Flow Injection Analysis LC-MS Optimization: A Complete Guide for Robust Method Development

This article provides a comprehensive guide to optimizing Flow Injection Analysis (FIA) for Liquid Chromatography-Mass Spectrometry (LC-MS).

Flow Injection Analysis LC-MS Optimization: A Complete Guide for Robust Method Development

Abstract

This article provides a comprehensive guide to optimizing Flow Injection Analysis (FIA) for Liquid Chromatography-Mass Spectrometry (LC-MS). Aimed at researchers and drug development professionals, it covers foundational principles, practical methodological workflows, systematic troubleshooting for common issues like peak tailing and ghost peaks, and rigorous validation techniques. By integrating exploratory, application-focused, and comparative content, this guide serves as a strategic resource for accelerating compound-dependent parameter optimization, enhancing sensitivity, and ensuring robust, reproducible results in biomedical analysis.

Understanding Flow Injection Analysis: Principles and Strategic Advantages in LC-MS

Core Concept of Flow Injection Analysis

Flow Injection Analysis (FIA) is a versatile sample introduction and online pretreatment technology designed for high-throughput analytical chemistry. In the context of LC-MS, FIA serves as a powerful alternative to chromatographic separation for specific applications where ultra-fast analysis is prioritized over physical compound separation [1].

The core principle of FIA involves the injection of a defined, discrete sample volume into a continuously flowing, non-segmented carrier stream. This sample plug is then transported toward the detector through a manifold system. As the sample moves through the tubing, it undergoes controlled, reproducible dispersion due to convection and diffusion processes characteristic of laminar flow, forming a concentration gradient [1]. This results in a transient, Gaussian-like signal at the detector, with the peak height, area, or shape providing quantitative and qualitative information about the analyte [1].

A key parameter in FIA is the dispersion coefficient (D), defined as the ratio of the initial concentration of the injected sample to the concentration at the peak maximum. This coefficient is categorized based on application needs:

- Small dispersion (D ≤ 3): Minimal dilution, used when no peak broadening is desired

- Medium dispersion (3 ≤ D ≤ 10): Moderate dilution, enables reagent mixing

- Large dispersion (D ≥ 10): Significant dilution, useful for sample dilution [1]

FIA-MS Workflow and System Configuration

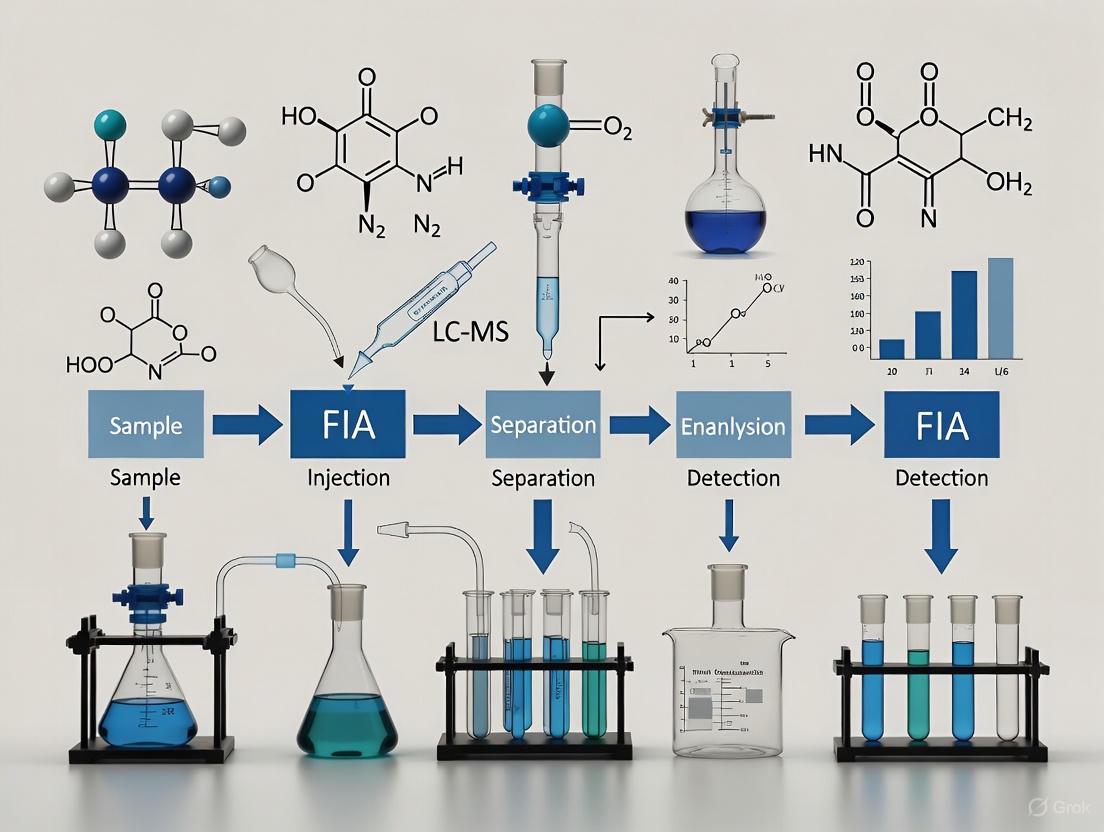

Generic FIA-MS Workflow

The following diagram illustrates the logical flow and components of a standard FIA-MS analysis:

Experimental Setup Configurations

Different experimental applications require specific FIA configurations. The diagram below compares setups for general analysis, dynamic titration, and diffusion measurements:

Key Applications and Methodologies

Application Protocol: Dynamic Titration for Binding Constant Determination

Purpose: To determine dissociation constants (Kd) of noncovalent complexes with high throughput and minimal sample consumption [1].

Experimental Setup:

- A known concentration of host molecule is continuously infused via a syringe pump

- A defined volume of guest molecule is injected through a rotary valve into a dispersion loop

- The compositional gradient forms in the dispersion loop and mixes with the host stream

- The mixture is directly analyzed by ESI-MS [1]

Procedure:

- Prepare a stock solution of host molecule at constant concentration

- Prepare a single solution of guest molecule at appropriate concentration

- Set carrier flow rate to achieve medium dispersion (3 ≤ D ≤ 10)

- Infuse host solution at constant flow rate (typically 0.1-0.5 mL/min)

- Inject guest sample (typically 10-100 µL) and acquire MS data in full scan or selected ion monitoring mode

- Monitor intensities of free host, free guest, and complex ions

- Export intensity data and fit to a 1:1 equilibrium binding model using appropriate algorithms [1]

Advantages over Conventional Titration:

- Time efficiency: Complete analysis in minutes versus hours

- Reduced sample consumption: Single guest solution versus multiple preparations

- Automation potential: Easily integrated with autosamplers for high-throughput screening [1]

Application Protocol: Automated Shotgun Lipidomics

Purpose: To perform comprehensive, high-throughput lipid profiling without chromatographic separation [2].

Experimental Setup:

- HPLC system replumbed with PEEKsil tubing to minimize carryover

- Binary pump for mobile phase delivery

- Thermostated autosampler for sample introduction

- High-resolution mass spectrometer (e.g., TripleTOF system) [2]

MS/MSALL Acquisition Parameters:

- Ionization: ESI with positive mode (+4500V) or negative mode (-4200V)

- Source temperature: 400°C

- Gas settings: Curtain gas (25), Gas 1 (18), Gas 2 (30)

- Acquisition: TOF MS scan (0.5-1 sec) followed by sequential MS/MS scans stepped across mass range (200-2250 m/z)

- Isolation windows: Optimized for lipid analyte mass defects [2]

Procedure:

- Prepare lipid extracts using modified Folch method

- Reconstitute in methylene chloride/methanol (50:50) with 5mM ammonium acetate

- Set injection volume to 50 µL

- Use isocratic flow with wash steps between injections

- Acquire data using Infusion MS/MSALL method

- Process data with LipidView software for lipid identification and quantification [2]

Performance Characteristics:

- Reproducibility: %RSD for peak area: 1.83-3.20%

- Carryover: <0.16% after optimized wash protocol

- Throughput: 15 minutes per sample including wash and equilibration [2]

Optimization Strategies and Parameters

Critical FIA-MS Parameters

Table 1: Key Optimization Parameters for FIA-MS Methods

| Parameter Category | Specific Parameters | Optimization Considerations | Impact on Performance |

|---|---|---|---|

| FIA System Parameters | Sample injection volume | Typically 10-100 µL; affects sensitivity and dispersion | Larger volumes increase sensitivity but may broaden peaks |

| Carrier flow rate | 0.1-1.0 mL/min; affects dispersion and analysis time | Higher flow rates reduce analysis time but may decrease ionization efficiency | |

| Tubing length and diameter | Determines extent of dispersion | Longer, narrower tubing increases dispersion | |

| MS Source Parameters | Capillary voltage | 2000-4000 V; critical for ionization efficiency | Higher voltage improves sensitivity but may cause arcing or increased chemical noise [3] |

| Drying gas flow rate and temperature | 8-12 L/min; 300-400°C | Optimizes desolvation; higher temperatures improve desolvation but may degrade thermolabile compounds [3] | |

| Nebulizer gas pressure | 20-50 psi | Affects aerosol formation and ionization stability [4] | |

| MS Analyzer Parameters | Fragmentor voltage | Compound-dependent (e.g., 149 V for forskolin) | Controls in-source fragmentation; higher voltages increase fragmentation [3] |

| Collision energy | Optimized for each transition in MS/MS | Affects fragment ion abundance and signal-to-noise [4] |

