Optimized Liquid-Liquid Extraction Protocol for UFLC-DAD Analysis: A Comprehensive Guide from Method Development to Validation

This article provides a complete framework for developing and optimizing liquid-liquid extraction (LLE) protocols specifically for Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) analysis.

Optimized Liquid-Liquid Extraction Protocol for UFLC-DAD Analysis: A Comprehensive Guide from Method Development to Validation

Abstract

This article provides a complete framework for developing and optimizing liquid-liquid extraction (LLE) protocols specifically for Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) analysis. Tailored for researchers and drug development professionals, it covers fundamental principles of LLE and UFLC-DAD, detailed methodological workflows for various sample matrices, systematic troubleshooting for common issues like emulsion formation and poor recovery, and rigorous method validation according to regulatory standards. By integrating traditional LLE with modern techniques like dispersive liquid-liquid microextraction (DLLME), this guide serves as an essential resource for achieving high-quality, reproducible analytical results in biomedical and pharmaceutical applications.

Understanding LLE and UFLC-DAD: Core Principles for Effective Analysis

The Role of Liquid-Liquid Extraction in Modern Chromatographic Analysis

Liquid-liquid extraction (LLE) remains a cornerstone sample preparation technique in modern analytical laboratories, particularly as a front-end to powerful chromatographic systems like Ultra-Fast Liquid Chromatography (UFLC). This technique leverages the differential solubility of analytes in two immiscible liquids, typically an aqueous phase and a water-immiscible organic solvent, to achieve a clean and effective separation of target compounds from complex matrices [1]. The critical role of LLE is to purify and concentrate analytes, thereby protecting the chromatographic system from matrix effects and enhancing detection sensitivity [2]. In the context of UFLC coupled with photodiode array detection (DAD), effective sample preparation via LLE is indispensable for obtaining reliable, reproducible, and high-quality data, especially in demanding fields such as pharmaceutical analysis, food chemistry, and environmental monitoring [3] [4]. This article details advanced LLE strategies and provides actionable protocols designed to be seamlessly integrated into workflows involving UFLC-DAD analysis.

Fundamental Principles and Modern LLE Strategies

The fundamental mechanism of LLE relies on the partitioning of an analyte between two immiscible liquid phases, a process governed by its partition coefficient (KD) [1]. In practice, the effectiveness of this extraction is measured by the distribution ratio (D), which accounts for the total concentration of all chemical forms of the analyte in each phase. A high distribution ratio indicates a favorable transfer of the analyte into the extracting solvent [1].

The success of an LLE protocol is highly dependent on several key variables. Two of the most important variables influencing analyte recovery from a biological sample matrix are the sample pH and the choice of organic solvent [2]. Adjusting the sample pH can suppress the ionization of acidic or basic analytes, rendering them more lipophilic and enhancing their partitioning into the organic phase. The solvent must be chosen based on its ability to solubilize the target analytes effectively while maintaining immiscibility with the aqueous sample [2].

Modern adaptations of LLE have been developed to address various analytical challenges, as summarized in the table below.

Table 1: Advanced Liquid-Liquid Extraction Techniques and Their Applications

| Technique | Core Principle | Key Advantages | Typical Applications |

|---|---|---|---|

| Salting-Out LLE (SALLE) | Addition of high concentrations of salts (e.g., MgSO₄, NaCl) to a mixture of water and a water-miscible solvent (e.g., acetonitrile) induces phase separation [5]. | - Excellent for highly polar, water-soluble compounds.- Uses MS-friendly solvents.- High recovery rates for a broad range of analytes [5]. | Extraction of polar drugs from plasma; multiresidue pesticide analysis in food samples [5]. |

| Dispersive Liquid-Liquid Microextraction (DLLME) | A water-immiscible extraction solvent is dispersed in the aqueous sample via a disperser solvent, forming a cloudy suspension of microdroplets to maximize extraction surface area [6]. | - Minimal solvent consumption (µL volumes).- Rapid extraction kinetics.- High enrichment factors [6]. | Pre-concentration of organic pollutants, pesticides, and pharmaceuticals from water samples [6]. |

| Low-Temperature Partitioning (LTP) | A water-miscible solvent is used for extraction, and phase separation is induced by freezing the aqueous phase at low temperatures [7]. | - Simplicity and effectiveness.- Serves as a purification step by freezing out matrix components.- Avoids emulsion formation [7]. | Analysis of pesticides in fruits, vegetables, and analysis of drugs in biological fluids [7]. |

Detailed Experimental Protocols

Protocol 1: Conventional LLE for Bioanalytical UFLC-DAD

This protocol is adapted from the sample preparation for the simultaneous quantification of antiepileptic drugs in human plasma, demonstrating a robust approach for complex biological matrices [2].

1. Reagent and Solution Preparation:

- Aqueous Phase: Adjust the pH of the plasma or buffer solution using acids (e.g., ortho-phosphoric acid) or bases to a value that ensures the analytes are in their neutral form. This is a critical optimization step [2].

- Organic Solvent: Select a suitable water-immiscible solvent such as ethyl acetate or dichloromethane.

- Internal Standard Solution: Prepare a solution of a suitable internal standard (e.g., entacapone) in the organic solvent or a miscible solvent like methanol [2].

2. Extraction Procedure: a. Pipette 200 µL of plasma sample into a microcentrifuge tube. b. Add 50 µL of internal standard solution and vortex mix for 30 seconds. c. Add 500 µL of the selected organic solvent. d. Vortex mix vigorously for 3 minutes to ensure complete partitioning. e. Centrifuge the mixture at 10,000 × g for 5 minutes to achieve clean phase separation. f. Carefully transfer the upper (organic) layer to a new clean tube. g. Evaporate the organic extract to dryness under a gentle stream of nitrogen gas in a water bath at 40°C. h. Reconstitute the dry residue with 100 µL of the UFLC mobile phase initial conditions, vortex for 1 minute, and transfer to an autosampler vial for analysis [2].

3. UFLC-DAD Analysis:

- Column: Reversed-phase C18 column (e.g., 150 mm × 4.6 mm, 5 µm).

- Temperature: 40°C.

- Mobile Phase: Gradient elution with 0.1% ortho-phosphoric acid (pH 2.79) and acetonitrile.

- Flow Rate: 1.0 mL/min.

- Detection: Monitor analytes at their specific λmax (e.g., 320 nm for perampanel, 306 nm for lamotrigine) [2].

Protocol 2: SALLE for Pharmaceutical Analysis

This protocol, suitable for high-throughput analysis in 96-well plates, outlines the extraction of drugs from plasma using acetonitrile and a salting-out agent [5].

1. Reagent Preparation:

- Salting-Out Agent: Prepare a 2 M solution of magnesium sulfate (MgSO₄) or use saturated sodium chloride (NaCl).

- Extraction Solvent: HPLC-grade acetonitrile.

- Calibration Standards: Prepare in blank (drug-free) plasma.

2. Extraction Procedure: a. Transfer 100 µL of plasma (calibrator, quality control, or unknown) to a well of a 96-well plate. b. Add 200 µL of acetonitrile to the well to precipitate proteins. c. Add 50 µL of the 2 M MgSO₄ solution to induce phase separation. d. Seal the plate and mix thoroughly by shaking for 5 minutes. e. Centrifuge the plate at 3,000 × g for 10 minutes to complete phase separation. The acetonitrile layer will form the upper phase. f. Directly inject an aliquot of the upper organic layer into the UFLC-DAD system [5].

Protocol 3: LLE for Carbonyl Compounds in Food Matrices

This method details the extraction of toxic carbonyl compounds (CCs) from heated soybean oil, requiring a derivatization step for analysis [3] [8].

1. Derivatization and Extraction:

- Derivatization Reagent: 2,4-dinitrophenylhydrazine (2,4-DNPH). This reagent reacts with aldehydes and ketones to form stable hydrazones which are easily detectable by UV-Vis and MS [3].

- Extraction Solvent: Acetonitrile was found to be optimal [3].

2. Procedure: a. Weigh approximately 1 g of oil sample into a glass vial. b. Add 1.5 mL of acetonitrile and 0.5 mL of the 2,4-DNPH solution. c. Manually stir the mixture for 3 minutes to ensure thorough contact. d. Sonicate the mixture for 30 minutes to complete the reaction and extraction. e. Centrifuge the mixture, and filter the supernatant through a 0.20 µm membrane before UFLC injection [3].

3. UFLC-DAD-ESI-MS Analysis:

- The hydrazone derivatives are separated using a C18 column with a gradient of water and acetonitrile.

- DAD detection is typically performed at 300-400 nm.

