Mastering Sample Preparation for UV-Vis Analysis in Pharmaceutical Formulations: A Guide from Fundamentals to GMP Compliance

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on sample preparation for UV-Vis spectroscopy in pharmaceutical quality control and R&D.

Mastering Sample Preparation for UV-Vis Analysis in Pharmaceutical Formulations: A Guide from Fundamentals to GMP Compliance

Abstract

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on sample preparation for UV-Vis spectroscopy in pharmaceutical quality control and R&D. It covers the foundational principles of UV-Vis spectroscopy and its critical role in ensuring drug identity, purity, and potency. The content details methodological workflows for various formulation types, addresses common troubleshooting and optimization challenges, and outlines the rigorous validation and comparative strategies required for regulatory compliance under ICH and FDA guidelines. By synthesizing foundational knowledge with advanced practical applications, this guide aims to enhance analytical accuracy, efficiency, and data reliability in pharmaceutical development.

The Pillars of Precision: Core Principles of UV-Vis and Pharmaceutical Sample Integrity

UV-Vis spectroscopy is a cornerstone analytical technique in pharmaceutical quality assurance and quality control (QA/QC). It provides a rapid, reliable, and non-destructive means to ensure that drugs meet stringent regulatory standards for identity, purity, and potency [1]. This document details the application of UV-Vis spectroscopy within the critical framework of pharmaceutical analysis, with a specific focus on the sample preparation protocols essential for accurate and reproducible results.

Ultraviolet-Visible (UV-Vis) spectroscopy measures the absorption of light in the ultraviolet and visible regions of the electromagnetic spectrum by a sample. The fundamental principle is that the amount of light absorbed is directly proportional to the concentration of the absorbing species in a solution, as described by the Beer-Lambert Law [2]. In the highly regulated pharmaceutical industry, this technique is indispensable for verifying that Active Pharmaceutical Ingredients (APIs) and finished drug products conform to predefined specifications for identity, strength, quality, and purity [3] [1].

Regulatory bodies like the FDA mandate that pharmaceutical manufacturers provide proof of their quality control efforts, addressing critical attributes such as identity, assay, impurities, and dissolution [3]. UV-Vis spectroscopy is a validated tool for meeting these requirements, supporting everything from raw material inspection to final product release testing.

Key Applications in Pharmaceutical QA/QC

The following table summarizes the primary applications of UV-Vis spectroscopy in ensuring the identity, purity, and potency of pharmaceuticals.

Table 1: Key QA/QC Applications of UV-Vis Spectroscopy

| QA/QC Parameter | Application | Typical UV-Vis Protocol | Regulatory Citation |

|---|---|---|---|

| Identity Testing | Verification of chemical identity via absorption spectrum | Comparison of sample spectrum against a reference standard [1] [4]. | USP, EP, JP [4] |

| Potency/Assay | Quantification of Active Pharmaceutical Ingredient (API) concentration | Measurement of absorbance at λ~max~ and calculation via calibration curve [1]. | USP <611>, ICH Q2(R1) [1] [4] |

| Purity & Impurity Profiling | Detection of unwanted contaminants or degradation products | Spectral scan for unexpected absorbance peaks; specific tests for impurities like in ethanol [1] [5]. | USP, EP [5] |

| Dissolution Testing | Monitoring the release of API from solid dosage forms | Periodic sampling and analysis of dissolution medium [3] [1]. | USP <711> [3] [4] |

| Color Analysis | Quantitative assessment of drug product color for consistency and stability | Measurement of % Transmittance or Reflectance across the visible spectrum [6]. | USP <1061>, ASTM [6] |

Detailed Protocols and Sample Preparation

Proper sample preparation is paramount to obtaining accurate, precise, and regulatory-compliant results. Inadequate preparation is a leading cause of signal interference and out-of-specification findings [1].

Protocol for Identity Verification of an API (e.g., Ibuprofen)

This protocol follows the general monographs for ibuprofen as outlined in the USP and EP [4].

1. Principle: The identity of a substance is confirmed by matching the characteristic absorption spectrum of the sample to that of a compendial reference standard.

2. The Scientist's Toolkit:

Table 2: Essential Research Reagents and Materials for Identity Verification

| Item | Function | Critical Notes |

|---|---|---|

| Reference Standard | Provides the benchmark spectral fingerprint for comparison. | Must be a certified and traceable standard. |

| UV-Transparent Solvent (e.g., Methanol) | Dissolves the analyte without interfering in the UV range. | Must be spectroscopically pure; check cutoff wavelength. |

| Quartz Cuvettes (matched pair) | Holds the sample and reference solutions for analysis. | Quartz is essential for UV range; ensure clean, scratch-free surfaces. |

| Analytical Balance | Precisely weighs the sample and reference standard. | Regular calibration is required for data integrity. |

| Volumetric Flasks | Precisely dilutes the sample and standard to the target concentration. |

3. Procedure:

- Step 1: Solution Preparation. Accurately weigh the ibuprofen sample and the USP/EP reference standard. Dissolve both in the same specified solvent (e.g., methanol) to prepare solutions of a specified concentration, typically within the linear range of the instrument (absorbance < 1.0) [2] [4].

- Step 2: Blank Preparation. Prepare a blank solution containing only the solvent.

- Step 3: Spectral Acquisition. Using a double-beam UV-Vis spectrophotometer, scan both the sample and standard solutions across the specified wavelength range (e.g., 200-350 nm) against the solvent blank.

- Step 4: Data Analysis. The wavelength of maximum absorption (λ~max~) in the sample spectrum should coincide with that of the reference standard spectrum, typically within a specified tolerance (e.g., ±2 nm). The overall spectral profile should be identical.

Protocol for Potency Assay and Content Uniformity

This protocol is used to verify the labeled amount of API in a dosage form, a critical potency test [1].

1. Principle: The concentration of the API is determined by measuring absorbance at its λ~max~ and comparing it to a calibration curve constructed from standard solutions of known concentration.

2. Procedure:

- Step 1: Standard Curve Preparation. Prepare a series of at least five standard solutions of the API reference standard covering a concentration range that yields absorbances between 0.1 and 1.0 AU. Use an appropriate solvent that completely dissolves the API and does not interfere.

- Step 2: Sample Preparation. For a tablet, crush and homogenize a representative number of tablets. Accurately weigh a portion of the powder equivalent to one dose. Extract the API using an appropriate solvent, followed by dilution to the final volume. The solution will likely require filtration or centrifugation to become optically clear [1].

- Step 3: Absorbance Measurement. Measure the absorbance of each standard and the prepared sample solution at the determined λ~max~ (e.g., 280 nm for many compounds) against a solvent blank.

- Step 4: Quantification. Plot the absorbance versus concentration for the standard solutions to generate a calibration curve. The equation of the line (y = mx + c) is used to calculate the concentration of the API in the sample solution, which is then back-calculated to the amount per dosage unit.

Critical Sample Preparation Considerations

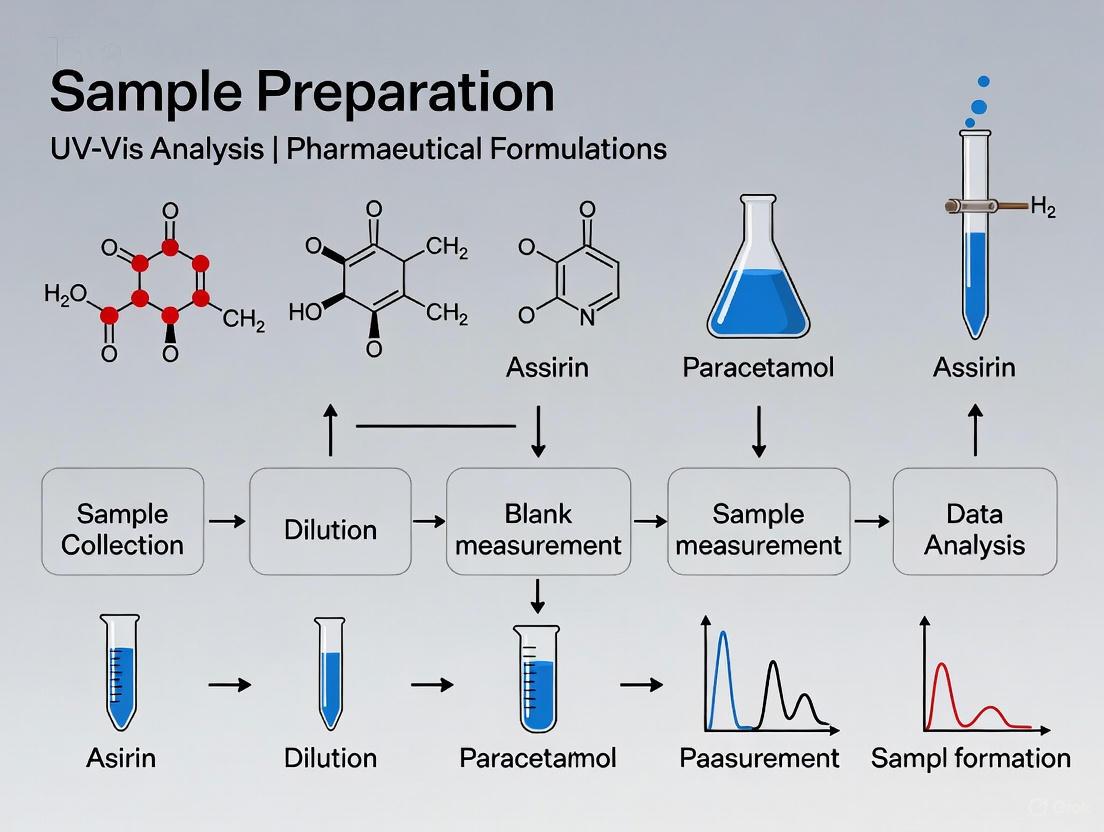

The workflow below outlines the key decision points in sample preparation to ensure data quality and regulatory compliance.

