Analytical Method Transfer Protocol: A Comprehensive Guide for Seamless Laboratory Transitions

This article provides a complete guide to analytical method transfer (AMT) for researchers, scientists, and drug development professionals.

Analytical Method Transfer Protocol: A Comprehensive Guide for Seamless Laboratory Transitions

Abstract

This article provides a complete guide to analytical method transfer (AMT) for researchers, scientists, and drug development professionals. It covers the foundational principles of AMT, detailing its importance in regulatory compliance and product quality assurance. The guide explores methodological approaches like comparative testing and co-validation, offers strategies for troubleshooting common pitfalls, and outlines the validation process to demonstrate equivalence between laboratories. By synthesizing best practices from regulatory guidelines and industry experts, this resource aims to equip professionals with the knowledge to execute efficient, compliant, and successful method transfers.

Understanding Analytical Method Transfer: The Foundation of Equivalence

Analytical Method Transfer (AMT) represents a critical, documented process within the pharmaceutical and biotechnology industries that qualifies a receiving laboratory to execute an analytical testing procedure that originated in a transferring laboratory. This formal process ensures that the receiving unit possesses the necessary procedural knowledge, technical capability, and instrumentation to perform the analytical method as intended, thereby guaranteeing that test results are equivalent to those generated by the original laboratory [1] [2]. As regulatory agencies mandate this transfer to ensure the consistency and quality of pharmaceuticals [1], AMT forms an indispensable component of technology transfers, whether for changes in production sites, outsourcing of testing activities, or multi-site operations [3] [4]. This guide objectively examines the core methodologies, experimental protocols, and comparative performance of different transfer approaches, providing researchers and drug development professionals with a structured framework for implementing robust AMT protocols.

Analytical Method Transfer is fundamentally a quality assurance process that establishes documented evidence that an analytical procedure performs equivalently in the receiving laboratory as it does in the originating laboratory [2] [5]. The ultimate purpose of any newly developed and validated method is its reliable application in Quality Control laboratories for the release of Active Pharmaceutical Ingredients (APIs) and finished products, making its successful transfer paramount [1]. The process is governed by regulatory guidelines, including United States Pharmacopeia (USP) General Chapter 〈1224〉, and requires meticulous documentation that can be audited by regulatory agencies [1] [6].

The necessity for AMT arises in various scenarios, including multi-site operations within the same company, transfer to or from Contract Research/Manufacturing Organizations (CROs/CMOs), implementation on new equipment or technology platforms, and rollout of method improvements or optimizations [4]. At its core, AMT demonstrates "equivalence" or "comparability" between laboratories, ensuring that the method's critical performance characteristics—accuracy, precision, specificity, linearity, range, detection limit, quantitation limit, and robustness—remain consistent across both sites [4].

Core Methodologies in Analytical Method Transfer

The search results reveal four primary, recognized methodologies for conducting Analytical Method Transfer. The selection of an appropriate methodology depends on factors such as the method's complexity, its regulatory status, the experience of the receiving laboratory, and the overall risk assessment [1] [3] [4].

Comparative Testing

Comparative Testing is the most frequently employed transfer approach [1] [3] [5]. This methodology requires both the transferring (sending) and receiving laboratories to analyze a predetermined number of samples from the same homogeneous lot [1] [7]. The experimental design typically involves multiple analysts, instruments, and days to establish intermediate precision. The results from both laboratories are statistically compared against pre-defined acceptance criteria to demonstrate equivalence [4]. This approach is particularly suitable for well-established, validated methods where both laboratories share similar equipment and expertise [4].

Co-validation

Co-validation, or joint validation, occurs when the receiving laboratory participates in the initial validation of the analytical method [1] [3]. In this model, the receiving unit acts as part of the validation team, specifically performing the intermediate precision (reproducibility) experiments that generate data for assessing inter-laboratory variability [3] [5]. This approach is highly efficient for methods developed specifically for multi-site use or when transfer occurs before the analytical method has been fully validated [3]. The acceptance criteria are defined within the validation protocol itself, based on product specifications and the method's intended purpose [3].

Revalidation or Partial Revalidation

Revalidation involves the receiving laboratory performing a complete or partial repetition of the original method validation [1] [2]. This approach is beneficial when the transferring laboratory is unavailable for comparative testing, when the original validation did not comply with ICH requirements, or when the method is being transferred to a laboratory with significantly different equipment, personnel, or environmental conditions [3] [4]. For partial revalidation, only the parameters anticipated to be most affected by the transfer—typically accuracy and precision—are evaluated [1] [3].

Transfer Waiver

A Transfer Waiver is a justified omission of the formal transfer process [1] [2]. This option is applicable only in specific, well-documented circumstances where the risk of failure is negligible. Justifications for a waiver include the use of pharmacopoeial methods (which require verification but not formal transfer), transfer of a method for a new product strength with comparable composition and methodology, transfer of a general method (e.g., visual inspection, weighing), or when personnel responsible for the method's development or validation move to the receiving unit [3] [2] [6]. This approach requires robust scientific justification and documented risk assessment, as it receives high regulatory scrutiny [4].

Table 1: Comparative Analysis of Analytical Method Transfer Types

| Transfer Type | Experimental Design | Best Suited For | Key Advantages | Key Limitations |

|---|---|---|---|---|

| Comparative Testing | Both labs analyze identical samples; results statistically compared [4]. | Established, validated methods; similar lab capabilities [4]. | Direct comparison provides strong evidence of equivalence; most recognized path [3]. | Requires careful sample preparation and handling; dependent on statistical analysis [4]. |

| Co-validation | Method validation and transfer occur simultaneously; receiving lab performs intermediate precision [3] [5]. | New methods; methods developed for multi-site use [4]. | Highly efficient; builds inter-laboratory consistency from the outset [3]. | Requires high collaboration and harmonized protocols; tight coordination needed [4]. |

| Revalidation | Receiving lab performs full or partial validation of the method [2] [4]. | Significant differences in lab conditions/equipment; substantial method changes [4]. | Most rigorous approach; demonstrates receiving lab's independent capability [4]. | Resource-intensive; essentially repeats original validation work [4]. |

| Transfer Waiver | No comparative testing performed [2]. | Highly experienced receiving lab; identical conditions; simple, robust methods [4]. | Saves significant time and resources; efficient for low-risk scenarios [2]. | Rarely applicable; requires strong scientific and risk justification [4]. |

Experimental Protocol and Workflow

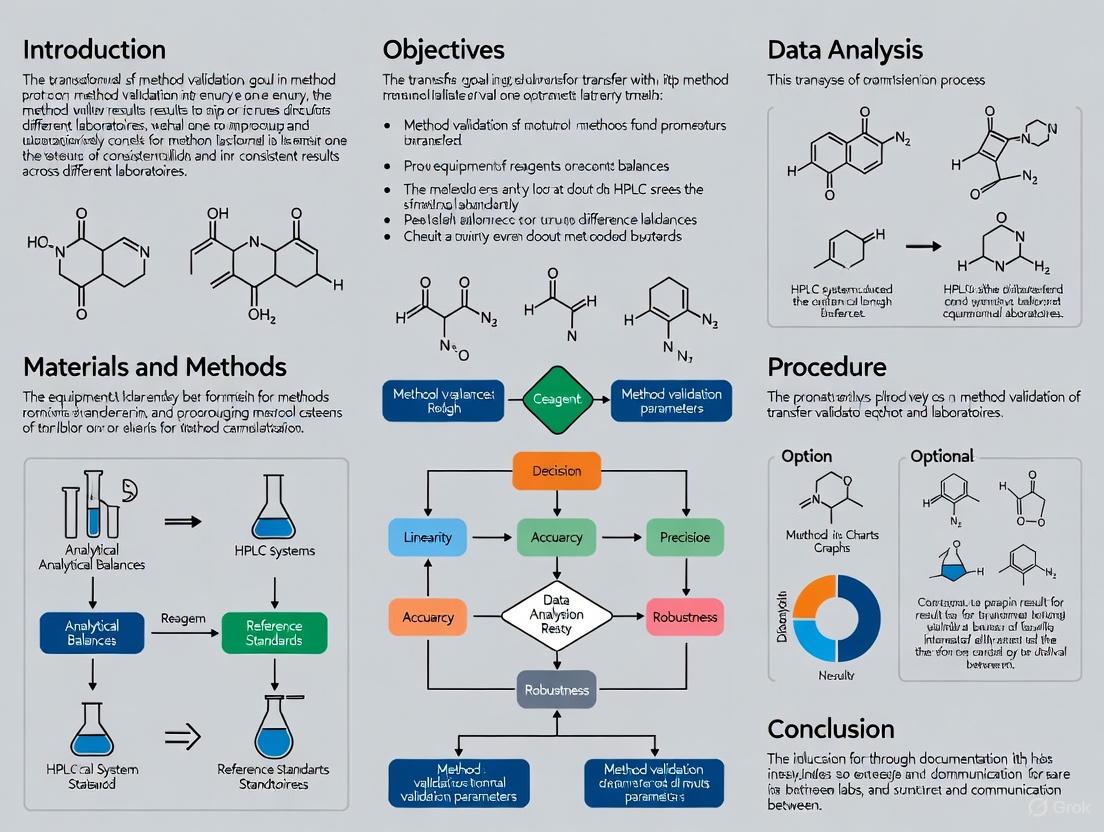

A successful Analytical Method Transfer follows a structured, phased workflow that ensures regulatory compliance and operational success. The following diagram illustrates the comprehensive, multi-stage process from initial assessment through final reporting and ongoing monitoring.

