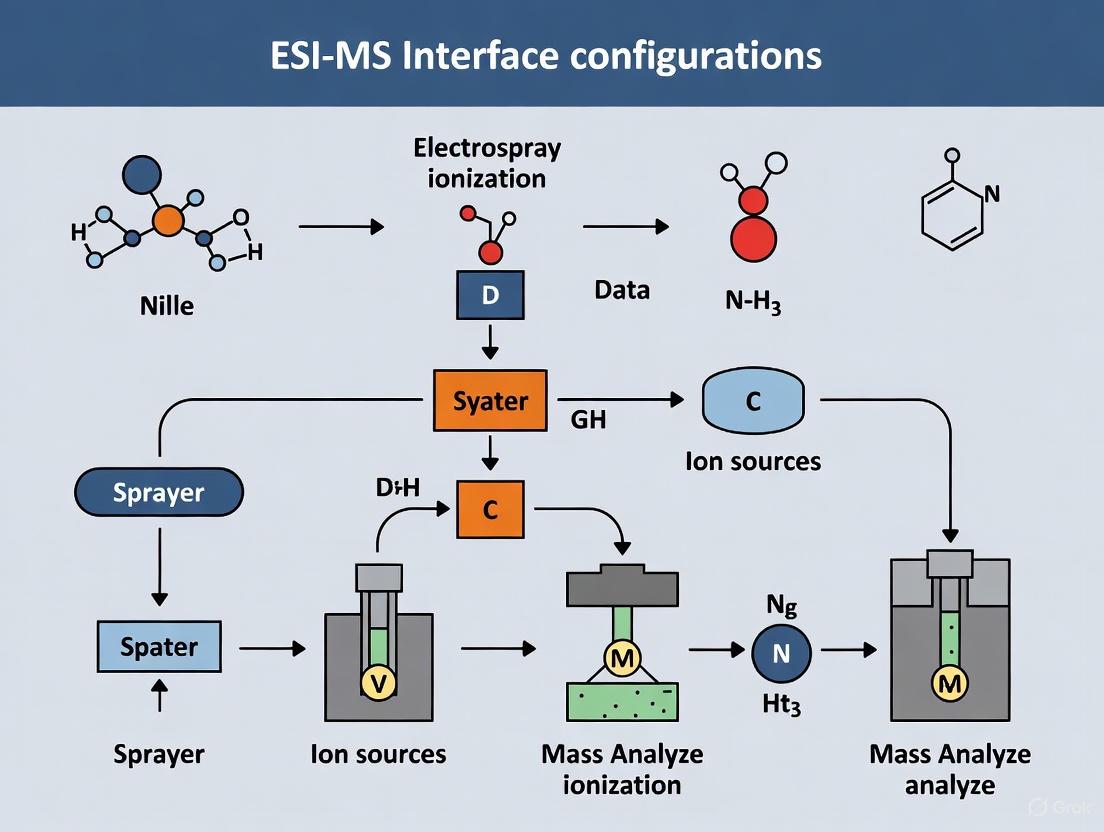

ESI-MS Interface Configurations: A Comprehensive Guide from Fundamentals to Advanced Applications

This article provides a thorough exploration of Electrospray Ionization Mass Spectrometry (ESI-MS) interface configurations, tailored for researchers, scientists, and drug development professionals.

ESI-MS Interface Configurations: A Comprehensive Guide from Fundamentals to Advanced Applications

Abstract

This article provides a thorough exploration of Electrospray Ionization Mass Spectrometry (ESI-MS) interface configurations, tailored for researchers, scientists, and drug development professionals. It covers the fundamental principles of ESI-MS operation and ion formation mechanisms, details practical methodologies and configurations for analyzing diverse samples from small molecules to intact proteins, offers systematic strategies for troubleshooting and optimizing sensitivity and signal stability, and presents validation techniques and comparative analyses of different interface designs. The content synthesizes current research and best practices to serve as a critical resource for enhancing analytical performance in biomedical and clinical research applications.

Understanding ESI-MS: Core Principles and Interface Architecture

Electrospray Ionization Mass Spectrometry (ESI-MS) represents a cornerstone technique in modern analytical science, enabling the sensitive and accurate analysis of biomolecules. This soft ionization technique overcomes the traditional limitations of mass spectrometry when applied to large, thermally labile, and non-volatile molecules, such as proteins and nucleic acids. The development of ESI-MS has fundamentally reshaped fields like proteomics, metabolomics, and pharmaceutical research by allowing the transfer of ions directly from solution to the gas phase without significant fragmentation. The technique's core innovation lies in its ability to produce multiply charged ions, effectively extending the mass range of analyzers to accommodate macromolecules in the kiloDalton to MegaDalton range. This technical guide traces the remarkable evolution of ESI-MS from its conceptual origins to its current status as an indispensable tool in biomolecular analysis, framed within ongoing research to optimize ESI-MS interface configurations for enhanced sensitivity and efficiency.

Historical Development and Key Innovations

The historical pathway of ESI-MS demonstrates how interdisciplinary collaboration and incremental engineering refinements transformed a theoretical concept into a Nobel Prize-winning technology.

The Pioneering Work of Malcolm Dole

The foundation for ESI-MS was laid in 1968 by Malcolm Dole, a physical chemist at Northwestern University. Drawing inspiration from observing electrospray processes in industrial car painting, Dole hypothesized that the same principle could be applied to ionize synthetic polymers for mass spectrometric characterization [1]. His experiments utilized electrospray to produce gas-phase ions of polystyrene and measured them using a Faraday cage detector [1]. Although this early system lacked the sophisticated mass analyzers needed for precise separation and detection, Dole successfully established that electrospray could function as a soft ionization technique, producing molecular ions without significant fragmentation [1]. Despite this promising proof of concept, the technological limitations of his time, particularly the absence of suitable mass analyzers for high molecular weight ions, prevented immediate widespread adoption of his method.

The Breakthrough by John B. Fenn

The transformative advancement in ESI-MS came from John B. Fenn's research group at Yale University, who in the mid-1980s addressed the critical challenges that had hindered Dole's approach [1]. Fenn's background in molecular beams and nozzle-skimmer systems proved essential to this breakthrough. His key innovation was the design of a robust ESI source that could efficiently ionize intact biological macromolecules, particularly proteins [1]. A pivotal aspect of this design was optimizing the distance between the spray needle and the sampling cone and introducing counterflow nitrogen gas to enhance stability and reproducibility [2]. Fenn's system demonstrated that ESI could produce multiply charged ions of proteins, which reduced the mass-to-charge (m/z) ratios of large molecules, bringing them within the measurable range of common mass analyzers [1]. This multiply-charging phenomenon effectively "extended the mass range" of mass spectrometers [3]. For this groundbreaking work, which opened new frontiers for analyzing biological macromolecules, Fenn shared the Nobel Prize in Chemistry in 2002 [1] [3].

Subsequent Technical Refinements

Following Fenn's initial demonstrations, numerous researchers contributed crucial refinements that enhanced the practicality and performance of ESI-MS:

- Introduction of the Glass Capillary Transition: In 1985, Whitehouse incorporated a glass capillary transition structure, creating a seamless pressure interface between atmospheric conditions and the mass spectrometer's vacuum chamber. This became a foundational element in commercial ESI source designs [2].

- Pneumatic-Assisted Spraying: In 1987, Bruins and colleagues integrated pneumatic-assisted spraying (nebulization), enabling the technique to tolerate higher liquid flow rates up to 0.2 mL/min. This advancement significantly improved the compatibility of ESI with liquid chromatography (LC) systems, paving the way for robust LC-MS applications [2].

- Low-Flow-Rate Techniques: The development of micro-electrospray (microspray) and nano-electrospray (nanospray) in the 1990s, operating at flow rates ranging from nL/min to low μL/min, dramatically improved ionization efficiency. These low-flow techniques generate smaller initial droplets, leading to more efficient desolvation and ion production, thereby enhancing overall sensitivity [3] [2].

Table: Major Historical Milestones in ESI-MS Development

| Year | Researcher | Innovation | Impact |

|---|---|---|---|

| 1968 | Malcolm Dole | Initial electrospray ionization concept for polymers | Proof of concept for soft ionization of large molecules [1] |

| 1984 | John B. Fenn | Practical ESI source for biomolecules | Enabled ionization of intact proteins; introduced multiple charging [1] |

| 1985 | Whitehouse | Glass capillary transition interface | Created better pressure interface for commercial instruments [2] |

| 1987 | Bruins et al. | Pneumatic-assisted spraying | Allowed higher flow rates, improved LC-MS compatibility [2] |

| 1990s | Multiple groups | Microspray and nanospray | Enhanced ionization efficiency at low flow rates [3] |

| 2002 | John B. Fenn | Nobel Prize in Chemistry | Recognized transformative impact on chemical analysis [1] |

Fundamental Mechanisms of Electrospray Ionization

Understanding the ESI process requires examining both the physical mechanisms of ion formation and the architectural components that enable this transformation from solution to gas-phase ions.

