Correcting Baseline Drift in UV-Vis Spectroscopy: A Complete Guide for Robust Pharmaceutical Analysis

This article provides a comprehensive guide for researchers and drug development professionals on addressing baseline drift in UV-Vis spectroscopy.

Correcting Baseline Drift in UV-Vis Spectroscopy: A Complete Guide for Robust Pharmaceutical Analysis

Abstract

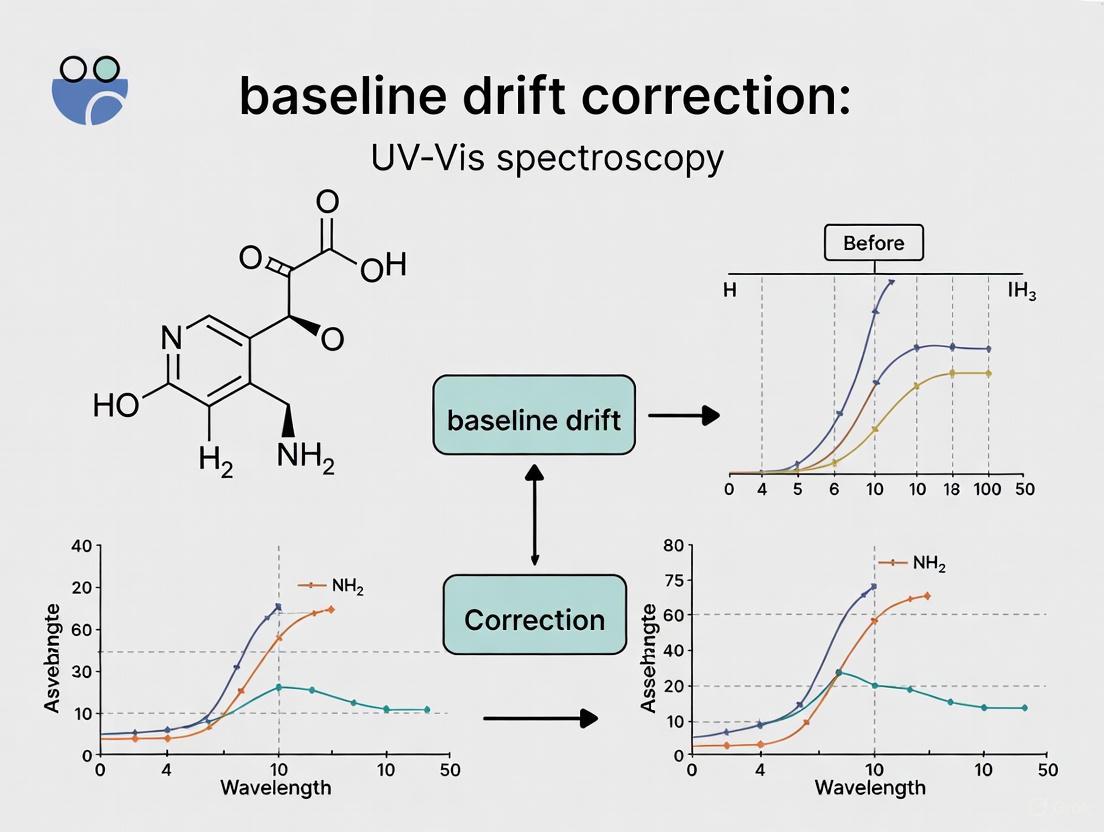

This article provides a comprehensive guide for researchers and drug development professionals on addressing baseline drift in UV-Vis spectroscopy. Covering foundational principles to advanced applications, it details the root causes of drift—from mobile phase effects and temperature fluctuations to instrumental artifacts. The scope includes practical methodologies for baseline correction, targeted troubleshooting protocols for common HPLC and spectrophotometry issues, and validation strategies ensuring data integrity compliant with modern regulatory standards. By integrating traditional techniques with emerging machine learning approaches, this resource aims to enhance measurement accuracy and reliability in biomedical research and quality control.

Understanding Baseline Drift: Root Causes and Impact on Data Integrity

Defining Baseline Drift and Its Effect on Quantitative Analysis

Definition and Importance of Baseline Stability

In the context of UV-Vis spectroscopy and chromatography, baseline drift is defined as a slow, long-term change in the detector's baseline signal, often appearing as a curved or sloping line rather than a stable, flat one [1]. It is classified as a type of long-term noise that can significantly impact the accuracy and reliability of quantitative measurements [1] [2].

A stable baseline is fundamental for precise quantitative analysis. The baseline represents the detector's signal when only the mobile phase or solvent is eluting or being measured. It serves as the fundamental reference point from which all analyte-derived signals are measured [3]. When this baseline drifts, it introduces errors in the determination of critical parameters such as peak height and peak area [1]. These inaccuracies directly affect the calculation of analyte concentration, potentially leading to incorrect conclusions in research, quality control, and drug development.

Primary Causes of Baseline Drift

Baseline drift can originate from a variety of instrumental, chemical, and environmental factors. The table below summarizes the most common causes.

Table: Common Causes of Baseline Drift and Their Origins

| Cause Category | Specific Examples |

|---|---|

| Instrumental Factors | Fluctuations in lamp intensity, detector sensitivity degradation, dirty flow cells, trapped air bubbles in the detector, sticky pump check valves, inconsistent mobile phase composition due to pump problems [4] [3] [5]. |

| Mobile Phase & Solvent Effects | Mobile phase impurities that are highly retained on the column, solvent programming (gradient elution) where solvents have different UV absorbances, inadequate degassing, inconsistent solvent mixing, changes in refractive index [3] [6]. |

| Environmental Influences | Temperature fluctuations in the laboratory, changes in humidity, external vibrations [4] [3]. |

| Sample & Column Issues | Column stationary phase bleed or degradation, contaminants from the sample matrix (e.g., impurities, bubbles, scattering particles), inadequate column equilibration [4] [5] [6]. |

Detailed Look at Chemical Causes

In liquid chromatography, mobile phase issues are a frequent source of baseline anomalies [3]. These can be categorized as follows:

- Accumulating Impurities: Impurities in the mobile phase solvents or additives can accumulate on the head of the column during the initial isocratic conditions or the early part of a gradient. They are then eluted as a broad peak or a drift later in the run, often during a column wash with a strong solvent [3].

- UV-Absorbing Solvents: During gradient elution in HPLC or flash chromatography, a rising or falling baseline is often simply due to the different UV absorbance properties of the two solvents. For example, in a reversed-phase water-acetonitrile gradient, or a normal-phase hexanes-ethyl acetate gradient, the baseline profile reflects the changing composition of these solvents as one absorbs more UV light than the other [6].

- Ghost Peaks: Impurities with physicochemical properties similar to the analytes can manifest as "ghost peaks" in the chromatogram, even when no sample is injected, complicating integration and identification [3].

Impact on Quantitative Analysis

Baseline drift directly compromises the integrity of quantitative data. The consequences are most acutely observed during the peak integration process, where the accurate demarcation of a peak's start and end points is critical.

Diagram: The Impact of Baseline Drift on Quantitative Results

The specific quantitative errors introduced by baseline drift include:

- Inaccurate Peak Area and Height: These are the fundamental parameters for quantification. A drifting baseline causes the reported values for peak area and height to be either greater or smaller than the true values, depending on the direction of the drift [1] [2].

- Incorrect Peak Integration: The integration software may incorrectly set the start and end points of a peak against a sloping baseline, leading to either the inclusion of extra area that is not part of the peak or the exclusion of part of the true peak area [5].

- Reduced Sensitivity and Signal-to-Noise Ratio: A high or drifting baseline can mask small analyte peaks, reducing the effective sensitivity of the method and impacting the detection and quantification of low-concentration analytes [5].

- Concentration Calculation Errors: Since concentration is directly proportional to peak area or height, any error in these primary measurements translates directly into an error in the reported concentration [7]. An uncorrected baseline drift can lead to concentration inaccuracies of 20% or more [7].

Troubleshooting and Correction Methodologies

Proactive Prevention and Instrument Maintenance

Preventing baseline drift begins with proper instrument care and setup.

- Regular Calibration and Maintenance: Perform regular calibration using standard reference materials. Conduct routine maintenance, including cleaning optical components and checking lamp alignment [4].

- Environmental Control: Ensure the instrument is housed in a stable environment with controlled temperature and humidity, and protected from vibrations [4].

- Mobile Phase Management: Use high-purity solvents appropriate for your application (e.g., HPLC or LC-MS grade). Degas all mobile phases thoroughly before use. For gradient methods where possible, add the same concentration of UV-absorbing additives (e.g., formic acid) to both solvents to maintain a constant background absorbance [3] [5].