- MS detection is used for confirmation and identification of unknown CCs [3].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for LLE Protocols in UFLC-DAD Analysis

| Reagent/Material | Function/Purpose | Application Example |

|---|---|---|

| Acetonitrile | Polar aprotic solvent; used for protein precipitation, as an extraction solvent in SALLE, and for extracting polar compounds [3] [5]. | SALLE of drugs from plasma [5]; Extraction of carbonyls from oil [3]. |

| Ethyl Acetate | Medium-polarity organic solvent; effective for extracting a wide range of medium-polarity organic compounds. | LLE of pharmaceuticals from biological fluids [2]. |

| Magnesium Sulfate (MgSO₄) | Salting-out agent; dissolves in water, reducing the solubility of organic molecules and water-miscible solvents, thereby inducing phase separation [5]. | QuEChERS and SALLE methods for pesticides and drugs [5]. |

| 2,4-Dinitrophenylhydrazine (2,4-DNPH) | Derivatizing agent; reacts with carbonyl functional groups (aldehydes, ketones) to form colored hydrazone derivatives with strong UV absorption [3]. | Analysis of aldehydes (e.g., acrolein, 4-HNE) in oxidized oils [3] [8]. |

| Ortho-Phosphoric Acid | Mobile phase additive; provides low pH to suppress silanol activity in reversed-phase chromatography and to control ionization of acidic/basic analytes [2]. | Mobile phase for separation of antiepileptic drugs [2]. |

| C18 Reversed-Phase Column | Stationary phase; separates analytes based on hydrophobicity, the most common mode for UFLC analysis of organic molecules. | Separation of flavonoids, pharmaceuticals, and carbonyl derivative [2] [9]. |

Workflow Visualization and Data Analysis

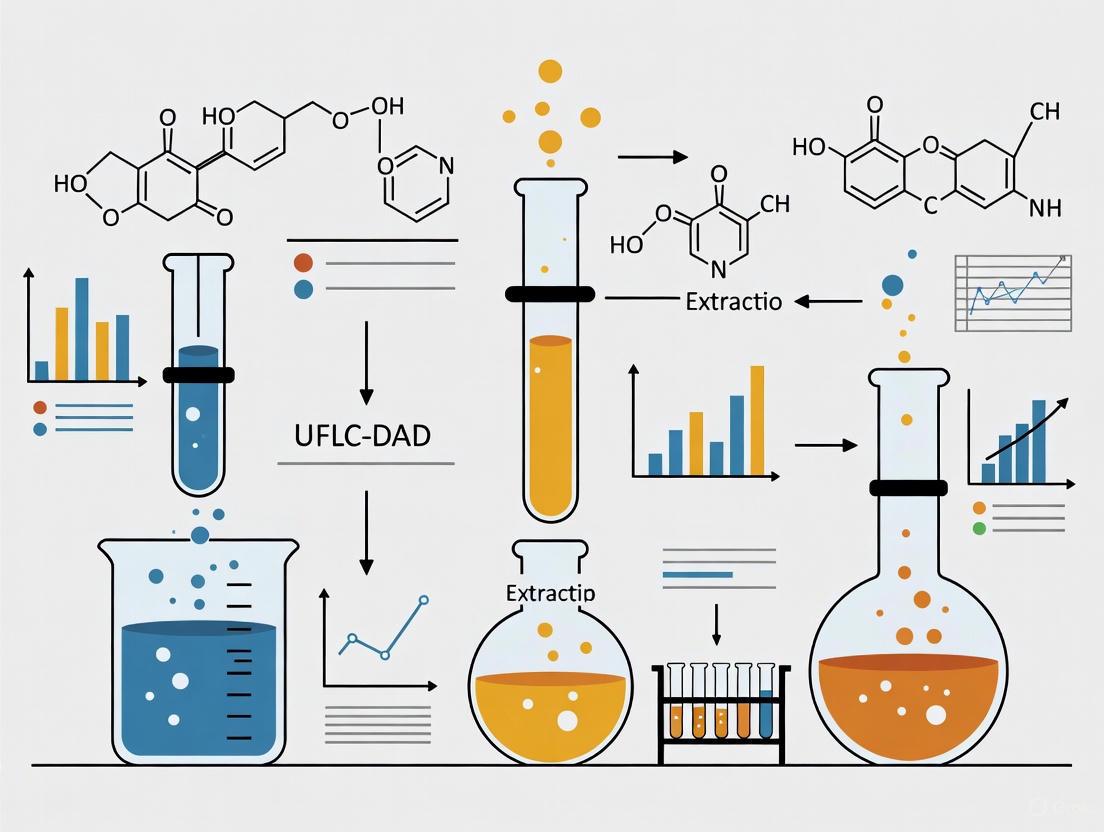

The following diagram illustrates the logical decision-making process for selecting and applying the appropriate LLE technique based on the nature of the sample and analytes.

Quantitative Method Performance and Validation

The performance of LLE methods coupled with UFLC-DAD is rigorously validated by key parameters. The following table compiles representative quantitative data from published applications, demonstrating the effectiveness of these techniques.

Table 3: Quantitative Performance of LLE-UFLC-DAD Methods from Literature

| Analytes / Application | LLE Technique | Linear Range (µg/mL) | Recovery (%) | Limit of Detection (LOD) | Reference |

|---|---|---|---|---|---|

| Perampanel & Lamotrigine (Human Plasma) | Conventional LLE | Perampanel: 0.03-4.5Lamotrigine: 0.25-30 | > 89% | Not Specified | [2] |

| Carbonyl Compounds (Soybean Oil) | LLE with Derivatization | 0.2 - 10.0 | 70.7 - 85.0 (at LLOQ) | 0.03 - 0.1 µg/mL | [3] [8] |

| Metoprolol Tartrate (Tablets) | Not Specified (Direct UFLC analysis) | 2 - 14 µg/mL | 98.0 - 102.0% | 0.27 µg/mL | [4] |

The validation of these methods ensures they are fit for purpose. For instance, the method for carbonyl compounds was shown to be precise and accurate, with detection limits low enough to monitor the formation of toxic compounds like acrolein and 4-hydroxy-2-nonenal in thermally stressed oils [3] [8]. Similarly, the LLE method for antiepileptic drugs demonstrated high recovery and a wide linear range, making it suitable for therapeutic drug monitoring [2].

Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) represents a significant advancement in analytical instrumentation that addresses the growing demand for high-throughput analysis without compromising resolution or data integrity. This technology has become indispensable in modern pharmaceutical analysis, particularly in complex research applications such as the analysis of botanical extracts and their metabolites. The core strength of UFLC-DAD lies in its ability to perform rapid separations while simultaneously acquiring comprehensive spectral data for each analyte, enabling both quantification and confirmation in a single analytical run.

The fundamental advantage of UFLC-DAD systems over conventional HPLC stems from their ability to operate at significantly higher pressures (typically up to 6000 psi or greater) while utilizing stationary phases with smaller particle sizes (sub-2μm). This combination facilitates superior chromatographic efficiency and dramatically reduced analysis times. When coupled with the rich three-dimensional data (time-absorption-wavelength) provided by the DAD detector, researchers obtain a powerful analytical tool for method development and validation in complex matrices. The application of this technology is particularly valuable in pharmaceutical research, where it has been successfully employed to identify and quantify numerous compounds in biological samples, as demonstrated in studies analyzing Scutellaria baicalensis (Chinese skullcap) extracts in rat models, where researchers identified 36 different flavonoid compounds and 13 novel metabolites across bile, plasma, and urine matrices [10].

Core Technological Principles

Ultra-Fast Separation Mechanisms

The remarkable speed of UFLC systems originates from fundamental improvements in chromatographic hardware and chemistry. The velocity of separations is primarily achieved through the use of columns packed with smaller porous particles (typically 1.8-2.2μm), which dramatically reduce diffusion paths and resistance to mass transfer. According to the Van Deemter equation, which describes the relationship between linear velocity and plate height, these smaller particles maintain efficiency even at elevated flow rates, allowing for faster separations without significant loss of resolution. The reduced particle size, however, necessitates higher operating pressures to maintain optimal flow rates, requiring specialized pumps and fluidics capable of sustaining pressures up to 6000-10000 psi.

The hydraulic systems in UFLC instruments are engineered for minimal delay volume and rapid mixing, enabling the use of steeper gradient slopes and faster column re-equilibration. Modern UFLC systems typically exhibit delay volumes of 100-200μL, compared to 500-1000μL in conventional HPLC systems. This reduction in delay volume, combined with improved gradient formation technology, allows for gradient cycle times that are 3-5 times faster than conventional systems while maintaining reproducibility. The kinetic performance gains are most evident in the analysis of complex samples, such as in the characterization of Huanglian Jiedu Decoction, where 17 major chemical components were successfully separated and identified using UFLC-DAD-ESI-MS/MS methodologies [10].

Enhanced Resolution Characteristics

Chromatographic resolution (Rs) in UFLC systems demonstrates significant improvement over conventional HPLC due to increased efficiency (theoretical plates, N) and enhanced selectivity (α). The relationship is defined by the resolution equation: Rs = (√N/4) × (α-1) × (k/(1+k)), where k is the retention factor. The sub-2μm particles used in UFLC typically generate 50-70% more theoretical plates per unit time compared to 3-5μm particles used in conventional HPLC. This enhanced efficiency manifests as sharper peaks with reduced peak broadening, leading to improved sensitivity and better separation of closely eluting compounds.

The diode array detector contributes significantly to effective resolution through its spectral discrimination capabilities. Even when chromatographic peaks are not fully separated, the DAD can mathematically resolve co-eluting compounds by identifying wavelength ratios or through spectral deconvolution algorithms. This orthogonal approach to resolution is particularly valuable in complex natural product analyses, such as the metabolic study of naringin following human intestinal bacteria incubation, where multiple metabolites including naringenin, phloretin, and phloroglucinol were identified despite their structural similarities [10]. The DAD achieves this spectral resolution through simultaneous monitoring of multiple wavelengths (typically 190-800nm) with high wavelength accuracy (<1nm) and photometric linearity across a wide concentration range.