The Electrospray Process: Step by Step

Electrospray ionization occurs at atmospheric pressure and involves a sequence of carefully orchestrated events that convert analyte molecules in solution to gas-phase ions [4]:

Droplet Formation: A dilute analyte solution (typically < mM concentration) is pumped through a metal capillary or needle (emitter) to which a high voltage (2-6 kV) is applied. This strong electric field causes the liquid at the tip to form a conical shape known as a Taylor cone. When the electrostatic forces overcome the surface tension of the liquid, the cone tip emits a fine mist of highly charged droplets [4] [3] [2].

Droplet Shrinking and Coulomb Fission: The charged droplets travel toward the mass spectrometer inlet through a region often supplemented with a warm drying gas (typically nitrogen). As solvent evaporates from the droplets, their size decreases while their charge density increases. When a droplet reaches the Rayleigh limit (where electrostatic repulsion equals surface tension), it becomes unstable and undergoes Coulomb fission, dividing into smaller daughter droplets [3] [2].

Gas-Phase Ion Release: The process of solvent evaporation and Coulomb fission repeats through several generations, progressively producing smaller and more highly charged droplets. The final stage of ion formation is explained by two primary models. The Charge Residue Model (CRM) proposes that repeated droplet fission eventually yields droplets containing a single analyte molecule, with the charge remaining on the molecule after final solvent evaporation. This model is thought to dominate for large biomolecules like folded proteins [3]. The Ion Evaporation Model (IEM) suggests that when droplets become sufficiently small (~10-20 nm radius), the electric field at their surface becomes strong enough to directly desorb (field-emit) solvated ions into the gas phase. This mechanism is believed to be more relevant for smaller analyte ions [3].

Instrumentation and Architecture

A typical ESI-mass spectrometer consists of three fundamental components: the ion source, mass analyzer, and detector [1]. The ion source operates at atmospheric pressure, while the mass analyzer and detector require high vacuum (typically 10⁻³ to 10⁻⁶ torr) for proper operation [1]. The interface region between the atmospheric pressure source and high vacuum analyzer is particularly critical, employing pressure gradients and voltage gradients to efficiently transfer ions while maintaining the necessary vacuum conditions [1].

Evolution of ESI-MS Interface Configurations

The interface between the ESI source and mass analyzer represents a critical area of ongoing research and development, with different configurations offering distinct advantages in ionization and transmission efficiency.

Conventional ESI-MS Interfaces

Traditional ESI-MS interfaces typically employ a single heated metal capillary (typically 7.6 cm long, 490 μm i.d.) that serves multiple functions: it samples the aerosol generated at atmospheric pressure, facilitates additional desolvation through heating (typically to 120°C), and forms the initial pressure reduction stage into the mass spectrometer [5]. In this configuration, the ESI emitter is positioned approximately 2-3 mm from the capillary inlet [5]. While this design has proven effective for many applications, significant ion losses occur due to limited flow through the inlet and collisions with surfaces during transit through the interface capillary and subsequent apertures [5].

Advanced Interface Designs

Research to overcome the limitations of conventional interfaces has led to several innovative designs:

Multi-Capillary Inlet Interface: This configuration utilizes multiple inlet capillaries (e.g., seven arranged hexagonally) instead of a single capillary, increasing the total sampling area and potentially capturing more of the electrospray plume. However, studies indicate that despite measuring higher transmitted electric currents, these systems don't always demonstrate proportional improvements in analyte signal intensity, suggesting that much of the additional current may come from residual solvent or cluster ions rather than desolvated analyte ions [5].

Subambient Pressure Ionization with Nanoelectrospray (SPIN): A significant conceptual advancement, the SPIN interface removes the constraint of a sampling inlet capillary entirely by placing the ESI emitter inside the first vacuum stage of the mass spectrometer (at ~19-22 Torr), adjacent to the entrance of an electrodynamic ion funnel [5]. This configuration minimizes losses associated with the atmospheric-to-vacuum transition and has demonstrated remarkable ion utilization efficiencies exceeding 50% in optimized conditions [5]. The SPIN interface requires careful control of emitter position and use of heated desolvation gas (CO₂ at ~160°C) to ensure complete solvent removal and stable electrospray operation in the reduced pressure environment [5].

Ion Funnel Technology: Both conventional and SPIN interfaces often incorporate electrodynamic ion funnels in the subsequent vacuum stages. These devices use superimposed RF and DC electric fields to efficiently focus and transmit ions through regions of pressure transition, significantly reducing losses compared to traditional skimmer-based interfaces [5]. The RF voltages (e.g., 100-300 V peak-to-peak) create repulsive pseudopotential barriers that prevent ions from drifting toward the electrodes, while the DC gradients (e.g., 19 V/cm) propel ions forward through the funnel [5].

Table: Performance Comparison of ESI-MS Interface Configurations

| Interface Type | Ionization Location | Key Features | Reported Advantages | Ion Utilization Efficiency |

|---|---|---|---|---|

| Single Capillary | Atmospheric pressure | Heated metal capillary, ~2 mm emitter distance | Simplicity, robustness | Lower than SPIN configurations [5] |

| Multi-Capillary | Atmospheric pressure | Multiple inlet capillaries | Higher total current transmission | Limited improvement for analyte ions [5] |

| SPIN (Subambient Pressure Ionization) | First vacuum stage (~19-22 Torr) | Emitter in vacuum, ion funnel proximity | Reduced transmission losses, efficient desolvation | >50% demonstrated [5] |

Experimental Protocols for ESI-MS Interface Evaluation

Research into ESI-MS interface configurations requires systematic methodologies to evaluate ionization and transmission efficiencies. The following protocol outlines a comprehensive approach for comparing different interface designs.

Current Measurement Methodology

A critical technique for assessing interface performance involves precisely measuring the total gas phase ion current transmitted through the interface:

Instrument Setup: Utilize a mass spectrometer with a modified interface that allows replacement of different inlet configurations (single capillary, multi-capillary, SPIN). The instrument should be equipped with a tandem ion funnel interface where the low-pressure ion funnel can function as a charge collector [5].

Current Measurement: Connect the DC voltage lines of the low-pressure ion funnel to a picoammeter (e.g., Keithley Model 6485). The ion funnel electrodes effectively collect the charge from all transmitted ions. Each reported current value should represent an average of at least 100 consecutive measurements to ensure statistical reliability [5].

Data Correlation: Correlate the measured electric current with the total ion current (TIC) and extracted ion currents (EIC) for specific analytes measured in the corresponding mass spectra. This correlation helps distinguish between total charge transmission and the transmission of desolvated analyte ions specifically [5].

Systematic Comparison Protocol

To objectively evaluate different interface configurations, implement the following experimental procedure:

Standardized Solution Preparation: Prepare peptide standard solutions (e.g., 1 μM and 100 nM mixtures of angiotensin I, angiotensin II, bradykinin, and other well-characterized peptides) in 0.1% formic acid in 10% acetonitrile/water. Using standardized solutions ensures consistent analyte properties across different interface tests [5].

Emitter Preparation: Fabricate consistent electrospray emitters by chemically etching fused silica capillaries (O.D. 150 μm, I.D. 10 μm) to create fine tips suitable for nanoelectrospray. For array studies, prepare emitter arrays with individual coaxial sheath gas capillaries for each emitter [5].

Parameter Optimization: For each interface configuration, systematically optimize key parameters including:

- Interface temperature (for capillary inlets)

- Ion funnel RF voltages (typically 100-300 V peak-to-peak) and DC gradients

- Emitter position relative to the inlet

- Desolvation gas flow rate and temperature [5]

Data Collection: Acquire mass spectra over a defined m/z range (e.g., 200-1000) with consistent acquisition times (e.g., 1 minute summation). Measure both the electric current and mass spectral intensities for each configuration under identical solution and flow rate conditions [5].

Efficiency Calculation: Determine the ion utilization efficiency by comparing the number of analyte ions reaching the detector (derived from mass spectral data) to the number of analyte molecules consumed from the solution during the same period. This provides a quantitative measure of overall interface performance [5].

