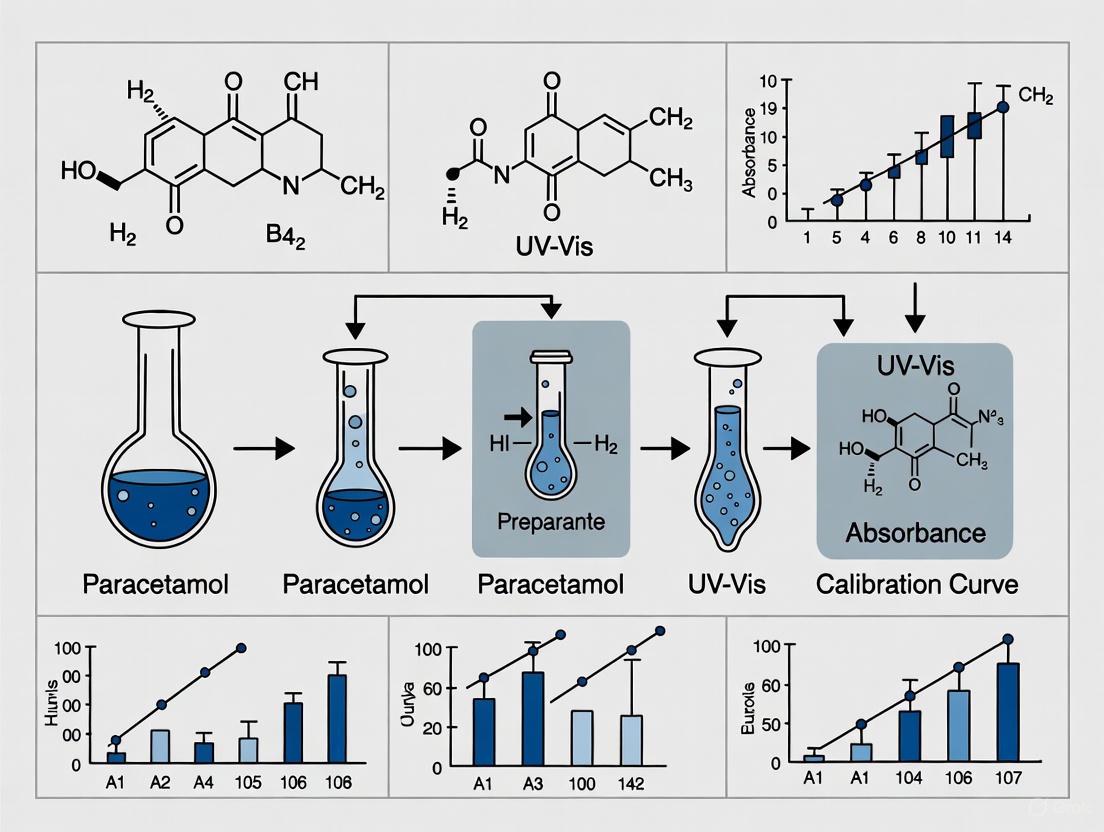

Advanced UV-Visible Spectrophotometric Method Development and Validation for Paracetamol Tablet Analysis

This article provides a comprehensive guide for researchers and pharmaceutical scientists on developing and validating robust UV-Visible spectrophotometric methods for paracetamol analysis in tablet formulations.

Advanced UV-Visible Spectrophotometric Method Development and Validation for Paracetamol Tablet Analysis

Abstract

This article provides a comprehensive guide for researchers and pharmaceutical scientists on developing and validating robust UV-Visible spectrophotometric methods for paracetamol analysis in tablet formulations. It covers foundational principles of UV-Vis spectroscopy and paracetamol's spectral characteristics, explores advanced methodologies including chemometric techniques and signal processing for complex mixtures, addresses critical troubleshooting and optimization strategies for common analytical challenges, and outlines rigorous validation protocols per ICH guidelines with comparative analysis against reference methods like HPLC. The content synthesizes current research to deliver a practical framework for implementing accurate, precise, and cost-effective spectrophotometric methods in pharmaceutical quality control and drug development settings.

Fundamental Principles and Spectral Characteristics of Paracetamol

Core Principles of UV-Visible Spectrophotometry and Beer-Lambert Law

UV-Visible spectrophotometry is a fundamental analytical technique in pharmaceutical research, enabling the identification and quantification of compounds based on their interaction with ultraviolet and visible light. For researchers focused on method development, such as for paracetamol tablet analysis, a deep understanding of the Beer-Lambert Law is indispensable for ensuring accurate, precise, and valid results. This document outlines the core principles, detailed protocols, and practical applications of UV-Vis spectrophotometry within the context of pharmaceutical method development, providing a structured framework for scientists and drug development professionals.

Core Theoretical Principles

The Beer-Lambert Law

The Beer-Lambert Law (also referred to as Beer's Law) is the central quantitative relationship governing absorption spectroscopy [1] [2]. It states that the absorbance of light by a solution is directly proportional to the concentration of the absorbing species and the path length the light takes through the solution. The mathematical expression of the law is:

A = ε × l × c

Where:

- A is the Absorbance (a dimensionless quantity) [2].

- ε is the Molar Absorptivity (or molar extinction coefficient), with units of L·mol⁻¹·cm⁻¹ [1].

- l is the Path Length of the cuvette, typically 1 cm [2].

- c is the Molar Concentration of the analyte in mol·L⁻¹ [1].

The law derives from the relationship between the incident light intensity ((I0)) and the transmitted light intensity ((I)) [1] [2]: [ A = \log{10} \left( \dfrac{I_o}{I} \right) ]

This relationship means that for a given path length and compound, absorbance increases linearly with concentration, forming the basis for quantitative analysis.

Transmittance and Absorbance

Transmittance (T) and Absorbance (A) are two key parameters for describing light attenuation [2].

- Transmittance is defined as the fraction of incident light that passes through a sample: ( T = I / I_0 ). It is often expressed as a percentage (%T).

- Absorbance has a logarithmic relationship to transmittance: ( A = \log{10} (1/T) = -\log{10} T ).

The table below shows the inverse logarithmic relationship between transmittance and absorbance [2].

Table 1: Relationship Between Absorbance and Transmittance

| Absorbance (A) | Transmittance (%T) |

|---|---|

| 0 | 100% |

| 1 | 10% |

| 2 | 1% |

| 3 | 0.1% |

| 4 | 0.01% |

A UV-Vis spectrophotometer consists of several key components [3]:

- Light Source: Typically a deuterium lamp (UV) and a tungsten or halogen lamp (Visible).

- Monochromator: Contains a diffraction grating or prism to select a specific wavelength of light.

- Cuvette Holder: Holds the sample and reference cuvettes. Standard path length is 1 cm.

- Detector: Measures the intensity of the transmitted light and converts it into an electrical signal.

The fundamental relationship between these components and the measurement process can be visualized as follows:

Quantitative Analysis and Method Validation

Calibration and Quantitative Determination

The primary application of the Beer-Lambert law in pharmaceutical analysis is the determination of unknown concentrations via a calibration curve [2]. A series of standard solutions with known concentrations are prepared, and their absorbance is measured at a specific wavelength. A plot of absorbance versus concentration yields a calibration curve, which should be linear within the working range. The concentration of an unknown sample is then determined from its absorbance using the equation of the calibration line.

Table 2: Exemplary Calibration Data for Paracetamol and Ibuprofen

| Concentration (µg/mL) | Paracetamol Absorbance (at 243 nm) | Ibuprofen Absorbance (at 221 nm) |

|---|---|---|

| 5 | 0.172 | - |

| 10 | 0.343 | - |

| 15 | 0.515 | - |

| 20 | 0.686 | 0.210 |

| 25 | 0.858 | - |

| 30 | 1.029 | - |

| 12 | - | 0.126 |

| 20 | - | 0.210 |

| 32 | - | 0.336 |

Note: Data is simulated based on typical linear relationships from research examples [4].

Analytical Method Validation

For a method to be suitable for drug analysis, it must be validated according to international guidelines (e.g., ICH). Key parameters and typical acceptance criteria for a UV-Vis method, as demonstrated in studies on paracetamol and other drugs, are summarized below [5].

Table 3: Key Validation Parameters for a UV-Vis Spectrophotometric Method

| Validation Parameter | Target Value / Outcome | Example from Literature |

|---|---|---|

| Linearity | Correlation coefficient (R²) > 0.999 | Terbinafine HCl: R² = 0.999 [5] |

| Range | e.g., 5-30 µg/mL | Paracetamol (via reaction): up to 6 µg/mL [6] |

| Accuracy (% Recovery) | 98-102% | Terbinafine HCl: 98.54-99.98% [5] |

| Precision (% RSD) | < 2% | Terbinafine HCl: Intraday & Interday RSD < 2% [5] |

| LOD (Limit of Detection) | e.g., 0.10 µg/mL | Paracetamol (via reaction): 0.10 µg/mL [6] |

| LOQ (Limit of Quantification) | e.g., 0.42 µg/mL | Terbinafine HCl: 0.42 µg [5] |

Experimental Protocols for Paracetamol Analysis

Protocol 1: Standard Solution Preparation and λ_max Determination

This protocol is the first step in method development, aimed at identifying the optimal wavelength for analysis.

Workflow: Wavelength Selection and Calibration

Materials and Reagents:

- Active Pharmaceutical Ingredient (API): Paracetamol reference standard.

