Mastering Desolvation Temperature in APCI-MS: Optimization for Pharmaceutical and Biomedical Analysis

This article provides a comprehensive guide for researchers and drug development professionals on optimizing desolvation temperature in Atmospheric Pressure Chemical Ionization (APCI) for mass spectrometry.

Mastering Desolvation Temperature in APCI-MS: Optimization for Pharmaceutical and Biomedical Analysis

Abstract

This article provides a comprehensive guide for researchers and drug development professionals on optimizing desolvation temperature in Atmospheric Pressure Chemical Ionization (APCI) for mass spectrometry. It covers the fundamental principles of APCI and the critical role of temperature in the desolvation process. The content details systematic methodological approaches for temperature optimization, including the use of Design of Experiments (DoE), and offers practical troubleshooting strategies for common issues like low sensitivity and thermal degradation. Furthermore, it validates optimization protocols through case studies from pharmaceutical analysis and compares APCI performance with other ionization techniques like ESI, providing a solid foundation for developing robust, sensitive, and reliable LC-APCI-MS/MS methods in biomedical research and quality control.

The Core Principle: Understanding Desolvation Temperature's Role in APCI

The APCI Process: A Step-by-Step Guide

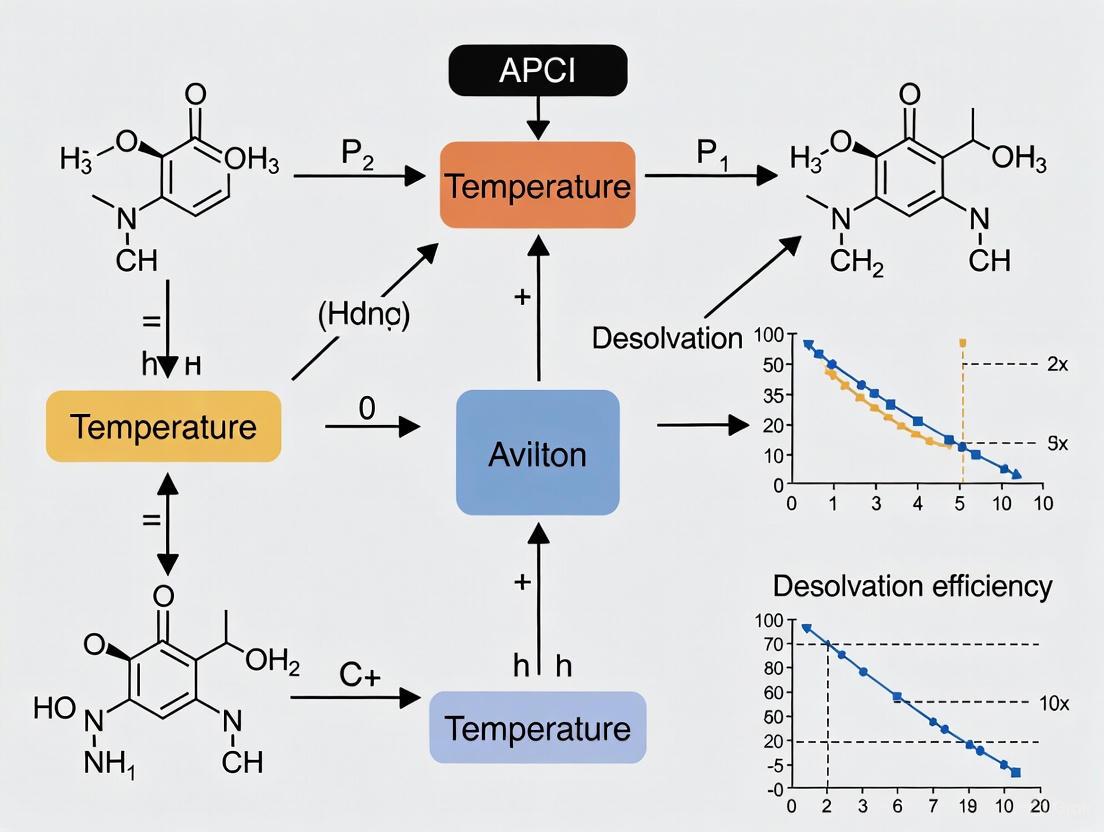

The Atmospheric Pressure Chemical Ionization (APCI) process is a cornerstone technique for analyzing a wide range of low molecular weight, thermally stable compounds. The following diagram illustrates the complete pathway from sample introduction to ion formation.

Figure 1: The complete APCI pathway from sample introduction to ion detection.

Stage 1: Nebulization and Vaporization

The process begins when the sample solution (typically LC eluate) is introduced into the nebulizer probe at flow rates commonly between 0.2 and 2.0 mL/min [1]. A concurrent flow of nebulizer gas (usually nitrogen) helps generate a fine spray of droplets [1]. The heated nebulizer then rapidly vaporizes this spray, converting it into a gas-phase mist containing both solvent and neutral analyte molecules [1]. This early desolvation is crucial for minimizing thermal degradation of the analyte.

Stage 2: Corona Discharge Ionization

The gas-phase mist enters the ionization region where a corona discharge needle under high potential (2-3 kV) generates a stable discharge [2] [1]. This discharge does not directly ionize the analyte but creates primary reagent ions from the solvent molecules present in the mist [1].

Stage 3: Gas-Phase Ion-Molecule Reactions

These primary reagent ions then undergo a series of ion-molecule reactions with the neutral analyte molecules to form stable analyte ions [1]. In positive ion mode with protic solvents, this typically results in protonated molecules [M+H]⁺, while negative ion mode can generate deprotonated molecules [M-H]⁻ or adduct ions [2] [1].

Stage 4: Ion Transfer and Detection

Finally, the formed analyte ions are guided through ion focusing lenses from the atmospheric pressure region into the high-vacuum environment of the mass analyzer, where they are separated and detected based on their mass-to-charge ratio [1].

Temperature Optimization for Desolvation: Experimental Protocols

Method 1: UPLC-APCI-MS/MS for Steroidal Hormones in Wastewater

This validated method demonstrates optimal temperature parameters for complex environmental analysis [3].

Sample Preparation:

- Extraction: Used Oasis HLB 96-well Solid-Phase Extraction plates for 5 mL of untreated wastewater samples [3].

- Elution: Employed ethyl acetate and n-hexane combination to increase elution strength for highly nonpolar analytes [3].

LC Conditions:

- Column: ACQUITY Premier BEH C18 Column, 130Å, 1.7 µm, 2.1 × 100 mm [3]

- Column Temperature: 65°C [3]

- Mobile Phase: A: 0.2 mM ammonium fluoride in water; B: Methanol with gradient elution [3]

MS Conditions:

- Instrument: Xevo TQ-XS Tandem Quadrupole [3]

- Desolvation Temperature: 550°C [3]

- Source Temperature: 150°C [3]

- Corona Voltage: 0.8 kV (positive), 1.2 kV (negative) [3]

Method 2: LC-APCI-MS/MS for Nitrosamines in Pharmaceuticals

This green analytical method showcases temperature optimization for sensitive pharmaceutical impurity detection [4].

Sample Preparation:

- Matrix: Sitagliptin Phosphate Monohydrate API [4]

- Preparation: Simple dissolution in water followed by filtration using 0.2 µm PVDF filter [4]

- Standards: Prepared in methanol with serial dilution [4]

LC Conditions:

- Column: Agilent Poroshell EC C18 (150 mm length) [4]

- Column Oven Temperature: 50°C [4]

- Sample Cooler Temperature: 6°C [4]

- Mobile Phase: Gradient with 0.1% formic acid in water and mixture of 50% methanol and 50% acetonitrile [4]

MS Conditions:

Critical Temperature Parameters Table

Table 1: Optimal temperature settings for different APCI applications

| Parameter | Steroidal Hormones Method [3] | Nitrosamines Method [4] | Function & Impact |

|---|---|---|---|

| Desolvation Temperature | 550°C | Not Specified | Vaporizes liquid droplets; higher temperatures improve desolvation but may degrade thermolabile compounds |

| Source Temperature | 150°C | Not Specified | Maintains overall source environment; affects solvent and analyte vaporization |

| Column Temperature | 65°C | 50°C | Optimizes chromatographic separation and retention time stability |

| Sample Temperature | 10°C | 6°C | Preserves sample integrity in autosampler before analysis |

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key reagents and materials for APCI-MS method development

| Reagent/Material | Function in APCI Analysis | Example Applications |

|---|---|---|

| Oasis HLB SPE | Sample clean-up and pre-concentration; reduces matrix effects | Extraction of 27 multiclass steroidal hormones from wastewater [3] |

| Methanol & Acetonitrile (LC-MS Grade) | Mobile phase components; efficient desolvation and ionization | Mobile phase for nitrosamine separation with 50:50 mixture [4] |

| Formic Acid & Ammonium Formate | Mobile phase additives; enhance protonation/deprotonation | 0.1% formic acid for improved ionization of nitrosamines [4] |

| Porous Shell C18 Columns | Fast, efficient chromatographic separation | Poroshell EC-C18 for nitrosamines; BEH C18 for steroidal hormones [3] [4] |

| APCI Tuning Mix | Instrument calibration and performance verification | Essential for maintaining corona discharge stability and mass accuracy [5] |

Troubleshooting Guide: Common APCI Issues and Solutions

FAQ 1: Why is my corona current fluctuating, and how does temperature affect this?

