Optimizing Nebulizer Gas Flow Rates for Enhanced Pharmaceutical Aerosol Delivery: A Comprehensive Guide for Researchers

This article provides a systematic review of the critical role of nebulizing gas flow rate in the efficacy of pharmaceutical aerosol delivery.

Optimizing Nebulizer Gas Flow Rates for Enhanced Pharmaceutical Aerosol Delivery: A Comprehensive Guide for Researchers

Abstract

This article provides a systematic review of the critical role of nebulizing gas flow rate in the efficacy of pharmaceutical aerosol delivery. Aimed at researchers, scientists, and drug development professionals, it explores the foundational principles governing flow rate's impact on aerosol characteristics, including droplet size distribution and respirable dose. The content delves into methodological approaches for application across different patient interfaces and ventilation systems, addresses key challenges and optimization strategies through advanced component design and synchronization techniques, and evaluates validation methods and comparative performance of nebulizer technologies. By synthesizing current research and in vitro findings, this resource offers a scientific framework for optimizing flow parameters to maximize lung deposition and therapeutic outcomes in both invasive and non-invasive ventilation scenarios.

The Science of Flow Rate: How Gas Flow Governs Aerosol Generation and Characteristics

Fundamental Principles of Nebulizer Gas Flow and Aerosolization

Nebulizer gas flow is the fundamental force driving the conversion of liquid pharmaceutical solutions into inhalable aerosols. Medical air-compression nebulizers, the most widely used type, operate on Bernoulli's theorem and the Venturi effect [1] [2]. As compressed gas passes through a progressively narrowing nozzle, its velocity increases dramatically, creating a negative pressure zone that draws aqueous medicine into the airflow, atomizing it into fine droplets [1]. This process of primary atomization is followed by secondary atomization where finer droplets are selected through baffle systems that intercept larger droplets, allowing them to return to the nebulization chamber for recirculation while smaller particles are made available for patient inhalation [1].

The efficiency of this aerosolization process directly determines therapeutic outcomes by influencing where drugs deposit within the respiratory tract. Understanding and optimizing gas flow parameters enables researchers and clinicians to target specific pulmonary regions, from the upper airways to the deep alveolar space, maximizing local drug concentration while minimizing systemic side effects [3].

Core Principles of Aerosolization

Physics of Gas-Driven Aerosol Generation

The aerosolization process in jet nebulizers involves complex fluid dynamics where gas flow characteristics determine the initial liquid breakup. When high-pressure gas passes through the nozzle, the dramatic velocity increase creates shear forces that tear the liquid solution into filaments and eventually droplets [1]. The kinetic energy transferred from the gas to the liquid must overcome both the liquid's surface tension and viscous forces to achieve successful atomization.

The size distribution of generated aerosols follows predictable patterns based on the energy input from the gas flow. Higher gas velocities generally produce smaller droplets, though this relationship is moderated by other factors including liquid properties and nebulizer chamber geometry. The median droplet size represents a dynamic equilibrium between primary atomization at the nozzle and secondary selection processes at the baffles [1].

Aerosol Deposition Mechanisms in the Respiratory Tract

Once generated, aerosol particles deposit in different respiratory regions based on their size and the patient's breathing pattern:

- Inertial Impaction: Predominates in the first 10 airway generations where high velocity and turbulence cause larger particles (>5-10 μm) to impact airway surfaces, making this mechanism ideal for targeting upper airways and large bronchi [3].

- Gravitational Sedimentation: Becomes significant in smaller airways (generations 5-16) where air velocity decreases, allowing medium-sized particles (1-5 μm) to settle by gravity, suitable for bronchiolar targeting [3].

- Diffusion (Brownian Motion): Dominates at the alveolar level where minimal air velocity exists, enabling submicron particles to deposit through random molecular motion, essential for alveolar delivery [3].

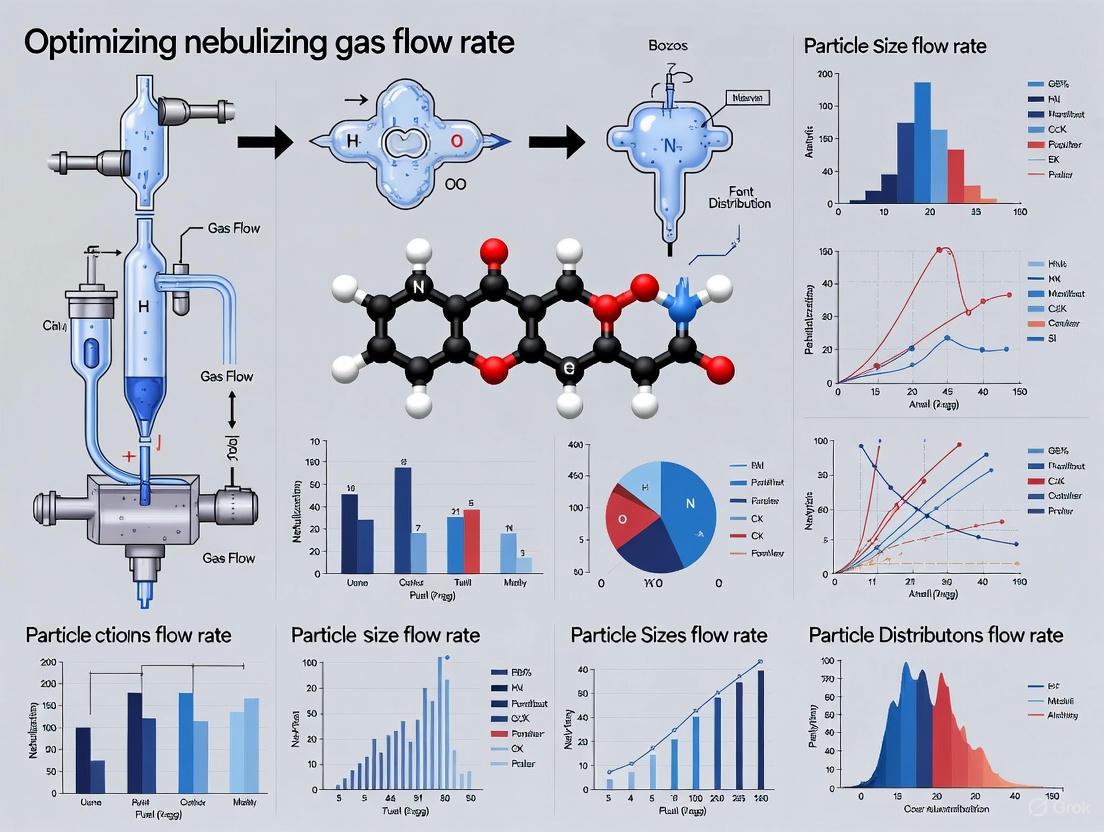

The following diagram illustrates the fundamental workflow of nebulizer gas flow and aerosol deposition:

Diagram 1: Nebulizer gas flow and aerosol deposition workflow.

Critical Factors Influencing Aerosolization Efficiency

Gas Flow Parameters

The supply gas pressure and resulting flow characteristics are primary determinants of nebulizer performance:

- Supply Gas Pressure: Directly influences critical output metrics. Increasing from 50 to 150 kPa can reduce Dv90 (diameter below which 90% of droplets fall) by up to 29.5% in nebulizers with 0.8 mm orifice diameters, creating finer aerosols [2].

- Gas Flow Rate: Varies with pressure and nozzle design. Studies document flow rates from 2.48 to 16.02 L/min for supply gas and 14.28 to 41.38 L/min for jet gas across different operational parameters [2].

- Nozzle Orifice Diameter: Affects the fundamental fluid dynamics. Smaller orifices (0.4 mm) produce higher velocity jets at the same pressure but may exhibit anomalous droplet size increases at higher pressures, while larger orifices (0.6-0.8 mm) demonstrate more consistent refinement of droplet size with increasing pressure [2].

Nebulizer Design Elements

The physical design of nebulizer components significantly moderates gas flow effects:

- Baffle Design: Strategic placement and geometry dramatically affect droplet size distribution. Studies show rounded, conical, flat, and concave baffle shapes effectively reduce sizes of atomized droplets, with mass medium aerodynamic diameter (MMAD) approximately 1.5 times higher in nebulizers without baffles [1].

- Cavity Dimensions: The resonant cavity (Hartmann whistle) between nozzle and baffle, characterized by width (W), depth (D), and insertion distance (S), influences particle size distribution through standing wave patterns and secondary atomization effects [1].

- Liquid Flow Path: Diameter of the liquid feed channel affects liquid flow rate, which combines with gas-liquid pressure differential to determine the final aerosol output concentration [1].

Formulation Characteristics

The physical and chemical properties of the nebulized solution interact with gas flow parameters:

- Solution Osmolarity: Significantly affects droplet size distribution at the nebulizer outlet. Various diluents (0.9% NaCl, 0.45% NaCl, deionized water) produce measurably different MMAD values, with hypertonic saline (3%) demonstrating improved clinical outcomes in some applications [1].

- Surface Tension and Viscosity: Higher values generally increase droplet size by resisting atomization, requiring optimization of gas flow parameters to achieve target aerosol distributions [1] [2].