- Solvent: Distilled water, ethanol, or phosphate buffer (pH 7.2) [5] [4].

- Volumetric flasks (e.g., 100 mL, 10 mL).

- Pipettes and micropipettes.

- UV-Vis spectrophotometer with 1 cm quartz cuvettes.

Procedure:

- Stock Solution (1000 µg/mL): Accurately weigh 100 mg of paracetamol reference standard. Transfer quantitatively to a 100 mL volumetric flask, dissolve, and make up to volume with the chosen solvent [5].

- Working Solution (10 µg/mL): Pipette 1.0 mL of the stock solution into a 100 mL volumetric flask and dilute to volume with solvent.

- Spectral Scanning: Fill a 1 cm quartz cuvette with the working solution. Place the solvent blank in the reference holder. Scan the absorption spectrum over the wavelength range of 200-400 nm.

- λmax Determination: Identify the wavelength of maximum absorption (λmax) from the resulting spectrum. For paracetamol, this is typically observed at 243 nm in ethanol-NaOH solvent systems and around 283 nm in aqueous systems [5] [4].

Protocol 2: Tablet Assay and Recovery Study

This protocol is for quantifying the drug content in a formulated tablet and validating the method's accuracy.

Materials and Reagents:

- Paracetamol tablets (commercially available).

- Paracetamol reference standard.

- Same solvents and glassware as in Protocol 1.

- Ultrasonic bath.

Procedure:

- Sample Preparation:

- Weigh and finely powder 20 tablets [7].

- Accurately weigh a portion of the powder equivalent to about 100 mg of paracetamol into a 100 mL volumetric flask.

- Add approximately 70 mL of solvent, sonicate for 20-30 minutes with intermittent shaking to ensure complete dissolution, and cool to room temperature [5].

- Dilute to volume with solvent and mix well. Filter the solution, discarding the first few mL of the filtrate.

- Dilution:

- Pipette an appropriate volume of the filtrate (e.g., 1-5 mL, depending on expected concentration) into a 100 mL volumetric flask and dilute to volume with solvent to achieve a concentration within the linear range of the calibration curve.

- Absorbance Measurement:

- Measure the absorbance of the final sample solution at the predetermined λ_max against the solvent blank.

- Concentration Calculation:

- Calculate the concentration of the sample using the linear regression equation from the calibration curve.

- Determine the weight of paracetamol in the tablet and the percentage of the label claim using standard calculations.

- Accuracy (Recovery) Study:

- To pre-analyzed tablet powder, add known amounts of the paracetamol reference standard at three different levels (e.g., 80%, 100%, 120% of the label claim) [5].

- Process and analyze these samples as described above.

- Calculate the percentage recovery of the added standard.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 4: Key Research Reagent Solutions and Materials

| Item | Function / Purpose | Example & Notes |

|---|---|---|

| Reference Standard | Provides a highly pure substance for calibration; essential for accurate quantification. | Paracetamol BP/USP reference standard. |

| Phosphate Buffer (pH 7.2) | Acts as a spectrophotometric solvent; maintains pH to ensure consistent analyte form and absorbance. | 250 mL 0.2M KH₂PO₄ + 175 mL 0.2M NaOH, diluted to 1L [8]. |

| Ethanol-NaOH Mixture | Solvent system for drugs with poor water solubility; can enhance solubility and stabilize the analyte. | 3:1 ratio of Ethanol to NaOH solution [4]. |

| Ammonium Molybdate | Reagent for derivatization; reacts with specific functional groups to form a colored complex (Molybdenum Blue). | Used for spectrophotometric determination of paracetamol [6]. |

| Quartz Cuvettes (1 cm) | Holds the sample solution for analysis; quartz is transparent to UV light. | Ensure clean, scratch-free surfaces for accurate readings. |

| Volumetric Glassware | For precise preparation and dilution of standard and sample solutions. | Use Class A flasks and pipettes for highest accuracy. |

| Membrane Filters (0.45 µm) | Clarifies sample solutions by removing particulate matter from tablet extracts. | Prevents light scattering and ensures a clear path for the beam. |

Critical Considerations and Limitations

While the Beer-Lambert law is foundational, several factors can cause deviations from ideal behavior and must be considered during method development [9] [3].

- Chemical Deviations: Occur at high concentrations (>0.01 M) due to molecular interactions or changes in the refractive index of the solution [9] [3]. The linear relationship between A and c may break down.

- Spectral Limitations: Stray light within the instrument or a bandwidth that is too wide can lead to inaccurate absorbance measurements, particularly at high absorbance values [3].

- Instrumental Factors: Dirty cuvettes, misalignment, and detector non-linearity can introduce errors [3].

- Electromagnetic Effects: The BBL law is a simplification of light-matter interactions. Effects such as band shifts and intensity changes can arise from the wave nature of light, especially in non-liquid samples or at interfaces [9].

Spectral Properties and Absorbance Maxima of Paracetamol

This application note details the critical spectral properties and experimental protocols for the analysis of paracetamol (also known as acetaminophen) using UV-Visible spectrophotometry. Framed within a broader thesis on method development for paracetamol in solid dosage forms, this document provides researchers and pharmaceutical scientists with validated methodologies and key parameters essential for accurate quantitative determination in bulk drug substances and formulated tablets. The fundamental principle underpinning these methods is the Beer-Lambert Law, which establishes a linear relationship between the absorbance of a solution and the concentration of the analyte, enabling precise quantification [10]. Understanding the absorbance characteristics of paracetamol, including its maximum absorbance wavelength (λmax) and how it is influenced by solvent systems, is a cornerstone of robust analytical method development for quality control in drug development.

Quantitative Spectral Data

The absorbance maximum of paracetamol is not fixed and can exhibit bathochromic or hypsochromic shifts depending on the solvent's polarity, pH, and chemical composition. The following table consolidates key spectral data for paracetamol from various validated solvent systems.

Table 1: Absorbance Maxima and Validation Parameters of Paracetamol in Different Solvent Systems

| Solvent System | Reported λmax (nm) | Linear Range (μg/mL) | Correlation Coefficient (R²) | LOD (μg/mL) | LOQ (μg/mL) | Reference |

|---|---|---|---|---|---|---|

| Methanol | 243, 200 | 2 - 44 | 0.998 | 0.432 | 1.440 | [11] [12] |

| Phosphate Buffer (pH 6.8) & Methanol (3:1) | 246 | 2 - 24 | 0.999 | 0.328 | 0.984 | [11] |

| Ethanol & 0.1M NaOH (3:1) | 243, 257 | 2 - 10 | Adheres to Beer's Law | 0.198 | 0.538 | [13] |

| 0.1N NaOH | 257 | 10 (for calibration) | Adheres to Beer's Law | - | - | [13] |

| Water (as function of pH) | Varies with pH | - | - | - | - | [14] |

Key Observations on Spectral Behavior

- Solvent-Dependent Shifts: Paracetamol consistently exhibits two primary absorbance bands in the UV region. The specific λmax can shift; for instance, a notable shift from 243 nm in pure methanol to 246 nm in a methanol-phosphate buffer mixture is observed [11].

- Effect of Alkaline Medium: In alkaline solvents like sodium hydroxide, the deprotonation of the phenolic hydroxyl group in paracetamol can cause a significant bathochromic shift, moving the λmax to a longer wavelength around 257 nm [13] [14].

- Method Suitability: The choice of solvent system directly impacts the sensitivity and selectivity of the method. The mixture of ethanol and sodium hydroxide (3:1), for example, is particularly effective for the simultaneous analysis of paracetamol and ibuprofen in combined dosage forms, as it ensures good solubility for both drugs with minimal spectral interference [13].

Experimental Protocols

Protocol 1: Standard Method for Paracetamol in Methanol or Phosphate Buffer-Methanol Mixture

This is a general and robust method suitable for the analysis of paracetamol in bulk powder and tablet formulations [11].

Workflow Overview

Materials and Procedure

Step 1: Standard Stock Solution Preparation

- Accurately weigh 100 mg of paracetamol reference standard and transfer it to a 100 mL volumetric flask.

- Add approximately 70 mL of your chosen solvent—either pure methanol or a mixture of methanol and phosphate buffer pH 6.8 in a 1:3 ratio. Vortex mix and sonicate for 10 minutes to ensure complete dissolution.

- Dilute to volume with the same solvent to obtain a primary stock solution of 1000 µg/mL.

- Filter this solution through Whatman filter paper No. 41 to remove any particulate matter.

Step 2: Working Standard Solution Preparation

- Pipette 10 mL of the filtered primary stock solution into another 100 mL volumetric flask.

- Dilute to volume with phosphate buffer pH 6.8 to obtain a secondary stock solution of 100 µg/mL.

Step 3: Calibration Curve Construction

- From the 100 µg/mL secondary stock, prepare a series of standard solutions with concentrations covering the range of 2–24 µg/mL (e.g., 2, 4, 8, 12, 16, 20, 24 µg/mL) using phosphate buffer pH 6.8 as the diluent.

- Measure the absorbance of each standard solution at the predetermined λmax (243 nm for pure methanol or 246 nm for the mixed solvent system) against a solvent blank.

- Plot the average absorbance (y-axis) against the corresponding concentration (x-axis) and determine the regression equation.

Method Validation Notes: This method has been validated showing a correlation coefficient (R²) > 0.999. Intra-day and inter-day precision (RSD) were reported to be less than 0.3% and 0.6%, respectively, with accuracy ranging from 99.92% to 100.94% [11] [12].