Symptoms: Corona current fluctuates between 2-10 µA (set point 4 µA); poor reproducibility [6].

Causes and Solutions:

- Primary Cause: Dirty corona pin - Remove and clean with a mildly abrasive pad under running water. Dry thoroughly and reinstall at the same angle [6].

- Temperature Connection: High desolvation temperatures can accelerate contamination buildup. Ensure proper gas flows to minimize deposition on the corona needle.

- Additional Checks: Verify nitrogen supply pressure (80-100 psi) and replace clogged gas filters if necessary [5].

FAQ 2: Why am I getting no signal despite good nebulizer spray?

Symptoms: No peaks in tuning, only noise, despite normal nebulizer spray appearance [5].

Troubleshooting Protocol:

- Check the Capillary: Clean the capillary using Alconox powdered cleaner (15 minutes sonication maximum), followed by thorough rinsing with water and drying with clean air stream [5].

- Inspect Spray Shield: Clean both the outer surface and internal components; use mesh cloth as manual specifies without solvents [5].

- Verify Pump Down Process: After maintenance, pump down MS with nitrogen flow and allow overnight thermal equilibration (≥11 hours) before tuning [5].

- Temperature Parameters: Confirm desolvation temperature is properly calibrated; inaccurate readings can prevent vaporization.

FAQ 3: Why is my positive mode tuning failing when negative mode works?

Symptoms: Successful negative ion tuning but only noise in positive mode [5].

Diagnosis and Resolution:

- Corona Needle Alignment: Positive and negative modes use different ionization pathways; misaligned corona needle after cleaning can preferentially affect one mode [5] [1].

- Solvent Composition: Residual solvents or additives from previous analyses may suppress positive ionization; perform extended flushing with appropriate solvents [7].

- Source Contamination: Even with good negative mode response, specific contaminants can suppress positive ionization; thorough source cleaning is recommended [5].

FAQ 4: How does makeup solvent composition interact with desolvation temperature?

Critical Considerations:

- Additive Concentration: APCI typically requires higher additive concentrations (formic acid, ammonia) than ESI for signal enhancement [7].

- Water Content: Higher water content can decrease response due to increased surface tension, requiring optimized desolvation temperatures [7].

- Organic Modifier: Different alcohols (methanol, ethanol, isopropanol) have varying vaporization characteristics that require temperature adjustment [7].

- Optimization Rule: Higher additive concentrations generally require higher desolvation temperatures for efficient vaporization, but excessive temperatures can degrade analyte [7].

In Atmospheric Pressure Chemical Ionization (APCI) mass spectrometry, the heated nebulizer serves as the critical interface where liquid sample transitions into gas-phase ions. This transformation is fundamentally governed by precise temperature control, which drives the efficient desolvation necessary for optimal ionization. The heated nebulizer achieves this by rapidly vaporizing the liquid sample using a combination of high temperatures (typically 350-550°C) and nebulizer gas, creating a fine mist where solvent molecules evaporate, leaving behind neutral analyte molecules for subsequent chemical ionization [1] [8]. Within the broader context of temperature optimization research in APCI, understanding and controlling this thermal desolvation process is paramount for achieving high sensitivity, reducing fragmentation, and ensuring reproducible results across pharmaceutical, environmental, and biomedical applications.

Troubleshooting Guides

Problem 1: Inconsistent Ion Signal or Signal Loss

- Question: My APCI analysis shows fluctuating ion signals or a complete loss of signal. Could this be related to nebulizer temperature?

- Investigation: Begin by verifying the physical connections of your gas lines and ensuring the nebulizer gas pressure is stable. Check the heater unit for any visible damage and confirm the temperature reading matches your setpoint.

- Solution: Temperature-related signal loss often stems from insufficient heating. Gradually increase the nebulizer temperature in 10-20°C increments while monitoring a standard compound's signal intensity. If the signal improves with increased temperature, the initial setting was likely too low for complete desolvation of your solvent system. Ensure the temperature remains within the manufacturer's specified range and the thermal stability of your analytes.

Problem 2: Excessive Fragmentation or Thermal Decomposition

- Question: My spectra show unexpected fragments and a weak molecular ion, suggesting possible thermal degradation. How can I confirm and fix this?

- Investigation: Compare the observed fragments against known fragmentation patterns of your analyte. Thermally-induced fragments often differ from collision-induced dissociation (CID) patterns. Check if the decomposition is reproducible and increases with analysis time.

- Solution: This is a classic sign of excessive nebulizer temperature. Reduce the temperature in 20-30°C increments and re-analyze a stable standard. The optimal temperature provides a strong molecular ion signal with minimal non-CID fragmentation. For thermally labile compounds, you may need to operate at the lower end of the viable temperature range, balancing desolvation efficiency with analyte stability [8].

Problem 3: High Chemical Background or Solvent-Cluster Ions

- Question: My background signal is high, with prominent solvent cluster ions that interfere with my target analytes.

- Investigation: Inspect the mass spectrum for peaks corresponding to common solvent clusters (e.g., methanol, water, acetonitrile). Verify that your mobile phase is thoroughly degassed.

- Solution: Persistent solvent clusters indicate incomplete desolvation. Increase the nebulizer temperature progressively. Also, ensure the nebulizer gas flow rate is optimized; a higher gas flow can work synergistically with heat to improve droplet breakup and solvent evaporation. A post-nebulizer heating element, if available, can provide additional desolvation energy.

Frequently Asked Questions (FAQs)

Q1: What is the typical operating temperature range for an APCI heated nebulizer, and how do I select a starting point?

The standard operational range for an APCI heated nebulizer is generally between 350°C and 550°C [8]. A prudent starting point is 450°C, which offers a good balance for many common solvents (e.g., water, methanol, acetonitrile) and moderately stable analytes. The optimal setting must be determined empirically by infusing a standard solution of your analyte and adjusting the temperature to maximize the signal for the molecular ion ([M+H]⁺ or [M-H]⁻) while minimizing background and decomposition.

Q2: My analyte is thermally unstable. What are my options within an APCI workflow?

For thermally unstable compounds, several strategies can mitigate degradation:

- Minimize Temperature: Use the lowest possible nebulizer temperature that still provides a stable spray and sufficient ion signal.

- Optimize Gas Flow: Increasing the nebulizer gas flow can sometimes improve aerosolization and desolvation at lower temperatures.

- Solvent Modification: Altering the solvent composition to one with a lower boiling point can facilitate easier desolvation.

- Alternative Techniques: If significant degradation persists, consider switching to a softer ionization method like nano-APCI (nAPCI) [9] or Electrospray Ionization (ESI), which does not rely on thermal vaporization and is better suited for labile molecules.

Q3: How does nebulizer temperature specifically affect the ionization mechanism in APCI?

Temperature is the primary driver of the initial desolvation and vaporization step. The process can be visualized as follows:

The nebulizer temperature does not directly cause the ionization (that is the role of the corona discharge), but by ensuring complete vaporization, it creates the ideal gas-phase environment for highly efficient ion-molecule reactions to occur, leading to robust and sensitive analyte ionization [1] [8].

Q4: Can I use APCI with purely non-polar solvents?

Yes, this is a key advantage of APCI over ESI. Since ionization occurs in the gas phase after vaporization, "it is unnecessary for the solvent to be polar and able to carry a charge" [8]. APCI is well-suited for use with non-polar solvents, which are efficiently vaporized in the heated nebulizer. The resulting gas-phase molecules are then ionized via charge transfer or other mechanisms initiated by the corona discharge.

Quantitative Data and Optimization Parameters

Table 1: APCI Heated Nebulizer Operational Parameters and Optimization Guide

| Parameter | Typical Range | Optimal Starting Point | Effect on Desolvation | Impact on Signal |

|---|---|---|---|---|

| Nebulizer Temperature | 350°C - 550°C [8] | 450°C | Higher temperature increases solvent vaporization rate. | Increases signal to a point; excessive heat causes decomposition. |

| Nebulizer Gas Flow | Instrument-specific (e.g., N₂) | Manufacturer's recommendation | Higher flow creates finer aerosol for faster drying. | Improves signal by enhancing desolvation; too high can cool the system. |

| Liquid Flow Rate | 0.2 - 2.0 mL/min [1] | 0.5 mL/min | Lower flows are easier to vaporize completely. | Higher flows may require higher T/Gas for same efficiency. |

| Solvent Boiling Point | N/A | Use lower BP if possible | Lower boiling point solvents vaporize more readily. | Allows for lower operating temperatures, preserving labile analytes. |

Experimental Protocol: Systematic Optimization of Nebulizer Temperature

This protocol provides a step-by-step methodology for empirically determining the optimal heated nebulizer temperature for a specific APCI application.