Quantitative Data on Gas Flow Effects

Gas Pressure and Flow Rate Relationships

Table 1: Effect of supply gas pressure on nebulizer performance parameters [2].

| Supply Gas Pressure (kPa) | Supply Gas Flow Rate (L/min) | Jet Gas Flow Rate (L/min) | Atomizing Rate (mL/min) | Dv90 (μm) |

|---|---|---|---|---|

| 50 | 2.48 - 4.15 | 14.28 - 18.45 | 0.12 - 0.21 | 7.09 - 9.87 |

| 100 | 5.82 - 9.64 | 22.56 - 28.94 | 0.24 - 0.39 | 6.45 - 8.91 |

| 150 | 9.33 - 16.02 | 31.85 - 41.38 | 0.38 - 0.62 | 5.67 - 8.47 |

Nozzle Design Impact on Output

Table 2: Performance characteristics across different nozzle orifice diameters at 100 kPa [2].

| Nozzle Orifice Diameter (mm) | Gas Flow Rate (L/min) | Dv90 (μm) | Effective Output Dose (mg/L) | *Spray Concentration (Light Blocking %) * |

|---|---|---|---|---|

| 0.4 | 5.82 | 8.91 | 12.4 - 15.8 | 28.5 - 36.1 |

| 0.6 | 7.73 | 7.26 | 13.1 - 16.2 | 32.8 - 40.5 |

| 0.8 | 9.64 | 6.45 | 12.9 - 16.5 | 35.2 - 44.9 |

Respiratory Deposition by Particle Size

Table 3: Relationship between aerosol particle size and respiratory deposition patterns [1] [3].

| Particle Size (μm) | Primary Deposition Region | Deposition Mechanism | Therapeutic Applications |

|---|---|---|---|

| >10 | Upper Respiratory Tract (Nasopharyngeal) | Inertial Impaction | Upper Airway Conditions |

| 5-10 | Lower Respiratory Tract (Bronchial) | Inertial Impaction & Sedimentation | Asthma, COPD, Bronchitis |

| 1-5 | Alveolar Region | Gravitational Sedimentation | Pneumonia, Systemic Delivery |

| <1 | Alveolar Region | Diffusion (Brownian Motion) | Severe Pneumonia, Pulmonary Infections |

Experimental Protocols for Gas Flow Optimization

Protocol: Characterizing Droplet Size Distribution

Objective: To measure the droplet size distribution of a nebulizer under controlled gas flow parameters.

Materials:

- Laser Particle Size Analyzer (LPSA)

- Calibrated air compressor (0-150 kPa range)

- Precision gas flow meter (e.g., SIARGO-MF5700)

- Electronic balance (0.1 mg resolution, e.g., LICHEN-FA324TC)

- Test nebulizer unit

- Controlled environment chamber (20±2°C, 50±5% RH)

Methodology:

- Connect the nebulizer to the air compressor through the gas flow meter.

- Fill the nebulizer with 5 mL of standardized test solution (0.9% saline or formulation mimic).

- Set the supply gas pressure to the initial test condition (e.g., 50 kPa).

- Allow the system to stabilize for 30 seconds after initiation.

- Position the LPSA sampling inlet 10 cm from the nebulizer mouthpiece at a 45° angle.

- Record droplet size distribution (Dv10, Dv50, Dv90) over a 60-second sampling period.

- Simultaneously record gas flow rate and collect output for atomizing rate determination.

- Repeat measurements across pressure range (50, 100, 150 kPa) with fresh solution.

- Perform triplicate measurements for each condition.

Data Analysis:

- Calculate MMAD (Mass Median Aerodynamic Diameter) and GSD (Geometric Standard Deviation)

- Determine fine particle fraction (FPF) as percentage of particles <5μm

- Plot relationship between gas pressure and key size parameters

- Calculate emitted dose (ED) and effective output dose (EOD)

Protocol: Evaluating Baffle Design Modifications

Objective: To quantify the impact of baffle geometry on aerosol output under standardized gas flow conditions.

Materials:

- 3D printing system (SLA recommended for precision)

- CAD models of baffle variants (varying W, D, S dimensions)

- Cascade impactor (e.g., Marple 290 or Next Generation Impactor)

- Constant pressure gas supply (8 L/min recommended)

- Analytical balance (0.01 mg resolution)

Methodology:

- Fabricate baffle variants using 3D printing with medical-grade resin.

- Assemble nebulizer cups with each baffle configuration.

- Load with 5 mL of standardized formulation containing tracer compound.

- Operate at fixed gas flow rate (8 L/min) for exactly 2 minutes.

- Collect aerosol using cascade impactor with appropriate flow rate.

- Wash each stage with known volume of appropriate solvent.

- Analyze tracer concentration per stage using validated analytical method.

- Calculate stage-specific deposited mass and cumulative distribution.

- Determine MMAD and FPF for each baffle configuration.

Data Analysis:

- Compare MMAD values across baffle designs using ANOVA

- Optimize baffle dimensions for target particle size range (1-5μm)

- Correlate specific geometric parameters with aerosol performance

The Scientist's Toolkit: Essential Research Materials

Table 4: Essential reagents and materials for nebulization research.

| Item | Function/Application | Research Considerations |

|---|---|---|

| Laser Particle Size Analyzer | Measures droplet size distribution in real-time | Calibrate with standard particles; consider refractive index of test solutions |

| Cascade Impactor | Aerodynamic size separation by inertial impaction | Use with appropriate flow rate; stage coating prevents particle bounce |

| Precision Air Compressor | Delivers consistent gas pressure and flow | Requires regular calibration; pulsation damping may be necessary |

| Hot-Wire Anemometer (e.g., HTI-HT9829) | Measures jet gas velocity at nozzle outlet | Position carefully to avoid flow disturbance; account for turbulence |

| Electronic Balance (0.1 mg resolution) | Determines atomizing rate by mass loss | Environmental factors (vibration, drafts) affect precision |

| 3D Printing System (SLA) | Fabricates custom nebulizer components | Medical-grade biocompatible resins required for drug contact surfaces |

| Test Solutions (0.9% saline, hypertonic saline) | Standardized formulation for performance comparison | Osmolarity and viscosity affect atomization; match physiological properties |

| Fluorescent Tracers (e.g., fluorescein) | Quantifies deposition patterns in experimental models | Validate stability during nebulization; check for surface adsorption |

Advanced Research Applications

Personalized Aerosol Delivery

The recognition that fixed aerosol output parameters may not suit all patients has driven research into personalized nebulization systems. Gas flow control enables adaptation to patient-specific factors including age, disease state, and respiratory pattern [2]. Pediatric patients particularly benefit from modified aerosol characteristics due to their smaller airway dimensions and different breathing patterns compared to adults.

Advanced research explores real-time gas flow modulation synchronized with patient inspiration to maximize lung deposition while minimizing drug waste. This approach, combined with vibrating mesh nebulizer technology, demonstrates particularly efficient alveolar distribution in both healthy and injured lungs [4].

Disease-Specific Optimization

Pathological changes in airway anatomy significantly alter aerosol deposition patterns. Diseases such as COPD and asthma cause airway remodeling and mucous retention that create a proximal shift in deposition [3]. Regional lung diseases further complicate delivery through heterogeneous ventilation, with studies demonstrating lower deposition in atelectatic or poorly ventilated areas [3].

Gas flow optimization must account for these pathological factors. Research shows that despite decreased deposition in severely injured lung regions, nebulized antibiotics still achieve higher lung tissue concentrations than intravenous administration in experimental pneumonia models [3]. This confirms the clinical value of optimized nebulization even in challenging disease states.

Impact of Flow Rate on Droplet Size Distribution and MMAD

In pharmaceutical aerosol inhalation therapy, the efficiency of drug delivery to the respiratory tract is predominantly governed by the droplet size distribution of the generated aerosol [1]. The Mass Median Aerodynamic Diameter (MMAD) is a critical parameter that determines the deposition site of medication within the pulmonary system [1]. Optimal drug delivery requires precise control over droplet size, which is significantly influenced by the nebulizing gas flow rate [2]. This application note systematically examines the impact of gas flow rate on droplet characteristics and provides detailed protocols for researchers and drug development professionals to optimize nebulization parameters for enhanced therapeutic outcomes.

Theoretical Background and Key Principles

Aerosol inhalation therapy serves as an effective method for treating respiratory conditions such as asthma and chronic obstructive pulmonary disease (COPD) by delivering medication directly to the affected organs [1]. The targeted deposition of these aerosols is intrinsically linked to droplet size:

- Large particles (>10 μm): Primarily deposit in the upper respiratory tract (nasopharyngeal region)

- Medium-sized particles (5–10 μm): Deposit in the lower respiratory tract (bronchial region)

- Small particles (1–5 μm): Reach the alveolar region with high efficiency [1]

Air-compression nebulizers, which operate based on Bernoulli's theorem and the Venturi effect, utilize high-speed gas flow to atomize liquid medications into fine droplets [2]. In these systems, the supply gas pressure and flow rate are primary controllable parameters that directly influence atomization characteristics, including droplet size distribution, atomization rate, and spray concentration [2].