Diagram 1: Sample Preparation Workflow

- Solvent Selection: The solvent must be optically transparent in the spectral region of interest. For UV measurements below ~300 nm, high-purity solvents like water, acetonitrile, or hexane are required. The solvent's UV cutoff wavelength must be known and should be lower than the analyte's λ~max~ [1].

- Pathlength and Dilution: Standard cuvettes have a 1 cm pathlength. If the sample absorbance is too high (>1.0 AU), the sample must be diluted to remain within the instrument's linear dynamic range. Alternatively, cuvettes with a shorter pathlength (e.g., 1 mm) can be used, especially with limited sample volume [2] [7].

- Clarity and Particulates: Samples must be free of particulates that cause light scattering, leading to erroneously high absorbance readings. Filtration or centrifugation is often a critical final step before analysis [1].

- Cuvette Material: For any analysis involving UV light (wavelengths < ~350 nm), quartz cuvettes are mandatory as they are transparent in this range. Glass or plastic cuvettes, which absorb UV light, may only be used for visible light measurements [2].

Regulatory Compliance and Instrument Qualification

UV-Vis methods used for pharmaceutical release must be validated according to international guidelines such as ICH Q2(R1) [1]. This involves establishing method parameters including accuracy, precision, specificity, linearity, range, and robustness.

Furthermore, the instruments themselves must be qualified upon installation (IQ/OQ) and their performance verified at regular intervals according to pharmacopeial standards such as USP <857>, Ph. Eur. 2.2.5, and JP <2.24> [8]. Parameters verified typically include wavelength accuracy, photometric accuracy, stray light, and resolution. Data integrity is paramount, and systems must be compliant with 21 CFR Part 11, requiring features like electronic signatures and audit trails [4] [8].

UV-Vis spectroscopy remains a vital, versatile, and robust tool in the pharmaceutical analyst's arsenal. Its ability to provide fast, accurate, and non-destructive analysis of identity, purity, and potency makes it indispensable for QA/QC. However, the reliability of the data is profoundly dependent on rigorous sample preparation and strict adherence to validated methodologies and regulatory guidelines. By following the detailed protocols and considerations outlined in this document, pharmaceutical professionals can ensure the safety, efficacy, and quality of drug products, thereby protecting public health.

In the field of pharmaceutical research, the quantitative analysis of active pharmaceutical ingredients (APIs) and impurities is fundamental to ensuring drug efficacy and safety. UV-Visible spectrophotometry serves as a cornerstone technique for this purpose, and its quantitative application is almost entirely reliant on the Beer-Lambert Law (also known as Beer's Law). This principle provides the foundational relationship between the concentration of an analyte in solution and the amount of light it absorbs, enabling scientists to make precise and accurate determinations. For drug development professionals, a thorough understanding of this law—including its correct application, its limitations, and the necessary experimental controls—is critical for generating reliable analytical data that meets rigorous quality control standards. This application note details the practical implementation of the Beer-Lambert Law in the context of pharmaceutical formulation analysis [2] [9].

Theoretical Foundation

The Beer-Lambert Law Equation

The Beer-Lambert Law establishes a linear relationship between the absorbance of light by a solution and the concentration of the absorbing species within it, as well as the path length the light travels through the solution. It is formally stated as:

[ A = \varepsilon l c ]

Where:

- A is the Absorbance (a dimensionless quantity).

- ε is the Molar Absorptivity (or molar absorption coefficient), with typical units of L mol⁻¹ cm⁻¹.

- l is the Path Length of the light through the solution, measured in cm.

- c is the Molar Concentration of the absorbing solute, measured in mol L⁻¹ [10] [11] [9].

Absorbance itself is defined logarithmically from the ratio of incident light intensity ((I_0)) to transmitted light intensity ((I)):

[ A = \log{10} \left( \frac{I0}{I} \right) ]

This logarithmic relationship means that absorbance increases as the transmittance of light through the sample decreases. The following table shows this inverse correlation [10] [11]:

Table 1: Relationship between Absorbance and Transmittance

| Absorbance (A) | Percent Transmittance (%T) |

|---|---|

| 0 | 100% |

| 0.3 | 50% |

| 1 | 10% |

| 2 | 1% |

| 3 | 0.1% |

Conceptual Diagram of the Beer-Lambert Law

The following diagram illustrates the core concepts and relationships defined by the Beer-Lambert Law.

Experimental Protocol: Developing a Calibration Curve for an API

This protocol outlines the steps to create a calibration curve for an active pharmaceutical ingredient using UV-Vis spectrophotometry, enabling the quantification of the API in an unknown sample, such as a formulated drug product extract.

Materials and Equipment

Table 2: Essential Research Reagent Solutions and Materials

| Item | Specification / Function |

|---|---|

| UV-Vis Spectrophotometer | Equipped with a deuterium lamp (UV) and tungsten/halogen lamp (visible light). Must use quartz cuvettes for UV analysis [2]. |

| Cuvettes | Quartz for UV light analysis (below ~350 nm); optical glass or plastic may be suitable for visible light only [2]. |

| Analytical Balance | For accurate weighing of standards. |

| Volumetric Flasks | Class A, for precise preparation of stock and standard solutions. |

| Reference Solvent | High-purity solvent used to prepare the API stock and standard solutions. This serves as the "blank." |

| API Reference Standard | Certified, high-purity material of known identity and potency. |

Step-by-Step Procedure

Preparation of Stock Solution: Accurately weigh a known quantity of the pure API reference standard. Quantitatively transfer it to a volumetric flask and dilute to volume with the appropriate solvent to create a stock solution of known concentration (e.g., 1 mg/mL).

Preparation of Standard Solutions: Using serial dilution, prepare a series of at least 5 standard solutions covering a concentration range where the API is expected to follow the Beer-Lambert Law. For example, prepare standards at 25%, 50%, 75%, 100%, and 125% of the target assay concentration.

Spectrophotometer Setup: a. Turn on the instrument and allow the lamps to warm up for the time specified by the manufacturer. b. Select the wavelength of maximum absorption (λ_max) for the API, as determined from a prior spectral scan. c. Fill a cuvette with the reference solvent (blank), place it in the sample holder, and record a baseline absorbance or set the instrument to 100% transmittance.

Measurement of Standards: a. Rinse the cuvette multiple times with a small portion of the first standard solution. b. Fill the cuvette with the standard, place it in the spectrophotometer, and record the absorbance. c. Repeat this process for all standard solutions and for the unknown sample solution. Measure each solution in duplicate or triplicate.

Data Analysis and Calibration: a. Calculate the average absorbance for each standard solution. b. Plot the average absorbance (y-axis) versus the corresponding known concentration (x-axis) to create a scatter plot. c. Perform a linear regression analysis on the data points to obtain the equation of the calibration curve in the form (y = mx + b), where (y) is absorbance, (m) is the slope (equivalent to (εl)), (x) is concentration, and (b) is the y-intercept. A valid curve should have a correlation coefficient (R²) > 0.995.

Quantification of Unknown: Use the regression equation from the calibration curve to calculate the concentration of the API in the unknown sample based on its measured absorbance.

Table 3: Example Data Table for Calibration Curve of a Hypothetical API

| Standard Solution | Concentration (μg/mL) | Absorbance (Average, n=3) |

|---|---|---|

| 1 | 10.0 | 0.205 |

| 2 | 20.0 | 0.395 |

| 3 | 30.0 | 0.612 |

| 4 | 40.0 | 0.798 |

| 5 | 50.0 | 1.005 |

| Unknown Sample | Unknown | 0.570 |

Critical Considerations and Limitations in Pharmaceutical Applications

The Beer-Lambert Law is an idealization, and several factors can lead to deviations from the predicted linear behavior, potentially compromising quantitative accuracy.