Research Reagent Solutions for ESI-MS Interface Studies

Table: Essential Reagents and Materials for ESI-MS Interface Research

| Reagent/Material | Specifications | Function in Experiment |

|---|---|---|

| Fused Silica Capillaries | O.D. 150 μm, I.D. 10 μm (Polymicro Technologies) | Fabrication of nanoelectrospray emitters for consistent ion production [5] |

| Standard Peptide Mixture | Angiotensin I, Angiotensin II, Bradykinin, others (Sigma-Aldrich) | Well-characterized analytes for standardized performance evaluation across interfaces [5] |

| Mobile Phase Solvents | HPLC-grade water, acetonitrile, methanol (Fisher Scientific) | Preparation of analyte solutions with consistent properties [5] |

| Ionization Additives | Formic acid, acetic acid (0.1-1%) | Enhance conductivity and provide proton source for efficient ionization [3] |

| Nebulization/Drying Gases | High-purity nitrogen, carbon dioxide | Assist droplet formation and desolvation in different interface configurations [5] |

Applications in Modern Biomolecular Analysis

The evolution of ESI-MS interfaces has enabled diverse applications across biomedical research and clinical analysis:

Proteomics and Biomarker Discovery: ESI-MS, particularly when coupled with liquid chromatography (LC-ESI-MS), has become a fundamental tool for large-scale protein identification and quantification. The intact-protein analysis system (IPAS) coupled with immunodepletion of abundant proteins and isobaric tagging (e.g., iTRAQ) enables quantitative profiling of complex proteomes, identifying approximately 1,500 proteins with high confidence from human plasma samples [6].

Metabolomics and Clinical Chemistry: ESI-tandem-MS enables simultaneous measurement of numerous metabolites in complex biological samples. This capability is particularly valuable in clinical settings for screening inborn errors of metabolism, including disorders of amino acid, fatty acid, purine, and pyrimidine metabolism [4]. The technique's high sensitivity and specificity make it suitable for analyzing limited sample volumes at femtomole concentration levels [4].

Pharmaceutical Research: ESI-LC-MS supports multiple stages of drug development, including pharmacokinetic studies, metabolic stability assessment, and therapeutic drug monitoring. The technique's ability to detect and quantify drugs and their metabolites at low concentrations in biological matrices provides critical data for dosage optimization and safety assessment [2].

The evolution of ESI-MS from Malcolm Dole's initial experiments to contemporary interface configurations represents a remarkable journey of scientific innovation and technical refinement. The trajectory from simple capillary inlets to sophisticated subambient pressure interfaces with ion funnel technology has progressively enhanced ionization efficiency and ion transmission characteristics. Current research continues to optimize ESI-MS interfaces, with approaches like the SPIN interface demonstrating that substantial improvements in overall ion utilization efficiency are achievable through fundamental redesigns of the ionization and transmission pathway. As these interface technologies mature and become commercially implemented, they will further expand the application boundaries of ESI-MS in biomolecular research, enabling more sensitive, rapid, and comprehensive analysis of complex biological systems. The ongoing research into ESI-MS interface configurations continues to be a vital area of development that underpins advances across proteomics, metabolomics, and pharmaceutical sciences.

Electrospray Ionization Mass Spectrometry (ESI-MS) has emerged as a cornerstone analytical technique in modern laboratories, enabling the sensitive and robust analysis of a wide range of molecules, from small metabolites to large intact proteins [4]. Its capability to gently ionize non-volatile and thermally labile biomolecules directly from liquid solutions has made it indispensable in fields such as proteomics, metabolomics, pharmaceutical sciences, and clinical diagnostics [4] [2]. This guide provides an in-depth examination of the three core component systems of an ESI-MS instrument: the ion source, which creates gas-phase ions from a liquid sample; the mass analyzer, which separates these ions based on their mass-to-charge ratio (m/z); and the detector, which quantifies the separated ions. Understanding the design, function, and interplay of these components is fundamental to leveraging the full power of ESI-MS in research and development.

The Electrospray Ionization (ESI) Source

The ESI source is responsible for the soft ionization of analytes, transferring them from a liquid phase at atmospheric pressure into the gas phase as ions suitable for mass analysis [3]. This process is pivotal for preserving the structural integrity of fragile biomolecules during ionization.

Mechanism of Ion Formation

The electrospray process involves a sequence of coordinated physical events, summarized in the workflow below:

The process begins when a sample solution is introduced through a capillary needle (or emitter) maintained at a high voltage, typically between 2.5 and 6.0 kV [4] [7]. This strong electric field charges the liquid surface, inducing the formation of a Taylor cone at the capillary tip. From the apex of this cone, a fine jet of highly charged droplets is emitted [2]. These droplets, stabilized by a flow of nebulizing gas (often nitrogen), travel towards the mass spectrometer inlet [4]. As they move, the solvent evaporates with the aid of a heated drying gas, causing the droplets to shrink and dramatically increase their surface charge density. Upon reaching the Rayleigh limit, where electrostatic repulsion overcomes surface tension, the droplets undergo Coulomb fission, disintegrating into smaller, progeny droplets [3]. This cycle of evaporation and fission repeats until the conditions are met for the direct release of gas-phase analyte ions. Two primary models explain this final step: the Ion Evaporation Model (IEM), which suggests the direct field desorption of solvated ions from very small droplets, and the Charge Residue Model (CRM), which proposes that ions form after complete solvent evaporation from droplets containing a single analyte ion [3].

ESI Source Configuration and Optimization

Optimal ESI source performance is critical for signal stability and sensitivity. Key operational parameters that require optimization include:

- Capillary Voltage: The high voltage applied to the electrospray needle to charge the liquid and form the Taylor cone.

- Nebulizer Gas Pressure: A gas stream that shears the liquid to assist in forming a fine aerosol, enabling higher flow rates.

- Drying Gas Flow and Temperature: A stream of heated inert gas (e.g., nitrogen) that accelerates solvent evaporation from the charged droplets [4] [8].

Optimizing these parameters in a multivariate manner using approaches like Design of Experiments (DoE) is more efficient than the traditional one-variable-at-a-time (OVAT) strategy, as it accounts for interactions between factors [8]. For instance, a study optimizing an ESI source for metabolite analysis used a fractional factorial design to screen factors and then a central composite design to find optimal settings, significantly increasing sensitivity for poorly ionizing compounds [8].

Table 1: Key Parameters for ESI Source Optimization

| Parameter | Typical Range | Function |

|---|---|---|

| Capillary Voltage | 2000 - 4000 V [8] | Applies high voltage to the liquid to create charged droplets. |

| Nebulizer Pressure | 10 - 50 psi [8] | Shears the liquid into a fine spray of charged droplets. |

| Drying Gas Flow Rate | 4 - 12 L/min [8] | Evaporates solvent from charged droplets. |

| Drying Gas Temperature | 200 - 340 °C [8] | Provides heat to assist solvent evaporation. |

Mass Analyzer Systems

Following ionization, the gas-phase ions are electrostatically guided into the mass analyzer, a core component under high vacuum that separates ions based on their mass-to-charge (m/z) ratios. Different types of mass analyzers offer varying trade-offs in terms of mass resolution, accuracy, speed, and cost [4].

Quadrupole Mass Analyzer

The quadrupole is one of the most common and robust mass analyzers found in clinical and analytical laboratories [4]. It consists of four parallel, hyperbolic metal rods. A direct current (DC) voltage and a radio frequency (RF) alternating current voltage are applied to opposite pairs of rods, creating a complex oscillating electric field. For a given DC/RF ratio, only ions of a specific m/z value will have a stable oscillating trajectory and pass through the quadrupole to reach the detector. All other ions will have unstable trajectories and collide with the rods. A mass spectrum is generated by systematically scanning the DC and RF voltages to allow different m/z ions to pass through sequentially [4].

Ion Trap Mass Analyzer

Ion trap analyers, including 3D quadrupole ion traps, confine and store ions in a dynamic electric field within a defined space. A common configuration uses three electrodes: a ring electrode and two end-cap electrodes. By applying specific RF voltages to these electrodes, ions of a broad m/z range can be trapped in stable oscillating orbits within the cavity. To generate a mass spectrum, the RF potentials are scanned to sequentially destabilize the trajectories of ions of increasing m/z, ejecting them from the trap towards the detector [4]. A key advantage of ion traps is their ability to perform multiple rounds of tandem mass spectrometry (MSⁿ), where a selected ion can be fragmented, and its product ions can then be trapped and fragmented further, providing detailed structural information [4].

Tandem Mass Spectrometry (MS/MS) with Triple-Quadrupole

Tandem mass spectrometry (MS/MS) is a powerful technique for obtaining structural information and enhancing analytical specificity. In a triple-quadrupole instrument, three quadrupoles are arranged in series [4]. The first quadrupole (Q1) acts as a mass filter, selecting a specific precursor ion of interest. The second quadrupole (Q2), operated in RF-only mode, serves as a collision cell where the selected ions are fragmented through Collision-Induced Dissociation (CID) with an inert gas like argon. The third quadrupole (Q3) then analyzes the resulting product ions. This configuration enables several vital scan modes, illustrated in the following diagram:

Table 2: Common Scan Modes in a Tandem Quadrupole Mass Spectrometer

| Scan Mode | Q1 Function | Q3 Function | Primary Application |

|---|---|---|---|

| Product Ion Scan | Static (selects one m/z) | Scans a mass range | Structural elucidation of a specific precursor ion [4]. |

| Precursor Ion Scan | Scans a mass range | Static (monitors one product m/z) | Identifying all precursors that fragment to produce a common product ion [4]. |

| Neutral Loss Scan | Scans a mass range | Scans synchronously with a constant m/z offset | Monitoring the loss of a common neutral fragment (e.g., loss of 102 Da from butylated amino acids) [4]. |

| Multiple Reaction Monitoring (MRM) | Static (selects one m/z) | Static (selects one product m/z) | Highly sensitive and specific quantitative analysis [4] [8]. |

Detector and Data System

After separation by the mass analyzer, the ion beams, now resolved by m/z, must be converted into a measurable electrical signal. This is the function of the detector. While various detector types exist (e.g., electron multipliers, Faraday cups), a common type for quantitative ESI-MS work is the electron multiplier. When ions strike the conversion dynode of the multiplier, they release secondary electrons. These electrons are then accelerated through a series of dynodes, each causing an electron cascade, resulting in a measurable electrical current that is amplified several million-fold [4]. The resulting signal is processed by a data system, which records the intensity of the signal at each m/z value and presents the information as a mass spectrum—a plot of ion abundance versus m/z.