Spectral Confirmation Capabilities

The diode array detector provides critical compound identification power through its ability to capture full UV-Vis spectra for each chromatographic peak. This capability transforms the detector from a simple quantification device into a powerful confirmation tool. Unlike single-wavelength or variable wavelength detectors that capture data at only one or a few wavelengths, the DAD simultaneously monitors the entire spectral range throughout the chromatographic run, creating a three-dimensional data array (time-absorbance-wavelength) that contains rich chemical information.

Spectral confirmation occurs through several mechanisms, including spectral matching, peak purity assessment, and spectral contrast techniques. Library matching algorithms compare the spectrum of an unknown peak against a database of reference spectra, generating match factors that help confirm identity. Peak purity algorithms evaluate whether a chromatographic peak represents a single compound or contains co-eluting impurities by comparing spectra across different regions of the peak. In pharmaceutical impurity profiling, these capabilities are particularly valuable for detecting and identifying low-level impurities and degradation products, which is essential for comprehensive impurity assessment as outlined in recent reviews of chemical drug impurity control [11]. The application of these spectral confirmation techniques was demonstrated in the analysis of naringin metabolites, where the DAD helped confirm the identity of specific acetylated derivatives through their characteristic spectral signatures [10].

Integration with Liquid-Liquid Extraction

LLE Protocol for Complex Matrices

Liquid-liquid extraction (LLE) serves as a crucial sample preparation technique for UFLC-DAD analysis, particularly when dealing with complex biological matrices that contain numerous interfering compounds. The following optimized protocol has been specifically developed for the extraction of flavonoid compounds from biological samples prior to UFLC-DAD analysis, based on methodologies successfully applied in pharmaceutical research [10]:

Sample Preparation: Transfer 1.0 mL of biological sample (plasma, urine, or bile) to a 15 mL glass centrifuge tube. For tissue homogenates, use 500 mg tissue homogenized in 2 mL phosphate buffer (pH 7.4).

Protein Precipitation: Add 3 volumes (3 mL) of ice-cold acetonitrile to the sample. Vortex vigorously for 60 seconds, then centrifuge at 4,500 × g for 10 minutes at 4°C. Carefully transfer the supernatant to a new glass tube.

Extraction Procedure: Add 5 mL of ethyl acetate-diethyl ether mixture (4:1, v/v) to the supernatant. Vortex for 2 minutes, then shake mechanically for 15 minutes. Centrifuge at 3,000 × g for 10 minutes to achieve complete phase separation.

Back-Extraction (Optional): For improved selectivity, perform back-extraction of the organic layer with 2 mL of 0.1 M sodium phosphate buffer (pH 6.0) to remove acidic interferents.

Concentration and Reconstitution: Transfer the organic layer to a clean evaporation tube and evaporate to dryness under a gentle nitrogen stream at 40°C. Reconstitute the residue in 200 μL of initial mobile phase (typically 10% methanol in water). Vortex for 60 seconds and centrifuge at 14,000 × g for 5 minutes before transferring to UFLC vials.

This LLE protocol effectively removes proteins and phospholipids while maintaining high recovery (>85%) for most flavonoid compounds. The sample preparation workflow is visualized in the following diagram:

Figure 1: LLE Workflow for UFLC-DAD Sample Preparation

Method Validation and Quality Control

To ensure reliable integration with UFLC-DAD analysis, the LLE methodology requires comprehensive validation following established pharmaceutical guidelines. Critical validation parameters include:

Extraction Efficiency: Assessed by comparing peak areas of extracted samples against unextracted standards at three concentration levels (low, medium, high). Acceptable recovery should be 85-115% with RSD < 15% for most compounds.

Matrix Effects: Evaluated using the post-extraction spiking technique, calculating the matrix factor (MF) as the peak area ratio of an analyte in matrix versus neat solution. Signal suppression/enhancement should be less than 20%.

Processed Sample Stability: Determined by re-analyzing extracted samples after storage in the autosampler (typically 4°C for 24-48 hours). The deviation from initial analysis should be within ±15%.

Quality control samples prepared at low, medium, and high concentrations should be included in each analytical batch to monitor ongoing performance. For the analysis of complex botanical extracts like Scutellaria baicalensis, additional validation should include metabolite stability assessment under extraction conditions, as some flavonoid metabolites may be susceptible to degradation during sample preparation [10].

Quantitative Performance Data

System Performance Specifications

UFLC-DAD systems demonstrate distinct advantages across multiple performance parameters compared to conventional HPLC, particularly when applied to pharmaceutical analysis. The quantitative performance characteristics are summarized in Table 1, with data compiled from applications in pharmaceutical research including metabolite identification and impurity profiling [10] [11].

Table 1: Comparative Performance Metrics of UFLC-DAD vs. Conventional HPLC

| Performance Parameter | UFLC-DAD System | Conventional HPLC-DAD | Measurement Conditions |

|---|---|---|---|

| Analysis Speed | 3-5x faster | Baseline | Gradient separation of 10 compounds |

| Theoretical Plates | >20,000 per column | 10,000-15,000 per column | 150mm column length, isocratic conditions |

| Peak Capacity | 1.8-2.2x higher | Baseline | 10-minute gradient, 150mm column |

| Pressure Capability | Up to 6,000 psi (415 bar) | 2,900-4,000 psi (200-275 bar) | Maximum system pressure |

| Detection Sensitivity | 2-3x improvement | Baseline | Signal-to-noise ratio for low-abundance compounds |

| Spectral Acquisition Rate | Up to 100 Hz | 10-20 Hz | Full spectrum acquisition |

| Wavelength Accuracy | ±1 nm | ±1-2 nm | Across 190-800 nm range |

| Carryover | <0.05% | 0.1-0.2% | Between consecutive injections |

| Mobile Phase Consumption | 40-60% reduction | Baseline | Per analysis |

The sensitivity improvements are particularly valuable in pharmaceutical applications such as the detection of low-abundance metabolites in biological samples. In the study of Scutellaria baicalensis metabolism, the UFLC-DAD system enabled detection of 15 flavonoid compounds in plasma samples, demonstrating the technique's capability for comprehensive metabolite profiling [10].

Analytical Figures of Merit

The quantitative performance of UFLC-DAD methods for pharmaceutical analysis has been rigorously characterized through validation studies. Table 2 summarizes key figures of merit for representative applications, demonstrating the capability to meet stringent pharmaceutical method requirements.

Table 2: Quantitative Performance for Pharmaceutical Compounds

| Analyte Class | Linear Range (μg/mL) | Correlation Coefficient (R²) | LOD (ng/mL) | LOQ (ng/mL) | Precision (RSD%) | Application Reference |

|---|---|---|---|---|---|---|

| Flavonoid Glycosides | 0.05-50 | 0.9994-0.9999 | 0.1-0.5 | 0.5-1.5 | 1.26-4.77 | Scutellaria analysis [10] |

| Terpene Lactones | 0.01-20 | >0.9990 | 0.05-0.2 | 0.2-0.5 | <5.0 | Botanical extracts |

| Alkaloids | 0.02-100 | >0.9995 | 0.2-1.0 | 0.5-3.0 | 1.5-6.0 | Pharmaceutical formulations |

| Phenolic Acids | 0.1-200 | >0.998 | 0.5-2.0 | 1.5-5.0 | 2.0-8.0 | Herbal medicine profiling |

| Pharmaceutical Impurities | 0.001-1.0 | >0.995 | 0.01-0.05 | 0.03-0.15 | <10.0 | Impurity profiling [11] |

The exceptional linearity and sensitivity demonstrated in these applications highlight why UFLC-DAD has become the technique of choice for quantitative analysis of complex pharmaceutical samples. The method validation for Huanglian Jiedu Decoction analysis demonstrated excellent linearity (R² values of 0.9994-0.9999) across the calibrated range, with precision RSD values of 1.66%-3.67% for repeatability and 1.26%-4.77% for stability [10].

Application Protocols

Method Development Protocol

Developing a robust UFLC-DAD method for pharmaceutical analysis requires systematic optimization of multiple parameters. The following protocol outlines a comprehensive approach for method development:

Sample Preparation Optimization

- LLE Solvent Selection: Test different solvent combinations (ethyl acetate, methyl tert-butyl ether, dichloromethane) with varying polarities to maximize recovery of target analytes.

- pH Adjustment: Adjust sample pH to 2.0, 7.0, and 9.0 using appropriate buffers to evaluate recovery dependence on ionization state.

- Extraction Efficiency: Perform triplicate extractions at low, medium, and high concentrations to determine optimal extraction conditions.

Chromatographic Screening

- Column Selection: Evaluate 3-5 different stationary phases (C18, phenyl-hexyl, polar-embedded C18) with identical dimensions (100mm × 2.1mm, 1.8-2.2μm).

- Mobile Phase Optimization: Test acetonitrile and methanol with different modifiers (formic acid, ammonium formate, ammonium acetate) at concentrations of 0.05-0.2%.

- Gradient Screening: Perform rapid scouting gradients from 5-95% organic phase in 10 minutes to determine optimal starting conditions.