Protocol 2: Simultaneous Analysis of Paracetamol and Ibuprofen in an Ethanol-NaOH Solvent System

This method is optimized for fixed-dose combination products containing both paracetamol and ibuprofen [13].

Workflow Overview

Materials and Procedure

Step 1: Mixed Solvent System Preparation

- Prepare the solvent mixture by combining 75 mL of absolute ethanol with 25 mL of 0.1 M sodium hydroxide solution (a 3:1 ratio). This mixture enhances the solubility of ibuprofen, which may not dissolve adequately in ethanol alone.

Step 2: Standard Stock Solutions Preparation

- Separately weigh 25 mg of paracetamol and 25 mg of ibuprofen.

- Transfer each drug to separate 100 mL volumetric flasks. Dissolve and dilute to volume with the ethanol-NaOH solvent mixture to obtain stock solutions of 250 µg/mL for each drug.

Step 3: Dilution and Spectral Acquisition

- Make further dilutions of the individual stock solutions with distilled water to create a calibration series in the range of 10–50 µg/mL for each drug.

- Using a UV-Vis spectrophotometer, scan the solutions of pure paracetamol and pure ibuprofen across the 200–400 nm range to identify their respective absorbance maxima. Paracetamol typically shows a maximum at 243 nm, while ibuprofen shows a maximum at 221 nm [13].

- Measure the absorbance of the standard solutions at both wavelengths.

Step 4: Data Analysis using Simultaneous Equations

- The concentrations of paracetamol (CP) and ibuprofen (CI) in a mixture can be calculated using the following simultaneous equations, based on the absorptivity values of each drug at the two wavelengths:

A1 = (ax1 * C_P) + (ay1 * C_I)(Equation for λ1, 243 nm)A2 = (ax2 * C_P) + (ay2 * C_I)(Equation for λ2, 221 nm)

- Where A1 and A2 are the absorbances of the mixture at the two wavelengths, ax1 and ax2 are the absorptivities of paracetamol at λ1 and λ2, and ay1 and ay2 are the absorptivities of ibuprofen at λ1 and λ2.

- The concentrations of paracetamol (CP) and ibuprofen (CI) in a mixture can be calculated using the following simultaneous equations, based on the absorptivity values of each drug at the two wavelengths:

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials and Reagents for Paracetamol UV Spectrophotometric Analysis

| Reagent/Material | Specification/Function | Application Example |

|---|---|---|

| Paracetamol Reference Standard | High-purity compound for preparing calibration standards; essential for accurate quantification. | Used in all protocols to create primary stock solutions. |

| UV-Grade Methanol | High-purity solvent to minimize UV background interference; commonly used for dissolving paracetamol. | Main solvent in Protocol 1 [11]. |

| Phosphate Buffer (pH 6.8) | Mimics physiological pH; used as a diluent to create a stable and reproducible analytical environment. | Diluent in mixed solvent system and for calibration curves [11]. |

| Sodium Hydroxide (0.1 M) | Alkaline medium that ionizes paracetamol, causing a spectral shift; improves solubility in combination drugs. | Component of ethanol-NaOH solvent system for simultaneous analysis (Protocol 2) [13]. |

| UV-Grade Ethanol | Solvent for dissolving active ingredients, particularly useful in combination drug analysis. | Component of ethanol-NaOH solvent system (Protocol 2) [13]. |

| Volumetric Flasks | For precise preparation and dilution of standard and sample solutions. | Used in all solution preparation steps. |

| Quartz Cuvettes | For holding samples in the spectrophotometer; transparent to UV light. | Required for all absorbance measurements. |

| Whatman Filter Paper (No. 41) | For clarification of sample solutions to remove insoluble excipients or particulates. | Filtration of tablet sample solutions prior to analysis [11]. |

Advanced Considerations: The Role of pH and Chemometrics

For complex matrices where excipients cause significant spectral interference, advanced strategies beyond direct spectrophotometry are required.

- pH-Dependent Spectral Analysis: The UV spectrum of paracetamol is highly sensitive to pH due to the ionization of its hydroxyl group. The acid dissociation constant (pKa) of paracetamol is a critical parameter, and spectral shifts across a pH gradient (e.g., from 4 to 12) can be exploited for analysis [14].

- Multiway Chemometric Models: Techniques such as PARAFAC (Parallel Factor Analysis) can be applied to a three-way dataset (absorbance vs. wavelength vs. pH). This advanced mathematical approach can successfully resolve the paracetamol spectrum even in the presence of overlapping excipient signals, enabling accurate quantification without physical separation steps [14]. This is particularly valuable for analyzing syrup formulations or other complex dosage forms.

Solvent Selection and Optimization for Paracetamol Analysis

Within the framework of method development for paracetamol tablet analysis using UV-Vis spectrophotometry, the selection and optimization of the solvent system is a critical foundational step. The choice of solvent directly influences key analytical parameters including solubility, spectral characteristics, chemical stability, and the ultimate accuracy and precision of the quantification method. This document provides detailed application notes and protocols to guide researchers and drug development professionals in selecting and optimizing solvent systems for the UV-Vis spectrophotometric analysis of paracetamol, with particular emphasis on addressing challenges in multi-component formulations.

Solvent Systems and Spectral Characteristics

The optimal solvent system must ensure complete dissolution of the analyte, provide a stable spectral profile, and minimize interference with excipients or other active ingredients. The following table summarizes validated solvent systems for paracetamol analysis, including systems suitable for challenging combination products.

Table 1: Solvent Systems and Spectral Properties for Paracetamol Analysis

| Analytical Context | Recommended Solvent System | Paracetamol λmax (nm) | Linearity Range (µg/mL) | Key Advantages | Citations |

|---|---|---|---|---|---|

| General Analysis | Methanol | 243-257 | 2.5 - 30 | Good solubility, minimal interference, common solvent. | [15] [10] |

| Paracetamol & Ibuprofen | Ethanol + 0.1 M NaOH (3:1) | 243 | 2 - 10 | Enhances ibuprofen solubility; distinct, stable peaks for both drugs. | [13] [16] |

| Paracetamol & Meloxicam | Methanol (with minimal DMF for MEL) | 262 (1D trough) | 2.5 - 30 | Resolves severe spectral overlap via 1D derivative. | [15] |

| Paracetamol & Domperidone | Methanol | N/A (Ratio Difference) | 3 - 70 | Effective for analyzing drugs with a 25:1 ratio (PAR:DOM). | [15] |

| Paracetamol & Caffeine | Acetate Buffer : Methanol (30:70) | 258 | Meeting pharmacopoeial specs | Zero-crossing derivative method resolves overlapping spectra. | [17] |

For the analysis of paracetamol with ibuprofen, a mixed solvent system of ethanol and 0.1 M sodium hydroxide (NaOH) in a 3:1 ratio has been demonstrated as particularly effective [13] [16]. This system enhances the solubility of ibuprofen, which may not dissolve well in ethanol alone, while maintaining the chemical stability of both compounds. In this solvent, paracetamol and ibuprofen exhibit distinct absorbance maxima at 243 nm and 221 nm, respectively, with minimal spectral interference and no significant alteration of peak positions or intensities due to the alkaline component [13].

Detailed Experimental Protocols

Protocol for Simultaneous Analysis of Paracetamol and Ibuprofen

This protocol details the use of an ethanol-NaOH solvent system for the simultaneous estimation of paracetamol and ibuprofen in combined dosage forms [13].

Materials and Equipment

- UV-Vis Spectrophotometer equipped with 1 cm quartz cells [13].

- Analytical balance [13].

- Paracetamol and Ibuprofen reference standards.

- Ethanol (absolute) and 0.1 M Sodium Hydroxide (NaOH) solution.

- Volumetric flasks (10 mL, 100 mL), pipettes, and other standard laboratory glassware.

Preparation of Standard Stock Solutions

- Paracetamol Stock Solution (1000 µg/mL): Accurately weigh 25 mg of paracetamol reference standard and transfer to a 25 mL volumetric flask. Dissolve and make up to volume with the ethanol-NaOH (3:1) solvent mixture [13].

- Ibuprofen Stock Solution (1000 µg/mL): Accurately weigh 25 mg of ibuprofen reference standard and transfer to a separate 25 mL volumetric flask. Dissolve and make up to volume with the same ethanol-NaOH (3:1) solvent mixture [13].

Construction of Calibration Curves

- Prepare Working Solutions: From the stock solutions, prepare a series of working standard solutions for each drug. For paracetamol and ibuprofen, dilute appropriate volumes to obtain concentrations within the range of 2–10 µg/mL using the ethanol-NaOH solvent [13].

- Spectral Acquisition: Scan the absorbance of each working solution across the 200–400 nm range against a blank of the ethanol-NaOH (3:1) solvent [13].

- Measurement and Plotting: Record the absorbance of paracetamol at 243 nm and ibuprofen at 221 nm. Plot the absorbance values against the corresponding concentrations for each drug to construct the calibration curves [13].

- Validation: Ensure the calibration curves demonstrate linearity adhering to Beer-Lambert's law. The correlation coefficient (R²) should typically be ≥0.999 for a robust method.

Protocol for Analysis of Paracetamol with Severely Overlapping Spectra

This protocol employs derivative and ratio spectrophotometry to resolve paracetamol from drugs with significant spectral overlap, such as meloxicam or domperidone [15].

