Optimizing Solid Phase Extraction: A Comprehensive Guide to Maximizing Efficiency and Recovery

This article provides a systematic guide for researchers and scientists on optimizing Solid Phase Extraction (SPE) to achieve high efficiency and recovery in complex sample matrices.

Optimizing Solid Phase Extraction: A Comprehensive Guide to Maximizing Efficiency and Recovery

Abstract

This article provides a systematic guide for researchers and scientists on optimizing Solid Phase Extraction (SPE) to achieve high efficiency and recovery in complex sample matrices. Covering foundational principles to advanced applications, it details the critical role of sorbent chemistry, method parameter optimization, and strategic troubleshooting for common pitfalls like low recovery and poor reproducibility. The content also explores innovative sorbent materials and multi-step protocols for challenging analyses, supported by recent case studies from environmental and bioanalytical chemistry. Finally, it outlines rigorous method validation protocols and comparative sorbent studies to ensure reliable, reproducible results in drug development and clinical research.

Core Principles of SPE: Building a Foundation for Efficient Extraction

Solid Phase Extraction (SPE) is a cornerstone sample preparation technique that separates analytes from a complex matrix using a solid sorbent. Its effectiveness hinges on exploiting specific chemical interactions, primarily governed by three core retention mechanisms: Reversed-Phase, Ion-Exchange, and Mixed-Mode. Mastering these mechanisms is critical for researchers and drug development professionals to optimize extraction efficiency, ensuring high analyte recovery and purity for subsequent analytical methods like LC-MS [1] [2].

SPE functions as a form of "silent chromatography," where selective retention and elution occur without a detector, relying on a fundamental understanding of chemistry to control the process [2]. The choice of mechanism depends on the physicochemical properties of your analyte and sample matrix. Selecting the appropriate sorbent and optimizing the protocol conditions are the most significant factors in developing a robust and efficient SPE method [3].

Troubleshooting Common SPE Problems

This section addresses frequent challenges encountered during SPE experiments, providing targeted solutions based on the underlying retention principles.

FAQ: How Do I Solve the Problem of Low Recovery?

Low analyte recovery is a common issue where the final extract yields an unexpectedly low signal. This can stem from problems during the loading, washing, or elution stages [4] [5].

- Problem: Analytes are lost in the loading or wash fractions because they are not retained on the sorbent.

- Solution: Ensure the sorbent is properly conditioned before use [6]. Choose a sorbent with a greater selectivity for your analytes [6] [5]. Adjust the sample pH to increase the analyte's affinity for the sorbent—for example, for ion-exchange, ensure the pH charges both the sorbent and the analyte [6]. Decrease the sample loading flow rate to increase interaction time [6] [5].

- Problem: Analytes are retained too strongly and are not eluting completely.

- Problem: The sorbent capacity is exceeded, causing analyte breakthrough during loading.

FAQ: What Causes Poor Reproducibility and How Can I Fix It?

A lack of consistency between replicate extractions undermines the reliability of your data. This is often related to inconsistencies in sorbent conditioning, flow rates, or solvent strength [4] [5].

- Problem: The sorbent bed dried out before or after conditioning.

- Problem: Inconsistent or improper flow rate.

- Problem: The wash solvent is too strong, partially eluting the analyte.

- Problem: Cartridge overload or inconsistent sample pre-treatment.

FAQ: Why Is My Extract Still Dirty After Cleanup?

Unsatisfactory cleanup occurs when interferences co-elute with your analytes, which can lead to ion suppression in MS, chromatographic interference, and inaccurate quantification [7].

- Problem: Wrong purification strategy or sorbent selectivity.

- Problem: Poorly chosen wash or elution solvents.

- Problem: Leachables from the cartridge itself.

FAQ: How Can I Manage Flow Rate Issues?

Flow rate problems can affect retention efficiency and method timing [4].

- Problem: Slow flow rates due to clogging.

- Problem: Slow flow due to high sample viscosity.