- Proper Column Care: Equilibrate the column thoroughly with the initial mobile phase (at least 2 column volumes) before starting a run. Condition new columns according to the manufacturer's instructions and clean used columns regularly to remove accumulated contaminants [5] [6].

Correction Techniques and Algorithms

When baseline drift occurs, several computational and mathematical techniques can be applied to correct the data.

Table: Common Baseline Correction Techniques

| Technique | Principle | Best For |

|---|---|---|

| Blank Subtraction | A blank sample (mobile phase only) is run and its signal is subtracted from the sample chromatogram [2] [5]. | Simple, consistent baseline offsets. Less ideal for 2D data with run-to-run misalignment [1]. |

| Polynomial Fitting | A polynomial function (linear or higher-order) is fitted to the baseline regions of the chromatogram and then subtracted from the entire signal [8] [2]. | Modeling more complex, curved baseline shapes. |

| Reference Wavelength | In UV detection, a wavelength is selected where the analyte does not absorb. The signal at this reference wavelength is used to correct for drift at the analytical wavelength [7] [2] [5]. | UV-Vis spectroscopy and HPLC-UV methods with a suitable reference wavelength. |

| Wavelet Transform | The signal is processed to separate high-frequency (noise), middle-frequency (peaks), and low-frequency (baseline) components. The baseline is reconstructed and subtracted [1]. | Complex chromatograms with severe, non-linear drift. |

| Automatic Software Correction | Modern instruments often have built-in algorithms (e.g., "rolling ball") that automatically detect and correct baseline drift in real-time or during data processing [4] [6]. | All users, especially for routine analysis. |

Experimental Protocol: Establishing a Baseline Correction Wavelength

For custom methods in UV-Vis spectroscopy, the optimal baseline correction wavelength must be determined empirically. The following protocol, adapted from DeNovix technical documentation, provides a detailed methodology [7]:

- Instrument Preparation: Ensure both the top and bottom measurement surfaces of the instrument are clean.

- Disable Baseline Correction: Launch the UV-Vis application and access the settings to deselect any existing baseline correction (set it to 'None').

- Measure the Blank:

- Pipette 1 µL of the pure solvent (e.g., dH₂O) onto the measurement surface.

- Take a measurement and remove the solvent with a dry lab wipe.

- Pipette a fresh 1 µL aliquot of the pure solvent and measure again. The resulting spectrum should be a relatively flat line along the baseline. If significant absorbance is observed in any region, clean the surfaces and repeat this step.

- Measure the Sample Buffer:

- Pipette 1 µL of the sample buffer (the solvent your analyte is dissolved in) onto the surface and measure it.

- Examine the spectrum to ensure the buffer does not have significant absorbance at the wavelength you intend to use for correction (e.g., 340 nm or 750 nm).

- Measure the Sample:

- Pipette 1 µL of your sample onto the surface and measure it.

- Confirm that the sample itself does not have significant absorbance at the intended correction wavelength.

- Select Wavelength: Based on the results, select a wavelength for baseline correction. A general recommendation is 340 nm for UV-only ranges (190–350 nm) and 750 nm for methods using ranges that extend into the visible spectrum [7].

The workflow for this systematic approach is outlined below.

Diagram: Workflow for Establishing a Baseline Correction Wavelength

Frequently Asked Questions (FAQs)

Q1: My UV baseline rises steadily during a gradient run. Is this normal? Yes, this is a very common occurrence. It is typically caused by the different UV absorbance properties of the two solvents used in the gradient. For example, in a reversed-phase water-acetonitrile gradient, acetonitrile may absorb more UV at low wavelengths than water, causing the baseline to rise as the proportion of acetonitrile increases. Solutions include using a baseline correction feature on your instrument, adding the same UV-absorbing additive to both solvents, or selecting a detection wavelength where both solvents are relatively transparent [3] [6].

Q2: Can a dirty spectrophotometer flow cell cause baseline drift? Absolutely. Contamination or air bubbles trapped in the detector's flow cell are a common physical cause of baseline noise and drift. Regular cleaning and maintenance of the flow cell according to the manufacturer's instructions are essential for stable performance [5] [9].

Q3: How does improper column equilibration lead to baseline drift? In both normal-phase and reversed-phase chromatography, the stationary phase must be fully equilibrated with the initial mobile phase composition before the analytical run begins. Inadequate equilibration (using less than the recommended volume of solvent) means the column is not in a stable state, leading to a drifting baseline as it slowly equilibrates during the run. Always ensure equilibration with at least 2 column volumes of the initial mobile phase [6].

Q4: What is the simplest way to correct for baseline drift after data acquisition? The simplest and most common method is blank subtraction. This involves running a "blank" sample that contains only the mobile phase or solvent, then subtracting that blank chromatogram from your sample chromatograms. Many software packages also offer automated polynomial fitting or smoothing functions for this purpose [1] [2].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table: Key Materials for Managing Baseline Drift

| Item | Function in Managing Baseline Drift |

|---|---|

| HPLC/LC-MS Grade Solvents | High-purity solvents minimize UV-absorbing impurities that contribute to a high or drifting baseline and "ghost peaks" [3]. |

| UV-Transparent Additives | Using additives like phosphates (instead of formate/acetate) for low-wavelength UV detection can reduce the background absorbance and baseline shift during gradients [3]. |

| Matched Cuvettes | In UV-Vis spectroscopy, using a pair of cuvettes with identical optical properties for the sample and reference beams ensures a stable baseline [4]. |

| Degassing System | A system for degassing solvents (e.g., sparging with helium, sonication, or online degassing) removes dissolved air, which can cause bubbles and baseline instability in the detector [5]. |

| Standard Reference Materials | Used for regular instrument calibration to ensure detector response is accurate and stable, helping to identify and correct for systematic drift [4]. |

| Column Cleaning Solvents | A series of strong solvents (e.g., methanol, acetonitrile, acetone) is used to clean reversed-phase columns and remove accumulated contaminants that can cause baseline drift and ghost peaks [6]. |

Frequently Asked Questions

Q1: Why does my UV-Vis baseline rise or fall during a gradient method? The most common reason is that the solvents used in your mobile phase absorb UV light at different wavelengths [6]. During a gradient run, the proportion of each solvent changes, which alters the overall absorbance of the mobile phase itself, causing the baseline to drift [3]. This is especially pronounced when detecting at low wavelengths (e.g., below 230 nm) where many common solvents and additives have significant UV absorbance [10].

Q2: What other factors related to the mobile phase can cause a noisy or unstable baseline?

- Impurities: Chemical impurities in solvents or additives can accumulate on the column and then elute, causing broad peaks or a shifting baseline [3].

- Inadequate Equilibration: If the chromatography column is not fully equilibrated with the starting mobile phase, it can lead to baseline instability at the beginning of a run [6].

- Pump Problems: Inconsistent flow from one pump channel in a binary system can cause fluctuations in mobile phase composition, leading to a saw-tooth pattern in the baseline [3].

Q3: How can I reduce baseline drift caused by solvent absorbance?

- Use a Higher Wavelength: If your analytes still absorb light, select a detection wavelength above the UV "cut-off" of your solvents where they are largely transparent [6] [10].

- Match Additive Concentration: Ensure that any UV-absorbing buffer or modifier is present at the same concentration in both the A and B solvents of your gradient. This keeps the absorbance constant throughout the run [3].

- Employ Baseline Correction: Use your instrument's software capability to correct for the solvent's UV absorption in real-time, if available [6].

Troubleshooting Guide: Baseline Anomalies

| Problem Symptom | Likely Cause | Corrective Action |

|---|---|---|

| Smooth but steady rise or drop during gradient | Differential UV absorbance of mobile phase solvents [6]. | • Match buffer/additive in both solvents [3].• Use higher detection wavelength [6] [10].• Use instrument baseline correction [6]. |

| Saw-tooth or erratic baseline | Inconsistent pump delivery; faulty check valve or trapped air bubble [3]. | • Purge pump lines.• Inspect and clean/replace check valves.• Ensure mobile phases are degassed [3]. |

| Broad, large peak at end of gradient | Elution of retained impurities from solvents or samples accumulated on-column [3]. | • Use higher purity (e.g., HPLC-grade) solvents.• Incorporate a stronger column wash step post-run.• Replace used column if contaminated [6] [3]. |

| High baseline noise at low wavelengths | High absorbance from mobile phase components (e.g., solvents, salts, pH modifiers) near their UV cut-off [10]. | • Use solvents with low UV cut-off (e.g., HPLC-grade methanol, acetonitrile).• Use volatile buffers like ammonium formate/acetate at low concentrations [10].• Ensure mobile phase is free of particles and bubbles [4]. |

| Sudden shift in baseline level | Mobile phase contamination, air bubble in detector flow cell, or change in solvent batch [3] [11]. | • Prepare fresh mobile phase.• Purge detector flow cell.• Document solvent lot numbers. |

Experimental Protocol: Investigating Mobile Phase-Induced Baseline Drift

This protocol helps you systematically diagnose and resolve baseline drift originating from mobile phase disparities.