Research Reagent Solutions

Table 2: Essential Materials for FIA-MS Experiments

| Reagent/Material | Function/Application | Examples/Specifications |

|---|---|---|

| Mobile Phase/ Carrier Solvents | Transport medium for sample introduction | Methanol, acetonitrile, methylene chloride/methanol (50:50) with 5mM ammonium acetate for lipidomics [2] |

| Additives/ Modifiers | Enhance ionization efficiency and stability | 1 mM sodium acetate, ammonium acetate, formic acid, acetic acid (0.05-0.1%) [3] |

| System Tubing | Sample transport with minimal adsorption | PEEKsil tubing for reduced carryover, especially for lipid analysis [2] |

| Reference Standards | System calibration and method validation | Forskolin for food supplement analysis [3], bovine heart extract for lipidomics [2] |

Troubleshooting and Quality Control

Common FIA-MS Issues and Solutions

Carryover Reduction Strategies:

- Implement aggressive wash protocols with increased flow rates during wash steps

- Use PEEKsil tubing instead of standard PEEK to minimize lipid adsorption

- Include blank injections after high-concentration samples to monitor carryover [2]

Signal Variability Mitigation:

- Ensure stable temperature control for both autosampler and source

- Maintain consistent nebulizer and drying gas flows

- Use internal standards to correct for injection-to-injection variability [5]

Reproducibility Enhancement:

- Implement system suitability testing procedures

- Monitor total ion current (TIC) stability and peak shape consistency

- Use automated quality control metrics within instrument software [5] [2]

Method Validation Parameters

For quantitative FIA-MS methods, key validation parameters include:

- Precision: %RSD for replicate injections (target <5%)

- Carryover: Typically <0.2% for acceptable performance

- Signal stability: Assessed through TIC monitoring over multiple injections

- Linearity: Evaluated through calibration curves in quantitative applications [3] [2]

Flow Injection Analysis coupled with Mass Spectrometry represents a powerful platform for high-throughput analysis in drug development and applied research. By understanding the core principles, optimization strategies, and application-specific protocols detailed in this document, researchers can effectively implement FIA-MS methodologies to accelerate compound screening, binding studies, and lipidomic profiling while maintaining data quality and reproducibility.

In the pursuit of optimization in liquid chromatography-tandem mass spectrometry (LC-MS/MS), the question of whether to include the chromatographic column is central. Flow Injection Analysis (FIA) and liquid chromatography represent two distinct approaches, each with its own performance characteristics. FIA involves the direct injection of samples into the mass spectrometer, bypassing the chromatographic column to maximize analytical throughput. In contrast, LC-MS/MS utilizes on-column separation to resolve analytes from complex matrices prior to detection. This application note details the comparative performance of these techniques and provides structured protocols to guide researchers in selecting and implementing the appropriate method based on their specific analytical requirements in drug development and clinical research.

Comparative Performance Data

The decision between FIA and LC-MS/MS methods hinges on understanding their quantitative performance characteristics. The following tables summarize key metrics derived from published studies across different applications.

Table 1: General Method Performance Comparison between FIA-MS/MS and LC-MS/MS

| Performance Metric | FIA-MS/MS | LC-MS/MS |

|---|---|---|

| Analysis Time | < 60 seconds per sample [6] | ~10 minutes per sample [6] |

| Typical Recovery Range | 79-117% (at higher concentrations) [6] | 100-117% (across tested concentrations) [6] |

| Typical Relative Standard Deviation (RSD) | < 15% [6] | < 9% [6] |

| Instrument LOQ (Matrix-Dependent) | 0.12 - 0.35 ppb [6] | 0.02 - 0.06 ppb [6] |

| Impact of Matrix Effects | High (no chromatographic separation) [6] [7] | Reduced (analytes separated from matrix) [6] [7] |

| Isobaric Interference Risk | High [6] | Low [6] |

Table 2: Application-Specific Performance and Outcomes

| Application Context | Analytes | Key Findings | Recommendation |

|---|---|---|---|

| Newborn Screening [8] | Very-long-chain acylcarnitines (ACs) & lysophosphatidylcholines (LPCs) | FIA-MS/MS optimized as first-tier screen; LC-MS/MS used as second-tier confirmation reduced false positives. | FIA suitable for high-throughput primary screening; LC-MS/MS provides confirmatory precision. |

| Mycotoxin Analysis [6] | Ochratoxin A in food matrices | FIA-MS/MS failed to detect analyte at 1 ppb; LC-MS/MS provided reliable quantification at all levels (1-100 ppb). | LC-MS/MS is essential for low-concentration analytes and complex food matrices. |

| Therapeutic Drug Monitoring [9] | Imatinib in human plasma | Both methods provided comparable results for patient samples; FIA offered higher throughput for routine monitoring. | FIA is viable for high-throughput analysis of specific drugs in clinical matrices. |

| Lipidomics [2] | Complex lipid profiles | Automated FIA MS/MS'ALL workflow demonstrated excellent reproducibility (%RSD 1.83-4.27%) and minimal carryover. | FIA is powerful for untargeted, high-throughput lipidomic profiling. |

Experimental Protocols

Protocol for FIA-MS/MS Analysis of Mycotoxins

This protocol is adapted from a study comparing the determination of ochratoxin A in food commodities [6].

Sample Preparation:

- Fortification: Add 13C uniformly labeled ochratoxin A as an internal standard (13C-IS) to samples.

- Extraction: Prepare samples by solvent extraction, followed by dilution and filtration.

- Preparation for Analysis: Transfer the prepared extract into a suitable vial for the autosampler.

Instrumentation and Conditions:

- Platform: Triple quadrupole tandem mass spectrometer.

- Sample Introduction: Flow injection (bypassing the LC column).

- Mobile Phase: Direct infusion of sample extract.

- Analysis Time: < 60 seconds per sample.

- Detection: Multiple Reaction Monitoring (MRM) mode.

Critical Notes: This method is applicable for concentrations at 5 ppb and above. It is not recommended for detecting ochratoxin A at 1 ppb in complex matrices like corn, oat, or grape juice due to insufficient sensitivity caused by ion suppression [6].

Protocol for LC-MS/MS Analysis of Mycotoxins

This protocol provides a reliable method for quantifying ochratoxin A at lower concentrations, including the 1 ppb level [6].

Sample Preparation:

- Fortification: Use 13C uniformly labeled ochratoxin A as an internal standard (13C-IS).

- Extraction: Prepare samples by solvent extraction, dilution, and filtration.

Instrumentation and Conditions:

- Platform: Triple quadrupole tandem mass spectrometer coupled with a liquid chromatography system.

- Chromatography: Utilize a reverse-phase LC column.

- Mobile Phase: Acid buffer/methanol or acetonitrile gradient.

- Run Time: 10 minutes per sample.

- Ionization: Electrospray Ionization (ESI).

- Detection: Multiple Reaction Monitoring (MRM) mode.

Protocol for FIA-MS/MS in Lipidomics

This protocol outlines an automated, high-throughput shotgun lipidomics approach [2].

Sample Preparation:

- Extraction: Serum samples are extracted using a modified Folch method.

- Reconstitution: Reconstitute the organic phase in methylene chloride/methanol (50/50) with 5mM ammonium acetate in autosampler vials.

Instrumentation and Conditions:

- System: TripleTOF 6600 System or equivalent high-resolution mass spectrometer.

- Infusion: Automated FIA using a standard HPLC system. Increased flow rate during the wash step is critical to minimize carryover. PEEKsil tubing is recommended for all plumbing to reduce analyte adhesion [2].

- Acquisition Method: Infusion MS/MS'ALL, consisting of a TOF MS scan followed by a series of high-sensitivity MS/MS scans stepped across the entire lipidome mass range (e.g., 200-2250 m/z).

- Source Conditions: Optimize for both positive and negative modes (e.g., Spray voltage +4500V/-4200V, Temperature 400°C).

Data Processing: Process acquired data using software (e.g., LipidView) for lipid profile extraction, followed by statistical analysis (e.g., in MarkerView Software).

Workflow and Decision Pathways

The fundamental difference between FIA and LC-MS/MS workflows lies in the presence or absence of chromatographic separation. The following diagram illustrates the core steps and decision points for each method.

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table lists key reagents and materials critical for implementing the FIA and LC-MS/MS protocols discussed.