Diagram 1: Analytical Method Transfer Workflow

Phase 1: Pre-Transfer Planning and Assessment

The initial phase focuses on comprehensive preparation, which is crucial for the transfer's success [8].

- Define Scope & Objectives: Clearly articulate why the method is being transferred and define specific, measurable success criteria [4] [8].

- Form Cross-Functional Teams: Designate leads and team members from both transferring and receiving labs, including representatives from Analytical Development, QA/QC, and Operations [4] [8].

- Gather Method Documentation: Collect all relevant method validation reports, development reports, current Standard Operating Procedures (SOPs), raw data, and instrument specifications from the transferring lab [4] [8].

- Conduct Gap Analysis: Compare equipment, reagents, software, environmental conditions, and personnel expertise between the two labs to identify potential discrepancies [3] [4].

- Perform Risk Assessment: Identify potential challenges (e.g., complex method, unique equipment, inexperienced personnel) and develop appropriate mitigation strategies [1] [4].

- Select Transfer Approach: Based on the risk assessment and method characteristics, choose the most appropriate transfer methodology (Comparative Testing, Co-validation, Revalidation, or Waiver) [4].

- Develop Detailed Transfer Protocol: Create a comprehensive protocol specifying method details, responsibilities, materials, equipment, sample preparation, analytical procedure, acceptance criteria, statistical analysis plan, and deviation handling process [1] [3] [4].

- Secure Management Approval: Obtain formal approval for the transfer protocol from all relevant stakeholders, including Quality Assurance [4].

Phase 2: Execution and Data Generation

This phase involves the hands-on implementation of the approved transfer protocol.

- Personnel Training: Ensure receiving lab analysts are thoroughly trained by transferring lab personnel, with all training sessions formally documented [1] [4] [6].

- Equipment Readiness: Verify that all necessary equipment at the receiving lab is properly qualified, calibrated, and maintained according to established schedules [2] [4].

- Sample Preparation & Distribution: Prepare and characterize homogeneous, representative samples (e.g., spiked samples, production batches, placebo) for comparative testing, ensuring proper handling and shipment to maintain sample integrity [4].

- Execute Protocol: Both laboratories perform the analytical method according to the approved protocol, typically involving multiple analysts, instruments, and days to establish intermediate precision [4] [6].

- Document Everything: Meticulously record all raw data, instrument printouts, calculations, and any deviations encountered during the execution phase [4] [8].

Phase 3: Data Evaluation and Reporting

This phase focuses on analyzing the generated data and formalizing the transfer outcome.

- Data Compilation: Collect all data from both laboratories in a standardized format to facilitate comparison [4].

- Statistical Analysis: Perform statistical comparison as outlined in the protocol, which may include t-tests, F-tests, equivalence testing, or ANOVA to objectively evaluate inter-laboratory differences [4] [7].

- Evaluate Against Acceptance Criteria: Compare the results against the pre-defined acceptance criteria established in the transfer protocol [4] [8].

- Investigate Deviations: If acceptance criteria are not met, conduct thorough investigations to determine the root cause, document findings, and implement corrective actions before proceeding [3] [4].

- Draft Transfer Report: Prepare a comprehensive report summarizing the transfer activities, results, statistical analysis, deviations, and conclusions regarding the success of the transfer [1] [4].

- QA Review and Approval: The transfer report, along with all supporting documentation, undergoes rigorous review and formal approval by Quality Assurance to ensure compliance [4].

Phase 4: Post-Transfer Activities

The final phase ensures the sustainable implementation of the method in the receiving laboratory.

- SOP Development/Revision: The receiving laboratory develops or updates its Standard Operating Procedures for the transferred method, incorporating any site-specific nuances while maintaining equivalency [4].

- Routine Testing: The receiving laboratory begins using the method for routine GMP testing, with all data becoming reportable for regulatory purposes [8].

- Ongoing Performance Monitoring: Continuously monitor the method's performance through system suitability tests, quality control charts, and trending analyses to ensure continued reliability [4].

Acceptance Criteria and Performance Metrics

Establishing scientifically sound acceptance criteria is fundamental to demonstrating a successful method transfer. These criteria should be based on the method's validation data and performance characteristics, taking into account ICH requirements and product specifications [3].

Table 2: Typical Acceptance Criteria for Analytical Method Transfer

| Test | Experimental Design | Typical Acceptance Criteria | Statistical Measures |

|---|---|---|---|

| Identification | Positive (or negative) identification obtained at receiving site [3]. | Positive identification matching reference standard [3]. | Qualitative comparison; no statistical analysis required. |

| Assay | 2 Analysts × 3 test samples in triplicate using different instruments/columns/independent solution preparations [6]. | Absolute difference between the sites' mean results: 2-3% [3] [6]. | Comparison of mean variability; % Relative Standard Deviation (RSD) of replicates < 5.0% [6]. |

| Related Substances (Impurities) | 2 Analysts × 3 test samples in triplicate using spiked samples where necessary [6]. | Absolute difference between results: < 25.0% for low-level impurities; Recovery of 80-120% for spiked impurities [3] [6]. | % RSD of replicate standards < 5.0%; comparison of result variability [6]. |

| Dissolution | Analysis of identical samples at multiple time points by both laboratories [3]. | Absolute difference in mean results: NMT 10% at time points when < 85% dissolved; NMT 5% at time points when > 85% dissolved [3]. | Statistical comparison of mean results at each time point. |

| Cleaning Validation | 2 Analysts × 3 test samples in triplicate using samples spiked at three different concentration levels [6]. | All samples spiked above specified limit must fail; all samples below specified limit must pass [6]. | Qualitative pass/fail determination with demonstrated specificity. |

The Scientist's Toolkit: Essential Research Reagent Solutions

Successful execution of an Analytical Method Transfer requires meticulous preparation and the availability of specific, quality-controlled materials. The following table details key reagent solutions and materials essential for the transfer process.

Table 3: Essential Research Reagents and Materials for Analytical Method Transfer

| Item Category | Specific Examples | Function in AMT | Critical Quality Attributes |

|---|---|---|---|

| Reference Standards | Drug substance standards; impurity standards; system suitability standards [3] [7]. | Quantitation of analytes; demonstration of method specificity and system performance [7]. | Certified purity and identity; proper storage conditions; established stability [4]. |

| Critical Reagents | HPLC mobile phase components; derivatization agents; digestion buffers [8]. | Execution of method as defined in protocol; maintenance of chromatographic performance [8]. | Manufacturer and grade as specified in method; preparation documentation; expiry dating [4]. |

| Chromatographic Columns | C18, C8, phenyl, HILIC, or other specified stationary phases [6]. | Reproducibility of separation; achievement of system suitability criteria [6]. | Equivalent specification to original column; column performance certificate; appropriate conditioning [6]. |

| Sample Materials | Homogeneous lot of API; finished product; placebo; spiked samples [4] [7]. | Comparative testing between laboratories; demonstration of accuracy and precision [7]. | Representative of routine samples; established stability for transfer duration; certificates of analysis [4] [7]. |

| System Suitability Materials | Resolution mixtures; tailing factor solutions; precision standards [7]. | Verification that the analytical system is operating adequately for the intended analysis before and during testing [7]. | Consistent performance to established criteria; demonstration of method robustness [7]. |

| 2-(Methylthio)-4,5-diphenyloxazole | 2-(Methylthio)-4,5-diphenyloxazole | RUO | Supplier | High-purity 2-(Methylthio)-4,5-diphenyloxazole for research applications. For Research Use Only. Not for human or veterinary use. | Bench Chemicals |

| Dilithium germanate | Dilithium Germanate | High-Purity Research Chemical | Dilithium germanate is a key material for solid-state electrolyte and photonics research. For Research Use Only. Not for human or veterinary use. | Bench Chemicals |

Analytical Method Transfer represents a critical juncture in the lifecycle of an analytical procedure, marking its transition from development to routine application in quality control. The documented process, when executed following a structured methodology with clearly defined acceptance criteria, provides assurance that the receiving laboratory can generate reliable, reproducible, and regulatory-compliant data equivalent to that produced by the originating laboratory [1] [4]. Among the various approaches, Comparative Testing remains the most prevalent for established methods, while Co-validation offers efficiency for new methods destined for multi-site use [3] [4].