DAD Parameter Configuration

- Spectral Acquisition: Set acquisition range from 200-400nm for most pharmaceutical compounds, extending to 600nm for colored compounds.

- Resolution and Sampling Rate: Configure spectral acquisition rate of 20-40 Hz with 1-2nm spectral resolution for optimal peak characterization.

- Monitoring Wavelengths: Select primary quantification wavelength based on maximum absorbance, with secondary wavelengths for peak purity assessment.

Method Fine-Tuning and Validation

- Gradient Optimization: Adjust gradient slope, shape, and initial/final conditions to achieve critical separation of co-eluting peaks.

- Temperature Optimization: Evaluate separation at 30, 40, and 50°C to assess temperature effects on resolution and backpressure.

- Comprehensive Validation: Validate final method according to ICH guidelines for specificity, linearity, accuracy, precision, and robustness.

This systematic approach to method development was employed in the optimization of analytical methods for complex matrices such as Huanglian Jiedu Decoction, where 17 major chemical components were successfully separated and quantified [10].

System Suitability Testing Protocol

To ensure consistent performance of the UFLC-DAD system for pharmaceutical applications, implement the following system suitability testing protocol before each analytical batch:

Preparation of System Suitability Solution

- Prepare a reference standard containing at least 3 representative analytes covering the polarity range of samples.

- Include one early-eluting, one mid-eluting, and one late-eluting compound to assess overall chromatographic performance.

- Prepare at a concentration that gives 50-75% of the detector's full-scale response at the primary wavelength.

Chromatographic Performance Assessment

- Theoretical Plates (N): Inject system suitability solution and calculate plates for mid-eluting peak: N > 15,000 for 100mm column.

- Tailing Factor (T): Measure for all peaks in suitability solution: T ≤ 1.5 for symmetrical peaks.

- Retention Time Stability: Three consecutive injections should have RSD of retention time ≤ 0.5%.

- Resolution (Rs): Between two closely eluting peaks in suitability solution: Rs ≥ 2.0.

DAD Performance Verification

- Wavelength Accuracy: Verify using holmium oxide or caffeine reference standards: ±1 nm across UV range.

- Photometric Linearity: Five-point calibration from 5-95% of detector saturation: R² ≥ 0.999.

- Spectral Reproducibility: Compare spectra for reference standard across multiple injections: match factor ≥ 995.

Carryover Assessment

- Inject blank solvent following the highest calibration standard: response in blank ≤ 0.2% of highest standard.

This comprehensive suitability testing ensures the UFLC-DAD system performs within specified parameters, which is particularly critical for pharmaceutical applications requiring high data integrity, such as impurity profiling studies that form the foundation of chemical drug safety assessment [11].

Essential Research Reagent Solutions

The successful implementation of UFLC-DAD methods relies on carefully selected reagents and materials that ensure optimal performance and reproducibility. The following table details essential research reagent solutions for pharmaceutical applications integrated with liquid-liquid extraction.

Table 3: Essential Research Reagents for UFLC-DAD Analysis

| Reagent/Material | Specification | Function in Analysis | Application Notes |

|---|---|---|---|

| Acetonitrile (HPLC Grade) | ≥99.9% purity, UV transparent | Primary organic mobile phase component | Low UV cutoff (190-195nm), suitable for low-wavelength detection |

| Methanol (HPLC Grade) | ≥99.9% purity, low carbonyl content | Alternative organic modifier | Higher elution strength for polar compounds, higher UV cutoff (205nm) |

| Water (HPLC Grade) | 18.2 MΩ·cm resistivity, TOC < 5 ppb | Aqueous mobile phase component | Prevents baseline noise and ghost peaks in gradient elution |

| Formic Acid (LC-MS Grade) | ≥99.5% purity, low non-volatile residue | Mobile phase additive for acidic compounds | Enhances ionization in MS-compatible methods, typically 0.05-0.1% |

| Ammonium Acetate (HPLC Grade) | ≥99.0% purity, low UV absorbance | Buffer for pH control in mobile phase | Volatile salt compatible with MS detection, typically 2-10 mM |

| Ethyl Acetate (HPLC Grade) | ≥99.8% purity, low acidic content | Extraction solvent for LLE | Medium polarity solvent for medium-polarity analytes |

| Diethyl Ether (Anhydrous) | ≥99.8% purity, stabilized with BHT | Co-solvent in LLE mixtures | Enhances extraction efficiency for non-polar compounds |

| Phosphate Buffer Salts | ACS reagent grade, low heavy metal content | Biological sample preservation | Maintains pH during extraction, prevents analyte degradation |

The selection of appropriate reagents is critical for maintaining robust system performance, particularly when analyzing complex samples such as herbal medicine extracts where multiple compound classes with varying polarities must be addressed simultaneously [10]. The purity specifications directly impact baseline noise, detection limits, and method reproducibility.

Advanced Applications and Workflows

Impurity Profiling in Pharmaceutical Development

UFLC-DAD has become an indispensable tool for comprehensive impurity profiling in pharmaceutical development, addressing the increasingly stringent requirements for chemical drug quality control. The technology enables simultaneous detection, identification, and quantification of process-related impurities and degradation products at levels as low as 0.03-0.05% of the active pharmaceutical ingredient. The workflow for impurity profiling integrates forced degradation studies with systematic method development to ensure adequate separation of all potential impurities.

The critical role of impurity profiling in pharmaceutical quality control has been extensively documented, with recent reviews highlighting the formation of a mature control procedure for impurity profiles in drugs in China after nearly ten years of continuous development [11]. The impurity assessment process follows a logical decision pathway, as illustrated below:

Figure 2: Impurity Assessment Decision Pathway

Metabolite Identification in Biological Samples

The combination of UFLC separation efficiency with DAD spectral confirmation provides a powerful platform for metabolite identification in complex biological matrices. This application is particularly valuable in pharmaceutical development for understanding drug metabolism and identifying active metabolites. The workflow typically involves:

Sample Collection and Preparation: Biological samples (plasma, urine, bile) are collected at multiple time points following drug administration and processed using optimized LLE protocols.

Chromatographic Separation: UFLC conditions are optimized to separate parent compound and potential metabolites, typically using gradient elution with 0.1% formic acid in water and acetonitrile.

Spectral Analysis: DAD captures full UV-Vis spectra for each chromatographic peak, enabling preliminary identification based on spectral characteristics and shifts compared to parent compound.

Data Interpretation: Metabolites are identified based on retention time shifts, spectral profile changes, and comparison with synthetic standards when available.

This approach was successfully applied in the study of Scutellaria baicalensis metabolism in rats, where 36 different flavonoid compounds were identified, including 13 novel metabolites, with the UFLC-DAD system enabling characterization of metabolic pathways including glucuronidation, sulfation, and methylation [10]. The comprehensive metabolite identification workflow demonstrates how UFLC-DAD serves as an essential tool in modern pharmaceutical research, particularly when studying the complex metabolism of natural products and their potential therapeutic applications.

Liquid-liquid extraction (LLE) serves as a critical sample preparation step prior to Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) analysis. The efficiency of this extraction directly impacts the sensitivity, accuracy, and reliability of the subsequent chromatographic results. Selecting an appropriate extraction solvent requires careful consideration of a triad of interconnected properties: polarity, density, and compatibility with the analytical system. For ionogenic analytes, this selection process becomes more complex, as the pH of the aqueous phase must be controlled to ensure the analyte exists in its neutral form for optimal partitioning into the organic phase [12] [13]. The fundamental goal is to maximize the recovery of target analytes while minimizing the co-extraction of matrix interferences, thereby ensuring the quality of the UFLC-DAD data.

This application note provides a structured framework for selecting and optimizing extraction solvents, with a specific focus on protocols compatible with UFLC-DAD analysis. We summarize key solvent properties in tabular format, detail validated experimental methodologies, and visualize the decision-making workflow to support researchers in developing robust and efficient sample preparation procedures.

Fundamental Principles and Solvent Properties

The Role of Polarity, Density, and System Compatibility

The success of an LLE protocol hinges on understanding the physicochemical properties of both the target analytes and the potential extraction solvents.

- Parity and LogP/D: The partition coefficient (LogP/D) is a crucial predictor of an analyte's distribution between two immiscible phases. A highly positive LogP value indicates a strong preference for the organic phase, while a negative value suggests the analyte will remain in the aqueous phase. The polarity of the extraction solvent should be matched to the polarity of the analyte for maximum recovery. For more polar analytes (lower LogP), a more polar organic solvent is required [12].

- Density: The density of the extraction solvent relative to water determines the physical handling of the LLE procedure. Solvents denser than water (e.g., chloroform, dichloromethane) will form the lower layer, while those lighter than water (e.g., hexane, ethyl acetate, methyl tert-butyl ether [MTBE]) will form the upper layer. This dictates how the phases are separated after extraction [14] [13].

- Compatibility with UFLC-DAD: The chosen solvent must be volatile for easy concentration prior to injection and should not introduce interfering compounds that could generate background noise in the DAD. Strongly UV-absorbing solvents are typically unsuitable. Furthermore, the solvent must be miscible with the initial mobile phase of the chromatographic method to avoid peak distortion [13].

Solvent Property Comparison Table

The following table summarizes the key characteristics of common solvents used in LLE protocols.