Experimental Protocols and Applications

Protocol: ESI Source Optimization Using Design of Experiments (DoE)

Objective: To systematically optimize ESI source parameters (e.g., for maximum sensitivity of a target analyte) [8].

- Select Factors and Responses: Identify key ESI parameters (factors) to optimize, such as capillary voltage, nebulizer pressure, drying gas flow, and temperature. Define the measurable output (response), such as the peak area or height of a target analyte in Multiple Reaction Monitoring (MRM) mode.

- Screening Design: Use a fractional factorial design (e.g., a two-level FFD) to screen a larger number of factors with a minimal number of experimental runs. This identifies which factors have a significant effect on the response.

- Response Surface Modeling: For the significant factors, apply a more detailed design like a Central Composite Design (CCD) or Box-Behnken Design (BBD) to model the response surface. This design explores factor interactions and curvature in the response.

- Data Analysis and Visualization: Use statistical software to build a mathematical model linking the factors to the response. Generate response surface plots to visualize the relationship.

- Prediction and Verification: The model predicts the optimal parameter settings for maximizing the response. These settings are then tested experimentally to confirm the improvement.

Application: Protein Analysis and Molecular Weight Determination

ESI-MS is exceptionally well-suited for protein analysis because it often produces multiply charged ions, [M + nH]ⁿ⁺, effectively extending the mass range of the analyzer [9] [7]. The resulting spectrum appears as a peak envelope, with each peak corresponding to a different charge state (z) of the same molecule. The molecular weight (MW) of the neutral protein can be calculated from any two adjacent peaks in this envelope using the following equations, where M₁ and M₂ are the m/z values for two adjacent charge states, and A is the mass of the adduct (e.g., 1.01 for H⁺) [9]:

[z2 = \frac{M1 - A}{M2 - M1} \quad \text{and} \quad MW = z2 (M2 - A)]

Table 3: Example ESI-MS Data for Ubiquitin (Theoretical MW ~8560 Da) [9]

| Charge State (z) | Theoretical m/z of [M+zH]ᶻ⁺ |

|---|---|

| 13 | 659 |

| 12 | 714 |

| 11 | 779 |

| 10 | 857 |

| 9 | 952 |

| 8 | 1071 |

The Scientist's Toolkit: Key Research Reagents and Materials

Successful ESI-MS analysis requires careful selection of solvents and additives to ensure efficient ionization and stable spray formation.

Table 4: Essential Reagents for ESI-MS Analysis

| Item | Function / Role in ESI-MS |

|---|---|

| LC-MS Grade Solvents (Water, Methanol, Acetonitrile) | High-purity solvents minimize chemical noise and background signals. Their volatility aids droplet desolvation [3]. |

| Volatile Acids (e.g., Formic Acid, Acetic Acid) 0.06% | Adds protons to the solution to facilitate analyte protonation ([M+H]⁺) in positive ion mode. Increases solution conductivity for stable electrospray [8] [3]. |

| Volatile Bases (e.g., Ammonium Acetate, Ammonium Hydroxide) | Promotes analyte deprotonation ([M-H]⁻) for analysis in negative ion mode. Can be used as a buffer. |

| Nitrogen Gas (≥99.98%) | Serves as the nebulizing and drying gas in the ESI source [4] [8]. |

| Collision Gas (e.g., Argon) | An inert gas used in the collision cell (Q2) of a tandem MS for Collision-Induced Dissociation (CID) [4] [8]. |

| Tuning & Calibration Solutions | A mixture of known ions (e.g., ESI-L Tuning Mix) for mass accuracy calibration and instrument performance optimization [8]. |

Critical Considerations and Troubleshooting

A major challenge in quantitative ESI-MS, particularly with complex samples like biological fluids, is the matrix effect [10]. This phenomenon occurs when co-eluting compounds from the sample matrix alter the ionization efficiency of the analyte, most commonly causing ion suppression (a reduction in signal). To assess and mitigate matrix effects:

- Assessment: Use the post-extraction addition method, comparing the analyte response in a pure solution to its response when spiked into a processed sample matrix [10].

- Mitigation: Employ extensive sample cleanup, improve chromatographic separation to shift the analyte's retention time away from the interfering compounds, and use a stable isotope-labeled internal standard (SIL-IS) which experiences the same suppression as the analyte, correcting for it [10].

Electrospray Ionization (ESI) represents a pivotal soft ionization technique in modern mass spectrometry, enabling the transfer of ions from a liquid phase into the gas phase with minimal fragmentation. This process is fundamental to the analysis of a broad spectrum of analytes, from small organic molecules to large biological macromolecules like proteins and nucleic acids [1]. The development of ESI has fundamentally advanced fields such as proteomics and drug development by allowing the precise mass determination of thermally labile and non-volatile compounds [1] [3]. Framed within broader research on ESI-MS interface configurations, this guide details the core physical and chemical mechanisms that govern the transformation of a solution into gaseous ions, a process critical for robust and sensitive mass spectrometric analysis.

Historical and Theoretical Foundations

The electrospray phenomenon has a rich history, with foundational work dating back to the observations of Lord Rayleigh in 1882 on the charge capacity of liquid droplets [3]. The modern implementation for mass spectrometry was pioneered by Malcolm Dole in the 1960s [1] [3], but it was the groundbreaking work of John B. Fenn and his team in the late 1980s that demonstrated its utility for analyzing large biomolecules, an achievement recognized with the Nobel Prize in Chemistry in 2002 [1] [3]. The theoretical underpinning of the electrospray process involves the application of a strong electric field (typically 2-6 kV) to a liquid emerging from a capillary, which disperses the liquid into a fine aerosol of charged droplets [1] [11]. The stability of this spray is often described by the Taylor cone, a conical meniscus formed when the electrostatic repulsion within the liquid balances its surface tension [3].

Table 1: Key Historical Milestones in ESI Development

| Year | Contributor(s) | Key Achievement |

|---|---|---|

| 1882 | Lord Rayleigh | Theoretical estimation of the maximum charge a liquid droplet can carry (Rayleigh limit) [3]. |

| 1968 | Malcolm Dole | First use of electrospray ionization with mass spectrometry [3]. |

| 1984 | Yamashita & Fenn / Gall et al. | Independent first reports of electrospray ionization as a mass spectrometry interface [3]. |

| 1988-1989 | Fenn and Colleagues | Groundbreaking application of ESI-MS for the ionization of intact proteins [1]. |

| 2002 | John B. Fenn | Awarded Nobel Prize in Chemistry for the development of ESI-MS for biological macromolecules [1] [3]. |

The Stepwise Electrospray Mechanism

The formation of gas-phase ions from a solution via electrospray is a multi-stage process involving droplet formation, solvent evaporation, and finally, ion release.

Droplet Formation and Charging

The process initiates when a sample solution is pumped through a metal capillary (needle) to which a high voltage (typically ±3-5 kV) is applied [11] [12]. This creates a strong electric field that penetrates the liquid at the capillary tip. The electrostatic stress deforms the liquid meniscus into a Taylor cone, from the apex of which a fine jet emerges that breaks up into a mist of highly charged droplets [1] [13] [12]. The polarity of the charges on the droplets corresponds to the polarity of the voltage applied. The formation of a stable spray can be assisted by a coaxial flow of nebulizing gas (e.g., nitrogen) which helps direct the spray and restrict initial droplet size [1] [14].

Droplet Shrinking and Coulomb Fission

The charged droplets are directed towards the mass spectrometer's sampling orifice, drifting through a region of atmospheric pressure. A counter-current flow of heated drying gas (e.g., nitrogen) promotes the evaporation of the volatile solvent from these droplets [1] [11]. As the droplets shrink in size, their charge density increases. Upon reaching the Rayleigh limit—the point where the electrostatic repulsion between the charges equals the surface tension holding the droplet together—the droplet becomes unstable and undergoes Coulomb fission, disintegrating into smaller, progeny droplets [3]. This cycle of solvent evaporation and Coulomb fission repeats iteratively, producing ever-smaller and more highly charged droplets [3] [12].