Table 3: Essential Research Reagent Solutions

| Item | Function / Application | Example from Literature |

|---|---|---|

| 13C Uniformly Labeled Internal Standards | Corrects for matrix effects and losses during sample preparation; essential for accurate quantification in both FIA and LC-MS/MS. | 13C-ochratoxin A used in mycotoxin analysis [6]. |

| Deuterated Internal Standards (e.g., d8-Imatinib) | Serves as an internal standard for therapeutic drug monitoring, compensating for variability in sample preparation and ionization. | d8-Imatinib mesylate used for quantifying imatinib in plasma [9]. |

| LC/MS Grade Solvents (Methanol, Acetonitrile, Formic Acid) | Used in mobile phase and sample preparation to minimize background noise and contamination, ensuring optimal MS performance. | Used in both ochratoxin A and imatinib method development [6] [9]. |

| Characterized Reference Materials (e.g., Bovine Heart Extract) | Complex biological standard used for system suitability testing, workflow development, and assessing reproducibility in lipidomics. | Bovine Heart Extract (BHE) used to evaluate FIA-MS/MS'ALL reproducibility [2]. |

| PEEKsil Tubing | Specialized inert tubing used to replace standard HPLC tubing after the autosampler to minimize carryover, especially critical for sticky molecules like lipids. | Implementation resulted in carryover of <0.16% in lipidomics workflow [2]. |

| Reverse Phase LC Columns (e.g., C18 with sub-2µm particles) | Provides high-resolution separation of analytes from matrix components prior to MS detection, reducing ion suppression and isobaric interference. | C18 column with 1.7µm particles used for fast, high-efficiency separation of imatinib [9]. |

The choice between FIA and LC-MS/MS is not a matter of one technique being superior to the other, but rather of selecting the right tool for the specific analytical question. FIA-MS/MS is the definitive choice for maximizing throughput in targeted, high-throughput applications such as newborn screening [8], routine therapeutic drug monitoring [9], and untargeted lipidomic profiling [2], where analysis speed is critical and analyte concentrations are sufficiently high. Conversely, LC-MS/MS is indispensable when method robustness, sensitivity for trace-level analysis, and specificity in complex matrices are the primary concerns, as demonstrated in mycotoxin testing [6] and when comprehensive analyte identification is required. By applying the structured protocols and decision frameworks outlined in this application note, scientists can strategically bypass the chromatographic column to gain efficiency without compromising the integrity of their data, thereby optimizing resource allocation and accelerating research and development timelines.

Rapid Optimization of MS Parameters and High-Throughput Screening

Flow Injection Analysis (FIA) coupled with mass spectrometry represents a powerful approach for high-throughput screening in modern analytical laboratories. By eliminating chromatographic separation, FIA-MS enables direct sample introduction into the mass spectrometer, significantly reducing analysis times to as little as 60 seconds per sample [6]. This technique is particularly valuable in applications requiring rapid analysis of large sample batches, such as drug discovery, lipidomics, and toxicological screening [2] [10]. However, the absence of chromatographic separation places greater emphasis on optimal mass spectrometer parameter configuration to maintain analytical sensitivity and specificity despite potential matrix effects.

The successful implementation of FIA-MS workflows hinges on two critical components: systematic optimization of instrument parameters to maximize signal response for target compounds, and robust experimental design to ensure reproducibility across large sample sets. This application note details standardized protocols for rapid MS parameter optimization and high-throughput FIA screening, providing researchers with practical methodologies to enhance workflow efficiency while maintaining data quality within the context of LC-MS optimization research.

Key Concepts and Definitions

Flow Injection Analysis (FIA): A technique where samples are directly injected into a flowing carrier stream for introduction into the mass spectrometer without chromatographic separation [11] [6].

Multiple Reaction Monitoring (MRM): A highly sensitive targeted mass spectrometry method that selectively detects and quantifies specific molecules based on precursor-to-fragment ion transitions [12].

Ion Suppression: A phenomenon where co-eluting matrix components reduce ionization efficiency of target analytes, leading to decreased signal intensity [13].

Collision Energy (CE): The voltage applied in the collision cell to fragment precursor ions, optimized based on the mass-to-charge ratio (m/z) of the target compound [12].

Matrix Effects: The influence of co-extracted sample components on the ionization efficiency of target analytes, particularly impactful in FIA due to the absence of chromatographic separation [6].

Protocol 1: Rapid Optimization of MS/MS Parameters

Background and Principles

Sensitivity in MRM-based mass spectrometry depends critically on the tuning of instrument parameters for optimal peptide fragmentation and maximal transmission of desired product ions [12]. While generalized equations exist for parameters like collision energy, these may fail to produce maximum signal response under diverse experimental conditions [12]. Bond fragmentation efficiency depends on peptide residue content and proton mobility, meaning particular residues or residue combinations may not generate maximum response when fragmented under generalized conditions [12]. This protocol describes a streamlined workflow for rapid determination of optimal instrument parameters for each MRM transition.

Experimental Workflow

The following diagram illustrates the comprehensive workflow for rapid optimization of MS parameters:

Materials and Equipment

Table 1: Essential Research Reagent Solutions

| Item | Function/Application | Example Specifications |

|---|---|---|

| Triple quadrupole mass spectrometer | Targeted mass analysis with MRM capability | Waters Quattro Premier or ABI 4000 QTRAP [12] |

| Standard protein/analyte mixture | System performance testing and optimization | 1 nmol of each protein in ammonium bicarbonate [12] |

| Sequencing-grade trypsin | Protein digestion for peptide analysis | Promega, 1:40 (w/w) ratio [12] |

| Solid-phase extraction cartridges | Sample clean-up | Waters Oasis MCX cartridge [12] |

| Mobile phase components | LC-MS analysis | 0.1% formic acid, acetonitrile, HPLC-grade water [12] [11] |

| MRM software | Data analysis and optimization | Mr. M software package [12] |

Step-by-Step Procedure

Prepare MRM Transition List: Generate an initial list of MRM transitions for target compounds. For peptide analysis, use tools like SpectraST to create a consensus spectral library from MS/MS data [12]. Filter to include high-probability transitions.

Reprogram m/z Values: Use a scripting tool (e.g., Perl script) to subtly adjust the second decimal place of precursor and product m/z values to code for different instrument parameters [12]. This creates unique MRM targets for each parameter value while maintaining the same actual transition.

Program Parameter Range: For each MRM transition, program a range of parameter values. For collision energy optimization, use values from 6V less to 6V more than the equation-derived value in 2V steps [12]. The generalized CE equation provided by Waters is: CE = 0.034 × (m/z precursor) + 1.314 [12].

Execute Single Run: Analyze the samples using the modified MRM method with all parameter variations within a single LC-MS run to avoid run-to-run variability [12].

Data Analysis: Process data using MRM software (e.g., Mr. M) to determine optimal instrument parameters for each transition based on maximal product ion signal [12].

Validation: Validate optimized parameters by comparing signal intensity to pre-optimization values.

Protocol 2: High-Throughput Screening Using FIA-MS

Background and Principles

Flow Injection Analysis-MS enables rapid screening by directly introducing samples into the mass spectrometer, bypassing time-consuming chromatographic separation [11] [6]. This approach is particularly valuable in lipidomics [2] and toxicology screening [10], where analysis of hundreds of compounds is required. The MS/MSALL workflow provides an automated, untargeted acquisition strategy that has low carryover and excellent reproducibility [2]. This protocol describes an optimized FIA method for high-throughput screening applications.

Experimental Workflow

The following diagram illustrates the FIA-MS high-throughput screening workflow:

Materials and Equipment

Table 2: FIA-MS Screening Solutions

| Item | Function/Application | Example Specifications |

|---|---|---|

| UHPLC system with autosampler | Automated sample introduction | Shimadzu UHPLC system [2] |

| PEEKsil tubing | Minimize carryover | 50μm I.D. hybrid electrodes [2] |

| TripleTOF mass spectrometer | High-resolution MS and MS/MS analysis | SCIEX TripleTOF 6600 System [2] |

| LipidView software | Automated data processing and lipid profiling | LipidView Software 1.3 [2] |

| MarkerView software | Statistical analysis and visualization | MarkerView Software [2] |

| Mobile phase for lipidomics | Sample delivery and ionization | Methylene chloride/methanol (50/50) with 5mM ammonium acetate [2] |

Step-by-Step Procedure

Sample Preparation: For lipidomics applications, prepare samples using modified Folch method. Extract serum samples and reconstitute the organic phase in methylene chloride/methanol (50/50) with 5mM ammonium acetate [2].

System Configuration: Replace all tubing on the HPLC system after the autosampler with PEEKsil tubing, including the sample loop, to minimize carryover [2]. Use a 50μm I.D. hybrid electrode to maintain low backpressure.

FIA Method Setup: Configure the LC system for flow injection without a column. Use a mobile phase of methylene chloride/methanol (50/50) with 5mM ammonium acetate at a flow rate of 0.2 mL/min [11] [2]. Set injection volume to 50μL [2].

MS/MSALL Acquisition: Program the mass spectrometer to acquire data using Infusion MS/MSALL mode, consisting of a TOF MS scan (5 sec) and series of MS/MS scans (300 msec) stepped across the mass range of interest (e.g., 200-2250 m/z for lipidomics) [2]. Optimize Q1 isolation windows for analyte mass defects.

Ion Source Optimization: Set source parameters for positive and negative mode operation: spray voltage +4500V/-4200V, temperature 400°C, curtain gas 25, Gas 1 18, Gas 2 30 [2].

Data Acquisition: Establish a 5.3-minute data acquisition window to provide stable and reproducible MS signal. Include wash and equilibration steps for a total run time of 15 minutes [2].