Table 1: Properties of Common Liquid-Liquid Extraction Solvents [14] [12] [13]

| Solvent | Polarity Index (P') | Density (g/mL) | Water Solubility | UV Cutoff (nm) | Key Considerations |

|---|---|---|---|---|---|

| n-Hexane | 0.1 | ~0.66 (Lighter) | Very Low | 210 | Excellent for non-polar lipids; highly non-specific. |

| Toluene | 2.4 | ~0.87 (Lighter) | Very Low | 285 | Suitable for aromatics; higher UV cutoff. |

| Methyl tert-butyl ether (MTBE) | 2.5 | ~0.74 (Lighter) | Moderate (~4%) | 210 | Good for medium-polarity analytes; alternative to chloroform. |

| Ethyl Acetate | 4.4 | ~0.90 (Lighter) | ~8% | 260 | Good for a wide polarity range; higher water solubility. |

| Chloroform | 4.1 | ~1.49 (Heavier) | Slightly Soluble | 245 | Traditional for lipids; toxic, forms emulsions. |

| Dichloromethane (DCM) | 3.1 | ~1.33 (Heavier) | Slightly Soluble | 245 | Versatile; denser than water; common health hazard. |

The Scientist's Toolkit: Essential Reagents for LLE Optimization

Table 2: Key Research Reagent Solutions for LLE Protocol Development

| Reagent / Solution | Function in LLE Protocol |

|---|---|

| Ammonium Metavanadate | Derivatization agent for analyzing oxidizing compounds like hydrogen peroxide via UFLC-DAD by forming a detectable complex [15]. |

| 2,4-Dinitrophenylhydrazine (2,4-DNPH) | Derivatization reagent for carbonyl compounds (aldehydes, ketones); forms stable hydrazones for sensitive DAD or MS detection [3]. |

| Acetic Acid / Formic Acid | Acid modifiers used to adjust the pH of the mobile phase or aqueous sample to suppress ionization of acidic/basic analytes, improving peak shape and extraction efficiency [16]. |

| Sodium Sulfate | Inert salt used for "salting out"—increasing the ionic strength of the aqueous phase to decrease analyte solubility and drive partitioning into the organic phase [12]. |

| Ion-Pairing Reagents | Added to the extraction solvent or mobile phase to form neutral complexes with ionic analytes, enabling their extraction into organic solvents [13]. |

Experimental Protocols

Protocol 1: Standard Liquid-Liquid Extraction for UFLC-DAD

This protocol is adapted from methods used for the extraction of drugs and lipids from aqueous matrices [14] [13].

Materials:

- Aqueous sample (e.g., biofluid, extract)

- Organic extraction solvent (e.g., MTBE, Ethyl Acetate, DCM)

- Equipment: Centrifuge tubes, micropipettes, vortex mixer, centrifuge, evaporator (e.g., nitrogen blow-down system)

Procedure:

- Sample Preparation: Transfer a measured volume of the aqueous sample (e.g., 1 mL) into a suitable centrifuge tube.

- pH Adjustment: For ionizable analytes, adjust the pH of the aqueous sample. For basic analytes, set the pH to at least 2 units above the pKa. For acidic analytes, set the pH to at least 2 units below the pKa [12]. Use appropriate buffers for control.

- Solvent Addition: Add a volume of organic extraction solvent. A generic optimum organic-to-aqueous phase ratio to begin optimization is 7:1 [12].

- Extraction: Securely cap the tube and mix vigorously for 1-5 minutes using a vortex mixer to ensure complete contact between the two phases.

- Phase Separation: Centrifuge the mixture at a relative centrifugal force (RCF) of 2000-3000 x g for 5-10 minutes to achieve clean phase separation.

- Solvent Recovery: Carefully collect the organic phase. If the solvent is lighter than water, collect from the top. If denser, collect from the bottom using a micropipette or by draining.

- Concentration (if needed): Gently evaporate the organic extract to dryness under a stream of nitrogen or in a vacuum concentrator.

- Reconstitution: Reconstitute the dry residue in a solvent that is compatible with the initial UFLC-DAD mobile phase (e.g., methanol, acetonitrile, or a mixture with aqueous buffer).

- Analysis: Inject the reconstituted sample into the UFLC-DAD system.

Protocol 2: Dispersive Liquid-Liquid Microextraction (DLLME)

DLLME is a miniaturized, efficient technique ideal for sample-limited situations or for achieving high pre-concentration factors, as demonstrated in pesticide and carbonyl compound analysis [3] [17].

Materials:

- Aqueous sample

- Extraction solvent (high-density, water-immiscible, e.g., chlorobenzene, carbon tetrachloride)

- Disperser solvent (water-miscible, e.g., acetone, acetonitrile, methanol)

- Equipment: Conical-bottom centrifuge tubes, syringes, centrifuge

Procedure:

- Solution Preparation: In a syringe, rapidly draw a mixture containing the disperser solvent (e.g., 1 mL of acetone) and the extraction solvent (e.g., 50 µL of chlorobenzene).

- Injection: Quickly inject this mixture into a centrifuge tube containing the aqueous sample (e.g., 5 mL). A cloudy solution will form, consisting of fine droplets of the extraction solvent dispersed throughout the aqueous phase, providing a large surface area for rapid extraction.

- Centrifugation: Centrifuge the tube for a short period (e.g., 2-5 minutes at high speed) to sediment the dense extraction solvent droplets at the bottom of the conical tube.

- Analysis: The sedimented phase can be directly injected or diluted with a compatible solvent for UFLC-DAD analysis.

Workflow and Decision Pathways

The following diagram illustrates the logical decision process for selecting an appropriate extraction solvent and technique.

Diagram 1: Solvent Selection and LLE Workflow

Advanced Optimization and Troubleshooting

Employing Experimental Design (DoE) for Method Optimization

For robust method development, a one-factor-at-a-time (OFAT) approach can be inefficient. Utilizing a Design of Experiments (DoE) approach allows for the simultaneous evaluation of multiple factors and their interactions, making the optimization process faster and more systematic [16]. Critical factors to investigate in a factorial design for LLE include:

- Extraction solvent type and volume

- pH of the aqueous phase

- Ionic strength (concentration of salting-out agent)

- Extraction time (mixing duration)

Troubleshooting Common LLE Challenges

- Low Recovery: Confirm the pH is correctly set for ionizable analytes. Increase the extraction time or vigor. Consider a solvent with more matched polarity, or use a mixed solvent system. Implement multiple extractions with fresh solvent.

- Emulsion Formation: This is a common issue with complex matrices. Remedies include centrifugation at higher speed, adding a small amount of salt, gently swirling the container, or using a different, less emulsion-prone solvent like MTBE [13].

- High Background Noise in UFLC-DAD Chromatogram: Ensure the extraction solvent is of high purity (HPLC grade) and is sufficiently volatile to be completely removed during the concentration step. A "back-extraction" or a clean-up step using solid-phase extraction (SPE) may be necessary to remove co-extracted interferences [13].

Selecting the optimal extraction solvent is a critical, multi-parameter decision that balances polarity, density, and system compatibility to ensure successful UFLC-DAD analysis. By leveraging the fundamental principles, standardized protocols, and structured workflow outlined in this application note, researchers can systematically develop and optimize LLE methods. This approach enhances extraction efficiency, improves data quality, and accelerates progress in drug development and other analytical research fields.

The Synergy Between LLE Clean-up and UFLC-DAD Detection

In modern analytical chemistry, the combination of sample preparation and detection techniques is pivotal for the accurate quantification of target analytes in complex matrices. Liquid-Liquid Extraction (LLE) is a robust sample clean-up procedure that effectively isolates and purifies analytes from interfering substances. When coupled with Ultra-Fast Liquid Chromatography Diode Array Detection (UFLC-DAD), it creates a powerful analytical synergy. This protocol details the application of this combined methodology for the detection of organophosphate pesticide (OP) metabolites in human urine, a critical application for human biomonitoring and exposure risk assessment [18].

The principle of this synergy is straightforward: the LLE clean-up reduces matrix effects and concentrates the analytes, which in turn allows the UFLC-DAD system to operate at its maximum potential, providing high-resolution separation, sensitive detection, and reliable quantification [18]. This is especially crucial for biological samples like urine, which contain numerous endogenous compounds that can interfere with analysis.

Experimental Protocols

Key Reagent Solutions

The following table lists the essential reagents and materials required for the LLE and UFLC-DAD analysis of dialkyl phosphate (DAP) metabolites.

Table 1: Essential Research Reagents and Materials

| Reagent/Material | Function/Application |

|---|---|

| Ethyl Acetate | Extraction solvent for LLE [18] |

| Acetonitrile (ACN) | Reconstitution solvent for the dried extract prior to UFLC-DAD analysis [18] |

| DAP Metabolite Standards | Reference standards for calibration (e.g., DEP, DETP, DEDTP, DMP, DMTP, DMDTP) [18] |

| Ultrapure Water | Component of mobile phase for chromatography |

| C18 Chromatography Column | Reversed-phase stationary phase for UFLC separation [19] |

Detailed LLE Clean-up Procedure for Urine Samples

This protocol is optimized for the extraction of six DAP metabolites from human urine [18].

- Sample Aliquot: Transfer a 200 µL volume of the urine sample into a 2 mL Eppendorf tube.