Fundamental Limitations of the Law

- Chemical and Instrumental Deviations: The law assumes monochromatic light, non-interacting absorbing species, and a homogeneous solution without scattering [12] [13]. Real-world deviations include:

- Scattering and Reflection: In biological or turbid samples, light scattering (e.g., from cellular components or protein aggregates) can cause significant apparent absorption, leading to overestimation of concentration. This is particularly relevant for biopharmaceuticals [13].

- Molecular Interactions: At high concentrations, solute molecules can interact, altering their absorptivity. This includes phenomena like dimerization or stacking, which is why the law is typically applicable only in diluted solutions [12] [14].

- Stray Light and Instrumental Noise: Imperfections in the spectrophotometer, such as stray light or detector non-linearity, can cause deviations, especially at high absorbances (typically >1) [2] [9].

Best Practices for Robust Quantification

Work within the Linear Range: The calibration curve must be linear. For many systems, this requires keeping analyte concentrations such that the measured absorbance is below 1.0, and preferably between 0.1 and 0.8, to minimize relative error and stay within the instrument's dynamic range [2].

Use an Appropriate Blank: The blank solution must compensate for all absorbance not originating from the analyte of interest. For a pharmaceutical formulation, this may require a placebo solution containing all excipients but not the API.

Account for Sample Form: The standard BLL is for transmission measurements. For solid dosage forms, reflectance measurements may be required for color analysis, as per USP methodologies [6].

Understand Advanced Modifications: In complex matrices like living tissues or concentrated biological fluids, the standard BLL fails. Researchers in related areas (e.g., in vivo oxygen saturation measurement) use a Modified Beer-Lambert Law (MBLL) that incorporates a Differential Pathlength Factor (DPF) to account for increased photon pathlength due to scattering [13].

In the development and quality control (QC) of pharmaceutical formulations, the accuracy, reproducibility, and regulatory compliance of analytical data are non-negotiable [8]. Ultraviolet-Visible (UV-Vis) spectroscopy is a cornerstone technique for tasks ranging from raw material identification and dissolution testing to biomolecule quantification and assay development. The reliability of these analyses is fundamentally rooted in the performance and understanding of the instrument's core components. This Application Note details the essential components of a UV-Vis spectrophotometer, framed within the stringent requirements of pharmaceutical research. It provides detailed methodologies for instrument qualification and quantitative analysis, supporting robust sample preparation and data integrity in compliance with global pharmacopoeia standards [8] [15].

Core Components and Their Function in Pharmaceutical Analysis

A UV-Vis spectrophotometer operates on a relatively straightforward principle, yet its optical configuration is critical for generating reliable data. The instrument measures the amount of ultraviolet or visible light absorbed by a sample in solution, which is then related to the analyte's concentration via the Beer-Lambert Law [2]. The following sections break down this process into its essential components.

The Journey of Light: A Simplified Workflow

The diagram below illustrates the logical sequence and relationship between the key components of a single-beam UV-Vis spectrophotometer during the measurement of a pharmaceutical sample.

Detailed Breakdown of Key Components

Light Source

A stable light source emitting across a broad wavelength range is fundamental. Instruments often use two lamps to cover the full UV-Vis spectrum [2] [16].

- Deuterium Lamp: Provides intense, continuous light in the UV range (190 - 350 nm) and is essential for analyzing active pharmaceutical ingredients (APIs) with UV chromophores [16].

- Tungsten-Halogen Lamp: Covers the visible range (330 - 3200 nm), used for colorimetric assays common in pharmaceutical QC, such as the Bradford or BCA protein assays [2] [16]. The switch between lamps typically occurs seamlessly between 300-350 nm [2].

Wavelength Selection System: Monochromator

The monochromator is critical for selecting discrete wavelengths from the broad-spectrum light source. Its quality directly determines the instrument's spectral resolution and purity of light [17] [16].

- Key Elements: It consists of an entrance slit, a dispersive element (diffraction grating), and an exit slit [17].

- Diffraction Grating: This is the heart of the monochromator. A grating with a higher groove density (e.g., ≥ 1200 grooves per mm) provides better optical resolution, which is necessary for distinguishing sharp absorption peaks in API spectra [2]. The grating is rotated to select specific wavelengths.

- Spectral Bandwidth (SBW): The width of the exit slit determines the SBW, which is the narrow band of wavelengths that ultimately reaches the sample. A narrower SBW (e.g., 1 nm) provides better peak resolution, which is crucial for identifying and quantifying APIs in complex mixtures, while a wider SBW (e.g., 5 nm) allows more light through, improving signal-to-noise for dilute samples but with poorer resolution [16].

Sample Compartment

The prepared sample, contained in an appropriate cuvette, is placed here. The choice of cuvette material is a critical sample preparation consideration [2].

- Quartz Cuvettes: Are essential for UV analysis (below 350 nm) as quartz is transparent to UV light. Plastic and glass cuvettes absorb UV light and are suitable only for measurements in the visible range [2].

- Path Length: Standard path length is 1 cm. For highly concentrated samples, a shorter path length (e.g., 1 mm) can be used to keep absorbance within the ideal linear range (below 1 AU), thereby avoiding dilution and potential error [2] [18].

Detector

The detector converts the transmitted light intensity into an electrical signal. The choice of detector impacts the sensitivity and signal-to-noise ratio of the measurement [2] [16].

- Photomultiplier Tube (PMT): Highly sensitive detectors that amplify the initial photoelectric signal through a series of dynodes. They are excellent for detecting very low light levels and are widely used in high-performance spectrophotometers [2] [16].

- Silicon Photodiode: Less sensitive than PMTs but offer a faster response time, broader spectral range, and are a cost-effective alternative. They are commonly found in diode-array detectors and many modern instruments [2] [16].

Table 1: Essential Components of a UV-Vis Spectrophotometer and Their Pharmaceutical Relevance

| Component | Key Types | Function | Pharmaceutical Application Consideration |

|---|---|---|---|

| Light Source | Deuterium Lamp, Tungsten-Halogen Lamp [2] [16] | Provides continuous light across UV and/or visible spectra. | Lamp stability and intensity are critical for reproducibility in quantitative QC assays. |

| Monochromator | Diffraction Grating-based (Czerny-Turner) [17] [19] | Isolates a narrow band of wavelengths to probe the sample. | Spectral bandwidth must be set per pharmacopoeial methods (e.g., USP <857>) for method compliance [8]. |

| Sample Holder | Quartz Cuvette (UV), Glass/Plastic Cuvette (Vis) [2] | Holds the sample solution in the consistent light path. | Quartz is mandatory for UV analysis of APIs; path length must be known and accurate for concentration calculations. |

| Detector | Photomultiplier Tube (PMT), Silicon Photodiode [2] [16] | Measures the intensity of light transmitted through the sample. | High sensitivity (PMT) is needed for low-concentration impurities; linearity is key for accurate quantification over a wide range. |

Critical Performance Parameters for Pharmaceutical QC

Understanding instrument parameters that affect data quality is vital for developing and validating analytical methods.

- Beer-Lambert Law and Absorbance Linearity: The foundational principle for quantification states that absorbance (A) is proportional to concentration (c): A = εlc, where ε is the molar absorptivity and l is the path length [2]. A spectrometer's absorbance linearity defines the range over which this relationship holds true. Instruments with linearity up to 2 Absorbance Units (AU) allow for accurate measurement of highly concentrated samples without dilution, preserving sample integrity and saving time [18].

- Stray Light: This is any light that reaches the detector without passing through the sample at the intended wavelength. It becomes a significant source of error at high absorbances, causing deviations from the Beer-Lambert Law and resulting in inaccurate concentration readings [16]. Double-monochromator instruments are specifically designed to minimize stray light for the most demanding applications [16].

- Photometric Accuracy and Precision: For regulated environments, instruments must meet strict criteria for accuracy (closeness to a true value) and precision (repeatability). Specifications are often defined against certified reference materials (CRMs), with requirements such as an absorbance accuracy of ±0.005 A and a precision (standard deviation) of less than 0.5% being typical for "fitness-for-purpose" in pharmaceutical control [20].

Application in Pharmaceutical Research: Diffusion Coefficient Measurement

Understanding the diffusion coefficient of an API is critical for predicting release rates from formulated products. The following protocol adapts a method using a standard UV-Vis spectrometer to investigate the effect of dissolution media on drug diffusivity [15].

Protocol: Measuring API Diffusion Coefficient in Dissolution Media

1. Principle: A 3D-printed cover with a defined open slit is attached to a standard quartz cuvette. The drug diffuses from a high-concentration zone at the cuvette bottom to the slit area. The local drug concentration at the slit is measured as a function of time using UV-Vis absorbance, and the diffusion coefficient is calculated based on Fick's law of diffusion [15].

