Optimized Sample Preparation for Metoprolol Tartrate Extraction from Tablets: Methods, Troubleshooting, and Validation

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on the sample preparation for extracting metoprolol tartrate from tablet formulations.

Optimized Sample Preparation for Metoprolol Tartrate Extraction from Tablets: Methods, Troubleshooting, and Validation

Abstract

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on the sample preparation for extracting metoprolol tartrate from tablet formulations. It covers the foundational chemistry and properties of metoprolol tartrate, explores established and advanced extraction methodologies including spectrophotometric and HPLC techniques, addresses common troubleshooting and optimization challenges, and outlines rigorous validation procedures. The scope is designed to support quality control and research by detailing reliable, efficient protocols for accurate drug quantification and analysis.

Understanding Metoprolol Tartrate: Chemical Properties and Pre-Extraction Analysis

Chemical Structure and Key Functional Groups of Metoprolol Tartrate

Chemical Characterization

Metoprolol tartrate is a selective β1-adrenergic receptor blocking agent with the chemical name (±)-1-(Isopropylamino)-3-[p-(2-methoxyethyl)phenoxy]-2-propanol L-(+)-tartrate (2:1) salt [1]. The compound exists as a white, practically odorless, crystalline powder with a molecular weight of 684.82 g/mol [1]. It demonstrates high solubility in water, alcohol, chloroform, and methylene chloride, slight solubility in acetone, and insolubility in ether [1].

Table 1: Key Chemical Properties of Metoprolol Tartrate

| Property | Description |

|---|---|

| Chemical Formula | (C({15})H({25})NO({3}))({2})·C({4})H({6})O(_{6}) |

| Molecular Weight | 684.82 g/mol [1] |

| Appearance | White, practically odorless, crystalline powder [1] |

| Solubility | Very soluble in water; freely soluble in methylene chloride, chloroform, and alcohol; slightly soluble in acetone; insoluble in ether [1] |

Structural Components and Functional Groups

The molecular structure of metoprolol tartrate consists of a metoprolol base molecule combined with a tartrate counterion in a 2:1 ratio. The key functional groups present in the molecule are critical to its biological activity and physicochemical properties.

Table 2: Key Functional Groups of Metoprolol Tartrate and Their Significance

| Functional Group | Structural Location | Role and Significance |

|---|---|---|

| Secondary Amino Group | Isopropylamine chain | Facilitates β1-adrenergic receptor binding through hydrogen bonding and ionic interactions; crucial for pharmacological activity [2]. |

| Ether Linkage | Phenoxy-propanol bridge | Provides structural connectivity and influences molecular flexibility and receptor fit. |

| Aromatic Ring | Para-substituted phenyl | Creates hydrophobic interactions with receptor binding pockets. |

| Methoxyethyl Side Chain | Para-position of aromatic ring | Enhances β1-selectivity (cardioselectivity) and influences drug distribution [2]. |

| Hydroxyl Group | Propanol terminal | Participates in hydrogen bonding with biological targets; contributes to water solubility. |

| Tartrate Counterion | Salt form with basic nitrogen | Improves chemical stability, crystallinity, and aqueous solubility for formulation [1]. |

The relative beta1-selectivity of metoprolol is attributed to its specific molecular structure, particularly the methoxyethyl substituent on the aromatic ring. This selectivity means metoprolol preferentially blocks β1-adrenergic receptors located primarily in the heart while having less effect on β2-receptors in the lungs and vascular smooth muscle [2] [1]. However, this selectivity is dose-dependent and may diminish at higher concentrations [1].

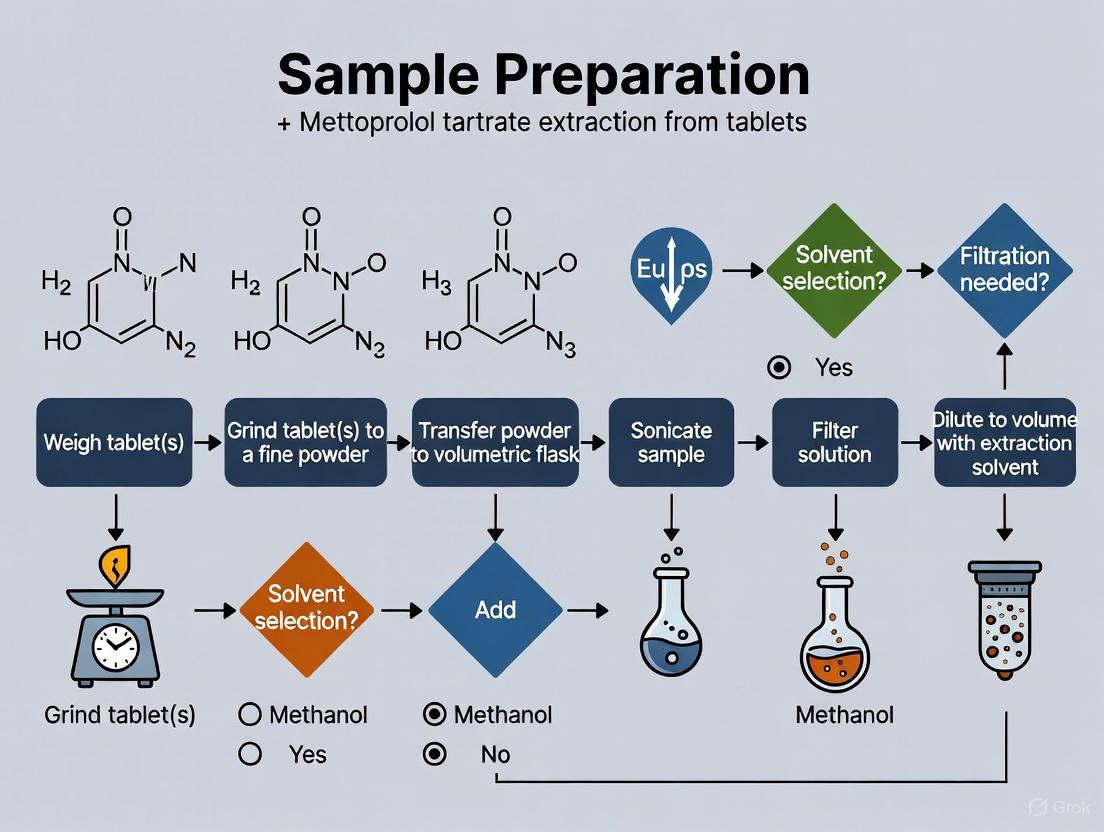

Diagram 1: The relationship between metoprolol's structure and analysis workflow. Its key functional groups influence each stage of the sample preparation and analysis process.

Sample Preparation and Extraction Protocols

Extraction from Pharmaceutical Tablets

Metoprolol tartrate immediate-release tablets typically contain the active pharmaceutical ingredient with excipients such as microcrystalline cellulose, lactose monohydrate, povidone, croscarmellose sodium, colloidal silicon dioxide, magnesium stearate, hypromellose, titanium dioxide, and macrogol [1]. For analytical sample preparation, the following protocol is recommended:

- Tablet Commimution: Weigh and grind representative tablet samples using a mortar and pestle to create a homogeneous powder.

- Solvent Extraction: Transfer an accurately weighed portion of the powder to a volumetric flask. Add a suitable solvent (e.g., methanol, water, or a mixture) and sonicate for 15-30 minutes to facilitate complete dissolution of metoprolol tartrate.

- Clarification: Centrifuge the mixture or filter through a 0.45 μm membrane filter to remove insoluble excipients.

- Dilution: Dilute the supernatant or filtrate to an appropriate concentration with the mobile phase or solvent compatible with the subsequent analytical technique.

Preparation of Biological Samples

The analysis of metoprolol in biological matrices requires specific sample preparation to remove interfering components and concentrate the analyte.

Plasma/Serum Sample Preparation: [3]

- Pipette 0.4 mL of plasma into a microcentrifuge tube.

- Add 0.225 mL of methanol and 0.2 mL of trichloroacetic acid solution (25% w/v) for protein precipitation.

- Vortex mix the sample thoroughly, then sonicate for 2 minutes.

- Centrifuge at 13,000 rpm for 10 minutes.

- Collect the clear supernatant for analysis by LC-MS/MS or HPLC.

Urine Sample Preparation: [3]

- Pipette 0.4 mL of urine into a glass test tube.

- Add 0.425 mL of methanol to precipitate salts and other interfering substances.

- Sonicate the mixture for 2 minutes.

- Centrifuge to separate the precipitate and collect the supernatant for analysis.

Exhaled Breath Condensate (EBC): EBC samples can be analyzed directly without pre-treatment after collection, due to their less complex matrix [3].

Analytical Methodology and Instrumentation

Liquid Chromatography-Mass Spectrometry (LC-MS/MS) Conditions

The following conditions have been established for the reliable quantification of metoprolol in various biological samples [3]:

Chromatography:

- Column: Zorbax RR Eclipse C18 (100 mm × 4.6 mm i.d., 3.5 μm particle size)

- Column Temperature: 30 °C

- Mobile Phase: Methanol and 0.1% formic acid (65:35, v/v)

- Flow Rate: 0.6 mL/min

- Injection Volume: 50 μL

Mass Spectrometry (Triple Quadrupole):

- Ionization Mode: Electrospray Ionization (ESI)

- Detection Mode: Multiple Reaction Monitoring (MRM)

- Precursor Ion (m/z): 268.1

- Product Ion (m/z): 116.2

- Cone Voltage: 35 V

- Collision Energy: 35 eV

- Source Temperature: 110 °C

- Desolvation Temperature: 350 °C

Method Validation Data

The developed LC-MS/MS method demonstrates excellent performance characteristics for the quantification of metoprolol [3].

