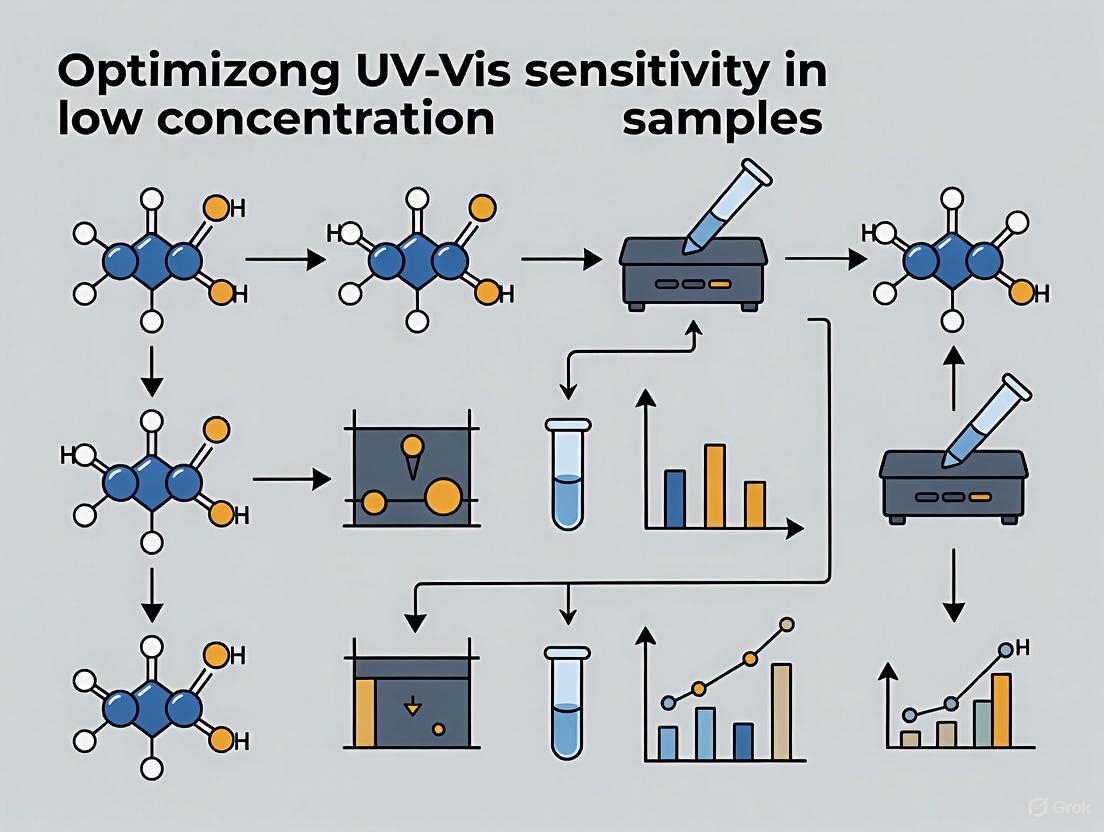

The following diagram illustrates the systematic approach to optimizing UV-Vis methods for low concentration analysis:

Advanced Correction Techniques

For complex matrices with significant background interference, the following correction methodology can be implemented:

Successfully applying the Beer-Lambert Law to low-concentration samples requires a comprehensive understanding of its limitations and the implementation of appropriate correction strategies. By utilizing the troubleshooting guides, experimental protocols, and method optimization workflows presented in this technical resource, researchers can significantly improve the accuracy and reliability of their UV-Vis spectroscopic analyses. The key to success lies in systematic method validation, proper instrumentation care, and selecting the most appropriate analytical approach for each specific application.

Technical Support Center: Pekarian Function Implementation

This technical support center provides troubleshooting guides and FAQs to help researchers successfully implement the Pekarian function for analyzing UV-Vis spectra of conjugated molecules and proteins in solution. These resources address common experimental challenges when working with low-concentration samples.

Troubleshooting Guide: Common Experimental Issues

Issue: Poor Fit Quality with Pekarian Function

- Problem Statement: The Pekarian function fit does not converge or shows high residuals when fitting UV-Vis spectra of conjugated molecules.

- Symptoms: High chi-squared values, systematic residual patterns, parameter uncertainty exceeding 15%.

- Environment: Solution spectra with overlapping bands, typically organic conjugated compounds in toluene or similar solvents.

Possible Causes:

- Incorrect initial parameter estimates

- Excessive noise in baseline region

- Overlooking minor overlapping transitions

- Temperature effects on band shape

Resolution Process:

- Set Initial Parameters: Start with literature values: S ≈ 0.8-1.2, Ω ≈ 1300-1400 cm⁻¹ for conjugated systems [8]

- Baseline Correction: Truncate spectrum to avoid interference from solvent absorption (<370 nm for toluene) [8]

- Check Components: Fit requiring 1-3 Pekarian functions for overlapping bands [9]

- Temperature Control: Maintain constant temperature; σ0 increases from 437 to 500 with temperature rise from 5°C to 90°C [8]

Validation: Weighted average 〈νge*〉 = ν0 + Ω×S should match TD-DFT calculations [8]

- Escalation: If uncertainty persists, use homemade PekarFit Python script for detailed output [9]

Issue: Low Sensitivity for Protein Concentration Analysis

- Problem Statement: Inaccurate protein quantification at low concentrations using direct UV absorbance at 280 nm.

- Symptoms: Poor correlation at concentrations <0.1 mg/mL, high variability in replicate measurements.

- Environment: Protein solutions, particularly HBOCs (hemoglobin-based oxygen carriers) with low encapsulation efficiency.

Possible Causes:

- Interference from nucleic acids or other contaminants

- Protein composition variations affecting absorbance

- Exceeding linear range of spectrophotometer

Resolution Process:

- Method Selection: Implement SLS-Hb method for specificity and sensitivity [10]

- Path Length Adjustment: Use 100 mm cell path instead of 10 mm for low concentration samples [11]

- Sample Purification: Remove contaminants through additional purification steps [12]

- Replicate Measurements: Perform minimum triplicate readings with statistical analysis [12]

Validation: Compare with orthogonal methods (BCA, Bradford) for validation [10]

- Escalation: For persistent issues, employ microvolume spectrophotometry (NanoDrop) for limited samples [12]

Issue: Band Shape Distortion at Low Temperatures

- Problem Statement: Non-centrosymmetric band shapes appearing at temperatures below 150°C.

- Symptoms: Asymmetric bands, poor Gaussian/Lorentzian fits, temperature-dependent parameters.

- Environment: Low-temperature measurements of organic conjugated derivatives in solution.

Possible Causes:

- Vibronic effects becoming prominent at lower temperatures

- Internal molecular rotation restrictions

- Solvatochromic shifts being overlooked

Resolution Process:

- Function Selection: Apply modified Pekarian function with five parameters [8]

- Parameter Monitoring: Track temperature dependence of σ0 and δ parameters [8]

- Vibrational Modes: Use k=0-8 progression terms in PF equations [8]

- Solvent Effects: Account for solvatochromic shifts in parameter interpretation

Validation: Verify S parameter remains temperature-independent (S=0.87 for rubrene) [8]

- Escalation: For gas-phase spectra, incorporate multiple vibrational modes [8]

Pekarian Function Parameters and Experimental Values

Table 1: Optimized Pekarian Function Parameters for Rubrene in Toluene [8]

| Parameter | Description | Value at 20°C | Temperature Dependence |

|---|---|---|---|

| S | Huang-Rhys factor (average phonon number) | 0.87 | Temperature-independent |

| ν₀ | Zero-phonon line position | 18,941 cm⁻¹ | Increases from 18,923 to 19,030 cm⁻¹ (5-90°C) |

| Ω | Effective vibrational wavenumber | 1,353.7 cm⁻¹ | Weak dependence: 1,352-1,365 cm⁻¹ (5-90°C) |

| σ₀ | Gaussian broadening | 448.3 | Increases from 437 to 500 (5-90°C) |

| δ | Global correction for other modes | 15.1 | Decreases from 20 to 0 (5-90°C) |