The success of any AMT exercise hinges on comprehensive planning, robust communication between transferring and receiving units, adequate personnel training, and meticulous documentation [1] [3] [4]. Furthermore, a thorough understanding of the method's capabilities and limitations, coupled with a science- and risk-based approach to protocol design and execution, ensures that the transfer process not only meets regulatory expectations but also establishes a solid foundation for the method's long-term performance in its new environment [3] [4]. For researchers and drug development professionals, mastering the principles and practices of Analytical Method Transfer is therefore indispensable for maintaining product quality and regulatory compliance across the global pharmaceutical landscape.

The Critical Importance of AMT for Regulatory Compliance and Patient Safety

Analytical Method Transfer (AMT) is a critical documented process that qualifies a receiving laboratory to use an analytical procedure that originated in a transferring laboratory, ensuring it performs with equivalent accuracy, precision, and reliability [4] [9]. In the pharmaceutical industry, this process is not merely a logistical formality but a scientific and regulatory imperative [10] [4]. A successfully transferred method guarantees that analytical data—from the identity of raw materials to the level of impurities in a final product—remains consistent and reliable across different locations, instruments, and analysts [10]. This consistency is the bedrock of drug quality, making AMT a vital activity for regulatory compliance and, ultimately, for ensuring the safety and efficacy of medicines reaching patients [10] [11].

The Regulatory Imperative of Analytical Method Transfer

Regulatory bodies worldwide mandate that analytical methods used for quality control must be reliable, irrespective of where the testing is performed. Analytical Method Transfer provides the documented evidence required to meet these expectations.

- Foundation for Compliance: Regulatory agencies, including the FDA, EMA, and WHO, require proof that a method works correctly in any laboratory that uses it [10]. A successful AMT demonstrates this, forming a core part of a site's Good Manufacturing Practice (GMP) obligations, particularly for contract manufacturing and testing [11].

- Consequences of Failure: A poorly executed transfer can lead to significant regulatory and operational risks, including delayed product releases, costly retesting, and observations during regulatory inspections [4]. Common inspection findings include unqualified equipment for the method's range, failure to follow the transfer protocol, and insufficient testing on an inadequate number of batches [11].

- A Shared Responsibility: Regulatory compliance is a shared responsibility between the transferring and receiving laboratories [11]. A collaborative approach, supported by a formal process and thorough documentation, gives confidence in the data generated after the AMT is completed.

Comparing Core Method Transfer Approaches

The United States Pharmacopeia (USP) <1224> outlines several recognized approaches for transferring an analytical method [4] [12]. The choice of strategy depends on factors such as the method's complexity, its validation status, and the risk involved.

The table below summarizes the primary approaches:

| Transfer Approach | Description | Best Suited For | Key Considerations |

|---|---|---|---|

| Comparative Testing [4] [3] | Both labs analyze identical samples; results are statistically compared. | Well-established, validated methods; labs with similar capabilities. | Most common approach; requires robust statistical analysis and homogeneous samples. |

| Co-validation [4] [12] | The method is validated simultaneously by both the transferring and receiving labs. | New methods or methods being developed for multi-site use from the outset. | Resource-intensive; fosters shared ownership and deep understanding from the start. |

| Revalidation [4] [3] | The receiving lab performs a full or partial revalidation of the method. | Significant differences in lab conditions/equipment or substantial method changes. | Most rigorous approach; treats the method as if it were new to the receiving site. |

| Transfer Waiver [4] | The formal transfer process is waived based on strong justification. | Highly experienced receiving lab; simple, robust methods like some pharmacopoeial methods. | Rare; subject to high regulatory scrutiny and requires robust scientific justification. |

Quantitative Acceptance Criteria for Method Transfer

A successful transfer hinges on pre-defined, justified acceptance criteria for the method's performance characteristics. These criteria, detailed in the transfer protocol, provide the objective measure for success.

The following table outlines typical acceptance criteria for common analytical tests:

| Analytical Test | Typical Acceptance Criteria |

|---|---|

| Identification [3] | Positive (or negative) identification obtained at the receiving site. |

| Assay [3] | Absolute difference between the results from the two sites: 2-3%. |

| Related Substances (Impurities) [3] | Absolute difference criteria vary by impurity level. For low-level impurities, recovery of 80-120% for spiked samples may be used. |

| Dissolution [3] | Absolute difference in the mean results:• NMT 10% at time points when <85% is dissolved• NMT 5% at time points when >85% is dissolved |

Experimental Protocol for a Comparative Method Transfer

The comparative testing approach is the most frequently used method [11]. The following workflow details the standardized protocol for executing this transfer, from initial planning to final reporting.

Diagram Title: AMT Comparative Testing Workflow

Phase 1: Pre-Transfer Planning and Assessment

This foundational phase determines the project's roadmap [4].

- Define Scope & Objectives: Clearly articulate the reason for the transfer and define what constitutes success using specific, measurable acceptance criteria [4].

- Form Cross-Functional Teams: Designate leads and team members from both labs, including Analytical Development, QA/QC, and Operations [4].

- Gather Method Documentation: Collect all method validation reports, development reports, Standard Operating Procedures (SOPs), and historical data from the transferring lab [4] [3].

- Conduct Gap & Risk Analysis: Compare equipment, reagents, software, and personnel expertise between the two labs to identify potential discrepancies [4] [3]. A formal risk assessment helps identify critical parameters that could impact the results [10] [11].

- Develop & Approve Transfer Protocol: This critical document, requiring Quality Assurance (QA) approval, must specify method details, responsibilities, experimental design, acceptance criteria, and the statistical analysis plan [4] [3].

Phase 2: Execution and Data Generation

This phase focuses on the practical implementation of the protocol.

- Train Receiving Lab Analysts: The transferring lab must provide effective training to convey method-specific knowledge, including critical parameters and troubleshooting tips [4] [12]. All training must be documented.

- Verify Equipment & Reagents: Ensure all instruments at the receiving lab are properly qualified, calibrated, and maintained. Use traceable and qualified reference standards and reagents at both sites [4].

- Execute Protocol: Parallel Testing: Both labs analyze a pre-defined number of samples from the same homogeneous batch, often with multiple injections, as per the approved protocol [4] [11] [3].

Phase 3: Data Evaluation and Reporting

The generated data is rigorously analyzed to determine the transfer's outcome.

- Perform Statistical Analysis: Compare the results from both laboratories using statistical tools pre-defined in the protocol, such as t-tests, F-tests, or equivalence testing [4] [3].

- Evaluate Against Acceptance Criteria: Compare the statistical outcomes with the pre-defined acceptance criteria to determine if they are met [4].

- Investigate Any Deviations: Any deviations from the protocol or out-of-specification results must be thoroughly investigated and documented [3].

- Draft & Approve Transfer Report: A comprehensive report summarizing the activities, results, and conclusions is prepared. The report must clearly state whether the transfer was successful and requires QA approval [4] [3].

Phase 4: Post-Transfer Activities

Upon successful transfer, the method is implemented for routine use.

- Develop/Update Site SOPs: The receiving laboratory formally adopts the method by creating or updating its own SOPs [4].