Production of Gas-Phase Ions

The final step, the release of free, gas-phase ions from these nanometre-sized charged droplets, is explained by two primary models, the applicability of which depends on the analyte's properties [3].

- Charged Residue Model (CRM): This model, applicable to large macromolecules like proteins, proposes that the solvent evaporation and fission cycles continue until the droplet is reduced to a size that contains only a single analyte molecule. The final evaporation of the last solvent molecules leaves the analyte holding the droplet's residual charge, thus forming a gas-phase ion [3] [12].

- Ion Evaporation Model (IEM): This model is considered dominant for smaller ions. It suggests that as the droplet radius becomes very small, the electric field at its surface becomes intense enough to directly desorb or "evaporate" solvated ions from the droplet surface into the gas phase before the solvent fully evaporates [3].

For large, folded proteins, the Charged Residue Model is generally accepted, while the Ion Evaporation Model applies to smaller ion species [3]. A third model, the Chain Ejection Model (CEM), has been proposed for disordered polymers and unfolded proteins [3].

Diagram 1: ESI Mechanism from Droplets to Ions

Experimental Protocols for ESI-MS Analysis

Protocol: Optimization of ESI Source Parameters

This protocol provides a systematic approach for tuning an ESI source to maximize sensitivity and stability for a specific analyte [14].

- Sample Preparation: Prepare a standard solution of the target analyte (typically 10⁻⁶ - 10⁻⁴ M) in a volatile, reversed-phase compatible solvent (e.g., methanol/water or acetonitrile/water mixture). The use of high-purity solvents and plastic vials is recommended to minimize contamination from metal ions that can form adducts [3] [14].

- Initial Instrument Setup: Install the appropriate LC column (semi-micro columns with 2 mm ID are preferred for optimal ESI sensitivity at flow rates of 0.2-0.8 mL/min) [11]. Use an isocratic or gradient method that elutes the analyte.

- Sprayer Voltage Optimization: Begin with a lower voltage (e.g., 2.5-3.0 kV) and infuse the standard solution. Gradually increase the voltage while monitoring the total ion count (TIC) and signal stability. The goal is to find the voltage that provides the highest stable signal without inducing electrical discharge, which can manifest as signal instability and the appearance of solvent cluster ions [14].

- Sprayer Position Optimization: Adjust the position of the ESI sprayer relative to the sampling cone. As a general guide, smaller polar analytes often benefit from the sprayer being positioned farther from the cone, while larger hydrophobic analytes may yield a better signal with the sprayer closer to the cone [14].

- Gas Flow and Temperature Optimization: Optimize the flow rate of the nebulizing and drying gases, as well as the desolvation temperature (often set around 100-400°C). Higher temperatures and gas flows aid desolvation but must be balanced to prevent premature evaporation or analyte degradation [14] [11].

- Cone Voltage Optimization: Adjust the cone voltage (or declustering potential), which is responsible for extracting ions into the vacuum and declustering solvated ions. Typical values range from 10-60 V. Higher voltages can induce in-source fragmentation, which may be desirable for structural information but should be minimized if the intact molecular ion is the target [14].

Protocol: Evaluating Ionization Efficiency and Matrix Effects

This methodology is adapted from research comparing ESI with other ionization techniques and is crucial for robust assay development, particularly in quantitative bioanalysis [15].

- Solution Preparation: Prepare calibration standards of the analyte (e.g., Levonorgestrel) in a pure solvent and in a blank biological matrix (e.g., human plasma) that has been processed through extraction (e.g., liquid-liquid extraction with cyclohexane) [15].

- LC-MS/MS Analysis: Analyze both sets of standards using the optimized LC-ESI-MS/MS method. The mobile phase should consist of a volatile buffer like methanol with 0.01% formic acid to facilitate protonation and evaporation [15] [11].

- Data Analysis: Construct calibration curves for the analyte in pure solvent and in the post-extraction matrix. The slope of the calibration curve in pure solvent represents the inherent ionization efficiency. A significant difference in the slopes between the two curves indicates the presence of matrix effects (ion suppression or enhancement). A shallower slope in the matrix indicates ion suppression [15].

- Comparison with APCI: To assess the best ionization source for the application, repeat the experiment using an Atmospheric Pressure Chemical Ionization (APCI) source. APCI, which involves vaporization followed by gas-phase chemical ionization, is often less susceptible to matrix effects from salts and non-volatile compounds compared to ESI [15] [11].

Table 2: Key Solvent Properties for ESI Optimization [14]

| Solvent | Surface Tension (dyne/cm) | Viscosity (cP) | ESI Consideration |

|---|---|---|---|

| Water | 72.80 | 1.00 | High surface tension requires higher spray voltage; often mixed with organic solvents. |

| Methanol | 22.5 | 0.59 | Low surface tension promotes stable Taylor cone; common ESI solvent. |

| Acetonitrile | 19.10 | 0.38 | Very low surface tension and viscosity; excellent for desolvation and LC separation. |

| Isopropanol | 21.79 | 2.40 | Low surface tension but high viscosity; can be added as a modifier (1-2%). |

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful ESI-MS analysis requires careful selection of reagents and materials to ensure optimal ionization, minimize interference, and maintain instrument integrity.

Table 3: Essential Research Reagent Solutions for ESI-MS

| Item | Function/Description | Technical Consideration |

|---|---|---|

| High-Purity Volatile Solvents (e.g., Methanol, Acetonitrile, Water) | Form the mobile phase for LC separation and the medium for electrospray. | Use LC-MS grade to minimize metal ion contaminants that cause adduct formation [14]. |

| Volatile Additives (e.g., Formic Acid, Acetic Acid, Ammonium Acetate) | Modify pH to promote analyte protonation (positive mode) or deprotonation (negative mode). | Concentrations of 0.1-1.0% are typical. Acidic additives aid positive ion mode; ammonium acetate is used for neutral compounds or volatile buffering [11]. |

| Liquid-Liquid Extraction Solvents (e.g., Cyclohexane, Ethyl Acetate) | Isolate analytes from complex biological matrices like plasma. | Removes salts and phospholipids that cause ion suppression, thereby improving sensitivity and accuracy [15]. |

| Nebulizing & Drying Gas (e.g., High-Purity Nitrogen) | Assist in aerosolization and desolvation of the electrosprayed droplets. | Must be oil-free and dry. Flow rates and temperature are critical optimized parameters [1] [14]. |

| Plastic Sample Vials | Store samples and standards prior to injection. | Preferred over glass to prevent leaching of metal ions (e.g., Na+, K+) that form unwanted adducts [14]. |

Advanced Configurations and Emerging Directions

The fundamental ESI process has been adapted into various configurations to extend its capabilities. Nano-electrospray Ionization (nano-ESI) utilizes emitters with apertures of 1-3 µm and operates at very low flow rates (nL/min), generating smaller initial droplets for improved ionization efficiency and reduced sample consumption [3]. Another advanced configuration is the sub-atmospheric pressure ESI (SAP-ESI), which operates at low pressure (e.g., 25 torr) and can be coupled with high-energy in-source collision-induced dissociation (IS-CID) to fragment solvent complexes and extract "naked" elemental ions from solutions, pushing ESI into the realm of elemental analysis [16].

Furthermore, ESI serves as the foundation for several ambient ionization techniques. In Desorption Electrospray Ionization (DESI), an ESI spray is directed at a sample surface under ambient conditions, desorbing and ionizing molecules for direct analysis without sample preparation [3].

The electrospray process, transforming analytes in solution into gas-phase ions via charged droplets, is a cornerstone of modern mass spectrometry. A deep understanding of its mechanisms—from Taylor cone formation and Coulomb fission to the final ion release via CRM or IEM—is essential for researchers to effectively configure and optimize ESI-MS interfaces. By applying systematic experimental protocols for parameter tuning and matrix effect evaluation, and by utilizing the appropriate reagents detailed in this guide, scientists can harness the full power of ESI-MS. This enables a wide range of applications, from the sensitive quantification of pharmaceutical compounds in biological fluids to the detailed structural characterization of complex biomacromolecules.

Electrospray Ionization Mass Spectrometry (ESI-MS) has revolutionized the analysis of biological macromolecules, with multiple charging serving as the fundamental phenomenon enabling this capability. Multiple charging describes the process whereby macromolecules such as proteins, peptides, and oligosaccharides acquire numerous positive or negative charges during the ESI process [17] [18]. This charging is not merely incidental but rather the crucial feature that allows large molecules to be analyzed using conventional mass analyzers with limited m/z ranges [18]. When a protein acquires multiple protons, it appears at lower m/z values (since m/z = mass/number of charges), effectively extending the mass range of the instrument and enabling the study of proteins with molecular weights exceeding 100 kDa [19].