For Paracetamol and Meloxicam (Mixture I)

- Stock Solutions: Prepare a 1000 µg/mL paracetamol standard solution in methanol. Prepare meloxicam stock solution (1000 µg/mL) by first dissolving in a minimal volume of dimethylformamide (DMF) and then diluting to volume with methanol. Protect from light [15].

- First-Order Derivative (1D) Spectrophotometry:

- Generate the first-derivative spectra of the standard and sample solutions.

- For paracetamol, measure the amplitude from the zero line to the trough at 262 nm. At this wavelength, the derivative spectrum of meloxicam shows zero crossing, thus causing no interference [15].

- Construct the calibration curve by plotting the 1D amplitude at 262 nm against the paracetamol concentration.

For Paracetamol and Domperidone (Mixture II)

- Stock Solutions: Prepare standard solutions of paracetamol and domperidone (1000 µg/mL each) in methanol [15].

- Ratio Difference Method:

- Obtain the absorption spectra of the sample and standard solutions.

- To analyze paracetamol, divide the stored absorption spectra by the spectrum of a standard 50 µg/mL domperidone solution (the "divisor") to obtain the ratio spectra [15].

- For the quantitation of paracetamol, record the difference between the amplitudes of the ratio spectrum at 256 nm and 288 nm.

- Plot this difference against the corresponding paracetamol concentrations to build the calibration curve [15].

Workflow and Decision Pathway

The following diagram illustrates the logical workflow for selecting and optimizing a solvent and method based on the analytical goal.

The Scientist's Toolkit: Essential Research Reagents

Table 2: Key Reagents and Materials for Method Development

| Reagent/Material | Function in Analysis | Application Notes |

|---|---|---|

| Methanol | Primary solvent for dissolution and dilution. | Provides good solubility for paracetamol; suitable for direct and derivative UV methods [15]. |

| Ethanol-NaOH Mixture | Mixed solvent for analyzing paracetamol-ibuprofen combinations. | The alkaline component (NaOH) enhances solubility of acidic drugs like ibuprofen and ensures distinct spectral peaks [13] [16]. |

| Dimethylformamide (DMF) | Co-solvent for poorly water-soluble drugs. | Used in minimal quantities to dissolve drugs like meloxicam before final dilution with methanol [15]. |

| Paracetamol Reference Standard | Primary standard for calibration. | Essential for constructing accurate and validated calibration curves. Purity must be certified. |

| Quartz Cuvettes | Holder for sample solution in spectrophotometer. | Required for UV range measurements; must be matched for double-beam instruments [15]. |

Instrumentation Parameters and Optimal Measurement Conditions

Within the framework of method development for paracetamol tablet analysis, the selection of appropriate instrumentation parameters and measurement conditions is a critical determinant of success in UV-Vis spectrophotometry. This technique remains a cornerstone in pharmaceutical analysis due to its simplicity, cost-effectiveness, and reliability for routine quality control [10] [18]. The fundamental principle governing quantitative analysis is the Beer-Lambert law, which establishes a linear relationship between absorbance and concentration, expressed as A = abc, where A is absorbance, a is absorptivity, b is the path length, and c is the concentration of the analyte [10] [18]. For researchers and drug development professionals, optimizing these parameters ensures the generation of accurate, precise, and validatable data for pharmaceutical formulations.

Key Instrumentation Parameters

The core parameters of a UV-Vis spectrophotometer directly influence the sensitivity, accuracy, and overall performance of the analytical method for paracetamol.

Wavelength Selection

Identifying the wavelength of maximum absorption (λmax) is paramount for achieving optimal sensitivity. For paracetamol, this parameter can vary depending on the solvent system employed.

- In 0.1N HCl and Phosphate Buffer (pH 6.8): Paracetamol exhibits a consistent absorbance maximum at 243 nm [19].

- In Methanol: The λmax has been reported at 248.8 nm [20].

- In an Ethanol-Sodium Hydroxide Solvent System: A shift in the absorption maximum to 257 nm can be observed [13].

This solvent-dependent shift underscores the necessity of establishing the exact λmax for paracetamol within the specific solvent system chosen for the analysis.

Spectral Bandwidth and Path Length

The use of a standard 1 cm path length quartz cuvette is nearly universal in these analyses [5] [20] [21]. The spectral bandwidth, a function of the spectrophotometer's monochromator, should be specified to ensure minimal stray light and adherence to the Beer-Lambert law. While a bandwidth of 1-2 nm is typical for modern instruments, the specific setting should be confirmed and held constant throughout the analysis to maintain consistency.

Optimal Solvent and Sample Conditions

The choice of solvent system is a critical methodological decision that affects solubility, stability, and the resulting spectral characteristics of paracetamol.

Solvent Systems for Paracetamol

| Solvent System | Composition | Reported λmax (nm) | Key Considerations |

|---|---|---|---|

| Aqueous Acidic | 0.1N Hydrochloric Acid (HCl) | 243 [19] | Provides a stable acidic environment; suitable for dissolution studies in simulated gastric fluid. |

| Buffered Solution | Phosphate Buffer pH 6.8 | 243 [19] | Biorelevant medium for dissolution studies simulating intestinal conditions. |

| Alkaline Solvent Mixture | Ethanol & 0.1M NaOH (3:1 or 75:25) | 257 [13] | Enhances solubility; ionization of paracetamol's phenolic group can cause a bathochromic (red) shift. |

| Organic Solvent | Methanol | 248.8 [20] | Good solubility for paracetamol; commonly used for stock solution preparation. |

Sample Preparation Protocol

A typical sample preparation workflow for the analysis of paracetamol in tablet formulations is as follows:

- Stock Solution Preparation: Accurately weigh a quantity of powdered tablets equivalent to about 100 mg of paracetamol. Transfer this powder to a 100 mL volumetric flask. Add approximately 50-70 mL of the chosen solvent (e.g., 0.1N HCl, methanol) and sonicate for 10-15 minutes to ensure complete dissolution of the active ingredient. Dilute to volume with the same solvent to obtain a stock solution of known concentration (e.g., 1000 µg/mL) [19].

- Filtration: Filter the solution using a membrane filter (e.g., 0.45 µm) to remove insoluble excipients and ensure a particulate-free solution [19].

- Dilution to Linear Range: Make an appropriate dilution of the filtrate with the solvent to bring the concentration within the validated linear range of the method, typically between 5-25 µg/mL [20] [19]. For instance, a 1 mL aliquot of the 1000 µg/mL stock can be diluted to 100 mL to yield a 10 µg/mL working standard.

Method Validation Parameters

For any analytical method to be suitable for drug development and quality control, it must be validated as per International Council for Harmonisation (ICH) guidelines. The following table summarizes typical validation parameters and their target values for a paracetamol UV-Vis method, as evidenced by research on similar drugs.

| Validation Parameter | Experimental Procedure | Target Acceptance Criteria |

|---|---|---|

| Linearity & Range | Prepare and analyze standard solutions at multiple concentrations (e.g., 5-30 µg/mL) [5] [20]. | Correlation coefficient (r²) ≥ 0.998 [5] [20]. |

| Accuracy (Recovery) | Spike pre-analyzed samples with standard at 80%, 100%, and 120% of the label claim and re-analyze [5]. | % Recovery between 98% - 102% [5] [20]. |

| Precision | Analyze multiple replicates (n=3-6) of the same sample concentration intra-day and inter-day [5]. | % RSD (Relative Standard Deviation) < 2.0% [5]. |

| LOD & LOQ | Calculate based on standard deviation of the response and the slope of the calibration curve (LOD=3.3σ/S, LOQ=10σ/S) [5]. | Signal-to-noise ratio ~3:1 for LOD and ~10:1 for LOQ [13]. |

| Specificity | Demonstrate that excipients in the tablet formulation do not interfere with the analyte's measurement at the λmax [19]. | No interference from blank or placebo at the analytical wavelength. |

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table details the key materials required for the development and application of a UV-Vis spectrophotometric method for paracetamol tablets.

| Item | Function / Application |

|---|---|

| Double-beam UV-Vis Spectrophotometer | Primary instrument for measuring light absorption by the sample solution; double-beam design compensates for source fluctuations [20] [19]. |

| Quartz Cuvettes (1 cm path length) | Holds the sample and reference solutions; quartz is transparent across the UV-Vis range [13] [21]. |

| Analytical Balance | Used for the accurate weighing of standard drugs and tablet powder [13] [21]. |

| Paracetamol Reference Standard | Highly purified material used to prepare calibration standards for quantitative analysis. |

| Volumetric Flasks | For precise preparation of standard and sample solutions [5] [19]. |

| Membrane Filters (0.45 µm) | Clarification of sample solutions by removing insoluble particulate matter from tablet excipients [19]. |

| Sonicator / Ultrasonic Bath | Aids in the complete dissolution and degassing of samples in volumetric flasks [20]. |

| pH Meter | Essential for the preparation of buffered dissolution media, such as 0.1N HCl and Phosphate Buffer pH 6.8 [19] [21]. |

Advanced Applications: Analysis in Multi-Component Formulations

A significant challenge in pharmaceutical analysis is the quantification of paracetamol in fixed-dose combinations (FDCs), where spectral overlap with other active ingredients occurs. UV-Vis spectrophotometry, accounting for approximately 37.9% of analytical methods for ibuprofen and paracetamol FDCs, remains a viable and economical technique [10]. Strategies to resolve overlapping spectra include:

- Simultaneous Equation Method: This method utilizes the absorptivity values of each drug at two different wavelengths (e.g., λmax of paracetamol and λmax of the second drug) to set up and solve a pair of equations for their respective concentrations [13] [10].