The Scientist's Toolkit: Essential Reagents and Materials

The reliability of an AMT depends on the quality and consistency of the materials used. The table below lists key reagent solutions and their critical functions in ensuring a successful transfer.

| Item | Critical Function in AMT |

|---|---|

| Qualified Reference Standards | Serves as the benchmark for method accuracy and calibration; traceability and stability are paramount [4]. |

| Validated Instruments & Columns | Ensures data integrity; equipment (especially HPLC/GC) must be qualified for the method's specific range and conditions [10] [11]. |

| Specified Lot of Reagents & Solvents | Prevents variability; using the same grade and supplier of solvents and buffers as validated is crucial for robustness [10]. |

| Stable & Homogeneous Test Samples | Forms the basis for comparative testing; samples must be representative and remain stable throughout the testing window [4]. |

| Detailed Method Transfer Protocol | The master document that defines all aspects of the transfer, ensuring regulatory compliance and a shared understanding [4] [3]. |

| Oleyltrimethylammonium chloride | Oleyltrimethylammonium Chloride | High-Purity Reagent |

| Anthracene-1-sulfonic Acid | Anthracene-1-sulfonic Acid | High-Purity Reagent |

Analytical Method Transfer is far more than a procedural hurdle; it is a fundamental component of the pharmaceutical quality system. A meticulously planned and executed AMT, supported by rigorous experimental protocols and clear acceptance criteria, provides the documented evidence required for regulatory compliance. More importantly, it ensures that every laboratory involved in the testing of a drug product can generate trustworthy data. This reliability directly safeguards patient safety by ensuring that medicines are consistently of the correct identity, strength, quality, and purity, no matter where they are tested. In an era of globalized pharmaceutical manufacturing and complex supply chains, the role of AMT as a guardian of product quality and patient welfare has never been more critical.

In the highly regulated pharmaceutical industry, the reliability and consistency of analytical methods are fundamental to ensuring drug safety and efficacy. Analytical Method Transfer (AMT) is a critical, documented process that verifies a laboratory (the "receiving unit") can successfully execute a validated analytical method originally developed and used by another laboratory (the "transferring unit") and produce equivalent results [10]. This process is not a mere formality but a scientific and regulatory imperative to guarantee that methods perform consistently across different locations, instruments, and personnel [4]. The core principle is to establish equivalence or comparability between the two laboratories, ensuring the method's performance characteristics—such as accuracy, precision, and specificity—remain consistent [4]. This guide explores the key scenarios that necessitate method transfer and objectively compares the primary approaches used within the industry.

Understanding the Need for Method Transfer

The transfer of analytical methods is driven by several common operational scenarios in drug development and manufacturing. A failure to properly execute these transfers can lead to significant issues, including delayed product releases, costly retesting, and regulatory non-compliance [4].

The most frequent scenarios requiring AMT include:

- Multi-site Operations: When a method developed and validated at one research or manufacturing site needs to be implemented at another facility within the same company to decentralize testing or increase capacity [4].

- Partnerships with CROs/CMOs/CDMOs: Transferring methods to or from external contract research and manufacturing organizations is a cornerstone of modern pharmaceutical outsourcing [4]. This is crucial for tasks like stability studies, release testing, or when a contract organization takes over manufacturing [10].

- Technology and Equipment Changes: Adapting an existing method to new instrumentation or analytical platforms at a different location [4].

- Method or Process Improvements: Rolling out a refined or optimized analytical method across multiple laboratory sites [4].

- Post-Approval Changes: Changes in the manufacturing site for a commercial product often require the associated analytical methods to be transferred to the new site's quality control laboratory [3].

Comparative Analysis of Method Transfer Approaches

Regulatory bodies like the USP (General Chapter <1224>) outline several accepted approaches for method transfer [4]. The choice of strategy depends on factors like the method's complexity, its regulatory status, the experience of the receiving lab, and the level of risk involved [4]. The following table summarizes the four primary transfer protocols for easy comparison.

| Transfer Approach | Experimental Protocol & Methodology | Best-Suited Context | Key Advantages | Key Limitations & Risks |

|---|---|---|---|---|

| Comparative Testing | Both laboratories analyze the same set of homogeneous, representative samples (e.g., from a production batch, spiked samples) using the identical method. Results are statistically compared using pre-defined tests (e.g., t-tests, F-tests, equivalence testing) [4] [10]. | Well-established, validated methods where both labs have similar capabilities and equipment [4]. | Most common and widely accepted approach; provides direct, empirical evidence of equivalence [3]. | Requires careful sample preparation and handling; statistical analysis must be robust and pre-defined [4]. |

| Co-validation | The analytical method is validated simultaneously by both the transferring and receiving laboratories as part of a joint effort. This is often detailed in a shared validation protocol [10] [3]. | New methods, or when a method is being developed specifically for multi-site use from the outset [4]. | Fosters shared ownership and deep understanding from the start; can be more efficient than sequential validation and transfer [12]. | Can be resource-intensive; requires exceptionally close collaboration and harmonized protocols [4]. |

| Revalidation | The receiving laboratory performs a full or partial revalidation of the method as if it were new, following established validation guidelines (e.g., ICH Q2(R1)) [4] [10]. | Significant differences in lab conditions/equipment; substantial method changes; or when the original validation is inadequate [4] [3]. | Most rigorous approach; builds high confidence as the receiving lab demonstrates full method mastery independently [4]. | Most resource- and time-intensive approach; may be unnecessary for well-understood methods [10]. |

| Transfer Waiver | No experimental transfer work is conducted. Waiver is justified based on prior data, such as the receiving lab's existing proficiency with the method or the method's simplicity [4] [3]. | Highly experienced receiving lab; identical conditions; simple, robust compendial methods (e.g., USP) that only require verification [4] [3]. | Saves significant time and resources; efficient for low-risk scenarios. | Rarely applicable; carries high regulatory scrutiny and requires exhaustive scientific justification and risk assessment [4]. |

Workflow for a Successful Analytical Method Transfer

The following diagram illustrates the typical phased workflow for a successful analytical method transfer, integrating elements from the various approaches described above.

The Scientist's Toolkit: Essential Reagents and Materials

The success of an analytical method transfer hinges not only on the protocol but also on the quality and consistency of the materials used. The table below details key reagent solutions and materials critical for ensuring reproducible results.

| Item | Critical Function & Rationale | Best Practice Considerations |

|---|---|---|

| Reference Standards | Qualified substances with known purity and identity used to calibrate instruments and quantify results [3]. | Use traceable and qualified standards from reputable sources. Confirm stability and storage conditions to ensure integrity throughout the transfer process [4]. |

| Chromatographic Columns | The stationary phase in HPLC/GC systems; critical for separating analytes. | Specify the exact brand, model, and chemistry (e.g., C18, 250mm x 4.6mm, 5µm). Column variability is a major source of transfer failure, so aligning specifications between labs is essential [10]. |

| Chemical Reagents & Solvents | High-purity solvents and chemicals used in mobile phases, sample solutions, and derivatization. | Specify grade (e.g., HPLC-grade) and supplier. Differences in solvent quality or water pH can significantly alter chromatographic performance and results [10]. |

| Stable Test Samples | Representative samples of the drug substance or product being analyzed [3]. | Use homogeneous samples from a single, well-characterized batch. Ensure samples are stable for the duration of testing and that shipping conditions do not compromise integrity [4] [10]. |

| System Suitability Solutions | A mixture of key analytes used to verify that the total analytical system is functioning adequately at the time of testing. | The solution and acceptance criteria should be defined in the method. It serves as a final check that the entire system (instrument, column, reagents, operator) is performing as required before sample analysis begins [10]. |

| Beryllium diammonium tetrafluoride | Beryllium Diammonium Tetrafluoride | RUO Supplier | Beryllium diammonium tetrafluoride for materials science & synthesis. High-purity reagent for research applications. For Research Use Only. |

| Tris(1-phenylbutane-1,3-dionato-O,O')iron | Tris(1-phenylbutane-1,3-dionato-O,O')iron, CAS:14323-17-2, MF:C30H27FeO6, MW:539.4 g/mol | Chemical Reagent |

The increasing reliance on multi-site operations and partnerships with CROs, CMOs, and CDMOs makes robust analytical method transfer protocols more vital than ever [13] [14]. There is no one-size-fits-all approach; the choice between comparative testing, co-validation, revalidation, or a waiver must be driven by a thorough risk assessment that considers method complexity, inter-lab differences, and regulatory expectations [10] [3].