1. Objective: To identify the nebulizer temperature that maximizes the signal for the molecular ion of a target analyte while minimizing thermal decomposition and background noise.

2. Materials and Reagents:

- APCI-mass spectrometer system

- Syringe pump for direct infusion

- Standard solution of target analyte (e.g., 1 µg/mL in a suitable solvent)

- HPLC-grade solvent matching your intended mobile phase

3. Procedure:

- Step 1: Initial Setup. Install the standard solution in a syringe and connect it to the APCI source via the syringe pump. Set a constant flow rate (e.g., 0.3 mL/min). Set the nebulizer gas flow to the manufacturer's recommended setting.

- Step 2: Baseline Acquisition. Set the nebulizer temperature to a low value (e.g., 300°C) and initiate data acquisition. Monitor the extracted ion chromatogram (EIC) for the [M+H]⁺ ion of your standard and the total ion chromatogram (TIC).

- Step 3: Temperature Ramping. Increase the nebulizer temperature by 25°C increments. Allow the system to stabilize for 2-3 minutes at each new temperature before recording the average signal intensity of the [M+H]⁺ ion over a 1-minute period.

- Step 4: Data Recording. At each temperature, record the following:

- Average intensity of the molecular ion ([M+H]⁺).

- Intensity of any major fragment ions that suggest thermal decomposition.

- Signal-to-noise ratio (S/N) for the molecular ion.

- Step 5: Analysis and Determination. Continue until the molecular ion signal plateaus and then begins to decrease, or significant new fragments appear. The optimal temperature is the one that provides the highest S/N for the molecular ion before the onset of excessive fragmentation.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for APCI Desolvation Research

| Item | Function in Desolvation Research | Example & Rationale |

|---|---|---|

| Thermally Stable Standards | Used to calibrate and optimize the temperature response of the system without degradation. | Caffeine or pesticides; their stability allows isolation of temperature effects from decomposition. |

| Labile Probe Compounds | Used to test the gentleness of the source and establish lower temperature limits. | Certain steroids or glycosides; they decompose predictably, signaling excessive thermal stress. |

| Range of HPLC Solvents | To study solvent effects on vaporization efficiency and required temperature. | Water, Methanol, Acetonitrile, Toluene; covers a wide range of polarity and boiling point. |

| Nebulizer Gas (N₂) | The inert gas used to create the aerosol. Purity is critical to prevent chemical noise. | High-purity (≥99.99%) nitrogen gas; ensures consistent aerosol formation and prevents corona discharge issues. |

| Direct Injection Probe (DIP) | Allows for solid sample introduction, bypassing the LC system for direct source testing. | Bruker's DirectProbe [10]; useful for analyzing pure standards and studying thermal behavior directly. |

Troubleshooting Guides

Common Instrumental Issues and Solutions

The following table outlines frequent problems related to desolvation and thermal stability, their likely causes, and recommended corrective actions.

| Symptom | Potential Cause | Solution |

|---|---|---|

| Low Ion Intensity/Signal | Desolvation temperature too low, leading to incomplete solvent evaporation [11] [8]. | Gradually increase the desolvation temperature in 10-20°C increments. |

| High Chemical Noise/Background | Desolvation gas flow rate is suboptimal, causing inefficient aerosol formation [12]. | Optimize the nebulizing gas flow rate to ensure proper aerosol droplet size. |

| Analyte Degradation/Fragmentation | Desolvation temperature is too high, exceeding the analyte's thermal stability [11] [8]. | Reduce the desolvation temperature immediately. Implement a temperature gradient test to find the maximum safe level. |

| Inconsistent Results/Signal Drop | Contamination of the APCI source from sample buildup [12]. | Perform routine cleaning of the APCI source, including the vaporizer tube and corona discharge needle. |

| Ion Suppression | High concentration of matrix components co-eluting with the analyte [11]. | Improve chromatographic separation or simplify sample preparation to reduce matrix effects. |

Step-by-Step Protocol: Optimizing Desolvation Temperature

Objective: To systematically determine the optimal desolvation temperature that maximizes signal intensity without causing thermal degradation of the analyte.

Materials:

- Standard solution of the target analyte.

- LC-APCI-MS system.

- Data acquisition software.

Procedure:

- Initial Conditions: Set the APCI source to the manufacturer's recommended starting parameters. A typical initial desolvation temperature is 350°C [8].

- Baseline Analysis: Inject the standard and record the chromatogram. Note the peak area (signal intensity) and check for signs of fragmentation or new peaks indicating degradation products.

- Temperature Ramp: Increase the desolvation temperature by 50°C (e.g., to 400°C). Repeat the injection and data recording.

- Iterate and Observe: Continue this process, increasing the temperature in 50°C steps, until a noticeable decrease in the parent ion signal or the appearance of degradation products is observed. The maximum operating temperature for many APCI sources is 550°C [11] [8].

- Fine-Tuning: Once the upper temperature limit is identified, fine-tune the temperature in smaller, 10°C increments around the point of highest signal stability to determine the optimum.

Data Interpretation:

- Optimal Temperature: The temperature that yields the highest signal intensity for the target analyte without fragmentation or degradation.

- Acceptable Range: A plateau where signal intensity is stable over a 20-30°C range indicates a robust operating window.

Frequently Asked Questions (FAQs)

Q: What is the fundamental trade-off between desolvation efficiency and analyte thermal stability in APCI?

A: The core trade-off is that higher desolvation temperatures efficiently evaporate solvent from the aerosol droplets, which is essential for liberating the analyte molecules for gas-phase ionization and achieving high signal intensity [11] [8]. However, this same thermal energy can also fragment or decompose thermally labile analytes before they ever get ionized, leading to signal loss or confusing spectra [11]. Finding the right balance is key.

Q: My analyte is thermally labile. What are my alternatives if APCI causes degradation?

A: If your analyte cannot withstand APCI temperatures, consider switching to an alternative ionization technique. Electrospray Ionization (ESI) is often a suitable substitute as it ionizes molecules directly from the liquid phase at much lower temperatures and is generally better suited for polar, ionic, and thermally unstable compounds [12].

Q: How does the solvent composition influence the required desolvation temperature?

A: The choice of solvent directly impacts the desolvation process. Solvents with higher boiling points and higher latent heat of vaporization require more thermal energy to evaporate. This often necessitates a higher desolvation temperature setting, which in turn increases the thermal stress on the analyte [12].

Q: Beyond temperature, what other parameters can I adjust to improve desolvation?

A: The nebulizer gas flow rate is a critical parameter. An optimal gas flow helps produce a fine, uniform aerosol with a high surface-to-volume ratio, which significantly enhances the efficiency of solvent evaporation even at moderately high temperatures [12] [11].

Key Parameters for Desolvation and Ionization in APCI

This table summarizes the core operational parameters involved in the APCI process, based on compiled methodologies [12] [11] [8].

| Parameter | Typical Range | Function |

|---|---|---|

| Desolvation Temperature | 350°C - 550°C | Vaporizes solvent from the aerosol droplets [11] [8]. |

| Nebulizer Gas Flow | Instrument-specific (e.g., Nitrogen) | Forms a fine aerosol from the LC eluent and assists in desolvation [11]. |

| Corona Discharge Voltage | Several kilovolts (kV) | Creates a plasma of reagent ions and electrons to initiate chemical ionization in the gas phase [12] [8]. |

| Vaporizer Temperature | ~400°C - 550°C | Heats the entire LC effluent to ensure complete volatilization before it reaches the corona discharge [11]. |

The Scientist's Toolkit: Research Reagent Solutions

Essential Materials for APCI-MS Analysis

| Item | Function |

|---|---|

| Nitrogen Gas | Serves as the high-purity nebulizing and desolvation gas to create the aerosol and assist in evaporation [11]. |

| Formic Acid | A common mobile phase additive (e.g., 0.1%) that promotes protonation of solvent molecules, facilitating the ionization process in positive mode [4]. |

| LC-MS Grade Solvents (Methanol, Acetonitrile, Water) | High-purity solvents minimize background noise and signal interference; their composition affects desolvation efficiency and ionization [12] [4]. |

| Volatile Buffers (e.g., Ammonium Acetate) | Used to control pH in the mobile phase without leaving residues that can contaminate the ion source. |

Workflow and Relationship Diagrams

C APCI Desolvation and Ionization Pathway

D Decision Logic for Temperature Optimization

Experimental Protocols: Optimizing Desolvation Parameters

Methodology for a High-Throughput Multiclass Steroid Analysis

This detailed protocol for determining 27 steroidal hormones in untreated wastewater using UPLC-APCI-MS/MS provides specific, validated parameters for desolvation temperature and its interacting factors [13].