- Area Under Curve (AUC) Method: Instead of absorbance at a single point, the area under the curve for a selected wavelength range is used for calculation, which can offer better accuracy for overlapping spectra [20].

Advanced Spectrophotometric Techniques and Practical Applications

Direct Spectrophotometric Assay for Single-Component Formulations

Within the framework of method development for paracetamol (PAR) tablet analysis, UV-Visible spectrophotometry remains a cornerstone technique in pharmaceutical quality control. Its enduring popularity stems from its inherent simplicity, cost-effectiveness, and robustness for the analysis of single-component formulations [10]. This Application Note provides a detailed protocol for the development and validation of a direct UV-Visible spectrophotometric method for the assay of paracetamol in its tablet dosage form, adhering to fundamental spectrophotometric principles and regulatory guidelines [18].

The technique is governed by the Beer-Lambert law, which establishes a linear relationship between the absorbance (A) of a solution and the concentration (c) of the analyte. The law is mathematically expressed as A = a b c, where 'a' is the absorptivity, and 'b' is the path length of the radiation through the sample [18]. For routine quantitative analysis, the selection of the wavelength of maximum absorption (λmax) is critical, as it ensures maximum sensitivity and minimizes errors due to slight instrumental wavelength shifts [18].

Principle and Theory

In a direct spectrophotometric assay for a single-component formulation, the active pharmaceutical ingredient (API) is dissolved in a suitable solvent and its absorbance is measured at a predetermined wavelength of maximum absorption [18]. The fundamental requirement is that the API's spectrum is sufficiently resolved from the spectra of excipients and other formulation components, ensuring no significant interference at the analytical wavelength.

The quantification can be performed using one of three principal procedures [18]:

- Use of Standard Absorptivity Value: The concentration is calculated directly using a known standard absorptivity value (A1%, 1 cm).

- Calibration Graph: The absorbance of a series of standard solutions is measured, and a calibration graph is constructed. The concentration of the analyte in the sample is determined by interpolating its absorbance from this graph.

- Single-Point Standardization: The concentration of the analyte is calculated by directly comparing the absorbance of the sample solution with that of a standard solution of known concentration, using the formula: Ctest = (Atest × Cstd) / Astd [18].

For paracetamol, a well-defined λmax in the UV region allows for straightforward and accurate quantification using these principles.

Materials and Experimental Requirements

The Scientist's Toolkit: Research Reagent Solutions

The following table details the essential materials and reagents required for the successful execution of this analytical method.

Table 1: Essential Research Reagents and Materials

| Item | Specification / Function |

|---|---|

| Active Pharmaceutical Ingredient (API) | Paracetamol reference standard of known purity, for preparation of calibration standards. |

| Tablet Formulation | Paracetamol tablet formulation, for sample preparation. |

| Solvent | UV-grade Methanol, Water, or other transparent solvent for dissolving the analyte. |

| Volumetric Flasks | Class A volumetric flasks of various capacities (e.g., 10 mL, 100 mL) for precise solution preparation. |

| Micropipettes | For accurate and precise transfer of liquid volumes. |

| UV-Vis Spectrophotometer | Instrument capable of measuring absorbance in the 200-400 nm range. |

| Quartz Cuvettes | High-transparency quartz cells with a standard 1 cm path length. |

| Analytical Balance | For accurate weighing of standard and sample powders. |

| Sonicator / Bath | To aid in the dissolution and extraction of the API from the tablet matrix. |

Instrumental Conditions

- Analytical Technique: UV-Visible Spectrophotometry [18]

- Wavelength (λmax): Determined experimentally for the standard solution (typically ~249 nm for Paracetamol in methanol, though this must be verified) [22]

- Path Length: 1 cm

- Solvent: Methanol [22] [18]

- Baseline Correction: A baseline correction wavelength should be empirically determined. A general recommendation is 340 nm for UV-only wavelength ranges to account for instrument noise and light-scattering particulates [23].

Experimental Protocol

The following diagram illustrates the logical workflow for the direct spectrophotometric assay of a single-component formulation.

Step-by-Step Procedure

Step 1: Preparation of Stock Standard Solution

Accurately weigh and transfer 10 mg of paracetamol reference standard into a 100 mL volumetric flask. Add approximately 60 mL of methanol, shake manually or sonicate to dissolve the powder completely, and then dilute to volume with methanol to obtain a primary stock solution with a concentration of 100 µg/mL [22].

Step 2: Spectral Scanning and Determination of λmax

Dilute an aliquot of the primary stock solution appropriately with methanol to obtain a working standard solution (e.g., 10 µg/mL). Scan this solution over the UV range (e.g., 200-400 nm) against a methanol blank. Identify the wavelength of maximum absorption (λmax), which will be used for all subsequent quantitative measurements [22] [18].

Step 3: Construction of Calibration Curve

Prepare a series of standard solutions by transferring accurate aliquots (e.g., 0.5, 1.0, 1.5, 2.0, 2.5 mL) of the primary stock solution into a set of 10 mL volumetric flasks. Dilute each to the mark with methanol to create concentrations spanning a suitable range (e.g., 5–25 µg/mL) [22]. Measure the absorbance of each solution at the predetermined λmax against a solvent blank. Plot a graph of absorbance versus concentration and determine the regression equation.

Step 4: Sample Preparation (Tablet Formulation)

Accurately weigh and finely powder not less than 20 tablets. Transfer a portion of the powder, equivalent to about 5 mg of paracetamol, into a 100 mL volumetric flask. Add about 60 mL of methanol, shake or sonicate for 20-30 minutes to ensure complete extraction of the API [22] [15]. Dilute to volume with methanol, mix well, and filter (e.g., using Whatmann filter paper no. 41). Further dilute the filtrate appropriately with methanol to yield a final concentration within the linear range of the calibration curve.

Step 5: Absorbance Measurement and Calculation

Measure the absorbance of the final prepared sample solution at the analytical wavelength. Calculate the concentration of paracetamol in the sample solution using the regression equation from the calibration curve. Alternatively, use a single-point standardization method with a concurrently analyzed standard [18]. The amount of paracetamol per tablet can then be back-calculated, considering all dilution factors.

Method Validation

The developed spectrophotometric method must be validated as per ICH guidelines to ensure it is suitable for its intended purpose [22] [18]. Key validation parameters and their typical acceptance criteria, as demonstrated in published methods for paracetamol, are summarized below.

Table 2: Validation Parameters and Typical Results for Paracetamol Assay

| Validation Parameter | Protocol Description | Typical Results for Paracetamol |

|---|---|---|

| Linearity & Range | Prepare and analyze standard solutions at multiple concentrations (e.g., 5 levels). | 5–25 µg/mL [22]. Correlation coefficient (r) of at least 0.9991 [15]. |

| Accuracy (Recovery) | Perform recovery study by spiking pre-analyzed sample with standard at three levels (e.g., 80%, 100%, 120%). | Recovery results close to 100% [22]. |

| Precision | 1. Repeatability: Analyze multiple preparations (n=5) of the same sample.2. Intermediate Precision: Perform analysis on different days or by different analysts. | Relative Standard Deviation (RSD) < 2% for both intra-day and inter-day analysis [22]. |

| Specificity | Demonstrate that the absorbance measured in the sample is due to the API alone, with no interference from excipients or impurities. | No interference from other excipients observed in the analysis of marketed tablet formulations [22]. |

| LOD (Limit of Detection) | LOD = 3.3 × N/S, where N is the standard deviation of the response and S is the slope of the calibration curve. | Can be as low as 0.10 µg/mL [22]. |

| LOQ (Limit of Quantification) | LOQ = 10 × N/S, where N is the standard deviation of the response and S is the slope of the calibration curve. | Can be as low as 0.32 µg/mL [22]. |

Troubleshooting and Best Practices

- Baseline Offset: An incorrect baseline can lead to significant errors in concentration calculations. Always apply a baseline correction at a wavelength where neither the sample nor the solvent absorbs, such as 340 nm [23].

- Adherence to Beer-Lambert Law: Ensure that the absorbance readings for both standard and sample solutions fall within the linear range of the calibration curve, ideally below an absorbance of 2.0 for optimal accuracy [18].

- Solvent Compatibility: The solvent used must be transparent at the analytical wavelength and should not react with the analyte. Methanol has been successfully used as a solvent for paracetamol analysis [22] [18].

- Complete Extraction: Ensure sufficient sonication time during sample preparation to guarantee complete extraction of the active ingredient from the tablet matrix [15].

The simultaneous quantification of active pharmaceutical ingredients (APIs) in fixed-dose combination products, such as those containing paracetamol (acetaminophen) and ibuprofen, presents a significant challenge in pharmaceutical analysis due to extensive spectral overlap in the UV region [7] [8]. Traditional ultraviolet-visible (UV-Vis) spectrophotometry cannot resolve these overlapping absorption bands, historically necessitating separation-based techniques like high-performance liquid chromatography (HPLC) [10]. However, mathematical signal transformation methods now enable accurate multicomponent analysis without prior physical separation, offering cost-effective, rapid, and eco-friendly alternatives for quality control in drug development and manufacturing [7] [8] [24]. This document details the application of derivative and wavelet transform techniques for the simultaneous determination of paracetamol and ibuprofen, framed within method development for UV-Vis spectrophotometry research.