Table 3: Analytical Method Performance for Metoprolol Quantification

| Parameter | EBC | Plasma | Urine |

|---|---|---|---|

| Linear Range (μg·L⁻¹) | 0.6 – 500 | 0.4 – 500 | 0.7 – 10,000 |

| Coefficient of Determination (R²) | 0.9998 | 0.9941 | 0.9963 |

| Limit of Detection (LOD, μg·L⁻¹) | 0.18 | 0.12 | 0.21 |

| Limit of Quantification (LOQ, μg·L⁻¹) | 0.60 | 0.40 | 0.70 |

| Intra-Day Precision (% RSD) | 5.2 – 6.1 | 5.2 – 6.1 | 5.2 – 6.1 |

| Inter-Day Precision (% RSD) | 3.3 – 4.6 | 3.3 – 4.6 | 3.3 – 4.6 |

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 4: Key Reagents and Materials for Metoprolol Tartrate Research

| Item | Function/Application | Example / Specification |

|---|---|---|

| Metoprolol Tartrate Standard | Analytical reference standard for calibration and quantification | Certified Reference Material (CRM) from accredited suppliers (e.g., Daru Pakhsh) [3] |

| HPLC-Grade Methanol | Mobile phase component; extraction solvent | ≥99.9% purity, low UV absorbance |

| Formic Acid | Mobile phase additive to improve ionization in LC-MS | LC-MS Grade, ~0.1% v/v in mobile phase [3] |

| Trichloroacetic Acid (TCA) | Protein precipitation agent for plasma/serum samples | 25% w/v solution [3] |

| Reverse-Phase HPLC Column | Chromatographic separation of metoprolol from matrix components | C18 column (e.g., Zorbax Eclipse C18, 100x4.6mm, 3.5μm) [3] |

| Solid Phase Extraction (SPE) Cartridges | Sample clean-up and concentration for complex matrices | Mixed-mode or C18 sorbents |

| Mass Spectrometer | Sensitive and selective detection and quantification | Triple Quadrupole LC-MS/MS with ESI source [3] |

Diagram 2: Primary metabolic pathway of metoprolol. The drug is primarily metabolized by the hepatic enzyme CYP2D6, which exhibits genetic polymorphism, leading to significant inter-individual variability in plasma concentrations [1] [3].

Application in Research and Development

The precise understanding of metoprolol tartrate's chemical structure is fundamental for developing robust analytical methods for pharmaceutical quality control and bioequivalence studies. In a recent cross-sectional study, the mean metoprolol levels in biological samples from patients receiving a mean daily dose of 82.7 ± 29.9 mg were found to be 5.35 μg·L⁻¹ in EBC, 70.76 μg·L⁻¹ in plasma, and 1943.1 μg·L⁻¹ in urine, highlighting significant distribution differences [3]. The correlation between daily dose and concentration was significant for plasma and urine but not for EBC, suggesting complex distribution and excretion kinetics influenced by factors such as metabolic phenotype (CYP2D6), age, sex, and drug interactions [3]. These findings are crucial for guiding therapeutic drug monitoring and advancing personalized medicine approaches for metoprolol.

Physicochemical Properties Relevant to Solubility and Extraction

Metoprolol tartrate is a selective β₁-adrenergic receptor blocking agent widely used for treating cardiovascular disorders such as hypertension, angina pectoris, and cardiac arrhythmias [4]. As part of quality control and bioequivalence studies, efficient extraction of the active pharmaceutical ingredient from its dosage form is a critical sample preparation step. This application note details the key physicochemical properties of metoprolol tartrate relevant to its solubility and extraction, particularly from solid oral dosage forms, providing validated protocols for researchers and drug development professionals. The methodologies presented herein are framed within the broader context of sample preparation for metoprolol tartrate research, emphasizing principles that ensure high recovery, selectivity, and analytical accuracy.

Physicochemical Profile of Metoprolol Tartrate

Metoprolol tartrate is a 2:1 salt comprising a racemic mixture of metoprolol enantiomers and dextrotartaric acid [4]. Understanding its fundamental properties is essential for developing efficient extraction protocols.

Table 1: Fundamental Physicochemical Properties of Metoprolol Tartrate

| Property | Description / Value | Reference |

|---|---|---|

| Chemical Name | 2:1 salt of (±)-1-(Isopropylamino)-3-[4-(2-methoxyethyl)phenoxy]propan-2-ol with (2R,3R)-2,3-dihydroxysuccinic acid | [5] [4] |

| Molecular Formula | (C₁₅H₂₅NO₃)₂·C₄H₆O₆ | [5] |

| Molecular Weight | 684.82 g/mol | [5] |

| CAS Number | 56392-17-7 | [5] |

| Melting Point | 120 °C | [5] |

| BCS Classification | Class I (High Solubility, High Permeability) | [5] |

Solubility and Partitioning Characteristics

Solubility is a primary determinant in choosing an appropriate extraction solvent. Metoprolol tartrate is highly soluble in water and various organic solvents, as quantified in the table below.

Table 2: Solubility Profile of Metoprolol Tartrate

| Solvent | Solubility | Experimental Conditions | Reference |

|---|---|---|---|

| Water | >1000 mg/mL | At room temperature | [5] |

| Methanol | >500 mg/mL | At room temperature | [5] |

| Chloroform | 496 mg/mL | At room temperature | [5] |

| Ethanol | 31 mg/mL | At 25°C | [5] |

| Dimethyl Sulfoxide (DMSO) | 100 mg/mL | At 25°C | [5] |

| Key Implications | High aqueous solubility facilitates extraction into polar solvents like water or methanol. Miscibility with organic solvents allows for solvent switching or concentration steps. |

The drug substance exhibits low protein binding (10-12%) and a volume of distribution of 5.6 L/kg, indicating extensive distribution into tissues rather than plasma, which is less relevant for tablet extraction but critical for bioanalytical methods [5].

Core Extraction Principles and Sorbent Selection

Solid-phase extraction (SPE) is a preferred sample preparation technique that removes interfering compounds from a sample and can enrich analytes of interest, thereby improving analytical results in HPLC, GC, and MS analyses [6]. The selection of the SPE sorbent is governed by the analyte's properties, the sample matrix, and the sample volume [7].

The following workflow outlines a systematic approach for selecting the appropriate SPE mechanism for metoprolol tartrate:

SPE Sorbent Selection Guide for Metoprolol Tartrate

| SPE Mechanism | Sorbent Chemistry Examples | Basis for Selection | Applicable Sample Matrix |

|---|---|---|---|

| Reversed-Phase (Non-polar) | C18, C8, C6, Phenyl | Retains the hydrophobic aromatic ring of metoprolol from polar (aqueous) matrices. | Aqueous solutions, diluted biological fluids [6] [7]. |

| Cation Exchange | Strong Cation Exchange (SCX, e.g., sulfonic acid), Weak Cation Exchange (WCX, e.g., carboxylic acid) | Retains the protonated secondary amine group of metoprolol (pKa ~9.7) via ionic interaction. | Aqueous solutions at a pH where the amine is protonated (pH < pKa) [7]. |

| Mixed-Mode | C8/SCX, C18/SCX | Combines hydrophobic (C8/C18) and ionic (SCX) retention mechanisms, offering high selectivity for basic compounds like metoprolol. | Complex matrices (e.g., biological samples) where high purity extracts are required [7]. |

Detailed Experimental Protocols

Protocol 1: Solid-Phase Extraction from Tablet Formulation

This protocol utilizes a mixed-mode cation exchange SPE for selective extraction of metoprolol tartrate from tablet excipients.

Research Reagent Solutions

| Item | Function / Specification |

|---|---|

| Mixed-Mode Cation Exchange SPE Cartridges | e.g., 60 mg, 3 mL capacity. Provides dual retention mechanisms for high selectivity. |

| Methanol (HPLC Grade) | For cartridge conditioning and elution. |

| Deionized Water | For cartridge equilibration and washing. |

| Ammonium Hydroxide Solution | e.g., 2-5% in water. For adjusting elution solvent pH to deprotonate the amine. |

| Ammonium Acetate Buffer (0.1 M, pH 4.0) | For conditioning and washing at a pH that ensures analyte protonation and retention. |

| Centrifuge | For clarifying sample solutions after extraction from tablets. |

| Volumetric Flasks & Pipettes | For accurate solution preparation and transfer. |

Step-by-Step Procedure:

- Sample Pre-treatment:

- Weigh and finely powder not less than 20 tablets.

- Accurately weigh a portion of the powder equivalent to about 50 mg of metoprolol tartrate into a 100 mL volumetric flask.

- Add approximately 70 mL of deionized water, sonicate for 20 minutes, and shake vigorously for another 10 minutes.

- Dilute to volume with deionized water, mix, and filter or centrifuge to remove insoluble tablet excipients.

SPE Cartridge Conditioning:

- Mount the SPE cartridge on a vacuum manifold.