- Problem: Variable flow rates between cartridges.

- Solution: Use a controlled manifold or a positive-displacement pump to ensure reproducible flows across all samples [4].

Core SPE Retention Mechanisms and Experimental Optimization

Reversed-Phase Mechanism

- Principle: This mechanism relies on nonpolar interactions (van der Waals forces) between hydrophobic analytes and the nonfunctionalized sorbent surface. It is best for retaining nonpolar analytes from a polar (aqueous) sample matrix [3] [2].

- Sorbent Examples: C18 (Octadecyl), C8 (Octyl), C6, C2, cyclohexyl, and hydrophobic polymeric sorbents like Styrene-Divinylbenzene (SDVB) or HLB [3].

- Optimal Conditions:

- Conditioning: Use methanol or acetonitrile followed by water or a buffer to wet the sorbent and create a compatible environment for the sample [6].

- Loading: The sample should be dissolved in a polar solvent (e.g., water or a weak buffer).

- Washing: Use a slightly polar solvent (e.g., 5-20% methanol or acetonitrile in water) to remove polar matrix interferences without eluting the analyte.

- Elution: Use a strong organic solvent (e.g., methanol, acetonitrile, or tetrahydrofuran) to disrupt the nonpolar interactions [3].

Ion-Exchange Mechanism

- Principle: This mechanism separates analytes based on electrostatic attraction between charged analytes and an oppositely charged sorbent surface. It is ideal for extracting ionic or ionizable compounds [3] [2].

- Sorbent Examples:

- Cation Exchange: Retains positively charged analytes. SCX (Strong Cation Exchange) and WCX (Weak Cation Exchange).

- Anion Exchange: Retains negatively charged analytes. SAX (Strong Anion Exchange) and WAX (Weak Anion Exchange) [3].

- Optimal Conditions:

- Conditioning: Use methanol followed by a buffer that charges both the sorbent and the analyte [6].

- Loading: The sample pH must be adjusted so that both the analyte and the sorbent are charged. For a weak acid (anion), set pH > pKa; for a weak base (cation), set pH < pKa [2].

- Washing: Use a buffer to remove weakly retained interferences. A solvent with a small amount of organic can remove nonpolar impurities.

- Elution: Use a buffer with a high ionic strength (competing ion), a pH that neutralizes the analyte's charge, or a counter-ion solution to displace the analyte [3].

Mixed-Mode Mechanism

- Principle: Mixed-mode sorbents combine two or more retention mechanisms, typically reversed-phase and ion-exchange, within a single sorbent. This allows for highly selective extraction of analytes that possess both hydrophobic and ionic characteristics [3] [7].

- Sorbent Examples: Polymer-based sorbents with embedded ion-exchange functional groups (e.g., MCX for Mixed-Mode Cation Exchange, MAX for Mixed-Mode Anion Exchange).

- Optimal Conditions:

- The protocol is designed to leverage both mechanisms independently.

- Loading: The sample is applied at a pH where ionic interactions are active, ensuring retention via both mechanisms.

- Washing: A wash with a solvent containing a small amount of organic acid or base can selectively disrupt one interaction while preserving the other, enabling fractionation.

- Elution: Elution is often a two-step process. First, a solvent is used to disrupt one mechanism (e.g., an organic solvent to elute nonpolar compounds), followed by a solvent that disrupts the second mechanism (e.g., a basic solvent with organic to elute acidic compounds) [3].