2. The Scientist's Toolkit: Essential Materials

Table 2: Key Reagents and Materials for Diffusion Coefficient Studies

| Item | Function/Description | Example/Specification |

|---|---|---|

| API/Protein Solution | The analyte of interest. | Prepared in relevant dissolution medium (e.g., buffer at pH 6.8). |

| Dissolution Media | Simulates the biological environment for drug release. | Aqueous buffers, biorelevant media (e.g., FaSSIF), polymer solutions. |

| Quartz Cuvette | Holds the sample for UV-Vis analysis. | 1 cm pathlength; required for UV transparency [2]. |

| 3D-Printed Slit Cover | Creates a defined diffusion path for localized concentration measurement. | Custom-designed to fit standard cuvette; slit dimensions are critical. |

| UV-Vis Spectrophotometer | Measures absorbance at the slit over time. | Equipped with a deuterium lamp for UV analysis; temperature control recommended. |

3. Experimental Workflow:

The multi-step process for determining the diffusion coefficient is outlined below, from sample preparation to data analysis.

4. Step-by-Step Procedure:

- Sample Preparation: Prepare a concentrated solution of the small molecule or protein API in the selected dissolution medium (e.g., phosphate buffer saline). Filter the solution if necessary to remove any particulate matter [15].

- Instrument Setup: Assemble the 3D-printed slit cover onto a quartz cuvette. Place the cuvette in the spectrophotometer's sample compartment. Set the spectrophotometer to the wavelength of maximum absorbance (λmax) for the API, previously determined by a full wavelength scan. Configure the software for kinetic mode, setting appropriate measurement intervals for the duration of the experiment (e.g., every 30 seconds for 1-2 hours) [15].

- Loading and Measurement:

- Carefully pipette the concentrated API solution into the prepared cuvette, ensuring no air bubbles are trapped.

- Immediately start the kinetic measurement. The API will begin to diffuse upwards towards the slit.

- The instrument will automatically record the absorbance at the slit location at each time interval, generating a profile of increasing concentration over time.

- Data Analysis:

- Export the time (t) and absorbance (A) data. Convert absorbance to concentration (C) using a pre-established calibration curve (A = εlc).

- Fit the concentration-time data to the solution of Fick's second law of diffusion, as described in the source literature [15]. This can be done using analytical equations or numerical fitting in software like MATLAB or Python.

- The diffusion coefficient (D) is the primary output of this model fitting.

- Investigation of Media Effects: Repeat the entire procedure for the same API in different dissolution media (e.g., buffers of varying pH or viscosity). Compare the calculated diffusion coefficients to understand how formulation conditions affect molecular diffusivity. Studies suggest different aqueous media can affect the diffusion coefficients of small molecules by <10% and proteins by <15% [15].

The path from a light source to a detector in a UV-Vis spectrophotometer encompasses a sophisticated optical system where each component—the source, monochromator, sample holder, and detector—plays a critical role in generating accurate and reliable data. For pharmaceutical scientists, a deep understanding of these components and associated performance parameters like absorbance linearity and photometric accuracy is essential for developing robust methods and ensuring regulatory compliance. Furthermore, as demonstrated by the diffusion coefficient protocol, the versatility of the UV-Vis spectrometer can be extended with innovative approaches to solve complex biopharmaceutical problems, making it an indispensable tool in modern drug development and quality control.

Why Sample Preparation is the Most Critical Step in Your Analytical Workflow

In pharmaceutical development, the integrity of analytical data is paramount. While advanced spectroscopic instruments like UV-Vis are critical for quantifying Active Pharmaceutical Ingredients (APIs), the data they generate is only as reliable as the samples they analyze. Sample preparation is the foundational step that transforms a raw, complex formulation into a solution suitable for instrumental analysis. Errors introduced at this stage are not merely carried forward; they are often amplified, leading to inaccurate potency assessments, stability profiles, and ultimately, decisions that can compromise product quality and patient safety [21] [22]. This application note, framed within UV-Vis analysis of pharmaceutical formulations, details why meticulous sample preparation is indispensable and provides validated protocols to ensure data reliability.

The Impact of Sample Preparation on Analytical Results

Sample preparation is the critical bridge between a raw pharmaceutical product and the analytical instrument. Its quality directly dictates the accuracy, precision, and sensitivity of the final result.

- Error Amplification: Any inconsistency, contamination, or incomplete extraction during sample preparation introduces errors that the analytical instrument cannot distinguish from true signal. For instance, an incomplete extraction of an API from a tablet matrix will lead to an underestimation of potency, regardless of the sensitivity of the subsequent UV-Vis spectrophotometer [22].

- Foundation for Accuracy: Proper sample preparation ensures the sample is representative, homogeneous, and free of interferents that could affect the spectroscopic reading. A well-prepared sample allows the UV-Vis instrument to perform at its optimum, providing accurate quantification of the analyte as demonstrated in the validation data in Section 4 [23].

- Direct Correlation to Data Quality: The relationship between sample preparation rigor and the final analytical result is direct and profound. The following workflow illustrates how errors at the sample preparation stage propagate through the entire analytical process, ultimately compromising data integrity.

The Scientist's Toolkit: Essential Reagents and Materials

A successful sample preparation workflow relies on high-quality, purpose-specific materials. The following table details key reagents and consumables essential for the sample preparation of pharmaceutical formulations for UV-Vis analysis.

Table 1: Key Research Reagent Solutions for Sample Preparation

| Item | Function in Sample Preparation |

|---|---|

| Primary Solvent (e.g., Methanol) | Dissolves the Active Pharmaceutical Ingredient (API) from the solid dosage form to create a primary stock solution [23]. |

| Artificial Biological Fluids (e.g., AVF pH 4.1) | Mimics the physiological environment for dissolution testing and analysis of formulations designed for specific administration routes [23]. |

| Certified Reference Materials (CRMs) | Serves as a benchmark with known purity and composition to calibrate instruments and validate the entire analytical method for accuracy [24]. |

| Ultrapure Water Purification System | Produces water free of ions and organic impurities that could interfere with UV-Vis analysis, crucial for preparing blanks, buffers, and dilution solvents [25]. |

| Filters and Solid-Phase Extraction (SPE) Columns | Removes particulate matter and interfering compounds from the sample matrix, clarifying the solution and reducing background noise in the spectrophotometer [22]. |

| Standardized Tubes and Plates | Provides consistent, inert containers for sample processing and storage, minimizing analyte adsorption and cross-contamination [22]. |

Case Study: UV-Vis Analysis of Voriconazole

A recent study on the development and validation of a UV-Vis method for estimating the antifungal drug Voriconazole provides a clear illustration of a robust sample preparation protocol and its critical role in achieving valid analytical results [23].

Sample Preparation Protocol

This protocol is adapted from the method developed by Kanojiya et al. (2025) for the analysis of Voriconazole in bulk powder and formulated products [23].

- Materials: Voriconazole standard, methanol (HPLC grade), artificial vaginal fluid (AVF) pH 4.1, volumetric flasks (10 mL, 100 mL), analytical balance, micropipettes, ultrasonic bath, syringe filters (0.45 µm).

- Standard Stock Solution (100 µg/mL): Accurately weigh 10 mg of Voriconazole standard and transfer to a 100 mL volumetric flask. Dissolve and dilute to volume with methanol (for bulk analysis) or AVF pH 4.1 (for formulation analysis). Sonicate for 5 minutes to ensure complete dissolution.

- Calibration Curve Standards: From the stock solution, prepare a series of working standards in the concentration range of 10–50 µg/mL by performing appropriate serial dilutions using the same solvent (methanol or AVF).

- Tablet Sample Preparation: Weigh and finely powder not less than 10 tablets. Accurately weigh a portion of the powder equivalent to 10 mg of Voriconazole and transfer to a 100 mL volumetric flask. Add approximately 70 mL of solvent (methanol or AVF pH 4.1), sonicate for 20 minutes with intermittent shaking to ensure complete drug extraction, and dilute to volume. Filter a portion of the solution through a 0.45 µm syringe filter, discarding the first few mL of the filtrate.

- UV-Vis Analysis: Measure the absorbance of the standard and sample solutions at 256 nm against a blank of the respective solvent.

Method Validation and Results

The sample preparation method and subsequent analysis were rigorously validated as per ICH guidelines. The quantitative results, summarized in the table below, demonstrate the high performance achieved through a well-controlled preparation process [23].