Table 2: Comparison of Hb Quantification Methods for Low Concentration Samples [10]

| Method | Specificity | Linear Range (mg/mL) | Advantages | Limitations |

|---|---|---|---|---|

| SLS-Hb | High | 0-2.0 | Specific, cost-effective, safe | Requires specific reagent |

| Cyanmet-Hb | High | 0-1.5 | Hb-specific, standardized | Uses toxic cyanide reagents |

| BCA Assay | Low | 0-1.5 | Sensitive, compatible with additives | Affected by other proteins |

| Bradford (CB) | Low | 0-1.0 | Rapid, simple procedure | Interference from detergents |

| A₂₈₀ | Low | 0-2.0 | Non-destructive, simple | Nucleic acid contamination |

Frequently Asked Questions (FAQs)

Q1: When should I use the Pekarian function instead of Gaussian or Lorentzian functions for UV-Vis spectra?

Use the Pekarian function when analyzing spectra of conjugated organic compounds that show vibronic progression, particularly at lower temperatures (<150°C) where bands become non-centrosymmetric [8]. PF is specifically superior for donor-acceptor substituted dyes exhibiting varying resolution in solution and solid state [8]. Gaussian/Lorentzian functions risk misinterpretation as they don't account for the intrinsic asymmetry in single absorption and emission bands at low temperatures [8].

Q2: What software tools can I use to implement Pekarian function fitting?

You can use commercial software like PeakFit or Origin with user-defined functions [9] [8]. Alternatively, a homemade PekarFit Python script is available that provides identical fitting results with more detailed outputs for deeper insight into the fitting process [8]. The Python implementation is particularly valuable for batch processing multiple spectra and customizing output parameters.

Q3: How does the Pekarian function improve sensitivity for low-concentration protein analysis?

While the Pekarian function primarily addresses band shape analysis, its accurate decomposition of overlapping signals enables better quantification of minor components in mixtures [9] [8]. For direct protein concentration measurement at low concentrations, combine PF analysis with sensitivity enhancement techniques including extended path length cells (100mm), method-specific assays (SLS-Hb), and orthogonal validation [12] [10] [11].

Q4: What are the critical parameters to monitor for reproducibility in Pekarian function fitting?

The five critical parameters requiring optimization are: S (Huang-Rhys factor), ν₀ (zero-phonon line), Ω (vibrational wavenumber), σ₀ (Gaussian broadening), and δ (global correction) [8]. For reproducibility, maintain constant temperature as σ₀ and δ show significant temperature dependence. The S parameter should remain temperature-independent, providing a reliability check [8].

Q5: How can I distinguish true protein signal from interference in low-concentration UV-Vis measurements?

First, obtain the full absorbance spectrum and check for characteristic protein peaks (280 nm for aromatic amino acids, Soret band ~410 nm for hemoglobin) [12] [10]. Use Hb-specific methods like SLS-Hb or CN-Hb that minimize interference from non-protein contaminants [10]. For conjugated molecules, the Pekarian function helps separate overlapping electronic transitions from noise or background interference [9] [8].

Experimental Workflow and Diagnostic Procedures

Parameter Relationships in Pekarian Function

The Scientist's Toolkit: Essential Research Materials

Table 3: Research Reagent Solutions for UV-Vis Spectral Analysis [12] [10] [11]

| Item | Function | Application Notes |

|---|---|---|

| Quartz Cuvettes | Sample holder for UV measurements | High transparency down to 200 nm; required for UV range measurements |

| SLS Reagent | Hemoglobin-specific quantification | Enables specific Hb measurement without toxic cyanide reagents |

| BCA Assay Kit | General protein quantification | Use for total protein measurement; sensitive to 0.1 mg/mL |

| Toluene Solvent | For conjugated organic compounds | High purity; truncate spectrum <370 nm to avoid solvent interference |

| TRIS Buffer | Protein stabilization and pH control | High-purity to minimize UV absorbance interference |

| PekarFit Python Script | PF spectral deconvolution | Provides detailed fitting parameters beyond commercial software |

Troubleshooting Guides and FAQs

FAQ: Pathlength and Sensitivity

How does pathlength affect my detection limit for low-concentration samples? According to the Beer-Lambert law (A = εcl), absorbance (A) is directly proportional to pathlength (l). Therefore, increasing the pathlength increases the measured absorbance for a given sample concentration, improving the signal and lowering your detection limit. For example, moving from a 1 mm to a 10 mm pathlength can provide a ten-fold increase in absorbance signal [5]. However, practical limitations like sample volume and instrument geometry exist. Alternative strategies to effectively increase pathlength in microfluidic systems include using U- or Z-shaped flow cells [13].

My sample absorbance is too high (>1.5 AU). What should I do? An absorbance value above 1.5 often falls outside the optimal linear range and can lead to detector saturation and unreliable data [14]. You have two primary options:

- Dilute the sample to bring it within the ideal 0.1-1.0 AU range [14].

- Use a shorter pathlength cuvette. For instance, switching from a standard 10 mm cuvette to a 1 mm cuvette will theoretically lower the absorbance by a factor of 10 [5]. Variable pathlength technology, which automates this process, can rapidly determine the optimal pathlength without manual dilution [15].

What is the relationship between pathlength and dynamic range? Pathlength directly determines the effective concentration range your instrument can measure. A longer pathlength enhances sensitivity for dilute samples but causes concentrated samples to exceed the upper absorbance limit quickly. A shorter pathlength sacrifices sensitivity for low concentrations but allows measurement of much higher concentrations without dilution. Variable pathlength cells exploit this principle, effectively expanding the dynamic range by allowing a single sample to be measured at multiple pathlengths within one setup [16].

How can I validate that my absorbance readings are reliable and within the linear range? A powerful method for internal data validation is to use a variable pathlength cell. By measuring the absorbance of your sample at multiple, continuous pathlengths in a single experiment, you can directly verify the linearity of the absorbance versus pathlength relationship as dictated by the Beer-Lambert law. If the data is linear, your measurement is reliable. Any non-linearity indicates a problem, such as detector saturation at high absorbance or stray light at low absorbance [16].

FAQ: Detector Performance

What are the key differences between a Photomultiplier Tube (PMT) and a Photodiode detector? The choice of detector impacts sensitivity and suitability for different applications. The key differences are summarized in the table below.

Table: Comparison of UV-Vis Detector Types

| Detector Type | Principle of Operation | Best For | Sensitivity |

|---|---|---|---|

| Photomultiplier Tube (PMT) [17] | Based on the photoelectric effect, ejecting electrons and multiplying the signal [5]. | Applications requiring detection of very low light levels. | Very High |

| Photodiode / CCD (as in PDA/DAD) [17] | Semiconductor-based; generates a current proportional to light intensity [5]. | Routine quantitative analysis, simultaneous multi-wavelength detection, and peak purity assessment [17]. | High (sufficient for most applications) |

My baseline is noisy. What could be the cause? Baseline noise can stem from several sources related to the detector and other components:

- Old Light Source: A degrading deuterium or tungsten/halogen lamp is a common cause of increased noise and should be replaced [14].

- Dirty Optical Components: Dust or contaminants on the flow cell windows, mirrors, or lenses can scatter light [14].

- Electrical Interference: Ensure the instrument is on a stable power supply and properly grounded.

- Stray Light: This is light reaching the detector at wavelengths outside the selected band, often caused by internal reflections or external light leaks, and it severely impacts linearity at high absorbance [17].