Signal Transformation Fundamentals

Derivative Transform Approach

Derivative spectrophotometry transforms zero-order absorption spectra into first- or higher-order derivative spectra, which enhances spectral resolution by converting shoulder peaks into distinct, measurable signals [7] [25]. The Savitzky-Golay algorithm is the most common method for differentiation and simultaneous smoothing of spectral data. This algorithm applies a polynomial fit across a moving window of 2n+1 measurement points on the absorbance spectrum [7]. The derivative at the window center is calculated from the polynomial coefficients. The first-order derivative spectrum is obtained by measuring the amplitude at zero-crossing points, where one component's derivative signal is zero, allowing for the selective quantification of the other component [25].

Wavelet Transform Approach

Wavelet transform (WT) is a powerful signal processing tool that decomposes a complex signal, such as a severely overlapping UV spectrum, into simpler components across different frequency (scale) and time (wavelength) domains [24] [26]. This dual localization capability makes it superior to Fourier transforms for analyzing non-stationary signals like UV absorption spectra [26]. The continuous wavelet transform (CWT) is particularly useful for detailed resolution of overlapping spectral bands and is defined mathematically by:

[Wf(a,b) = \int{-\infty}^{\infty} f(t) \psi_{a,b}(t) dt]

where ( \psi_{a,b}(t) ) represents a scaled and translated version of the mother wavelet function [7] [24]. The discrete wavelet transform (DWT) and fractional wavelet transform (FWT) are also employed for specific applications involving digitized signals and optimized spectral recovery [7]. Unlike derivative methods, WT can effectively manage high noise levels and baseline drifts without significant signal deterioration [24] [26].

Application Notes: Paracetamol and Ibuprofen Analysis

Quantitative Analytical Data

The following table summarizes validated parameters for the simultaneous determination of paracetamol and ibuprofen using signal transformation methods.

Table 1: Quantitative Method Parameters for Paracetamol and Ibuprofen Analysis

| Parameter | Derivative Method | Wavelet Transform Method | HPLC (Reference) |

|---|---|---|---|

| Linear Range (Paracetamol) | 20–40 mg/L [8] | 20–40 mg/L [8] | Not Specified |

| Linear Range (Ibuprofen) | 12–32 mg/L [7] | 12–32 mg/L [7] | Not Specified |

| Wavelength (Paracetamol) | Measured at IBU's zero-crossing point [25] | Transformed signal amplitude [7] | 225 nm [8] |

| Wavelength (Ibuprofen) | Measured at PAR's zero-crossing point [25] | Transformed signal amplitude [7] | 225 nm [8] |

| Accuracy (% Recovery) | 99.1–101.5% [8] | Comparable to HPLC [7] | 100% (Reference) |

| Precision (% RSD) | < 2% [8] | Comparable to HPLC [7] | Not Specified |

| Key Advantage | Simplicity, wide availability of algorithms [25] | Superior resolution of severely overlapping spectra [7] [24] | Official pharmacopeial method [8] |

Experimental Protocol: Simultaneous Determination in Tablets

Equipment and Software

- Spectrophotometer: Double-beam UV-Vis spectrophotometer (e.g., UNICAM UV 300) with 1 cm quartz cells [7] [8].

- Software: Spectral data acquisition software (e.g., VISION32) and computational tools for signal processing (e.g., MATLAB with Wavelet Toolbox) [7] [8].

Reagent Solutions

Table 2: Essential Research Reagents and Materials

| Reagent/Material | Specification | Primary Function |

|---|---|---|

| Paracetamol Reference Standard | High Purity (e.g., 99.5%) [7] | Primary calibration standard for accurate quantification |

| Ibuprofen Reference Standard | High Purity (e.g., 100.0%) [7] | Primary calibration standard for accurate quantification |

| Phosphate Buffer (pH 7.2) | 0.01 M - 0.2 M [7] [8] | Spectrophotometric solvent; suitable for dissolution tests |

| Methanol / Ethanol | Analytical Grade [10] | Alternative solvent or mobile phase component for HPLC |

| NaOH Solution | 0.1 N [27] | Alternative solvent for simple, economical methods |

| Membrane Filter | 0.45 μm porosity [7] [8] | Clarification of sample solutions before analysis |

Sample Preparation Procedure

- Stock Solutions: Accurately weigh and dissolve paracetamol and ibuprofen reference standards in phosphate buffer pH 7.2 to prepare individual stock solutions of 500 mg/L [7].

- Calibration Standards: From the stock solutions, prepare a series of mixed standard solutions in 25 mL or 100 mL volumetric flasks to span the linear concentration ranges of 20–40 mg/L for paracetamol and 12–32 mg/L for ibuprofen [7] [8].

- Tablet Sample Solution:

- Finely powder twenty tablets [7] [8].

- Accurately weigh a portion equivalent to one tablet and transfer to a 100 mL volumetric flask.

- Add approximately 50 mL of phosphate buffer pH 7.2 and sonicate for 20 minutes to dissolve the APIs.

- Dilute to volume with the same solvent and mix well.

- Perform an appropriate dilution to obtain a test solution with nominal concentrations of approximately 32.5 mg/L paracetamol and 20 mg/L ibuprofen [7]. Filter through a 0.45 μm membrane before analysis.

Spectral Acquisition and Data Transformation

- Zero-Order Spectra: Record the absorption spectra of all calibration standards and the sample solution against a blank (phosphate buffer pH 7.2) over the wavelength range of 200–300 nm with a data interval of 0.1–0.2 nm [7] [8].

- Derivative Method:

- Process the saved spectra using the Savitzky-Golay algorithm (e.g., 3rd-order polynomial, 125 convolution coefficients) to obtain the first-derivative spectra [8].

- For paracetamol quantification, measure the derivative amplitude at the wavelength where ibuprofen's derivative spectrum crosses zero (its zero-crossing point).

- For ibuprofen quantification, measure the derivative amplitude at paracetamol's zero-crossing point [25].

- Wavelet Transform Method:

- Export the zero-order spectral data (wavelength vs. absorbance) to MATLAB.

- Apply a continuous wavelet transform (CWT) using a suitable mother wavelet (e.g.,

sym6,haar,coif1,mexh) and optimize the scale parameter for highest spectral recovery [7] [24]. - Construct calibration graphs by measuring the amplitudes of the transformed signals for paracetamol and ibuprofen at specified wavelengths and use these to determine the concentrations in the sample solution [7].

Workflow Visualization

The following diagram illustrates the logical workflow for the simultaneous analysis of paracetamol and ibuprofen in tablets using signal transformation methods.

Derivative and wavelet transform methods provide robust, accurate, and precise alternatives to HPLC for the routine analysis and quality control of combined paracetamol and ibuprofen dosage forms [7] [8]. The protocols outlined herein enable researchers and drug development professionals to resolve severely overlapping UV spectra efficiently. The wavelet transform approach, in particular, offers enhanced signal processing capabilities that effectively manage spectral noise and complexity, ensuring reliable results without the need for costly and time-consuming separation procedures [24] [26]. These methods adhere to the principles of green analytical chemistry by minimizing solvent use and waste generation [25].

Chemometric Modeling with PCR and PLS for Multicomponent Analysis

Ultraviolet-Visible (UV-Vis) spectrophotometry is a fundamental technique in pharmaceutical analysis, prized for its simplicity, cost-effectiveness, and rapid results. However, its application to complex multi-component formulations is often hindered by significant spectral overlap, which makes quantifying individual analytes with ordinary spectrophotometry challenging. Chemometric modeling has emerged as a powerful solution, enabling the resolution of such complex mixtures through mathematical and statistical techniques. Among these, Principal Component Regression (PCR) and Partial Least Squares (PLS) regression represent two of the most robust and widely adopted multivariate calibration methods.

Framed within broader thesis research on method development for paracetamol tablet analysis, this document provides detailed application notes and protocols for implementing PCR and PLS. These techniques facilitate the simultaneous quantification of active pharmaceutical ingredients (APIs) in multi-component tablets without prior physical separation, streamlining the analytical process for drug development and quality control.

Theoretical Background

Principal Component Regression (PCR)

PCR is a two-step multivariate calibration method. The first step involves Principal Component Analysis (PCA), which decomposes the spectral data matrix (X) into a set of orthogonal, latent variables called Principal Components (PCs). These PCs are linear combinations of the original variables (wavelengths) and are calculated to capture the maximum possible variance in the spectral data itself, without considering the concentration data. The second step is a regression step, where the selected PCs are used as independent variables to build a model predicting the analyte concentrations (Y). By discarding minor PCs associated with noise, PCR can often yield more stable and robust models than classical univariate regression [28] [29].

Partial Least Squares (PLS) Regression

Unlike PCR, PLS is a one-step algorithm that simultaneously decomposes both the spectral matrix (X) and the concentration matrix (Y). PLS seeks to find latent variables (called PLS components) that not only explain the variance in the spectral data but also have maximum covariance with the concentration data of the analyte(s) of interest. This direct consideration of the response variable during dimension reduction often allows PLS to model the relationship between spectra and concentrations with fewer components than PCR, though this does not necessarily translate to superior predictive performance in all cases [30] [29]. PLS can be implemented for a single analyte (PLS1) or multiple analytes simultaneously (PLS2).