Data Processing: Process all data using LipidView Software for lipid profiling, then export to MarkerView Software for principal component analysis and statistical evaluation [2].

Comparative Performance Data

Method Comparison

Table 3: Performance Comparison of FIA-MS/MS vs. LC-MS/MS

| Parameter | FIA-MS/MS | LC-MS/MS | References |

|---|---|---|---|

| Analysis time | <60 seconds/sample | 10 minutes/sample | [6] |

| Recovery (5-100 ppb) | 79-117% | 100-117% | [6] |

| Detection limit (ochratoxin A) | 0.12-0.35 ppb | 0.02-0.06 ppb | [6] |

| Reproducibility (RSD) | 2-15% | 2-8% | [6] |

| Carryover | 0.146-0.156% (reduced to 0.025-0.061% with PEEKsil) | Typically lower | [2] [6] |

| Matrix effects | Significant without separation | Reduced with chromatographic separation | [6] [13] |

Optimization Outcomes

Table 4: Impact of Parameter Optimization on MS Performance

| Optimization Aspect | Before Optimization | After Optimization | Key Factors |

|---|---|---|---|

| MRM sensitivity | Variable signal response | Maximal product ion signal | Collision energy, cone voltage [12] |

| Ion suppression | Up to 20% signal reduction | Minimized through sample cleanup | Solid-phase extraction, mobile phase optimization [13] |

| Run-to-run reproducibility | >15% RSD | 2.1-4.27% RSD for peak height | Automated FIA, system conditioning [2] |

| Lipid profiling variability | Not specified | Minimal variation in class profiles | MS/MSALL workflow, standardized extraction [2] |

| High-throughput screening | Limited by LC separation | 231 compounds in 15 minutes | Optimized MRM transitions, minimal retention [10] |

Troubleshooting and Technical Notes

Common Challenges and Solutions

Ion Suppression in FIA: A primary limitation of FIA-MS is increased susceptibility to ion suppression from co-eluting matrix components [6] [13]. Mitigation strategies include extensive sample dilution, improved sample cleanup techniques such as solid-phase extraction, and implementation of matrix-matched calibration standards [6].

Carryover Issues: Significant carryover (0.146-0.156%) has been observed in FIA systems when analyzing high-concentration samples [2]. This can be reduced to 0.025-0.061% by replacing standard tubing with PEEKsil tubing throughout the system and implementing rigorous wash steps between injections [2].

Parameter Optimization Stability: Optimized instrument parameters may not remain stable over time due to variations in gas pressure or instrument voltage drift [12]. Periodic recalibration is recommended, particularly for quantitative applications requiring long-term reproducibility.

Application-Specific Considerations

Toxicology Screening: For comprehensive drug screening, predefined MRM transitions for 231 compounds including illegal drugs, sedatives, and psychotropic drugs can be implemented with analysis times under 15 minutes [10]. Semi-quantitation is possible using internal standard-based calibration curves.

Lipidomics Profiling: The MS/MSALL workflow enables comprehensive lipid coverage without predefinition of targets [2]. Data can be extracted in silico to mimic precursor ion and neutral loss scans, providing flexibility in data analysis long after acquisition.

Method Selection Criteria: FIA-MS is recommended for high-throughput applications where moderate sensitivity suffices and sample composition is relatively consistent [6]. LC-MS/MS remains preferable for complex matrices or when maximum sensitivity is required, particularly near detection limits [6].

Within the framework of liquid chromatography-mass spectrometry (LC-MS) optimization, Flow Injection Analysis (FIA) serves as a powerful technique for rapid sample introduction and analysis, bypassing the chromatographic column to achieve high throughput. The core principle of FIA involves the injection of a precise sample volume into a continuously flowing, unsegmented carrier stream [14] [15]. The hardware configuration that facilitates this—comprising the pumps, injection valves, tubing, unions, and connectors—is collectively known as the FIA manifold. The reproducibility and quality of FIA-MS data are critically dependent on the precise configuration and selection of these components, as they govern sample dispersion and mixing kinetics prior to MS detection [14] [1]. This application note details the essential hardware setup for a robust and optimized FIA-MS system.

Core Hardware Components of an FIA Manifold

A basic FIA manifold is composed of several key subsystems that work in concert to transport, inject, and prepare the sample for detection.

System Components and Their Functions

Table 1: Core Components of a Flow Injection Analysis Manifold

| Component | Function & Description | Key Configuration Parameters |

|---|---|---|

| Propulsion Unit (Pump) | Generates a constant, pulseless flow of the carrier solvent, transporting the sample plug through the system. | Flow Rate: Typically 0.5-2.0 mL/min; must be stable and reproducible [15]. |

| Sample Injection Valve | Introduces a precise, discrete volume of sample into the flowing carrier stream without flow disruption. A rotary valve with a sample loop is standard. | Injection Volume: Usually 50-150 µL [15]; defined by the loop size. Type: Often a 6-port, 2-position rotary valve [16] [1]. |

| Manifold Tubing / Reactor | The conduit where the sample disperses into the carrier and mixes with reagents. It also serves as the reaction chamber. | Material: Chemically inert (e.g., Teflon, PEEK) [15]. Diameter: Typically 0.5-0.8 mm [15]. Length & Coiling: Determines reaction time; coiled to promote mixing [14] [15]. |

| Connectors & Unions | Low-dead-volume fittings used to connect sections of tubing and other components, ensuring leak-free flow paths. | Type: Low-dead-volume unions, tees, and crosses. Material: Compatible with solvents and pressures used. |

| Detector (MS) | The flow-through sensor that generates the analytical signal. In FIA-MS, this is the mass spectrometer's ion source. | Flow Cell: The ESI or APCI probe serves as the flow cell. Compatibility: Mobile phase must be suitable for MS ionization. |

Research Reagent Solutions and Essential Materials

Table 2: Essential Materials for FIA-MS Manifold Setup

| Item | Typical Specification | Primary Function in FIA-MS |

|---|---|---|

| Carrier Solvent | HPLC-grade methanol, acetonitrile, water, or volatile buffers (e.g., ammonium formate/acetate). | Dissolves the sample and forms the liquid transport stream into the MS ion source. |

| Peristaltic or Syringe Pump | Capable of delivering 0.1-5.0 mL/min with high precision. | Propels the carrier stream and any added reagents through the manifold [14] [15]. |

| Six-Port Rotary Injection Valve | Equipped with a fixed-volume sample loop (e.g., 10-200 µL). | Introduces a sharp, well-defined sample plug into the carrier stream for reproducible injection [16] [1]. |

| Tubing (PEEK or Teflon) | Internal diameter: 0.25-0.75 mm. | Forms the flow path and reactor; smaller diameters limit dispersion [15]. |

| Low-Dead-Volume (LDV) Unions | Zero-dead-volume (ZDV) or nano-volume fittings in 1/16" outer diameter. | Connects tubing segments and injector to detector with minimal band broadening and peak tailing. |

| Mixing Tee | A low-volume "T" or "Y" union. | Merges the main carrier stream with a second reagent stream introduced via a second pump [1]. |

Flow Path Configuration and Dispersion Dynamics

The physical and chemical processes occurring within the flow path after sample injection are fundamental to FIA.

The Dispersion Process

Upon injection, the sample forms a discrete plug within the carrier stream. As it is transported, this plug undergoes dispersion—a controlled mixing process with the carrier stream governed by convection and diffusion [14].

- Convection: Results from the laminar flow profile in narrow-bore tubing, where the fluid at the center moves faster than the fluid at the walls, creating a parabolic profile that stretches the sample plug [14].

- Radial Diffusion: The movement of sample molecules from areas of high concentration (center of the plug) to low concentration (the carrier stream and tubing walls). This is critical for mixing the sample with the carrier and any reagents, and for controlling the shape of the flow profile [14].

The degree of dispersion is quantified by the dispersion coefficient (D), defined as the ratio of the analyte concentration before and after the dispersion process [1]. The configuration can be tailored for different needs:

- Limited Dispersion (D ≤ 3): Used when minimal dilution is desired, achieved with short, straight tubing.

- Medium Dispersion (3 < D < 10): Used when mixing with reagents is required, achieved with coiled reaction tubing.

- Large Dispersion (D ≥ 10): Used for automatic sample dilution [1].

Diagram 1: Sample dispersion process in FIA tubing.

Configuring the Flow Path for MS Detection

For FIA-MS, the flow path must be optimized to deliver a sharp, well-defined analyte band to the mass spectrometer's ion source.

- Minimize Extra-Column Volume: Use the shortest possible length of narrow-bore tubing (e.g., 0.005" - 0.02" inner diameter) between the injector and the MS source. All connections must be made with low-dead-volume unions to reduce peak broadening [15].

- Coiled Reactor: To promote radial diffusion for efficient mixing (e.g., for on-line dilution or dynamic titration) while limiting axial dispersion, the reaction tubing is often coiled. This induces secondary flow patterns that enhance mixing without excessively broadening the sample band [15].

- Multi-Stream Manifolds: More complex experiments may use a multi-channel manifold where a second pump delivers a reagent or a host molecule for binding studies via a mixing tee [1]. This setup is the basis for advanced techniques like dynamic titration for determining dissociation constants (K~d~).