- Internal Standard Addition: Add 100 µL of the internal standard solution to the urine sample. The use of an internal standard corrects for variability in the extraction and analysis process.

- Extraction: Add 800 µL of cold ethyl acetate to the tube.

- Mixing: Vigorously shake the mixture for 1 minute to ensure thorough contact between the organic and aqueous phases.

- Precipitation: Place the mixture on ice for 10 minutes to precipitate interfering proteins and other substances.

- Centrifugation: Centrifuge the sample at 10,000 rpm for 10 minutes. This step separates the organic layer (supernatant) from the aqueous and precipitated pellet.

- Collection: Carefully transfer the resulting supernatant (organic layer) to a new 10 mL tube.

- Evaporation: Dry the supernatant under a gentle stream of nitrogen gas.

- Reconstitution: Reconstitute the dried extract with 500 µL of acetonitrile (ACN) to make it compatible with the UFLC system.

- Analysis: Transfer the reconstituted solution to a vial for injection into the UFLC-DAD system.

The following workflow diagram illustrates the LLE clean-up procedure:

Instrumental Analysis: UFLC-DAD Conditions

The following parameters are recommended for the chromatographic separation and detection of DAP metabolites. These are based on typical UFLC-DAD configurations [20] and the requirements for separating small, polar molecules [18].

- Chromatography System: UFLC system (e.g., Shimadzu Prominence series) [20].

- Detection: Diode Array Detector (DAD). Wavelength selection depends on the absorbance characteristics of the target analytes. For compounds lacking strong chromophores, a low wavelength (e.g., 200-210 nm) may be necessary [21].

- Column: Reversed-phase C18 column [19].

- Mobile Phase: A binary gradient is typically used, consisting of:

- Gradient Program: A typical gradient may start with a high percentage of aqueous phase and ramp to a high percentage of organic phase to elute less polar compounds. The specific profile must be optimized for the target DAP metabolites [21].

- Flow Rate: 0.2 - 0.5 mL/min [21].

- Column Temperature: 25 °C [21].

- Injection Volume: 1 - 10 µL [18].

Results and Data Presentation

Performance Metrics of the LLE-UFLC-DAD Method

The combination of LLE and UFLC-DAD has been rigorously validated for the analysis of DAP metabolites in urine. The table below summarizes key performance data, demonstrating the effectiveness of this synergistic approach [18].

Table 2: Validation Data for LLE-UFLC-DAD Analysis of DAP Metabolites

| Parameter | Value / Range | Notes |

|---|---|---|

| Analytes | DEP, DETP, DEDTP, DMP, DMTP, DMDTP | Six dialkyl phosphate metabolites [18] |

| Recovery Rate | 93% - 102% | Indicates high extraction efficiency of the LLE procedure [18] |

| Repeatability (RSD) | 0.62% - 5.46% | High precision of the method [18] |

| Limit of Detection (LOD) | 0.0201 - 0.0697 ng/mL | High sensitivity for trace-level analysis [18] |

| Limit of Quantification (LOQ) | 0.0609 - 0.2112 ng/mL | [18] |

| Linearity (R²) | > 0.996 | Reliable quantification across the calibration range [18] |

| Sample Volume | 200 µL | Requires less sample than alternative methods [18] |

| Extraction Time | Short | Contributes to high throughput [18] |

Comparative Analysis of Sample Preparation Techniques

LLE was selected after a comprehensive evaluation against other common extraction techniques. The following table compares LLE with QuEChERS and lyophilization for this specific application, highlighting the advantages of LLE in this context [18].

Table 3: Comparison of Sample Preparation Methods for DAP Metabolites

| Method | Recovery | Matrix Effect | Ease of Use | Extraction Time |

|---|---|---|---|---|

| Liquid-Liquid Extraction (LLE) | High [18] | Low [18] | Easy to handle [18] | Short [18] |

| QuEChERS | Lower than LLE [18] | Higher than LLE [18] | Moderate | Moderate |

| Lyophilization | Lower than LLE [18] | Higher than LLE [18] | Requires specialized equipment | Long |

Discussion

The Synergistic Workflow

The synergy between LLE and UFLC-DAD is not merely sequential but integrative. The LLE clean-up protocol directly enhances the performance of the subsequent UFLC-DAD analysis by providing a purified sample, which leads to cleaner chromatograms, reduced baseline noise, and enhanced signal-to-noise ratios for the target analytes. This process is summarized in the following logic diagram.

Application in Human Biomonitoring

The validated LLE-UFLC-DAD method has been successfully applied to analyze 150 urine samples from farmers and non-farmers, proving its utility in real-world biomonitoring studies [18]. The method's high sensitivity allows for the detection of trace-level metabolites, which is essential for assessing exposure to low doses of organophosphate pesticides, associated with various adverse health effects including neurological disorders and endocrine disruption [18]. The robustness of the method, evidenced by its high recoveries and precision, ensures that the data generated is reliable for risk assessment and public health decision-making.

This application note has detailed a robust and efficient protocol combining LLE clean-up with UFLC-DAD detection for analyzing pesticide metabolites in a complex biological matrix. The demonstrated synergy between these techniques results in a method that is sensitive, precise, and practical for high-throughput laboratories. The key advantages include reduced sample and solvent consumption, shorter analysis times, and superior performance characteristics compared to alternative sample preparation methods. This makes the LLE-UFLC-DAD combination a powerful tool for advancing research in environmental exposure assessment, toxicology, and public health.

Step-by-Step LLE Protocol Development for UFLC-DAD

Within the context of developing a robust liquid-liquid extraction (LLE) protocol for Ultra-Fast Liquid Chromatography with Diode-Array Detection (UFLC-DAD) analysis, systematic method development is paramount. This process ensures the reliability, accuracy, and reproducibility of analytical results, which are critical for researchers, scientists, and drug development professionals. A meticulously developed method minimizes analytical variability, providing confidence in data used for critical decisions in pharmaceutical development and quality control. This application note details a step-by-step protocol from initial sample preparation to final chromatographic injection, with a specific focus on LLE as a sample preparation technique.

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table catalogues the essential materials and reagents required for the liquid-liquid extraction and subsequent UFLC-DAD analysis.

Table 1: Key Research Reagent Solutions and Essential Materials

| Item | Function/Brief Explanation |

|---|---|

| Aqueous Sample | The matrix containing the analytes of interest (e.g., plasma, urine, buffer solution). |

| Organic Solvent (e.g., Ethyl Acetate, Diethyl Ether) | Immiscible solvent used to extract analytes from the aqueous phase based on solubility and partition coefficient. |

| Acid/Base Modifiers | Reagents (e.g., acetic acid, ammonium hydroxide) used to adjust sample pH, manipulating analyte polarity to enhance extraction efficiency [2]. |

| Internal Standard Solution | A known compound, not present in the original sample, added to correct for variability during sample processing and instrument analysis. |

| UFLC-DAD System | The analytical instrument for separation (chromatography) and detection; the DAD provides spectral confirmation of analyte identity [16]. |

| Analytical Standards | High-purity compounds used for calibration, identification, and quantification of target analytes. |

Experimental Workflow and Protocol

This section outlines the comprehensive methodology for sample preparation via LLE and analysis via UFLC-DAD.

Detailed Liquid-Liquid Extraction Protocol

- Sample Pre-treatment: Transfer a precise volume (e.g., 1.0 mL) of the aqueous sample (e.g., plasma) into a suitable glass tube.

- Internal Standard Addition: Add a known, precise volume of the internal standard solution to the sample. Vortex mix thoroughly to ensure homogeneity.

- pH Adjustment: Adjust the pH of the sample using an appropriate acid or base modifier. For instance, add 50 µL of acetic acid to achieve a pH of 3.5, which can optimize the extraction of certain ionizable compounds [2].

- Solvent Addition: Add a measured volume of the selected organic solvent (e.g., 5 mL of ethyl acetate) to the sample tube.

- Extraction: Seal the tube and agitate vigorously for a predetermined time (e.g., 10 minutes) using a mechanical shaker or vortex mixer to facilitate the partitioning of analytes into the organic phase.

- Phase Separation: Centrifuge the tubes (e.g., at 4000 rpm for 10 minutes) to achieve clean separation of the organic and aqueous layers.

- Collection: Carefully transfer the upper organic layer to a new, clean tube, avoiding the aqueous phase and any interfacial precipitate.

- Evaporation and Reconstitution: Evaporate the organic extract to dryness under a gentle stream of nitrogen gas in a warm water bath. Reconstitute the dry residue with a precise, small volume of the UFLC mobile phase or a compatible solvent (e.g., 200 µL of methanol-water mixture). Vortex mix thoroughly to dissolve the residue.

- Filtration: Transfer the reconstituted solution to an autosampler vial, potentially using a syringe filter (e.g., 0.22 µm) to remove any particulate matter prior to injection.

UFLC-DAD Method Development and Optimization

The transition from HPLC to UFLC allows for higher efficiency and shorter run times through the use of columns packed with smaller particles and systems that operate at higher pressures [16]. The development of the chromatographic method can be significantly accelerated by employing a Design of Experiments (DoE) approach, such as factorial design, which allows for the simultaneous evaluation of multiple factors to establish optimal conditions more practically and rationally than a traditional one-factor-at-a-time empirical approach [16].