LC Conditions:

- LC System: ACQUITY UPLC I-Class Plus

- Column: ACQUITY Premier BEH C18 Column, 130Å, 1.7 µm, 2.1 x 100 mm

- Column Temperature: 65 °C

- Injection Volume: 10 µL

- Mobile Phases: A: 0.2 mM ammonium fluoride in water; B: Methanol

- Gradient: Linear flow gradient with increased flow rate at 100% eluent B to reduce carryover

MS Conditions:

- Mass Spectrometer: Waters Xevo TQ-XS Tandem Quadrupole

- Ionization Mode: APCI with positive/negative polarity switching

- Desolvation Temperature: 550 °C

- Source Temperature: 150 °C

- Desolvation Gas Flow: 1000 L/h

- Cone Gas Flow: 150 L/h

- Corona Voltage: 0.8 kV (+ve), 1.2 kV (-ve)

Sample Preparation:

- Extraction: Oasis HLB 96-well Solid-Phase Extraction (SPE) plate

- Sample Volume: 5 mL acidified untreated wastewater

- Elution Solvent: Ethyl acetate and n-hexane combination to increase elution strength for highly nonpolar analytes

General Parameter Optimization Workflow

For method development, a systematic approach to optimizing desolvation parameters is recommended [14] [15]:

- Begin with Autotune: Use instrument autotune routines as a starting point for initial parameter settings

- Manual Tune Key Parameters: Adjust voltages, temperatures, and gas flows to optimize signals

- Set Robust Values: Choose parameter values on a maximum plateau where small changes don't produce large response variations

- Optimize SRM Conditions: Adjust collision energy (CE) voltage to yield product ions with 10-15% of the parent ion remaining

- Evaluate Chromatographic Separation: Run full scan acquisitions on representative samples to identify coelution problems that may cause ionization suppression

Table 1: Recommended Parameter Ranges for APCI Desolvation Optimization

| Parameter | Recommended Range | Function | Interaction with Desolvation Temperature |

|---|---|---|---|

| Desolvation Temperature | 400-550°C | Evaporates solvent droplets | Primary parameter; increased temperature requires adjusted gas flows |

| Desolvation Gas Flow | 500-1000 L/h | Assists solvent evaporation | Higher flows may allow lower temperatures; synergistic effect |

| Nebulizer Gas Flow | Varies by instrument | Controls droplet size | Affects evaporation efficiency; optimize with temperature |

| Source Temperature | 100-150°C | Heats the ion source area | Supports desolvation process; typically lower than desolvation temperature |

| Cone Gas Flow | 50-150 L/h | Guides ions into mass analyzer | Prevents contamination; independent of desolvation temperature |

| Corona Current | 2-4 µA (APCI) | Creates reactant ions | Functionally separate from temperature optimization |

Troubleshooting Guides & FAQs

Frequently Asked Questions

Q1: What are the symptoms of insufficient desolvation temperature, and how do I resolve them? A: Symptoms include signal instability, increased chemical noise, and reduced sensitivity. This occurs because incomplete solvent evaporation leads to larger, incompletely desolvated droplets entering the mass analyzer. Resolution involves systematically increasing desolvation temperature in 10-25°C increments while monitoring signal response. Also ensure desolvation gas flow is appropriately scaled - at higher flow rates, higher temperatures are typically needed [16].

Q2: How does solvent composition affect the optimal desolvation temperature setting? A: Solvent composition significantly impacts desolvation efficiency. Aqueous solvents have higher surface tension and require higher temperatures for effective desolvation. Adding 1-2% v/v of low surface tension solvents like methanol or isopropanol to highly aqueous eluents can improve desolvation efficiency and may allow lower operating temperatures [17]. The changing eluent composition during gradient analyses means the "sweet spot" for ion production varies with solvent composition [17].

Q3: My method uses high flow rates. How should I adjust desolvation parameters? A: Higher flow rates require increased desolvation gas flows and temperatures. Modern systems like Waters Xevo series often have Intellistart software that automatically sets appropriate gas flows and desolvation temperatures when you enter a flow rate [16]. Manual optimization may be needed for specific applications - position the probe appropriately away from the sample cone to avoid nonlinear data and sample suppression [16].

Q4: What are the key differences between ESI and APCI regarding desolvation parameter optimization? A: While both sources require desolvation, APCI typically operates at higher desolvation temperatures (commonly 400-550°C) compared to ESI. APCI relies on gas-phase chemical ionization after complete desolvation, whereas ESI involves ion formation from charged droplets. APCI is generally more tolerant of higher flow rates and less affected by solvent composition variations, but requires careful optimization of corona current and source temperatures [7].

Troubleshooting Common Desolvation Problems

Table 2: Troubleshooting Guide for Desolvation-Related Issues

| Problem | Potential Causes | Diagnostic Steps | Solutions |

|---|---|---|---|

| Signal Instability | Incomplete desolvation, temperature fluctuations | Check for solvent clusters in mass spectrum | Increase desolvation temperature 10-25°C; optimize gas flows; add 1-2% organic modifier to aqueous eluents [17] |

| Reduced Sensitivity | Suboptimal desolvation, high aqueous content, low gas flows | Compare response across different solvent compositions | Increase desolvation temperature and gas flow; optimize nebulizer gas; consider APCI for low-polarity compounds [14] [7] |

| High Chemical Noise | Contamination, insufficient declustering, poor desolvation | Examine baseline in blank injections | Increase desolvation temperature; optimize cone voltage for declustering; clean ion source [17] |

| Carryover Between Injections | Incomplete desolvation of late-eluting compounds, source contamination | Inject blanks after high concentration samples | Implement strong wash steps; increase flow rate at 100% B in gradient; increase desolvation temperature for late-eluting compounds [13] |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials and Reagents for APCI-MS Method Development

| Item | Function | Application Notes |

|---|---|---|

| Ammonium Formate | Mobile phase additive for LC-MS | Use 0.2-10 mM concentrations; volatile salt compatible with MS detection [13] [15] |

| Formic Acid | Mobile phase modifier (0.1% typical) | Improves protonation in positive ion mode; concentration critical for response [13] [18] |

| Methanol, Acetonitrile (LC-MS Grade) | Organic mobile phase components | Low UV cutoff, minimal impurities; acetonitrile provides different selectivity than methanol [13] [18] |

| Oasis HLB SPE Cartridges/Plates | Sample clean-up and concentration | Suitable for diverse analyte polarities; used in high-throughput 96-well format [13] |

| C18 Chromatography Columns | Reversed-phase separation | BEH C18 columns provide good retention and peak shape for diverse compounds [13] |

| Makeup Solvent Systems | Post-column addition for SFC-MS or to enhance ionization | Methanol with additives (formic acid, ammonium formate, ammonia) at various concentrations [7] |

Experimental Workflow Visualization

Diagram 1: Desolvation Parameter Optimization Workflow

Table 4: Quantitative Data from Featured Studies Demonstrating Optimized Parameters

| Study Application | Desolvation Temperature | Desolvation Gas Flow | Cone Gas Flow | Solvent System | Achieved Sensitivity |

|---|---|---|---|---|---|

| 27 Steroidal Hormones in Wastewater [13] | 550°C | 1000 L/h | 150 L/h | Methanol/0.2 mM ammonium fluoride in water | LLOQs up to 0.2 ng/mL with only 5 mL sample volume |

| Nitrosamines in Sitagliptin API [18] | Not specified (standard APCI method) | Not specified | Not specified | 0.1% formic acid in water / MeOH:ACN (50:50) | LOQ for NMAP: 13.65 ng/g (below 10% specification limit) |

| SFC-APCI-MS with Makeup Solvent [7] | 500°C (ESI), similar for APCI | 1000 L/h | 150 L/h | Various makeup solvents with additives | Enhanced response with optimized makeup composition |

Systematic Strategies for Optimizing Desolvation Temperature

For generations, the One-Factor-At-a-Time (OFAT) approach has been a default methodology for optimizing experiments in many labs. In this traditional process, a researcher optimizes one variable, such as temperature, while keeping all other parameters constant, then moves to the next variable, like gas flow rate [19]. While intuitive, this method carries significant drawbacks: it is inefficient, requiring a large number of experiments, and it completely fails to capture interaction effects between variables [19]. For instance, the ideal temperature for a process might depend on the solvent composition, a relationship that OFAT is likely to miss.

Design of Experiments (DoE) provides a powerful, systematic alternative. Already a workhorse in the chemical industry, DoE is a statistical methodology that allows researchers to study multiple factors and their interactions simultaneously while requiring fewer experiments to capture the effects and dependency of variables on the response[s) of interest [19]. This guide will introduce you to the principles of DoE and demonstrate its practical application for optimizing critical parameters like desolvation temperature in Atmospheric Pressure Chemical Ionization (APCI) research.

DoE Fundamentals: Core Principles and Workflow

Key Statistical Principles of DoE

At its core, a DoE model represents your system's response (e.g., ion signal intensity) as a mathematical function of your input variables. The model includes several key components [19]:

- Main Effects (β₁x₁, β₂x₂...): These terms describe the individual impact of each variable (like temperature or gas flow) on the response. This is similar to the information gathered from an OFAT approach.