Table 2: Validation Parameters for the UV-Vis Determination of Voriconazole [23]

| Validation Parameter | Result in Methanol | Result in AVF pH 4.1 |

|---|---|---|

| Linearity Range (µg/mL) | 10 - 50 | 10 - 50 |

| Correlation Coefficient (R²) | 0.998 | 0.999 |

| Accuracy (% Recovery) | 98 - 102% | 98 - 102% |

| Limit of Detection (LOD) (µg/mL) | 2.55 | 2.00 |

| Limit of Quantification (LOQ) (µg/mL) | 7.75 | 6.08 |

A Standardized Sample Preparation Workflow

Adhering to a standardized workflow is key to ensuring reproducibility and reliability in pharmaceutical analysis. The following chart outlines a generalized, robust protocol for preparing solid oral dosage forms for UV-Vis analysis.

In the rigorous world of pharmaceutical analysis, the pathway to reliable and meaningful data is paved long before the sample is placed in the spectrophotometer. As demonstrated, sample preparation is not a mere preliminary step but the most critical phase where the battle for data accuracy is won or lost. A meticulously developed and executed sample preparation protocol, as exemplified in the voriconazole case study, ensures that the powerful analytical instrumentation used in modern labs, such as UV-Vis, can perform to its full potential. By standardizing workflows, understanding the function of key reagents, and implementing rigorous validation, scientists and researchers can transform this fundamental process from a potential source of error into a cornerstone of quality and confidence in drug development.

Ultraviolet-Visible (UV-Vis) spectroscopy stands as a cornerstone analytical technique within pharmaceutical research and development, providing a rapid, cost-effective, and non-destructive means for analyzing drug substances and products [1] [26]. The technique operates on the principle of measuring the absorption of light in the 190 to 800 nm range, which corresponds to electronic transitions in molecules with chromophores [27] [1]. The fundamental relationship between absorbance and concentration is governed by the Beer-Lambert law (A = ε·c·l), making it inherently quantitative and ideal for determining the concentration of Active Pharmaceutical Ingredients (APIs) in various matrices [26]. This application note details standard methodologies and protocols for the UV-Vis analysis of common pharmaceutical formulations, contextualized within a broader research thesis on sample preparation. The content is structured to provide drug development professionals with detailed application notes and experimentally validated protocols, emphasizing robust sample preparation to ensure data accuracy and regulatory compliance.

Theoretical Foundations and Relevance to Sample Preparation

The interaction of light with matter in the UV-Vis range is dominated by electronic transitions in molecules possessing aromatic or conjugated pi-electron systems [27]. This makes the technique particularly suitable for the vast majority of organic APIs, which often contain such chromophores. The resulting spectrum serves as both a qualitative fingerprint and a quantitative tool [26].

The choice of solvent is a critical component of sample preparation, as it must not only dissolve the analyte but also be transparent in the spectral region of interest. Common solvents include water, methanol, and 0.1N hydrochloric acid, selected for their low UV cutoff and compatibility with the API [1] [26]. Proper sample preparation must also account for the removal of particulates that cause light scattering, ensuring that absorbance measurements are accurate and reproducible [1]. For solid dosage forms, the preparation process must efficiently extract the API from the excipient matrix without inducing degradation, a key consideration in research on formulation stability.

Figure 1: UV-Vis Analysis Workflow for Pharmaceutical Formulations. This diagram outlines the generalized workflow from sample preparation to result validation, highlighting the critical sample preparation stage common to all formulation types.

Applications in Pharmaceutical Analysis

UV-Vis spectroscopy is a versatile tool applied across multiple stages of drug development and quality control. Its applications are critical for ensuring the identity, potency, purity, and performance of pharmaceutical products.

Table 1: Key Applications of UV-Vis Spectroscopy in Pharmaceutical Analysis

| Application | Objective | Typical Formulations | Key Sample Preparation Considerations |

|---|---|---|---|

| Drug Assay & Potency [1] [26] | Quantify the percentage of API in a dosage form. | Tablets, Capsules, Oral Liquids | Complete extraction of API from excipients; dilution into linear Beer-Lambert range (Abs ~0.1-1.0 AU). |

| Content Uniformity [28] [26] | Ensure each individual dosage unit contains API within a specified range. | Tablets, Capsules | Individual unit processing; use of a validated, robust method for high precision. |

| Dissolution Testing [1] [26] | Monitor the rate and extent of API release from a solid dosage form. | Tablets, Capsules | Withdrawal and filtration of aliquots from dissolution vessels at specified time points. |

| Impurity Profiling [1] [26] | Detect and quantify UV-absorbing impurities or degradation products. | APIs, Finished Products | Sample preparation should not introduce artifacts; may involve comparison of spectral shapes or use of HPLC-UV. |

| Stability Studies [26] | Track changes in drug potency or formation of degradants over time. | All Formulations | Comparison of absorbance at λ_max and full spectral overlay against a fresh reference standard. |

Advanced and Emerging Applications

The role of UV-Vis is expanding with technological and methodological advancements. UV-Vis Diffuse Reflectance Spectroscopy (UV-Vis DRS) allows for the direct, non-destructive analysis of solid powder mixtures, fulfilling green chemistry principles by eliminating solvent use [29]. This technique is particularly suited for Process Analytical Technology (PAT) initiatives for real-time monitoring of blend homogeneity in solid formulations [29]. Furthermore, in the context of emerging point-of-care (POC) manufacturing and personalized medicine, UV-Vis serves as a vital at-line method for verifying API ink concentration prior to drop-on-demand dispensing, ensuring dosing accuracy for narrow therapeutic index drugs [28].

Experimental Protocols

Protocol 1: API Assay and Content Uniformity of Tablet Formulations

This protocol details the analysis for the total assay of a batch and the content uniformity of individual tablets, using a representative study on a commercial tablet (e.g., Neo Nisidine containing acetylsalicylic acid, paracetamol, and caffeine) as a model [29].

4.1.1 Research Reagent Solutions and Materials

Table 2: Essential Materials for Tablet Analysis

| Item | Function / Specification |

|---|---|

| UV-Vis Spectrophotometer | Double-beam instrument preferred for stability; equipped with 1 cm matched quartz cuvettes [26]. |

| Analytical Balance | Precision of 0.1 mg for accurate weighing of samples and standards. |

| Reference Standard | Certified API of known purity and identity for calibration [1]. |

| Solvent | Appropriately purified and transparent in the spectral region of analysis (e.g., 0.1N HCl, methanol, water) [26]. |

| Volumetric Flasks | Class A, of various capacities (e.g., 10 mL, 100 mL, 1000 mL) for precise dilution. |

| Syringe Filters | 0.45 µm porosity, compatible with the solvent, for sample clarification after extraction [1]. |

4.1.2 Procedure

- Standard Solution Preparation: Accurately weigh about 50 mg of the API reference standard into a 100 mL volumetric flask. Dissolve and dilute to volume with the appropriate solvent to create a primary stock solution (e.g., 500 µg/mL). Serially dilute this stock to prepare a series of standard solutions (e.g., 5, 10, 15, 20 µg/mL) covering the expected sample concentration.

- Sample Solution Preparation (For Total Assay):

- Accurately weigh and finely powder not less than 20 tablets.

- Transfer an accurately weighed portion of the powder, equivalent to about 50 mg of the API, into a 100 mL volumetric flask.

- Add approximately 70 mL of solvent, shake or sonicate for 15-30 minutes to ensure complete extraction of the API.

- Dilute to volume with the solvent and mix well.

- Filter a portion of the solution through a 0.45 µm syringe filter, discarding the first few mL of the filtrate.

- Pipette a precise volume of the clear filtrate and perform a secondary dilution to bring the concentration within the linear range of the calibration curve.

- Sample Solution Preparation (For Content Uniformity):

- Individually place one whole tablet into a suitable volumetric flask (e.g., 100 mL or 250 mL based on dosage).

- Add a sufficient volume of solvent to dissolve the API, sonicate for 30 minutes with intermittent shaking.

- Dilute to volume, filter, and dilute as described in step 4.1.2.2.

- Spectrum Acquisition and Quantification:

- Using the solvent as a blank, zero the spectrophotometer.

- Scan the standard solutions and determine the wavelength of maximum absorption (λmax).

- Measure the absorbance of all standard and sample solutions at the predetermined λmax.

- Generate a calibration curve by plotting the absorbance of the standard solutions versus their concentrations. Perform linear regression to obtain the equation of the line.

- Calculate the concentration of the API in the sample solutions using the regression equation. Back-calculate to determine the average API content per tablet (for total assay) or the individual content of each tablet (for content uniformity).

Protocol 2: Analysis of Liquid Dosage Forms (Oral Solutions)

This protocol is designed for the assay of APIs in simple oral solutions or suspensions. For suspensions, an appropriate filtration or centrifugation step is added to ensure a clear solution for analysis.

4.2.1 Procedure

- Standard Solution Preparation: Prepare as described in Protocol 4.1.2.1.

- Sample Solution Preparation:

- For solutions: Pipette a measured volume of the well-mixed liquid dosage form directly into a volumetric flask. Dilute quantitatively with solvent to produce a solution within the Beer-Lambert linear range.