Ultimately, success is rooted in more than just technical execution. Comprehensive planning, robust communication, and meticulous documentation form the foundation of a seamless transfer. By systematically applying these principles and selecting the most appropriate transfer strategy, pharmaceutical companies and their partners can mitigate risks, ensure regulatory compliance, and maintain the unwavering product quality that safeguards patient safety [4] [3].

In the field of drug development and manufacturing, demonstrating that two laboratories can produce equivalent and comparable results is a fundamental requirement. Establishing comparability is essential whenever a manufacturing process, analytical method, or production location is changed. Regulatory agencies, such as the FDA, require a documented process to show that any change does not adversely impact the product's safety, identity, strength, quality, purity, or potency [15]. The core statistical approach for this demonstration is equivalence testing, which provides evidence that differences in measurements between two laboratories are small enough to be considered practically insignificant [15]. This guide outlines the principles, protocols, and data analysis techniques required to establish robust evidence of inter-laboratory equivalence.

The Statistical Foundation: Equivalence Testing

Why Equivalence Testing Trumps Significance Testing

A common misconception is using significance testing (e.g., a t-test aiming for a p-value > 0.05) to demonstrate comparability. This approach is flawed because a non-significant p-value merely indicates "insufficient evidence to conclude a difference." It does not confirm that the results are equivalent. The test might be unable to detect a meaningful difference due to high variability or an insufficient number of replicates [15].

Equivalence testing inverts this logic. It proactively tests the hypothesis that the means from two laboratories differ by an amount that is less than a pre-defined, acceptable margin. This margin, often called the "equivalence interval" or "acceptance criterion," represents a threshold of practical insignificance. The most common statistical method for this is the Two One-Sided T-test (TOST) procedure [15].

The Two One-Sided T-Test (TOST) Procedure

The TOST approach tests two simultaneous hypotheses:

- That the true difference between the laboratory means is greater than the lower practical limit (LPL).

- That the true difference is less than the upper practical limit (UPL).

If both hypotheses can be rejected, it provides statistical evidence that the difference lies entirely within the acceptable range (LPL to UPL). The following diagram illustrates the logical decision-making process of the TOST.

Setting Risk-Based Acceptance Criteria

The equivalence interval (LPL and UPL) is not arbitrary; it should be based on scientific knowledge, product experience, and clinical relevance [15]. A risk-based approach is recommended:

Table 1: Risk-Based Acceptance Criteria for Equivalence Intervals

| Risk Level | Typical Acceptance Criterion (as % of tolerance) |

|---|---|

| High Risk | 5% - 10% |

| Medium Risk | 11% - 25% |

| Low Risk | 26% - 50% |

Higher-risk situations, where a small difference could significantly impact product quality or patient safety, warrant tighter (smaller) acceptance criteria. The impact on process capability and out-of-specification (OOS) rates should also be evaluated [15].

Experimental Protocols for Method Transfer

The process of qualifying a receiving laboratory to use an analytical method developed by a transferring laboratory is known as Analytical Method Transfer (AMT) [2]. The following workflow maps the key stages and decision points in a typical transfer process.

Types of Analytical Method Transfers

There are several accepted approaches to conduct a method transfer, each suitable for different circumstances [2]:

- Comparative Testing: The most common approach. The same lot of a product, API, or device is analyzed by both the transferring and receiving laboratories. The results are compared against pre-defined acceptance criteria in a protocol.

- Co-validation between Laboratories: The transferring and receiving laboratories collaborate in an inter-laboratory validation study. This assesses the reproducibility of the method.

- Revalidation or Partial Revalidation: The receiving laboratory performs a complete or partial validation of the method, as outlined in guidelines like USP <1225>.

- Transfer Waiver: A justified omission of the formal transfer process. This is based on a risk analysis and is only applicable when the receiving laboratory has extensive existing experience and knowledge with the method or similar methods [2].

Key Reagents and Materials

Successful method transfer relies on critical materials and documentation. The table below lists essential items and their functions.

Table 2: Essential Research Reagent Solutions and Materials for Method Transfer

| Item | Function / Purpose |

|---|---|

| Reference Standards | Provides a known and qualified benchmark to calibrate instruments and validate method performance in the receiving lab [2]. |

| Test Article (Single Lot) | A single, homogeneous lot of the product, API, or device is used for comparative testing to isolate method performance from process variability [2]. |

| Validated Method Document | The unambiguous, detailed procedure from the transferring lab. It is the core document being qualified [2]. |

| Qualified/Calibrated Equipment | Laboratory systems at the receiving lab must be verified for availability and proper qualification/calibration to ensure data integrity [2]. |

| System Suitability Controls | Quality control samples used to verify that the analytical system is operating correctly before and during the analysis. |

Case Study: Inter-Laboratory Validation of a Neutralizing Antibody Assay

A 2024 study provides a robust, real-world example of establishing comparability for a complex, cell-based assay. The research focused on standardizing a microneutralization (MN) assay for anti-AAV9 neutralizing antibodies (NAbs) across multiple laboratories [16].

Experimental Methodology

- Objective: To establish a standardized MN assay and assess its intra- and inter-laboratory reproducibility.

- Assay Principle: The assay measures the inhibition of recombinant AAV9 vector transduction in a susceptible cell line (HEK293). The readout is luciferase activity (Relative Luminescence Units, RLU) [16].

- Sample Preparation: Human serum or plasma samples were pre-treated at 56°C for 30 minutes. Samples were serially diluted two-fold, starting at 1:20, and incubated with the AAV9 vector [16].

- Experimental Steps:

- Virus-sample mixture incubated for 1 hour at 37°C.

- HEK293 cells were added and incubated for 48-72 hours.

- Luciferase activity in the supernatant was measured.

- Transduction Inhibition (TI) was calculated as:

[1 − (RLUtest − RLUcell control)/(RLUvirus control − RLUcell control)] × 100%. - The IC50 titer (dilution that inhibits 50% of transduction) was determined using 4-parameter logistic (4PL) regression [16].

- Quality Control: A monoclonal antibody in human negative serum was used as a system suitability control, requiring an inter-assay titer variation of less than a 4-fold difference [16].

Key Quantitative Findings and Data Presentation

The study generated clear quantitative data on the assay's performance, which is summarized in the table below.

Table 3: Performance Data from Anti-AAV9 Neutralizing Antibody Assay Validation

| Performance Parameter | Result | Acceptance Criterion |

|---|---|---|

| Sensitivity | 54 ng/mL | Not Specified |

| Specificity (vs. AAV8) | No cross-reactivity at 20 μg/mL | Not Specified |

| Intra-Assay Precision (Variation for Low Positive QC) | 7% - 35% | Not Specified |

| Inter-Assay Precision (Variation for Low Positive QC) | 22% - 41% | Not Specified |

| Intra-Laboratory Reproducibility (%GCV of blind samples) | 18% - 59% | Not Specified |

| Inter-Laboratory Reproducibility (%GCV of blind samples) | 23% - 46% | System QC: <50% %GCV |

%GCV: Geometric Coefficient of Variation [16].

The data in Table 3 demonstrates that the method, despite being a complex bioassay, showed excellent reproducibility both within and between laboratories, as all %GCV values for the blind samples met the system suitability requirement of <50% [16]. This successful transfer and validation provide a template for standardizing similar methods across the industry.

Best Practices for Reporting and Documentation

Clear reporting is critical for regulatory submissions and internal decision-making.

- Structured Report: A comprehensive transfer report should include a title page, abstract, introduction, methodology, results, and a discussion/conclusion [17].

- Present Quantitative and Qualitative Data Together: Use tables and figures to present quantitative findings, but always provide context, interpretation, and rationale for the acceptance criteria used [18].

- Include Confidence Intervals: When reporting equivalence test results, including confidence intervals is a best practice, as they visually represent the estimate and precision of the difference between laboratories [15].

- Document Deviations: Any deviations from the pre-approved protocol must be documented and their impact assessed [2].

Establishing equivalence and comparability between laboratories is a systematic, documented process grounded in sound statistical principles. Moving from flawed significance testing to proactive equivalence testing (TOST) ensures that demonstrated comparability is both statistically and practically significant. The foundation of a successful transfer is a risk-based protocol with pre-defined acceptance criteria, supported by a rigorous experimental design and comprehensive training. As demonstrated by the inter-laboratory assay validation case study, these principles are universally applicable, from simple chemical tests to complex biological methods, and are essential for ensuring consistent, reliable data across the global scientific landscape.