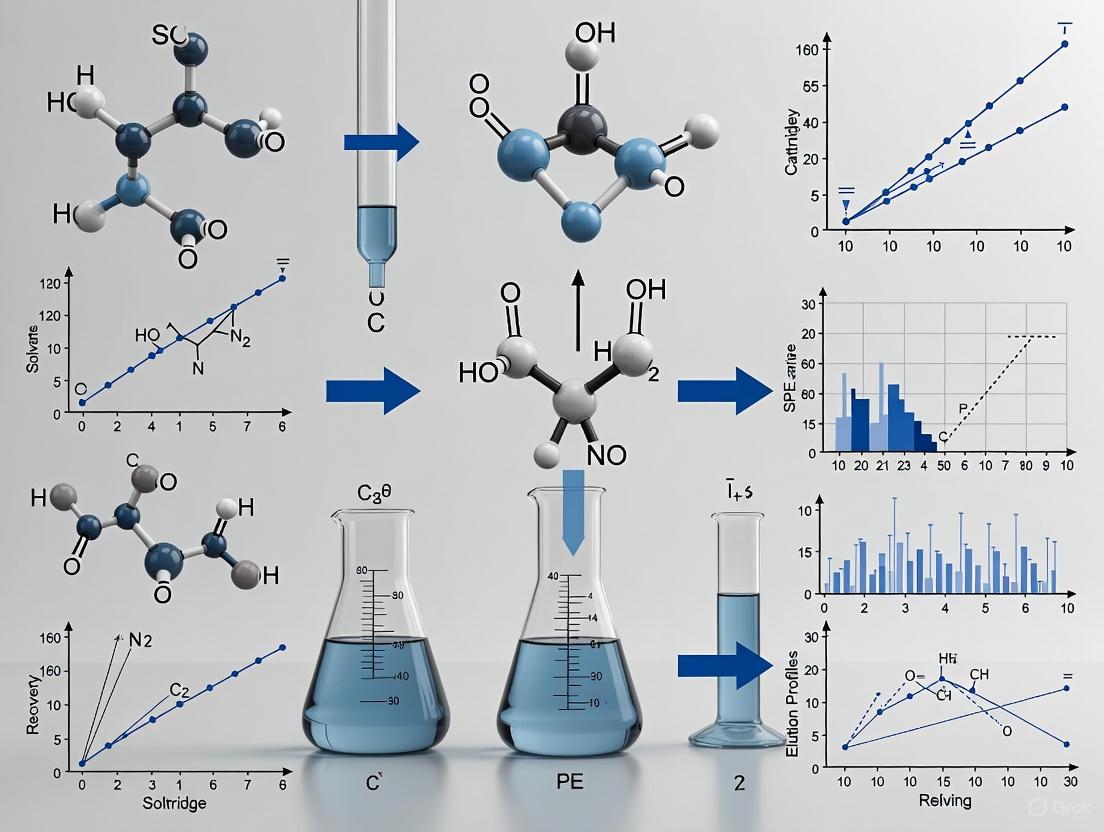

The following workflow diagram illustrates the logical decision process for selecting and optimizing an SPE method based on the analyte's properties.

Essential SPE Materials and Reagents

The following table details key reagents and materials crucial for successful SPE method development and execution.

- Table: Research Reagent Solutions for SPE

| Item | Function & Explanation |

|---|---|

| C18 Sorbent | The most common reversed-phase sorbent; used for extracting nonpolar analytes from polar matrices via hydrophobic interactions [3]. |

| HLB Sorbent | A hydrophilic-lipophilic balanced polymer sorbent; versatile for a wide range of acidic, basic, and neutral compounds without premature breakthrough [4]. |

| SCX / SAX Sorbents | Strong Cation/Anion Exchange sorbents; used for selective extraction of basic (SCX) or acidic (SAX) analytes via strong electrostatic interactions [3]. |

| Methanol & Acetonitrile | Common organic solvents used for conditioning reversed-phase sorbents, washing, and, most critically, as strong elution solvents [6] [3]. |

| Buffers (e.g., Phosphate, Acetate) | Used to control the pH of the sample and solvents. Critical for ion-exchange and mixed-mode SPE to ensure analytes and sorbents are in the correct charge state [6] [2]. |

| Acids & Bases (e.g., Formic Acid, NH₃) | Additives to adjust solvent pH for precise control of ionization, enabling selective elution in ion-exchange and mixed-mode protocols [4] [2]. |

Quantitative Guide to Sorbent Capacity and Selection

Understanding sorbent capacity is vital to prevent analyte breakthrough. The following table provides approximate capacity estimates for common sorbent types, which can guide cartridge selection based on your sample mass [4].