The importance of multiple charging extends beyond simple mass determination. For researchers in drug development and structural biology, the charge state distribution provides valuable insights into protein conformation, solvent accessibility, and even dynamics of folding and unfolding [18]. The charge state distribution observed in ESI mass spectra serves as a sensitive indicator of a protein's solution-phase structure, where folded, native proteins typically produce a narrow distribution of low charge states, while denatured proteins yield a broader distribution of higher charge states [18]. This intrinsic relationship between structure and charging behavior makes ESI-MS an indispensable tool for characterizing therapeutic proteins and their complexes in modern biopharmaceutical development.

Fundamental Mechanisms of Multiple Charging

The Electrospray Process and Droplet Formation

The journey to multiple charging begins with the electrospray process itself. In ESI, a sample solution containing the analyte is injected through a capillary needle to which a high voltage (typically 2-6 kV) is applied [19]. This creates a strong electric field that causes the liquid to nebulize into a fine mist of charged droplets [19]. The charged droplets, carrying an excess of one type of ion (typically positive ions in positive-ion mode), are directed toward the mass spectrometer inlet by the electric field [19]. As these droplets travel through the atmosphere or a heated capillary (typically maintained at 100-300°C), the solvent continuously evaporates, reducing the droplet size while maintaining the same charge [19]. This process increases the charge density on the droplet surface until the droplet reaches the Rayleigh limit, the point at which Coulombic repulsion overcomes surface tension, causing the droplet to fission into smaller offspring droplets [19]. This evaporation-fission cycle repeats until ultimately leading to the production of completely desolvated, gas-phase ions [19].

From Droplets to Gas-Phase Ions: Competing Models

Two primary models explain the final stage of ion formation from charged droplets:

Charge Residue Model (CRM): Proposed by Malcolm Dole and later refined by John Fenn, this model suggests that continued solvent evaporation and droplet fission eventually produce droplets containing only a single analyte molecule. When the final solvent molecule evaporates, the charge that was on the droplet surface remains on the analyte molecule [18]. This model particularly explains the multiple charging of large proteins and complexes.

Ion Evaporation Model (IEM): Proposed by Iribarne and Thomson, this model suggests that before the droplet reaches the Rayleigh limit, the strong electric field at the droplet surface can cause direct desorption of pre-formed ions from the solution into the gas phase [19]. This mechanism is thought to dominate for smaller ions and peptides.

For large biomolecules, the CRM appears to be the dominant mechanism, successfully explaining the correlation observed between the number of charges a molecule can acquire and its physical size [18].

Factors Governing Charge State Distributions

Protein Characteristics and Solution Conditions

The charge state distribution (CSD) observed for a protein in ESI-MS is influenced by multiple factors related to the protein itself and the solution from which it is sprayed:

Molecular Size and Shape: For folded, native proteins, there is a strong correlation between the protein's physical dimensions (specifically its surface area) and the number of charges it acquires [17] [18]. Compact, globular proteins exhibit lower charge states, while unfolded, extended chains accommodate more charges due to reduced Coulombic repulsion and increased protonation site availability [18].

Number of Ionizable Sites: The maximum possible charge state is theoretically limited by the number of basic amino acid residues (arginine, lysine, histidine) and the N-terminus for positive-ion mode ESI [18]. However, in practice, the observed charge states are almost always lower than the number of basic sites due to charge-charge repulsion effects in the gas phase [18].

Solvent Composition and Protein Conformation: Solvents that promote native structure (aqueous buffers at physiological pH) yield lower charge states, while denaturing conditions (presence of organic solvents like acetonitrile, acidic pH, or additives like glycerol) produce higher charge states by unfolding the protein and making more basic sites available for protonation [18].

Role of Acidic Residues: Interestingly, chemical modification experiments have shown that capping carboxylic acid groups (aspartic acid, glutamic acid, C-terminus) with neutral functional groups yields little change in CSD, indicating that carboxyl groups do not play a significant role in limiting the positive charging of denatured proteins in ESI [18]. This challenges the hypothesis that gas-phase salt bridges involving deprotonated carboxyl groups significantly reduce charging.

Experimental and Instrumental Parameters

The observed CSD is also affected by instrumental conditions and experimental design:

Interface Configuration and Ion Transmission: The design of the ESI-MS interface significantly impacts the transmission efficiency of ions into the mass analyzer. Different configurations, such as single inlet capillary, multi-inlet capillary, and subambient pressure ionization with nanoelectrospray (SPIN) interfaces, exhibit varying ion utilization efficiencies, which can affect the observed signal intensities for different charge states [5].

ESI Flow Rates: Operating at nanoflow rates (nL/min range), known as nanoESI, significantly improves ionization efficiency compared to higher flow rates. NanoESI produces smaller initial droplets, leading to more efficient desolvation and ion production, which can influence the detected CSD [5].

Voltage Settings and Gas Temperatures: The voltages applied to the ESI needle, the temperature of the desolvation capillary, and the use of sheath gases all influence the desolvation and ion declustering process, thereby affecting the CSD [19].

Experimental Methodologies for CSD Analysis

Standard ESI-MS Protocol for Protein Analysis

The following detailed methodology is adapted from procedures cited in current literature for analyzing protein charge state distributions [18] [19]:

Sample Preparation:

- Prepare a 1-10 µM protein solution in a suitable volatile buffer (e.g., 10-100 mM ammonium acetate for native analysis, or 0.1% formic acid in water/acetonitrile for denatured analysis) [18] [19].

- For denatured conditions, use a mixture of water and organic solvent (e.g., 49:49:2 water/acetonitrile/formic acid). For native conditions, use aqueous ammonium acetate.

- Centrifuge samples at >14,000 rpm for 10 minutes to remove particulate matter prior to analysis.

Instrumentation Setup:

- Utilize an ESI-MS system equipped with a heated capillary interface. A tandem quadrupole, time-of-flight (TOF), or Orbitrap mass analyzer is suitable [5] [20].

- For direct infusion, use a syringe pump to infuse sample at a flow rate of 3-10 µL/min for conventional ESI, or 200-500 nL/min for nanoESI [5] [19].

- Connect a fused-silica ESI emitter (O.D. ~150 µm, I.D. ~10-50 µm) to the syringe via a metal union for voltage contact [5].

ESI Source and MS Parameters:

- ESI Voltage: Apply 2-4 kV to the metal union (positive ion mode) [19].

- Desolvation Temperature: Set the heated capillary temperature between 150-300°C, optimizing for full desolvation without thermal degradation [19].

- Nebulizing/Gas Flow: Adjust sheath and drying gas flows (if available) to stabilize the spray.

- Mass Spectrometer: Set the mass analyzer to scan over an m/z range sufficient to capture the expected charge state envelope (e.g., m/z 500-3000 for a 30 kDa protein). For high-resolution mass analyzers (e.g., Orbitrap), set a resolution of at least 30,000 to resolve charge states clearly [20].

Data Acquisition and Analysis:

- Acquire data for 1-3 minutes and sum the spectra to improve signal-to-noise.

- Use the instrument's deconvolution software algorithm to transform the multiple-charged spectrum into a zero-charge mass spectrum. Input the correct charge state range and charge carrier (e.g., H+) for the deconvolution.

- Analyze the relative abundances of different charge states to infer structural information.

Chemical Modification Protocol for Charge State Manipulation

To experimentally probe the role of specific functional groups in charging, systematic chemical modification can be employed [18]:

Amine Alkylation (Adds Fixed Positive Charges):

- React the protein with 2-5 molar excess of N-(2-bromoethyl)-N,N-dimethylammonium bromide in 50 mM HEPES buffer, pH 7.5, for 2 hours at 37°C [18].

- This modification quaternizes lysine side chains, appending fixed positive charges.

Carboxylic Acid Capping (Neutral Modification):

- Activate carboxyl groups by reaction with a carbodiimide (e.g., EDC).

- Subsequently, incubate with a nucleophile such as a neutral amine (e.g., methylamine) to form neutral amides [18].

- Purify the modified protein using dialysis or size-exclusion chromatography before MS analysis.

MS Analysis of Modified Proteins:

- Analyze the modified proteins using the standard ESI-MS protocol described above.

- Compare the CSD of the modified protein to the unmodified control. Amine alkylation with fixed charges typically results in a significant shift to higher charge states, while carboxylic acid capping typically shows minimal effect on the CSD of denatured proteins [18].

Quantitative Analysis of ESI-MS Interface Performance

The sensitivity of ESI-MS is largely governed by the ionization efficiency in the source and the ion transmission efficiency through the interface. The ion utilization efficiency is a key metric, defined as the proportion of analyte molecules in solution that are converted to gas phase ions and transmitted through the interface to the detector [5]. The performance of different interface configurations can be systematically evaluated by measuring the total transmitted gas phase ion current and correlating it with the observed ion abundance in the mass spectrum [5].