Analytical method transfer is a critical, documented process in the pharmaceutical industry that qualifies a receiving laboratory to use an analytical method originally developed and validated in a different (transferring) laboratory [10] [4]. Its fundamental purpose is to provide documented evidence that the transferred analytical method performs in the new laboratory with the same level of accuracy, precision, and reliability as in the original laboratory, despite differences in analysts, equipment, and environmental conditions [10] [19]. This process is not a mere formality but a regulatory imperative to ensure the consistency, quality, and safety of pharmaceutical products when testing is moved between sites, such as from research and development (R&D) to a quality control (QC) lab, or to a contract manufacturing organization (CMO) [10] [3].

The success of a method transfer is demonstrated by establishing "equivalence" or "comparability" between the data generated at the transferring and receiving laboratories [4]. Regulatory agencies worldwide, including the US Food and Drug Administration (FDA), the European Medicines Agency (EMA), and others, require proof that analytical methods are reliable and reproducible across different testing sites [10] [20].

Comparative Analysis of Key Regulatory Guidelines

A thorough understanding of the guidelines from the United States Pharmacopeia (USP), the FDA, and the EMA is essential for successful regulatory compliance. The following table provides a high-level comparison of these core documents.

| Guideline | Primary Focus & Scope | Recommended Transfer Approaches | Key Emphases and Requirements |

|---|---|---|---|

| USP General Chapter <1224> [10] [4] | Standardizing the transfer of analytical procedures; provides a conceptual framework. | • Comparative Testing• Co-validation• Revalidation• Transfer Waiver | Promotes a science- and risk-based approach. Emphasizes testing homogeneous lots of material and using pre-defined acceptance criteria [20]. |

| FDA Guidance for Industry: Analytical Procedures and Methods Validation (2015) [10] [20] | Part of a broader guidance on method development, validation, and lifecycle management. | • Comparative studies to evaluate accuracy, precision, and inter-laboratory variability. | For stability-indicating methods, recommends both labs analyze forced degradation samples or samples with product-related impurities [20]. Focuses on integrated data to demonstrate reliability. |

| EMA Guideline on the Transfer of Analytical Methods (2014) [10] [20] | A dedicated guideline outlining expectations for method transfer protocols and execution. | • Protocol must define standards, samples, transport/storage conditions, and acceptance criteria. | Stresses that acceptance criteria must be consistent with method validation and align with ICH/VICH expectations. Highlights the need for a detailed, pre-approved protocol [20]. |

Deeper Dive into Regulatory Expectations

- USP <1224>: This chapter is not a binding regulatory requirement but is a highly influential and widely accepted standard. It outlines different transfer approaches, with comparative testing being the most common, where both labs analyze the same homogeneous samples and results are statistically compared [10] [4]. It encourages laboratories to select the transfer strategy based on risk assessment, method complexity, and the receiving lab's experience [10].

- FDA Guidance: The FDA's approach is integrated into its overall view of the method lifecycle. It emphasizes the assessment of inter-laboratory variability to ensure the method is robust across different environments. The FDA also pays close attention to the transfer of stability-indicating methods, expecting both laboratories to demonstrate that they can accurately detect and quantify impurities and degradation products [20].

- EMA Guideline: The EMA provides very specific directives on the content of the transfer protocol. It requires that the protocol explicitly details the materials, samples, and acceptance criteria to be used [20]. This underscores the EMA's focus on meticulous prior planning and comprehensive documentation to ensure the transfer is well-controlled and its outcomes are unambiguous.

Standardized Experimental Protocol for Method Transfer

A successful analytical method transfer follows a structured, multi-phase process from planning to closure. The workflow below illustrates the key stages and their logical sequence.

Phase I: Pre-Transfer Planning

The foundation of a successful transfer is laid during the planning phase. This involves forming a team with representatives from both the sending and receiving units, including analytical experts and quality assurance (QA) [4]. The sending laboratory must provide all method documentation, including the validation report, development data, and standard operating procedures (SOPs) [3]. A critical step is conducting a gap analysis and risk assessment to identify differences in equipment, reagents, analyst skills, and environmental conditions that could impact the method's performance [4] [3]. Mitigation strategies, such as additional training or equipment qualification, are planned at this stage.

Phase II: Protocol Development and Approval

A pre-approved, detailed protocol is the cornerstone of a compliant transfer [10] [4]. This document must include:

- Objective and Scope: Clear statement of the transfer's purpose and the methods involved.

- Responsibilities: Defined roles for both the sending and receiving laboratories [10].

- Experimental Design: The number of samples, replicates, and analysts to be used [20]. For example, one common approach is to have at least two analysts independently analyze three lots of product in triplicate [20].

- Acceptance Criteria: Pre-defined, statistically justified criteria for evaluating equivalence. These are often based on the method's validation data, particularly its reproducibility [3]. The table below provides examples of typical acceptance criteria for common tests.

| Test | Typical Acceptance Criteria |

|---|---|

| Identification | Positive (or negative) identification obtained at the receiving site [3]. |

| Assay | The absolute difference between the mean results from the two sites should not exceed 2-3% [3]. |

| Related Substances | Requirements for absolute difference depend on impurity level. For low levels, recovery criteria (e.g., 80-120%) for spiked impurities may be used [3]. |

| Dissolution | Absolute difference in mean results: NMT 10% at time points <85% dissolved; NMT 5% at time points >85% dissolved [3]. |

Phase III: Execution and Training

Before testing begins, analysts at the receiving lab must be thoroughly trained by experts from the transferring laboratory [4] [3]. This training should cover not only the procedural steps but also the "tacit knowledge," such as troubleshooting tips and an understanding of the method's critical parameters [3] [12]. All equipment must be qualified and calibrated. Both laboratories then execute the approved protocol, analyzing the same homogeneous and stable samples—often drawn from a centrally managed "method transfer kit" (MTK) to ensure consistency across multiple transfers [20].

Phase IV: Data Analysis and Reporting

Data from both laboratories are compiled and compared using the statistical methods specified in the protocol (e.g., t-tests, F-tests, equivalence testing) [10] [4]. The results are evaluated against the pre-defined acceptance criteria. Any deviations or out-of-specification (OOS) results must be thoroughly investigated [3]. All activities, data, and investigations are summarized in a final transfer report, which concludes whether the transfer was successful and qualifies the receiving lab to use the method [10].

Phase V: Project Close-Out

The process is finalized when the transfer report is approved by the Quality Assurance (QA) department [10] [4]. The receiving laboratory then implements the method by incorporating it into its local SOPs and begins using it for routine testing.

The Scientist's Toolkit: Essential Materials for Successful Transfer

The consistency and quality of materials used during transfer are crucial for obtaining comparable results. The following table details key reagent solutions and materials.

| Item / Solution | Critical Function & Justification |

|---|---|

| Method Transfer Kit (MTK) [20] | A centrally managed kit containing representative, homogeneous samples (e.g., drug product batches, impurity-spiked samples) for all transfers. Function: Eliminates sample-to-sample variability, allowing focus on inter-laboratory method performance. |

| Qualified Reference Standards [4] | Well-characterized standards with certified purity and concentration. Function: Serves as the benchmark for calibrating the method and ensuring the accuracy and traceability of all quantitative results. |

| System Suitability Test Solutions [21] [22] | A standardized solution or mixture used to verify that the chromatographic system (or other instrument) is performing adequately before sample analysis. Function: Ensures the integrity of the entire analytical system for the specific method on a given day. |

| Chromatographic Columns [10] | The specific type, make, and model of the HPLC or GC column as defined in the method. Function: Different columns have varying selectivity; using the specified column is critical for reproducing separation, resolution, and retention times. |

| Reagents & Solvents [10] | High-purity solvents and reagents of the specified grade. Function: Variations in reagent quality (e.g., HPLC-grade vs. technical grade) can introduce impurities, affect baseline noise, and alter method sensitivity and reproducibility. |

| 2-Pyrazoline, 4-ethyl-1-methyl-5-propyl- | 2-Pyrazoline, 4-ethyl-1-methyl-5-propyl-, CAS:14339-24-3, MF:C9H18N2, MW:154.25 g/mol |

| 1-Cyclopropyl-2-nitrobenzene | 1-Cyclopropyl-2-nitrobenzene | High Purity |

Common Challenges and Best Practices

Frequently Encountered Challenges

- Instrument Disparities: Differences in instrument brands, models, modules (e.g., gradient delay volume in HPLC), or calibration status are a leading cause of transfer failure [10] [22].