- Table: Sorbent Capacity Guidelines

| Sorbent Type | Typical Capacity | Example Calculation (for a 100 mg cartridge) |

|---|---|---|

| Silica-based (e.g., C18, C8) | ≤ 5% of sorbent mass | 100 mg × 0.05 = 5 mg of analyte maximum |

| Polymeric (e.g., HLB, SDVB) | ≤ 15% of sorbent mass | 100 mg × 0.15 = 15 mg of analyte maximum |

| Ion-Exchange Resins | 0.25 - 1.0 mmol/g | 100 mg (0.1 g) × 1.0 mmol/g = 0.1 mmol of a monovalent ion |

Optimizing extraction efficiency in SPE is a systematic process grounded in a deep understanding of retention mechanisms. By accurately characterizing the chemical properties of your analyte—its polarity, ionization constants (pKa), and solubility—you can rationally select the most appropriate sorbent and design a protocol with the correct solvent conditions for conditioning, loading, washing, and elution. When troubleshooting, methodically checking for analyte loss at each step and applying the solutions outlined in this guide will lead to robust, reproducible, and high-performing SPE methods, ultimately enhancing the quality and reliability of your analytical data.

FAQs: Core Concepts and Troubleshooting

Q1: What is the fundamental difference between logP and logD, and why does it matter for SPE?

- logP (Partition Coefficient) is a constant for a given compound. It measures the partitioning of the neutral (unionized) form of a molecule between an organic solvent (typically octanol) and water. It is a pure measure of a compound's intrinsic lipophilicity [8] [9].

- logD (Distribution Coefficient) is pH-dependent. It measures the distribution of all forms of the molecule (both ionized and unionized) between the two phases. LogD, therefore, reflects the true lipophilicity of a compound at a specific pH [8].

- Why it matters: The ionization state of your analyte, governed by the pH of your sample solution, dramatically impacts its retention and elution in SPE. For ionizable compounds, logD provides a much more accurate predictor of SPE behavior than logP. A high logD (e.g., >2) indicates high lipophilicity and strong retention on reversed-phase sorbents, while a low logD (e.g., <0) suggests high hydrophilicity and weak retention [8].

Q2: How do pKa and pH interact to control analyte retention and elution?

The pKa is the pH at which half of the molecules of an ionizable compound are in their ionized form. The relationship between pH and pKa dictates the analyte's charge state, which in turn controls its affinity for the sorbent [8] [9].

- For Retention: Adjust the sample pH to ensure the analyte is uncharged so it has maximum affinity for the sorbent.

- For acidic analytes (e.g., with carboxylic acid groups), ensure the sample pH is at least 2 units below the pKa to suppress ionization and promote retention on reversed-phase sorbents [6] [5].

- For basic analytes (e.g., with amine groups), ensure the sample pH is at least 2 units above the pKa to deprotonate the base and promote retention [6] [5].

- For Elution: Use an elution solvent with a pH that ionizes the analyte, making it hydrophilic and disrupting its interaction with the sorbent. For an acidic analyte, use a basic eluent; for a basic analyte, use an acidic eluent [6].

Q3: I'm getting poor recovery of my target analyte. What are the first parameters to check related to analyte chemistry?

Poor recovery can stem from analyte loss during loading, washing, or elution. The table below guides your troubleshooting based on analyte chemistry.