Quantitative Analysis: Flow Rate Impact on Droplet Characteristics

Effect of Supply Gas Pressure on Flow Rate and Droplet Size

Table 1: Impact of supply gas pressure on gas flow rates and droplet size distribution [2]

| Supply Gas Pressure (kPa) | Supply Gas Flow Rate (L/min) | Jet Gas Flow Rate (L/min) | Dv90 (μm) for 0.6 mm Nozzle | Dv90 (μm) for 0.8 mm Nozzle |

|---|---|---|---|---|

| 50 | 2.48 - 6.42* | 14.28 - 23.01* | 6.85 | 8.91 |

| 100 | 5.87 - 11.34* | 24.15 - 32.67* | 5.47 | 7.12 |

| 150 | 8.91 - 16.02* | 32.67 - 41.38* | 4.78 | 6.28 |

*Range represents variation across different nozzle orifice diameters (0.4-0.8 mm)

MMAD Variation with Nebulizer Operating Parameters

Table 2: MMAD variations across different nebulizer designs and operating conditions [1] [5]

| Nebulizer Type / Condition | MMAD (μm) | Operating Parameters | Notes |

|---|---|---|---|

| Commercial Brand 1 | 9.8 - 14.8 | Standard compressor | Baseline performance |

| Commercial Brand 4 | 0.93 - 3.5 | Standard compressor | Optimal baseline performance |

| With Baffles | ~4.0 - 6.0 | Standard compressor | Estimated from 1.5x reduction |

| Without Baffles | ~6.0 - 9.0 | Standard compressor | Estimated increase |

| ACI at 28.3 L/min | Lower MMAD | Standard testing | Industry standard flow rate |

| ACI at 18 L/min | Higher MMAD | Simulated patient use | More representative of actual patient conditions [5] |

Effective Output Dose (EOD) Considerations

The Effective Output Dose (EOD) represents the mass of drug contained in each liter of air jetted by the nebulizer, providing a crucial metric for estimating the dose inhaled by patients with each inspiration [2]. Research demonstrates that EOD increases with elevated supply gas pressure but shows no significant correlation with nozzle orifice diameter [2].

Figure 1: Relationship between nebulizer operating parameters and droplet characteristics. Increased gas flow rate, achieved through higher supply pressure or smaller nozzle diameter, enhances atomization efficiency and reduces MMAD.

Experimental Protocols

Protocol 1: Measuring Droplet Size Distribution Using Cascade Impaction

Principle: Cascade impactors separate aerosolized droplets by size through a series of stages with progressively smaller cut-off diameters, allowing for determination of MMAD and geometric standard deviation (GSD) [1] [5].

Materials:

- Andersen Cascade Impactor (ACI) or Marple 290 cascade impactor

- Air-compression nebulizer system

- Electronic balance (accuracy ±0.1 mg)

- Calibrated flow meter

- Vacuum pump with flow control

- Environmental control chamber (for humidity/temperature regulation)

Procedure:

- Equipment Setup: Assemble the cascade impactor according to manufacturer specifications. Connect the vacuum pump and adjust to the desired flow rate (e.g., 28.3 L/min for standard testing or 18 L/min for patient-representative conditions) [5].

- Flow Rate Calibration: Use a calibrated flow meter to verify and adjust the operating flow rate through the impactor. Record environmental conditions (temperature, relative humidity).

- Nebulizer Preparation: Fill the nebulizer with a known volume (typically 2-5 mL) of the drug formulation. Weigh the nebulizer assembly to determine initial mass.

- Aerosol Collection: Activate the nebulizer and simultaneously start aerosol collection through the impactor. Ensure a tight seal between the nebulizer outlet and impactor inlet.

- Sample Collection: Run the nebulizer until either the solution is depleted or a specific collection time has elapsed (typically 2-5 minutes).

- Mass Determination: Carefully disassemble the impactor and quantify the drug mass on each stage using appropriate analytical methods (HPLC, UV-Vis spectroscopy, or gravimetric analysis).

- Data Analysis: Plot the cumulative percentage of drug mass against the aerodynamic cut-off diameter for each stage. Determine MMAD as the diameter where the curve crosses 50% cumulative mass.

Critical Considerations:

- Conduct experiments at controlled relative humidity levels, as ambient humidity can significantly affect droplet size measurements [5].

- For patient-representative data, consider using 18 L/min impactor flow rate rather than the standard 28.3 L/min [5].

- Perform replicate measurements (n≥3) to ensure statistical significance.

Protocol 2: Investigating Supply Gas Pressure Effects on Atomization

Principle: Systematic variation of supply gas pressure while measuring resultant gas flow rates, atomization rate, and droplet size distribution [2].

Materials:

- Customizable air-compression nebulizer with interchangeable nozzles

- Regulated air compressor (0-200 kPa)

- Precision gas flow meter

- Laser Particle Size Analyzer (LPSA)

- Electronic balance (accuracy ±0.1 mg)

- Temperature and humidity sensors

Procedure:

- Nozzle Selection: Install nebulizer nozzle with specific orifice diameter (e.g., 0.4 mm, 0.6 mm, 0.8 mm).

- System Calibration: Calibrate gas flow meter and pressure regulator. Verify accuracy with reference instruments.

- Parameter Setting: Set the supply gas pressure to the initial test condition (e.g., 50 kPa).

- Flow Rate Measurement: Record the supply gas flow rate and jet gas flow rate using the calibrated flow meter and hot-wire anemometer, respectively.

- Atomization Rate Determination: Measure the mass of nebulized solution over a fixed time period (typically 1-2 minutes) using an electronic balance.

- Droplet Size Analysis: Direct the aerosol output to the LPSA for real-time droplet size distribution measurement.

- Iterative Testing: Repeat steps 3-6 across a range of supply gas pressures (e.g., 50, 100, 150 kPa).

- EOD Calculation: Calculate Effective Output Dose using the formula: EOD = (Drug concentration × Atomization rate) / Jet gas flow rate.

Critical Considerations:

- Maintain consistent environmental conditions (temperature, humidity) throughout testing.

- Allow system stabilization at each new pressure setting before recording measurements.

- Test multiple nozzle diameters to understand interaction effects between orifice size and gas flow rate.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Essential materials and equipment for nebulization optimization research

| Item | Function/Application | Specification Notes |

|---|---|---|

| Cascade Impactor | Separates aerosol droplets by size for MMAD determination | Andersen or Marple-type; adjustable flow rate capability (e.g., 18-28.3 L/min) [5] |

| Laser Particle Size Analyzer | Real-time droplet size distribution measurement | Benchtop models with appropriate sizing range (0.1-1000 μm) |

| Benchtop NMR Spectrometer | Non-destructive droplet size distribution in emulsions | MQR time-domain NMR with pulsed-field gradient capability [6] |

| Precision Air Compressor | Controlled gas supply for nebulization | Adjustable pressure (0-200 kPa), stable output [2] |

| Flow Meters | Accurate measurement of gas flow rates | Calibrated for relevant range (e.g., 2-50 L/min) [2] |

| Hot-Wire Anemometer | Jet gas flow velocity measurement | HTI-HT9829 or equivalent [2] |

| Computational Fluid Dynamics Software | Simulation of droplet drying parameters and atomization performance | Capable of multiphase flow modeling with evaporation [7] |

| 3D Printing System | Rapid prototyping of nebulizer components | SLA or similar for high-resolution baffle designs [1] |

Advanced Research Applications

Computational Fluid Dynamics (CFD) in Process Optimization

Computational Fluid Dynamics provides powerful capabilities for simulating the complex multiphase flow and drying kinetics in nebulization systems [7]. CFD implementations can capture:

- Droplet trajectory and residence time distributions within the drying chamber

- Local temperature and relative humidity profiles affecting droplet evaporation

- Drying parameters (κavg, κmax) correlated with final particle characteristics

- Surface enrichment of specific constituents during droplet drying

CFD-guided optimization has demonstrated improved lung delivery efficiency exceeding 60% of the loaded dose in dry powder inhaler formulations [7].

Innovative Measurement Techniques

Time-domain NMR spectroscopy offers a non-destructive alternative for droplet size distribution measurement in emulsions, based on the phenomenon of restricted diffusion [6]. This method:

- Requires minimal sample preparation and avoids structure distortion

- Eliminates the need for hazardous solvents or contrast agents

- Provides excellent repeatability for quality control applications

- Allows further analysis of the same sample by other techniques

The nebulizing gas flow rate serves as a critical process parameter that directly controls droplet size distribution and MMAD in pharmaceutical aerosol products. Through systematic investigation using the protocols outlined in this application note, researchers can optimize flow rate conditions to target specific regions of the respiratory tract. The integration of advanced analytical methods, including cascade impaction, laser diffraction, and computational modeling, provides comprehensive characterization capabilities for developing next-generation nebulized therapies with enhanced pulmonary delivery efficiency.

Correlation Between Flow Rate and Respirable Dose Efficiency

The optimization of nebulizing gas flow rate is a critical parameter in pharmaceutical research and development for inhaled therapeutics. The respirable dose, defined as the fraction of the delivered drug mass residing in particles small enough to reach the lower respiratory tract (typically <5 µm in aerodynamic diameter), is directly influenced by the flow dynamics during aerosol generation [8]. For jet nebulizers, the gas flow rate is a primary determinant of aerosol output rate and particle size distribution, which in turn governs the respirable drug delivery rate (RDDR)—a key efficacy parameter for nebulizer systems [9]. This application note details the correlation between flow rate and respirable dose efficiency, providing standardized protocols for in vitro assessment to support robust pharmaceutical development.