Experimental Protocols

Protocol 1: Implementing a Variable Pathlength Measurement for Data Validation

This protocol is adapted from research on variable pathlength cells for computer vision and can be conceptually applied to spectrophotometers with variable pathlength capabilities [16].

1. Objective: To verify the linearity of absorbance with pathlength for a given sample, ensuring data reliability and identifying the optimal quantification pathlength.

2. Materials:

- Variable pathlength cell (e.g., a triangular cell or a commercial system like the Solo VPE) [16] [15].

- Stable light source (e.g., LED pad) [16].

- Detector (e.g., CMOS camera, spectrophotometer) [16].

- Sample and reference blank solutions.

3. Methodology:

- Step 1: Setup. Place the variable pathlength cell on the light source. Ensure the detector is fixed and settings (e.g., ISO, aperture, white balance for a camera; or slit width for a spectrometer) are locked [16].

- Step 2: Blank Measurement. Fill the cell with the blank solution (e.g., solvent). Acquire an image or spectrum to record the reference light intensity (I₀) across the pathlength gradient [16].

- Step 3: Sample Measurement. Introduce the sample into the cell, ensuring it fills the entire pathlength gradient. Acquire a second image or spectrum under identical conditions to record the transmitted light intensity (I) [16].

- Step 4: Data Processing. For each position (and thus each pathlength) along the gradient, calculate the absorbance: A = -log(I / I₀). Plot absorbance (A) versus pathlength (l) [16].

4. Data Interpretation: A linear plot of A vs. l confirms that the absorbance readings are reliable and follow the Beer-Lambert law. The slope of the line is equal to εc. Non-linearity at longer pathlengths suggests the absorbance is too high for the detector, indicating a need for dilution or a shorter pathlength for quantification. Non-linearity at the shortest pathlengths may indicate the signal is too close to the system's noise floor [16].

Protocol 2: Enhancing Sensitivity in Microfluidic Systems via Extended Pathlength

This protocol is based on research for enhancing sensitivity in droplet microfluidics by converting droplets into a single-phase flow for measurement in a long-pathlength cell [13].

1. Objective: To overcome sensitivity limitations imposed by short optical pathlengths (typically <1 mm) in microfluidic channels.

2. Materials:

- T-junction droplet microfluidic chip [13].

- Reagents for assay (e.g., phosphate assay reagents) and sample [13].

- Carrier oil (e.g., Fluorinert FC-40) [13].

- PTFE membrane for oil removal [13].

- 3D-printed U-shape flow cell with integrated optical fibers (e.g., 5-20 mm pathlength) [13].

- LED light source and light-to-voltage converter (LVC) or spectrometer [13].

3. Methodology:

- Step 1: Droplet Generation and Reaction. Generate droplets containing the sample and reagents at a T-junction. Allow adequate residence time in a delay line for the reaction to complete [13].

- Step 2: Oil Removal. Direct the droplet stream through a PTFE membrane module. The hydrophobic membrane allows the continuous oil phase to be extracted, leaving a single-phase aqueous stream [13].

- Step 3: Long-Pathlength Absorbance Measurement. Guide the merged aqueous stream into a U-shape flow cell with a significantly longer pathlength (e.g., 5-20 mm). Measure the absorbance using the integrated optical fibers coupled to an LED and detector [13].

- Step 4: Calibration. Perform a calibration curve with standard concentrations under the same flow conditions.

4. Data Interpretation: This method combines the benefits of rapid, segregated mixing in droplets with the enhanced sensitivity of a long-pathlength measurement in a continuous flow, effectively lowering the limit of detection for colorimetric assays in microfluidic systems [13].

The Scientist's Toolkit: Research Reagent Solutions

Table: Essential Materials for Advanced UV-Vis Pathlength Experiments

| Item | Function / Application | Example / Specification |

|---|---|---|

| Variable Pathlength Cuvette | Allows continuous or discrete change of pathlength for data validation and dynamic range extension. | Triangular glass-plastic 3D-printed cell [16]; Commercial Solo VPE system [15]. |

| Long-Pathlength U/Z-Cell | Increases optical pathlength in flow systems to enhance sensitivity for low-concentration analytes. | 3D-printed U-shape flow cell with 5-20 mm pathlength [13]. |

| PTFE Membrane | Used to separate carrier oil from droplets in microfluidics, enabling single-phase analysis in long-pathlength cells. | Hydrophobic membrane for oil extraction [13]. |

| Quartz Cuvettes | Hold samples for analysis; quartz is transparent down to ~190 nm, essential for UV range measurements. | Standard 10 mm pathlength; various volumes available [5]. |

| Optical Filters & Monochromators | Select specific wavelengths of light for measurement, critical for isolating analyte signal. | Monochromators with 1200+ grooves/mm; bandpass filters [5]. |

| Certified Reference Materials | Used for regular instrument calibration to ensure accuracy and data integrity. | Potassium dichromate solutions [14]. |

Workflow and Relationship Diagrams

Diagram 1: Pathlength Validation Workflow

Diagram 2: Pathlength vs. Performance

Selecting Optimal Solvents and Wavelengths to Maximize Signal-to-Noise Ratio

Frequently Asked Questions (FAQs)

Q1: Why is the signal-to-noise ratio (SNR) critical for my UV-Vis analysis? A high SNR is fundamental for obtaining precise and accurate data, especially when analyzing low-concentration samples. The SNR quantifies how much your desired signal stands above the background statistical noise. [18] A low SNR can mask your analyte's signal, leading to poor detection limits and unreliable quantification. [19]

Q2: How does my choice of solvent affect the SNR? The solvent must be transparent in the wavelength region where your analyte absorbs. If the solvent itself absorbs significantly, it creates a high background signal, which increases noise and reduces the light available to reach the detector, thereby severely degrading the SNR. [5] [20] Always use high-purity, spectrophotometric-grade solvents.

Q3: What is the simplest way to find the best wavelength for maximum SNR? Perform an absorbance wavelength scan to identify your analyte's peak absorbance wavelength ((\lambda{\text{max}})). Operating at (\lambda{\text{max}}) provides the strongest signal. [20] [19] For complex mixtures, choose a wavelength where the analyte's absorption is distinct to minimize interference from other compounds. [20]

Q4: My absorbance reading is too high (>1 AU). What should I do? Absorbance values above 1 can lead to detector saturation and unreliable data because insufficient light reaches the detector. [5] To fix this, you can either dilute your sample or use a cuvette with a shorter path length. [21] [5] This simple step reduces the probability of light scattering and brings the measurement back into the instrument's optimal dynamic range.

Troubleshooting Guide: Improving Signal-to-Noise Ratio

| Problem Area | Symptom | Possible Cause | Solution |

|---|---|---|---|

| Solvent Selection | High baseline absorbance/noise. | Solvent absorbs in measurement range; contaminated or low-purity solvents. [20] | Use UV-transparent solvents (e.g., quartz cuvettes, HPLC-grade solvents). [20] [19] |

| Wavelength Selection | Low signal, poor sensitivity. | Not measuring at analyte's (\lambda_{\text{max}}). [20] | Perform wavelength scan to find and use (\lambda_{\text{max}}). [20] |

| Sample Preparation | Absorbance >1.0 AU, non-linear response. | Sample concentration too high. [21] [5] | Dilute sample or use cuvette with shorter path length. [21] [5] [20] |

| Instrumentation | Baseline drift, inconsistent readings. | Dirty cuvettes, scratched cuvettes, unstable light source, or lack of warm-up time. [21] [20] [22] | Clean/handle cuvettes properly; allow lamp warm-up (20 mins for halogen). [21] [20] |

| Detection Limit | Inability to quantify low-concentration analytes. | Inherent detector noise dominates signal. [19] | Increase signal via path length/wavelength; reduce noise via signal averaging/temperature control. [19] |

Experimental Protocols for SNR Optimization

Protocol 1: Initial Instrument Setup and Verification

- Power On and Warm-up: Turn on the spectrophotometer and allow the light source to stabilize. Tungsten halogen or arc lamps typically require around 20 minutes to achieve consistent output. [21]

- Blank Measurement: Fill a clean, appropriate cuvette with your pure solvent (blank) and perform the baseline correction. This step is critical for establishing the 0 Absorbance reference and accounts for any solvent or cuvette absorbance. [5] [20]

- Baseline Stability Check: Scan the blank solution over your desired wavelength range. The baseline should be flat and stable. Significant drift or noise indicates an instrument issue that must be resolved before sample measurement. [20] [22]

Protocol 2: Wavelength Scan to Determine (\lambda_{\text{max}})

- Objective: To identify the wavelength of maximum absorbance for your analyte.