- Pass 2 mL of methanol through the cartridge at a flow rate of ~1 mL/min. Do not let the sorbent bed run dry.

- Equilibrate the cartridge with 2 mL of 0.1 M ammonium acetate buffer (pH 4.0).

Sample Application:

- Load a suitable aliquot (e.g., 1-5 mL) of the clarified sample solution onto the conditioned cartridge.

- Maintain a slow, drop-wise flow rate (~1 mL/min) to maximize analyte retention.

Wash Step:

- Wash the cartridge with 2-3 mL of 0.1 M ammonium acetate buffer (pH 4.0) to remove weakly retained interferences.

- Optionally, wash with 1-2 mL of 20% methanol in water to remove less polar impurities. Dry the cartridge under vacuum for 1-2 minutes.

Elution:

- Elute the retained metoprolol tartrate into a clean collection tube using 2 x 1 mL aliquots of a mixture of methanol and ammonium hydroxide (e.g., 98:2 v/v).

- The basic eluent neutralizes the analyte, disrupting the ionic interaction, while the organic solvent disrupts the hydrophobic interactions.

Post-Elution Processing:

Protocol 2: Spectrophotometric Determination via Complexation

This protocol provides a simple and accurate method for quantifying metoprolol tartrate in extracted samples based on complex formation with copper(II) ions [8].

Step-by-Step Procedure:

- Reagent Preparation:

- Copper(II) Solution: Prepare a 0.5% (w/v) solution of CuCl₂·2H₂O in deionized water.

- Britton-Robinson Buffer: Prepare a universal buffer of pH 6.0.

- Standard Solution: Prepare a stock solution of pure metoprolol tartrate in water at a concentration of 0.2 mg/mL.

Calibration Curve:

- Pipette aliquots of the standard solution (e.g., 0.425 mL to 3.5 mL, representing 85 μg to 700 μg of MPT) into a series of 10 mL volumetric flasks.

- To each flask, add 1 mL of Britton-Robinson buffer (pH 6.0) and 1 mL of the copper(II) chloride solution.

- Mix well and heat in a thermostatically controlled water bath at 35°C for 20 minutes.

- Cool the solutions rapidly to room temperature and dilute to the mark with deionized water.

- Measure the absorbance of each solution at 675 nm against a reagent blank.

- Plot absorbance versus concentration to generate the calibration curve.

Sample Analysis:

- Take a suitable aliquot of the extracted sample solution (from Protocol 5.1 or a direct tablet extract) and subject it to the same complexation procedure described above.

- Measure the absorbance and determine the concentration of metoprolol tartrate using the regression equation from the calibration curve [8].

Table 3: Method Performance Data for Spectrophotometric Complexation Assay

| Parameter | Value / Observation | Reference |

|---|---|---|

| Analytical Wavelength | 675 nm | [8] |

| Beer's Law Range | 8.5 - 70 μg/mL | [8] |

| Correlation Coefficient (r) | 0.998 | [8] |

| Limit of Detection (LOD) | 5.56 μg/mL | [8] |

| Complex Stoichiometry | 1:1 (MPT:Cu²⁺) | [8] |

| Optimal pH | 6.0 | [8] |

Critical Methodological Considerations

- SPE Sorbent Capacity: The sorbent mass must be appropriate for the analyte mass. A general rule is that the mass of retained solute should be 1-5% of the sorbent mass for silica-based sorbents [7]. For a 60 mg cartridge, this translates to a capacity of 0.6-3 mg of total retained material.

- Flow Rate Control: During SPE, a typical flow rate of 1 mL/minute is recommended. Excessive flow rates can lead to channeling and inconsistent extraction efficiency due to insufficient interaction time between the analyte and sorbent [6].

- Stability of Extracts: Metoprolol tartrate is soluble in water and ethanol. Solutions and extracted samples should be stored in tightly sealed containers, protected from light, and kept at room temperature. Tablets should be protected from moisture and freezing [4].

Excipients are inactive ingredients incorporated into pharmaceutical formulations to play a vital role in drug delivery beyond simply serving as inert carriers [9]. These components are critically important for enhancing stability, improving safety and effectiveness, ensuring patient compliance, and guaranteeing that medications perform precisely as intended [9]. In solid oral dosage forms such as metoprolol tartrate tablets, excipients fulfill specialized functions including binding ingredients together, facilitating tablet disintegration, ensuring uniform drug distribution, and enabling efficient manufacturing processes [9].

The global excipients market, valued between $8.85 and $9.3 billion in 2024, is projected to reach $14–17 billion by 2032–2034, reflecting a compound annual growth rate of 5.5–7.5% and underscoring the expanding role and innovation in excipient technology [9]. For researchers focused on sample preparation and extraction of active pharmaceutical ingredients (APIs) like metoprolol tartrate, understanding excipient composition and potential interferences is paramount to developing accurate analytical methods, ensuring complete API recovery, and obtaining reliable quantification results [10] [11]. Excipients, while pharmacologically inactive, can significantly interfere with analytical techniques through various mechanisms including matrix effects, physical interactions, and chemical incompatibilities [11] [12].

Classification and Functions of Common Tablet Excipients

Excipients are systematically classified based on their specific functions within pharmaceutical formulations. The table below summarizes the primary categories, their purposes, common examples, and key formulation considerations relevant to analytical extraction.

Table 1: Classification, Functions, and Considerations of Common Tablet Excipients

| Function | Primary Purpose | Common Examples | Formulation & Analytical Considerations |

|---|---|---|---|

| Diluents/Fillers | Add bulk to ensure appropriate tablet size and weight [9]. | Lactose, Microcrystalline Cellulose (MCC), Dicalcium Phosphate, Mannitol [9]. | Must be inert and compatible with API; lactose can pose issues for patients with intolerance [9] [13]. |

| Binders | Hold powder particles together, providing tablet strength and integrity [9]. | Cellulose derivatives (e.g., HPMC, MC), Starches, Polyvinylpyrrolidone (Povidone), Gelatin [9]. | Overly strong binding can slow tablet disintegration and potentially hinder API dissolution during extraction [9]. |

| Disintegrants | Facilitate tablet breakup in gastrointestinal fluids to release the drug [9]. | Croscarmellose Sodium, Sodium Starch Glycolate, Crospovidone, Low-substituted Hydroxypropyl Cellulose [9]. | Critical for drug release; must balance rapid disintegration with tablet hardness and stability [9]. |

| Lubricants | Reduce friction during tablet compression and ejection from manufacturing equipment [9]. | Magnesium Stearate, Stearic Acid, Sodium Stearyl Fumarate [9]. | Hydrophobic lubricants like magnesium stearate can retard drug dissolution and create a physical barrier to API extraction [9] [12]. |

| Glidants | Improve powder flow properties during manufacturing [9]. | Colloidal Silicon Dioxide, Talc [9]. | Overuse can impact compressibility and drug content uniformity [9]. |

Additional excipient categories include coating agents (e.g., Hypromellose, Ethylcellulose) for protection and controlled release, and specialized solubility-enhancing excipients (e.g., Cyclodextrins, Povidone) used to improve the bioavailability of poorly soluble drugs [14] [9].

Excipient Composition of Metoprolol Tartrate Tablets

A specific example of excipient composition can be found in the Metoprolol Tartrate 25 mg tablets monograph. According to the official product information, this formulation contains two excipients with known effects [13]:

- Lactose monohydrate (14.00 mg/tablet): Functions primarily as a diluent [13].

- Sodium (0.07 - 0.105 mg/tablet): Likely present as part of a salt-based excipient [13].

This formulation illustrates a critical point for researchers: the presence of lactose must be considered during method development, especially for patients with lactose intolerance, though its primary analytical impact is typically minimal. However, the complete excipient profile, including binders and disintegrants not specified in the patient leaflet, can significantly influence the sample preparation strategy for metoprolol extraction [13].

Mechanisms of Excipient Interference in Analytical Science

Excipients can compromise analytical results through several distinct mechanisms during sample preparation and analysis of APIs like metoprolol tartrate.

Bioanalytical Matrix Effects

Matrix effects represent a major challenge, particularly in chromatographic techniques like LC-MS/MS. Excipients present in the sample but absent in the calibration standards can cause ion suppression or enhancement, leading to over- or under-estimation of the API concentration [11]. The severity of this interference is often concentration-dependent, and the variable composition of generic formulations can exacerbate the problem [11]. For high-potency drugs like metoprolol, which are administered in low doses, the need to limit sample dilution amplifies the relative concentration of excipients in the final extract, thereby increasing their potential for interference [10].

Physicochemical Interactions

Excipients can physically or chemically interact with the API, altering its properties and complicating extraction.

- Eutectic Mixture Formation: Some polymeric excipients can form eutectic mixtures with APIs, lowering the melting point and potentially altering crystallinity and dissolution behavior [12]. A study on metformin generics found that such interactions in a generic product significantly reduced the drug's melting point and enthalpy of fusion, which was linked to a slower drug release rate [12].

- Polymer Interference: Polymeric excipients used for controlled release or as binders can hinder complete API extraction during sample preparation. They may impede solvent penetration or even actively adsorb the API, reducing recovery yields [10]. Furthermore, these polymers can foul analytical instrumentation, depositing on chromatographic columns and reducing column lifetime and performance [10].