Table 1: Comparison of ESI-MS Interface Configurations and Performance Characteristics

| Interface Configuration | Key Features | Ion Utilization Efficiency | Typical Applications |

|---|---|---|---|

| Single Inlet Capillary [5] | Single metal or glass capillary (e.g., 7.6 cm long, 490 µm i.d.); heated to 120°C; emitter positioned ~2 mm from inlet. | Baseline efficiency; significant ion losses due to limited flow through inlet and surface collisions. | General purpose LC-MS and direct infusion analysis. |

| Multi-Capillary Inlet [5] | Multiple inlet capillaries (e.g., seven) arranged in a hexagonal pattern; increases sampling area. | Higher transmitted ion current than single capillary design. | Applications requiring increased ion flux. |

| SPIN (Subambient Pressure Ionization) [5] | ESI emitter placed inside the first vacuum stage (~20 Torr); adjacent to ion funnel; removes inlet capillary constraint. | Highest reported efficiency; improved focusing and transmission of gas-phase ions. | High-sensitivity applications, nanoESI, and coupling with emitter arrays. |

Table 2: Impact of Chemical Modifications on Protein Charge State Distributions (Representative Data) [18]

| Protein / Modification Type | Functional Groups Modified | Effect on Average Charge State | Molecular Interpretation |

|---|---|---|---|

| Unmodified Protein | N/A | Baseline | Governed by number of basic sites, structure, and Coulombic repulsion. |

| Carboxyl Group Capping (Neutral) | Asp, Glu, C-terminus | Minimal to no change | Demonstrates carboxyl groups do not significantly limit positive charging in ESI. |

| Amine Alkylation (Adds Basic Sites) | Lysine side chains | Moderate increase | Increases number of protonation sites, but added sites are subject to repulsion. |

| Fixed Charge Modification | Lysine side chains | Significant increase, but not by the full number of fixed charges added | Fixed charges reduce proton acquisition due to enhanced Coulombic repulsion, which lowers the gas-phase basicity of other sites. |

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Key Research Reagents and Materials for ESI-MS Studies of Biomolecules

| Item | Function / Role in Analysis | Example Specifications / Notes |

|---|---|---|

| Volatile Buffers [18] [19] | Maintain pH in solution without leaving non-volatile salts that clog the MS interface. | Ammonium acetate (for "native" MS), Formic Acid (for denaturing MS). Concentration typically 10-100 mM. |

| Organic Solvents [15] [19] | Aid in solubility, droplet formation, and desolvation; used for chromatographic separation. | HPLC-grade Methanol, Acetonitrile. Often used with 0.1% acid modifier. |

| Chemical Modification Reagents [18] | Probe the role of specific functional groups in charging behavior. | N-(2-bromoethyl)-N,N-dimethylammonium bromide (for fixed charges), Carbodiimides like EDC (for carboxyl activation). |

| Fused Silica Emitters [5] | NanoESI capillaries for producing stable, low-flow-rate electrospray. | O.D. ~150 µm, I.D. ~10-50 µm; often chemically etched to a fine tip [5]. |

| Syringe Pump [5] | Provides precise, stable flow of sample solution for direct infusion experiments. | Flow rate range from ~50 nL/min to 20 µL/min. |

| Peptide/Protein Standards [5] | System tuning, calibration, and method validation. | Angiotensin I, Fibrinopeptide A, Ubiquitin. Prepare stock solutions at 1 mg/mL in 0.1% formic acid. |

Multiple charging is not merely an interesting artifact of ESI but the very cornerstone that enables the analysis of large biomolecules by mass spectrometry. The charge state distribution provides a rich source of information on protein conformation and solvation dynamics. Understanding the factors that govern this distribution—from protein characteristics and solution conditions to instrumental interface configurations—is crucial for researchers aiming to optimize methods for characterizing complex biologics, protein-polymer conjugates, and other macromolecular therapeutics. Future advancements in interface designs, such as the SPIN interface, and refined techniques for manipulating charge states through chemical and physical means promise to further extend the frontiers of mass spectrometry, driving innovations in structural biology, biotechnology, and drug development.

Diagram: ESI-MS Process and Multiple Charging

The following diagram illustrates the complete electrospray ionization process leading to multiple charging, from droplet formation to the detection of multiply-charged protein ions.

ESI Process Leading to Multiple Charging - This workflow depicts the journey of a protein from solution to a detected multiply-charged ion, highlighting key stages like droplet fission and the Charge Residue Model.

The electrospray ionization mass spectrometry (ESI-MS) interface represents one of the most critical technological advancements in analytical chemistry, enabling the seamless transition of ions from atmospheric pressure to the high vacuum required for mass analysis. This atmospheric pressure ionization (API) technique has revolutionized the analysis of biomolecules, pharmaceuticals, and complex organic compounds by allowing the direct introduction of liquid samples into the mass spectrometer. The interface serves as a sophisticated pressure reduction system that maintains the delicate balance between preserving ion integrity and achieving the necessary vacuum conditions for mass separation and detection.

The fundamental challenge addressed by the ESI-MS interface lies in bridging two disparate environments: the atmospheric pressure region where ionization occurs and the high vacuum region (typically 10⁻⁵ to 10⁻⁸ Torr) necessary for mass analysis. Without proper interface design, the expanding gas from atmospheric pressure would overwhelm the vacuum system, rendering mass analysis impossible. The development of efficient ion transmission pathways has therefore been paramount to the success of ESI-MS, particularly for applications in proteomics, metabolomics, and pharmaceutical research where sensitivity and robustness are critical requirements.

Fundamental Principles of Electrospray Ionization

The electrospray ionization process begins at atmospheric pressure, where a high voltage (typically 2.5-6.0 kV) is applied to a liquid sample flowing through a capillary needle [4]. This creates a strong electric field that disperses the effluent into a fine aerosol of charged droplets. The formation of stable charged droplets follows a three-step process: (1) dispersal of a fine spray of charged droplets, (2) solvent evaporation through the assistance of heated drying gas (usually nitrogen), and (3) ion ejection via Coulombic fission when the Rayleigh stability limit is exceeded [4] [2].

As solvent evaporation continues, the charged droplets undergo repeated Coulombic explosions, continuously reducing their size until individual desolvated ions are released into the gas phase. This "soft ionization" mechanism preserves molecular integrity and is particularly advantageous for the analysis of large, non-volatile, and thermally labile biomolecules that would fragment under other ionization methods. The efficiency of this process is highly dependent on solvent properties, flow rates, and the presence of additives such as formic or acetic acid (typically 0.1-0.5%), which improve protonation efficiency [4] [21].

Table 1: Critical Parameters in the ESI Process

| Parameter | Typical Range | Effect on Ionization |

|---|---|---|

| Applied Voltage | 2.5-6.0 kV | Determines initial droplet charge and spray stability [4] |

| Nebulizing Gas | Nitrogen, variable pressure | Enhances droplet formation at higher flow rates [4] |

| Drying Gas Temperature | Variable, up to 500°C | Facilitates solvent evaporation from charged droplets [2] |

| Sample Flow Rate | Nano-liters to milliliters per minute | Affects droplet size and ionization efficiency [2] |

| Acid Additives | 0.1-0.5% formic/acetic acid | Promotes protonation for positive ion mode [21] |

A key characteristic of ESI is the production of multiply charged ions for macromolecules, which effectively extends the mass range of analyzers by reducing the mass-to-charge ratio (m/z). This phenomenon is particularly beneficial for protein analysis, as it allows conventional mass analyzers to detect molecules with molecular weights exceeding 100,000 Daltons. The electrospray process is also remarkably efficient, capable of detecting analytes at femtomole quantities in microliter sample volumes, making it indispensable for applications where sample quantity is limited [4].

The Stepwise Ion Transmission Pathway

Atmospheric Pressure Region

The ion transmission pathway begins at the ESI needle tip maintained at atmospheric pressure, where the Taylor cone formation and subsequent charged droplet emission occur. The initial charged droplets, typically 1-10 μm in diameter, are directed toward the mass spectrometer inlet by a combination of electric field gradients and gas dynamics. The sampling orifice or capillary serves as the entry point into the vacuum system and is strategically designed to maximize ion uptake while minimizing neutral species and solvent vapor intake [2].

The atmospheric pressure region employs countercurrent drying gas (usually nitrogen) to facilitate desolvation by accelerating solvent evaporation from the charged droplets. This region is characterized by turbulent flow conditions and intense desolvation processes, where droplets undergo multiple cycles of solvent evaporation and Coulombic fission. The efficiency of these initial stages profoundly impacts overall sensitivity, as incomplete desolvation results in adduct formation and signal suppression [2].

Pressure Reduction Stages

The transition from atmospheric pressure (760 Torr) to high vacuum (10⁻⁵ to 10⁻⁸ Torr) requires multiple stages of pressure reduction, each employing different pumping technologies and ion guidance methods. Modern ESI interfaces typically incorporate three distinct pressure regions:

Intermediate Vacuum Stage (1-10 Torr): Following the initial sampling orifice, ions enter a region pumped by roughing pumps or medium-capacity turbomolecular pumps. This region often contains RF-only focusing devices such as skimmers, cones, or ion funnels that use electrostatic fields to concentrate ions while allowing uncharged species to be pumped away. The ion funnel technology, in particular, has dramatically improved transmission efficiency through this region by creating a traveling wave potential that confines and guides ions toward subsequent stages [4].