- Procedure:

- Prepare a sample of your analyte at a concentration that gives an absorbance below 1.0.

- Place the sample in the spectrophotometer.

- Run an absorbance scan across a relevant wavelength range (e.g., 200-800 nm).

- Identify the peak(s) in the resulting spectrum. The highest point is the (\lambda_{\text{max}}), which should be used for quantitative measurements to maximize the signal. [20]

Protocol 3: Solvent Compatibility Testing

- Objective: To verify that your chosen solvent does not create excessive background noise.

- Procedure:

- Perform a wavelength scan with your proposed solvent in the sample cuvette and an air or water blank (depending on instrument type).

- Examine the resulting spectrum. The solvent should show minimal absorbance across your measurement range. High absorbance (e.g., >1.5 AU) indicates the solvent is unsuitable for those wavelengths. [5] [20] Refer to the solvent transparency table below for guidance.

Data Presentation: Solvent and Wavelength Guidelines

Table 1: UV Cutoff of Common Solvents

The "UV cutoff" is the wavelength below which the solvent absorbs too much light (Absorbance >1.0) for reliable measurements. Always choose a solvent with a cutoff well below your analyte's (\lambda_{\text{max}}).

| Solvent | UV Cutoff (nm) | Notes |

|---|---|---|

| Water | ~190 nm | Excellent for far-UV, use high-purity HPLC grade. [5] |

| Acetonitrile | ~190 nm | Preferred for HPLC UV-Vis detection. [19] |

| n-Hexane | ~200 nm | Common for non-polar analytes. |

| Methanol | ~205 nm | Common solvent, transparent in most visible ranges. |

| Ethanol | ~210 nm | Common solvent, transparent in most visible ranges. |

| Chloroform | ~245 nm | Use with care, absorbs significantly in mid-UV. |

| Acetone | ~330 nm | Avoid for UV measurements above its cutoff. |

Table 2: Troubleshooting SNR with Quantitative Data

This table connects practical issues with measurable SNR parameters.

| Issue | Impact on Signal | Impact on Noise | Corrective Action & Expected Outcome |

|---|---|---|---|

| Overly Concentrated Sample (A > 1) | Signal saturates, becomes non-linear. [5] | Increased light scattering can raise noise. | Dilute sample. Outcome: Absorbance reading returns to linear range (0.1-1.0 A), improving quantitation. [5] [20] |

| Solvent Absorbance | Attenuates light, reducing signal. [5] | High background absorption increases noise. [19] | Change solvent. Outcome: Lower baseline absorbance, leading to a direct increase in SNR. [20] |

| Sub-Optimal Wavelength | Lower signal strength. [20] [19] | Noise level remains constant. | Measure at (\lambda_{\text{max}}). Outcome: Maximum analyte signal is achieved, thus maximizing SNR. [20] |

| Dirty or Scratched Cuvette | Scatters light, reducing signal. | Scattered light contributes to noise. [20] | Clean or replace cuvette. Outcome: Reduced light scattering, restoring signal and lowering noise. [20] |

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function & Importance |

|---|---|

| Quartz Cuvettes | Essential for UV range measurements as quartz is transparent down to ~190 nm. Plastic and glass cuvettes absorb most UV light. [5] |

| HPLC-Grade Solvents | High-purity solvents minimize UV-absorbing contaminants that contribute to background noise and baseline drift. [19] |

| Potassium Dichromate | A common standard reference material (SRM) used for regular calibration of the spectrophotometer to ensure wavelength accuracy and photometric linearity. [20] |

| Certified Spectral Fluorescence Standards | Dye solutions with certified emission spectra (e.g., BAM F001b-F005b) used to determine the wavelength-dependent spectral responsivity of the instrument, which is critical for obtaining accurate, instrument-independent fluorescence data. [23] |

| Stable Light Source | A properly warmed-up and stable lamp (xenon, tungsten halogen, or deuterium) is crucial for consistent illumination and a stable baseline, which directly reduces noise. [21] [5] |

| Integrating Sphere (for ΦPL) | An accessory required for measuring quantitative photoluminescence quantum yield (ΦPL), a key parameter for evaluating the efficiency of luminescent compounds. [21] [24] |

Workflow for SNR Optimization

The diagram below outlines a systematic workflow for diagnosing and resolving common SNR issues in UV-Vis spectroscopy.

Advanced Techniques and Practical Protocols for Enhanced Sensitivity

Implementing Derivative and Area Under the Curve (AUC) Spectrophotometry

This technical support center provides targeted guidance for researchers implementing advanced UV-Vis spectrophotometric techniques to enhance sensitivity for low-concentration samples in pharmaceutical and bioanalytical research.

Core Principles and Methodologies

Fundamental Principles of Advanced Spectrophotometry

Derivative Spectrophotometry transforms traditional absorption spectra into their first, second, or higher-order derivatives. This transformation helps resolve overlapping spectral peaks that are indistinguishable in zero-order (conventional) absorption spectra, thereby improving selectivity in multi-component analysis [7] [25]. The first-order derivative spectrum represents the rate of change of absorbance with wavelength, effectively pinpointing wavelengths where the slope of the absorption spectrum is steepest [7].

Area Under the Curve (AUC) Spectrophotometry involves calculating the integrated area under the absorption spectrum across a selected wavelength range, rather than relying on absorbance at a single wavelength [7]. This approach offers enhanced analytical sensitivity and more robust measurements for drug quantification, as it is less affected by minor instrumental shifts or baseline noise [7].

Detailed Experimental Protocols

Protocol 1: Implementing First-Order Derivative Spectrophotometry

- Instrument Setup: Use a double-beam UV-Vis spectrophotometer with derivative capability. Ensure the instrument is calibrated and a baseline correction is performed with a blank solvent [7] [26].

- Preliminary Spectral Scan: Obtain the zero-order absorption spectrum (e.g., from 400-200 nm) of the standard analyte solution to identify the characteristic absorption peak [7].

- Derivative Parameter Selection: Access the derivative mode on your instrument software. Common initial parameters are a Δλ (delta lambda) of 8 nm and a scaling factor of 10 to generate the first-order derivative spectrum [25].

- Wavelength Selection for Quantification: In the first-derivative spectrum, identify the wavelength corresponding to a distinct peak, trough, or a zero-crossing point (where the derivative value is zero for an interfering substance) [7] [25].

- Calibration Curve: Measure the derivative absorbance values (amplitude from baseline to the peak or trough) at the selected wavelength for a series of standard solutions. Plot these values against concentration to construct the calibration curve [7] [25].

Protocol 2: Implementing Area Under the Curve (AUC) Spectrophotometry

- Spectral Collection: Record the zero-order absorption spectrum of the standard and sample solutions within a suitable range [7].

- Wavelength Range Selection: Choose a specific, broad wavelength range over which the integration will be performed. This range should be on the flank of a major absorption band where the analyte exhibits significant and consistent absorption [7].

- Area Calculation: Use the spectrophotometer's software to calculate the area under the curve (AUC) for the selected wavelength range. The software typically uses mathematical algorithms for numerical integration.