Impact on Dissolution and Extraction

The primary function of disintegrants and lubricants can directly conflict with efficient API extraction in a laboratory setting. As demonstrated in quality control tests, a formulation with a higher mean resistance force (harder tablet) and a longer disintegration time will likely require more vigorous mechanical or solvent action to liberate the API completely from the tablet matrix [12]. This is critical for sample preparation, as incomplete disintegration or dissolution of the tablet will directly lead to low and variable analytical recovery of metoprolol.

Experimental Protocols for Investigating Excipient Interference

To ensure accurate analytical results for metoprolol tartrate, researchers should employ the following experimental protocols to identify and mitigate excipient interference.

Protocol for Assessing Matrix Effects in Bioanalysis

This protocol is designed to quantify and correct for ion suppression/enhancement caused by excipients in LC-MS/MS methods.

Diagram: LC-MS/MS Matrix Effect Assessment Workflow

Procedure:

- Sample Preparation:

- Post-extraction Spiked Samples (A): Prepare a minimum of 6 different lots of blank biological matrix (e.g., plasma). Extract these samples using your validated protocol. Immediately after extraction, spike a known concentration of metoprolol tartrate standard into the cleaned-up extract [11].

- Pure Standard Solutions (B): Prepare the same concentration of metoprolol tartrate standard in pure mobile phase or reconstitution solvent. These represent the "neat" samples without matrix [11].

- LC-MS/MS Analysis: Analyze all samples (A and B) in a single batch using the intended analytical method.

- Calculation: For each lot of matrix, calculate the Matrix Effect (ME%) using the formula:

- ME% = (Mean Peak Area of Post-extraction Spiked Sample A / Mean Peak Area of Pure Standard Solution B) × 100% [11].

- Interpretation: An ME% close to 100% indicates negligible matrix effect. Significant deviation from 100% indicates ion suppression (<100%) or enhancement (>100%) attributable to the co-extracted matrix components, including residual excipients or their metabolites. The precision (CV%) of the ME% across the different lots should also be calculated, with a CV% < 15% typically indicating consistent matrix effects [11].

Protocol for Solid-State Characterization of API-Excipient Compatibility

Thermal methods like Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) are fast, reliable tools for detecting incompatibilities between an API and excipients during pre-formulation or when troubleshooting generic drug products [15] [12].

Diagram: Thermal Analysis for API-Excipient Compatibility

Procedure:

- Sample Preparation:

- Weigh 2-5 mg of each sample into standard DSC/TGA crucibles.

- Samples should include: (i) pure metoprolol tartrate, (ii) individual excipients under investigation, and (iii) 1:1 (w/w) physical mixtures of metoprolol with each excipient.

- Instrumental Analysis:

- DSC: Run samples from 25°C to 300°C at a heating rate of 10°C/min under a nitrogen purge (50 mL/min). Seal crucibles with a pinhole lid [12].

- TGA: Run samples under the same temperature program, monitoring weight loss.

- Data Analysis: Overlay the thermograms of the pure API, the physical mixture, and the individual excipient.

- Interpretation: Compare the thermal profiles. Indicators of a potential incompatibility include:

- Disappearance or significant shifting of the characteristic melting endotherm of metoprolol tartrate.

- Appearance of new endothermic or exothermic peaks not present in the individual components.

- Significant changes in the enthalpy of fusion [12].

- Unexpected weight loss events in the TGA profile of the physical mixture that are not a simple addition of the individual component profiles [12].

The Scientist's Toolkit: Key Reagents and Materials

The following table details essential research reagents and materials for studying metoprolol tartrate extraction and excipient interference.

Table 2: Essential Research Reagents and Materials for Metoprolol Extraction Studies

| Item | Function/Application | Specific Examples / Notes |

|---|---|---|

| Metoprolol Tartrate Reference Standard | Primary standard for calibration curves, method development, and quantification. | High-purity certified material from a reputable supplier (e.g., USP). |

| Chromatographic Solvents | Mobile phase preparation and sample extraction. | HPLC-grade Acetonitrile, Methanol, Water; Ammonium acetate/formate for MS compatibility. |

| Solid-Phase Extraction (SPE) Cartridges | Sample clean-up to remove excipients and biological matrix components. | Reversed-phase C18; Mixed-mode cation exchange can be selective for metoprolol [10]. |

| Simulated Biorelevant Media | For in-vitro dissolution and extraction studies. | Phosphate buffers at various pH (1.2, 4.5, 6.8); Fasted State Simulated Intestinal Fluid (FaSSIF). |

| DSC & TGA Instrumentation | Detecting API-excipient incompatibilities and solid-state characterization. | Sealed crucibles with pinhole lids; Nitrogen purge gas [12]. |

| LC-MS/MS System | Sensitive and selective detection and quantification of metoprolol, especially in biological matrices. | Triple quadrupole mass spectrometer with ESI source; C18 analytical column (e.g., 50 x 2.1 mm, 1.8 µm). |

Excipients are indispensable for formulating effective and stable metoprolol tartrate tablets, but their presence introduces significant complexity to the sample preparation and analytical process. A comprehensive understanding of their functions, properties, and potential interferences is not merely an academic exercise but a practical necessity for researchers in drug development and bioanalysis. By employing systematic protocols for assessing matrix effects and API-excipient compatibility, and by utilizing the appropriate toolkit of reagents and analytical techniques, scientists can develop robust, accurate, and reliable methods for the extraction and quantification of metoprolol tartrate, thereby ensuring the validity of their research outcomes.

Within the framework of sample preparation for pharmaceutical analysis, the extraction process is a critical foundational step that directly influences the accuracy, reliability, and efficiency of subsequent analytical determinations. This application note delineates the specific analytical targets for the extraction of metoprolol tartrate from immediate-release tablet formulations, situating the discussion within a broader research context on sample preparation. Metoprolol tartrate, a selective β1-adrenergic receptor blocking agent, is widely used in the management of hypertension and other cardiovascular disorders [16] [17]. The primary objective of the extraction process is to completely and reproducibly isolate the active pharmaceutical ingredient (API) from the excipient matrix of the tablet, thereby producing a clean, representative sample solution suitable for precise quantitative analysis, typically by Reverse-Phase High-Performance Liquid Chromatography (RP-HPLC) [18]. Defining clear goals for this extraction is paramount for developing a robust analytical method that can be applied in quality control (QC) laboratories for assay and dissolution testing, formulation development, and stability studies.

Defining Key Analytical Targets for Extraction

The success of the extraction process is measured against several key analytical targets. These targets are not isolated; they are interconnected and collectively ensure the analytical method meets its intended purpose, as guided by International Conference on Harmonisation (ICH) validation requirements [19].

Target 1: Quantitative Recovery of Analyte. The extraction procedure must achieve a consistent and complete release of metoprolol tartrate from the tablet matrix. The accepted benchmark for recovery, as established in validation protocols, is typically 98.0% to 102.0% when compared to a certified reference standard [18] [19]. Incomplete recovery leads to a negative bias in the assay, directly compromising the accuracy of the dosage form's potency determination.

Target 2: Specificity and Selectivity. The extraction process, in conjunction with the chromatographic separation, must ensure that the measured response is solely attributable to the analyte of interest. This involves demonstrating a lack of interference from common tablet excipients (e.g., binders, fillers, disintegrants, lubricants) and any potential degradation products that may form under stress conditions [19]. Specificity is often verified using peak purity tests with photodiode-array (PDA) or mass spectrometric (MS) detection.

Target 3: Precision and Reproducibility. The extraction methodology must yield highly consistent results. This is measured at multiple levels:

- Repeatability (Intra-assay Precision): Expressed as the Relative Standard Deviation (%RSD) of multiple extractions from a homogeneous sample batch. An acceptable %RSD is typically less than 1.0% for the assay of a drug product [18] [19].

- Intermediate Precision: Demonstrates the reliability of the extraction and analysis when performed under varying conditions within the same laboratory, such as different analysts, equipment, or days.

Target 4: Preparation for Dissolution Profile Comparison. For dissolution testing, the extraction of metoprolol from the dissolution medium is a critical step in generating a complete and accurate release profile. These profiles are essential for comparing test and reference formulations and can support biowaiver claims. The extraction from the medium must be efficient and compatible with the analytical technique to allow for proper comparison using metrics like the similarity factor (f2) [20] [21].

Table 1: Key Analytical Performance Targets for the Extraction and Analysis of Metoprolol Tartrate from Tablets

| Performance Characteristic | Definition & Goal of Extraction | Typical Acceptance Criteria | Primary Influence on Method |

|---|---|---|---|

| Accuracy (Recovery) | Completeness of API release from the matrix. | 98-102% recovery [18] | Ensures the measured concentration reflects the true potency of the tablet. |

| Precision | Consistency of extraction results. | %RSD < 1.0% (Repeatability) [18] | Ensures reliability and reproducibility of the method during routine use. |

| Specificity | Freedom from interference by other components. | No interference from excipients or degradants [19] | Guarantees that the analytical signal is specific to metoprolol tartrate. |

| Linearity & Range | The ability to obtain results proportional to analyte concentration. | Demonstrated across 80-120% of test concentration [19] | Validates that the extraction is consistent across a range of concentrations. |

Detailed Experimental Protocols

Protocol 1: Extraction and HPLC Analysis for Tablet Assay

This protocol details a precise and accurate method for the extraction and simultaneous analysis of metoprolol tartrate from a tablet formulation using RP-HPLC, based on a validated procedure from the literature [18].