- For suspensions: Pipette a measured volume of the homogenized suspension into a volumetric flask. Extract and dilute as for a solution, then filter through a 0.45 µm filter to obtain a clear analyte solution.

- Spectrum Acquisition and Quantification:

- Follow the same procedure as in Protocol 4.1.2.4. Measure the absorbance of the diluted sample solution and calculate the API concentration using the calibration curve. Report the result as the amount of API per unit volume (e.g., mg/mL).

Protocol 3: Dissolution Testing with UV-Vis Analysis

This protocol outlines the use of UV-Vis for analyzing samples withdrawn from dissolution apparatus.

4.3.1 Procedure

- Dissolution Medium: Select an appropriate medium as per pharmacopeial guidelines (e.g., pH 6.8 phosphate buffer, 0.1N HCl). The volume is typically 500-900 mL, maintained at 37±0.5°C.

- Standard Solution: Prepare a standard solution of the API in the dissolution medium at a concentration equivalent to the final concentration upon 100% dissolution of the dosage form (C~100%~).

- Dissolution Run:

- Place one dosage unit into each vessel of the dissolution apparatus and start the test.

- At specified time intervals (e.g., 10, 15, 30, 45 minutes), withdraw a predetermined volume (e.g., 5-10 mL) from each vessel, ensuring the sampling position is not perturbed.

- Immediately replace the withdrawn volume with fresh, pre-warmed medium to maintain a constant volume.

- Sample Analysis:

- Filter each withdrawn sample through a 0.45 µm filter.

- Measure the absorbance of the standard and each filtered test sample at the API's λ_max, using fresh dissolution medium as the blank.

- Calculate the percentage of API dissolved at each time point using the formula:

% Dissolved = (A_sample / A_standard) * 100%.

Advanced Chemometric Protocol: Solid Analysis via UV-Vis DRS with Net Analyte Signal

For direct analysis of solid formulations without dissolution, UV-Vis DRS coupled with multivariate calibration can be employed [29].

4.4.1 Procedure

- Sample Preparation: Prepare homogeneous solid powder mixtures of the API and excipients using geometric dilution to simulate the final formulation. For standard addition, spike the real tablet powder with known increments of pure API (e.g., 0%, 5%, 10%, 15% w/w) [29].

- Spectrum Acquisition: Pack each powder mixture into a sample cup and acquire its diffuse reflectance spectrum using a UV-Vis spectrophotometer equipped with an integrating sphere.

- Data Processing: Transform reflectance data (R) to apparent absorbance (A = log(1/R)). Process the multidimensional spectral data using the Net Analyte Signal (NAS) algorithm. NAS calculates the part of the spectrum that is unique to the analyte of interest, orthogonal to the spectra of all other components in the mixture [29].

- Quantification: Construct a pseudo-univariate calibration curve by plotting the magnitude of the NAS versus the concentration of the added API for each standard addition sample. The concentration of the API in the unknown sample is determined from the x-intercept of this curve [29].

Data Analysis and Regulatory Considerations

For univariate analysis, standard calibration curves are constructed, and the correlation coefficient (R²), slope, and intercept are reported [1]. The Limit of Detection (LOD) and Limit of Quantitation (LOQ) can be calculated based on the standard deviation of the response and the slope of the calibration curve. In complex matrices, such as those analyzed by UV-Vis DRS, multivariate techniques like Partial Least Squares Regression (PLSR) or the Net Analyte Signal (NAS) method are required to handle spectral overlaps [27] [29].

All analytical procedures must be validated according to ICH Q2(R1) guidelines, establishing parameters such as accuracy, precision, specificity, linearity, and range [1]. Compliance with good manufacturing practice (GMP) regulations (e.g., 21 CFR Part 211) is mandatory, which includes strict controls on instrument calibration, qualification (IQ/OQ/PQ), and documentation adhering to ALCOA+ principles (Attributable, Legible, Contemporaneous, Original, and Accurate) [1].

Figure 2: Conceptual Diagram of a Double-Beam UV-Vis Spectrophotometer. The diagram illustrates the instrument's key components and the principle of simultaneous measurement of sample (I) and reference (I₀) beams, which corrects for source instability and solvent absorption.

From Theory to Practice: Optimized Sample Preparation Workflows for Different Formulations

Ultraviolet-visible (UV-Vis) spectroscopy is an indispensable analytical technique in pharmaceutical research, used for tasks ranging from drug identification and nucleic acid purity checks to quality control [2]. The technique measures the amount of discrete wavelengths of UV or visible light that are absorbed by or transmitted through a sample [2]. The reliability of these analyses is profoundly influenced by the sample composition and the solvent environment.

The core principle governing quantitative UV-Vis analysis is the Beer-Lambert Law, which states that absorbance (A) is proportional to the concentration (c) of the analyte, the path length (b) of the sample holder, and the molar absorptivity (ε) of the compound [30]. Any component of the sample matrix that alters this relationship constitutes an interference. The central challenge in sample preparation is to select a solvent that completely dissolves the pharmaceutical analyte without itself absorbing significantly in the spectral region of interest. A poorly chosen solvent can introduce significant errors, reducing the accuracy, precision, and overall reliability of the analytical method.

This application note provides a structured framework for researchers to select optimal solvents, thereby minimizing interference and maximizing solubility for the UV-Vis analysis of pharmaceutical formulations.

Understanding Solvent Interference and UV Transparency

The Nature of Solvent Interference

In an ideal scenario, the absorbance spectrum of a solution containing a single analyte should be a single, well-defined absorption band at its wavelength of maximum absorbance (λmax). In real pharmaceutical samples, the spectrum is influenced by the presence of the solvent and other excipients [31]. These interferences can be physical or chemical in nature.

- Physical Interferences: Scattering of light caused by the presence of suspended solid impurities or undissolved analyte in the solution is a common physical interference [31]. This scattering results in a background absorbance that elevates the apparent absorbance of the analyte of interest, leading to positive errors in quantification.

- Chemical Interferences: These arise from the presence of other UV-absorbing compounds in the solution [31]. In pharmaceutical formulations, these can include excipients, stabilizers, preservatives, or impurities. Their absorption bands can overlap with those of the active pharmaceutical ingredient (API), causing spectral overlap and making accurate quantification difficult.

The UV Cut-Off Concept

A fundamental property of any solvent is its UV cut-off wavelength. This is the wavelength below which the solvent itself absorbs significant UV light (typically with an absorbance >1 AU in a 1 cm pathlength). Using a solvent at wavelengths below its cut-off is not feasible because the solvent absorbance will overwhelm the signal from the analyte, resulting in a poor signal-to-noise ratio.

The solvent's cut-off is a critical parameter because it defines the usable UV spectrum for your analysis. For an analyte with a λmax of 250 nm, a solvent with a cut-off of 220 nm would be suitable, whereas a solvent with a cut-off of 260 nm would not.

Key Criteria for Solvent Selection

Selecting the right solvent requires a balanced consideration of multiple factors. The following table summarizes the primary and secondary criteria for evaluation.

Table 1: Key Criteria for Analytical Solvent Selection

| Criterion | Description | Impact on Analysis |

|---|---|---|

| UV Transparency | The wavelength range where solvent absorbance is minimal (above its UV cut-off). | Determines the available spectral window for analyte detection; using a solvent below its cut-off causes high background noise [2]. |

| Solubility Power | The ability to dissolve the target analyte at the required concentration. | Ensures the analyte is in solution for accurate measurement; prevents light scattering from particulates [31]. |

| Chemical Inertness | The solvent should not react with the analyte. | Preserves the chemical integrity of the analyte, ensuring the spectrum measured is accurate. |

| Purity Grade | Solvents must be of high-purity "HPLC" or "Spectroscopic" grade. | Minimizes interference from UV-absorbing impurities present in lower-grade solvents. |

| Pathlength Compatibility | The solvent's absorptivity must be compatible with the chosen cuvette pathlength. | A highly absorbing solvent may require a shorter pathlength cuvette to keep the background absorbance within the instrument's measurable range. |

A Systematic Workflow for Solvent Evaluation

The following diagram outlines a logical, step-by-step protocol for evaluating and selecting a solvent for your UV-Vis analysis.

Experimental Protocol for Solvent Screening

Materials:

- Active Pharmaceutical Ingredient (API)

- Candidate solvents (e.g., water, methanol, acetonitrile, hexane) of spectroscopic grade

- Volumetric flasks (e.g., 10 mL)

- Analytical balance

- Ultrasonic bath

- UV-Vis spectrophotometer with quartz cuvettes (required for UV range) [2]

Method:

- Define Analytical Wavelength: Determine the λmax of your target API using a literature search or a preliminary scan in a known, compatible solvent.

- Preselect Solvents: Compile a list of solvents with UV cut-off values well below the analyte's λmax to ensure a usable baseline.