- Calibration Curve: Plot the calculated AUC values for standard solutions against their respective concentrations. This calibration curve is used to determine the concentration of unknown samples [7].

Troubleshooting Common Experimental Issues

Table 1: Common Issues and Solutions in Derivative and AUC Spectrophotometry

| Problem | Possible Cause | Solution |

|---|---|---|

| Noisy or unstable derivative spectrum [26] | Instrument drift; Dirty cuvettes; Incorrect Δλ setting. | Perform baseline correction; Use clean, scratch-free cuvettes; Increase the Δλ value to smooth the spectrum [25] [26]. |

| Poor linearity in calibration curve [26] | Sample concentration too high; Incorrect path length; Stray light. | Dilute samples to ensure absorbance is within the ideal 0.1-1.0 range; Verify cuvette path length is correct and accounted for in calculations [27] [26]. |

| Inaccurate AUC measurement | Incorrect baseline or poorly selected wavelength range. | Always zero the instrument with a blank; Re-evaluate and adjust the integration wavelength range to ensure it is on a relevant part of the spectrum [7] [27]. |

| Low sensitivity in derivative mode | Suboptimal wavelength or scaling factor. | Experiment with different wavelengths (e.g., peak-to-trough measurements) and adjust the scaling factor to enhance signal response [25]. |

| Irreproducible results between runs [26] | Temperature fluctuations; Inconsistent sample volumes; Solvent effects. | Use a thermostatic cell holder; Ensure consistent sample volumes in the cuvette; Use high-purity solvents that do not absorb in the measured range [26]. |

Frequently Asked Questions (FAQs)

Q1: When should I choose derivative spectrophotometry over the conventional (zero-order) method? Use derivative spectrophotometry when you need to resolve and quantify individual components in a mixture with significantly overlapping absorption spectra, or to eliminate interference from sample matrices [7] [25].

Q2: What is the main advantage of the AUC approach compared to single-wavelength measurement? The AUC method offers enhanced analytical sensitivity because it utilizes the absorbance information across a range of wavelengths. This makes the measurement more robust against minor baseline shifts, background noise, or instrumental drift that can affect a single data point [7].

Q3: My derivative spectrum shows a lot of noise. What is the first parameter I should adjust? The first parameter to adjust is Δλ (delta lambda). Increasing the Δλ value will smooth the derivative spectrum and reduce noise, though it may slightly decrease resolution. Finding a balance is key [25].

Q4: Can these advanced techniques be used for analysis in biological matrices like plasma or urine? Yes. These methods have been successfully validated for analyzing drugs in spiked human urine and other biological fluids, demonstrating excellent accuracy and precision with percent recoveries close to 100% [7].

Q5: How do I select the optimal wavelength range for AUC analysis? The range should be selected on a portion of the absorption spectrum where the analyte has significant and characteristic absorption, typically on the ascending or descending flank of a major peak. The range should be broad enough for a reliable measurement but specific to the analyte [7].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Reagents and Materials for Advanced Spectrophotometry

| Item | Function | Specification Notes |

|---|---|---|

| High-Purity Solvent [27] [26] | Dissolves the analyte without interfering with absorption in the measured range. | Use spectroscopic grade (e.g., methanol, water). Check that the solvent's cutoff wavelength is below your measurement range [7] [27]. |

| Standard Reference Material [7] [26] | Used for instrument calibration and method validation. | Certified reference standard of the target analyte with known purity (e.g., pharmaceutical-grade Tafamidis Meglumine) [7]. |

| Quartz Cuvettes [27] [26] | Holds the sample for analysis. | Must be used for UV range measurements. Ensure they are clean, scratch-free, and have a known path length (typically 1 cm) [27]. |

| Buffer Salts [26] | Maintains a stable pH in the sample solution, which can critical for the stability of some analytes. | Use high-purity salts to prepare buffers that do not absorb in the spectral region of interest. |

| Volumetric Flasks & Pipettes [7] | For accurate preparation and dilution of standard and sample solutions. | Use Class A glassware and calibrated pipettes to ensure precision in concentration. |

Experimental Workflow and Decision Pathway

The following diagram illustrates the logical workflow for developing and troubleshooting an analytical method using derivative or AUC spectrophotometry.

Proper sample preparation is a critical foundation for obtaining reliable and reproducible data in UV-Vis spectroscopy, especially when working with low-concentration samples. This guide provides comprehensive troubleshooting and methodological support for researchers preparing both solution and thin-film samples. The protocols and FAQs presented here are framed within the broader context of optimizing UV-Vis sensitivity, where proper sample handling directly influences detection limits, signal-to-noise ratios, and overall analytical accuracy for drug development and material science applications.

Experimental Workflows

The sample preparation process differs significantly between solution and thin-film analyses. The following workflows outline the key steps for each method.

Detailed Methodologies

Solution-Based Sample Preparation

Objective: Prepare a homogeneous solution with optimal concentration for UV-Vis analysis, ensuring the absorbance falls within the instrument's dynamic range (typically 0.1-1.0 AU) [5] [28].

Materials:

- Analytical balance (precision ±0.1 mg)

- Volumetric flasks (appropriate size for dilution series)

- Precision pipettes and clean tips

- UV-transparent cuvettes (quartz for UV range, see Section 5.1)

- Appropriate solvent (HPLC grade or higher)

- Syringe filters (0.45 µm porosity, compatible with solvent) [29]

Procedure:

- Calculate required concentrations: Use Beer-Lambert law (A = ε × c × l) to estimate the concentration needed to achieve absorbance between 0.1-1.0 AU for your analyte. Always prepare slightly more volume than needed to account for handling losses [30].

Weigh solid samples: Using an analytical balance, weigh the precise amount of analyte needed. Record the exact mass to calculate final concentration.

Dissolve in appropriate solvent: Transfer the analyte to a volumetric flask and add solvent to approximately 80% of the final volume. Mix until completely dissolved, then dilute to the final volume.

Filter if necessary: For samples that may contain particulates, filter through a 0.45 µm syringe filter compatible with your solvent system. Pre-rinse the filter with 1 mL of solvent to remove potential leachates [29].

Transfer to cuvette: Pipette the solution into a clean quartz cuvette, filling it to the appropriate level (typically ¾ full). Handle cuvettes only by the opaque sides with gloved hands to prevent fingerprints [21].

Inspect for air bubbles: Gently tap the cuvette or invert it carefully if necessary to dislodge any air bubbles that could scatter light [21].

Thin-Film Sample Preparation

Objective: Prepare uniform, high-quality thin films on appropriate substrates for optical analysis, with controlled thickness and minimal defects [31] [32].

Materials:

- Plasma cleaner or UV-ozone treatment system

- Precursor materials (e.g., metal salts, polymers)

- High-purity solvents (e.g., ethylene glycol monomethyl ether - EGME)

- Acetic acid (to suppress hydrolysis)

- Spin coater with programmable parameters

- Hotplate or furnace for annealing

- Filtering system (13 mm/0.45 µm filter) [32]

Procedure (adapted from multi-component oxide film preparation) [32]:

- Substrate preparation:

- Cut glass or silicon substrates to appropriate size (e.g., 1 × 1.5 cm)

- Clean substrates sequentially with detergent, deionized water, and organic solvents

- Perform plasma treatment for 5 minutes to improve adhesion

Precursor solution preparation:

- Dissolve precursor materials in EGME at desired concentration (0.6-1.0 M)

- Add acetic acid to suppress hydrolysis of metal ions

- Stir the solution in atmosphere for 8 hours

- Filter through 0.45 µm filter

- Age the filtered precursor for 24 hours before use

Spin-coating parameters:

- Dispense 50 µL of precursor onto substrate center

- First stage: 1000 rpm for 6 seconds (spread phase)

- Second stage: 5000 rpm for 30 seconds (thinning phase)