I. Principle The powdered tablet material is dissolved and sonicated in methanol to efficiently extract metoprolol tartrate. The resulting solution is filtered to remove particulate matter and insoluble excipients. The filtrate is then analyzed using an isocratic RP-HPLC system with UV detection, enabling quantification against a reference standard.

II. Apparatus and Reagents

- HPLC System: Binary solvent delivery pump, manual/auto injector, column thermostat, and UV/VIS detector.

- Analytical Balance (0.1 mg sensitivity)

- Ultrasonic Bath

- Volumetric Flasks (50 mL, 100 mL)

- Syringe Filters: Nylon, 0.45 µm pore size

- HPLC Column: C18 column (e.g., Inertsil ODS-3, 250 mm x 4.6 mm, 5 µm)

- Metoprolol Tartrate Reference Standard

- Methanol (HPLC Grade)

- Dibasic Potassium Phosphate (AR Grade)

- HPLC Grade Water

III. Procedure Step 1: Mobile Phase Preparation Prepare a mixture of 7.7 g/L dibasic potassium phosphate buffer and methanol in a 60:40 (v/v) ratio. Filter the mixture through a 0.45 µm membrane filter and degas in an ultrasonic bath.

Step 2: Standard Solution Preparation

- Accurately weigh about 25 mg of metoprolol tartrate reference standard and transfer to a 50 mL volumetric flask.

- Add approximately 30 mL of methanol and sonicate to dissolve.

- Dilute to volume with methanol and mix thoroughly. This yields a stock solution with a concentration of approximately 500 µg/mL.

Step 3: Sample Solution Preparation (Extraction)

- Weigh and finely powder not less than 20 tablets.

- Accurately weigh a portion of the powder, equivalent to about 12.5 mg of metoprolol tartrate, and transfer to a 100 mL volumetric flask.

- Add about 50 mL of methanol.

- Sonicate for 15-20 minutes with intermittent shaking, ensuring complete dispersion and dissolution of the API.

- Allow the solution to cool to room temperature.

- Dilute to volume with methanol and mix well.

- Filter a portion of the solution through a 0.45 µm syringe filter, discarding the first few mL of the filtrate.

Step 4: Chromatographic Analysis

- Set the HPLC conditions:

- Detection Wavelength: 226 nm

- Flow Rate: 1.0 mL/min

- Injection Volume: 20 µL

- Column Temperature: Ambient

- Inject the standard and sample solutions in duplicate/triplicate. The typical retention time for metoprolol tartrate under these conditions is approximately 10.81 minutes [18].

Step 5: Calculation Calculate the drug content in the tablet using the following formula: % Label Claim = (At/As) x (Cs/Ct) x (Vs/Vt) x (Average Tablet Weight / Weight of Powder Taken) x 100 x P Where:

- At and As = Peak areas of metoprolol from sample and standard injections, respectively.

- Cs = Concentration of the standard solution (mg/mL).

- Ct = Theoretical concentration of the sample solution (mg/mL).

- Vs and Vt = Volume of standard and sample solutions, respectively.

- P = Potency of the reference standard (on as-is basis).

Diagram 1: Sample Preparation and Extraction Workflow for Tablet Analysis

Protocol 2: Sample Preparation for Dissolution Testing

This protocol describes the preparation of samples from a dissolution test for metoprolol tartrate immediate-release tablets, which can be analyzed using the HPLC method in Protocol 1.

I. Principle Tablets are dissolved in a dissolution apparatus (USP Apparatus I or II). Samples of the dissolution medium are withdrawn at specified time intervals, filtered to remove any undissolved particles or insoluble excipients, and then analyzed to construct a release profile.

II. Apparatus and Reagents

- Dissolution Test Apparatus (USP Apparatus I or II)

- UV-Vis Spectrophotometer or HPLC System

- Syringe Filters: Nylon, 0.45 µm

- Dissolution Medium: 900 mL of degassed simulated gastric fluid (without enzymes) or other suitable medium as per monograph.

- Methanol (HPLC Grade)

III. Procedure

- Set the dissolution apparatus parameters: 900 mL of medium at 37°C ± 0.5°C and a paddle speed of 50 rpm [20].

- Place one tablet in each vessel and start the test.

- At predetermined time intervals (e.g., 5, 10, 15, 20, 30, and 45 minutes), withdraw a 5 mL aliquot from a zone midway between the top of the paddle and the surface of the medium, not less than 1 cm from the vessel wall.

- Immediately filter each aliquot through a 0.45 µm nylon filter.

- If needed, dilute the filtrate with the dissolution medium or methanol to remain within the linear range of the analytical method.

- Analyze the filtered samples using the HPLC method described in Protocol 3.1 or by UV spectrophotometry at 273 nm [20].

- Calculate the cumulative percentage of metoprolol tartrate dissolved at each time point, applying a volume correction for the withdrawn samples.

The Scientist's Toolkit: Research Reagent Solutions

The following table catalogues the essential materials and reagents required to execute the extraction and analysis protocols successfully.

Table 2: Key Research Reagents and Materials for Metoprolol Tartrate Extraction and Analysis

| Item | Specification / Function | Critical Parameters & Notes |

|---|---|---|

| Metoprolol Tartrate Reference Standard | Certified pure substance for preparing calibration standards. | Potency and purity must be certified; used as a benchmark for all quantitative calculations. |

| Methanol | HPLC Grade; primary solvent for extracting the API from the tablet matrix. | Low UV cutoff, low in impurities. Ensures complete dissolution and clean chromatographic baseline. |

| Dibasic Potassium Phosphate | Analytical Reagent Grade; component of the mobile phase buffer. | Required for preparing 7.7 g/L phosphate buffer solution to control mobile phase pH. |

| C18 HPLC Column | 250 mm x 4.6 mm, 5 µm particle size; for chromatographic separation. | The stationary phase for reverse-phase separation. Inertsil ODS-3 is an example [18]. |

| Simulated Gastric Fluid (without enzymes) | Dissolution medium for in vitro release testing. | Mimics the gastric environment; must be degassed prior to use to prevent bubble formation. |

| 0.45 µm Nylon Membrane Filter | For filtration of mobile phase and sample solutions. | Removes particulate matter that could damage the HPLC system or interfere with analysis. |

A meticulously defined extraction process is the cornerstone of any reliable analytical method for determining drug content in solid dosage forms. For metoprolol tartrate tablets, the primary goals of quantitative recovery, specificity, and precision are non-negotiable for ensuring product quality, safety, and efficacy. The protocols detailed herein provide a validated framework for achieving these analytical targets. By adhering to these structured procedures and utilizing the specified research reagents, scientists and drug development professionals can generate accurate, reproducible, and meaningful data that supports robust quality control, formulation optimization, and regulatory submissions.

Established Extraction Protocols: From Simple Solvent Extraction to Advanced Techniques

Solvent extraction, also known as liquid-liquid extraction (LLE), is a fundamental separation technique widely employed in pharmaceutical analysis for isolating and purifying active pharmaceutical ingredients (APIs) from complex matrices such as tablet formulations [22] [23]. This technique leverages the differential solubility of compounds between two immiscible liquid phases, typically aqueous and organic [24]. In the context of analytical method development for metoprolol tartrate, a β1-selective adrenoceptor antagonist used for cardiovascular conditions, efficient extraction is a critical sample preparation step prior to quantitative analysis [16]. The selection and optimization of extraction parameters directly influence the recovery, precision, and accuracy of the analytical method, forming a cornerstone of reliable drug quality assessment and pharmacokinetic studies [23].

Theoretical Principles of Solvent Extraction

The efficiency of solvent extraction is governed by several physicochemical principles. The partition coefficient (K_d) is a fundamental parameter defined as the ratio of the concentration of a solute in the organic phase to its concentration in the aqueous phase at equilibrium [22]. For ionizable compounds like metoprolol, the distribution ratio (D), which accounts for all chemical species of the solute, is more practically relevant. The fraction extracted (E) is given by the equation:

E = [Kd * Vorg / (Kd * Vorg + V_aq)]

where Vorg and Vaq are the volumes of the organic and aqueous phases, respectively [23]. Metoprolol, possessing a basic amine functional group, exhibits pH-dependent partitioning. When the aqueous phase pH is adjusted to at least 1.5 units above its pKa (≈9.7), the molecule is predominantly in its neutral form, favoring partitioning into the organic phase [23]. Conversely, at low pH, the protonated, ionic species remains in the aqueous phase. This principle enables selective extraction and back-extraction (washing) to separate the API from excipients and impurities [23].

Solvent Selection and Optimization for Metoprolol Tartrate

Critical Solvent Properties

The choice of extraction solvent is paramount for achieving high recovery of the target analyte. An ideal solvent for LLE possesses the following characteristics [23]:

- Low solubility in water (<10%) to minimize solvent loss and volume changes.

- High volatility for easy removal and concentration of the analyte post-extraction.

- Compatibility with subsequent analytical techniques (e.g., non-UV absorbing for HPLC-UV).

- High purity to avoid concentration of impurities.