Impact of Flow Rate and Breathing Pattern on Delivered Dose

Table 1: The Influence of Breathing Pattern and Nebulizer Type on Drug Delivery

| Parameter | Impact on Delivered Dose/Respirable Delivered Dose (RDD) | Magnitude of Effect | Citation |

|---|---|---|---|

| Inhalation:Exhalation (I:E) Ratio | Progressive reduction in Delivered Dose (DD) and RDD with increasing exhalation time. | RDD at I:E 1:4 was as little as 40% of the dose at I:E 1:1 for non-breath-activated nebulizers. | [8] |

| Nebulizer Type (General Performance) | Significant variance in delivered dose between different brands. | >4-fold difference in RDD observed between non-breath-activated nebulizers. | [8] |

| Breath-Activated Nebulizers | DD and RDD are largely independent of I:E ratio. | <20% change in RDD between I:E ratios of 1:1 and 1:4 for breath-activated jet nebulizers. | [8] |

| Nebulizer Type (RDDR Comparison) | The Respirable Drug Delivery Rate (RDDR) varies significantly between jet nebulizer systems. | The system with the highest RDDR displayed a value approximately three-fold higher than the system with the lowest RDDR. | [9] |

| High-Flow Nasal Cannula (HFNC) Flow Rate | In a "quiet" breathing pattern, the inhaled dose decreases with increasing gas flow rates. | The percentage of the loaded dose reaching the lung model can be very small, but is optimized at lower flows (e.g., 30 L/min) and with specific nebulizer placement. | [10] |

Table 2: Delivered Dose Efficiency Across Different Breathing Patterns (from BioMedical Engineering OnLine, 2021)

| Breathing Pattern | Tidal Volume (mL) | Respiration Rate (BPM) | I:E Ratio | Typical Delivered Dose Efficiency (Relative to ISO Standard) |

|---|---|---|---|---|

| ISO 27427:2013 | 500 | 15 | 1:1 | Baseline (Highest) |

| Normal Adult | 500 | 15 | 1:2 | Significant reduction |

| Asthma Adult | 290 | 25 | 1:2.5 | Further reduction |

| COPD | 494 | 20 | 1:4 | Lowest |

Experimental Protocols

Protocol 1: Assessment of Nebulizer Efficiency Using a Breathing Simulator

This protocol is designed to quantify the delivered dose and calculate the Respirable Drug Delivery Rate (RDDR) under simulated physiological conditions [9] [11] [12].

Materials and Equipment

- Nebulizer system(s) under test

- Breathing simulator (e.g., PARI COMPAS) capable of generating defined tidal volumes, frequencies, and I:E ratios

- Adult airway model (e.g., VTA-M, RDDonline)

- Next Generation Impactor (NGI) or equivalent particle sizing instrument

- High-Performance Liquid Chromatography (HPLC) system with UV detector

- Analytical balance

- Drug solution (e.g., 0.1% w/v salbutamol sulfate or a solution of your target pharmaceutical)

Procedure

- System Preparation: Fill the nebulizer with a precise volume (e.g., 2 mL) of the drug solution. Weigh the entire assembly to determine the initial mass.

- Breathing Simulation Setup: Program the breathing simulator to the desired pattern. The ISO 27427:2013 standard pattern is a common baseline: 500 mL tidal volume, 15 breaths per minute, and a 1:1 I:E ratio [8] [9].

- Aerosol Collection for Delivered Dose (DD): Connect the nebulizer to the breathing simulator and an appropriate filter placed after the airway model to capture the aerosol that would be inhaled. Activate the nebulizer and run the simulator until nebulization is complete (sputtering for jet nebulizers or no visible aerosol for mesh devices) [11] [12].

- Particle Size Analysis: Determine the aerosol's particle size distribution using the NGI at a defined flow rate (e.g., 15 L/min). This allows for the calculation of the Respirable Fraction (RF), which is the fraction of particles <5 µm [9].

- Data Analysis:

- Emitted Dose (ED): Determine gravimetrically or via drug assay of the nebulizer before and after treatment.

- Delivered Dose (DD): Quantify the amount of drug collected on the inhalation filter using HPLC.

- Respirable Delivered Dose (RDD): Calculate as RDD = DD × RF.

- Respirable Drug Delivery Rate (RDDR): Calculate as RDDR = (Aerosol Output Rate) × RF. The aerosol output rate is the emitted dose divided by the nebulization time [9].

Protocol 2: Optimizing Flow Rate for Nebulization within a High-Flow Nasal Cannula (HFNC) Circuit

This protocol defines the methodology for evaluating and optimizing aerosol delivery integrated with HFNC therapy, a complex clinical scenario where flow rate is a dominant variable [13] [10].

Materials and Equipment

- HFNC system (e.g., Airvo2)

- Vibrating Mesh Nebulizer (VMN) (e.g., Aerogen Solo)

- Adult or child airway model

- Heated humidifier chamber

- Drug solution (e.g., 2.5 mg albuterol)

- Collection filter apparatus

Procedure

- Circuit Setup: Place the VMN immediately upstream of the humidifier chamber. This position has been shown to be one of the most efficient for drug delivery [10].

- HFNC and Breathing Parameters: Set the HFNC to a specific gas flow rate (e.g., 30 L/min, 37 °C, 100% relative humidity). Program the breathing simulator to an appropriate pattern (e.g., "quiet" or "distressed" breathing).

- Nebulization: Add the drug solution to the nebulizer and initiate the HFNC flow. Start nebulization after the circuit is stabilized.

- Sample Collection: Collect the aerosol that passes through the airway model onto a filter.

- Variation of Flow Rate: Repeat the experiment at different HFNC flow rates (e.g., 10 L/min, 30 L/min, 50 L/min) while keeping all other parameters constant.

- Data Analysis: Quantify the drug on the filter for each condition. The results will demonstrate an inverse relationship between HFNC flow rate and inhaled dose under quiet breathing conditions, allowing for the identification of an optimal flow rate that balances therapy and delivery efficiency [10].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Materials for Nebulizer Efficiency and Flow Rate Studies

| Item | Function/Description | Example Models/Details |

|---|---|---|

| Breathing Simulator | Reproduces human breathing patterns (tidal volume, rate, I:E ratio) for in vitro testing. | PARI COMPAS; Custom systems with linear actuators and air cylinders. |

| Anatomical Airway Model | Mimics the geometry of the human upper airway, providing realistic deposition data. | VTA-M (Adult); 3D-printed pediatric models. |

| Cascade Impactor | Measures the aerodynamic particle size distribution (APSD) of aerosols. | Next Generation Impactor (NGI). |

| Laser Diffraction Analyzer | Provides real-time particle size analysis of the aerosol plume. | Malvern Spraytec. |

| Vibrating Mesh Nebulizer (VMN) | Aerosol generator known for high delivery efficiency and low residual volume; essential for HFNC studies. | Aerogen Solo, NE-SM1 NEPLUS. |

| Breath-Enhanced Jet Nebulizer | A type of jet nebulizer with a design that increases aerosol output during patient inhalation. | PARI LC SPRINT (used with PARI BOY compressor). |

| Analytical Quantification System | Precisely measures the amount of drug collected in filters or deposited in impactor stages. | HPLC with UV detection. |

Workflow for Nebulizer Efficiency Testing

The following diagram illustrates the logical workflow and decision points in a comprehensive nebulizer efficiency study.

Diagram 1: Experimental Workflow for Nebulizer Efficiency Assessment. This workflow integrates the selection of critical parameters (nebulizer, breathing pattern) with standardized experimental and analytical steps to determine key performance metrics like Delivered Dose (DD) and Respirable Drug Delivery Rate (RDDR).

The gas flow rate is a fundamental parameter that exhibits a strong and complex correlation with respirable dose efficiency. Key findings confirm that:

- Standardized testing using a single breathing pattern is insufficient to predict performance across the range of patterns seen in patients with respiratory diseases [8] [11].

- The Respirable Drug Delivery Rate (RDDR) serves as a superior, clinically relevant parameter for comparing nebulizer systems, as it integrates both aerosol output rate and respirable fraction [9].

- In integrated systems like HFNC, lower flow rates (e.g., 30 L/min) and strategic nebulizer placement (upstream of the humidifier) are critical for maximizing drug delivery [13] [10].

The experimental protocols outlined herein provide a framework for pharmaceutical researchers to systematically optimize nebulizing gas flow rates, ensuring the development of efficient and therapeutically effective inhaled products.

Understanding Depositional Losses in Delivery Circuits

In pharmaceutical aerosol research, depositional losses refer to the portion of a drug that is lost within the delivery circuit before it reaches the intended respiratory target. These losses significantly reduce delivery efficiency and therapeutic efficacy, particularly in nebulizer systems used for inhaled medications. For researchers optimizing nebulizing gas flow rates, understanding and minimizing these losses is paramount to developing effective drug delivery systems. Depositional mechanisms are influenced by multiple factors including particle characteristics, airway geometry, and breathing patterns [14]. This application note examines the primary mechanisms of depositional losses, provides quantitative data on key influencing factors, details standardized measurement protocols, and offers evidence-based strategies for circuit optimization.

Mechanisms of Depositional Losses

Therapeutic aerosol deposition in delivery circuits and respiratory systems occurs through several physical mechanisms, each dominant under different conditions.

Inertial Impaction: This mechanism predominates for larger particles (>0.5 μm) and in regions with high airflow velocity or directional changes, such as in the oropharyngeal region and at circuit bends. Particles cannot follow the abrupt changes in airflow streamlines and impact surfaces. In nebulizer circuits, impaction is significant at connection points, valves, and the proximal endotracheal tube [14] [15].

Sedimentation: This process results from gravitational settling and is primarily responsible for deposition in the smaller airways and alveolar region where airflow velocities are low. Its effect is most pronounced for particles in the 1-5 μm size range during breath-holding pauses [14].

Diffusion (Brownian Motion): For very small particles (<0.2 μm) and nanoparticles, random molecular motion causes deposition by diffusion, which becomes particularly important in the deep lung regions [14] [16].