- Optimize parameters based on desired thickness and material properties

Thermal treatment:

- Pre-anneal at 130°C to remove residual solvent

- Final anneal at 300°C for 1.5 hours in air to form final film structure

- Control heating and cooling rates to prevent stress and cracking

Troubleshooting Guides

Common Preparation Issues and Solutions

Table 1: Troubleshooting Solution Sample Preparation

| Problem | Possible Causes | Solutions | Prevention Tips |

|---|---|---|---|

| Unexpected peaks in spectrum [21] | Contaminated cuvette or sample | Thoroughly clean cuvettes with appropriate solvents; prepare fresh samples | Handle cuvettes with gloved hands; use high-purity reagents |

| Absorbance too high (>1.0 AU) [5] [28] | Sample concentration too high | Dilute sample; use cuvette with shorter path length | Calculate expected absorbance using Beer-Lambert law before preparation |

| Noisy or unstable baseline [21] [28] | Air bubbles in light path; insufficient lamp warm-up | Tap cuvette gently; allow lamp to warm up for 20+ minutes (halogen/tungsten) | Let light source warm up properly; degas solutions if necessary |

| Sample leaking from container [30] | Incorrect container size; overfilling | Use appropriately sized container; fill to ¾ capacity | Pre-label appropriately sized containers before starting preparation |

| Inconsistent results between replicates [33] | Improper mixing; evaporation | Mix solutions thoroughly; cap containers when not in use | Standardize mixing times and techniques; work in controlled environment |

Table 2: Troubleshooting Thin-Film Sample Preparation

| Problem | Possible Causes | Solutions | Prevention Tips |

|---|---|---|---|

| Non-uniform film thickness [31] | Improper spin speed; unstable substrate | Optimize spin coating parameters; ensure secure substrate mounting | Calibrate spin coater regularly; use clean, flat substrates |

| Pinholes or defects [21] | Dirty substrate; particulate contamination | Improve substrate cleaning; filter precursor solutions | Use plasma cleaning; work in clean environment |

| Poor adhesion to substrate [32] | Incorrect surface energy; contamination | Implement plasma treatment; optimize substrate preparation | Standardize substrate cleaning protocol; test adhesion early |

| Incorrect film thickness [32] | Wrong solution concentration/viscosity | Adjust concentration; characterize solution properties | Measure solution viscosity and surface tension before deposition |

| Cracking during annealing [32] | Too rapid heating/cooling; stress mismatch | Optimize thermal profile; consider graded annealing | Program controlled heating/cooling rates; match CTE of film and substrate |

Advanced Troubleshooting: Low Concentration Samples

Table 3: Optimizing Sensitivity for Low Concentration Samples

| Challenge | Optimization Strategy | Expected Improvement |

|---|---|---|

| Signal below detection limit | Pre-concentration techniques (TFME, SPME) [34] | 10-100x sensitivity improvement |

| High background noise | Use high-purity solvents; proper blank subtraction | Improved signal-to-noise ratio |

| Matrix interference | Selective extraction; standard addition method [34] | More accurate quantification |

| Path length limitations | Use longer path length cuvettes or liquid waveguides | Increased effective absorbance |

| Scattering effects | Filter samples; use integrating spheres | Reduced measurement artifacts |

Frequently Asked Questions (FAQs)

General Preparation Questions

Q1: What type of cuvette should I use for UV-Vis measurements? A: Quartz cuvettes are required for UV range measurements (below 350 nm) as they transmit UV light effectively. For visible-only measurements, glass or plastic cuvettes may be used. Disposable plastic cuvettes should only be used with compatible solvents, as some solvents can dissolve plastics [21] [5].

Q2: How can I improve reproducibility in my sample preparation? A: Implement strict protocols for each step: use calibrated pipettes, maintain consistent mixing times and techniques, pre-label all containers, and allow instruments to warm up properly (20+ minutes for tungsten/halogen lamps) [21] [33]. Digital tracking systems (LIMS) can also improve documentation and traceability [30].

Q3: Why is my blank measurement not zero? A: This can indicate contaminated solvent, dirty cuvettes, or incorrect blank selection. Ensure your blank contains all solution components except the analyte. Use high-purity solvents and meticulously clean cuvettes between measurements [21].

Solution-Specific Questions

Q4: My sample concentration is too high (A > 1.0). What are my options? A: You can either dilute the sample or use a cuvette with a shorter path length. If sample volume is limited, consider specialized micro-cuvettes designed for small volumes [21] [5].

Q5: How does solvent choice affect UV-Vis measurements? A: Solvents can have significant UV cutoffs (wavelengths below which they absorb strongly). Water and acetonitrile are transparent to about 190 nm, while chloroform absorbs below 245 nm. Always ensure your solvent doesn't absorb at your measurement wavelengths [5].

Thin-Film Specific Questions

Q6: How can I control thin-film thickness in solution-based preparation? A: Film thickness is primarily controlled by solution concentration, viscosity, and spin-coating parameters (speed, time, acceleration). Higher concentrations and viscosities generally produce thicker films, as do lower spin speeds [32].

Q7: What substrate treatments improve thin-film quality? A: Plasma treatment for 5 minutes significantly improves film adhesion and uniformity by increasing surface energy and removing organic contaminants. Chemical etching and UV-ozone treatment are also effective for specific substrate materials [32].

The Scientist's Toolkit: Essential Materials

Table 4: Essential Research Reagents and Materials

| Item | Function | Application Notes |

|---|---|---|

| Quartz cuvettes [21] [5] | Sample holder for UV-Vis measurements | Required for UV measurements; handle with gloves to prevent fingerprints |

| Syringe filters (0.45 µm) [29] [32] | Remove particulates from solutions | Choose membrane material compatible with solvent (PVDF for organics) |

| High-purity solvents | Dissolve analytes without interference | Check UV cutoff wavelength; use HPLC grade or better |

| Precision pipettes | Accurate liquid handling | Calibrate regularly; use appropriate size for volume being measured |

| Plasma cleaner [32] | Substrate surface treatment | Improves thin-film adhesion and uniformity |

| Programmable spin coater [32] | Thin-film deposition | Allows control of thickness through rotational speed |

| Analytical balance | Precise weighing of solids | Calibrate regularly; use in draft-free environment |

| Hotplate/annealing oven [32] | Thermal treatment of films | Programmable temperature profiles improve reproducibility |

Spectral Deconvolution with Modified Pekarian Functions for Overlapping Bands

The Challenge of Overlapping Bands in UV-Vis Spectroscopy

UV-Vis spectroscopy is a fundamental technique for sample characterization across chemical and biological disciplines, yet analysts frequently encounter complex spectra where multiple electronic transitions produce overlapping absorption bands. [21] [8] This overlap obscures crucial information about individual chromophores, reaction intermediates, or distinct electronic states, particularly when analyzing conjugated organic molecules, pharmaceuticals, or environmental samples with multiple absorbing species. [8] Traditional decomposition methods relying on symmetric Gaussian or Lorentzian functions often prove inadequate because real absorption and emission bands are inherently non-centrosymmetric, especially at lower temperatures typically encountered in laboratory environments. [8]

The Modified Pekarian Function Approach

The modified Pekarian Function (PF) provides a physically grounded alternative for fitting UV-Vis absorption and fluorescence spectra with high accuracy and reproducibility. [8] Originally developed to describe absorption bands associated with F-centers in crystals, the approach has been successfully adapted for analyzing conjugated organic compounds in solution. [8] Unlike purely mathematical fitting functions, PF incorporates vibronic coupling through the Huang–Rhys factor S, which represents the mean number of phonons accompanying an optical transition. [8] This physical basis makes it particularly suitable for analyzing conjugated molecules whose electronic properties are highly temperature-dependent and often exhibit significant solvatochromic shifts. [8]