- Favorable polarity and selectivity to maximize the distribution constant (K_d) for the target analyte.

For a relatively polar molecule like metoprolol tartrate, solvents of intermediate polarity are often most effective. Chloroform has been explicitly identified as the solvent of choice in official identification tests for metoprolol tartrate in tablet and injectable formulations [16]. The protocol involves rendering the aqueous phase basic with ammonium hydroxide to deprotonate metoprolol, followed by extraction into chloroform [16].

Table 1: Evaluation of Common Solvents for Metoprolol Extraction

| Solvent | Polarity Index (P') | Water Solubility (%) | Suitability for Metoprolol | Key Considerations |

|---|---|---|---|---|

| Chloroform | 4.1 | 0.8 | High | Official compendial method; good recovery [16]. |

| Dichloromethane | 3.1 | 1.3 | High | Similar to chloroform, with higher volatility. |

| Ethyl Acetate | 4.4 | 8.7 | Moderate | Higher water solubility can be a drawback. |

| Diethyl Ether | 2.8 | 6.0 | Moderate | High flammability and peroxide formation risk. |

| n-Hexane | 0.1 | 0.001 | Low | Too non-polar for effective metoprolol extraction. |

Optimization of Operational Parameters

Beyond solvent identity, several operational parameters require systematic optimization to maximize extraction efficiency and robustness.

Table 2: Key Optimization Parameters for Metoprolol Tartrate LLE

| Parameter | Optimal Condition / Effect | Recommendation for Metoprolol |

|---|---|---|

| pH of Aqueous Phase | Controls ionization state of analyte. | Adjust to ≥11.2 with NH₄OH or NaOH to ensure neutral species [23] [16]. |

| Phase Volume Ratio (Vorg/Vaq) | Impacts concentration factor and recovery. | A ratio of 1:1 to 1:2 is typical; multiple extractions with smaller volumes are more efficient than a single large volume [23]. |

| Extraction Time & Mixing | Governs kinetics of mass transfer. | Vigorous shaking for 5-15 minutes is usually sufficient to reach equilibrium. |

| Ionic Strength | "Salting-out" effect can decrease analyte solubility in water. | Addition of inert salts like NaCl or Na₂SO₄ can improve recovery [23] [24]. |

| Temperature | Affects solubility and partition coefficient. | Room temperature is standard; elevated temperatures are rarely needed. |

Advanced optimization can leverage computational approaches like COSMO-RS (Conductor-like Screening Model for Real Solvents), which uses a quantum chemistry-based method to predict thermodynamic properties and solubility, aiding in the rational selection of optimal solvents or solvent mixtures without exhaustive laboratory experimentation [25].

Detailed Application Protocol: Extraction of Metoprolol Tartrate from Tablets

This protocol describes the standard solvent extraction procedure for the isolation of metoprolol tartrate from tablet formulations prior to identification by Infrared (IR) spectroscopy, as adapted from compendial methods [16].

Research Reagent Solutions and Materials

Table 3: Scientist's Toolkit: Essential Materials and Reagents

| Item | Specification / Function |

|---|---|

| Metoprolol Tartrate Tablets | Ground to a fine, homogeneous powder. |

| Chloroform | HPLC or ACS grade; primary extraction solvent. |

| Ammonium Hydroxide Solution | ~1-3 M; used to alkalize the aqueous phase. |

| Anhydrous Sodium Sulfate (Na₂SO₄) | For drying the organic extract. |

| Volumetric Flasks / Separatory Funnels | For mixing and phase separation. |

| Water Bath / Nitrogen Evaporator | For gentle solvent evaporation and concentration. |

| Centrifuge | Optional, for breaking emulsions. |

| Potassium Bromide (KBr) | For preparation of IR pellets. |

Step-by-Step Experimental Procedure

Sample Preparation: Accurately weigh and finely grind a representative number of metoprolol tartrate tablets. Transfer a portion equivalent to approximately 136 mg of metoprolol tartrate into a suitable container [16].

Initial Dissolution and Basification: Add 25 mL of water and 4 mL of ammonium hydroxide solution to the powder. Stir or shake thoroughly to ensure complete wetting and dissolution of the API. The addition of base is critical to convert metoprolol to its free base form.

Liquid-Liquid Extraction: Transfer the mixture to a separatory funnel. Add a 25-30 mL portion of chloroform. Seal the funnel and shake vigorously for 10-15 minutes, with periodic venting to release pressure. Allow the phases to separate completely until a clear interface is established.

Phase Separation: Drain the lower organic layer (chloroform phase) into a clean, dry flask. If an emulsion forms at the interface, it can often be broken by gentle stirring, centrifugation, or by adding a small amount of salt [23].

Drying: Pass the collected chloroform extract through a bed of anhydrous sodium sulfate to remove any residual water.

Solvent Evaporation and Crystallization: Evaporate the chloroform extract just to dryness using a rotary evaporator or under a gentle stream of nitrogen. To promote crystallization, place the residue in a freezer for a period of time [16].

Analysis: The resulting crystals of metoprolol free base can be triturated with KBr and compressed into a pellet for FT-IR spectroscopic identification, completing the official compendial test [16].

Troubleshooting and Alternative Techniques

Common Challenges and Solutions

- Emulsion Formation: A frequent issue in LLE, often caused by tablet excipients or over-aggressive shaking. Remedies include using a different solvent (e.g., chloroform instead of ethyl acetate), gentle inversion mixing instead of shaking, adding a small volume of salt solution, or centrifugation [23] [24].

- Incomplete Recovery: If recovery is low, perform multiple extractions (e.g., 2-3 times) with fresh solvent. The combined efficiency for n extractions is given by 1 - [1/(1+Kd(Vorg/V_aq))^n] [23]. Also, verify the pH is sufficiently basic.

- Low Concentration Factor: For trace analysis, use a smaller volume of organic solvent relative to the aqueous phase to pre-concentrate the analyte [23].

Modern and Alternative Extraction Approaches

While traditional LLE is robust, newer techniques offer advantages of solvent reduction, automation, and speed.

- Solid Phase Extraction (SPE): Often provides higher selectivity, lower solvent consumption, and is easier to automate compared to LLE [22]. It is highly suitable for clean-up and concentration of metoprolol from biological fluids or complex samples.

- Solid-Liquid Extraction (SLE): Direct extraction of the powdered tablet with a solvent can be a simpler alternative, though it may co-extract more interferents [22] [26].

- Microwave-Assisted Extraction (MAE): Uses microwave energy to heat the solvent and sample rapidly, reducing extraction time and solvent volume [22].

- Automated Systems: Systems like the PromoChrom Automated SPE-03 can be adapted for high-throughput LLE or SPE workflows, improving reproducibility for large sample sets [22].

The effective isolation of metoprolol tartrate from its dosage form is a critical step in pharmaceutical analysis. Standard solvent extraction using chloroform under basic conditions remains a gold-standard, compendial-method-driven technique for this purpose [16]. Its success hinges on the rational selection and meticulous optimization of the solvent and key parameters, primarily pH. A deep understanding of the underlying principles of partition coefficients and the chemistry of the analyte allows researchers to develop robust, efficient, and reliable extraction methods. While traditional LLE is a cornerstone technique, the field continues to evolve with the integration of computational solvent optimization [25] and the adoption of more sustainable and automated sample preparation methods.

Spectrophotometric Method via Copper(II) Complexation

This application note details a validated protocol for the quantitative analysis of metoprolol tartrate (MPT) in pharmaceutical dosage forms. The method is based on the formation of a colored coordination complex between MPT and copper(II) ions in aqueous solution, followed by spectrophotometric detection [27]. The procedure is optimized for the context of sample preparation for MPT extraction from tablets, providing a framework for reliable and accurate determination of drug content. The formation of a stable, binuclear copper(II) complex (Cu~2~MPT~2~Cl~2~) offers a specific and sensitive means of analysis suitable for quality control and research applications [27].

Principle of the Method

Metoprolol tartrate, containing secondary amine and hydroxyl functional groups, acts as a ligand to form a blue-colored, binuclear complex with copper(II) ions at a weakly acidic pH [27]. The complex exhibits a maximum absorbance at 675 nm. The intensity of this absorbance is directly proportional to the concentration of MPT in the solution, allowing for quantitative determination based on the Beer-Lambert law [27] [28]. The method is characterized by its simplicity, as it requires minimal sample preparation and avoids the use of organic solvents for extraction.

Chemical Complexation Pathway

The Scientist's Toolkit: Key Research Reagent Solutions

Table 1: Essential Reagents and Materials for MPT-Cu(II) Complexation Analysis

| Reagent/Material | Specification/Function |

|---|---|

| Metoprolol Tartrate Standard | High-purity reference standard for calibration curve preparation. |

| Copper(II) Chloride Dihydrate (CuCl₂·2H₂O) | Source of Cu²⁺ ions for complex formation; prepared as 0.5% (w/v) aqueous solution [27]. |

| Britton-Robinson (BR) Buffer | Universal buffer system; maintains optimal reaction pH of 6.0 [27]. |

| Deionized Water | Solvent for all aqueous solutions to ensure absence of interfering ions [27]. |

| UV-Vis Spectrophotometer | Instrument for measuring absorbance of the complex at 675 nm. |

| Thermostatically Controlled Water Bath | Maintains consistent reaction temperature of 35°C for complex development [27]. |

Experimental Protocol

Reagent Preparation

- Stock MPT Solution (0.2 mg/mL): Accurately weigh and dissolve an appropriate amount of metoprolol tartrate standard in deionized water. This solution is stable for up to one week when stored at 4°C [27].