Relationship Between PCR and PLS

The choice between PCR and PLS has been a subject of extensive comparative studies in chemometrics. Theoretical and practical investigations have shown that while PLS often requires fewer latent variables to achieve an optimal model, there is generally no significant difference in the predictive ability between the two methods when the optimal number of components is used for PCR [30] [29]. The equivalence of PCR and PLS has been demonstrated within the sufficient dimension reduction framework, indicating no inherent theoretical advantage of one over the other in terms of prediction performance [29]. The selection often depends on the specific data set and the nature of the spectral interferences.

The following diagram illustrates the logical relationship and comparative workflow between PCR and PLS modeling:

Experimental Protocols

Reagent Solutions and Instrumentation

The success of chemometric methods relies on the preparation of accurate standard solutions and the use of properly calibrated instrumentation. The following table lists essential materials and their functions.

Table 1: Key Research Reagent Solutions and Instrumentation

| Item | Specification | Function/Role in Analysis |

|---|---|---|

| Paracetamol Standard | High Purity (e.g., 99.99%) [11] | Primary reference standard for calibration and validation. |

| Methanol | Analytical Reagent Grade [31] [32] | Solvent for preparing stock and working standard solutions. |

| Phosphate Buffer (pH 6.8) | Analytical Reagent Grade [11] | Aqueous solvent component for eco-friendly dilution. |

| UV-Vis Spectrophotometer | Double-beam, 1 nm bandwidth [22] [11] | Measures absorbance across the selected wavelength range. |

| Quartz Cuvettes | 10 mm path length, matched pair [22] [11] | Holds sample solutions for spectrophotometric measurement. |

| Analytical Balance | Precision 0.1 mg [22] | Accurately weighs standard compounds and tablet powder. |

Protocol 1: Calibration Set Design and Spectral Acquisition

This protocol outlines the creation of a robust calibration set, which is the foundation of a reliable chemometric model.

- Stock Solution Preparation: Accurately weigh 100 mg of each pure API (e.g., paracetamol, chlorpheniramine maleate, caffeine, ascorbic acid). Transfer each to a separate 100 mL volumetric flask, dissolve in and dilute to volume with methanol to obtain 1000 µg/mL stock solutions [32].

- Working Solution Preparation: Pipette 10 mL from each stock solution into separate 100 mL volumetric flasks and dilute to volume with methanol to obtain 100 µg/mL working standard solutions [32].

- Calibration Set Design: Prepare a series of mixtures containing varying concentrations of all analytes. A five-level, four-factor calibration design is effective for a quaternary mixture [32]. For a ternary mixture of Paracetamol (PAR), Sodium Ascorbate (ASC), and Chlorpheniramine (CHL) with a high ratio (150:140:1), an 18-mixture set with concentrations in the ranges of 5.05–30.3 mg/L for PAR, 2.04–30.60 mg/mL for ASC, and 0.20–5.05 mg/mL for CHL has been successfully applied [28].

- Spectral Acquisition: Scan the absorbance of each calibration mixture across an appropriate wavelength range (e.g., 200–350 nm [28] or 220–300 nm [32]) using a 1 nm interval. A finer data interval (e.g., 0.5 points/nm) can improve the quantification of minor components [28]. Export the spectral data (wavelengths and corresponding absorbance values) for chemometric processing.

Protocol 2: Data Preprocessing and Wavelength Selection

Raw spectral data often requires preprocessing to enhance the signal-to-noise ratio and improve model performance.

- Data Formatting: Compile the spectral data into a single matrix X (samples × wavelengths) and the known concentrations into a matrix Y (samples × analytes).

- Mean Centering: Subtract the average spectrum of the calibration set from each individual spectrum. This is a common preprocessing step that enhances the stability and interpretability of PCR and PLS models [32].

- Wavelength Selection (Optional but Recommended): Instead of using the entire spectrum, select informative wavelength regions to avoid uninformative or highly noisy regions. Techniques like Moving Window (MW) or Changeable Size Moving Window (CSMW) strategy can be employed. This reduces model complexity, removes collinear variables, and often leads to more precise predictions [30] [28].

Protocol 3: Model Development, Validation, and Application

This protocol covers the core steps of building, validating, and deploying the PCR and PLS models.

- Software and Computation: Import the preprocessed data matrices (X, Y) into chemometric software (e.g., MATLAB with PLS Toolbox, The Unscrambler X, or similar) [28] [32].

- Model Training:

- Split the data into a calibration/training set and a validation/test set.

- For PCR, perform PCA on the calibration spectral data and retain the significant principal components that capture spectral variance while excluding noise-related components.

- For PLS, specify the algorithm (PLS1 for single analyte or PLS2 for multiple analytes). The software will perform the simultaneous decomposition.

- Optimal Component Selection: Use cross-validation (e.g., leave-one-out cross-validation) on the calibration set to determine the optimal number of latent variables (LVs) for PLS or PCs for PCR. The optimal number is the one that minimizes the Root Mean Square Error of Cross-Validation (RMSECV) [28] [32].

- Model Validation: Use the external validation set, which was not used in model building, to assess the model's predictive power. Calculate the Root Mean Square Error of Prediction (RMSEP) and the Relative Error (RE%) to quantify accuracy [28].

- Application to Pharmaceutical Formulation:

- Prepare a sample solution from powdered tablets using the same solvent and dilution procedure as the standards [11].

- Record the spectrum of the sample solution.

- Use the developed PCR or PLS model to predict the concentration of each API in the sample.

The entire experimental workflow, from sample preparation to result interpretation, is summarized below:

Data Presentation and Analysis

Performance Metrics and Comparative Analysis

The following table summarizes typical validation results for chemometric models applied to multi-component pharmaceutical mixtures, including paracetamol-based formulations.

Table 2: Comparative Performance of Chemometric Models in Multicomponent Analysis

| Analytical Challenge / Mixture | Chemometric Method | Wavelength Range (nm) | Linear Range (μg/mL) | RMSEP / RMSECV | Reference |

|---|---|---|---|---|---|

| Paracetamol, CPM, Caffeine, Ascorbic Acid (Quaternary Mixture) | PLS1 | 220–300 | PARA: 4–20 | Low RMSECV values | [32] |

| PCR | 220–300 | PARA: 4–20 | reported, with PLS1 | [32] | |

| MCR-ALS | 220–300 | PARA: 4–20 | often showing slightly better accuracy. | [32] | |

| ANN | 220–300 | PARA: 4–20 | [32] | ||

| Paracetamol, Sodium Ascorbate, Chlorpheniramine (150:140:1 Ratio) | PLS1 (0.5 pt/nm) | 200–320 | CHL: 0.20–5.05 | Significantly improved accuracy for minor component (CHL) | [28] |

| Diphenylamine, Aniline, Phenol (Degradation Products) | PLS (with MW selection) | Selected Windows | 0.1–6.0 | Improved results with wavelength selection | [30] |

| PCR (with MW selection) | Selected Windows | 0.1–6.0 | Improved results with wavelength selection | [30] | |

| Paracetamol, Eperisone HCl (Binary Mixture) | Q-Absorbance Ratio | 249 & 260 (Iso-point) | PARA: 2–10 | % Recovery: 99.89% (PARA) | [22] |

Application to Tablet Formulation

The developed PCR and PLS models have been successfully applied to commercial tablet formulations. For instance, in the analysis of Grippostad C capsules, all four models (PCR, PLS, MCR-ALS, and ANN) provided satisfactory results with no significant difference in accuracy compared to official methods, demonstrating their suitability for routine quality control [32]. Another study on a paracetamol tablet (Paracip 500) using a univariate UV method reported a percent purity of 99.09%, with recovery rates at 80%, 100%, and 120% levels ranging from 100.00% to 102.10%, confirming the accuracy of spectrophotometric methods for paracetamol assay [11].

This application note has detailed the theoretical foundation and practical protocols for employing PCR and PLS regression in the spectrophotometric analysis of complex multi-component pharmaceutical formulations. Both methods have proven to be powerful, green, and viable alternatives to chromatographic techniques for the simultaneous quantification of APIs, such as paracetamol in combination with other drugs, without the need for prior separation.

The comparative studies indicate that while PLS may achieve optimal performance with fewer latent variables, both PCR and PLS offer comparable and excellent predictive accuracy when properly optimized. Key steps for success include a well-designed calibration set, appropriate wavelength selection, and rigorous validation. Integration of these chemometric models into pharmaceutical quality control laboratories can significantly enhance efficiency, reduce solvent consumption, and provide a robust framework for standard analysis.

Simultaneous Equation and Q-Absorbance Ratio Methods for Combination Products

The pharmaceutical industry increasingly relies on fixed-dose combination (FDC) products to achieve enhanced therapeutic effects through synergistic actions. Ibuprofen (IBU) and paracetamol (PAR) represents one such combination, gaining prominence in pain management due to its complementary mechanisms of action and favorable safety profile [10]. Ensuring the quality, safety, and efficacy of these combination products necessitates robust analytical methods for their simultaneous quantification in bulk and formulated dosages.

UV-Visible spectrophotometry remains a foundational technique in pharmaceutical analysis due to its simplicity, cost-effectiveness, and rapid implementation [18]. However, the simultaneous analysis of multiple active ingredients presents a significant challenge when their absorption spectra overlap. This application note, situated within a broader thesis on method development for paracetamol tablet analysis, details two well-established spectrophotometric techniques—the Simultaneous Equation (Vierodt's) method and the Q-Absorbance Ratio method. These methods effectively resolve overlapping spectra, enabling the precise and accurate quantification of individual components in a mixture without prior physical separation [33] [34]. Their utility is particularly valuable in routine quality control environments where high-throughput analysis is essential.