Table: Troubleshooting Poor Recovery in SPE

| Symptom | Potential Chemical Cause | Solutions |

|---|---|---|

| Analyte found in loading fraction (breakthrough) | Sample pH causes ionization, reducing sorbent affinity [6] [5]. | Adjust sample pH to ensure analyte is neutral. |

| Sample solvent is too strong, out-competing the sorbent [5] [4]. | Dilute sample with a weaker solvent (e.g., water). | |

| Sorbent capacity is exceeded [6] [4]. | Use a larger cartridge or reduce sample load. | |

| Analyte found in wash fraction | Wash solvent is too strong, prematurely eluting the analyte [6] [7]. | Reduce the strength (e.g., lower % organic) or volume of the wash solvent. |

| Analyte not eluted (stuck on sorbent) | Elution solvent is too weak or pH is incorrect [6] [4]. | Increase eluent strength (e.g., higher % organic) or adjust pH to ionize analyte. |

| Analyte has very strong (e.g., secondary) interactions with sorbent [5] [7]. | Use a stronger eluent, add modifiers, or switch to a less retentive sorbent. |

Q4: My extracts contain too many interfering compounds. How can I use analyte chemistry to improve cleanup?

- Optimize the Wash Solvent: The wash solvent should have the maximum strength possible to elute impurities without displacing your target analyte. Knowledge of your analyte's logD and pKa at the wash pH allows you to fine-tune this. Use a weak organic solvent or a buffer that keeps your analyte retained but elutes early-eluting interferents [5] [7].

- Leverage pH Selectivity: If your analyte and key interferences have different pKa values, you can use a selective wash at a specific pH to remove interferents while your analyte remains retained. For example, a mild basic wash can remove acidic interferents without affecting a neutral or basic analyte [6] [4].

- Switch Sorbent Mechanism: If using reversed-phase, consider a mixed-mode sorbent that combines reversed-phase and ion-exchange mechanisms. You can then use both pH and organic solvent strength to achieve superior cleanup [7].

Experimental Protocol: Systematically Optimizing SPE Using pKa and logD

The following workflow provides a step-by-step methodology for developing a robust SPE method based on the physicochemical properties of the analyte.

Step 1: Determine Analyte pKa and logP/logD Profile

- Action: Use reliable software or databases to obtain predicted or literature values for the analyte's pKa and logP. Calculate or model the logD profile across a physiologically relevant pH range (e.g., pH 1-12) [8] [9].

- Rationale: This foundational data informs all subsequent method development decisions.

Step 2: Select SPE Sorbent and Mechanism

- Action: Based on the logD at your intended sample pH, choose a sorbent.

- Reversed-phase (C18, HLB): Ideal for neutral, non-polar to moderately polar analytes (logD > 2 at sample pH). HLB is particularly versatile for a wider polarity range [10] [5].

- Ion-exchange (SAX, SCX, WCX, WAX): Ideal for charged analytes when the sample pH ensures the analyte and sorbent have opposite charges [4].

- Mixed-mode: Ideal for analytes possessing both hydrophobic and ionizable groups, allowing for orthogonal selectivity using both pH and solvent strength [7].

Step 3: Optimize Sample Conditioning and Loading

- Action:

- Condition the sorbent with a strong solvent (e.g., methanol for reversed-phase) followed by a weak solvent (e.g., water or buffer) that matches the sample solvent [6] [5].

- Adjust sample pH to maximize retention (see FAQ #2). Ensure the sample solvent is weak enough (e.g., < 5-10% organic) to prevent breakthrough.

- Load the sample at a controlled, slow flow rate (e.g., 1-2 mL/min) to ensure sufficient interaction time with the sorbent [4].

Step 4: Optimize Wash Step for Cleanup

- Action: After loading, wash with a solvent strong enough to remove undesirable matrix interferences but weak enough to leave the analyte fully retained. Test wash solutions with 5-20% organic solvent or buffers at a pH that selectively ionizes (and thus elutes) interferents [5] [7]. Always dry the cartridge if using water-immiscible elution solvents [5].

Step 5: Optimize Elution for Maximum Recovery

- Action: Elute with a strong solvent that disrupts analyte-sorbent interactions.