- Interaction Effects (β₁,₂x₁x₂...): These terms capture how the effect of one variable depends on the level of another variable. For example, they can reveal if the optimal temperature is different at high versus low gas flow rates—a critical insight OFAT cannot provide.

- Quadratic Effects (β₁,₁x₁x₁...): These terms account for nonlinear, curved responses, such as when a signal intensity increases with temperature up to a point, then begins to decrease.

The DoE Optimization Workflow

Implementing a DoE study follows a logical sequence from planning to execution and analysis. The workflow below outlines the critical stages to guide your experimentation.

Practical Application: DoE for Desolvation Temperature Optimization in APCI

Desolvation temperature is a critical parameter in APCI sources, as it governs the efficient evaporation of the solvent droplets to liberate gas-phase analyte molecules. Its effect is often intertwined with other source parameters.

Defining the Experiment

Let's frame a typical DoE for optimizing desolvation temperature and related parameters to maximize signal intensity.

- Objective: Maximize analyte signal intensity in an APCI-MS method.

- Key Factors and Ranges:

- Desolvation Gas Temperature: A continuous factor (e.g., 250°C to 450°C).

- Desolvation Gas Flow Rate: A continuous factor (e.g., 600 L/hr to 1000 L/hr).

- Vaporizer Temperature: A continuous factor (e.g., 300°C to 500°C).

- Responses:

- Primary: Signal Intensity of the target analyte (to be maximized).

- Secondary: Signal-to-Noise Ratio (to be maximized).

Essential Research Reagent Solutions

The table below details key materials and parameters relevant to setting up an APCI or ESI source optimization.

| Item/Parameter | Function & Importance in Optimization |

|---|---|

| HPLC-Grade Solvents | Low-salt solvents (e.g., methanol, acetonitrile) prevent metal adduct formation [20]. Their surface tension influences droplet formation and stability. |

| Nebulizing Gas | Typically nitrogen; its flow rate is optimized to restrict initial droplet size at the capillary tip for more efficient desolvation [20]. |

| Desolvation Gas | Typically high-temperature nitrogen; its flow and temperature are critical for rapid solvent evaporation in the source [20]. |

| Cone Voltage | Declustering potential; accelerates ions to remove solvent clusters and can induce in-source fragmentation for structural info (typically 10-60 V) [20]. |

Troubleshooting Common DoE Scenarios

FAQ: What should I do if my model has a poor fit or is not significant? This often indicates that important factors are missing from the model, or the ranges chosen for the factors were too narrow. Re-examine your system and consider screening a broader set of factors or wider ranges. Ensure your experimental measurements are precise and reproducible.

FAQ: I found the optimum, but the predicted performance seems unrealistic. How can I trust it? A model's predictions must always be confirmed with verification experiments. Run the process at the suggested optimal conditions. If the actual response aligns with the prediction, you can have high confidence in the model. A significant discrepancy means there may be unmodeled factor interactions or a problem with the data.

FAQ: My initial experiments resulted in zero yield (or no signal). Can I still use DoE? DoE performs best when there is a quantifiable response across the experimental range. Too many null results (like 0% yield or no signal) create severe outliers and skew the optimization [19]. Use preliminary OFAT-style scouting to identify a "design space" where you get a measurable, even if weak, signal before applying a formal DoE.

Experimental Protocol: A Screening Design for APCI Source

This protocol outlines the steps for a screening design to identify the most influential factors.

- Preparation:

- Prepare a standard solution of your analyte in a suitable LC-MS solvent (e.g., 50:50 methanol:water).

- Ensure a stable LC flow stream; isocratic conditions are suitable for this type of source study.

- Software Setup:

- In your DoE software (e.g., JMP, Minitab, Design-Expert), create a new "Screening Design."

- Add the three continuous factors: Desolvation Temperature, Desolvation Gas Flow, and Vaporizer Temperature, specifying the high and low levels you have chosen.

- Select a "Fractional Factorial" design type. For 3 factors, this will generate a full factorial of 8 experiments, which is manageable.

- Execution:

- The software will generate a randomized run order. Follow this order to infuse your standard solution into the APCI source.

- For each run, adjust the source parameters as specified by the design sheet.

- Record the response (Signal Intensity) for the analyte in each run.

- Analysis:

- Input the response data into the software.

- Generate a Pareto Chart of the effects to visually identify which factors and interactions are statistically significant.

- Use the model to create a contour plot or response surface plot to understand the relationship between the significant factors and your signal.

Advanced DoE Applications and Strategic Considerations

Once you are comfortable with screening designs, you can leverage the full power of DoE for more complex challenges.

Optimizing for Multiple Responses

A key advantage of DoE over OFAT is the ability to systematically optimize multiple responses at once [19]. For example, you may need to balance high signal intensity with minimal in-source fragmentation. DoE software uses a desirability function to find a compromise zone that simultaneously satisfies all your goals, whether they require maximization, minimization, or targeting a specific value.

Comparison of OFAT and DoE Approaches

The table below provides a direct comparison of the OFAT and DoE methodologies, highlighting the efficiency of the latter.

| Aspect | One-Variable-At-a-Time (OFAT) | Design of Experiments (DoE) |

|---|---|---|

| Efficiency | Low; requires many runs to probe few variables. High; models multiple variables and interactions in few runs. | |

| Interaction Effects | Cannot detect or quantify. Explicitly models and quantifies. | |

| Statistical Power | Low; no overall model or estimate of error. High; provides significance of factors and model robustness. | |

| Optimum Location | Risk of finding a false or local optimum. High confidence in finding the true, global optimum. | |

| Multiple Responses | Compromise-based; not systematic. Systematic optimization via desirability functions. |

Visualizing Multi-Factor Optimization

When optimizing for more than one response, the relationship between factors and the combined desirability can be visualized. The following diagram conceptualizes this process for two critical factors.

► FAQ: Parameter Correlation and Troubleshooting

Q1: How do I initially correlate my LC flow rate with desolvation temperature and gas flows? A robust starting point is essential. Based on established methodologies, you can use the following baseline conditions for a standard 0.2-0.6 mL/min LC flow rate [21] [18]:

| Parameter | Baseline Setting |

|---|---|

| LC Flow Rate | 0.2 - 0.6 mL/min |

| Desolvation Temperature | 500 - 550 °C |

| Desolvation Gas Flow | 1000 L/h |

| Nebulizer Gas Flow | Set to achieve a stable spray (e.g., 5.0 bar) |

These parameters provide a foundation. The high desolvation temperature and gas flow are critical for efficiently evaporating the liquid from the LC stream at atmospheric pressure, ensuring the analyte molecules are released into the gas phase for subsequent chemical ionization [1].

Q2: What are the symptoms of an incorrect desolvation temperature? Incorrect desolvation temperature directly impacts signal stability and sensitivity. Troubleshoot using this guide:

| Symptom | Possible Cause | Corrective Action |

|---|---|---|

| Low or unstable signal | Temperature too low; incomplete desolvation | Gradually increase temperature in 10-20 °C increments |

| No signal or high background | Temperature too high; thermal degradation of analyte | Reduce temperature; verify analyte thermal stability |

APCI requires analytes to be thermally stable to withstand the heated nebulizer environment. Excessive heat can cause decomposition before ionization occurs [1] [12].

Q3: My method uses a higher LC flow rate (e.g., 1.0-2.0 mL/min). Should I adjust the gas flows? Yes. APCI is compatible with higher flow rates, but this requires increased desolvation gas flow to handle the larger solvent volume. If you are scaling up your method, proportionally increase the desolvation gas flow to maintain efficient vaporization. The corona discharge mechanism in APCI is robust and generally less susceptible to matrix effects from higher flows compared to other ionization techniques [1].

► Experimental Protocol: Establishing Your Baseline

This protocol outlines the steps to empirically establish the correlation between LC flow rates and desolvation parameters for your specific APCI system.

1. Hypothesis and Objective We hypothesize that for a given LC flow rate, an optimal combination of desolvation temperature and gas flow exists that maximizes ion signal by ensuring complete solvent vaporization without causing thermal degradation of the analyte. The objective is to determine this correlation for a standard compound under controlled conditions.

2. Materials and Reagents

- APCI-MS System: An LC-MS system equipped with an APCI source. The Xevo TQ-XS is used in referenced studies [21] [7].

- LC Column: A suitable reversed-phase column (e.g., ACQUITY Premier BEH C18, 2.1 x 100 mm, 1.7 µm) [21].

- Mobile Phase: A consistent, MS-compatible solvent system (e.g., methanol with 0.1% formic acid).

- Standard Solution: A solution of a stable, well-characterized compound relevant to your research (e.g., a steroid hormone or pharmaceutical compound) at a concentration that provides a good signal-to-noise ratio [21] [18].

3. Step-by-Step Methodology

- Step 1: System Setup. Install and condition the LC column. Set the APCI source parameters to the baseline values provided in the FAQ above (e.g., Desolvation Temperature: 550°C, Desolvation Gas Flow: 1000 L/h) [21].

- Step 2: Define Flow Rate Levels. Choose at least three different LC flow rates covering your operational range (e.g., 0.3, 0.5, 0.8 mL/min).