1. Objective To isolate the contribution of the mobile phase to UV-Vis baseline drift and identify an appropriate correction strategy.

2. Materials and Equipment

- HPLC or UHPLC system with UV-Vis detector

- Solvent delivery system capable of generating gradients

- Data collection software

- HPLC-grade water and solvents (e.g., acetonitrile, methanol)

- Buffers or additives (e.g., formic acid, ammonium acetate)

- A blank column (a column packed with inert material) or a restrictor capillary

3. Procedure

Step 1: Establish Initial Conditions

- Install a blank column or capillary to remove the variable of the analytical column.

- Set the detector to the wavelength of interest for your method.

- Set the flow rate to a standard value (e.g., 1.0 mL/min).

Step 2: Run a Blank Gradient

- Solvent A: Your aqueous phase (e.g., water with 0.1% formic acid).

- Solvent B: Your organic phase (e.g., acetonitrile with 0.1% formic acid).

- Program a linear gradient that mirrors your analytical method (e.g., 5% B to 95% B over 20 minutes).

- Inject a small volume of pure solvent (or perform a blank injection) and start the run, recording the baseline.

Step 3: Analyze the Baseline Profile

- Observe the shape and magnitude of the baseline drift.

- A smooth, reproducible curve confirms the drift is due to the differential absorbance of Solvent A and Solvent B [3].

Step 4: Implement and Test Solutions

- Test A: Wavelength Selection. Repeat the blank gradient at a higher wavelength (e.g., 254 nm). The baseline drift should be significantly reduced if the solvents do not absorb strongly at this wavelength [10].

- Test B: Additive Balancing. Repeat the blank gradient, but now prepare Solvent B (acetonitrile) with the same concentration of formic acid as Solvent A. The baseline should be markedly flatter because the concentration of the UV-absorbing additive remains constant [3].

- Test C: Solvent Purity. If you suspect impurities, repeat the test with a new batch of high-purity solvents from a different supplier [3].

4. Data Interpretation Compare the baseline profiles from each test run. The most effective corrective action is the one that produces the flatest, most stable baseline while maintaining sufficient detection sensitivity for your analytes.

The following workflow summarizes the systematic troubleshooting process for mobile phase-induced baseline issues:

Research Reagent Solutions

The following table details key reagents and materials essential for managing mobile phase-related baseline issues.

| Item | Function & Rationale |

|---|---|

| HPLC-Grade Solvents | High-purity solvents minimize UV-absorbing impurities that contribute to baseline noise and ghost peaks [3]. |

| Volatile Buffers (e.g., Ammonium Formate, Ammonium Acetate) | These MS-compatible buffers often have lower UV cut-offs than phosphate, allowing for more sensitive low-wavelength detection [10]. |

| UV-Cutoff Guide | A reference table for solvent UV transparency is critical for selecting a detection wavelength that minimizes mobile phase absorbance [10]. |

| In-Line Degasser | Removes dissolved air from solvents to prevent bubble formation in the detector, which causes sudden, sharp baseline spikes [3]. |

| Blank Column / Restrictor | A column without stationary phase used specifically for diagnosing baseline problems originating from the mobile phase or pump, not the column itself [3]. |

| Certified Cuvettes/Cells | Quartz cuvettes for standalone UV-Vis or HPLC flow cells that are clean and free of scratches ensure that signal artifacts are not introduced by the sample holder [11] [12]. |

Troubleshooting Guides

Troubleshooting Guide 1: Resolving Baseline Drift

Problem: The instrument's baseline shows a steady upward or downward shift over time, leading to inaccurate absorbance readings [4].

| Symptom | Most Likely Cause | Immediate Corrective Action | Preventive Measures |

|---|---|---|---|

| Gradual baseline increase during a long session | Instrumental drift from lamp warming or detector instability [13] [4] | Allow sufficient instrument warm-up time (typically 30 minutes); perform baseline correction [14] [4] | Establish regular lamp replacement schedule; maintain stable power supply |

| Sudden baseline shifts or noise | Environmental fluctuations (temperature, humidity, vibrations) [4] | Check lab environment for drafts or equipment causing vibrations; recalibrate | Place instrument in temperature-controlled, low-vibration location [4] |

| Erratic baseline, particularly in UV range | Deuterium lamp aging or failure [14] | Check lamp hours; replace if exceeds manufacturer's lifetime | Keep a log of lamp usage hours; monitor performance regularly |

Troubleshooting Guide 2: Temperature-Related Inaccuracies

Problem: Temperature variations cause discrepancies in absorbance readings and sample stability [13].

| Symptom | Most Likely Cause | Immediate Corrective Action | Preventive Measures |

|---|---|---|---|

| Inconsistent results between replicates | Lack of temperature equilibration; samples measured at different temperatures [13] | Let all samples and solvents equilibrate to room temperature before measurement [13] | Use a thermostatic cell holder for temperature-sensitive assays [13] |

| Changing absorbance values over time in kinetic studies | Sample heating from the instrument's light source | Use a thermostatted cuvette holder; shield sample from source light | For precise work, use a spectrometer with a built-in Peltier temperature controller |

| Shift in absorption maxima | Temperature-dependent spectral changes in the analyte | Record and control temperature for all quantitative measurements | Document temperature conditions for all experiments for reproducibility |

Troubleshooting Guide 3: Lamp Stability Issues

Problem: The spectrophotometer's light source is unstable, causing poor signal-to-noise ratio and unreliable data [14].

| Symptom | Most Likely Cause | Immediate Corrective Action | Preventive Measures |

|---|---|---|---|

| Low light intensity or signal error alerts | Aging lamp nearing end of its usable life [14] | Check and replace lamp if necessary [14] | Keep a spare lamp; track usage hours in a logbook |

| Noise across all wavelengths | Unstable lamp output or electrical issues | Ensure instrument has warmed up for at least 30 minutes; check connections | Perform regular performance validation with stable standards |

| Unusual peaks or dips in the baseline | Contamination of lamp housing window | Inspect and clean the exterior of the lamp housing according to manual | Maintain a clean instrument environment; avoid touching lamp with bare hands |

Troubleshooting Guide 4: Cuvette Quality Defects

Problem: Imperfections in cuvettes lead to light scattering and path length inaccuracies [13].

| Symptom | Most Likely Cause | Immediate Corrective Action | Preventive Measures |

|---|---|---|---|

| High or noisy baseline, particularly at shorter wavelengths | Scratched, cracked, or dirty cuvettes causing light scatter [13] | Thoroughly clean cuvettes with appropriate solvent; inspect for damage; replace if scratched [13] | Use lint-free cloth for cleaning; store cuvettes in protective cases |

| Inconsistent readings between identical samples | Cuvette mismatch or incorrect orientation | Use matched cuvettes; always place in holder with the same orientation | Mark cuvettes for consistent orientation; use a matched set for an experiment |

| Absorbance values inconsistent with expected results | Incorrect path length or use of non-standard cuvette [13] | Verify cuvette path length (typically 1 cm); account for it in Beer-Lambert calculations [13] | Use only standard 1 cm path length cuvettes for routine quantitative work |

Frequently Asked Questions (FAQs)

1. How does temperature directly affect my UV-Vis absorbance measurements? Temperature impacts the absorbance spectrum of a compound by influencing molecular interactions and the refractive index of the solution. A temperature shift can alter the measured absorbance value, even for the same sample concentration. For reproducible quantitative results, maintaining a constant temperature is critical [13].

2. What is the most reliable way to monitor the health of my spectrophotometer's lamp? The most reliable method is to regularly track the lamp's usage hours and perform routine performance checks using stable reference materials, such as potassium dichromate solutions. A steady decrease in light intensity output or an increase in noise, especially in the UV region for deuterium lamps, signals that replacement is due [13] [14].

3. Can I use the same quartz cuvette for both UV and visible measurements? Yes, quartz or fused silica cuvettes are transparent across both the UV and visible light ranges and are the standard for measurements across this full spectrum. Plastic and glass cuvettes are not suitable for UV measurements as they absorb UV light [12].

4. My blank solution shows absorbance. Is this normal? A properly prepared blank should have minimal absorbance in your wavelength range of interest. Significant blank absorbance indicates that the solvent or cuvette may be contaminated, or that you have selected a solvent that itself absorbs light at the measured wavelengths (e.g., some buffers). Always use a high-purity solvent for the blank that is transparent in your analytical range [13] [7].

5. How often should I perform a full baseline correction on my instrument? A baseline correction (or blank measurement) should be performed at the start of every measurement session, whenever the solvent is changed, and periodically during long series of measurements to correct for any instrument drift [15] [4].