Electrostatic Attraction: Pharmaceutical aerosols may carry electrostatic charges from generation processes, especially in DPIs and pMDIs. These charges can induce attractive image forces with circuit walls, enhancing deposition regardless of other particle characteristics [14].

Interception: This occurs when a particle following an airstream comes close enough to a surface for its edge to make contact. This mechanism is particularly relevant for fibrous or elongated particles [14].

Quantitative Factors Influencing Depositional Losses

Impact of Nebulizer Positioning in Ventilator Circuits

The position of the nebulizer within the delivery circuit dramatically affects lung deposition efficiency. The table below summarizes preclinical scintigraphy data comparing different nebulizer positions under humidified and dry conditions [15].

Table 1: Respiratory Tract Deposition Fraction Based on Nebulizer Position

| Nebulizer Position | Humidified Conditions | Dry Conditions |

|---|---|---|

| Next to ventilator | - | 18% (±4%) |

| Right before humidifier | 25% (±3%) | - |

| 15 cm to Y-piece | 57% (±8%) | - |

| Right after Y-piece (proximal) | 43% (±11%) | 53% (±4%) |

Effect of Supply Gas Parameters on Aerosol Characteristics

Gas flow rate and pressure significantly influence aerosol characteristics and subsequent deposition patterns. Higher supply gas pressures generally increase the effective output dose (EOD), defined as the mass of drug contained in each liter of air jetted by the nebulizer [2].

Table 2: Effect of Supply Gas Pressure on Nebulizer Performance

| Supply Gas Pressure (kPa) | Nozzle Orifice Diameter (mm) | Droplet Size (Dv90, μm) | Atomizing Rate Trend | EOD Trend |

|---|---|---|---|---|

| 50-150 | 0.4 | 7.09 to 8.47 (increase) | Increase | Increase |

| 50-150 | 0.6 | Decrease | Increase | Increase |

| 50-150 | 0.8 | 29.5% decrease | Increase | Increase |

Particle Size and Regional Deposition

Particle size fundamentally determines deposition patterns through the respiratory tract. The following table summarizes typical deposition fractions based on aerodynamic diameter during mouth breathing [14].

Table 3: Regional Deposition Fractions by Particle Size (Mouth Breathing)

| Aerodynamic Diameter (μm) | Oral Deposition | Tracheobronchial Deposition | Pulmonary Deposition |

|---|---|---|---|

| 1 | Low | Moderate | High |

| 3 | Moderate | High | Moderate |

| 5 | High | Moderate | Low |

| >10 | Very High | Very Low | Negligible |

Experimental Protocols for Quantifying Depositional Losses

Scintigraphic Deposition Measurement

Purpose: To quantitatively measure regional aerosol deposition in respiratory tracts and delivery circuits using radiolabeled tracers.

Materials:

- Gamma camera (SPECT/CT system)

- 99mTechnetium-labeled diethylene-triamine-penta-acetic acid (99mTc-DTPA)

- Vibrating mesh nebulizer (e.g., Aerogen Solo)

- Mechanical ventilator system

- Ex vivo respiratory tract model or anatomical replica

- Data acquisition and analysis software

Procedure:

- Prepare the radiolabeled tracer by adding 100 MBq of 99mTc-DTPA to the nebulizer medication chamber (3 mL total volume).

- Record the initial radioactive dose using scintigraphic images (180-s anterior/posterior acquisitions).

- Assemble the delivery circuit with the nebulizer positioned at the test location.

- Initiate mechanical ventilation with standardized parameters (tidal volume: 540 mL, respiratory rate: 20/min, inspiratory flow: 35 L/min).

- Begin nebulization and continue for a standardized duration (minimum 15 minutes).

- After nebulization completion, acquire scintigraphic images of each circuit component and respiratory region.

- Quantify deposition fractions by measuring radioactivity in each region relative to the initial nominal dose.

- Calculate losses in individual circuit components (nebulizer, tubing, connectors, valves) by summing the residual radioactivity [15].

Characterization of Aerosol Generation Parameters

Purpose: To measure the effect of supply gas parameters on nebulizer output characteristics.

Materials:

- Medical air-compression nebulizer with variable nozzle designs

- Air compressor with pressure regulation (0-150 kPa capacity)

- Laser Particle Size Analyzer (e.g., Malvern Spraytec)

- Gas flow meter (e.g., SIARGO-MF5700)

- Electronic balance (e.g., LICHEN-FA324TC)

- Hot-wire anemometer (e.g., HTI-HT9829)

Procedure:

- Connect the nebulizer to the pressure-regulated air supply.

- Place the nebulizer outlet in line with the laser particle size analyzer measurement zone.

- For each pressure setting (e.g., 50, 100, 150 kPa):

- Measure the supply gas flow rate using the gas flow meter

- Record the atomizing rate by weighing the nebulizer before and after a timed operation

- Measure droplet size distribution using the laser particle analyzer

- Calculate the Effective Output Dose (EOD): EOD = (Drug concentration × Atomizing rate) / Gas flow rate

- Repeat measurements for different nozzle orifice diameters (0.4, 0.6, 0.8 mm)

- Analyze correlations between supply pressure, droplet size distribution, and output metrics [2].

Single-Breath Nanoparticle Deposition Measurement

Purpose: To measure respiratory tract deposition of nanoparticles in a single breath with controlled breathing parameters.

Materials:

- Electrospray aerosol generator (e.g., TSI 3480)

- Differential Mobility Analyzer (e.g., TSI 3071)

- Condensation Particle Counter (e.g., TSI 3760)

- Computer-controlled four-way valve system

- Breathing flow meter with data acquisition (100 Hz resolution)

Procedure:

- Generate monodisperse nanoparticles (e.g., 22, 50, 75, 100 nm) using the electrospray generator and DMA.

- Direct the aerosol to a reservoir with continuous refreshment and dilution to 2000-6000 particles/cm³.

- Instruct the subject to breathe particle-free air for 30 seconds, then exhale to residual volume.

- At the start of inhalation, switch the valve to the aerosol reservoir.

- After complete inhalation to total lung capacity, initiate a programmed breath-holding period (3-20 s).

- During exhalation, collect a 300 mL sample from the predetermined volumetric lung depth.

- Measure particle concentration in both inhaled and exhaled samples using the CPC.

- Calculate particle recovery (deposition fraction): R = 1 - (Cexhaled / Cinhaled) with correction for instrument losses [16].

Research Reagent Solutions and Materials

Table 4: Essential Research Materials for Deposition Studies

| Material/Equipment | Function | Example Models/Types |

|---|---|---|

| Vibrating Mesh Nebulizer | Generates therapeutic aerosol with high efficiency | Aerogen Solo |

| Condensation Particle Counter | Detects and counts nanoparticle concentrations | TSI 3760, TSI 3010 |

| Differential Mobility Analyzer | Classifies particles by electrical mobility to generate monodisperse aerosols | TSI 3071 |

| Laser Particle Size Analyzer | Measures droplet size distribution in real-time | Malvern Spraytec |

| Electrospray Aerosol Generator | Produces monodisperse nanoparticles from solution | TSI 3480 |

| 99mTechnetium-DTPA | Radiolabeled tracer for scintigraphic deposition imaging | Technescan DTPA |

| Scanning Mobility Particle Sizer | Characterizes aerosol size distribution | Custom SMPS systems |

| Gamma Camera System | Quantifies regional deposition through radiation detection | SPECT/CT systems |

Optimization Strategies and Circuit Design

Based on current evidence, the following strategies minimize depositional losses:

Nebulizer Positioning: Place the nebulizer 15 cm proximal to the Y-piece adapter in ventilator circuits to maximize lung deposition (57% vs 18% when placed next to the ventilator) [15].

Gas Humidification: Maintain gas humidification during nebulization, as it improves overall deposition efficiency compared to dry gas conditions while preventing potential tissue damage from dry aerosol delivery [15].

Pressure and Nozzle Optimization: Select appropriate nozzle orifice diameter (0.6-0.8 mm) and moderate supply pressures (100-150 kPa) to balance droplet size reduction and gas consumption [2] [17].

Flow Rate Considerations: Higher gas flow rates generally produce smaller droplets but increase turbulent losses. The gas-liquid ratio is the primary factor affecting aerosol size when baffle width is constant [17].

Circuit Geometry: Minimize directional changes, constrictions, and unnecessary connections in delivery circuits to reduce inertial impaction losses.

Visualization of Experimental Workflows

Experimental Workflow for Single-Breath Deposition Measurement [16]

Deposition Mechanisms and Their Dominant Regions [14]

Depositional losses in delivery circuits represent a significant challenge in pharmaceutical aerosol research, substantially impacting drug delivery efficiency and therapeutic outcomes. Through systematic characterization of deposition mechanisms, precise measurement using standardized protocols, and implementation of optimization strategies focused on nebulizer positioning and gas flow parameters, researchers can significantly enhance aerosol delivery efficiency. The methodologies outlined in this application note provide a framework for evidence-based optimization of nebulizing gas flow rates and circuit configurations, ultimately contributing to the development of more efficient pharmaceutical aerosol delivery systems.