- Step 3: Create a Parameter Matrix. For each LC flow rate, test a matrix of desolvation temperatures (e.g., 450, 500, 550°C) and desolvation gas flows (e.g., 800, 1000, 1200 L/h).

- Step 4: Data Acquisition. In a randomized order, infuse the standard solution directly into the MS or use a very short isocratic LC method. For each parameter combination, record the signal intensity (peak area or height) of the molecular ion for your standard over a 1-2 minute period.

- Step 5: Data Analysis. Plot a 3D response surface or contour map showing the signal intensity as a function of desolvation temperature and gas flow for each LC flow rate. The combination that yields the maximum stable signal is the optimal setting for that flow rate.

► Experimental Workflow and Parameter Relationships

The following diagram visualizes the experimental workflow and the core relationships between parameters that you will be establishing.

► The Scientist's Toolkit: Key Research Reagent Solutions

The following materials are essential for executing the described experiments and developing robust APCI methods.

| Item | Function in APCI Research |

|---|---|

| Soluplus | A polymeric carrier used in hot-melt extrusion (HME) to create solid dispersions of poorly soluble drugs, enhancing their bioavailability for analysis [22]. |

| Oasis HLB SPE | A solid-phase extraction sorbent used for efficient, high-throughput clean-up and preconcentration of analytes from complex matrices like wastewater prior to LC-APCI-MS analysis [21]. |

| APCI Makeup Solvents | Post-column additives (e.g., methanol with ammonium formate or formic acid) used to optimize ionization efficiency, particularly in SFC-APCI-MS, by providing protons or charges for ion-molecule reactions [7]. |

| Stable Isotope-Labeled Standards | Internal standards used for quantification to correct for matrix effects and variability in ionization efficiency, ensuring accurate and precise measurement of target analytes [21]. |

Frequently Asked Questions (FAQs)

Q1: Why is temperature optimization critical for APCI mass spectrometry? Temperature optimization is fundamental for achieving high sensitivity and robust performance in APCI. Proper temperatures ensure efficient desolvation (evaporation of the liquid droplets) and vaporization of the analyte into the gas phase, which is a prerequisite for the subsequent chemical ionization step. Inadequate temperatures can lead to poor evaporation of droplets, allowing them to enter the mass analyzer, causing signal instability, high background noise, and reduced sensitivity [23].

Q2: What are the key temperature parameters to optimize in an APCI source? The primary temperature parameters are the APCI vaporizer (probe) temperature and the source/desolvation temperature. The vaporizer temperature controls the heating of the nebulizer that converts the LC eluent into a gas-phase mist. The source or desolvation temperature helps to further ensure that the analyte is completely in the gas phase before ionization [1] [24].

Q3: My APCI probe temperature fluctuates wildly when the divert valve switches. Is this a problem? A significant temperature drop (e.g., ~40°C) when the divert valve switches flow to the source, followed by a recovery period of 2-3 minutes, is normal behavior for some APCI probes. The temperature equilibrium is dependent on the LC flow rate. The LC flow should be switched to the source with enough advance time to allow the temperature to re-stabilize at the setpoint before data acquisition [25].

Q4: I receive a "probe failed to settle" error. What should I do? This error can occur if the MS settings momentarily change to the values on a tune page that has different APCI probe temperature settings. The fix is to ensure the displayed tune page matches the ionization mode and polarity you are using for your analysis, and that the temperature settings are consistent [26].

Q5: How does APCI temperature optimization differ for thermally labile compounds? While APCI is generally considered a "soft" ionization technique, the heated nebulizer can still cause thermal degradation for labile compounds. If you observe signal loss at higher temperatures, it may indicate compound breakdown. As demonstrated in a case study, the signal for a thermally sensitive pesticide was completely lost when the desolvation temperature exceeded 500°C, whereas another compound benefited from the increased heat. A balance must be found for such sensitive analytes [24].

Troubleshooting Guide: Common APCI Temperature-Related Issues

| Symptom | Possible Cause | Solution |

|---|---|---|

| Low signal intensity / Poor sensitivity | Vaporizer temperature too low for complete vaporization [23]. | Gradually increase the APCI vaporizer temperature in steps (e.g., 25-50°C) and monitor the response. |

| High background noise | Incomplete desolvation; droplets entering the MS [23]. | Increase the APCI vaporizer temperature and/or the source desolvation temperature (if available). |

| "Probe failed to settle" error | Incorrect tune page polarity/temperature settings [26]. | Change the displayed MS tune page to the correct ionization mode and polarity for your method. |

| Probe temperature drops during divert valve switch | Normal system response to a change in liquid flow [25]. | Allow sufficient time for temperature to stabilize after the valve switches flow to the source. |

| Signal loss for specific compounds | Thermal degradation; temperature is too high [24]. | Systematically lower the vaporizer temperature to find a level that avoids decomposition. |

Optimized Temperature Parameters from a Case Study

The following table summarizes the successfully optimized LC-APCI-MS/MS conditions for the determination of 27 multiclass steroidal hormones and sterols in untreated wastewater, demonstrating a practical application of temperature optimization [27].

| Parameter | Optimized Setting |

|---|---|

| LC System | ACQUITY UPLC I-Class Plus |

| MS System | Xevo TQ-XS Tandem Quadrupole |

| Ionization Mode | APCI positive/negative polarity switching |

| Corona Voltage (+ve) | 0.8 kV |

| Corona Voltage (-ve) | 1.2 kV |

| Source Temperature | 150 °C |

| Desolvation Temperature | 550 °C |

| APCI Vaporizer Temperature | Not explicitly stated (part of the nebulizer probe) |

| Cone Gas Flow | 150 L/h |

| Desolvation Gas Flow | 1000 L/h |

Workflow for Systematic Temperature Optimization

The following diagram illustrates a logical, step-by-step workflow for troubleshooting and optimizing temperatures in your APCI method.

The Scientist's Toolkit: Essential Research Reagent Solutions

The table below lists key materials and reagents used in a successful, optimized APCI-LC/MS method, as referenced in the application note [27].

| Item | Function in the Workflow |

|---|---|

| ACQUITY Premier BEH C18 Column | Provides chromatographic separation with good peak shape and stable retention times for the target analytes, minimizing coextracted interferences. |

| Oasis HLB 96-well SPE Plate | Used for automated, high-throughput solid-phase extraction to clean up and concentrate analytes from the complex wastewater matrix. |

| Methanol (LC-MS Grade) | Serves as the organic mobile phase (B) for the UPLC gradient, critical for eluting analytes from the column. |

| Water with 0.2 mM Ammonium Fluoride | Serves as the aqueous mobile phase (A). The additive can help in controlling ionization and improving sensitivity. |

| Ethyl Acetate & n-Hexane | Used as an elution solvent combination in SPE. The mixture increases elution strength for highly nonpolar analytes like cholesterol. |

| Formic Acid (in Water) | Used to acidify the sample before SPE, which can improve the retention and recovery of certain analytes on the HLB sorbent. |

Within the broader research on desolvation processes in Atmospheric Pressure Chemical Ionization (APCI), temperature optimization emerges as a fundamental parameter for developing robust, sensitive, and green analytical methods. This case study examines the systematic optimization of temperature parameters in an LC-APCI-MS/MS method for quantifying genotoxic nitrosamine impurities in sitagliptin, an antidiabetic medication [18] [4]. Proper temperature control is pivotal for achieving the requisite sensitivity at trace levels while maintaining analytical sustainability through reduced solvent consumption and waste generation.

Experimental Methodology & Temperature Parameters

Instrumentation and Core APCI Workflow

The analysis was performed using an Acquity UPLC H-Class Plus system coupled with a Xevo TQ-S micro mass spectrometer [4]. The following workflow and temperature settings were implemented:

Chromatographic Conditions and Temperature Settings

The method employed specific temperature parameters to ensure optimal separation and detection of the four target nitrosamines: NDMA, NDIPA, NIPEA, and NMAP [18] [4].

Table: Chromatographic Method Parameters with Temperature Settings

| Parameter | Specification | Function/Rationale |

|---|---|---|

| Column | Agilent Poroshell EC C18 (150 mm) | Efficient separation of nitrosamines |

| Flow Rate | 0.6 mL/min | Balanced analysis time and resolution |

| Injection Volume | 40 µL | Enhanced detection sensitivity |

| Column Oven Temperature | 50°C | Optimized separation efficiency |

| Sample Cooler Temperature | 6°C | Sample stability preservation |

| Mobile Phase | Gradient: 0.1% FA in Water (A) vs. 50:50 MeOH:ACN (B) | Effective elution and ionization |

Research Reagent Solutions

Table: Essential Materials and Their Functions in the APCI-MS Method

| Reagent/Material | Function | Specifications |

|---|---|---|

| Nitrosamine Standards | Analytical reference standards | NDMA, NDIPA, NIPEA, NMAP; >99.8% purity [18] |

| Sitagliptin API | Test substance | Pharmaceutical-grade active ingredient [18] |

| Methanol & Acetonitrile | Mobile phase components | LC-MS grade; 50:50 mixture as solvent B [4] |

| Formic Acid | Mobile phase additive | 0.1% in water; promotes ionization [4] |

| Water | Mobile phase component | HPLC grade; ensures minimal background [18] |

| PVDF Filter | Sample cleanup | 0.2 µm; removes particulate matter [18] |

Temperature Optimization Strategy for APCI Sensitivity

Systematic Optimization Approach

Temperature optimization in APCI-MS requires a balanced approach that considers both ionization efficiency and analyte stability. The experimental design should account for:

- Initial Parameter Setting: Begin with manufacturer recommendations or literature values for similar compounds [28].