Table 1: Impact of Cuvette Quality on Absorbance Readings

| Cuvette Condition | Impact on Baseline Noise | Estimated Error in Concentration | Recommended Action |

|---|---|---|---|

| Clean, scratch-free | < 0.001 AU | < 1% | Continue use |

| Minor surface scratches | 0.005 - 0.01 AU | 2-5% | Use for qualitative work only |

| Visible scratches or cracks | > 0.02 AU | 5-15% | Replace immediately [13] |

| Dirty or fingerprinted | 0.01 - 0.05 AU | 5-30% | Clean thoroughly with suitable solvent [13] |

Table 2: Temperature Effects on Analytical Performance

| Parameter | Typical Acceptable Range | Impact if Uncontrolled | Control Method |

|---|---|---|---|

| Sample Temperature | ±2 °C for most assays [15] | Altered absorption spectra; poor reproducibility | Thermostatic cell holder [13] |

| Laboratory Ambient Temperature | 20-25 °C (as per manufacturer spec) | Instrument drift, component performance shift | Climate-controlled lab [4] |

| Solution Temperature after refrigeration | Full equilibration to lab temp | Evaporation, condensation on cuvette, concentration change | Let samples equilibrate 30+ minutes [13] |

Experimental Protocols

Protocol 1: Systematic Baseline Validation and Correction

Purpose: To establish a stable instrument baseline and correct for inherent drift and background absorption [15] [4].

- Instrument Preparation: Turn on the spectrophotometer and allow it to warm up for at least 30 minutes to stabilize the light source and detector [14].

- Blank Selection: Prepare a blank cuvette containing only the pure solvent or buffer used to dissolve your samples [13] [12].

- Initial Baseline Scan: Place the blank in the sample compartment and run a baseline scan or "auto-zero" function across your entire analytical wavelength range.

- Baseline Assessment: Examine the recorded baseline. It should be flat and close to zero absorbance in the regions where your analyte does not absorb. A sloping or noisy baseline indicates a need for instrument maintenance or cleaning [4].

- Application of Correction: Apply this baseline correction to all subsequent sample measurements. The instrument software will subtract the blank spectrum from your sample spectrum.

- Periodic Re-validation: For long experiments, re-measure the blank every 30-60 minutes to correct for any instrument drift [15].

Protocol 2: Lamp Stability and Performance Test

Purpose: To objectively assess the condition of the spectrophotometer's light source.

- Reference Standard: Use a stable reference material, such as a sealed holmium oxide or didymium glass filter, or a standard solution of potassium dichromate [13].

- Baseline Scan: With an empty compartment or a clean blank, perform a baseline scan from 190 nm to 800 nm.

- Intensity Check: Observe the signal intensity in the software. Most modern instruments will flag a "low light" error if intensity is too low. Manually, high signal noise suggests lamp issues [14].

- Wavelength Accuracy: Scan the standard and note the peak positions. Compare them to the certified values. Shifts in peak maxima can indicate lamp or optical alignment problems.

- Documentation: Record the signal-to-noise ratio at a specific wavelength (e.g., 500 nm) and track it over time. A consistent decline indicates the lamp is nearing end-of-life.

Protocol 3: Cuvette Quality Inspection and Matching

Purpose: To identify and eliminate cuvette-based errors from light scattering and path length variation [13].

- Visual Inspection: Hold each cuvette up to light and visually inspect all four windows for scratches, cracks, or chips. Cuvettes with any visible defects should be discarded [13].

- Blank Measurement Fill: Fill the cuvette with the pure solvent you will use for your experiments.

- Spectrum Scan: Place the cuvette in the holder, ensuring a consistent orientation (e.g., always using the same two optical windows). Scan over your intended wavelength range.

- Absorbance Acceptance Criteria: The absorbance of the blank should be low and flat. For UV work below 300 nm, this is critical. A cuvette that shows significantly higher absorbance than others in the set should not be used for sensitive measurements.

- Cuvette Matching (for quantitative work): For a set of cuvettes to be used in a single experiment, the absorbance readings for the same blank solution should not vary by more than 0.005 AU.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Reliable UV-Vis Spectroscopy

| Item | Function | Key Considerations |

|---|---|---|

| High-Purity Solvents (HPLC-grade water, spectral-grade solvents) | To prepare sample blanks and solutions with minimal background absorbance [13] [7] | Ensure the solvent has low absorbance in your analytical range; e.g., avoid solvents with aromatic rings for UV analysis [13] |

| Standard Reference Materials (Potassium dichromate, holmium oxide filters) | For instrument calibration and performance validation [13] | Use certified standards; ensure proper preparation and storage of solutions |

| Matched Quartz Cuvettes (1 cm path length) | To hold liquid samples for analysis in UV and Vis ranges [12] | Inspect for scratches; clean meticulously; use a matched set for an experiment to ensure path length consistency [13] |

| Stable Light Source Lamps (Deuterium, Tungsten-Halogen) | To provide intense, broad-spectrum light for measurements [12] | Monitor usage hours; keep a spare lamp to minimize instrument downtime [14] |

| Lint-Free Wipes | For cleaning and drying cuvette exteriors without introducing scratches or fibers [13] | Never use paper towels on optical surfaces; can cause fine scratches |

Workflow and Relationship Diagrams

The Critical Role of Detection Wavelength in Drift Magnitude

A stable baseline is the foundation of reliable UV-Vis data; understanding the role of detection wavelength is the first step to achieving it.

The detection wavelength you select is a primary factor determining the magnitude and behavior of baseline drift in UV-Vis spectroscopy and HPLC-UV. This drift occurs because the mobile phase solvents and additives themselves absorb light, and this absorbance changes as the solvent composition shifts during a gradient run. The intensity of this effect is highly dependent on the wavelength at which you are detecting.

This guide will help you diagnose and correct for wavelength-dependent baseline drift.

Troubleshooting Guide: Wavelength-Related Baseline Issues

The table below summarizes common baseline problems, their visual characteristics, and their primary solutions.

| Problem Scenario | What You See | Likely Cause | Corrective Action |

|---|---|---|---|

| Rising Baseline in Gradients [3] [6] | A smooth, steady increase in baseline as the % of organic solvent increases. | The organic solvent (e.g., ethyl acetate, THF) has significant UV absorbance at your detection wavelength [6]. | Select a wavelength where the solvent absorbance is minimal (e.g., >260 nm for ethyl acetate) [6]. |

| Falling Baseline in Gradients [3] | A smooth, steady decrease in baseline during the run. | The aqueous solvent (with a UV-absorbing additive like formic acid) is being replaced by a transparent organic solvent [3]. | Add the same concentration of the additive to the organic solvent to maintain a constant absorbance [3]. |

| Saw-tooth or Erratic Baseline [3] | A choppy, irregular baseline with sharp up-and-down movements. | Inconsistent mobile phase composition due to pump problems (e.g., sticky check valve, air bubble) at a wavelength sensitive to this change [3]. | Service the pump, check for air bubbles, and clean or replace check valves [3]. |

| High Baseline Across Entire Run [3] | The entire baseline is elevated, though it may be stable. | Impurities in the mobile phase solvents or additives that absorb UV light at your detection wavelength [3]. | Use fresh, high-quality solvents from a different supplier or different lot [3]. |

Experimental Protocol: Systematically Selecting the Optimal Detection Wavelength

This protocol provides a step-by-step method to empirically determine the best detection wavelength for minimizing baseline drift in a new method.

Objective

To identify a detection wavelength that provides a stable baseline and sufficient analyte sensitivity by characterizing the UV absorbance of the mobile phase system.

Materials and Equipment

- HPLC or UV-Vis system with gradient capability

- Diode-array or variable-wavelength detector

- Solvent degassing system

- Mobile Phase A and B, prepared as per method

- Syringe and syringe filters (0.45 µm)

Procedure

- System Preparation: Degas and thoroughly purge your system with both Mobile Phase A and B.

- Blank Gradient Run: Program a gradient method that mirrors your analytical method but injects no sample.

- Full Spectrum Scan: Using a diode-array detector, collect spectra continuously throughout the blank gradient run. If using a variable-wavelength detector, run the blank gradient at multiple candidate wavelengths.

- Data Analysis: Plot the baseline absorbance versus time for different wavelengths. Identify the wavelength where the baseline is flattest and the absorbance value is lowest.

- Analyte Sensitivity Check: Ensure your target analytes still have adequate absorbance at the selected wavelength for sensitive detection.

The logic of this experimental workflow is summarized in the diagram below.

Frequently Asked Questions

How does the UV cutoff of a solvent relate to baseline drift?