Applied Flow Rate Strategies for Different Delivery Systems and Patient Populations

Optimizing Flow Rates for Jet vs. Mesh Nebulizers

Nebulizers are critical devices in respiratory medicine, converting liquid medications into aerosols for inhalation. The efficiency of this drug delivery is profoundly influenced by the nebulizing gas flow rate, a key parameter that controls aerosol characteristics and deposition patterns in the lungs. For jet nebulizers (JNs), which operate on compressed gas, the flow rate is a primary, direct input. In contrast, vibrating mesh nebulizers (VMNs) use a vibrating piezoelectric element to push liquid through a mesh, and their "flow rate" often relates to the patient's inspiratory flow or the carrier gas flow in a circuit. This document provides application notes and experimental protocols for researchers and drug development professionals aiming to optimize these parameters for pharmaceutical aerosols.

Performance Data and Comparative Analysis

Quantitative Comparison of Nebulizer Technologies

The fundamental operational differences between JNs and VMNs lead to distinct performance profiles. The following table synthesizes key quantitative findings from recent research.

Table 1: Comparative Performance Metrics of Jet and Mesh Nebulizers

| Performance Parameter | Jet Nebulizer (JN) | Vibrating Mesh Nebulizer (VMN) | Citation & Context |

|---|---|---|---|

| Typical Delivered Dose (% of nominal dose) | 2.46% - 8.20% (Varies with breathing pattern) | 6.75% - 18.49% (Varies with breathing pattern) | In vitro model simulating spontaneous breathing [18]. |

| Relative Delivery Efficiency | Baseline | 2 to 3-fold higher than JN across all tested breathing patterns (normal, obstructive, restrictive) [18]. | In vitro model simulating spontaneous breathing [18]. |

| Improvement in Pulmonary Function (FEV1) | Significant improvement post-treatment | Significantly greater improvement post-treatment compared to JN [19]. | Clinical trial on pediatric asthma attacks [19]. |

| Improvement in Small Airway Function (FEF~25-75~) | Significant improvement post-treatment | Significantly greater improvement post-treatment compared to JN [19]. | Clinical trial on pediatric asthma attacks [19]. |

| Droplet Size Influence | Primarily determined by baffle design and gas pressure. | Smaller, more consistent particles; size can be tailored via mesh pore size [19] [20]. | Clinical and technical reviews [19] [20]. |

| Residual Drug Volume | Higher, leading to more waste [19]. | Lower, leading to higher inhaled dose [19]. | Clinical trial [19]. |

| Key Operational Parameter | Supply Gas Pressure/Flow Rate [2]. | Mesh pore size, vibration frequency, and formulation properties [21]. | Engineering and clinical studies [21] [2]. |

| Impact of Breathing Patterns | Delivery significantly reduced in obstructive/restrictive patterns vs. normal (e.g., ~65% reduction in severe obstruction) [18]. | Delivery significantly reduced in obstructive/restrictive patterns vs. normal, but absolute doses remain higher than JN [18]. | In vitro study [18]. |

Table 2: Impact of Jet Nebulizer Supply Gas Pressure on Atomization Characteristics

| Atomization Characteristic | Relationship with Increasing Supply Gas Pressure | Notes and Mechanisms |

|---|---|---|

| Supply Gas Flow Rate | Increases [2]. | Linear relationship with pressure. |

| Jet Gas Flow Velocity | Increases [2]. | Higher pressure generates higher velocity at the orifice. |

| Atomizing Rate | Increases [2]. | Higher gas velocity shears liquid more efficiently. |

| Droplet Size (D~v90~) | Decreases for orifice diameters ≥ 0.6 mm; may increase for smaller orifices (0.4 mm) at high pressure [2]. | Higher shear forces produce finer droplets. Anomalous increase in smaller orifices may be due to flow regime changes. |

| Droplet Size Uniformity | Improves (distribution narrows) [2]. | More stable and consistent atomization. |

| Spray Concentration | Increases [2]. | More liquid is aerosolized per unit volume of gas. |

| Effective Output Dose (EOD) | Increases [2]. | Represents the mass of drug per liter of air, indicating a higher effective dose per inspiration. |

Key Insights from Data

- VMN Superiority in Delivered Dose: Under identical conditions, VMNs consistently deliver a higher percentage of the nominal drug dose to the lungs, regardless of pathological breathing patterns [18]. This is attributed to their lower residual volume and ability to generate optimal droplet sizes without the need for a high-velocity gas stream [19].

- Criticality of JN Gas Pressure: For jet nebulizers, supply gas pressure is the master variable controlling nearly all atomization characteristics. Optimizing this parameter is essential for balancing droplet size (for deep lung penetration) and output rate (for treatment time) [2].

- Breathing Pattern is a Major Confounder: The patient's breathing pattern (normal, obstructive, restrictive) can cause a greater than 2.5-fold variation in delivered dose, irrespective of nebulizer type [18]. This underscores the need for in vitro testing under realistic breathing profiles.

Experimental Protocols

Protocol 1: Clinical Efficacy Comparison of JN vs. VMN

This protocol is based on a double-blind, randomized comparative clinical trial evaluating nebulizers in a pediatric asthma population [19].

1. Objective: To compare the efficacy of jet and mesh nebulizers in improving pulmonary function and vital signs in pediatric patients experiencing acute asthma exacerbations.

2. Materials:

- Nebulizers: Compressor nebulizer (CN) representing JN technology, and a vibrating mesh nebulizer (VMN).

- Drug: Short-acting β₂ agonist (e.g., Salbutamol solution).

- Equipment: Spirometer (for FEV1, FVC, FEF~25-75~), pulse oximeter, timer.

- Subjects: Patient cohort meeting inclusion criteria (e.g., aged 7-15, presenting with acute asthma attack).

3. Methodology:

- Study Design: Prospective, parallel, double-blind, randomized controlled trial.

- Randomization & Blinding: Patients are randomly assigned to JN or VMN groups. Treatments are administered by a third party to ensure blinding of both patients and outcome assessors.

- Intervention: All patients receive a standardized dose of Salbutamol via the assigned nebulizer.

- Data Collection:

- Baseline: Record demographic data, medical history, pre-treatment pulmonary function tests (FEV1, FVC, FEF~25-75~), and vital signs (respiratory rate, heart rate, SpO2).

- Post-treatment: Repeat pulmonary function tests and vital sign measurements immediately after the nebulization treatment is complete.

- Outcome Measures:

- Primary: Absolute and percent change in FEV1.

- Secondary: Changes in FEF~25-75~, FVC, respiratory rate, and heart rate.

- Statistical Analysis: Compare within-group and between-group changes using appropriate statistical tests (e.g., paired t-tests, ANOVA). A p-value < 0.05 is considered significant.

The workflow for this clinical evaluation is outlined below.

Protocol 2: In-Vitro Optimization of JN Gas Flow Rate

This protocol is derived from studies investigating the effect of operational parameters on nebulizer atomization characteristics [18] [2].

1. Objective: To determine the optimal supply gas pressure/flow rate for a jet nebulizer by characterizing its effect on droplet size distribution, atomizing rate, and effective output dose.

2. Materials:

- Test Nebulizer: Jet nebulizer(s) under investigation.

- Gas Supply: Compressed air or oxygen source with a precision pressure regulator and flow meter.

- Drug Simulant: 0.9% w/v Sodium Chloride (NaCl) solution or specific drug formulation.

- Equipment: Laser Particle Size Analyzer (LPSA), electronic balance (0.1 mg precision), filter setup, timer, hot-wire anemometer.

3. Methodology:

- Experimental Setup: Connect the gas supply to the nebulizer. Place the nebulizer cup on the balance and fill it with a fixed volume of the test solution (e.g., 2.5 mL or 5 mL).

- Variable Manipulation: Set the gas supply pressure to a series of predefined values (e.g., 50, 100, 150 kPa). For each pressure setting, record the corresponding gas flow rate (L/min).

- Data Collection at Each Pressure/Flow Setting:

- Atomizing Rate: Weigh the nebulizer before and after a fixed period of operation (e.g., 2 minutes). Calculate the mass loss per unit time (mg/min).

- Droplet Size Distribution: Direct the aerosol plume into the LPSA measurement zone. Record the volumetric median diameter (D~v50~) and the D~v90~ (diameter below which 90% of the droplet volume resides).

- Effective Output Dose (EOD): Collect the aerosol on an absolute filter for a known duration and volume of gas. Elute the drug and quantify it (e.g., via UV spectroscopy). Calculate EOD as (Mass of drug collected) / (Total gas volume used) (e.g., µg/L) [2].

- Data Analysis: Plot atomizing rate, D~v90~, and EOD against the supply gas pressure/flow rate. The "optimal" range is typically where a high EOD and atomizing rate coincide with a target D~v90~ of 1-5 µm for lower respiratory deposition.