- For reversed-phase, use a strong organic solvent like methanol or acetonitrile.

- For ion-exchange or mixed-mode, adjust the elution solvent's pH to neutralize the analyte's charge and/or include a competing salt or organic solvent [6] [4].

- Use the minimum volume of the weakest effective solvent (typically 2-4 x bed volume) to elute the analyte completely, ensuring concentration of the sample [10] [5]. Collect multiple fractions to confirm complete elution.

Case Study: Simultaneous Extraction of Efavirenz and Levonorgestrel

A 2025 study optimized SPE for the simultaneous extraction of an antiviral (efavirenz) and a contraceptive (levonorgestrel) from wastewater, demonstrating the practical application of these principles [10].

Table: Optimized SPE Parameters for Efavirenz and Levonorgestrel [10]

| Parameter | Tested Range | Optimal Condition | Recovery (EFA) | Recovery (LVG) |

|---|---|---|---|---|

| Solution pH | 2 - 12 | pH 2 | 67 - 83% | 70 - 95% |

| Elution Solvent | Methanol, Acetonitrile | 100% Methanol | - | - |

| Elution Volume | 3 - 6 mL | 4 mL | - | - |

| Sorbent | - | Oasis HLB (60 mg/3 mL) | - | - |

- Experimental Summary: The researchers systematically varied one parameter at a time. They used a synthetic solution containing 1 ppm of each analyte and a hydrophilic-lipophilic balance (HLB) cartridge. The cartridges were preconditioned with 5 mL of 10% methanol and 5 mL ultrapure water. After loading 100 mL of sample, cartridges were washed with 5 mL of 10% methanol and 5 mL water. The adsorbed analytes were eluted, dried under nitrogen, and reconstituted for HPLC analysis [10].

- Key Chemistry Insight: The optimal low pH (2) was critical. It likely ensured that any ionizable groups on the complex molecules (especially efavirenz) were in their neutral form, maximizing retention on the HLB sorbent via reversed-phase mechanisms and enabling high, simultaneous recoveries for both pharmaceuticals despite their different structures [10].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table: Key Materials for SPE Method Development

| Item | Function / Explanation |

|---|---|

| Hydrophilic-Lipophilic Balance (HLB) Sorbent | A versatile polymeric sorbent that retains a wide range of acidic, basic, and neutral compounds through both hydrophilic and hydrophobic interactions, making it an excellent first choice [10]. |

| C18 Sorbent | A classic reversed-phase sorbent ideal for retaining non-polar to moderately polar neutral compounds. |

| Ion-Exchange Sorbents (SAX, SCX, etc.) | Used for selective retention of ionized analytes. SAX (Strong Anion Exchange) for acids; SCX (Strong Cation Exchange) for bases [4]. |

| Buffers (e.g., Phosphate, Acetate) | To precisely control the pH of the sample and wash solutions, which is critical for managing the ionization state of the analyte. |

| Methanol and Acetonitrile | Common organic solvents used for conditioning reversed-phase sorbents, washing, and elution. They differ in elution strength and selectivity. |

| pH Meter | Essential for accurately preparing and verifying the pH of all aqueous solutions. |

| Vacuum Manifold | A device that holds multiple SPE cartridges and uses vacuum to pull solutions through them, allowing for parallel processing of samples [4]. |

Frequently Asked Questions: Sorbent Capacity and Breakthrough

1. What is the most common sign that my SPE cartridge is overloaded? The most common sign is a sudden drop in analyte recovery, often because the analyte is found in the load fraction or the waste, indicating it was not retained on the sorbent bed. This is known as "breakthrough" [11] [4].

2. How can I estimate the maximum sample mass my SPE sorbent can handle? Sorbent capacity is typically estimated as a percentage of the sorbent's own mass. For initial method development, you can use these general guidelines [4]:

- Silica-based sorbents: ~5% of sorbent mass.