The UV cutoff is the wavelength below which a solvent has significant absorbance (Abs > 1.0). Operating near or below a solvent's cutoff will cause intense baseline drift during a gradient, as the concentration of that absorbing solvent changes. Always select a detection wavelength at least 20-50 nm higher than the UV cutoff of your strongest-absorbing solvent [6].

My baseline is still drifting after selecting a new wavelength. What should I check next?

If wavelength selection alone doesn't solve the drift, perform this systematic check:

- Mobile Phase Quality: Confirm you are using fresh, high-purity solvents and additives. Impurities can be highly retained and elute as broad peaks or cause a raised baseline [3] [16].

- Column Equilibration: Ensure the column is fully re-equilibrated to the initial gradient conditions with at least 2 column volumes of mobile phase [6].

- Temperature Stability: Check for drafts or fluctuations in lab temperature, which can cause baseline drift, especially in refractive index detectors [3] [16].

- System Cleanliness: Flush the system to remove potential contaminants from previous runs [6] [16].

Can I use software to correct for drift instead of changing my method?

Yes, real-time baseline correction is a feature on some modern instruments. This software automatically subtracts the solvent's UV absorption during the run, effectively flattening the baseline [6]. However, this is a corrective measure and does not replace the need for a well-designed method with a thoughtfully chosen detection wavelength.

The Scientist's Toolkit: Key Reagents and Materials for Stable Baselines

| Item | Function | Consideration for Minimizing Drift |

|---|---|---|

| LC-MS Grade Solvents | High-purity solvents for mobile phase preparation. | Reduce baseline noise and ghost peaks from UV-absorbing impurities [3] [16]. |

| HPLC-Grade Additives | High-purity acids (e.g., TFA, Formic) and buffers. | Minimize baseline rise and contamination that accumulates on-column [3]. |

| In-Line Degasser | Removes dissolved gases from the mobile phase. | Prevents bubble formation in the flow cell, a common cause of erratic, noisy baselines [16]. |

| Static Mixer | Ensures thorough mixing of eluents before the column. | Reduces composition inconsistencies in low-wavelength methods, leading to a smoother baseline [16]. |

| Certified Wavelength Standards | Calibrates detector wavelength accuracy. | Ensures your selected detection wavelength is precise, which is critical for reproducible baseline performance [17]. |

Assessing the Impact on Peak Integration, Area, and Height Measurements

Troubleshooting Guides

FAQ 1: Why are my measured peak areas inconsistent between runs?

Inconsistent peak areas are frequently caused by baseline drift, which shifts the entire spectrum up or down, altering the calculated area under the peak [4]. This drift can stem from instrumental, environmental, or sample-related factors.

- Primary Cause: Baseline drift, often due to instrumental instability (e.g., fluctuations in lamp intensity or detector sensitivity), environmental changes (e.g., temperature, humidity), or sample matrix effects (e.g., impurities, scattering particles) [4].

- Impact: A drifting baseline directly changes the starting point for integration, leading to overestimation or underestimation of the true peak area [7].

- Solution:

- Instrument Maintenance: Ensure regular calibration and maintenance of the spectrophotometer, including checking the alignment and replacing aging lamps [18] [19].

- Environmental Control: House the instrument in a stable environment with controlled temperature and minimal vibrations [4].

- Apply Baseline Correction: Use the instrument's software to perform a baseline correction. This involves subtracting the absorbance value at a specific, non-absorbing wavelength (e.g., 340 nm for UV work, 750 nm for visible light) from the entire spectrum [7].

FAQ 2: How does baseline drift specifically affect peak height and integration?

Baseline drift primarily affects the accuracy of peak integration (area), while its effect on peak height is more indirect and typically less severe.

- Peak Area: This measurement is highly susceptible to baseline drift. Integration calculates the area between the spectral peak and the baseline. A drifting baseline changes the boundary of this calculation, directly leading to inaccurate area values [7] [4].

- Peak Height: The height of a peak is theoretically a concentration-dependent property governed by Beer's Law [20]. However, a significant vertical shift in the baseline will alter the measured absorbance value at the peak apex. The key difference is that peak height is not affected by flow rate or residence time in the detector in the same way peak area is [21].

The table below summarizes the core principles of how measurements are affected.

| Measurement | Theoretical Principle | Primary Impact of Baseline Drift |

|---|---|---|

| Peak Area | Proportional to the total mass of analyte detected; highly dependent on flow rate and residence time in the flow cell [21]. | High impact; directly shifts the integration boundary, causing significant over- or under-estimation [7]. |

| Peak Height | Governed by Beer's Law (A = εcl), related to analyte concentration at the peak apex [20]. | Lower direct impact; a vertical drift will change the absolute height reading, but the effect is typically less pronounced than on area [21]. |

FAQ 3: What are the established methods for correcting baseline artifacts in research?

Several robust mathematical techniques are used in research to correct for baseline artifacts and scatter, which are critical for obtaining accurate quantitative data.

- Baseline Subtraction: A fundamental approach where a baseline (e.g., from a blank measurement or a curve fitted to sample-free regions) is subtracted from the sample spectrum [22] [7].

- Rayleigh-Mie Scattering Correction: A specialized curve-fitting method for samples containing particulates or aggregates (e.g., proteins, viruses). It uses fundamental light scattering equations to model and subtract the scattering contribution from the absorbance spectrum [22].

- Asymmetric Least Squares (AsLS): A modern baseline estimation algorithm that fits a smooth baseline to the spectrum. It uses asymmetric weighting to ignore positive peaks and fit only the baseline components, effectively handling nonlinear drift [23].

- Multiplicative Scatter Correction (MSC) & Standard Normal Variate (SNV): Classical techniques commonly used in vibrational spectroscopy (like NIR) to correct for both additive and multiplicative scatter effects caused by particle size or sample packing variations [23].

The following workflow diagram illustrates the decision process for selecting and applying a baseline correction method.

Experimental Protocols

Protocol: Validating a Baseline Correction Wavelength

This protocol is essential for empirically determining the optimal wavelength for baseline correction when developing a new assay or working with unfamiliar samples or buffers [7].

- Preparation: Clean the measurement surfaces thoroughly. Launch the instrument's application and disable any existing baseline correction.

- Blank Measurement: Perform a blank measurement using the appropriate pure solvent (e.g., 1 µL of dH₂O). Remove the blank and pipette a fresh aliquot for the next step.

- Solvent/Buffer Check: Pipette 1 µL of the sample buffer (without the analyte) onto the measurement surface and take a spectrum.

- Analysis: Examine the resulting spectrum. The chosen baseline correction wavelength (e.g., 340 nm) must show no significant absorbance from the buffer itself. If absorbance is present, select a different wavelength (e.g., 400 nm or higher in the visible range) and repeat the buffer check.

- Sample Check (Optional but Recommended): Pipette 1 µL of the actual sample and measure its spectrum. Confirm that this sample also shows no significant absorbance at the selected baseline correction wavelength.

Protocol: Implementing Asymmetric Least Squares (AsLS) Baseline Correction

For advanced handling of nonlinear baselines, the AsLS algorithm can be implemented in data analysis software like Python, R, or MATLAB [23].

- Input Raw Data: Load the raw spectrum, which consists of a wavelength vector and an absorbance vector.

- Set Algorithm Parameters:

- Smoothness (λ): This parameter controls the smoothness of the fitted baseline. A higher value produces a smoother baseline. A typical starting point is between 10² and 10⁵.

- Asymmetry (p): This parameter determines the weight given to positive residuals (peaks). It should be set close to zero (e.g., 0.001 - 0.1) to strongly penalize the positive peaks and prevent them from being included in the baseline fit.

- Optimize and Iterate: Run the AsLS algorithm and visually inspect the fitted baseline. Adjust

λandpiteratively until the baseline follows the low-frequency drift of the spectrum without fitting the analytical peaks. - Subtract Baseline: Subtract the fitted baseline vector from the raw absorbance vector to obtain the corrected spectrum.

- Re-integrate Peaks: Perform peak integration on the corrected spectrum to obtain accurate area and height measurements.