- Reagent and Column Variability: Different batches of reagents or different sources/grades of chromatographic columns can lead to variations in results [10].

- Analyst Proficiency: Differences in training, experience, and technique between analysts at different sites can impact the execution of the method [10] [3].

- Environmental Conditions: Factors like temperature and humidity, which may not be fully controlled, can influence analytical results [10].

Strategies for Success and Compliance

- Early and Robust Planning: Begin the process early, engage QA from the start, and develop a comprehensive, unambiguous transfer protocol [4].

- Effective Communication and Collaboration: Establish direct communication channels between subject matter experts at both labs. Regular meetings help resolve issues quickly and facilitate crucial knowledge transfer [3] [12].

- Leverage Method Transfer Kits (MTKs): Using MTKs with pre-defined protocols and long-term stable samples streamlines multiple transfers, reduces duplication of effort, and ensures consistency [20].

- Ensure Equipment Equivalency and Qualification: Before transfer, align instrument specifications as much as possible and verify that all equipment at the receiving lab is properly qualified and calibrated [4].

- Adopt a Lifecycle Approach: Follow the principles of the Analytical Procedure Lifecycle (APLC), as described in USP <1220>, which encourages building robustness into the method during development and monitoring its performance post-transfer to ensure it remains fit-for-purpose [23].

Navigating the regulatory landscape for analytical method transfer requires a deep understanding of the guidelines provided by USP <1224>, the FDA, and the EMA. While each guideline has its nuances, they collectively emphasize a science- and risk-based approach, grounded in rigorous planning, clear documentation, and statistical evidence of equivalence. By adhering to a structured protocol, utilizing standardized materials like MTKs, and fostering strong collaboration between laboratories, pharmaceutical companies and CROs can ensure successful, efficient, and compliant method transfers. This not only fulfills regulatory obligations but, more importantly, safeguards product quality and patient safety by ensuring the reliability of analytical data across global manufacturing and testing networks.

Executing a Successful Transfer: Approaches, Protocol, and Step-by-Step Roadmap

Choosing the Right Transfer Approach: Comparative Testing, Co-validation, Revalidation, and Waivers

In the highly regulated pharmaceutical and biopharmaceutical industries, the transfer of analytical methods between laboratories is a critical and mandated process. It ensures that a method, when performed at a receiving laboratory, yields equivalent results to those obtained at the transferring laboratory, thereby guaranteeing the consistency, quality, and safety of drug products [4]. A failed or poorly executed transfer can lead to significant delays in product releases, costly retesting, and regulatory non-compliance [4]. This guide provides a detailed comparison of the four primary analytical method transfer approaches—Comparative Testing, Co-validation, Revalidation, and Transfer Waivers—to help researchers, scientists, and drug development professionals select and implement the most appropriate strategy for their specific context.

Summary Table of Analytical Method Transfer Approaches

| Transfer Approach | Core Principle | When to Use | Key Advantages | Key Challenges & Considerations |

|---|---|---|---|---|

| Comparative Testing [3] [4] [24] | Both labs analyze identical samples; results are statistically compared. | Well-established, validated methods; similar lab capabilities [3]. | Industry-standard; direct demonstration of equivalence; widely accepted by regulators [4]. | Requires careful sample homogeneity and handling; relies on robust statistical analysis [4]. |

| Co-validation [3] [25] [5] | Method is validated simultaneously by both transferring and receiving labs. | New methods or methods developed for multi-site use from the outset [3] [4]. | Highly efficient for qualifying multiple sites at once; builds reproducibility into validation [25] [5]. | Requires close collaboration and harmonized protocols; can be complex to manage [4]. |

| Revalidation [3] [4] [24] | Receiving lab performs a full or partial revalidation of the method. | Original lab unavailable; significant differences in equipment or conditions; method not originally ICH-compliant [3] [4]. | Most rigorous; qualifies the method independently at the new site; solves problem of unavailable originator [24]. | Most resource and time-intensive approach [4] [24]. |

| Transfer Waiver [3] [4] [5] | Formal transfer process is waived based on strong justification. | Receiving lab highly experienced with the method; compendial (e.g., USP) methods; only minor changes [3] [5]. | Saves significant time and resources; streamlines implementation [4]. | Rare; requires robust scientific and risk-based justification; subject to high regulatory scrutiny [4]. |

Experimental Protocols for Method Transfer

A successful transfer is built on a foundation of meticulous planning, execution, and documentation. The following workflow outlines the universal stages of a method transfer project, which should be tailored based on the selected approach.

Pre-Transfer Planning and Risk Assessment

Before a protocol is written, foundational activities are critical for success.

- Define Scope and Teams: Clearly articulate the method(s) being transferred and the objectives for success. Form cross-functional teams with designated leads from both the sending and receiving labs, including representatives from Analytical Development, QA/QC, and Operations [4].

- Gather Documentation: The sending unit must provide all relevant data, including the method description, validation report, development reports, and information on reference standards and reagents. Any prior risk assessments or "tacit knowledge" about the method should also be shared [3] [4].

- Perform Gap and Risk Analysis: Compare equipment, software, environmental conditions, and personnel expertise between the two labs [4]. The EU GMP guideline requires a gap analysis of the original validation to identify any need for supplementary work before transfer [3]. A risk assessment should identify potential challenges (e.g., method complexity, unique equipment) [4].

Developing the Transfer Protocol

The transfer protocol is the cornerstone document, typically written by the transferring laboratory but often drafted by the receiving unit [3]. It must be approved before execution and contain, at a minimum:

- Objective and Scope: A clear statement of the transfer's purpose [3].

- Responsibilities: Defined roles and requirements for both laboratories [3].

- Analytical Procedure: The detailed, step-by-step method to be used [3] [4].

- Experimental Design: The number of samples, batches, and replicates to be tested [3] [26].

- Acceptance Criteria: Pre-defined, statistically justified criteria for demonstrating equivalence [3] [4]. These are often based on the method's validation data and ICH requirements [3].

Key Experiments and Acceptance Criteria

The specific experiments run depend on the transfer approach and the method's purpose. For a standard comparative transfer of a quantitative method, the following are typical:

- Assay and Impurity Testing: A predetermined number of samples (e.g., a homogeneous lot from a production batch or spiked samples) are analyzed by both laboratories [3]. The results are compared using statistical tests (e.g., t-tests, F-tests, equivalence testing) [4].

- Typical Acceptance Criteria:

- Identification: Positive/negative identification must be obtained [3].

- Assay: The absolute difference between the sites' mean results is typically ≤ 2-3% [3].

- Related Substances: Criteria may vary by impurity level. For low-level impurities, recovery of 80-120% for spiked impurities is common. For higher levels (e.g., >0.5%), a absolute difference criterion is used [3].

- Dissolution: The absolute difference in mean results is typically ≤ 10% at time points when <85% is dissolved, and ≤ 5% when >85% is dissolved [3].

- Typical Acceptance Criteria:

- Precision (Repeatability and Intermediate Precision): The receiving laboratory performs replication experiments to assess the method's precision under normal operating conditions. This often involves a minimum of 20 replicate determinations on at least two levels of control materials [27] [26].

- Typical Acceptance Criteria: The calculated relative standard deviation (RSD or CV) is compared to pre-defined limits, often derived from the validation data or based on allowable total error (e.g., CV < 1/4 ATE) [26].

The Scientist's Toolkit: Essential Research Reagent Solutions

The reliability of a method transfer is dependent on the quality and consistency of the materials used. The following table details key reagent solutions and their critical functions in the process.