High Vacuum Stage (10⁻³ to 10⁻⁴ Torr): In this region, ions may pass through additional focusing elements such as RF-only quadrupoles or hexapoles that act as ion guides or collision cells. When operated with collision gas (typically argon), these devices can induce collision-induced dissociation (CID) for structural analysis. The pressure in this region is maintained by high-capacity turbomolecular pumps, and ion motion becomes increasingly dominated by electric fields rather than hydrodynamic flow [4].

Ultra-High Vacuum Stage (10⁻⁵ to 10⁻⁸ Torr): This final region houses the mass analyzer (quadrupole, time-of-flight, ion trap, or Orbitrap) where mass separation occurs. Ion optics in this region are precisely engineered to focus the ion beam into the analyzer while maintaining the stringent vacuum requirements necessary for resolution and sensitivity [4].

Table 2: Pressure Regions in ESI-MS Interface

| Vacuum Stage | Pressure Range | Primary Components | Ion Transmission Mechanism |

|---|---|---|---|

| Atmospheric Pressure | 760 Torr | ESI needle, drying gas, sampling cone | Droplet formation, desolvation, initial ion formation [2] |

| Intermediate Vacuum | 1-10 Torr | Skimmer cones, ion funnels | RF focusing, neutral gas separation [4] |

| High Vacuum | 10⁻³ to 10⁻⁴ Torr | RF-only multipoles, collision cells | Collisional focusing, CID fragmentation [4] |

| Ultra-High Vacuum | 10⁻⁵ to 10⁻⁸ Torr | Mass analyzer, detector | Mass-dependent separation, detection [4] |

Key Interface Components and Their Functions

The ESI-MS interface incorporates several critical components that collectively enable efficient ion transmission across dramatic pressure gradients. Each component addresses specific challenges in maintaining ion beam coherence while achieving the necessary pressure reduction:

The sampling orifice represents the first critical transition point, typically consisting of a small diameter capillary (0.1-0.5 mm) that limits gas inflow while permitting ion passage. These capillaries are often heated to prevent condensation and enhance desolvation. Modern interfaces may employ glass capillaries with conductive coatings to create optimal electrostatic gradients for ion focusing during this initial transition [2].

Ion funnels have emerged as revolutionary components in the intermediate pressure region, replacing traditional skimmer cones in many modern instruments. These devices consist of a series of ring electrodes with progressively decreasing inner diameters to which RF and DC voltages are applied. The resulting RF field creates a repulsive potential barrier that focuses ions toward the central axis, dramatically improving transmission efficiency compared to simple skimmer arrangements. Ion funnels can capture up to 50% of ions entering from the atmospheric pressure region, representing a significant improvement over previous technologies [4].

Differential pumping systems employ multiple vacuum stages separated by small apertures, with each stage maintained by separate pumping systems. This arrangement allows for a gradual pressure reduction without compromising ion transmission. The strategic placement of RF-only multipoles (quadrupoles, hexapoles, or octopoles) in these regions provides efficient ion focusing through collisional damping, where frequent low-energy collisions with background gas molecules cool the ion population and reduce their kinetic energy spread [4].

Collision cells represent an optional but functionally important interface component, typically located in the high vacuum region. When operated with higher collision energies (5-100 eV), these cells induce fragmentation of selected precursor ions via CID, generating product ions for structural elucidation. Modern instruments often employ curved collision cells (such as the "C-trap" in Orbitrap instruments) that effectively separate photons and neutral species from the ion beam, reducing chemical noise and improving detection limits [4].

Experimental Considerations for Optimal Ion Transmission

Solvent and Additive Selection

The choice of solvent and additives significantly impacts ionization efficiency and subsequent ion transmission through the interface. Reverse-phase LC conditions employing water/acetonitrile or water/methanol mixtures with 0.1% formic acid are most common for positive ion mode, providing optimal proton availability and solvent volatility. The presence of non-volatile buffers (phosphate, Tris) or high salt concentrations (>10 mM) should be avoided as they cause severe ion suppression and contamination of interface components [21].

The detrimental effects of alkali metal cations (Na⁺, K⁺) on ESI efficiency have been well-documented. Even trace amounts (below 1 ppm) can promote the formation of metal adducts ([M+Na]⁺, [M+K]⁺) at the expense of protonated molecules ([M+H]⁺), complicating spectral interpretation and reducing sensitivity. At concentrations exceeding 10 ppm, alkali metal adducts can become the dominant species, decreasing absolute sensitivity by 5-10 fold. This effect is particularly pronounced with peptides containing multiple acidic residues, such as human gastrin, which can exchange protons for metal cations at glutamic acid side chains [21].

Flow Rate Optimization

Ion transmission efficiency exhibits a strong dependence on sample flow rate, with different interface designs optimized for specific flow regimes. Nano-ESI sources (flow rates: 50-500 nL/min) provide the highest ionization efficiencies for sample-limited applications, generating smaller initial droplets that require less desolvation energy. Conventional ESI sources (flow rates: 0.1-1.0 mL/min) offer greater robustness but may require more aggressive desolvation conditions. Modern interface designs often incorporate pneumatic assist (nebulizing gas) to stabilize the electrospray process across a wider range of flow rates, improving method transferability between different LC configurations [2].

Voltage and Temperature Parameters

The precise optimization of voltage gradients throughout the ion transmission pathway is critical for maximizing signal intensity while minimizing unwanted fragmentation. Key parameters include the ESI needle voltage (typically 2.5-6.0 kV), sampling cone/skimmer voltages (10-100 V), and various lens element offsets that create smooth potential gradients for efficient ion transit. Interface temperature also plays a crucial role, with capillary temperatures (200-400°C) and drying gas temperatures (50-500°C) optimized to complete desolvation without thermal degradation of analytes [4] [2].

Table 3: Research Reagent Solutions for ESI-MS Analysis

| Reagent/Chemical | Function/Purpose | Typical Concentration | Considerations |

|---|---|---|---|

| Formic Acid | Protonation agent for positive ion mode; improves chromatographic peak shape | 0.1-0.5% in mobile phase | Volatile; compatible with MS detection; more effective than acetic acid for most applications [21] |

| Ammonium Acetate/Formate | Volatile buffer for pH control; alternative cation source | 1-50 mM | Provides ammonium adducts for certain compound classes; useful for negative ion mode [22] |

| Methanol/Acetonitrile | Organic modifiers for reverse-phase LC separation | Variable gradient | High volatility enhances desolvation; acetonitrile provides different selectivity than methanol [21] |

| Ammonium Hydroxide | Deprotonation agent for negative ion mode | 0.1-0.5% | Highly volatile basic modifier; suitable for compounds analyzing better in negative mode [22] |

| Trifluoroacetic Acid (TFA) | Ion-pairing reagent for peptide separation | 0.01-0.05% | Can cause ion suppression; use at minimal concentrations; formic acid generally preferred for MS [22] |

| Isopropanol | Strong organic solvent for cleaning and elution | 50-100% | Effective for removing non-polar contaminants from ESI source components; higher elution strength [22] |

Analytical Methodologies and Protocols

Standard ESI-MS Interface Optimization Protocol

A systematic approach to ESI-MS interface optimization ensures maximum sensitivity and robustness for specific application requirements. The following protocol outlines key optimization steps:

Initial Source Setup: Begin with manufacturer-recommended settings for your specific flow rate regime. Position the ESI needle at the recommended distance and angle relative to the sampling orifice (typically 2-10 mm, slightly off-axis). Set the nebulizing gas pressure to produce a stable spray without turbulence (usually 5-50 psi depending on flow rate) [2].

Voltage Parameter Optimization: Adjust the ESI needle voltage in 0.1-0.2 kV increments while monitoring the signal intensity of a reference compound. The optimal voltage typically produces maximum signal with minimal electrical discharge (evidenced by reduced baseline noise). Subsequently, optimize the sampling cone/skimmer voltage by scanning through a range of values (10-150 V) to find the setting that provides optimal transmission for your mass range of interest [4].

Temperature Optimization: Set the desolvation gas temperature based on mobile phase composition—higher aqueous content requires higher temperatures (typically 300-500°C), while high organic content may require lower temperatures (150-300°C) to prevent premature desolvation. Adjust while monitoring signal intensity and the presence of solvent cluster ions, which indicate incomplete desolvation [2].

Gas Flow Optimization: Fine-tune the desolvation gas flow rate (typically 5-20 L/min for conventional ESI) to achieve complete solvent removal without excessive ion cooling. Higher flows generally improve desolvation but may decrease sensitivity through ion scattering. The nebulizing gas should be set to the minimum value that produces a stable spray [4].