Research Reagent Solutions

The following table lists key materials and reagents essential for experiments focused on correcting baseline drift and ensuring measurement accuracy.

| Item | Function / Purpose |

|---|---|

| Holmium Oxide Filter | A certified reference material for validating the wavelength accuracy of the spectrophotometer, a critical pre-requisite for reliable measurements [19]. |

| Quartz Cuvettes | Provide optimal light transmission in the UV range (below 300 nm). Consistent pathlength (e.g., 10 mm) and clean, scratch-free surfaces are vital for accurate absorbance readings [19]. |

| Spectrophotometric-Grade Solvents | High-purity solvents (e.g., HPLC-grade) minimize background absorbance and UV-absorbing impurities that can contribute to baseline noise and drift [19]. |

| Certified Reference Materials (CRMs) | Solutions with precisely known absorbance values used to validate the accuracy and precision of the spectrophotometer's concentration measurements after baseline correction [19]. |

| Potassium Chloride (KCl) Solution | Used to calibrate for and assess the level of stray light in the UV region, which is a potential source of baseline error [19]. |

Proven Correction Techniques: From Basic Subtraction to Advanced Algorithms

Blank Subtraction and Polynomial Least Squares Fitting

Frequently Asked Questions (FAQs)

1. What is the primary purpose of blank subtraction in UV-Vis spectroscopy? The purpose of blank subtraction is to remove the background signal originating from the solvent, cuvette, or other matrix components, thereby isolating the analytical signal of the analyte. This process yields a cleaner chromatogram or spectrum and provides a more accurate baseline for quantification. When a calibration curve is constructed using blank-corrected measurements (F-F0), the resulting equation typically has a negligible intercept (y = mx), directly relating the instrument response to the analyte concentration [24] [25].

2. When should I use polynomial fitting instead of simple blank subtraction for baseline correction? Polynomial least squares fitting is advantageous when the baseline drift or artifact is complex and non-linear, which cannot be adequately corrected by simply subtracting a blank measurement. This method is particularly useful when dealing with significant light scattering from particulates or large molecules (e.g., protein aggregates) in the sample, as it models and subtracts the curved baseline based on the underlying scattering physics [22].

3. My sample has a different matrix than my calibration standards. Can blank subtraction handle this? No, standard blank subtraction and calibration curves assume that the sample and standards have an identical matrix. If the matrix is different (e.g., a different solvent), the blank for the sample will differ from the blank of the standards, leading to inaccuracies. In such cases, the standard addition method should be used instead, as it accounts for matrix effects by spiking the sample itself with known amounts of the analyte [25].

4. How do I choose the correct degree for a polynomial baseline fit? Selecting the polynomial degree involves a trade-off. A degree too low may not capture the baseline's curvature (underfitting), while a degree too high may model the noise and actual signal, distorting your data (overfitting) [26]. Start with a low degree (e.g., 2 or 3) and visually inspect the fit. The goal is to have the fitted curve follow the baseline drift without intersecting the analyte peaks. Techniques like cross-validation can help objectively find the optimal degree.

Troubleshooting Guides

Guide 1: Correcting Baseline Artifacts Using Blank Subtraction

Blank subtraction is a fundamental first step for correcting systematic baseline offsets.

- Symptoms: A constant vertical offset is observed across the entire spectrum or chromatogram when compared to a reference or expected baseline.

Procedure:

- Acquire a Blank Signal: Measure a solution containing all the components of your sample except for the analyte(s) of interest, using the same instrumental method [24].

- Apply the Subtraction: In your processing software, subtract the blank signal from your sample signal. The new signal is calculated as: New signal = sample signal - blank signal [24].

- Verification: After subtraction, the baseline in regions where no analyte signal is expected should be close to zero.

Software-Specific Steps for OpenLab CDS:

- In the Processing Method, navigate to General > Signals and select the Blank Subtraction tab [24].

- Under "Blank subtraction applied on", select the applicable injections (e.g., Samples only) [24].

- Choose your blank source:

- Select signal matching options (e.g., "Perform blank subtraction if signal names match") and reprocess the data [24].

Guide 2: Advanced Baseline Correction using Polynomial Least Squares Fitting

For non-linear baselines caused by complex scattering or instrumental drift, a polynomial fit provides a more robust correction.

- Symptoms: The baseline shows a curved, non-linear drift (e.g., upward or downward curvature), often encountered with samples containing particulates, aggregates, or in lentivirus analysis [22].

- Underlying Principle: This method uses a least squares algorithm to fit a polynomial curve to user-identified baseline regions of the spectrum (areas where no analyte peaks are present). This fitted curve models the baseline artifact, which is then subtracted from the entire spectrum [22] [27] [28].

The workflow for this correction is outlined below.

- Implementation Code Example (Python): The following Python code demonstrates the core computational steps for performing polynomial least squares fitting, which can be adapted for baseline correction.

- Troubleshooting the Fit:

- Underfitting (Baseline not fully captured): Increase the polynomial degree gradually [26].

- Overfitting (Model fits noise and peaks): Decrease the polynomial degree or select more representative baseline regions [26].

- Check the Fit: Always visualize the fitted polynomial overlaid on your original data to ensure it follows the baseline and not the analyte peaks.

The Scientist's Toolkit: Essential Materials and Reagents

The table below lists key reagents and materials used in UV-Vis spectroscopy experiments requiring baseline correction.

| Item | Function & Importance in Baseline Management |

|---|---|

| Quartz Cuvettes | Provide high transmission across UV and visible wavelengths. Essential for obtaining a clean, low-noise baseline. Reusable cuettes must be meticulously cleaned to avoid contaminant peaks [11]. |

| High-Purity Solvents | The solvent for the sample and blank must be identical and of high purity. Impurities can absorb light, creating a significant and variable background signal that interferes with blank subtraction [11] [4]. |

| Blank Matrix Solution | A solution matching the sample's composition (e.g., buffer, solvent, excipients) but without the analyte. It is used to measure and correct for the background signal, forming the basis of blank subtraction [24] [25]. |

| Standard Reference Materials | Used for regular instrument calibration. Proper calibration ensures instrumental baseline drift is minimized, making subsequent blank subtraction and baseline correction more reliable and accurate [4]. |

The following table provides a quick reference to diagnose common baseline problems and select an appropriate correction strategy.

| Problem Observed | Likely Cause | Recommended Correction Method |

|---|---|---|

| Constant vertical offset | Signal from solvent or cuvette | Simple Blank Subtraction [24] |

| Curved or sloping baseline | Instrumental drift, light scattering (Rayleigh/Mie) from large particles or aggregates [22] [4] | Polynomial Least-Squares Fitting [22] |

| Unusual or unexpected peaks | Contaminated cuvette or sample [11] | Clean or re-prepare sample/cuvette, then perform blank subtraction |

| High noise across the baseline | Dirty optical components, unstable light source, or bubbles in sample [11] [4] | Instrument maintenance, allow lamp warm-up, degas sample |

Wavelet Transform Methods for Frequency-Based Baseline Extraction

A technical support guide for researchers combating baseline drift in UV-Vis spectroscopy.

Welcome to the Technical Support Center for Advanced Spectral Analysis. This resource provides targeted troubleshooting guides and frequently asked questions to assist researchers in addressing the challenge of baseline drift during UV-Vis spectroscopy experiments, a common obstacle in pharmaceutical development and other quantitative analytical workflows.

Troubleshooting FAQs: Baseline Drift in UV-Vis Spectroscopy

What is baseline drift and why is it a problem in my UV-Vis data?

Baseline drift refers to an unwanted, slow shift in the baseline signal of your spectrum, unrelated to the analyte of interest. It can be caused by factors such as instrument instability, temperature fluctuations, contaminated cuvettes, or evaporation of solvent over time [11]. This drift is problematic because it obscures true analyte peaks, complicates accurate peak integration, and can significantly impact quantitative results, particularly for trace-level impurities where detection limits are critical [29].

How can I determine if my baseline issue is from the sample or the instrument?

First, check your sample and sample holder [11]. Ensure cuvettes are impeccably clean and you are using the correct type (e.g., quartz for UV-Vis regions). If the problem persists with a different, known-good sample, the issue is likely instrumental. Allow your light source to warm up for the recommended time (e.g., 20 minutes for tungsten halogen lamps) [11]. Consistent drift across all samples may also point to instrumental causes such as an aging lamp or electronic drift [30].

My baseline is unstable even after a blank correction. What should I check?

Follow this diagnostic checklist:

- Sample Temperature: Ensure temperature remains consistent, as changes can affect reaction rates and solute solubility [11].

- Solvent Evaporation: For long measurements, seal your cuvette to prevent solvent evaporation, which changes concentration [11].

- Effect of Solvents: Verify that your solvent is transparent in the spectral range you are using and does not interact with the cuvette material [11].

- Instrument Calibration: Perform a full baseline correction or recalibration [30].

When should I use mathematical correction like Wavelet Transform instead of re-running my experiment?

Mathematical baseline correction is a powerful option when re-collecting data is not feasible (e.g., with precious or irreplaceable samples) or when the raw data is largely good but affected by a consistent, low-frequency drift. Wavelet Transform is particularly useful as it preserves the original raw data [29], allowing you to experiment with correction parameters without losing the initial measurement. However, the best approach is always to collect the highest quality data possible first, using mathematical corrections as a refinement tool [29] [31].

Experimental Protocols

Detailed Methodology: Baseline Correction using Wavelet Transform

This protocol is adapted from applications in chromatography and Raman spectroscopy for UV-Vis spectral data [32] [31].