- Factor Selection: Identify critical chromatographic parameters as factors for the DoE. These typically include:

- Mobile Phase Composition: The ratio of organic solvent (e.g., methanol, acetonitrile) to aqueous buffer.

- Mobile Phase pH: The pH of the aqueous buffer, which can significantly impact the ionization and retention of ionizable analytes.

- Column Temperature: The temperature of the analytical column.

- Flow Rate: The rate of the mobile phase.

- Experimental Design: Create a factorial design (e.g., a 2^3 full factorial design) to systematically study the selected factors and their interactions.

- Execution and Analysis: Run the experiments as per the design and analyze the responses, such as peak resolution, tailing factor, and runtime. Use statistical analysis to identify significant factors and determine the optimal chromatographic conditions.

- Final Chromatographic Conditions (Example): Based on the optimization, a final method might be established. For instance:

- Column: A C18 column (e.g., 100 mm x 2.1 mm, 1.7 µm particles).

- Mobile Phase: Methanol and water (e.g., 60:40, v/v), pH adjusted to 3.5 with acetic acid [16].

- Flow Rate: 0.3 mL/min.

- Temperature: 30 °C.

- Detection: DAD with monitoring at the wavelength of maximum absorbance for the analytes (e.g., 290 nm).

- Injection Volume: 5 µL.

Data Presentation: Method Validation Parameters

Upon development, the analytical method must be validated to confirm its suitability for intended use. The following table summarizes typical validation parameters and results, based on data from analogous studies [16].

Table 2: Summary of Validation Parameters for a Representative UFLC-DAD Method

| Validation Parameter | Result for Compound A | Result for Compound B | Result for Compound C |

|---|---|---|---|

| Linearity (R²) | 0.9995 | 0.9999 | 0.9994 |

| Accuracy (% Recovery) | 99.71 - 100.46% | 98.69 - 101.47% | 99.71 - 100.22% |

| Precision (% RSD) | |||

| Intra-day | 1.48% | 2.00% | 1.24% |

| Inter-day | 2.81% | 1.56% | 2.20% |

| Robustness (Variation in Flow Rate) | Area RSD: 2.07% | Area RSD: 2.34% | Area RSD: 2.54% |

| Specificity (Similarity Index) | 979 | 973 | 959 |

Workflow and Optimization Strategy Visualization

Systematic LLE Workflow from Sample to Analysis

DoE for UFLC Method Optimization

Optimizing Solvent Systems for Different Analytic Classes (Acidic, Basic, Neutral)

The efficacy of Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) analysis is fundamentally dependent on the preceding sample preparation, where solvent selection plays a critical role. Liquid-Liquid Extraction (LLE) serves as a powerful technique to isolate, concentrate, and clean up analytes from complex matrices, thereby enhancing chromatographic performance and detector sensitivity. The core principle of LLE is the differential partitioning of analytes between two immiscible liquid phases—typically an aqueous phase and a water-immiscible organic solvent. Successful extraction hinges on maximizing the distribution constant (K_D), which describes the ratio of an analyte's concentration in the organic phase to its concentration in the aqueous phase at equilibrium [22].

Optimization must account for the distinct physicochemical properties of acidic, basic, and neutral compounds. For ionizable analytes (acids and bases), the solution pH is the primary parameter controlling their extraction efficiency, as it determines the fraction of molecules present in the neutral, extractable form. For all analyte classes, the intrinsic hydrophobicity, often quantified by the LogP value, and the polarity of the extraction solvent are equally critical [12]. This document provides a structured framework, complete with actionable protocols and data tables, to guide the systematic optimization of solvent systems for comprehensive drug development research.

Theoretical Foundations

Key Physicochemical Parameters

The design of an efficient LLE protocol is guided by two essential physicochemical properties of the target analytes.

- LogP/D: The partition coefficient, LogP (for neutral compounds) or LogD (for ionizable compounds at a specific pH), is a measure of hydrophobicity. It represents the logarithm of the ratio of an analyte's concentration in a water-immiscible organic solvent (typically n-octanol) to its concentration in the aqueous phase. A highly positive LogP/D value (e.g., >3) indicates a strong preference for the organic phase, facilitating easy extraction. Conversely, a low or negative LogP/D value (e.g., <1) signifies high hydrophilicity, which presents a challenge for extraction and may require a more polar solvent or salting-out strategies [12].

- pKa: The acid dissociation constant is crucial for ionizable analytes. It is the pH at which half of the molecules are in their ionized form and half are neutral. For acidic analytes, the neutral, protonated species (HA) is extractable, while the charged, deprotonated conjugate base (A⁻) is not. For basic analytes, the neutral, deprotonated species (B) is extractable, whereas the charged, protonated conjugate acid (BH⁺) is not. The relationship between pH, pKa, and the fraction of neutral species is given by the Henderson-Hasselbalch equation [12]:

- For acids: (\text{pH} = \text{p}Ka + \log\frac{[\text{A}^-]}{[\text{HA}]})

- For bases: (\text{pH} = \text{p}Ka + \log\frac{[\text{B}]}{[\text{BH}^+]})

Solvent Properties and Selection

The choice of organic solvent is paramount. An ideal extraction solvent should have low solubility in water (<10%), high volatility for easy post-extraction concentration, high purity to avoid interfering peaks, and compatibility with the subsequent UFLC-DAD analysis (e.g., low UV cutoff) [22]. Most importantly, its polarity and hydrogen-bonding properties should match those of the target analytes to maximize K_D. The following table summarizes common solvents used in LLE.

Table 1: Properties of Common Liquid-Liquid Extraction Solvents

| Solvent | Polarity Index (P') | Water Solubility (%) | UV Cutoff (nm) | Density (g/mL) | Common Applications |

|---|---|---|---|---|---|

| n-Hexane | 0.1 | 0.001 | 210 | 0.66 | Extraction of very non-polar compounds (e.g., lipids, hydrocarbons). |

| Toluene | 2.4 | 0.05 | 285 | 0.87 | Extraction of aromatic and moderately non-polar compounds. |

| Diethyl Ether | 2.8 | 6.0 | 220 | 0.71 | Extraction of medium-polarity compounds. Caution: Highly flammable. |

| Dichloromethane | 3.1 | 1.6 | 245 | 1.33 | General-purpose solvent for a wide range of medium-polarity analytes. |

| Ethyl Acetate | 4.4 | 8.7 | 260 | 0.90 | Excellent for polar to medium-polarity compounds; commonly used for drug extraction. |

| Chloroform | 4.1 | 0.8 | 245 | 1.50 | Used for medium-polarity compounds; can form hydrogen bonds. |

| 1-Butanol | 3.9 | 7.7 | 215 | 0.81 | Suitable for more hydrophilic analytes due to higher polarity [12] [22]. |

For polar analytes with low LogP values, selecting an organic solvent with a higher polarity index (such as ethyl acetate or 1-butanol) is necessary to achieve satisfactory recovery [12]. Furthermore, solvent mixtures can be employed to fine-tune selectivity and recovery. An optimum-polarity organic solvent can be selected conveniently by blending two solvents of different polarity (for example, hexane and chloroform), and measuring K_D versus the composition of the organic phase [22].

Optimized Protocols by Analyte Class

Protocol for Acidic Analytics

This protocol is designed for the extraction of organic acids (e.g., carboxylic acids, phenolic compounds). The key is to suppress ionization by adjusting the aqueous phase to a pH where the acid exists predominantly in its neutral form.

Workflow Overview:

Step-by-Step Procedure:

- Sample Preparation: Transfer a measured volume of the aqueous sample (e.g., 1-5 mL) into a suitable glass vial or test tube.

- pH Adjustment: Adjust the pH of the aqueous sample to at least 1.5–2.0 units below the pKa of the target acidic analyte(s). For example, for benzoic acid (pKa ≈ 4.2), adjust the pH to ~2.2. This can be done using a concentrated phosphoric acid or hydrochloric acid solution. Verify the final pH with a calibrated pH meter or micro-pH probe [12] [22].

- Organic Solvent Addition: Add a measured volume of the selected organic solvent. A generic optimum organic-to-aqueous phase ratio is often 7:1 [12]. For a 2 mL sample, this would require ~14 mL of solvent. For high-concentration samples or analytes with very high K_D, this ratio can be reduced.

- Mixing and Phase Separation: Cap the vial and mix vigorously for 2-5 minutes, using a vortex mixer or mechanical shaker, to ensure thorough contact between the phases and establish equilibrium. Allow the phases to separate completely. If an emulsion forms, centrifugation at 3000–5000 rpm for 2-5 minutes can aid in phase separation [22].

- Collection: Transfer the organic phase (the upper layer for low-density solvents like ethyl acetate, the lower layer for high-density solvents like DCM) to a clean vial.

- Analysis: The organic extract can be directly injected into the UFLC-DAD system if the solvent is compatible with the mobile phase. Otherwise, evaporate the solvent under a gentle stream of nitrogen or air and reconstitute the residue in the initial mobile phase.

Protocol for Basic Analytics

This protocol targets organic bases (e.g., amines, alkaloids). The principle is to ensure the basic analyte is in its neutral, deprotonated form to facilitate partitioning into the organic phase.

Workflow Overview:

Step-by-Step Procedure:

- Sample Preparation: Transfer a measured volume of the aqueous sample into a vial.