Experimental Protocol: System Setup and a Representative FIA-MS Experiment

Protocol: Assembly and Operational Verification of a Single-Channel FIA-MS Manifold

Objective: To assemble a basic FIA-MS flow path and verify its performance by generating a reproducible transient signal. Materials: See Table 2 for essential materials. Additionally, prepare a carrier stream (e.g., 50/50 methanol/water with 0.1% formic acid) and a standard solution (e.g., 1 µg/mL caffeine in carrier).

Assembly:

- Flush all tubing and the sample loop with the appropriate solvent prior to connection.

- Connect the outlet of the pump to the inlet port of the injection valve using a short piece of PEEK tubing and a LDV union.

- Connect the sample loop to the designated ports on the injection valve.

- Connect the outlet port of the injection valve to one end of the reaction coil (e.g., 50 cm of 0.5 mm ID PEEK tubing, coiled).

- Connect the other end of the reaction coil directly to the MS ion source (e.g., ESI probe) using the shortest possible piece of appropriate tubing.

System Startup:

- Prime the pump and the entire flow path with the carrier solvent at the desired flow rate (e.g., 0.5 mL/min). Ensure there are no leaks.

- Power on the mass spectrometer and establish stable instrument conditions.

Performance Verification:

- Fill the sample loop with the caffeine standard solution using a precision syringe.

- Activate the injection valve to introduce the sample into the carrier stream.

- Simultaneously, start data acquisition on the mass spectrometer, monitoring the ion trace for caffeine (e.g., m/z 195).

- A sharp, Gaussian-like peak should be observed. Record the peak height and peak width at half height.

- Repeat the injection at least five times to calculate the relative standard deviation (RSD) of the peak height and retention time. A well-configured system should yield an RSD of <2% for peak height [15].

Diagram 2: Basic FIA-MS workflow.

Application: Dynamic Titration for Binding Affinity (K~d~) Measurement

Objective: To rapidly determine the dissociation constant (K~d~) of a non-covalent host-guest complex using FIA-MS [1]. Principle: A concentration gradient of the guest molecule is created via FIA dispersion and mixed with a constant concentration of the host. The MS monitors the intensities of the free host, free guest, and the complex in real-time as the gradient passes through.

Materials:

- Two syringe or piston pumps.

- A six-port, two-position rotary valve with a sample loop.

- A dispersion loop (longer coil of tubing, e.g., 200 cm).

- A mixing tee.

- Host and guest molecule solutions in a compatible, volatile buffer.

- Mass spectrometer with an ESI source.

Procedure:

- Manifold Configuration: Configure the system as shown in Diagram 3. The carrier stream (from Pump 1) transports the injected guest plug through the dispersion loop. A second stream containing the host at a fixed concentration is introduced via Pump 2 and merged with the dispersed guest plug just before the MS via a mixing tee.

Execution:

- Set Pump 1 (carrier) and Pump 2 (host) to the same flow rate (e.g., 0.2 mL/min).

- Load the guest solution at a known concentration into the sample loop.

- Activate the injection valve.

- The MS is set to monitor the selected ions for the host, guest, and complex simultaneously.

Data Analysis:

- Export the intensity data for the complex ion over the time of the FIA peak.

- The concentration of the guest at each data point is known from the pre-calibrated dispersion profile of the system.

- Fit the data (guest concentration vs. complex intensity) to a 1:1 binding model (e.g., Langmuir isotherm) to calculate the K~d~ value.

This method offers a high-throughput alternative to conventional titration, completing a measurement in minutes with minimal sample consumption [1].

Concluding Remarks

The performance of an FIA-MS system is intrinsically linked to its hardware configuration. A meticulous approach to selecting and assembling the components—pumps, injection valves, tubing, and unions—is paramount for achieving a flow path with minimal dead volume and controlled dispersion. The protocols outlined herein provide a foundation for establishing a robust FIA-MS setup, enabling applications ranging from simple, high-throughput concentration screening to sophisticated solution-phase binding assays. Proper optimization of this hardware is a critical step in any broader research endeavor aimed at leveraging the full potential of flow injection analysis coupled to mass spectrometry.

Developing a Robust FIA-MS Method: A Step-by-Step Protocol

In liquid chromatography-mass spectrometry (LC-MS), the steps of sample preparation and the choice of solvents are not merely preliminary; they are foundational to the success of the entire analytical workflow. Proper sample preparation aims to remove interfering matrix components, prevent instrument contamination, and concentrate analytes of interest. Concurrently, the selection of solvents and additives directly governs the efficiency of electrospray ionization (ESI), the most prevalent ionization technique in LC-MS, by affecting droplet formation, desolvation, and ultimately, the generation of gas-phase ions [17] [18]. This application note provides detailed protocols and structured data to guide researchers in optimizing these critical first steps for robust and sensitive Flow Injection Analysis (FIA)-MS methods.

Core Principles and Impact on Ionization

The primary goal of sample preparation is to make the sample compatible with the MS system. Complex biological matrices can cause ion suppression, where co-eluting compounds interfere with the ionization of the target analyte, leading to reduced sensitivity and inaccurate quantification [19] [17]. Efficient sample clean-up mitigates this effect.

In ESI, the solvent is integral to the mechanism of ion formation. Key considerations include:

- Elution Strength and Composition: The elution power of the solvent from a prior LC step can be too strong for effective focusing at the head of a subsequent column or for stable ESI formation. Techniques like active solvent modulation (ASM) can be employed to reduce this elution force by adding a weaker solvent [19].

- Additives: Volatile acids (e.g., formic acid) and buffers (e.g., ammonium acetate) are used to enhance analyte ionization. Acids promote positive ion formation by protonating basic analytes, while ammonium acetate is suitable for both positive and negative modes.

- Compatibility: Solvents must be LC-MS grade to minimize background noise and prevent contamination of the ion source.

Optimizing Ion Source and Solvent Parameters

Ion source parameters are highly dependent on the solvent composition and flow rate. A systematic optimization of these parameters is crucial for maximizing signal intensity and stability.

Design of Experiments (DoE) for Systematic Optimization

The one-factor-at-a-time (OFAT) approach is inefficient and can miss interacting effects. Using Design of Experiments (DoE) and Response Surface Methodology (RSM) provides a statistically sound framework for finding optimal conditions [20] [21]. A study optimizing oxylipin analysis used a fractional factorial design to screen relevant factors like interface temperature and CID gas pressure, followed by a central composite design for optimization, which significantly improved signal-to-noise ratios [21].

Key Ion Source Parameters

Optimization of ESI parameters is essential for obtaining high-quality signal across a wide range of analytes. The table below summarizes optimal values for key parameters from an untargeted metabolomics study using an Orbitrap mass spectrometer [17].

Table 1: Optimized ESI Ion Source Parameters for Untargeted Analysis

| Parameter | Optimal Value (Positive Mode) | Optimal Value (Negative Mode) | Impact on Ionization |

|---|---|---|---|

| Spray Voltage | 2.5 – 3.5 kV | 2.5 – 3.0 kV | Applied potential for electrospray formation; critical for stable current. |

| Vaporization Temp. | 250 – 350 °C | 250 – 350 °C | Aids in solvent evaporation from charged droplets. |

| Ion Transfer Tube Temp. | 250 – 350 °C | 250 – 350 °C | Prevents condensation and ensures efficient ion transfer into mass analyzer. |

| Sheath Gas | 30 – 50 (arbitrary units) | 30 – 50 (arbitrary units) | Assists in nebulization and shapes the spray for stability. |

| Auxiliary Gas | ≥10 (arbitrary units) | ≥10 (arbitrary units) | Helps desolvate the droplets by sweeping the spray. |

| Needle Position | Farthest (Z), Closest (Y) to inlet | Farthest (Z), Closest (Y) to inlet | Fine-tunes spray position for maximum ion influx. |

Detailed Experimental Protocols

Protocol 1: Solid Phase Extraction (SPE) for Aqueous Samples

This protocol is adapted from a method developed for the multi-residue analysis of pharmaceuticals, pesticides, and UV filters in water [20].

Application: Pre-concentration and clean-up of micropollutants from surface water or other aqueous matrices. Principle: Analytes are isolated based on affinity to a solid sorbent, followed by washing and elution.

Workflow Overview: SPE for Aqueous Samples

Steps:

- Cartridge Conditioning: Sequentially pass methanol (e.g., 3-5 mL) and then LC-MS grade water (e.g., 3-5 mL) through the hydrophilic-lipophilic balance (HLB) SPE cartridge without letting it run dry.

- Sample Loading: Adjust the sample pH to 3-4 using a volatile acid like formic acid. Load the specified sample volume (e.g., 375 mL for water analysis) onto the cartridge at a steady flow rate (e.g., 5-10 mL/min).

- Washing: Wash the cartridge with LC-MS grade water (e.g., 3-5 mL) to remove polar matrix interferences.

- Drying: Apply a vacuum or air flow (e.g., 10-15 min) to dry the sorbent bed completely. This step is critical for removing water before elution.