1. Principle The Wavelet Transform (WT) decomposes a signal into different frequency components. The slowly varying baseline corresponds to the low-frequency contributions in the wavelet domain. By identifying and subtracting these contributions, the baseline can be effectively removed [32] [31].

2. Procedure

- Step 1: Decompose the Spectrum. Perform a wavelet decomposition of your original absorbance spectrum using a chosen wavelet type (e.g.,

'db6'- Daubechies 6) and a specified level (e.g.,level=7). - Step 2: Identify and Modify Baseline Coefficients. The baseline is primarily contained in the first, lowest-frequency coefficient array (

coefficients[0]). Set this approximation coefficient to zero. - Step 3: Reconstruct the Signal. Perform an inverse wavelet transform to reconstruct the spectrum without the baseline.

3. Critical Notes

- This method is a filtering process and can sometimes introduce distortions, such as dips below zero or overshoots near sharp peaks [31].

- The choice of wavelet family (e.g., Daubechies, Symlets) and decomposition level can be optimized for your specific spectral data [31].

Workflow Comparison: Baseline Correction Methods

The following diagram illustrates the logical workflow and key differences between the standard instrumental correction and the Wavelet Transform method.

Quantitative Comparison of Baseline Correction Methods

The table below summarizes the key characteristics of different baseline correction techniques to help you select the most appropriate one for your research.

| Method | Principle | Advantages | Limitations | Typical Application |

|---|---|---|---|---|

| Wavelet Transform | Frequency-based separation of signal using decompositions like Daubechies (db6) [31]. |

Preserves raw data; easily explainable; effective for broad, smooth baselines [29] [31]. | Can distort signals (e.g., dip below zero); requires selection of wavelet and level [31]. | HPLC, Raman, and UV-Vis spectra with low-frequency drift [32] [31]. |

| Asymmetric Least Squares (ALS) | Iteratively fits a smooth baseline by applying a higher penalty to positive deviations (peaks) [31]. | Less intuitive but often produces superior results; very effective for complex baselines [31]. | Requires tuning of parameters (e.g., lam=1e6, niter=5) [31]. |

XRF, Raman, and NIR spectra with fluctuating baselines [31]. |

| Instrumental Correction | Addresses the physical source of drift (e.g., warm-up lamp, clean cuvette) [11] [30]. | Corrects the problem at the source; most reliable long-term solution. | Can be time-consuming; requires troubleshooting skill; not applicable to existing data. | First-line action for all experimental work [11]. |

The Scientist's Toolkit: Essential Research Reagents & Materials

The following table details key materials and software solutions critical for successful baseline correction and high-quality UV-Vis spectroscopy.

| Item Name | Function / Application | Critical Specifications |

|---|---|---|

| Quartz Cuvettes | Sample holder for UV-Vis measurements. | High transmission in UV & visible regions; appropriate path length (e.g., 1 cm) [11]. |

| Certified Reference Standards | Calibration and verification of instrument accuracy [30]. | Relevant to analyte of interest; traceable certification. |

| HPLC-Grade Solvents | Dissolving samples for analysis. | High purity; low UV absorbance in the measured range to minimize background noise [11]. |

| PyWavelets Library (Python) | Open-source library for performing wavelet transforms for mathematical baseline correction [31]. | Supports multiple wavelet families (e.g., 'db6', 'sym4') and decomposition levels. |

| Chromeleon CDS | Chromatography Data System software featuring intelligent integration and smoothing algorithms like Savitsky-Golay [29]. | Cobra and SmartPeaks algorithms for automated peak integration and baseline correction. |

Penalized Least Squares and Robust Orthogonal Regression

FAQs and Troubleshooting Guides

Frequently Asked Questions

Q1: What are the core mathematical principles behind Penalized Least Squares (PLS) for baseline correction?

Penalized Least Squares estimates the baseline by solving an optimization problem that balances two objectives: how well the baseline fits the measured data and how smooth the baseline is. The core cost function is typically expressed as:

L(b) = (x - b)ᵀW(x - b) + λbᵀDᵀDb [33]

Here, (x - b)ᵀW(x - b) represents the fitness of the baseline b to the spectrum x, while λbᵀDᵀDb is a penalty term that enforces smoothness through the second-order difference matrix D. The regularization parameter λ controls the trade-off between fitness and smoothness. Asymmetric weights in matrix W can be used to down-weight potential peak regions, preventing them from being absorbed into the baseline estimate. [34] [33]

Q2: My baseline correction results are inconsistent across different samples. What could be wrong?

Inconsistent results often stem from two common issues in PLS methods:

- Incorrect Parameter Tuning: The performance of PLS is highly sensitive to parameters like the regularization coefficient

λand the asymmetry weight inW. Suboptimal values can lead to overfitting (the baseline follows peaks) or underfitting (the baseline does not capture the true drift). [34] - Violation of Smoothness Assumptions: PLS assumes the baseline is smoother than the Raman or UV-Vis signal peaks. This assumption can break down in the presence of high-frequency noise or when the fluorescence background has sharp features, leading to incorrect baselines. [34] [33] Consider trying a more robust method, such as Constrained Gaussian Radial Basis Function Fitting (CGF), which models the baseline directly and does not rely on iterative fitting, often yielding more stable results across diverse measurement scenarios. [34]

Q3: How do I choose between iterative reweighting algorithms like ALS and a constrained optimization approach like CGF?

The choice involves a trade-off between control, robustness, and computational efficiency. The table below compares these approaches.

Table: Comparison of Baseline Correction Algorithm Types

| Feature | Iterative Reweighting (e.g., ALS) | Constrained Optimization (e.g., CGF) |

|---|---|---|

| Core Mechanism | Iteratively applies asymmetric weights to suppress peaks during smoothing [34] [33] | Solves a one-time constrained curve-fitting problem using Gaussian radial basis functions [34] |

| Parameter Sensitivity | High; requires careful tuning of smoothness (λ) and asymmetry parameters [34] |

Lower; more intuitive parameter search and consistent performance [34] |

| Computational Load | Can be intensive due to multiple iterations until convergence [34] | Efficient and stable due to linear programming formulation [34] |

| Best Use Case | Well-understood spectra where baseline and peak shapes are predictable | Scenarios requiring robustness across diverse datasets with varying noise and drift [34] |

Q4: What are the primary causes of baseline drift in UV-Vis spectrophotometry?

Baseline drift can originate from multiple sources, which can be categorized as follows [4]:

- Instrumental Factors: Degradation or instability of light sources, detectors, and optical components.

- Environmental Influences: Fluctuations in temperature and humidity, or external vibrations.

- Sample and Matrix Effects: The presence of impurities, bubbles, or scattering particles in the sample or solvent.

- Operational Conditions: Improper instrument calibration, alignment, or handling.

Troubleshooting Guide: Common Issues and Solutions

Problem: Overestimated Baseline in Regions with Multiple Peaks

- Description: The corrected baseline appears too high, cutting into the peaks and reducing their apparent intensity. This is a common failure of standard methods. [34]

- Solution: Implement a method that directly constrains the baseline to lie below the spectral data. The CGF method, for example, formulates this as a constraint in its optimization, effectively preventing overestimation even in complex spectral regions with dense peaks. [34]

Problem: Algorithm is Too Sensitive to Noise

- Description: The estimated baseline is wavy or follows the noise in the spectrum rather than the underlying fluorescent drift.

- Solution:

- Apply a preliminary smoothing step to the raw spectrum before baseline correction. This is a standard preprocessing step used in conjunction with algorithms like CGF. [34]

- Increase the smoothness penalty parameter

λin PLS-based methods. However, this must be done carefully to avoid underfitting. [33]

Problem: Ineffective Correction for Sharp Fluorescence Features

- Description: The baseline correction fails to account for a sharp, rising fluorescence signal at the low-wavenumber region of a Raman spectrum.

- Solution: Ensure your method has sufficient flexibility. While baselines are generally smooth, some require more complex modeling. Methods that use a basis of broad Gaussian functions or B-splines can capture a wider range of baseline shapes without distorting the Raman peaks. [34] [35] [33]

Experimental Protocols and Workflows

Standard Operating Procedure: Baseline Correction using Penalized Least Squares

This protocol outlines the steps for correcting baseline drift in UV-Vis or Raman spectra using an Asymmetric Least Squares (ALS) approach. [33]

- Data Acquisition: Collect the raw spectral data

x. - Parameter Initialization: Define initial values for the smoothness parameter

λ(e.g., 10³ to 10⁷) and the asymmetry parameterp(e.g., 0.001 to 0.1) for the weight matrixW.pdetermines the penalty for points below the estimated baseline (presumed peaks). - Weight Assignment: Initialize the weight matrix

Was an identity matrix. - Iterative Optimization:

a. Baseline Estimation: Solve the linear system

b = (W + λDᵀD)⁻¹Wxto obtain the current baseline estimateb. [33] b. Weight Update: Update the diagonal elements ofWbased on the residualsx - b. Points where the spectrum is above the baseline (potential peaks) are given lower weights. c. Check Convergence: Compare the current baselinebwith the one from the previous iteration. If the change is below a predefined tolerance, proceed to the next step. Otherwise, return to step 4a. - Baseline Subtraction: Subtract the final estimated baseline

bfrom the raw spectrumxto obtain the corrected spectrumx' = x - b.