Implementing Pekarian Function Fitting: A Step-by-Step Methodology

Mathematical Formulation

The modified Pekarian functions for absorption (PFa) and fluorescence (PFf) spectra are expressed as follows: [8]

For absorption spectra (PFa):

For fluorescence spectra (PFf):

Where the summation runs from k=0 to k=8, which proves sufficient for most practical applications. [8]

Parameter Definitions and Physical Significance

The PF fitting process optimizes five key parameters that define the band shape, each with distinct physical meaning:

Table 1: Key Parameters in Pekarian Function Fitting

| Parameter | Physical Significance | Role in Spectral Fitting |

|---|---|---|

| S | Huang–Rhys factor representing mean number of vibration quanta dissipated during relaxation | Determines relative intensities of vibronic progression peaks |

| ν₀ | Position of the 0-0 transition (cm⁻¹) | Sets the electronic transition energy without vibrational contributions |

| Ω | Wavenumber of the principal vibrational mode (cm⁻¹) | Defines spacing between successive vibronic peaks |

| σ₀ | Gaussian broadening parameter (cm⁻¹) | Accounts for homogeneous and inhomogeneous broadening effects |

| δ | Global correction factor (cm⁻¹) | Compensates for contributions from secondary vibrational modes |

Experimental Workflow for Spectral Deconvolution

The following workflow outlines the complete process for implementing PF fitting to resolve overlapping bands:

Software Implementation Options

Researchers can implement PF fitting through multiple software pathways:

- Commercial Software: Use PeakFit or Origin with user-defined functions [8]

- Custom Scripting: Employ the homemade PekarFit Python script [8]

- Quantum Mechanical Validation: Compare weighted averages 〈νge*〉 = ν₀ + Ω × S with TD-DFT calculations [8]

Troubleshooting Guide & FAQs

Common Fitting Issues and Solutions

Q: The fitting algorithm fails to converge or produces physically unrealistic parameters. What should I check?

A: This typically indicates issues with initial parameter estimation or experimental artifacts:

- Verify baseline stability and ensure no unintended absorption features from contaminants [21]

- Check solvent absorption cutoff – truncate spectra where solvent interference occurs [8]

- Validate initial S parameter estimates (typically 0.5-2.0 for conjugated organic molecules) [8]

- Ensure Ω values fall within expected vibrational modes (500-3000 cm⁻¹ for organic compounds) [8]

Q: My deconvoluted spectra show unexpected residual peaks not assignable to my sample. What could cause this?

A: Unexpected peaks often originate from experimental artifacts rather than sample properties:

- Confirm cuvette cleanliness using solvent blanks [21]

- Check for sample contamination during preparation or deposition [21]

- Verify solvent purity and absence of fluorescent impurities [21]

- Ensure light source has stabilized (20+ minutes for halogen/arc lamps) [21]

Q: How does temperature affect PF fitting parameters, and how should I control for this?

A: Temperature significantly impacts several fitting parameters:

- σ₀ (broadness) shows strong temperature dependence (e.g., increases from 437 to 500 cm⁻¹ between 5-90°C for rubrene) [8]

- δ parameter decreases with rising temperature and may reach zero [8]

- ν₀ exhibits linear temperature dependence [8]

- Maintain consistent temperature control (±0.5°C) during measurements for comparable results [21]

Q: The resolved bands show poor reproducibility between replicate measurements. Where should I look for the issue?

A: Poor reproducibility typically stems from instrumental or sample presentation factors:

- Confirm consistent sample positioning within the beam path [21]

- Check for solvent evaporation during extended measurements, which increases concentration [21]

- Verify spectrometer warm-up time (20+ minutes for lamp stability) [21]

- Ensure consistent sample concentration within optimal absorbance range (0.1-1.0 AU) [35]

Optimization for Low-Concentration Samples

Q: How can I enhance sensitivity when working with low-concentration samples typical in pharmaceutical development?

A: Several strategies can improve signal quality for dilute samples:

- Use cuvettes with longer path lengths to increase absorption signal [21]

- Employ advanced detection methods like peptide-modified nanoparticles for specific analyte enrichment [36]

- Implement hybrid machine learning approaches that combine classification and regression algorithms to extract more information from noisy spectra [37]

- Consider electrochemical enrichment techniques when appropriate for your analyte [38]

Q: What specific considerations apply when using PF fitting for weakly absorbing species?

A: Weak signals present distinct challenges for quantitative fitting:

- Increase integration times while monitoring for photodegradation [21]

- Apply Savitzky-Golay smoothing before fitting to improve signal-to-noise without distorting band shapes [37]

- Use constraint parameters during fitting to prevent unphysical results from noise amplification

- Validate results with complementary techniques when possible [36] [38]

Advanced Applications & Integration with Complementary Techniques

Machine Learning Enhancement of Spectral Deconvolution

Recent advances demonstrate how machine learning can augment traditional PF fitting, particularly for complex environmental samples: [37]

- Hybrid Classification-Regression Models: Samples are first classified by concentration ratio categories, then processed through specialized regression submodels [37]

- Characteristic Wavelength Selection: Stability and Variable Permutation (SVP) algorithms identify optimal wavelength subsets, eliminating redundant spectral regions [37]

- Foreign Ion Interference Compensation: Integrated classification algorithms (Support Vector Machines, Logistic Regression, Random Forest) enhance specificity in complex matrices [37]

Research Reagent Solutions for Enhanced Sensitivity

Table 2: Essential Materials for Advanced UV-Vis Analysis of Low-Concentration Samples

| Material/Reagent | Function | Application Notes |

|---|---|---|

| Quartz Cuvettes | Sample containment | Essential for UV transmission; reusable preferred for cost efficiency [21] |

| Peptide-modified Fe₃O₄@Au Nanoparticles | Analyte enrichment and specific detection | Enables detection of specific analytes down to 0.074 pg mL⁻¹ [36] |

| 2-Amino Nicotinamide Modified Electrodes | Electrochemical pre-concentration | Enhances sensitivity for phenolic contaminants via π-π interactions and hydrogen bonding [38] |

| Organic Solvents (ACN, TBATFB) | Electrochemical media | Enable electropolymerization for sensor fabrication [38] |

| Multivariate Calibration Standards | Instrument calibration | Essential for quantifying overlapping spectra of compounds like nitrate/nitrite [37] |

Experimental Protocols

Standardized Protocol for PF Spectral Deconvolution

Materials and Equipment:

- UV-Vis spectrophotometer with temperature control [21]

- Quartz cuvettes (path length appropriate for sample concentration) [21]

- High-purity solvents matched to sample compatibility [21]

- PeakFit, Origin, or custom PekarFit Python software [8]

Procedure:

- Instrument Preparation: Allow light source to warm up for ≥20 minutes until stable [21]

- Baseline Collection: Measure reference spectrum with pure solvent in matched cuvette [35]

- Sample Measurement: Acquire spectrum ensuring maximum absorbance between 0.1-1.0 AU [35]

- Data Preprocessing: Truncate spectrum to remove solvent absorption regions [8]

- Initial Parameter Estimation: Estimate S, ν₀, Ω, σ₀, and δ based on similar compounds or theoretical predictions [8]

- Fitting Iteration: Apply PF fitting algorithm with appropriate constraints [8]

- Validation: Compare derived transition energies with quantum mechanical calculations [8]

Quality Control Considerations:

- Maintain constant temperature throughout measurement series [21]

- Replicate measurements to assess fitting reproducibility [8]

- Verify residuals show random distribution without systematic deviations [8]

Workflow for Complex Mixture Analysis

For samples with multiple overlapping components, the analysis requires additional steps as shown in the following decision pathway:

The modified Pekarian function approach provides a robust physically grounded methodology for deconvoluting overlapping bands in UV-Vis spectroscopy, particularly valuable for analyzing conjugated molecules and complex mixtures in pharmaceutical and environmental applications. When integrated with proper sample preparation, instrumental optimization, and machine learning enhancements, PF fitting enables researchers to extract maximum information from challenging spectra, advancing sensitivity and specificity in low-concentration analysis. The troubleshooting guidelines presented here address common experimental pitfalls while maintaining the physical significance of fitting parameters essential for meaningful spectroscopic interpretation.