The logical relationship between the controlled parameter and the measured outcomes is depicted below.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Materials and Equipment for Nebulizer Flow Rate Research

| Item | Function/Application | Example/Citation |

|---|---|---|

| Laser Particle Size Analyzer (LPSA) | Measures the size distribution of aerosolized droplets in real-time, a critical quality attribute. | [2] |

| Electronic Balance (High Precision) | Used in gravimetric analysis to determine nebulizer output and atomizing rate by measuring mass loss over time. | [22] [2] |

| Bubble Absorption Tube / Absolute Filter | Captures the aerosol plume for chemical quantification, enabling calculation of delivered dose or EOD. | [21] [2] |

| Breathing Simulator | Simulates realistic human breathing patterns (tidal volume, waveform, rate) for in vitro deposition studies. | QuickLung Breather; used to model normal, obstructive, and restrictive patterns [18]. |

| UV-Vis Spectrophotometer | Quantifies the amount of drug collected on a filter by measuring the absorbance of an eluted sample. | Used to determine albuterol concentration in deposition studies [18]. |

| Sodium Chloride (0.9% w/v) | A common isotonic solution used as a drug simulant for foundational atomization performance testing. | [21] [2] |

| Compressed Gas Source & Regulator | Provides a controllable and stable supply of compressed air or oxygen for operating jet nebulizers. | Requires a precision pressure regulator and flow meter [2]. |

| Anatomical Airway Model | A physical replica (e.g., mouth-throat model) of the human airways used to study regional aerosol deposition. | Idealized MT (mouth-throat) model [21]. |

Flow Rate Considerations for Non-Invasive Ventilation (NIV) and High-Flow Nasal Cannula (HFNC)

Non-invasive respiratory support is a cornerstone in the management of acute respiratory failure, with Non-Invasive Ventilation (NIV) and High-Flow Nasal Cannula (HFNC) representing two primary modalities [23]. For researchers in pharmaceutical development, understanding the technical parameters of these devices is crucial, particularly when designing studies for aerosolized drug delivery. The flow rate setting is a critical operational parameter that directly influences the physiological effects of respiratory support, patient comfort, and the efficacy of concomitant nebulized therapies [2] [24]. This document provides a detailed examination of flow rate considerations for NIV and HFNC, framing them within the context of optimizing pharmaceutical research and nebulized drug delivery.

Physiological and Technical Fundamentals of Gas Flow

Distinct Mechanisms of Action

NIV and HFNC operate on distinct principles, which dictates their respective flow rate parameters and clinical applications. NIV, which includes Continuous Positive Airway Pressure (CPAP) and Bilevel Positive Airway Pressure (BiPAP), provides pressurized gas delivery through an interface, creating positive pressure throughout the respiratory cycle [23]. The key settings are the applied pressures (e.g., Inspiratory Positive Airway Pressure - IPAP, Expiratory Positive Airway Pressure - EPAP). The resulting flow is variable and depends on both ventilator settings and patient effort.

In contrast, HFNC delivers a constant, high flow of heated and humidified gas through nasal cannulas. Its physiological effects include: [23]

- Provision of Low-Level PEEP: HFNC generates positive airway pressure (typically 1-4 cmH₂O), which is flow-dependent and increases with higher set flow rates [23].

- Anatomical Dead Space Washout: High flows facilitate continuous flushing of carbon dioxide from the upper airways, improving alveolar ventilation [23].

- Enhanced Patient Comfort: The heating and humidification of gases allow for high flow rates to be well-tolerated for prolonged periods [23].

Interface and Gas Conditioning

The interface is a critical component differentiating these modalities. NIV is typically administered via facemasks, oro-nasal masks, or helmets, which can create a sealed system necessary for higher pressure delivery but may cause discomfort, claustrophobia, or skin damage [23] [25]. HFNC uses dedicated, often larger-bore, nasal cannulas, which are generally better tolerated and allow for talking, eating, and drinking [23] [26]. The heated and humidified gas in HFNC is essential for patient tolerance at high flows and for maintaining airway mucosa integrity [23]. For pharmaceutical research, the interface and gas conditioning directly impact drug delivery efficiency and patient compliance during experimental protocols.

Flow Rate Parameters and Clinical Outcomes

HFNC Flow Rate Titration and Evidence

HFNC flow rates are actively titrated based on clinical goals. The following table summarizes standard flow rate ranges and their rationales, particularly relevant for designing drug delivery studies.

Table 1: HFNC Flow Rate Titration and Clinical Evidence

| Clinical Scenario | Recommended Flow Rate | Physiological Rationale & Research Considerations | Key Evidence |

|---|---|---|---|

| General AHRF / Post-Extubation | 40-60 L/min [23] [27] | Higher flows (e.g., 60 L/min) maximize PEEP effect and oxygenation in hypoxemic states. Sufficient flow must meet or exceed patient's peak inspiratory flow. | A 2025 RCT (n=169) found no significant difference in reintubation between 40 vs. 60 L/min post-extubation, but 40 L/min group required more escalation (27.9% vs 9.6%) [27]. |

| Hypercapnic Respiratory Failure (e.g., AECOPD) | 30-40 L/min [23] | Lower flows may be sufficient for CO₂ clearance. Higher flows do not consistently offer additional benefits in reducing inspiratory workload in hypercapnia [23]. | A 2025 meta-analysis of AECOPD patients showed no mortality/intubation difference vs NIV, but a trend toward higher treatment failure with HFNC [25]. |

| Patient Tolerance & Comfort | Titrate from 30-50 L/min, adjust temperature [23] | Patient comfort is crucial for adherence. Discomfort can arise from high flow or excessive humidification. Starting at a lower temperature (31°C) may improve initial comfort [23]. | HFNC consistently demonstrates significantly better patient tolerance and lower treatment intolerance compared to NIV interfaces [25] [26]. |

NIV Pressure Settings and resultant Flow

NIV is titrated using pressure settings rather than a direct flow parameter. The resultant flow is variable. The following table outlines standard pressure settings for different clinical conditions, which is vital for understanding the environment in which nebulized drugs are delivered.

Table 2: NIV Mode and Pressure Setting Guidelines

| Clinical Indication | Recommended NIV Mode & Initial Settings | Physiological Rationale | Research Implications |

|---|---|---|---|

| Acute Hypercapnic Respiratory Failure (e.g., AECOPD) | BiPAP (PS/PEEP) via facemask [23] [28] | Pressure Support (PS) unloads respiratory muscles and aids CO₂ clearance. PEEP counteracts intrinsic PEEP (auto-PEEP). | The strong evidence base for NIV in AECOPD makes it a common model for studying hypercapnia rescue therapies. |

| Cardiogenic Pulmonary Edema | CPAP or BiPAP [23] [28] | Positive pressure reduces left ventricular preload and afterload, improving cardiac output. | A stable hemodynamic profile is important for pharmacokinetic studies. |

| de novo Acute Hypoxemic Respiratory Failure | HFNC is often first-line. CPAP may be considered [23] [29] | CPAP increases end-expiratory lung volume and reduces intrapulmonary shunt, improving oxygenation. | High driver pressures and intense inspiratory effort in these patients may increase the risk of patient-self-inflicted lung injury (P-SILI) [23]. |

Comparative Physiological Effects

A 2025 randomized crossover physiological study in high-risk extubation patients directly compared the effects of NIV and HFNO [30]. The study demonstrated that:

- Inspiratory Efforts: Were significantly lower with NIV (simplified esophageal pressure–time product (sPTPes) of 196 cm H₂O·s/min) compared to HFNO (220 cm H₂O·s/min) [30].

- Tidal Volumes: Were larger with NIV (8.4 mL/kg PBW) compared to HFNO (6.9 mL/kg PBW) [30].

These findings suggest that NIV provides more substantial ventilatory support by reducing work of breathing and increasing tidal volume, which may influence drug distribution within the respiratory tract.

Experimental Protocols for Respiratory Support Research

Protocol 1: Comparing HFNC Flow Rates on Extubation Outcomes

This protocol is adapted from a 2025 RCT investigating 40 L/min vs. 60 L/min flow rates [27].

1. Objective: To determine if a higher HFNC flow rate (60 L/min) reduces the rate of reintubation or rescue NIV use within 48 hours after planned extubation, compared to a standard flow rate (40 L/min).

2. Study Population:

- Inclusion Criteria: Adult patients (≥18 years) intubated for >24 hours undergoing planned extubation.

- Exclusion Criteria: Pre-existing tracheostomy, do-not-reintubate order, or immediate need for reintubation post-extubation.

3. Randomization & Blinding:

- Open-label, parallel-group randomized controlled trial.

- Computer-generated randomization sequence.

4. Intervention Groups:

- Experimental Group (60 L/min): HFNC flow rate set at 60 L/min immediately post-extubation. Temperature set to 37°C, FiO₂ titrated to SpO₂ ≥ 92%.

- Control Group (40 L/min): HFNC flow rate set at 40 L/min. Temperature and FiO₂ management identical to the experimental group.

- The assigned flow rate is maintained for 24 hours.

5. Primary Outcome:

- Composite of reintubation or use of rescue NIV within 48 hours post-extubation.

6. Key Secondary Outcomes:

- Escalation of respiratory support (e.g., use of NIV or up-titration of HFNC settings).

- 28-day mortality.

- Patient comfort measured using a visual analogue scale (VAS).

7. Statistical Analysis:

- Intention-to-treat analysis.

- Primary outcome compared using Chi-square test, reporting risk difference with 95% confidence interval.

Protocol 2: Physiological Comparison of NIV vs. HFNC

This protocol is based on a 2025 physiological crossover study [30].

1. Objective: To compare the physiological effects of prophylactic NIV and HFNC on inspiratory efforts and tidal volumes in patients at high-risk of extubation failure.

2. Study Design: Prospective, randomized, crossover physiological study.

3. Study Population:

- Inclusion Criteria: Intubated patients >24 hours, high-risk of extubation failure (age >65 or underlying cardiac/respiratory disease), successful spontaneous breathing trial.

- Exclusion Criteria: Contraindication to nasogastric tube or NIV, do-not-reintubate order.

4. Intervention & Measurements:

- Instrumentation: Prior to extubation, insert an esophageal balloon catheter to measure esophageal pressure (Pes). Place an Electrical Impedance Tomography (EIT) belt.

- Randomized Crossover Sequence: After extubation, patients receive in random order:

- NIV Period (20 min): Delivered via facemask in PSV mode. PEEP ≥5 cmH₂O, PS titrated to expired Vt 6-8 mL/kg PBW.