- Elution: Elute the target analytes into a clean collection tube using 3.5 mL of ethanol. Let the solvent dwell in the cartridge for ~1 minute before applying gentle vacuum.

- Post-Processing: Evaporate the eluate to dryness under a gentle stream of nitrogen. Reconstitute the dried extract in an initial LC-MS mobile phase (e.g., 100 µL of water/methanol 95:5) and vortex thoroughly before analysis.

Validation: The described method achieved an average absolute recovery of 73% for 32 target micropollutants [20].

Protocol 2: Protein Precipitation for Biofluids

Application: Rapid removal of proteins from biological fluids like plasma or serum. Principle: Organic solvents denature and precipitate proteins, which are then removed by centrifugation.

Workflow Overview: Protein Precipitation

Steps:

- Precipitation: Transfer 100 µL of plasma/serum to a microcentrifuge tube. Add 300 µL of ice-cold acetonitrile or methanol (a 1:3 sample-to-solvent ratio is common).

- Mixing and Incubation: Vortex the mixture vigorously for 30-60 seconds. Incubate at 4°C for 10 minutes to ensure complete protein precipitation.

- Centrifugation: Centrifuge at high speed (e.g., 15,000 x g) for 10 minutes at 4°C to form a compact protein pellet.

- Collection and Reconstitution: Carefully transfer the clear supernatant to a new tube. Evaporate the solvent under nitrogen gas and reconstitute the residue in a compatible FIA solvent (e.g., 50% methanol with 0.1% formic acid).

Protocol 3: Solid-Phase Microextraction (SPME) for Metabolomics

This protocol outlines the preparation of a high-throughput 96-blade SPME platform for metabolite cleaning and enrichment, ideal for small-volume samples and integration with nanoflow LC-MS [22].

Application: Cleaning and enrichment of metabolites from complex biological samples for untargeted metabolomics. Principle: A coated blade extracts analytes directly from the sample, which are then desorbed in a compatible solvent.

Steps:

- Blade Preparation: Sonicate stainless-steel blades in concentrated HCl for 60 minutes. Rinse thoroughly with deionized water and dry in an oven at 150°C for 30 minutes [22].

- Coating Slurry Preparation: Dissolve 10% (w/w) polyacrylonitrile (PAN) particles in N,N-dimethylformamide (DMF) at 90°C. After cooling, mix a 1:1 (w/w) ratio of polystyrene-divinylbenzene with a weak anion exchanger (PS-DVB-WAX) and hydrophilic-lipophilic balance (HLB) sorbent into the PAN glue [22].

- Coating Application: Using a nitrogen-pressurized sprayer (<5 psi), apply a thin layer of the slurry onto the blades. Thermally cure the coating in an oven at 180°C for 2 minutes. Repeat this spray-and-cure process 10 times to achieve a uniform ~120 µm coating thickness [22].

- Metabolite Extraction: Condition the coated blades in methanol and water. Immerse the blades in the processed sample (e.g., biofluid or tissue homogenate) for a defined extraction time with agitation.

- Wash and Desorption: Rinse the blades briefly with water to remove salts. Desorb the metabolites by placing the blades in a desorption solvent (e.g., 80:20 ACN:MeOH with 0.1% formic acid) for a set time. The desorbed solution is then ready for FIA-MS analysis.

The Scientist's Toolkit

Table 2: Essential Reagents and Materials for Sample Preparation and FIA-MS

| Item | Function / Application |

|---|---|

| Hydrophilic-Lipophilic Balance (HLB) Sorbent | A versatile SPE sorbent for extracting a broad range of acidic, basic, and neutral compounds from aqueous matrices [20]. |

| LC-MS Grade Solvents (ACN, MeOH, Water) | High-purity solvents to minimize background noise and contamination in mass spectrometry [17] [22]. |

| Volatile Additives (Formic Acid, Ammonium Acetate) | Enhance ionization efficiency in the ESI source. Formic acid for positive mode, ammonium acetate for both positive and negative mode [17] [21]. |

| Polyacrylonitrile (PAN) Glue | A biocompatible polymer used as a binding agent in the fabrication of SPME coatings [22]. |

| C18 Stationary Phase | The most common reversed-phase material for LC separation and SPE, suitable for non-polar to mid-polar metabolites [17]. |

| Uniformly ¹³C-Labelled Yeast Extract | A complex internal standard mixture for pixel-wise normalization and compensation of matrix effects in quantitative mass spectrometry imaging and metabolomics [23]. |

In Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS), optimizing compound-dependent parameters is a critical step for achieving high sensitivity and selectivity. Following the initial dilution of a pure chemical standard, the next pivotal phase involves fine-tuning the mass spectrometer's parameters to uniquely identify and quantify the target analyte [24]. This document details a systematic, experimental protocol for optimizing the fragmentor voltage and collision energy, two parameters that directly control the formation and abundance of precursor and product ions. These optimized settings are foundational for constructing a specific and robust Multiple Reaction Monitoring (MRM) method, which is the cornerstone of quantitative analysis in complex matrices such as clinical and pharmaceutical samples [25] [26].

Key Concepts and Definitions

- Fragmentor Voltage: Also known as the orifice or declustering potential, this voltage is applied in the interface region between the ion source and the first quadrupole. Its primary function is to decluster solvated ions and focus the precursor ion of interest into the mass analyzer. An optimal voltage ensures maximum signal intensity for the precursor ion [24].

- Collision Energy (CE): The energy applied in the collision cell (Q2) to fragment the selected precursor ion through collisions with an inert gas (e.g., nitrogen or argon). The CE dictates the fragmentation pattern, determining the abundance of specific product ions. Optimizing CE is crucial for selecting the most intense and unique transitions for MRM [25] [24].

- Multiple Reaction Monitoring (MRM): A highly specific mass spectrometry mode that monitors one or more predefined precursor ion → product ion transitions. It significantly reduces chemical background noise, thereby enhancing selectivity and sensitivity for quantitative assays [25] [24].

Experimental Protocol: A Step-by-Step Guide

Preparation for Optimization

- Standard Solution: Utilize a pure, high-quality chemical standard of the target compound, dissolved in an appropriate solvent (e.g., a mixture of prospective mobile phases). The concentration should be suitable for instrument detection, typically in the range of 50 ppb to 2 ppm [24].

- Instrumentation: This protocol is applicable to tandem mass spectrometers, including triple quadrupole (QqQ) and Q-Trap instruments. The system should be equipped with an electrospray ionization (ESI) or atmospheric pressure chemical ionization (APCI) source [25] [24].

Optimizing the Fragmentor Voltage

The goal is to determine the voltage that yields the maximum signal for the precursor ion.

- Identify Precursor Ion: Begin by infusing the standard solution directly into the mass spectrometer (bypassing the LC column) in full scan mode. Common precursor ions include

[M+H]⁺or[M-H]⁻. If the signal is low, consider adducts like[M+NH₄]⁺or[M+Na]⁺[24]. - Voltage Ramp: Once the precursor mass is confirmed, switch to selected ion monitoring (SIM) mode for that mass. Ramp the fragmentor voltage over a defined range (e.g., 50V to 250V in 10-20V increments) while monitoring the ion intensity.

- Determine Optimum Value: Plot the signal intensity of the precursor ion against the fragmentor voltage. The voltage that produces the maximum stable signal is selected as the optimal fragmentor voltage. A suboptimal voltage can lead to insufficient declustering (low signal) or in-source fragmentation (premature fragmentation) [24].

Optimizing the Collision Energy

The goal is to determine the energy that generates the most abundant and characteristic product ions.

- Product Ion Scan: Using the optimized fragmentor voltage, introduce the precursor ion into the collision cell and perform a product ion scan. This involves scanning a range of masses in Q3 while ramping the collision energy to generate a spectrum of all possible fragments.

- Select Product Ions: From the product ion spectrum, select at least two abundant and characteristic product ions for each compound. The most intense transition is typically used for quantification, while the second is used for confirmatory identification [24].

- Fine-tune Collision Energy: For each selected precursor→product ion transition (MRM pair), systematically ramp the collision energy to find the value that provides the maximum response for that specific product ion. This can be automated with instrument software. The study on amantadine optimization, for instance, used a collision energy of 25 eV for its specific transitions [25].

Method Verification

- MRM Ratio Confirmation: A compound is positively identified only if both MRM transitions are detected and their intensity ratio matches that of the pure standard within a pre-defined acceptance range [24].

- Calibration Curve: Verify the optimized method by running a series of standard solutions at different concentrations. A linear response (

r > 0.995is typically required) confirms that the optimization is successful and the method is suitable for quantification [25] [24].

The following workflow summarizes the key steps of this optimization process.

Data Presentation and Analysis

The following tables summarize the key parameters and outcomes from the optimization process, drawing on examples from the literature.