Leveraging Microvolume UV-Vis for Scarce and Precious Samples

Troubleshooting Guide: Common Microvolume UV-Vis Issues and Solutions

Sample Measurement Problems

Problem: Unusual or Unexpected Peaks in Spectrum

- Potential Cause: Sample or measurement surface contamination [21]

- Solution: Thoroughly clean measurement pedestals with a soft, lint-free lab wipe moistened with deionized water. Handle only with gloved hands to avoid fingerprint contamination [21] [39]

- Potential Cause: Use of inappropriate cuvette type [21]

- Solution: Use quartz cuvettes for UV range measurements (below 310 nm). Plastic or glass cuvettes are only suitable for visible wavelength measurements [21] [39]

Problem: Low Absorbance Signal

- Potential Cause: Incorrect pathlength setting in software [40]

- Solution: Understand that UV-Vis data is typically reported at a normalized 1.0 mm pathlength, while Nucleic Acid or Protein A280 applications normalize to 10 mm, resulting in 10-fold higher absorbance values in the latter [40]

- Potential Cause: Sample concentration too low for detection limit [21]

- Solution: Concentrate sample if possible, or use the instrument's autopathlength function if available to optimize signal detection [40]

Problem: Inconsistent Replicate Measurements

- Potential Cause: Evaporation of sample during measurement [21]

- Solution: Work quickly with volatile samples, ensure proper droplet formation, and maintain consistent environmental conditions [21] [41]

- Potential Cause: Pipetting inconsistencies [41]

- Solution: Implement proper pipetting technique including prewetting steps, maintain consistent pipetting angle (<20° deviation), use appropriate tips that fit properly, and ensure pipettes are regularly calibrated [41]

Instrument Performance Issues

Problem: Noisy or Unstable Baseline

- Potential Cause: Insufficient instrument warm-up time [21]

- Solution: Allow tungsten halogen or arc lamps to warm up for approximately 20 minutes after turning on before taking measurements [21]

- Potential Cause: Environmental fluctuations [21]

- Solution: Ensure consistent room temperature and minimize drafts that might affect sensitive microvolume measurements

Problem: Inability to Initialize or Calibrate Instrument

- Potential Cause: Software communication error [42]

- Solution: Restart instrument, ensure correct software version, and verify proper connectivity via USB or Bluetooth [42]

- Potential Cause: Dirty calibration surface [39]

- Solution: Meticulously clean both upper and lower measurement surfaces before calibration

Frequently Asked Questions (FAQs)

Q1: When should I choose microvolume measurement over traditional cuvette measurement? Microvolume mode (using only 0.5-2 μL) is ideal for precious samples with limited volume, high-concentration nucleic acids and proteins that would require dilution in cuvettes, and routine quality control workflows. Cuvette mode remains preferable for volatile organic solvents (to reduce evaporation), OD600 microbial measurements, kinetic assays requiring continuous monitoring, and samples where the larger pathlength provides better detection limits for very dilute solutions [43] [44].

Q2: Why are my sample concentrations different between microvolume and cuvette measurements? Concentration calculations rely on accurate pathlength values. Microvolume instruments use software-determined pathlengths based on sample absorbance characteristics and physical properties, while cuvettes have a fixed pathlength (typically 10 mm). Ensure you understand how your instrument reports pathlength and whether it normalizes absorbance values [40]. Consistent sample preparation and pipetting technique are also critical [41].

Q3: How does Beer-Lambert law apply to microvolume measurements? The Beer-Lambert law (A = ε · b · c) remains fundamental, where absorbance (A) equals the molar absorptivity (ε) times pathlength (b) times concentration (c). Microvolume spectrophotometers use precisely known extinction coefficients (e.g., 50 ng·cm/μL for dsDNA) and automatically determine the actual pathlength (which can be as low as 0.05 mm) to calculate concentration without dilution [40] [44].

Q4: What are the key sample requirements for reliable microvolume measurements?

- Volume: Typically 0.5-2 μL depending on the instrument

- Surface Tension: Aqueous solutions work best as they form stable droplets

- Concentration: Should fall within the instrument's dynamic range (e.g., 2-3700 ng/μL for dsDNA)

- Purity: Avoid particulates that can scatter light and contaminants that affect surface tension [44]

Q5: How can I improve reproducibility with viscous or volatile samples? For viscous samples: Use reverse pipetting mode, employ wide-bore tips, allow longer aspiration times, and keep tips in the liquid longer during dispensing. For volatile samples: Work quickly, use rapid dispense modes, program prewetting steps on electronic pipettes, and consider using sealed containers when possible [41].

Quantitative Data Reference Tables

Dynamic Range of Microvolume Measurements for Common Analytes

| Analyte Type | Wavelength (nm) | Typical Dynamic Range | Minimum Sample Volume | Optimal A260/A280 Ratio |

|---|---|---|---|---|

| dsDNA | 260 nm | 2-3700 ng/μL [44] | 0.5-1 μL [43] | 1.8-2.0 [40] |

| RNA | 260 nm | 4-3000 ng/μL | 0.5-1 μL [43] | 2.0-2.2 [40] |

| Proteins (A280) | 280 nm | 0.1-100 mg/mL | 1-2 μL [43] | Varies by protein |

| Bacterial OD600 | 600 nm | 0.1-1.2 AU | 1 mL (cuvette) [43] | N/A |

Troubleshooting Reference Table for Absorbance Anomalies

| Symptom | Potential Causes | Immediate Actions | Preventive Measures |

|---|---|---|---|

| Abnormal A260/A280 ratios | Protein/phenol contamination [40] | Re-purify sample | Ensure complete protein removal during extraction |

| High baseline noise | Dirty pedestals, unstable light source [21] [39] | Clean measurement surfaces, allow lamp warm-up [21] [39] | Regular maintenance, proper warm-up time [21] |

| Irreproducible replicates | Pipetting error, evaporation [41] | Check pipette calibration, work faster with volatiles [41] | Implement reverse pipetting, use quality tips [41] |

| Unexpected peaks | Contaminants, cuvette material interference [21] | Check solvent purity, verify cuvette type [21] | Use high-purity solvents, appropriate cuvettes [21] |

Experimental Workflow for Optimal Results

The Scientist's Toolkit: Essential Research Reagent Solutions

| Reagent/Consumable | Function/Purpose | Application Notes |

|---|---|---|

| Quartz Cuvettes | UV-range measurements (<310 nm) [21] | Essential for accurate protein and nucleic acid quantification in UV range; reusable with proper cleaning |

| High-Quality Pipette Tips | Precise microvolume delivery [41] | Use manufacturer-recommended tips to ensure proper fit and prevent leaking/dripping [41] |

| Nuclease-Free Water | Blank calibration and sample dilution | Essential for nucleic acid work to prevent degradation |

| BSA Standard Solutions | Protein assay calibration | Used for creating standard curves for protein quantification |

| DNA/RNA Standard Solutions | Nucleic acid quantification calibration | Verify instrument performance and create standard curves |

| Lint-Free Laboratory Wipes | Measurement surface cleaning | Critical for maintaining clean optical surfaces without introducing fibers |

| Deionized Water | Routine surface cleaning | Effectively removes salt crystals and water-soluble contaminants |

Chemical Derivatization Strategies for Analytes Lacking Strong Chromophores

FAQs and Troubleshooting Guides

Frequently Asked Questions (FAQs)

Q1: Why is chemical derivatization necessary for analyzing compounds with weak or no chromophores?