- HFNC Period (20 min): Flow set to at least 40 L/min. Each period is followed by a washout period on standard oxygen.

- Data Collection: During the last 5 minutes of each 20-minute period, record:

- Airway flow, esophageal pressure (Pes), and EIT signals.

- Calculate primary outcome: simplified Pes-time-product per minute (sPTPes).

- Calculate secondary outcomes: Tidal volume (from EIT), transpulmonary pressure swings, dynamic compliance.

5. Statistical Analysis:

- Use Wilcoxon signed-rank test for paired comparisons of sPTPes and tidal volumes between NIV and HFNC periods.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials and Equipment for Respiratory Support Research

| Item | Function/Application in Research |

|---|---|

| High-Flow Nasal Cannula Device (e.g., Airvo2, Optiflow) | Delivers heated and humidified gas at precise flow rates (up to 60 L/min). Essential for studying HFNC-specific interventions [26]. |

| ICU/Transport Ventilator with NIV Mode (e.g., Carescape R860, Astral 150) | Provides pressure-controlled ventilation (CPAP, BiPAP) via non-invasive interfaces. Necessary for NIV protocol implementation [30] [26]. |

| Esophageal Balloon Catheter System | The gold standard for directly measuring inspiratory effort and work of breathing via esophageal pressure (Pes) monitoring [30]. |

| Electrical Impedance Tomography (EIT) | Non-invasive, real-time imaging modality for assessing regional lung ventilation and tidal volume distribution [23] [30]. |

| Vibrating Mesh Nebulizer (VMN) | Advanced nebulizer technology that can be integrated into HFNC or NIV circuits for efficient aerosolized drug delivery without interrupting therapy [26]. |

| Transcutaneous CO₂/SpO₂ Monitor | Provides non-invasive, continuous monitoring of gas exchange, crucial for assessing response to therapy [30]. |

Decision Pathways and Experimental Workflows

Flow Rate Selection and Escalation Pathway

Diagram 1: Clinical Decision Pathway for Initial Device and Flow Selection

Experimental Protocol for Physiological Comparison

Diagram 2: Crossover Study Workflow for Physiological Comparison

Flow rate is a fundamental parameter in non-invasive respiratory support, with significant implications for physiological effect and clinical outcome. HFNC flow rates between 40-60 L/min are recommended for hypoxemic respiratory failure, while hypercapnic failure often requires the pressure support afforded by NIV. For the pharmaceutical researcher, these settings create distinct environments for aerosol delivery and drug deposition. The structured protocols and decision pathways provided herein offer a framework for rigorous investigation into optimizing respiratory support parameters, with direct relevance to the development and testing of inhaled therapeutics. Future research should continue to integrate precise physiological measurements with clinical outcomes to further refine these application notes.

Pediatric and Infant-Specific Flow Rate Protocols

In the targeted delivery of inhaled pharmaceuticals to pediatric and infant populations, nebulizing gas flow rate stands as a critical parameter governing therapeutic efficacy. Optimization of this parameter is essential for overcoming the unique physiological and anatomical challenges presented by this patient demographic, including smaller airways, higher respiratory rates, and lower tidal volumes. The primary advantage of nebulized medication administration is that it treats the lung directly, avoiding systemic effects; however, lung deposition of the nebulized medication represents a relatively low fraction of the total dose, making efficient delivery paramount [31]. This document establishes application notes and experimental protocols for researchers and drug development professionals focused on enhancing drug delivery efficiency through precise flow rate control, with the goal of developing personalized atomization inhalation treatment plans tailored to pediatric patients [2].

Fundamental Principles of Pediatric Aerosol Delivery

Physiological Considerations by Age Group

Pediatric patients are not a homogenous group; their respiratory physiology evolves significantly from infancy through adolescence, directly impacting aerosol deposition patterns. Key physiological parameters influencing flow rate optimization are summarized in Table 1.

Table 1: Age-Based Physiological Parameters Relevant to Aerosol Delivery

| Age Group | Typical Tidal Volume (mL) | Typical Respiratory Rate (breaths/min) | Typical Inspiratory Flow (L/min) | Key Physiological Considerations |

|---|---|---|---|---|

| Preterm Neonates | 10-20 | 40-60 | 1.0-2.0 | Obligate nasal breathing, minimal breath-holding capacity, extremely small airways |

| Term Neonates (0-28 days) | 20-30 | 30-50 | 1.5-3.0 | Predominant nasal breathing, rapid respiratory rate, compliant chest wall |

| Infants (1-12 mos) | 30-50 | 25-40 | 2.5-4.5 | Transition to oral breathing, active respiratory patterns, developing coordination |

| Toddlers (1-3 yrs) | 50-100 | 20-35 | 3.5-6.0 | Variable cooperation, short attention span, ability to use mask interfaces |

| School-Age (6-11 yrs) | 100-250 | 16-25 | 6.0-12.0 | Ability to follow instructions, can typically use mouthpieces effectively |

| Adolescents (12-18 yrs) | 250-500 | 12-20 | 10.0-20.0 | Adult-like physiology, capable of complex inhalation maneuvers |

The selection of the correct nebulizer device is critical for successful administration in infants and children. Young children may not use a mouthpiece reliably; if the patient cannot hold a mouthpiece between the lips, a face mask should be used. Forcing the mask on a distressed patient will agitate them and may worsen respiratory distress [31].

Critical Atomization Characteristics

The efficiency of aerosol drug delivery is governed by several interdependent atomization characteristics that are directly influenced by the nebulizing gas flow rate:

- Droplet Size Distribution: The mass median aerodynamic diameter (MMAD) of aerosol droplets determines their deposition depth within the respiratory tract. Smaller droplets (1-5 µm) preferentially deposit in the alveolar region, while larger droplets (>5 µm) tend to deposit in the upper airways. For effective lower respiratory tract deposition, aerosols should have an MMAD of 1-5 µm [2].

- Atomizing Rate: The rate at which the drug solution is converted into aerosol, typically measured in mL/min. This parameter directly impacts treatment duration, which is a critical factor for pediatric patient compliance [2].

- Spray Concentration and Effective Output Dose (EOD): The EOD represents the mass of drug contained in each liter of air jetted by the nebulizer, providing a standardized metric to assess the effective dose inhaled by the patient with each inspiration [2].

- Nebulizer Output Flow Rate: The total flow of aerosol generated by the nebulizer, which must be compatible with the patient's inspiratory flow patterns to minimize drug loss during exhalation.

Quantitative Flow Rate and Atomization Data

Experimental Data on Flow Rate Parameters

Recent investigations have systematically quantified the relationship between supply gas pressure, resultant flow rates, and atomization characteristics in medical air-compression nebulizers. These relationships are fundamental to protocol development.

Table 2: Experimentally Measured Flow Parameters vs. Supply Pressure and Nozzle Diameter

| Supply Gas Pressure (kPa) | Nozzle Orifice Diameter (mm) | Supply Gas Flow Rate (L/min) | Jet Gas Flow Rate (L/min) | Resultant Droplet Size Dv90 (µm) |

|---|---|---|---|---|

| 50 | 0.4 | 2.48 | 14.28 | 7.09 |

| 50 | 0.6 | 5.85 | 22.15 | 8.92 |

| 50 | 0.8 | 8.41 | 29.64 | 9.33 |

| 100 | 0.4 | 6.95 | 25.31 | 7.65 |

| 100 | 0.6 | 10.24 | 31.08 | 7.21 |

| 100 | 0.8 | 12.88 | 35.42 | 7.54 |

| 150 | 0.4 | 11.02 | 33.74 | 8.47 |

| 150 | 0.6 | 13.56 | 37.15 | 6.58 |

| 150 | 0.8 | 16.02 | 41.38 | 6.58 |

Key findings from this data indicate that supply gas pressure significantly influences the atomization characteristics of air-compression nebulizers. With increasing supply gas pressure and nozzle orifice diameter, both the supply gas flow rate and jet gas flow rate increase substantially. The relationship between pressure and droplet size is complex, with the nebulizer with 0.8 mm orifice diameter showing a 29.5% decrease in Dv90 when pressure increased from 50 to 150 kPa, indicating a clear advantage in reducing the proportion of large droplets at higher pressures [2].

Research Reagent Solutions and Essential Materials

Table 3: Key Research Materials for Pediatric Flow Rate Studies

| Item | Function/Application in Research |

|---|---|

| Medical Air-Compression Nebulizers | Core device for aerosol generation; available with various nozzle orifice diameters (e.g., 0.4, 0.6, 0.8 mm) to study differential atomization [2] |

| Laser Particle Size Analyzer (LPSA) | Critical for measuring droplet size distribution (Dv10, Dv50, Dv90) to evaluate aerosol respirability [2] |

| Electronic Balance (e.g., LICHEN-FA324TC) | Precision measurement of atomizing rate by monitoring mass loss over time during nebulization [2] |

| Gas Flow Meter (e.g., SIARGO-MF5700) | Direct measurement of supply gas flow rate under various pressure conditions [2] |

| Hot-Wire Anemometer (e.g., HTI-HT9829) | Characterization of jet gas flow velocity at the nozzle outlet [2] |

| Age-Appropriated Airway Models | Anatomically accurate physical or computational models of pediatric airways for deposition studies |

| Simulated Lung Fluid | Physiologically relevant fluid media for in vitro dissolution and deposition testing |

| Pediatric Formulation Placebos | Drug-free formulations matching the physicochemical properties of active products for method development |