- pH Adjustment: Adjust the pH of the aqueous sample to at least 1.5–2.0 units above the pKa of the target basic analyte(s). For an amine with a pKa of 9.5, adjust the pH to ~11.5. This is typically achieved using sodium hydroxide or sodium carbonate solution [12] [22].

- Organic Solvent Addition: Add the selected organic solvent at the desired phase ratio (e.g., 7:1 organic-to-aqueous).

- Mixing and Phase Separation: Mix vigorously for 2-5 minutes. Allow phases to separate, using centrifugation if necessary.

- Collection: Transfer the organic phase to a clean vial.

- Analysis: Proceed with direct injection or solvent evaporation/reconstitution as described for acidic analytes.

Protocol for Neutral Analytics

The extraction of neutral compounds is the most straightforward, as their partitioning is not influenced by pH. Recovery depends solely on their LogP value and the polarity of the organic solvent.

Step-by-Step Procedure:

- Sample Preparation: Transfer the aqueous sample to a vial. No pH adjustment is required.

- Organic Solvent Addition: Add an organic solvent selected from Table 1 based on the analyte's polarity. A solvent like dichloromethane or ethyl acetate is often a good starting point for neutral compounds of medium polarity.

- Mixing and Phase Separation: Mix vigorously for 2-5 minutes. Allow phases to separate.

- Collection: Transfer the organic phase to a clean vial.

- Analysis: Proceed with direct injection or solvent evaporation/reconstitution.

Table 2: Summary of Optimization Strategies by Analyte Class

| Analyte Class | Key Parameter | Optimal Condition | Recommended Solvents | Notes |

|---|---|---|---|---|

| Acidic | Aqueous pH | pH ≤ pK_a - 2 | Ethyl Acetate, Dichloromethane | Ensures >99% of acid is in neutral (HA) form. |

| Basic | Aqueous pH | pH ≥ pK_a + 2 | Dichloromethane, Chloroform, Toluene | Ensures >99% of base is in neutral (B) form. |

| Neutral | Solvent Polarity | Match analyte polarity | See Table 1; Ethyl Acetate is a versatile choice. | Extraction efficiency is independent of pH. |

Advanced Optimization and Enhancement Techniques

Salting-Out Effect

The addition of high concentrations of inert, neutral salts (e.g., sodium chloride, sodium sulfate, ammonium sulfate) to the aqueous sample can significantly improve the recovery of hydrophilic analytes. This "salting-out" effect reduces the solubility of the analytes in the aqueous phase by competing for water molecules, thereby driving them into the organic phase [12] [22]. Studies have successfully used sodium chloride to saturate sample solutions, improving the recovery of phenolic compounds into the organic phase [23].

Protocol: After pH adjustment, add a salt such as sodium chloride to the aqueous sample to achieve a concentration of 3–5 M (e.g., ~0.3–0.5 g per mL of sample). Vortex until the salt is fully or nearly saturated, then proceed with the addition of the organic solvent and the rest of the LLE steps.

Back-Extraction for Selectivity

Back-extraction is a powerful technique to enhance the purity of the final extract, which is crucial for analyzing complex matrices. It involves a second extraction step where the target analytes are transferred back into a fresh aqueous phase, leaving many interfering neutral and charged compounds behind [12] [22].

Protocol for a Basic Analyte:

- Perform the initial LLE for basic analytes as described in Section 3.2. The basic analytes will be in the organic phase.

- Transfer the organic phase to a new vial containing a fresh, acidic aqueous buffer (e.g., pH 2–4, adjusted with phosphoric or hydrochloric acid).

- Mix vigorously and allow the phases to separate. The basic analytes will now be protonated (charged) and will partition back into the acidic aqueous phase.

- Collect this new aqueous phase. For UFLC analysis, this aqueous solution can often be injected directly. Alternatively, adjust its pH back to basic conditions and perform a final LLE to concentrate the analytes into a small volume of organic solvent.

Dispersive Liquid-Liquid Microextraction (DLLME)

DLLME is a miniaturized, rapid, and highly efficient version of LLE. It involves the rapid injection of a mixture of an extraction solvent (denser than water) and a disperser solvent (miscible with both) into an aqueous sample. This forms a cloudy solution of fine extraction solvent droplets, providing a vast surface area for instantaneous analyte extraction [24].

Protocol:

- Rapidly inject a mixture consisting of a few tens of microliters of extraction solvent (e.g., chlorobenzene, 1,1,2-trichloroethane) and around 1 mL of disperser solvent (e.g., acetone, methanol) into a 5 mL aqueous sample.

- A cloudy solution forms immediately. Gently mix to allow for extraction.

- Centrifuge to sediment the dense extraction solvent droplets at the bottom of the tube.

- Carefully collect a portion of the sedimented phase with a micro-syringe for analysis [22] [25].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for LLE Protocol Development

| Reagent/Material | Function/Application | Example Usage & Notes |

|---|---|---|

| LogP/D & pK_a Databases | Provides essential physicochemical data for initial method design. | ChemSpider, Chemicalize; used to predict extraction behavior and set initial pH [12]. |

| Buffering Agents | To precisely control the pH of the aqueous phase. | Phosphate, acetate, and carbonate buffers; crucial for ionizable analytes. |

| Salting-Out Agents | To decrease analyte solubility in the aqueous phase and improve recovery. | Sodium Chloride (NaCl), Sodium Sulfate (Na₂SO₄); used at near-saturation concentrations [12] [23]. |

| Ionic Liquids | Green alternative extraction solvents for microextraction techniques. | e.g., [C₆MIM][PF₆]; used in DLLME for sensitive analysis of pesticides and other contaminants [24]. |

| Derivatization Agents | To convert polar, hard-to-extract analytes into less polar, extractable derivatives. | Butyl Chloroformate; used to derivative primary amines for GC or HPLC analysis, improving extraction and chromatographic behavior [25]. |

The systematic optimization of solvent systems for LLE, grounded in the fundamental principles of analyte chemistry, is a prerequisite for robust and sensitive UFLC-DAD analysis. By strategically manipulating pH for ionizable compounds, carefully selecting solvents based on polarity, and employing advanced techniques such as salting-out and back-extraction, researchers can achieve high recovery and exceptional sample clean-up. The protocols and data tables provided herein serve as a comprehensive guide for developing and refining LLE methods tailored to acidic, basic, and neutral analyte classes within a drug development research context, ultimately ensuring the generation of high-quality chromatographic data.

In the development of robust liquid-liquid extraction (LLE) protocols for UFLC-DAD analysis, two parameters frequently emerge as critical determinants of success: pH adjustment and ionic strength. These factors exert profound influence over the partitioning behavior of analytes between immiscible liquid phases, directly impacting extraction efficiency, selectivity, and overall method performance. Proper manipulation of the aqueous phase environment enables analytical chemists to optimize the recovery of target compounds while minimizing co-extraction of interfering matrix components. This application note provides a structured framework for systematically investigating and optimizing these crucial parameters within the context of sample preparation for UFLC-DAD analysis, with specific applications drawn from recent scientific literature.

Theoretical Foundations

The efficiency of liquid-liquid extraction fundamentally depends on the differential solubility of analytes between two immiscible phases. pH adjustment directly modulates the ionization state of ionizable analytes, thereby altering their partition coefficients. For acidic compounds, low pH environments suppress ionization, increasing their affinity for organic solvents, while basic compounds exhibit enhanced extraction at elevated pH levels. This principle enables selective extraction of specific compound classes through precise pH control [26].

Ionic strength modification influences extraction efficiency through two primary mechanisms: the salting-out effect and solution dielectric constant alteration. The addition of neutral salts such as sodium chloride decreases the solubility of organic compounds in the aqueous phase, effectively driving them into the organic extractant. Simultaneously, increased ionic strength can modify the physical properties of the aqueous phase, potentially affecting mass transfer kinetics and phase separation behavior [27] [28].

Experimental Protocols

Systematic Optimization of pH and Ionic Strength

Materials and Reagents:

- Aqueous sample solution containing target analytes

- Hydrochloric acid (HCl) solution (0.1-1.0 M)

- Sodium hydroxide (NaOH) solution (0.1-1.0 M)

- Sodium chloride (NaCl) or other suitable salts

- Organic extraction solvent (ethyl acetate, dichloromethane, or similar)

- pH meter with calibrated electrode

- Centrifuge tubes with tight-sealing caps

- Centrifuge

- Vortex mixer

Procedure:

- Sample Preparation: Aliquot identical volumes of sample solution into a series of centrifuge tubes.

- pH Adjustment: Systematically adjust the pH of each tube across a relevant range (e.g., pH 2-10) using HCl or NaOH solutions. Monitor pH carefully with a calibrated pH meter.

- Ionic Strength Modification: To subsets of pH-adjusted samples, add varying amounts of NaCl (0-30% w/v) to create a matrix of pH and ionic strength conditions.

- Extraction: Add precisely measured volumes of organic extraction solvent to each tube (typical phase ratios 1:1 to 1:5 aqueous:organic).

- Equilibration: Securely cap tubes and mix thoroughly using a vortex mixer for 1-5 minutes.

- Phase Separation: Centrifuge tubes at 3000-5000 rpm for 5-10 minutes to achieve complete phase separation.

- Analysis: Carefully recover the organic phase and analyze via UFLC-DAD.