- Stepwise Adjustment: Systematically vary one temperature parameter at a time while monitoring signal response [29].

- Compound-Specific Evaluation: Assess temperature effects for each analyte, as different compounds may have optimal temperatures [29].

- Robustness Testing: Validate method performance across a temperature range (±5°C) to ensure reliability [30].

APCI Ion Source Temperature Considerations

Unlike ESI, which uses charged droplets, APCI vaporizes the LC eluent before chemical ionization [31]. The temperature optimization strategy must address:

The ionization process in APCI occurs through gas-phase reactions after the mobile phase is completely vaporized in a heated nebulizer chamber. The temperature must be high enough to ensure complete vaporization of the LC effluent but not so high that it causes thermal degradation of target analytes [29] [31]. Research demonstrates that signal intensity for certain compounds can decrease with increasing temperature as the chemical equilibrium may shift toward deprotonated species, while for other compounds, increased temperature may improve protonation yields by increasing reaction rate constants [28].

Troubleshooting Guide: Temperature-Related Issues

FAQ: Common Temperature Optimization Challenges

Q1: What are the signs of suboptimal APCI source temperature in nitrosamine analysis?

- Low sensitivity: Incomplete vaporization of mobile phase reduces ionization efficiency.

- Signal instability: Fluctuating temperatures cause inconsistent vaporization and ionization.

- Thermal degradation products: Appearance of unexpected peaks or fragments, particularly for thermally labile compounds [29].

Q2: How does temperature interact with other APCI parameters? Temperature optimization cannot be performed in isolation. Key interactions include:

- Nebulizer gas flow: Higher flows may require lower temperatures for efficient desolvation.

- Mobile phase composition: Aqueous phases require higher vaporization temperatures than organic-rich phases [20].

- Flow rate: Higher flow rates typically require higher temperatures for complete vaporization.

Q3: What is the recommended approach for multi-analyte methods with diverse properties? When analyzing multiple compounds with different thermal stabilities (as demonstrated with methamidophos and emamectin B1a benzoate where a 20% increase in response was achieved for one but complete signal loss occurred for the other at high temperatures [29]), set the temperature to optimize the most critical or least stable analytes, as stable compounds will still ionize adequately at lower temperatures.

Q4: How can I determine if my temperature is causing thermal degradation?

- Monitor for new peaks in chromatograms, particularly later eluting ones that may represent decomposition products.

- Compare mass spectra across different temperature settings for unexpected fragments.

- Evaluate peak shape; broadening or tailing can indicate degradation [29].

Q5: What are the best practices for transferring methods between instruments?

- Re-optimize temperature parameters when transferring methods, as source designs vary.

- Create a robustness curve around the temperature parameter to establish operable ranges.

- Document all source geometry and position settings along with temperature values [30].

Results: Quantitative Method Performance

The optimized temperature parameters, in conjunction with other method conditions, yielded exceptional sensitivity and compliance with regulatory requirements for nitrosamine detection [18] [4].

Table: Achieved Sensitivity for Target Nitrosamines with Optimized Conditions

| Nitrosamine Analyte | Abbreviation | LOQ (ng/g) | Specification Limit (ng/g) | LOQ as % of Limit |

|---|---|---|---|---|

| N-nitroso dimethylamine | NDMA | 74.19 | 750.00 | 9.9% |

| N-nitroso diisopropylamine | NDIPA | 20.36 | 207.03 | 9.8% |

| N-nitroso isopropyl ethyl amine | NIPEA | 19.62 | 207.03 | 9.5% |

| N-nitroso methyl aminopyridine | NMAP | 13.65 | 140.63 | 9.7% |

The method demonstrated strong linearity (correlation coefficients >0.996) across the validated range and excellent recovery (90.23-103.36%), confirming that the temperature parameters supported robust quantitative analysis [4]. The environmental impact was minimized through reduced solvent consumption with an 18-minute run time and elimination of derivatization or extraction requirements [18].

This case study demonstrates that systematic temperature optimization is crucial for developing sensitive, robust, and green LC-APCI-MS/MS methods for nitrosamine analysis. The optimized temperature parameters enabled reliable detection at levels below 10% of the specification limits while maintaining analytical efficiency and sustainability.

Best practices for temperature optimization in APCI methods:

- Prioritize compound stability over maximum signal intensity when setting temperatures.

- Document the complete source configuration, as geometry affects temperature gradients.

- Validate method robustness across a temperature range (±5°C) to ensure method reliability.

- Consider the thermal characteristics of all analytes, especially in multi-analyte methods.

- Re-evaluate temperature parameters when transferring methods between instruments or when mobile phase composition changes significantly.

These principles of temperature optimization support the development of reliable analytical methods that meet both regulatory requirements and sustainability goals in pharmaceutical analysis.

Solving Common Problems: A Troubleshooting Guide for APCI Desolvation

FAQ: Troubleshooting Incomplete Desolvation in APCI

What is incomplete desolvation and how does it cause low signal intensity?

Incomplete desolvation occurs when solvent molecules are not fully evaporated from the analyte ions in the Atmospheric Pressure Chemical Ionization (APCI) source. This incomplete process creates large, solvent-clustered ions that are less efficiently transmitted into the high-vacuum region of the mass spectrometer. The result is a significant reduction in signal intensity, increased chemical noise, and unstable ion currents, ultimately compromising method sensitivity and detection limits [29].

How can I diagnose incomplete desolvation as the root cause of my low signal?

Diagnosing incomplete desolvation involves checking for several key indicators in your data and system:

- High Chemical Noise: Look for an elevated and fluctuating baseline in your total ion chromatogram (TIC), particularly in the regions where your analytes elute.

- Signal Instability: Observe drifting or unpredictable signal intensities for your analytes during repeated injections.

- Solvent Cluster Ions: Examine the background mass spectrum for peaks corresponding to common solvent clusters (e.g., protonated methanol or acetonitrile clusters), which indicate residual solvent is entering the analyzer.

- Visual Source Inspection: If possible and safe, visually check the APCI source for condensation or the accumulation of residue, which can be a physical sign of poor desolvation.

What are the primary instrumental parameters to optimize for complete desolvation?

The following parameters are critical for efficient desolvation and should be systematically optimized. The table below summarizes their functions and typical value ranges.

Table 1: Key APCI Source Parameters for Desolvation Optimization

| Parameter | Function in Desolvation | Typical Range | Citation |

|---|---|---|---|

| Desolvation Temperature | Provides heat to vaporize the LC effluent and evaporate solvent molecules from ions. | 300 °C – 550 °C | [28] [29] |

| Desolvation Gas Flow | A stream of nitrogen that aids in breaking up the aerosol and carrying away solvent vapor. | Up to 1000 L/h | [32] [2] |

| Vaporizer Temperature | Heats the LC effluent to convert it into a fine aerosol/gas before it reaches the corona discharge. | ~400 °C | [2] |

| Nebulizing Gas Flow | Works with the vaporizer to create the initial fine aerosol from the liquid stream. | Instrument-dependent | [29] |

| Corona Current/Voltage | Initiates the chemical ionization process; can indirectly affect the energy in the plasma region. | 3.35 kV, 5 µA (example) | [2] |

Could my LC method be contributing to incomplete desolvation?

Yes, the Liquid Chromatography (LC) method parameters are intrinsically linked to desolvation efficiency.

- Mobile Phase Composition: Highly aqueous mobile phases have a higher boiling point and surface tension, making them more difficult to desolvate compared to organic-rich phases. A practical tip is to add a small percentage (1-2%) of a low-surface-tension solvent like isopropanol to highly aqueous eluents to improve spray stability and desolvation [20].

- Flow Rate: Higher flow rates introduce more solvent into the source per unit time, increasing the thermal energy required for complete desolvation. Ensure your source temperatures and gas flows are scaled appropriately for your LC flow rate [29].

A step-by-step protocol for optimizing desolvation to boost signal intensity.

Aim: To systematically optimize APCI source parameters to maximize signal intensity by ensuring complete desolvation. Principles: This protocol uses iterative injection of a standard to find the optimal settings for your specific analyte-LC method combination.

Materials:

- Standard solution of your target analyte at a mid-level concentration.

- LC-MS system with an APCI source.

- The intended LC method (mobile phase, column, gradient).

Method:

- Baseline Establishment: Inject your standard using the manufacturer's default or your current APCI source settings. Record the peak area and signal-to-noise (S/N) ratio of the analyte.