- Polymeric sorbents: ~15% of sorbent mass. For example, a 100 mg C18 cartridge can theoretically retain up to approximately 5 mg of analyte.

3. Besides sample mass, what other factors can cause breakthrough? Breakthrough can also be caused by the sample dissolution solvent being too strong, which prevents the analyte from interacting effectively with the stationary phase [11]. Additionally, a flow rate that is too high during sample loading does not provide sufficient contact time for the analyte to be retained [4].

4. My recoveries are low, but I don't think I've overloaded the cartridge. What else could be wrong? Low recovery can also result from an elution solvent that is too weak, an incorrect elution solvent pH for ionizable compounds, or using an insufficient volume of elution solvent to fully desorb the analyte [4].

5. How can I quickly test for breakthrough during method development? Collect and analyze the effluent that passes through the sorbent bed during the sample loading step. The presence of your target analyte in this liquid indicates that breakthrough has occurred [12].

Troubleshooting Guide: Preventing Overload and Breakthrough

| Problem | Likely Cause | Solution |

|---|---|---|

| Low analyte recovery; Analyte detected in load-through or wash fractions. | Sorbent overload: The mass of the analyte (and interferences) exceeds the sorbent's capacity. | Reduce the sample load or use a cartridge with more sorbent mass (e.g., switch from 100 mg to 500 mg) [4]. |

| Low recovery for a polar analyte in reversed-phase SPE. | Poor retention: The dissolution solvent is too strong or too non-polar, out-competing the sorbent. | Dissolve or suspend the sample in a weaker, more aqueous solvent (e.g., acidified water instead of MeCN/water mixtures) [11]. |

| Inconsistent recoveries between replicates. | Variable flow rate: Flow during sample loading is too fast, preventing equilibrium. | Lower the loading flow rate to ensure sufficient contact time between the sample and the sorbent [4]. |

| Breakthrough occurs even with small sample loads. | Sorbent chemistry mismatch: The sorbent's retention mechanism does not match the analyte's properties. | Choose a more appropriate sorbent (e.g., switch from C18 to a mixed-mode or ion-exchange sorbent for charged analytes) [4]. |

Sorbent Capacity Estimation Table

The table below provides a framework for estimating the adsorption capacity of different sorbent classes. These are approximate starting points for method development and should be verified experimentally [4].

| Sorbent Type | Typical Capacity (as % of Sorbent Mass) | Calculation Example (for 200 mg cartridge) | Primary Retention Mechanism |

|---|---|---|---|

| Silica-based (C18, C8, etc.) | ≤ 5% | 200 mg × 0.05 = 10 mg maximum load | Reversed-phase (non-polar) |

| Polymeric (e.g., HLB) | ≤ 15% | 200 mg × 0.15 = 30 mg maximum load | Reversed-phase |

| Ion-Exchange | 0.25 - 1.0 mmol/g | 0.2 g × 1.0 mmol/g = 0.2 mmol of charged analyte | Electrostatic (ionic) |

Experimental Protocol: Determining Breakthrough Volume and Capacity

This protocol provides a detailed methodology to empirically determine the maximum sample volume you can load before analyte loss (breakthrough volume) and to verify the sorbent's capacity.

Workflow Overview:

Materials and Reagents:

- SPE cartridge (e.g., 100 mg/1mL sorbent mass)

- Standard solution of the target analyte at a known concentration in a weak solvent (e.g., aqueous buffer)

- Appropriate conditioning and elution solvents (e.g., methanol, water)

- HPLC or GC system for analysis

- Test tubes or vials for fraction collection

Step-by-Step Procedure:

Prepare Standard Solutions: Dilute your analyte standard to a concentration relevant to your analysis in the sample solvent (e.g., a weak aqueous buffer). This solution should be chemically similar to your final processed sample [13].

Condition and Equilibrate the Sorbent: Condition the SPE cartridge with a suitable solvent (e.g., 2 x 1 mL methanol for reversed-phase), followed by an equilibration solvent that matches your sample matrix (e.g., 2 x 1 mL water). Do not let the sorbent bed run dry [14].