- Solubility Test: For each candidate solvent, attempt to dissolve the API to a concentration near the expected working range. Use gentle heating and sonication to aid dissolution. Visually inspect for undissolved particles, which cause light scattering [31].

- Blank Solvent Analysis: a. Fill a quartz cuvette with the pure, candidate solvent. This is your blank [2]. b. Using the spectrophotometer, record a baseline spectrum from 200 nm to at least 50 nm beyond the analyte's λmax. c. Examine the baseline for flatness and low absorbance in the region of interest. A steeply sloping or high-absorbance baseline indicates the solvent is unsuitable.

- Analyte Solution Analysis: a. Prepare a standard solution of the API in the candidate solvent at a known concentration. b. Using the blank from step 4, measure the absorbance spectrum of the standard solution. c. Assess the spectrum for a clear, undistorted absorption peak at the expected λmax.

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table details key materials and their functions for preparing samples for UV-Vis analysis.

Table 2: Essential Materials for UV-Vis Sample Preparation

| Item | Function / Rationale |

|---|---|

| Quartz Cuvettes | Required for UV range analysis as quartz is transparent to most UV light; glass and plastic cuvettes absorb UV light and are inappropriate [2]. |

| Spectroscopic Grade Solvents | High-purity solvents with minimal UV-absorbing impurities, essential for achieving a low background signal. |

| Volumetric Flasks | For accurate, precise preparation of standard and sample solutions to ensure correct concentration values. |

| Micro-pipettes or Syringes | For precise handling and transfer of small liquid volumes, especially when working with limited sample amounts. |

| Ultrasonic Bath | To aid in dissolving analytes and ensuring a homogeneous solution, free of micro-bubbles or undissolved particles that scatter light [31]. |

| Syringe Filters (0.45 μm or 0.2 μm) | For removing suspended particles from samples through filtration, thereby reducing physical light scattering interferences [31]. |

Advanced Techniques for Managing Interference

Even with careful solvent selection, complex pharmaceutical matrices may still present challenges. Several advanced techniques can be employed to overcome these.

- Derivative Spectroscopy: This is a powerful technique for background and noise correction [31]. By converting the normal absorbance spectrum into its first or second derivative, broad background absorption from the matrix can be effectively suppressed, resolving closely spaced or overlapping peaks from the API and an interferent.

- Multi-Component Analysis: Modern software in diode array detector (DAD) systems can deconvolute overlapping spectra [31]. If the spectra of the pure API and the interfering compound are known, the software can calculate their individual contributions to the total absorbance of the mixture, allowing for accurate quantification of the API.

- Three-Point Correction (Background Subtraction): For a sloping or curved baseline, this method selects two wavelengths close to the analytical wavelength (on either side) [31]. The background interference is estimated at the analytical wavelength by linear interpolation between these two points and then subtracted from the total measured absorbance.

The selection of an appropriate solvent is a critical step in the development of a robust and reliable UV-Vis spectroscopic method for pharmaceutical analysis. A methodical approach that prioritizes UV transparency and solubility power, while systematically evaluating potential interferences, is fundamental. By adhering to the protocols and principles outlined in this application note, researchers and drug development professionals can significantly enhance the quality of their analytical data, ensuring accurate quantification and characterization of active pharmaceutical ingredients.

In pharmaceutical research and quality control, UV-Visible (UV-Vis) spectroscopy serves as a fundamental analytical technique for characterizing solid dosage forms, quantifying active pharmaceutical ingredients (APIs), and detecting impurities [2] [5]. The reliability of these analyses is highly dependent on the quality of the sample preparation process. Proper sample preparation—encompassing extraction, filtration, and dilution—ensures that the measured absorbance accurately represents the analyte concentration, thereby guaranteeing the safety, efficacy, and quality of the final pharmaceutical product [32] [6]. This protocol details a systematic approach to preparing solid oral dosage forms (OSDs), such as tablets and capsules, for UV-Vis analysis.

Theoretical Foundations

UV-Vis spectroscopy measures the amount of ultraviolet or visible light absorbed by a sample. The fundamental principle governing quantitative analysis is the Beer-Lambert Law, which states that the absorbance (A) of a solution is directly proportional to the concentration (c) of the absorbing species and the path length (L) of the light through the solution [2]. The law is expressed as:

A = εlc

Where:

- A is the measured absorbance (no units)

- ε is the molar absorptivity (L·mol⁻¹·cm⁻¹)

- l is the path length of the cuvette (cm)

- c is the concentration of the analyte (mol·L⁻¹)

For this relationship to hold true, the sample must be in a form that allows light to pass through with minimal obstruction, which is achieved by creating a homogeneous, particulate-free solution of the analyte at an appropriate concentration [2] [32]. The sample preparation process for solid dosage forms is designed to meet these exact conditions, transitioning the API from a solid matrix into a clear solution suitable for spectroscopic analysis.

Materials and Equipment

Research Reagent Solutions and Essential Materials

Table 1: Key materials and equipment for sample preparation.

| Item | Specification/Function |

|---|---|

| UV-Vis Spectrophotometer | Double-beam instrument with a wide linear dynamic range is preferred [5]. |

| Cuvettes | Quartz cuvettes are mandatory for UV light transmission; path length typically 1 cm [2] [32]. |

| Solvent | High-purity solvent in which the API is freely soluble and that does not absorb significantly at the wavelength of interest (e.g., water, buffered solutions, alcohol) [32]. |

| Volumetric Flasks | For precise dilution and standard solution preparation. |

| Syringe Filters | Hydrophilic PVDF or nylon membranes with a pore size of 0.45 µm or less for removing fine particulates [32]. |

| Analytical Balance | For accurate weighing of the solid dosage form. |

| Ultrasonic Bath | To aid in the dissolution and extraction of the API from the dosage form matrix. |

Methodology

Sample Preparation Workflow

The following diagram illustrates the complete protocol for preparing solid dosage forms for UV-Vis analysis.

Detailed Experimental Protocols

Extraction Protocol

The goal of extraction is to completely dissolve the Active Pharmaceutical Ingredient (API) from the excipient matrix into a suitable solvent.

- Weighing: Accurately weigh the required number of tablets or the contents of capsules to obtain a quantity representative of the labeled API content. For a single unit, the entire dose may be used.

- Communition: If using tablets, gently crush them into a fine powder using a mortar and pestle to increase the surface area for extraction.

- Initial Dissolution: Quantitatively transfer the powder to an appropriate volumetric flask (e.g., 100 mL). Add a portion of the selected solvent (typically 50-70% of the final volume) to the flask.

- Agitation and Sonication: Seal the flask and agitate vigorously using a mechanical shaker or by hand. Subsequently, place the flask in an ultrasonic bath for 15-30 minutes to ensure complete dissolution of the API and to disrupt any agglomerates [32]. The choice of solvent is critical and should be based on the solubility properties of the API, which are determined during pre-formulation studies [33].

Filtration and Clarification Protocol

After extraction, the solution contains dissolved API but may also contain insoluble excipients that can cause light scattering and interfere with the UV-Vis measurement.

- Cooling: Allow the solution from the extraction step to cool to room temperature if heating was applied during sonication.

- Bring to Volume: Dilute the solution to the final mark on the volumetric flask with the solvent and mix thoroughly.

- Filtration: Pass a portion of the solution through a membrane filter with a pore size of 0.45 µm or less [32]. The initial 1-2 mL of the filtrate should be discarded to avoid potential analyte adsorption onto the filter membrane. The resulting filtrate should be a clear, particulate-free solution ready for analysis or further dilution.

Dilution Protocol

The concentration of the stock solution after extraction is often too high for UV-Vis analysis, as absorbance values should ideally be kept below 1.0 to remain within the instrument's linear dynamic range [2].

- Concentration Check: Perform a quick scan of the filtered stock solution to estimate the absorbance. If the maximum absorbance is greater than 1.0, further dilution is required.

- Serial Dilution: Prepare a series of dilutions using clean volumetric glassware. For example, a 1 in 10 dilution can be made by pipetting 5 mL of the stock solution into a 50 mL volumetric flask and diluting to volume with the solvent.

- Path Length Adjustment: As an alternative to dilution, using a cuvette with a shorter path length (e.g., 1 mm instead of 1 cm) can also lower the measured absorbance without altering the sample concentration, which is particularly useful when sample volume is limited [2] [32].