Theoretical Foundations

The Beer-Lambert Law

The quantitative basis of UV-Visible spectrophotometry is the Beer-Lambert law, which states that the absorbance (A) of a solution is directly proportional to the concentration (c) of the absorbing species and the path length (b) of the radiation through the sample [18]. Mathematically, this is expressed as: A = a b c where 'a' is the absorptivity coefficient. This direct relationship is fundamental to all quantitative spectrophotometric analysis.

- Simultaneous Equation Method: This approach is applicable when the absorption spectra of two components, X and Y, overlap, but each shows a distinct absorption maximum where the other exhibits significant absorption [34]. The concentration of each component is determined by solving a pair of simultaneous equations based on absorbance measurements at two different wavelengths and the respective absorptivity values.

- Q-Absorbance Ratio Method: This method requires the identification of an iso-absorptive point—a wavelength where the absorptivities of the two components are equal—in addition to the wavelength of maximum absorption of one component [33] [34]. The "Q" value is the ratio of absorbances at these two wavelengths and is used to calculate the concentrations.

Research Reagent Solutions

The following table catalogues essential materials and reagents required for the successful implementation of these analytical methods.

Table 1: Essential Research Reagents and Materials

| Reagent/Material | Specification | Primary Function |

|---|---|---|

| Paracetamol Reference Standard | Pharmaceutical grade (>99% purity) | Primary standard for calibration and method validation [7]. |

| Ibuprofen Reference Standard | Pharmaceutical grade (>99% purity) | Primary standard for calibration and method validation [7]. |

| Ethanol (Absolute) | HPLC/UV-Vis Grade | Primary solvent; ensures drug solubility and minimizes UV interference [13]. |

| Sodium Hydroxide (NaOH) | Analytical Grade | Enhances solubility of acidic drugs (e.g., ibuprofen) and can influence λmax [13]. |

| Phosphate Buffer (pH 7.2) | Analytical Grade | Provides a stable solvent medium for drugs stable at neutral pH [7]. |

| Methanol | HPLC Grade | Alternative solvent for drug dissolution and dilution [10]. |

| Volumetric Flasks | Class A, 10-100 mL | Precise preparation and dilution of standard and sample solutions. |

| Quartz Cuvettes | 1 cm path length | Holds sample solution for absorbance measurement in UV range. |

Application Notes & Protocols

Protocol 1: Simultaneous Equation Method for Paracetamol and Ibuprofen

Principle

This method relies on measuring the absorbance of a sample solution at two wavelengths: the λmax of paracetamol and the λmax of ibuprofen. The concentrations are calculated using a pair of simultaneous equations that incorporate the absorptivity values of each drug at both selected wavelengths [34].

Experimental Procedure

- Solvent System Preparation: Prepare a mixture of ethanol and 0.1 M sodium hydroxide in a 3:1 ratio (75 mL ethanol + 25 mL 0.1 M NaOH) [13].

- Standard Stock Solutions:

- Accurately weigh 25 mg of paracetamol and transfer to a 100 mL volumetric flask. Dissolve and make up to volume with the ethanol-NaOH solvent to obtain a 250 μg/mL stock solution.

- Repeat the process for ibuprofen to obtain a 250 μg/mL stock solution [13].

- Selection of Wavelengths: Scan the individual drug solutions in the range of 200-400 nm. Determine the absorbance maxima for each drug. For the paracetamol-ibuprofen combination, these are typically found at ~243 nm (λmax of PAR) and ~221 nm (λmax of IBU) [13].

- Calibration and Determination of Absorptivity:

- Dilute the stock solutions to prepare a series of standard solutions (e.g., 5-30 μg/mL for both drugs).

- Measure the absorbance of each paracetamol standard at both 243 nm (A₁) and 221 nm (A₂).

- Similarly, measure the absorbance of each ibuprofen standard at both 243 nm (A₃) and 221 nm (A₄).

- Calculate the mean absorptivity (A1%, 1cm) for each drug at both wavelengths. The absorptivity (a) is given by a = A / (c * b), where c is concentration in g/100mL.

- Sample Solution Preparation:

- Finely powder and accurately weigh tablet powder equivalent to one tablet.

- Transfer to a volumetric flask, add about 50 mL of solvent, sonicate for 20 minutes, and dilute to volume.

- Filter and further dilute to obtain a sample solution within the linear range of the calibration curve [7].

- Calculation:

- Measure the absorbance of the sample solution (A_sample) at 243 nm (λ₁) and 221 nm (λ₂).

- Use the following simultaneous equations to calculate the concentrations CPAR and CIBU (in μg/mL) in the sample solution:

- Aatλ₁ = aPARλ₁ * CPAR + aIBUλ₁ * CIBU

- Aatλ₂ = aPARλ₂ * CPAR + aIBUλ₂ * CIBU

Analytical Performance Data

The following table summarizes typical validation parameters for this method.

Table 2: Analytical Performance of the Simultaneous Equation Method for PAR and IBU

| Parameter | Paracetamol | Ibuprofen | Reference |

|---|---|---|---|

| Linear Range (μg/mL) | 1 – 15 / 5 – 30 | 2 – 20 / 5 – 30 | [10] |

| Wavelengths Used (nm) | 240 / 256 | 220 / 222.4 | [10] |

| Limit of Detection (LOD) (μg/mL) | 0.214 | 0.600 | [10] |

| Accuracy (% Recovery) | 100.02 ± 0.47* | 99.87 ± 0.53* | [34] |

| Precision (% RSD) | < 2% | < 2% | [13] |

| Remarks | *Reported for a different drug combination (Paracetamol & Zaltoprofen), demonstrating typical method performance. |

Protocol 2: Q-Absorbance Ratio Method for Paracetamol and Ibuprofen

Principle

This method involves measuring the absorbance of a sample solution at two wavelengths: the iso-absorptive point of the two drugs (where their absorptivities are equal) and the λmax of one component [33]. The ratio of these absorbances (the Q-value) is used to determine the concentration of each component in the mixture.

Experimental Procedure

- Solvent and Stock Solutions: Prepare as described in Protocol 4.1.2.

- Identification of Iso-absorptive Point:

- Prepare standard solutions of paracetamol and ibuprofen at the same concentration.

- Scan their absorbance spectra and overlay them. The point where the two spectra cross is the iso-absorptive point (λiso). For some PAR-IBU methods, this has been reported at 226.4 nm [10].

- Selection of λmax: Identify the λmax of one component, for example, ibuprofen at 222.4 nm (λIBU) [10].

- Calibration and Determination of Absorptivity:

- Prepare calibration curves for both pure drugs at both λiso and λIBU.

- Confirm that the absorptivities (A1%, 1cm) for both drugs are identical at λiso (aiso).

- Determine the absorptivity of ibuprofen at its λmax (aIBUλIBU) and at the iso-absorptive point (aIBUλiso). Note that aIBUλiso = aiso.

- Similarly, determine the absorptivity of paracetamol at the iso-point (aPARλiso = aiso) and at λIBU (aPAR_λIBU).

- Sample Analysis and Calculation:

- Measure the absorbance of the sample solution at the iso-absorptive point (Aiso) and at λIBU (AIBU).

- Calculate the Q-value: QM = AIBU / Aiso

- Calculate the concentration of ibuprofen (CIBU) and paracetamol (CPAR) in the sample using the following equations, where aIBUλIBU and aPARλIBU are the absorptivities of the pure drugs at λIBU, and aiso is the absorptivity at the iso-point:

- CIBU = (QM - QIBU) * (Aiso) / ( (QPAR - QIBU) * aiso )

- CPAR = (QPAR - QM) * (Aiso) / ( (QPAR - QIBU) * aiso )

- (Where QIBU = aIBUλIBU / aiso and QPAR = aPARλIBU / aiso)

Analytical Performance Data

The following table summarizes key performance metrics for the Q-Absorbance Ratio method.

Table 3: Analytical Performance of the Q-Absorbance Ratio Method for PAR and IBU

| Parameter | Details | Reference |

|---|---|---|

| Wavelengths Used | Iso-absorptive point: 226.4 nm; λmax (IBU): 256 nm | [10] |

| Linear Range (μg/mL) | 5–30 for both PAR and IBU | [10] |

| Accuracy (% Recovery) | 99.82 ± 0.48 (PAR), 99.84 ± 0.51 (IBU) | [34] |

| Precision (% RSD) | < 2% | [13] |

| Key Advantage | Simplifies calculation; less sensitive to minor errors in wavelength selection compared to the simultaneous equation method. | [33] |

| Remarks | *Reported for a different drug combination (Paracetamol & Zaltoprofen), demonstrating typical method performance. |

Method Validation and Comparative Analysis

Both the Simultaneous Equation and Q-Absorbance Ratio methods must be validated according to ICH guidelines to ensure reliability, accuracy, and precision for their intended use in pharmaceutical analysis [13] [18]. Key validation parameters include linearity, precision, accuracy, limit of detection (LOD), and limit of quantification (LOQ).

Table 4: Summary of Validation Parameters for UV-Spectrophotometric Methods

| Validation Parameter | Protocol & Acceptance Criteria |

|---|---|