- Copper(II) Solution (0.5% w/v): Dissolve 0.5 g of CuCl₂·2H₂O in 100 mL of deionized water.

- Britton-Robinson Buffer (pH 6.0): Prepare the buffer solution as per standard laboratory procedures and adjust the pH to 6.0.

Calibration Curve Construction

- Pipette aliquot volumes of the MPT stock solution to prepare a series of standard solutions covering the concentration range of 8.5 to 70 µg/mL in 10 mL volumetric flasks [27].

- To each flask, add 1.0 mL of BR buffer (pH 6.0) and 1.0 mL of the 0.5% Cu(II) solution [27].

- Mix the solutions thoroughly and heat for 20 minutes in a water bath maintained at 35°C to facilitate complex formation [27].

- After heating, cool the solutions rapidly to room temperature. Dilute to the mark with deionized water and mix well.

- Measure the absorbance of each solution at 675 nm against a reagent blank prepared similarly but without MPT.

- Plot the absorbance values against the corresponding MPT concentrations to construct the calibration curve.

Sample Preparation: Tablet Analysis

- Weigh and finely powder ten tablets.

- Transfer an accurately weighed portion of the powder, equivalent to about 40 mg of MPT, to a conical flask.

- Extract the drug by shaking with four 20 mL portions of deionized water. Filter the extracts quantitatively into a 100 mL volumetric flask.

- Dilute the combined filtrates to volume with deionized water to obtain the sample stock solution [27].

- Dilute an aliquot of this stock solution appropriately to fall within the linear range of the calibration curve (8.5–70 µg/mL).

- Subject the diluted sample solution to the analytical procedure described in Section 4.2 (steps 2-5).

- Determine the MPT concentration in the sample solution using the regression equation of the calibration curve.

Experimental Workflow for Tablet Analysis

Data Analysis and Method Validation

Table 2: Spectrophotometric Method Performance Characteristics for MPT Determination [27]

| Parameter | Result / Value |

|---|---|

| λmax | 675 nm |

| Beer's Law Range | 8.5 - 70 µg/mL |

| Regression Equation (Example) | A = a + bC (r = 0.998) |

| Molar Absorbivity | Reported for the binuclear complex |

| Limit of Detection (LOD) | 5.56 µg/mL |

| Limit of Quantification (LOQ) | 7.11 µg/mL |

| Optimum pH | 6.0 |

| Reaction Temperature | 35°C |

| Complex Stoichiometry | Binuclear (Cu(2)MPT(2)Cl(_2)) |

Discussion

The described method provides a robust and efficient approach for assaying metoprolol tartrate in tablet formulations. The direct complexation with copper(II) at pH 6.0 simplifies the analytical procedure by eliminating the need for extensive sample clean-up or extraction with organic solvents, as required in some other methods [27] [29]. The high selectivity of the reaction is demonstrated by the successful application to pharmaceutical dosage forms with minimal interference from common excipients.

The formation of the binuclear Cu(2)MPT(2)Cl(_2) complex is well-characterized, with confirmed stoichiometry and stability. The blue color of the complex provides a distinct analytical signal at 675 nm, a wavelength where interference from other tablet components is typically minimal. The method's validation data confirms its suitability for routine quality control analysis, offering good accuracy, precision, and linearity over a pharmaceutically relevant concentration range. This protocol fits seamlessly into broader thesis research on sample preparation, highlighting a key spectrophotometric strategy for drug quantification.

RP-HPLC Method for Simultaneous Estimation with Other Drugs

The development of robust, precise, and accurate Reverse Phase High-Performance Liquid Chromatography (RP-HPLC) methods is a critical component of pharmaceutical analysis, particularly for the simultaneous estimation of multiple drug components. Such methods are indispensable for quality control laboratories analyzing multiple therapeutics, clinical studies investigating combination therapies, and for supporting formulation development research [30]. Within the context of a broader thesis investigating sample preparation for metoprolol tartrate extraction from tablets, this application note provides a detailed protocol for a validated RP-HPLC method suitable for the simultaneous estimation of drugs in combination formulations. The systematic approach outlined here, from method selection to validation, ensures reliability and compliance with international regulatory standards.

Experimental Design and Methodology

Selection of the HPLC Method and Initial Conditions

Method development begins with a careful assessment of the analytes and the selection of an appropriate chromatographic system.

- Chromatography Mode: Reverse-phase HPLC is the recommended choice for the majority of pharmaceutical compounds due to its broad applicability and excellent resolving power. It is particularly suited for polar and semi-polar analytes [31].

- Stationary Phase: A C18-bonded silica column is the most widely used and recommended initial choice. For this protocol, columns such as the Hypersil BDS C18 (150 mm × 4.6 mm; 5 μm) or a Phenomenex Luna ODS C18 (250 mm × 4.6 mm; 5 μm) provide a strong starting point for method development [30] [32].

- Mobile Phase: A binary system is preferred for its simplicity. A mixture of a water-miscible organic solvent and an aqueous buffer is standard. Methanol-water or acetonitrile-water systems are most common. The pH of the aqueous component can be adjusted using acids like ortho-phosphoric acid (e.g., 0.1%) or buffers such as phosphate buffer to control the ionization of acidic or basic analytes, thereby influencing retention and peak shape [30] [32].

- Detection: A UV/Visible detector is standard for analytes containing chromophores. The wavelength should be set to the λmax of the primary analyte or an iso-absorptive point for multiple components to ensure optimal sensitivity for all compounds [33] [31].

- Elution Mode: Isocratic elution is sufficient for simple mixtures with a small number of components. For complex samples with a wide range of analyte polarities, gradient elution is necessary to achieve adequate resolution within a reasonable time [31].

Optimization Using Design of Experiments (DoE)

A systematic optimization using Quality by Design (QbD) principles is highly recommended to understand the method's robustness. A Box–Behnken Design (BBD) is an efficient response surface methodology for this purpose [32].

- Independent Variables: Critical method parameters such as the ratio of mobile phase, flow rate (e.g., 0.8-1.2 mL/min), pH of the aqueous buffer, and injection volume can be selected as independent variables [32].

- Responses: Key chromatographic outputs like retention time, peak area, resolution between critical pairs, and theoretical plate count are measured as responses.

- Data Analysis: The data is analyzed using statistical software to generate models and perturbation plots. A desirability function is then used to identify the optimal chromatographic conditions that satisfy all criteria simultaneously [32].

The following workflow outlines the stages of method development from inception to a validated protocol:

Detailed Experimental Protocol

Materials and Reagents

- Drug Substances: Pure reference standards of the drugs to be analyzed (e.g., Metoprolol Tartrate and other compatible drugs for simultaneous estimation).

- Chemicals: HPLC-grade solvents (Methanol, Acetonitrile), high-purity water (Milli-Q or equivalent), and buffer components (Ortho-phosphoric acid, Potassium dihydrogen phosphate, etc.).

- Equipment: HPLC system with quaternary pump, auto-sampler, thermostatted column compartment, and UV/Vis or Diode Array Detector (DAD). An analytical balance, pH meter, ultrasonic bath, and vacuum filtration assembly with 0.45 µm membrane filters are also required [30].

Preparation of Solutions

- Stock Standard Solutions (1000 µg/mL): Accurately weigh and transfer approximately 100 mg of each drug reference standard into separate 100 mL volumetric flasks. Dissolve and make up to volume with methanol or a suitable solvent. Sonicate to ensure complete dissolution [30].

- Working Standard Solutions (100 µg/mL): Pipette 10 mL from each stock solution into a 100 mL volumetric flask and dilute to volume with the mobile phase or diluent [30].

- Sample Solution (Tablet Extraction): Weigh and finely powder not less than 20 tablets. Accurately weigh a portion of the powder equivalent to the label claim of the drug(s) (e.g., ~100 mg of metoprolol tartrate) into a 100 mL volumetric flask. Add about 70 mL of diluent (e.g., methanol or mobile phase), sonicate for 15-20 minutes with intermittent shaking, and allow to cool to room temperature. Dilute to volume with the same solvent, mix well, and filter through a 0.45 µm membrane filter. Further dilute the filtrate as needed to obtain a concentration within the linear range of the calibration curve [33].

Chromatographic Conditions

- Column: Hypersil BDS C18 (150 mm × 4.6 mm, 5 µm) or equivalent.

- Mobile Phase: Methanol: Phosphate Buffer (10 mM, pH adjusted to 6.3 with KOH/OPA) in a ratio of 25:75 (v/v). Note: The ratio and pH should be optimized for the specific drug combination. [32]

- Flow Rate: 1.0 mL/min.

- Column Temperature: 25 ± 2 °C.

- Detection Wavelength: 230 nm (or as optimized for the drugs).

- Injection Volume: 20 µL.

- Run Time: Approximately 6-10 minutes, or as required to elute all components [30].