Essential Materials for Analytical Method Transfer

| Item | Function in Method Transfer | Critical Considerations |

|---|---|---|

| Reference Standards [4] | Serves as the primary benchmark for quantifying the analyte of interest and confirming method performance. | Must be of qualified purity and traceable to a recognized standard body. Stability and proper storage conditions are vital [4]. |

| Critical Reagents [28] | Specific reagents essential for method function (e.g., antibodies for ligand-binding assays, enzymes, specialized solvents). | Different lots of critical reagents can significantly impact results, especially in biological assays. Using the same lot at both sites is ideal, or multiple lots should be evaluated for robustness [28]. |

| Spiked Samples [3] [25] | Artificially created samples with a known amount of impurity or analyte added, used to demonstrate accuracy and specificity. | Crucial for impurity testing (e.g., in Size-Exclusion Chromatography). The spiking material must be representative and stable [3] [25]. |

| Homogeneous Sample Lots [4] | A single, uniform batch of material (e.g., drug substance or product) aliquoted and sent to both laboratories for comparative testing. | Ensures that any differences in results are due to laboratory performance, not sample variability. Sample homogeneity is a prerequisite for a valid comparison [4]. |

| System Suitability Solutions [3] | A preparation used to verify that the chromatographic or analytical system is performing adequately at the time of the test. | The transfer protocol must specify system suitability criteria (e.g., peak retention, resolution, tailing factor) that must be met before transfer data can be considered valid [3]. |

| 2,6,6-Trimethylcyclohexa-2,4-dienone | 2,6,6-Trimethylcyclohexa-2,4-dienone|CAS 13487-30-4 | High-purity 2,6,6-Trimethylcyclohexa-2,4-dienone (C9H12O) for organic synthesis research. A valuable dienone intermediate. For Research Use Only. Not for human or veterinary use. |

| Hexaboron dizinc undecaoxide | Hexaboron Dizinc Undecaoxide | High Purity | RUO | High-purity Hexaboron Dizinc Undecaoxide for materials science research. For Research Use Only. Not for human or veterinary use. |

Selecting the right transfer approach is not a one-size-fits-all decision but a strategic choice based on method status, laboratory capabilities, and regulatory requirements. Comparative testing remains the benchmark for transferring established methods, while co-validation offers an efficient path for new, multi-site methods. Revalidation is a powerful but resource-intensive solution for high-risk scenarios or unavailable originating labs, and the transfer waiver can streamline the process when justified by strong data and prior experience. By following a structured protocol that emphasizes rigorous planning, clear communication, and robust experimentation, laboratories can navigate the complexities of method transfer with confidence, ensuring data integrity and regulatory success throughout the product lifecycle.

Analytical method transfer is a critical, documented process in the pharmaceutical and biotechnology industries that qualifies a laboratory (the Receiving Unit or RU) to use an analytical testing procedure that originated in another laboratory (the Transferring Unit or TU) [29]. This process ensures that the Receiving Unit possesses the necessary procedural knowledge and ability to perform the transferred analytical procedure as intended, thereby guaranteeing that the method's performance remains consistent and reliable across different locations [30] [31]. The ultimate goal is to demonstrate that the RU can execute the method with equivalent accuracy, precision, and reliability as the TU, producing comparable results that ensure consistent product quality and patient safety [4].

A robust transfer protocol serves as the foundation for this entire process, providing a structured framework that defines objectives, delineates responsibilities, and establishes scientifically sound acceptance criteria. Without a well-crafted protocol, laboratories risk significant issues including delayed product releases, costly retesting, regulatory non-compliance, and ultimately, a loss of confidence in data integrity [4]. The protocol transforms the transfer from a mere administrative exercise into a scientifically rigorous demonstration of methodological consistency between laboratories.

Defining Clear Objectives and Scope

The initial and perhaps most crucial step in crafting a transfer protocol is to define clear, unambiguous objectives and scope. This foundational element sets the direction for the entire transfer process and ensures all stakeholders share a common understanding of what constitutes a successful transfer.

Core Objectives

The primary objective of any analytical method transfer is to generate documented evidence that the Receiving Laboratory is qualified to perform the analytical method and can generate data that is equivalent to that produced by the Transferring Laboratory [7]. This overarching goal can be broken down into several specific objectives:

- Demonstrate Equivalence: Prove that the method performs at the Receiving Unit with equivalent accuracy, precision, and reliability as demonstrated at the Transferring Unit [4].

- Ensure Regulatory Compliance: Provide documented evidence that satisfies regulatory requirements, showing the receiving lab is fully qualified to use the method for GMP reportable data [7].

- Facilitate Knowledge Transfer: Ensure all tacit knowledge, troubleshooting tips, and methodological nuances are effectively communicated from the TU to the RU [3].

- Establish Operational Readiness: Verify that the RU has the appropriate equipment, trained personnel, and necessary reagents to implement the method for routine use [31].

Scope Definition

A well-defined scope establishes the boundaries of the transfer activity and should clearly specify [29]:

- Methods Covered: List all analytical methods included in the transfer (e.g., HPLC assay, related substances, dissolution).

- Products and Materials: Identify the specific drug substances, intermediates, finished products, or raw materials to which the methods apply.

- Laboratories Involved: Name the specific Transferring and Receiving Units, including their locations.

- Applicable Techniques: Define the analytical techniques covered (e.g., HPLC, GC, UV, microbiological assays).

- Exclusions: Justify any methods excluded from transfer, such as general procedures lacking specialized techniques (e.g., pH, Loss on Drying) [29].

Key Components of a Transfer Protocol

A comprehensive transfer protocol serves as the master plan that guides all transfer activities. It must be pre-approved before any transfer activities commence and should contain specific sections that address critical aspects of the transfer process.

Responsibilities of Transferring and Receiving Units

Clear delineation of responsibilities is essential for accountability and smooth execution. The table below outlines typical responsibilities for both units involved in the transfer:

Table 1: Responsibilities of Transferring and Receiving Units

| Transferring Unit (TU) Responsibilities | Receiving Unit (RU) Responsibilities |

|---|---|

| Provide comprehensive method documentation and validation reports [31] [6] | Review methodology and acceptance criteria prior to protocol approval [31] [6] |

| Define experimental design, sampling methods, and acceptance criteria [6] | Ensure availability of qualified equipment and trained personnel [31] [6] |

| Supply necessary reference standards, reagents, and columns [29] | Execute the transfer protocol according to the approved design [6] |

| Provide method-specific training for RU analysts [31] [6] | Perform appropriate validation to support method implementation [6] |

| Assist in analysis and interpretation of QC testing results [6] | Maintain documentation system for recording data and results [6] |

| Participate in transfer study and collaborate with RU [31] | Generate and obtain approval of final transfer reports [6] |

| Review and approve transfer protocol and final report [31] | Communicate issues or concerns to TU during the transfer process [31] |

Experimental Design and Acceptance Criteria

The protocol must detail the experimental design, including the number of batches, analysts, replicates, and the specific tests to be performed. Similarly, predefined acceptance criteria are fundamental for objectively judging the success of the transfer.

Table 2: Typical Experimental Design and Acceptance Criteria for Common Tests

| Test Type | Experimental Design | Acceptance Criteria |

|---|---|---|

| Assay | 2 analysts × 3 test samples in triplicate using different instruments/columns/independent preparation [6] | Absolute difference between sites: 2-3% [3] [6] |

| Related Substances/Impurities | 2 analysts × 3 test samples in triplicate using different instruments/columns; spiked samples for recovery [6] | Difference < 25.0% for variability; %RSD of replicates < 5.0%; Recovery 80-120% for spiked impurities [3] [6] |

| Dissolution | Testing of multiple units from the same batch by both laboratories [3] | Absolute difference in mean results: ≤10% when <85% dissolved; ≤5% when >85% dissolved [3] |

| Cleaning Validation | 2 analysts × 3 test samples in triplicate using samples spiked at different concentration levels [6] | All samples spiked above specified limit must fail; all samples below specified limit must pass [6] |

| Identification | Comparison of identification results between laboratories [3] | Positive (or negative) identification obtained at receiving site matching transferring site [3] |

Method Transfer Approaches

The protocol should specify which transfer approach will be used based on the method's complexity, validated status, and the experience of the receiving laboratory. The most common approaches include:

- Comparative Testing: This is the most frequently used approach, where both laboratories analyze the same set of samples (e.g., from the same lots) and compare results against predefined acceptance criteria [31] [3] [4]. It is particularly suitable for well-established, validated methods when both labs have similar capabilities.

- Co-validation: In this approach, the receiving laboratory participates in the validation studies, particularly the intermediate precision study that assesses method reproducibility [31] [3]. This strategy is beneficial when methods are transferred before formal validation is complete or when developing methods specifically for multi-site use [30] [4].

- Revalidation: The receiving laboratory performs a full or partial revalidation of the method, repeating some or all validation experiments [31] [3] [7]. This resource-intensive approach is typically used when significant differences exist in lab conditions, equipment, or when the original validation was insufficient [4].