- Optimize Vaporizer/Nebulizer: Begin by adjusting the vaporizer temperature and nebulizing gas flow to establish a stable aerosol. Refer to your instrument's manual for recommended starting values.

- Systematically Ramp Desolvation Temperature: Increase the desolvation temperature in increments (e.g., 25-50 °C) across a series of injections. Monitor the analyte response. Critical: Continue increasing the temperature until the signal intensity plateaus or begins to decrease, which may indicate thermal degradation of the analyte [29].

- Optimize Desolvation Gas Flow: With the optimized temperature, now adjust the desolvation gas flow in steps. Find the flow rate that maximizes your analyte signal. There is often an interaction between temperature and gas flow, so minor re-adjustment of temperature may be necessary.

- Final Verification: Perform a final injection using the optimized parameters and confirm the improvement in signal intensity and S/N compared to the baseline.

Safety Notes: Always allow the source to cool before performing any maintenance. Be aware that the source region becomes extremely hot during operation.

Diagram 1: APCI Desolvation Troubleshooting Workflow. This flowchart outlines the diagnostic and optimization pathway for addressing low signal intensity caused by incomplete desolvation.

The Scientist's Toolkit: Essential Research Reagents & Materials

The following table lists key materials and reagents referenced in the experimental protocols for developing and troubleshooting APCI methods, particularly in the analysis of steroidal hormones and nitrosamines [32] [18].

Table 2: Key Research Reagents and Materials for APCI Method Development

| Item | Function/Application | Citation |

|---|---|---|

| Oasis HLB Solid-Phase Extraction (SPE) | Automated sample preparation for complex matrices (e.g., wastewater); reduces matrix effects and concentrates analytes. | [32] |

| ACQUITY Premier BEH C18 Column | UPLC column used to achieve good chromatographic resolution and peak shape for multiclass analytes like steroidal hormones, minimizing coeluted interferences. | [32] |

| Ammonium Fluoride / Formic Acid | Common mobile phase additives. Ammonium fluoride can improve ionization efficiency in negative mode, while formic acid promotes protonation in positive mode. | [32] [18] |

| LC-MS Grade Solvents (Water, Methanol, Acetonitrile) | High-purity solvents are essential to minimize background noise and contamination that can interfere with analyte signal and desolvation. | [18] [29] |

| Ethyl Acetate / n-Hexane | Solvent combination used in SPE elution to increase elution strength for highly nonpolar analytes (e.g., cholesterol). | [32] |

For scientists working with Atmospheric Pressure Chemical Ionization (APCI), unexpected fragmentation or the complete loss of analyte signal can critically compromise data integrity. Within the broader research on temperature optimization for APCI desolvation, this guide provides a targeted diagnostic and resolution workflow for issues stemming from thermal degradation.

Diagnostic Questions

Begin your investigation by answering the following questions. A "yes" to any suggests thermal degradation is a likely cause.

- Is your analyte thermally stable? Does your compound have a known history of decomposing at elevated temperatures? The APCI process involves a heated nebulizer, often operated between 400–550°C, to vaporize the analyte into the gas phase [11].

- Does the fragmentation pattern suggest thermal breakdown? Are you observing non-specific fragments or a significant loss of the parent ion intensity? While APCI is a "soft" ionization technique, the applied heat can still cause thermal decomposition distinct from collision-induced fragmentation [1] [33].

- Are you analyzing a 1-OMe Norditerpenoid Alkaloid or similar complex molecule? Research has demonstrated that certain alkaloids with a methoxy group (1-OMe) at carbon 1 show approximately double the fragmentation (∼60% fragment ion abundance) compared to their 1-OH counterparts (∼30% fragment ion abundance) due to differences in intramolecular hydrogen bonding and charge delocalization [33].

Step-by-Step Experimental Protocol for Diagnosis

Follow this protocol to confirm and diagnose thermal degradation in your APCI setup.

Step 1: Verify the Symptom with Standard Solutions

- Action: Inject a pure standard of your analyte.

- Methodology: Use a direct infusion or a simple isocratic LC method to introduce the compound to the APCI source. Avoid complex matrices at this stage to rule out matrix effects [34].

- Data Interpretation: Observe the mass spectrum for the same unexpected fragments or low parent ion signal seen in your original experiment. This confirms the issue is source-related, not sample preparation-related.

Step 2: Perform a Temperature Gradient Experiment

- Action: Systematically vary the APCI source heater temperature.

- Methodology: While infusing your standard, collect data at a series of increasing temperatures (e.g., 300°C, 400°C, 500°C). Keep all other source parameters (gas flows, corona needle voltage) constant.

- Data Interpretation: A steady decline in the parent ion signal

[M+H]+and a corresponding increase in fragment ions as the temperature rises is a clear indicator of thermal degradation [11]. The table below summarizes the key indicators.

Table 1: Diagnostic Indicators for Thermal Degradation

| Observation | Suggests Thermal Degradation? | Alternative Cause |

|---|---|---|

| Parent ion signal decreases as source temperature increases. | Yes, strongly | N/A |

| New, non-specific fragments appear at higher temperatures. | Yes | In-source collision-induced dissociation (CID) |

| Complete loss of signal for a known sensitive compound. | Yes | Ion suppression, source contamination, incorrect polarity |

| Signal is stable or improves with lower temperatures. | Yes, confirms diagnosis | N/A |

Step 3: Correlate with Structural Insights

- Action: Analyze the relationship between your compound's structure and its stability.

- Methodology: Review literature for thermal stability data on similar compounds. The case of Norditerpenoid Alkaloids shows that intramolecular hydrogen bonding (e.g., from a 1-OH group) can stabilize the molecular ion by delocalizing the positive charge

[N–H–O–H]+, whereas the 1-OMe analogue[N–H–O]+is less stabilized and more prone to fragmentation [33]. - Data Interpretation: If your compound lacks stabilizing structural features like hydrogen bonds and is prone to thermal stress, it is a high-risk candidate for degradation in APCI [33].

The following diagram illustrates the logical workflow for diagnosing thermal degradation.

Resolution Strategies and Optimization

Once thermal degradation is confirmed, implement these strategies to mitigate the issue.

Optimize APCI Source Temperatures

- Lower the Vaporizer/Heater Temperature: This is the most direct action. Systematically reduce the temperature from the manufacturer's default setting to the lowest point that still provides a stable and sensitive signal for your analyte [11]. The goal is to find a balance where desolvation is efficient but thermal insult is minimized.

- Optimize Auxiliary Gas Flows: Ensure the desolvation gas flow rate and temperature are properly set. Efficient gas-assisted desolvation can sometimes allow for operation at a lower vaporizer temperature while still effectively removing solvent [20].

Evaluate Alternative Ionization Methods

- Switch to Electrospray Ionization (ESI): If your analyte is polar and ionizable in solution, ESI is often the best alternative. ESI operates at or near ambient temperatures, virtually eliminating thermal degradation as a concern [11] [35]. It is particularly well-suited for molecules that are thermally unstable [1].

- Consider APPI: For less polar analytes that do not ionize well with ESI, Atmospheric Pressure Photoionization (APPI) can be a good alternative, as it may be performed with lower thermal stress than APCI depending on the source design.

Modify Chemical and Sample Conditions

- Leverage Stabilizing Chemistry: While not always possible, if you are working with synthetic derivatives, consider if a functional group (like a 1-OH in alkaloids that can form intramolecular H-bonds) could be introduced or preserved to enhance thermal stability in the gas phase [33].

- Ensure Sample Cleanliness: The presence of non-volatile salts and buffers can deposit on the source and create hot spots, leading to localized thermal degradation. Use volatile buffers (e.g., ammonium formate, ammonium acetate) and thoroughly desalt samples before analysis [34] [20].

Table 2: APCI Parameter Optimization Guide for Thermally Labile Compounds

| Parameter | Typical Range | Adjustment for Sensitive Analytes | Rationale |

|---|---|---|---|

| Vaporizer/Heater Temperature | 400–550°C [11] | Lower systematically (e.g., 250–350°C) | Reduces direct thermal energy causing decomposition. |

| Nebulizing/Desolvation Gas | Varies by instrument | Optimize flow and temperature | Improves efficient solvent removal at lower heater temps. |

| Corona Discharge Voltage | 2–3 kV [1] | Keep at standard setting | Ionization mechanism is separate from thermal stress. |

| Mobile Phase | LC-MS grade solvents | Use volatile buffers only | Prevents salt deposition and localized heating [34]. |

The Scientist's Toolkit: Essential Reagents and Materials

The following table lists key materials used in experiments cited in this guide, which are essential for studying and mitigating thermal degradation.

Table 3: Key Research Reagents and Materials

| Reagent/Material | Function in Experiment | Citation Context |

|---|---|---|

| Norditerpenoid Alkaloids (e.g., Condelphine) | Model compounds to study the effect of substituent (1-OH vs. 1-OMe) and configuration on thermal stability in APCI-MS. | [33] |