Table 1: Optimized MS Parameters for a Model Compound (Amantadine) [25]

| Parameter | Value for Amantadine | Value for Internal Standard (AMT-d15) | Function |

|---|---|---|---|

| Precursor Ion (Q1) | m/z 152.2 | m/z 167.0 | Selects the ion of interest |

| Product Ion 1 (Q2) | m/z 135.3 | m/z 150.3 | First fragmentation product |

| Product Ion 2 (Q3) | m/z 107.4 | m/z 118.1 | Second fragmentation product for MS³ |

| Declustering Potential | 43 V | 43 V | Optimized fragmentor voltage |

| Collision Energy | 25 eV | 25 eV | Energy for generating product ions |

| Dwell Time | 80 ms | 80 ms | Time spent monitoring each transition |

Table 2: Method Validation Metrics for an Optimized LC-MS³ Assay [25]

| Validation Parameter | Result | Acceptance Criteria |

|---|---|---|

| Linear Range | 50 - 1500 ng/mL | - |

| Correlation Coefficient (r) | > 0.995 | > 0.995 |

| Lower Limit of Quantification (LLOQ) | 50 ng/mL | - |

| Intra-day Precision (RSD%) | < 10.7% | < 15% |

| Inter-day Precision (RSD%) | < 8.0% | < 15% |

| Accuracy (Relative Error %) | 90.4 - 102.4% | 85-115% |

The Scientist's Toolkit: Essential Research Reagents and Materials

A successful optimization experiment requires specific, high-quality materials. The following table lists essential items and their functions.

Table 3: Essential Reagents and Materials for Parameter Optimization

| Item | Function | Example/Note |

|---|---|---|

| High-Purity Chemical Standard | Provides the target analyte for parameter optimization without interference. | Ensure purity >95% [24]. |

| HPLC-Grade Solvents | To dissolve the standard and prepare mobile phases; minimizes background noise. | e.g., Methanol, Acetonitrile, Water [24]. |

| Mobile Phase Additives | Enhance ionization efficiency and improve chromatographic peak shape. | e.g., 0.1% Formic Acid, Ammonium Formate [25] [24]. |

| Internal Standard | Corrects for variability in sample preparation and ionization; often a stable isotope-labeled analog. | e.g., Amantadine-d15 [25]. |

| Collision Gas | Inert gas used in the collision cell to induce fragmentation of the precursor ion. | High-purity Nitrogen or Argon [24]. |

| Syringe Pump/Infusion System | For direct introduction of the standard solution during initial MS parameter tuning. | - |

Advanced Applications and Considerations

The principles of parameter optimization are universally applicable across various MS techniques. For instance, Flow Injection Analysis-Mass Spectrometry (FIA-MS) leverages these optimized parameters for rapid, high-throughput screening without chromatographic separation, as demonstrated in the detection of fraud in herbal supplements [3] and newborn screening for X-linked adrenoleukodystrophy [8].

Advanced scanning modes like MS³ build directly upon optimized MRM parameters. In MS³, a product ion from an MRM transition is selected and fragmented further, adding an extra layer of selectivity. This is particularly valuable for eliminating complex matrix interference in biological samples, as shown in the amantadine study where the transition m/z 152.2→135.3→107.4 was used [25]. This highlights that robust optimization of the initial fragmentor voltage and collision energy is a prerequisite for deploying these more advanced, highly specific analytical techniques.

In liquid chromatography-mass spectrometry (LC-MS), the ionization source is a critical interface where analytes in the liquid eluent are converted into gas-phase ions for mass analysis. The performance of this process is highly dependent on the precise tuning of source parameters, which directly influences method sensitivity, robustness, and quantitative accuracy. This document details a systematic approach to optimizing three key source-dependent parameters—desolvation temperature, gas flows, and electrospray ionization (ESI) voltage—within the context of flow injection analysis, providing researchers with detailed protocols for method development.

Parameter Definitions and Optimization Ranges

The table below summarizes the core parameters to be optimized, their fundamental functions, and typical value ranges. These ranges are starting points and should be fine-tuned for specific instrument models and analytical applications.

Table 1: Key Source-Dependent Parameters for Optimization

| Parameter | Primary Function | Typical Optimization Range | Effect of Setting Too Low | Effect of Setting Too High |

|---|---|---|---|---|

| Desolvation Temperature | Evaporates solvent from charged droplets to liberate gas-phase ions [27]. | 200°C to 600°C [27] [28]. | Incomplete desolvation, leading to increased chemical noise and unstable spray. | Thermal degradation of analytes; precipitation of analytes in the capillary, causing clogging [29]. |

| Desolvation Gas Flow | Assists in droplet desolvation and shapes the spray plume [27]. | 800 L/h to 1200 L/h [28]. | Poor desolvation efficiency, reduced signal intensity. | Can cool the spray and deflect ions away from the cone, reducing signal [27]. |

| Nebulizer Gas Flow/Pressure | Pneumatically assists in nebulizing the liquid into fine droplets [27]. | Pressure optimized for specific flow rates (e.g., ~0.2 mL/min for pneumatically assisted ESI) [27]. | Unstable spray formation, large droplet size, reduced sensitivity. | Can cause turbulence, disrupting the stable spray and ion sampling. |

| ESI (Capillary) Voltage | Imparts charge on the liquid eluent, inducing Taylor cone formation and electrospray [27] [30]. | Typically 2-4 kV, depending on solvent composition and flow rate [27]. | Unstable or no electrospray. | Electrical discharge (arc-ing), particularly in negative ion mode; unwanted electrochemical side reactions; rim emission [27]. |

Experimental Protocols for Systematic Optimization

Initial Setup and Sample Infusion

A stable and controlled sample introduction is fundamental for reliable parameter tuning.

- Sample Preparation: Prepare a standard solution of the target analyte(s) at a concentration of approximately 1 µg/mL in a solvent that closely matches the initial mobile phase composition of the intended LC method [31].

- Flow Injection: Use a syringe pump or an LC pump to infuse the standard solution directly into the MS source, bypassing the chromatographic column. A flow rate of 10 µL/min is a common starting point [28].

- Mobile Phase: For initial ionization mode selection, a 50:50 mix of organic solvent (e.g., acetonitrile) and 10 mM ammonium formate buffer (adjusted to both pH 2.8 and 8.2) can be used to evaluate the optimal pH and polarity [31].

- Signal Monitoring: Tune the mass spectrometer to monitor the ion signal for the protonated or deprotonated molecule ([M+H]+ or [M-H]-) of the infused standard.

Detailed Optimization Procedure

The following step-by-step protocol ensures a logical and efficient optimization process.

- Establish a Baseline: Begin with manufacturer-recommended default settings for all source parameters.

- Optimize Gas Flows and Temperature:

- Set the ESI voltage to a moderate value (e.g., 3.0 kV).

- Systematically vary the nebulizer gas and desolvation gas flow rates while monitoring the total ion count (TIC) or the extracted ion chromatogram (XIC) signal for your analyte. The goal is to find values that produce a stable signal with maximum intensity [27].

- Adjust the desolvation temperature. Higher temperatures generally improve desolvation and signal stability but must be balanced against the risk of thermal degradation [29]. The optimal temperature is often linked to the mobile phase flow rate [28].

- Optimize ESI Voltage:

- With gas flows and temperature set to their newly found optimal values, perform a voltage scan (e.g., from 1.5 kV to 4.0 kV).

- Plot the signal intensity against the applied voltage. The goal is not always to find the absolute maximum signal, but to identify a stable plateau where minor fluctuations in voltage do not cause significant signal variation, ensuring method robustness [31].

- In negative ion mode, use lower voltages to avoid electrical discharge [27].

- Seek a Robust Maximum: For all parameters, the objective is to set values on a "maximum plateau" where small, inevitable variations in that variable do not produce a large change in instrument response, thus ensuring a robust analytical method [31].

- Fine-tune Cone Voltage: Although not the primary focus of this protocol, the cone voltage (or declustering potential) should be optimized subsequently. It controls ion declustering and can induce in-source fragmentation. Adjust it to maximize the precursor ion signal while minimizing unwanted fragmentation [27].

Advanced Method: Statistical Design of Experiments (DOE)

For complex methods or when analyzing the interaction of multiple parameters, a DOE approach is highly recommended over the one-factor-at-a-time (OFAT) method.

- Select Critical Parameters: Choose the factors to optimize (e.g., Desolvation Temperature, Nebulizer Gas, ESI Voltage).

- Define Ranges: Set realistic low and high levels for each factor based on preliminary experiments or literature.

- Generate Experimental Design: Use software (e.g., Design-Expert, R) to create a design matrix, such as a Central Composite Design (CCI), which efficiently explores the factor space and their interactions [32].

- Run Experiments and Analyze Response: Execute the experiments in the randomized order prescribed by the design and record the response (e.g., signal intensity, signal-to-noise ratio).

- Model and Predict: Use Response Surface Methodology (RSM) to build a mathematical model and identify the optimal parameter settings that maximize the desired response [33] [32].

Workflow Visualization

The following diagram outlines the logical sequence for tuning source-dependent parameters, integrating both initial optimization and advanced statistical approaches.

Research Reagent Solutions

The table below lists key reagents and materials essential for successfully executing the optimization protocols described in this document.