Validation Protocol

The method must be validated as per International Council for Harmonisation (ICH) guidelines to ensure it is suitable for its intended purpose [31]. The key validation parameters and their typical acceptance criteria are summarized below:

Table 1: Key Validation Parameters and Acceptance Criteria for an RP-HPLC Method

| Parameter | Protocol | Acceptance Criteria |

|---|---|---|

| System Suitability | Inject six replicates of standard solution. | RSD of peak area & retention time ≤ 2.0%; Theoretical plates > 2000; Tailing factor ≤ 2.0 [30] [31]. |

| Specificity | Inject blank (diluent), placebo, standard, and sample. Verify resolution from any potential interferents. | No interference from blank, placebo, or degradation products at the retention time of the analytes [34]. |

| Linearity & Range | Prepare and inject standard solutions at a minimum of 5 concentration levels (e.g., 10-50 µg/mL). Plot peak area vs. concentration. | Correlation coefficient (r²) ≥ 0.999 [30]. |

| Accuracy (Recovery) | Spike placebo with known amounts of standard at three levels (80%, 100%, 120%) in triplicate. Calculate % recovery. | Mean Recovery: 98.0 - 102.0% [33]. |

| Precision | Repeatability (Intra-day): Inject standard at 100% concentration level six times in one day.Intermediate Precision (Inter-day): Perform the assay on a different day, by a different analyst, or on a different instrument. | RSD ≤ 2.0% [30] [34]. |

| Robustness | Deliberately vary parameters (e.g., flow rate ±0.1 mL/min, mobile phase pH ±0.2, temperature ±2°C) and assess system suitability. | System suitability criteria are met in all varied conditions [34]. |

| LOD/LOQ | Determine based on signal-to-noise ratio (S/N). | LOD: S/N ≈ 3:1; LOQ: S/N ≈ 10:1 [30] [34]. |

The Scientist's Toolkit: Essential Research Reagents and Materials

A successful HPLC analysis relies on high-quality materials and reagents. The following table lists the essential items for the protocol described.

Table 2: Key Research Reagent Solutions and Essential Materials

| Item | Function / Explanation |

|---|---|

| C18 Column | The stationary phase for reverse-phase separation; provides hydrophobic interactions with analytes. |

| HPLC-Grade Methanol/Acetonitrile | Organic modifiers in the mobile phase; control the elution strength and selectivity. |

| HPLC-Grade Water | The aqueous component of the mobile phase; must be of high purity to minimize baseline noise. |

| Buffer Salts (e.g., K₂HPO₄, KH₂PO₄) | Used to prepare the aqueous buffer for controlling mobile phase pH, critical for reproducible retention of ionizable analytes. |

| Ortho-phosphoric Acid / Trifluoroacetic Acid (TFA) | Used to adjust mobile phase pH and improve peak shape for acidic or basic compounds. |

| Membrane Filters (0.45 µm or 0.22 µm) | For removing particulate matter from mobile phases and sample solutions to protect the HPLC column and system. |

| Reference Standards | Highly purified materials of known concentration and identity, used to prepare calibration standards for quantitative analysis. |

| Ultrasonic Bath | For efficient degassing of the mobile phase (preventing air bubbles in the system) and dissolving solid samples. |

Data Analysis and Interpretation

After running the samples under the validated conditions, data acquisition software (e.g., ChemStation, LabSolutions) is used to integrate the chromatographic peaks.

- Identification: Identify peaks in the sample chromatogram by comparing their retention times with those of the standard solutions.

- Quantification: Calculate the concentration of the drug(s) in the sample solution using the regression equation (y = mx + c) obtained from the calibration curve of the standard.

- Assay Calculation: The percentage of label claim in the tablet formulation can be calculated using the following formula:

% Assay = (Cs × D × V × 100) / (LC × W)

Where:

- Cs = Concentration of the drug in the sample solution obtained from the calibration curve (µg/mL)

- D = Dilution factor

- V = Volume of the sample solution (mL)

- LC = Label claim of the tablet (mg)

- W = Weight of the sample powder taken (mg)

The systematic approach to method development and validation, as detailed in this application note, provides a reliable framework for the simultaneous estimation of metoprolol tartrate with other drugs from tablet formulations, contributing critical analytical support to pharmaceutical development research.

In pharmaceutical analysis, the accuracy of quantitative results for Active Pharmaceutical Ingredients (APIs) in solid dosage forms is fundamentally dependent on the robustness of the sample preparation workflow. For drugs like metoprolol, a selective β1-adrenoreceptor antagonist used in managing cardiovascular diseases, ensuring precise and reproducible extraction is critical for quality control, bioequivalence studies, and formulation development [35]. The sample preparation process transforms a manufactured tablet into an analysis-ready solution, a procedure that, if not meticulously controlled, becomes a primary source of error and variability in high-performance liquid chromatography (HPLC) and other analytical techniques.

This application note details a standardized protocol for the weighing, pulverizing, and extracting of metoprolol from tablet formulations. The outlined workflow is designed to ensure the complete and consistent dissolution of the API while effectively separating it from the excipient matrix, thereby establishing a solid foundation for accurate and reliable analytical results. The principles discussed are framed within a broader research context on optimizing sample preparation for metoprolol, drawing on established preformulation data and regulated testing practices [36] [37].

Theoretical Background and Preformulation Considerations

A thorough understanding of the physicochemical properties of the API is a prerequisite for developing an effective sample preparation protocol. For metoprolol succinate, key preformulation parameters directly influence the choice of diluent, extraction technique, and overall workflow.

Stability studies are paramount for selecting a suitable diluent. Metoprolol succinate demonstrates excellent stability in distilled water, 0.1N HCl, and phosphate buffer (pH 6.8), with no significant degradation observed over 30 minutes, making any of these solvents viable choices for extraction [36]. Furthermore, the API's high solubility in water facilitates rapid dissolution from the dosage form [36].

Drug-excipient compatibility, a critical aspect of formulation stability, must also be considered during sample preparation. Compatibility studies conducted via infrared spectroscopy (IR) have confirmed no major interactions between metoprolol succinate and common excipients such as various grades of Hypromellose (HPMC), ethyl cellulose, colloidal anhydrous silica, microcrystalline cellulose, and sodium stearyl fumerate [36]. This indicates that these excipients are unlikely to interfere chemically during the extraction process.

Table 1: Key Preformulation Data for Metoprolol Succinate [36]

| Parameter | Result / Observation | Implication for Sample Preparation |

|---|---|---|

| Stability in Solvents | Stable in water, 0.1N HCl, and pH 6.8 phosphate buffer for at least 30 minutes. | These solvents are suitable for use as diluents without causing analyte degradation. |

| Solubility in Water | High solubility (≈ 95,896 µg/mL). | Aqueous-based solvents can effectively dissolve the API, avoiding the need for strong organic solvents initially. |

| Drug-Excipient Compatibility | No major interactions found with common tablet excipients. | Excipients are not expected to complicate the chemical extraction of the analyte. |

| % Compressibility | 13.94% | Suggests good flow properties, relevant for powder handling after pulverization. |

Experimental Protocols

Materials and Reagents

Table 2: Research Reagent Solutions and Essential Materials

| Item | Function / Application |

|---|---|

| Metoprolol Reference Standard | Certified API material used for preparing calibration standards and method validation [37]. |

| Metoprolol Tablets | The drug product to be analyzed. |

| Diluent (e.g., pH 6.8 Phosphate Buffer) | To solubilize and extract the API from the tablet matrix [36]. |

| Class A Volumetric Flasks | For precise, quantitative preparation of sample and standard solutions [37]. |

| Analytical Balance | For accurate weighing of samples and reference standards (recommended accuracy ±0.1 mg) [37]. |

| Porcelain Mortar and Pestle | For particle size reduction (pulverizing) of tablets to a fine powder [37]. |

| Ultrasonic Bath or Laboratory Shaker | To facilitate the complete dissolution of the API in the diluent [37]. |

| Syringe Filters (0.45 µm Nylon or PTFE) | To remove insoluble particulate matter from the sample solution prior to HPLC analysis [37]. |

| HPLC Vials | For holding the final, analysis-ready sample solution. |

Step-by-Step Workflow Protocol

Step 1: Weighing of Tablets and Particle Size Reduction

- Weigh Tablets: Accurately weigh 10-20 intact tablets to determine the average tablet weight (ATW) [37].

- Crush and Pulverize: Transfer the tablets to a clean porcelain mortar and crush them thoroughly using the pestle until a homogeneous fine powder is achieved. This particle size reduction is critical for increasing the surface area and ensuring complete and consistent extraction of the API [37].

- Weigh Sample Powder: Accurately weigh a portion of the powdered sample equivalent to the ATW (or the intended number of tablets) and quantitatively transfer it to an appropriately sized Class A volumetric flask (e.g., 100 mL or 1 L) using a powder funnel. Use the diluent to rinse any residual powder from the funnel into the flask [37].

Step 2: Solubilization and Extraction of the API

- Add Diluent: Fill the volumetric flask approximately halfway with the selected diluent (e.g., pH 6.8 phosphate buffer) [36].

- Initial Mixing: Manually swirl the flask to wet the powder and begin the dissolution process.

- Sonication or Shaking: For complete extraction, place the flask in an ultrasonic bath or on a mechanical shaker. The time required for complete dissolution must be optimized and validated during method development. Typically, sonication for 10-20 minutes with occasional swirling is effective. Visually inspect the solution to ensure all particulates have dissolved and the solution is clear [37].