Table 2: Troubleshooting common sample preparation issues.

| Issue | Potential Cause | Solution |

|---|---|---|

| Absorbance too high | Sample concentration is too high. | Dilute the sample further or use a cuvette with a shorter path length [2]. |

| Precipitation in solution | Solvent incompatibility or supersaturation. | Ensure the solvent is appropriate for the API. Filter the solution again or re-prepare with a different solvent system. |

| High background noise | Dirty cuvette or particulate in sample. | Ensure cuvettes are meticulously cleaned. Re-filter the sample using a finer pore size filter [32]. |

| Non-linear calibration | Stray light effects at high absorbance; chemical interactions. | Keep absorbance readings below 1.0. Verify the stability of the analyte in the solvent. |

Data Analysis and Validation

Quantitative Analysis

For API quantification, a calibration curve must be constructed using standard solutions of known concentration. The absorbance of the prepared sample is then measured, and its concentration is determined by interpolating from the calibration curve, followed by back-calculation to account for all dilution factors to determine the content in the original solid dosage form.

Method Validation

To ensure the sample preparation protocol and analytical method are fit for purpose, key validation parameters should be assessed:

- Accuracy: Determined by performing a spike recovery study, where a known amount of standard is added to the sample, with recovery ideally between 98-102%.

- Precision: Evaluated by repeatability (multiple preparations of the same sample) and intermediate precision (different days, analysts), expressed as % Relative Standard Deviation (%RSD).

- Specificity: The method should be able to unequivocally assess the analyte in the presence of excipients, which is confirmed by the absence of spectral interference from the placebo.

Robust and reproducible sample preparation is the cornerstone of reliable UV-Vis spectroscopic analysis of solid dosage forms. The protocols outlined herein for extraction, filtration, and dilution provide a structured framework for researchers to generate accurate data critical for drug development and quality assurance. Adherence to these procedures, coupled with an understanding of the underlying principles of UV-Vis spectroscopy, ensures the integrity of the analytical results and supports the overall goal of delivering safe and effective pharmaceutical products to patients.

Within the context of sample preparation for UV-Vis analysis in pharmaceutical research, the handling of liquid formulations presents distinct challenges. The accuracy of analytical results is fundamentally dependent on two key factors: appropriate dilution strategies to ensure the analyte concentration falls within the instrument's linear dynamic range, and the mitigation of matrix effects, where other components in the formulation interfere with the analysis of the target compound. This application note provides detailed protocols and considerations for researchers and drug development professionals to navigate these complexities, ensuring reliable and reproducible quantitative results from UV-Vis spectroscopic analysis.

Theoretical Background

Fundamentals of UV-Vis Spectroscopy in Quantitative Analysis

Ultraviolet-visible (UV-vis) spectroscopy is a cornerstone technique for obtaining the absorbance spectra of compounds in solution or as a solid [30]. The fundamental principle involves the absorbance of light energy, which excites electrons from the ground state to the first singlet excited state of the compound. The UV-vis region of the electromagnetic spectrum covers 1.5 - 6.2 eV, corresponding to a wavelength range of 800 - 200 nm [30]. Quantitative analysis is governed by the Beer-Lambert Law (Equation 1), which forms the basis for absorbance spectroscopy.

Equation 1: Beer-Lambert Law [ A = \varepsilon b c ] Where:

- ( A ) is the absorbance (unitless, often arbitrary units)

- ( \varepsilon ) is the molar absorptivity of the compound or molecule in solution (M⁻¹cm⁻¹)

- ( b ) is the path length of the cuvette (cm)

- ( c ) is the concentration of the solution (M) [30]

Understanding Matrix Effects

The "matrix" refers to all components of a sample other than the analyte of interest [34]. In pharmaceutical formulations, this can include excipients, preservatives, stabilizers, and impurities. The matrix effect is the alteration of the analyte signal caused by the presence of these co-eluting or co-absorbing matrix components [34]. In UV-Vis spectroscopy, this typically manifests as signal suppression or enhancement, leading to inaccurate concentration determinations. These effects are particularly problematic in complex biological matrices or in formulations with multiple active and inactive ingredients, where matrix components may have overlapping absorbance bands or scatter light, thereby compromising the accuracy of the analysis [34].

Materials and Methods

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 1: Essential materials and reagents for sample preparation in UV-Vis analysis.

| Item | Function/Brief Explanation |

|---|---|

| Quartz Cuvettes | Sample holder with high transmission of UV and visible light; available in various path lengths (e.g., 1 cm) to adjust effective absorbance [32]. |

| Volumetric Flasks | For accurate preparation and dilution of standard and sample solutions to ensure precise concentration [30]. |

| Digital Pipettes | For accurate and precise transfer of liquid volumes during serial dilution and sample preparation [30]. |

| Appropriate Solvent | High-purity solvent to dissolve the analyte; used to zero the instrument and as a diluent [30] [32]. |

| Filter Membranes | For removing particulate contaminants from solutions before analysis to prevent light scattering [32]. |

| Standard/Calibration Solutions | Known concentrations of the pure analyte for constructing a calibration curve [30]. |

Critical Considerations for Sample Preparation

The physical state of the sample—whether measured as a solution or a solid thin film—profoundly impacts the optical properties and the resulting data [32]. For liquid formulations, solution-based measurement is most common and involves confining the material within a controlled environment of known path length using a standard quartz cuvette [32]. Key considerations include:

- Solvent Choice: The solvent must dissolve the analyte completely and should not absorb significantly at the wavelengths of interest [32].

- Path Length Optimization: Using a cuvette with a smaller path length can be useful if the sample concentration cannot be reduced without altering results, or to minimize the volume of a precious sample [32].

- Concentration Optimization: The sample concentration must be optimized to ensure the absorbance is within the linear range of the detector. An overly concentrated sample will not transmit enough light, while an overly dilute sample will provide a weak signal [32].

Experimental Protocols

Protocol 1: Dilution of Liquid Formulations for UV-Vis Analysis

Objective: To accurately dilute a concentrated liquid pharmaceutical formulation to a concentration suitable for quantitative UV-Vis analysis.

Workflow:

Figure 1: Workflow for sample dilution.

Materials:

- Concentrated liquid formulation

- High-purity solvent (as determined in Section 3.1)

- Volumetric flasks (of appropriate sizes, e.g., 10 mL, 25 mL, 50 mL)

- Digital pipettes and calibrated pipette tips

- Analytical balance

Procedure:

- Solvent Selection: Choose a solvent that completely dissolves the formulation and is transparent in the spectral region to be scanned. A reference measurement should be taken of the cuvette filled with this pure solvent to establish a baseline [32].

- Initial Dilution: Using a digital pipette, transfer an accurately known volume of the concentrated formulation into a volumetric flask. Dilute to the mark with the selected solvent and mix thoroughly to ensure homogeneity [30].

- Concentration Estimation: If the approximate concentration is unknown, perform a preliminary scan of the initial dilution. If the maximum absorbance is significantly above 2, further dilution is required [32].

- Serial Dilution: For high concentrations, perform serial dilutions to achieve the desired concentration. For example, a 1:100 dilution can be accurately achieved with two sequential 1:10 dilutions.

- Filtration: If the solution appears cloudy or contains particulates, filter it using an appropriate syringe filter (e.g., 0.45 µm or 0.2 µm pore size) to prevent light scattering [32].

- Analysis: The diluted sample is now ready for UV-Vis analysis.

Protocol 2: Evaluation and Mitigation of Matrix Effects

Objective: To quantify the matrix effect in a liquid formulation and apply strategies to mitigate its impact on analytical accuracy.

Workflow:

Figure 2: Process for evaluating and mitigating matrix effects.

Materials:

- Pure analyte standard

- Placebo formulation (matrix without active ingredient)

- Solvent

- Volumetric flasks and pipettes

Procedure:

- Preparation of Neat Standard: Prepare a standard solution of the pure analyte dissolved directly in the solvent at a known concentration, ( C ).

- Preparation of Matrix-Matched Standard: Prepare a standard solution at the same concentration, ( C ), by spiking the pure analyte into the placebo formulation. This sample should undergo the same dilution and preparation procedure as the test formulation [35].

- UV-Vis Measurement: Measure the absorbance of both the neat standard and the matrix-matched standard at the analytical wavelength.

- Quantification of Matrix Effect: Calculate the matrix effect (ME) using the formula below. A value of 100% indicates no matrix effect, <100% indicates signal suppression, and >100% indicates signal enhancement. [ ME (\%) = \frac{A{\text{matrix-matched}}}{A{\text{neat}}} \times 100\% ] This formula is adapted from the principles used in mass spectrometry to quantify matrix effects [35].

- Interpretation and Action: A significant matrix effect (e.g., ME <85% or >115%) necessitates mitigation.

Mitigation Strategies:

- Standard Addition: This method involves spiking known amounts of the analyte into separate aliquots of the sample. The calibration curve is generated for each sample, effectively accounting for the matrix-induced signal change [34].

- Matrix-Matched Calibration: Construct the calibration curve using standards prepared in the placebo matrix, which experiences the same matrix effect as the sample [34].

- Sample Dilution: Diluting the sample can reduce the concentration of interfering matrix components below a threshold where they significantly affect the signal. However, this also dilutes the analyte and must be balanced with maintaining adequate detector response [34].