Table 2: Essential Research Reagents and Materials for LC-MS Optimization

| Reagent/Material | Function/Application | Critical Notes for Optimization |

|---|---|---|

| Ammonium Formate/ Acetate | Volatile buffer for mobile phase; maintains pH for consistent ionization [31] [32]. | Use high-purity LC-MS grade. Test at different pH levels (e.g., 2.8 and 8.2) to determine optimal ionization mode and efficiency [31]. |

| LC-MS Grade Solvents | Mobile phase constituents (e.g., water, acetonitrile, methanol). | Low metal ion content is critical to prevent adduct formation [M+Na]+, [M+K]+ which suppress the protonated molecule signal [27]. |

| Analyte Standards | Model compounds for parameter tuning. | Use pure, well-characterized compounds representative of your target analytes. Start with a concentration of ~1 µg/mL for infusion [31]. |

| Plastic Vials & Inserts | Sample containers for autosampler. | Preferred over glass to avoid leaching of metal ions that cause sodium/potassium adducts [27]. Use glass inserts if plasticizer interference is suspected [29]. |

| Syringe Pump & Infusion Set | For direct infusion of standards during tuning. | Enables stable introduction of analyte solution without chromatographic separation, allowing for direct observation of MS parameter effects [31] [30]. |

In modern drug development and analytical research, the demand for rapid analysis of thousands of samples has made Flow Injection Analysis-Mass Spectrometry (FIA-MS) an indispensable high-throughput technique. Unlike liquid chromatography-mass spectrometry (LC-MS), FIA-MS eliminates chromatographic separation, allowing samples to be directly injected into the mass spectrometer, which drastically reduces analysis time to seconds or minutes per sample [34] [35]. This application note details a strategic, optimized sequence for FIA-MS method development, enabling researchers to efficiently balance speed, sensitivity, and reproducibility in high-throughput screens for reaction optimization, metabolomics, and food supplement authentication [36] [37].

Table 1: Comparison of FIA-MS and LC-MS for High-Throughput Analysis

| Parameter | FIA-MS | Fast LC-MS |

|---|---|---|

| Analysis Time per Sample | ~10 seconds to 2 minutes [34] [37] | Several minutes [37] |

| Throughput | Very High | Medium |

| Chromatographic Separation | None | Required |

| Ion Suppression Effects | Potentially higher due to co-elution [37] | Reduced by separation |

| Ion Competition in Detector | Primary sensitivity limitation [34] | Mitigated by separation |

| Best Application Fit | Qualitative/Semi-quantitative screening of simple mixtures [37] | Quantitative analysis of complex mixtures [37] |

Key Principles and Strategic Advantages of FIA-MS

The core principle of FIA involves the injection of a discrete sample plug into a continuously flowing carrier stream, which transports the sample directly to the MS detector. This setup generates a transient, Gaussian-like signal from which data is extracted [35]. The primary advantage is speed; a typical FIA-MS run can be completed in under 30 seconds, enabling the analysis of a 96-well plate in approximately one hour [37].

A crucial strategic consideration is the ion competition effect. When a complex sample is injected without separation, highly abundant ions can overwhelm the MS detector's capacity (for example, the C-trap in Orbitrap systems), masking lower-abundance ions and reducing sensitivity. This ion competition in the detection system, rather than ion suppression at the ionization source, has been identified as the prime reason for sensitivity loss in FIA-MS [34]. The strategic FIA sequence addresses this directly by using the mass spectrometer's quadrupole to isolate specific m/z ranges, preventing detector overload and significantly enhancing the number of detectable features [34].

Experimental Protocol: A Strategic FIA-MS Sequence

Instrument Setup and Configuration

- Hardware Configuration: An LC-MS system is used, but the chromatographic column is replaced with a zero-dead-volume union or a short piece of PEEKsil tubing to connect the injector directly to the MS source [38] [2]. Using PEEKsil tubing over standard stainless steel is critical for minimizing carryover, especially for sticky molecules like lipids [2].

- Mobile Phase: Choose a solvent compatible with ESI and the samples, typically a methanol/water or acetonitrile/water mixture, often with a volatile additive like 0.1% formic acid or 5mM ammonium acetate [36] [2]. The mobile phase should be delivered at a constant flow rate, commonly between 0.2-0.4 mL/min [36] [2].

Step-by-Step Optimization Sequence

The following sequence ensures method robustness before high-throughput deployment.

Step 1: Infusion Optimization for Compound-Dependent Parameters

- Purpose: To find the optimal fragmentor voltage and collision energies for your specific analytes using a pure standard solution.

- Protocol: Use a syringe pump to continuously infuse a standard solution (e.g., 0.01 mg/mL) into the MS. While infusing, systematically vary parameters like the fragmentor voltage and collision energy to maximize the signal intensity of the precursor and key product ions [38].

Step 2: Initial FIA Scouting for Source Parameters

- Purpose: To rapidly optimize source parameters for maximum ionization efficiency and stability using the actual FIA setup.

- Protocol: With the column bypassed, perform flow injections of the standard. Use an experimental design (e.g., Box-Behnken) to vary and optimize key source parameters [36]:

- Response Variable: Maximize the peak area and stability of the analyte signal.

Step 3: Strategic Mass Range Scoping (Spectral Stitching)

- Purpose: To overcome ion competition and define the optimal m/z scan ranges for sensitive full-scan analysis.

- Protocol: This is a critical step for untargeted analyses. Inject a representative sample and configure the quadrupole to scan a large number of narrow, consecutive m/z windows (e.g., 122 windows of 20 m/z each over 70-2500 m/z) [34]. Analyze the resulting data to map the distribution of detectable m/z features.

- Output: A small set of optimized, non-uniform scan ranges that evenly distribute the ion flux, maximizing the number of reproducibly detected features without unnecessarily extending scan time [34].

Step 4: Carryover Assessment and Wash Cycle Optimization

- Purpose: To ensure that a sample does not contaminate subsequent injections, which is vital for data integrity.

- Protocol: Inject a high-concentration sample followed by a series of blank injections (pure mobile phase). Monitor the signal in the blank injections.

- Acceptance Criterion: Carryover should typically be <0.2%. If exceeded, optimize the wash procedure by increasing the wash solvent strength, volume, and flow rate [2]. An aggressive wash step can be incorporated into the automated sequence.

Step 5: Final Method Validation

- Purpose: To confirm the method's performance is fit-for-purpose.

- Protocol: Perform repeated injections (n=5-9) of a quality control sample to establish precision. The %RSD for peak areas should be <5% [2]. Create a calibration curve to assess linearity if quantitative results are required.

The following workflow diagram summarizes this strategic sequence:

Essential Reagents and Materials

Table 2: Research Reagent Solutions for FIA-MS Workflow

| Item | Function / Role | Example / Specification |

|---|---|---|

| Mobile Phase Solvents | Carrier stream for sample transport and ESI. | HPLC-grade methanol, acetonitrile, water [36] [2]. |

| Ionization Additives | Enhance ionization efficiency and signal stability. | 0.1% Formic Acid, 5mM Ammonium Acetate [36] [2]. |

| Tubing (Post-injector) | Connects autosampler to MS source; critical for low carryover. | PEEKsil tubing [2]. |

| Carrier Phase (for Segmentation) | Creates immiscible plugs for advanced fraction management. | Perfluorotributylamine (FC43) [39]. |

| System Suitability Standard | Verifies instrument performance and method robustness. | A stable compound relevant to the analysis (e.g., SAC for garlic supplements) [36]. |

Data Analysis and Workflow Integration

Modern FIA-MS data analysis leverages the high-resolution and accuracy of the full-scan data. In shotgun lipidomics, for example, the MS/MSALL workflow creates a complete digital record of all precursors and their fragments. This data can later be interrogated in silico to generate precursor ion scans (PIS) or neutral loss (NL) scans for specific lipid classes without re-running the sample [2].

For large-scale screening, data processing software (e.g., LipidView, MarkerView) is used to extract metabolite or lipid profiles, which are then subjected to multivariate statistical analysis like Principal Component Analysis (PCA) to identify differentiating features between sample groups, such as diseased versus control states [2].

Application in Dietary Supplement Authentication

FIA-MS has proven highly effective for the rapid screening of food supplements for quality and authenticity. In a study on aged garlic supplements (AGS), a 4-minute FIA-MS method was successfully validated for the quantitation of the bioactive marker S-allyl-L-cysteine (SAC). This high-throughput approach allowed researchers to quickly identify products with fraudulent compositions, such as those containing undeclared synthetic compounds or discrepancies in bioactive content [36] [3]. This application underscores FIA-MS's role as a powerful tool for rapid quality control and standardization in industries with high sample volumes.

Liquid Chromatography-Mass Spectrometry (LC-MS) represents a cornerstone technology in modern analytical chemistry, providing unparalleled sensitivity and specificity for the quantification of target analytes in complex matrices. Within the broader scope of LC-MS optimization research, Flow Injection Analysis-Mass Spectrometry (FIA-MS) has emerged as a powerful high-throughput alternative that eliminates the chromatographic separation step, instead relying on direct sample injection into the mass spectrometer. This application note details a structured case study investigating the application of FIA-MS for the rapid detection of fraud in Coleus forskohlii food supplements, contrasting this approach with a highly sensitive LC-MS/MS method developed for quantification of the antimalarial drug fosmidomycin in biological fluids [3] [40]. The study is contextualized within a thesis on LC-MS optimization, specifically examining the trade-offs between analysis speed, sensitivity, and selectivity when employing FIA-MS versus conventional LC-MS methodologies.