The following workflow diagram illustrates the iterative nature of this algorithm.

Advanced Protocol: Constrained Gaussian Radial Basis Function (CGF) Fitting

For scenarios requiring high robustness, the following non-iterative CGF method is recommended. [34]

- Preliminary Smoothing: Apply a smoothing filter (e.g., Savitzky-Golay) to the raw spectrum

yto mitigate high-frequency noise, producingȳ. [34] - Basis Function Setup: Define a set of Gaussian Radial Basis Functions (GRBFs) with centers evenly spaced across the spectral range. The widths of the Gaussians should be chosen to be broad to ensure they model the smooth baseline and not the sharp spectral peaks. [34]

- Constrained Optimization: Solve a linear programming problem to find the weights for the GRBFs. The key constraint is that the linear combination of GRBFs (the baseline) must be less than or equal to the smoothed spectrum

ȳat all points. This prevents overestimation. [34] - Baseline Calculation & Subtraction: Calculate the baseline

bas the weighted sum of the GRBFs and subtract it from the original raw spectrum.

The Scientist's Toolkit: Key Research Reagents and Materials

Table: Essential Materials for Spectroscopy and Baseline Correction Research

| Item / Reagent | Function / Application |

|---|---|

| Standard Reference Materials | Used for regular calibration of the spectrophotometer to ensure instrumental accuracy and minimize baseline drift originating from hardware. [4] |

| High-Purity Solvents | Essential for sample preparation. Impurities in solvents can cause significant baseline artifacts and spurious peaks. [4] |

| Matched Cuvettes | A pair of cuvettes with nearly identical optical properties, used for the sample and reference beam to cancel out solvent and cuvette-related baseline effects. [4] |

| Background Basis Matrix (K_bg) | A mathematical construct composed of basis vectors (e.g., from SVD of background spectra). It is used in advanced correction algorithms to model and subtract the Raman spectrum of background materials. [33] |

| Reference CA Matrix (S) | A library of reference spectra for target chemical agents (CAs) or analytes. It provides prior information for algorithms that simultaneously estimate the baseline and the analyte signal. [33] |

The Rolling Ball Algorithm for 2D Chromatographic Data

Baseline drift is a common challenge in 2D chromatographic data analysis, characterized by low-frequency signal variation that can interfere with accurate peak detection and quantification. This drift arises from multiple sources, including column stationary phase bleed, background ionization, and low-frequency variations in detector response or instrument-controlled parameters like temperature and flow [1]. In the context of UV-Vis spectroscopy research for drug development, correcting these artifacts is essential for obtaining reliable data.

The rolling-ball algorithm is a powerful morphological filter for estimating and subtracting background intensity. Originally proposed by Stanley R. Sternberg in 1983, this intuitive algorithm treats the image or spectrum as a topographic surface, where intensity values represent height [36] [37]. A ball of specified radius is rolled beneath this surface, and the ball's apex at each position estimates the local background. This approach effectively separates smooth baseline variations from sharper analytical signals of interest, making it particularly valuable for 2D chromatographic data [1].

Key Parameters of the Rolling Ball Algorithm

| Parameter | Recommended Setting | Function | Considerations |

|---|---|---|---|

| Radius | 100 (default) [37] | Controls the size of the rolling ball; determines the curvature of the estimated background. | Larger values fit broader, smoother baselines; smaller values capture more local variation. |

| Kernel Shape | Ball-shaped (default) [36] | Defines the structural element used for the rolling operation. | Ellipsoid kernels can be used for different spatial scales or anisotropic data. |

| nansafe | False (default) [37] | Determines handling of NaN values in the input data. | Set to True if the input contains NaN values to avoid computation errors. |

| num_threads | None (default) [37] | Specifies maximum threads for computation. | Uses OpenMP default; can be set to optimize processing speed for large 2D datasets. |

Frequently Asked Questions (FAQs)

What types of baseline drift is the rolling-ball algorithm best suited for?

The algorithm is particularly effective for correcting smooth, curved baselines commonly encountered in chromatographic studies due to temperature changes, solvent programming, or detector effects [1]. It excels at distinguishing these low-frequency variations from the sharper peaks representing analytes.

How do I choose the appropriate radius for my data?

The optimal radius depends on the scale of your features and the baseline curvature. As a starting point, use the default value of 100 [37]. For broader baseline features, increase the radius to prevent the ball from dipping into real peaks. For datasets with finer structure, a smaller radius may be necessary. Empirical testing on a representative dataset is recommended.

My features are dark on a bright background. How do I adjust the algorithm?

The standard rolling-ball implementation in skimage assumes bright features on a dark background. If your data has the opposite contrast (dark features on a bright background), you must invert the image before processing and then invert the result [36]. Critical: subtract the background from the original image within the same intensity scale to avoid integer underflow artifacts.

Can the rolling-ball algorithm be applied to higher-dimensional data?

Yes, a significant advantage of the scikit-image implementation is its native support for n-dimensional data [36]. You can directly apply it to 3D data stacks (e.g., z-stacked images or hyperspectral cubes) by using a kernel with matching dimensions. A kernel size of 1 along an axis means no filtering is applied along that dimension.

What are the alternatives to the rolling-ball algorithm?

Common alternatives include:

- Iterative Median Filter (IMF): Applies a median filter iteratively to estimate the baseline [38].

- Asymmetric Least Squares (ALS): Uses penalized least squares fitting with asymmetry to ignore peak regions [38].

- Polynomial Fitting: Fits a polynomial curve to baseline points [39].

- Wavelet-Based Methods: Uses frequency domain transformation to separate baseline [39] [1].

Troubleshooting Common Issues

Problem 1: Overly aggressive baseline correction removes real peaks

Solution:

- Increase the ball radius: A larger radius will create a smoother baseline that is less likely to follow real peaks.

- Check data scaling: For floating-point images normalized to [0, 1], the ball radius may be disproportionately large relative to signal intensity. Consider scaling your data or manually defining a kernel with appropriate intensity [36].

Problem 2: Incomplete baseline removal with residual drift

Solution:

- Decrease the ball radius: A smaller radius can capture more subtle baseline variations.

- Pre-process data: Ensure your data has the correct orientation (bright features on dark background) or apply inversion as needed [36].

- Use a shaped kernel: For anisotropic data where baseline characteristics differ along axes, consider using an ellipsoidal kernel with different radii [36].

Problem 3: Algorithm performance is too slow for large 2D datasets

Solution:

- Utilize threading: The

num_threadsparameter can be optimized for your system to parallelize computations [37]. - Subsample for testing: Use a representative subset of your data for parameter optimization before applying to the full dataset.

- Check data type: Some data types may require conversion or normalization for optimal processing speed.

Problem 4: Artifacts appear in the corrected data

Solution:

- Avoid integer underflow: When subtracting background from inverted images, perform operations in a way that maintains proper intensity scaling [36].

- Verify kernel dimensions: Ensure the kernel has the same number of dimensions as your input data.

- Inspect intermediate results: Check the estimated background separately to ensure it reasonably matches the true baseline without capturing real signal.

Experimental Protocol for 2D Chromatographic Data

Materials and Software Requirements

| Category | Item | Function/Purpose |

|---|---|---|

| Software | Python 3.7+ | Programming environment |

| scikit-image library | Provides restoration.rolling_ball() function |

|

| NumPy, Matplotlib | Data manipulation and visualization | |

| Data Input | 2D chromatographic data | Data matrix with baseline drift |

| Metadata | Information on acquisition parameters | |

| Computing | Multi-core processor | Speeds up processing via num_threads parameter |

Step-by-Step Procedure

Data Import and Validation

- Load your 2D chromatographic data into a NumPy array

- Verify data dimensions and data type

- Check for NaN values or outliers that may interfere with processing

Data Preprocessing

- Normalize intensity values if necessary

- Invert data if features are dark on a bright background using

util.invert() - For very large datasets, consider processing in blocks to manage memory usage

Parameter Optimization

- Start with the default radius of 100

- Process a representative subset of your data

- Visually inspect the estimated background using Matplotlib

- Adjust radius based on the scale of baseline features

Algorithm Application

Result Validation