Load Solution and Collect Fractions: Pass a known, relatively large volume of the standard solution (e.g., 50-100 mL for a 100 mg cartridge) through the sorbent bed at a controlled, slow flow rate (e.g., 1-3 mL/min) [4]. Collect the effluent as multiple small fractions (e.g., 5-10 mL each) in separate vials. Also, collect a final fraction during the elution step.

Analyze Fractions: Analyze all collected fractions (load fractions and elution fraction) using your HPLC or GC method to determine the analyte concentration in each [12].

Plot and Determine Breakthrough:

- Plot the analyte concentration detected in each load fraction against the cumulative volume that has passed through the cartridge.

- The breakthrough volume is identified at the point where the analyte concentration in the effluent rises significantly above the baseline (e.g., >5% of the initial loaded concentration).

- The sorbent's practical capacity is confirmed when near-complete recovery (>95%) is achieved in the elution fraction without significant analyte appearing in the load fractions.

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function in Capacity Estimation |

|---|---|

| C18 or C8 Cartridges | The universal reversed-phase sorbent for extracting non-polar to moderately polar compounds from aqueous matrices. Used for initial method scoping [15] [14]. |

| Hydrophilic-Lipophilic Balanced (HLB) Polymer | A polymeric sorbent with higher capacity (~15% by mass) than silica-based sorbents. It is versatile for a wide range of analytes and is less prone to overloading [4]. |

| Ion-Exchange Sorbents | Essential for isolating charged analytes. Capacity is defined by ionic exchange capacity (mmol/g). Use strong sorbents for weak ionizable analytes and weak sorbents for strong ions to ensure effective elution [12] [13]. |

| Mixed-Mode Sorbents | Combine reversed-phase and ion-exchange mechanisms for highly selective clean-up. They are excellent for complex matrices but require elution solvents that disrupt both interaction types [15] [13]. |

Advanced SPE Method Development: From Parameter Optimization to Real-World Applications

The following tables consolidate quantitative data from experimental studies to guide the optimization of critical Solid-Phase Extraction (SPE) parameters. These values serve as a reference point for method development.

Table 1: Optimized SPE Parameters for Specific Analytes This table summarizes the optimal conditions for extracting efavirenz and levonorgestrel from wastewater using Oasis HLB cartridges, as determined by a systematic study [10].

| Parameter | Tested Range | Optimal Value | Analyte | Recovery at Optimal Value |

|---|---|---|---|---|

| Solution pH | 2 - 12 | 2 | Efavirenz | 67% - 83% |

| Levonorgestrel | 70% - 94.6% | |||

| Elution Solvent | Methanol, Acetonitrile | 100% Methanol | Efavirenz | 67% - 83% |

| Levonorgestrel | 70% - 94.6% | |||

| Elution Volume | 3 - 6 mL | 4 mL | Efavirenz | 67% - 83% |

| Levonorgestrel | 70% - 94.6% |

Table 2: General SPE Sorbent and Solvent Selection Guide This table provides a generalized overview of sorbent types and their common applications to aid in initial method scoping [16] [17].

| Sorbent Type | Mechanism | Typical Analytes | Common Elution Solvents |

|---|---|---|---|

| HLB (Hydrophilic-Lipophilic Balanced) | Reversed-phase, retains acids, bases, and neutrals | Broad-range pharmaceuticals, organic pollutants | Methanol, Acetonitrile |

| C18 | Reversed-phase, hydrophobic interactions | Non-polar to moderately polar compounds | Methanol, Acetonitrile, Tetrahydrofuran |

| Mixed-Mode (e.g., MCX, MAX) | Reversed-phase + ion exchange | Acidic/Basic compounds with high selectivity | Methanol with acid/base or salt |

| Silica | Normal-phase, polar interactions | Polar compounds | Hexane, Toluene, Chloroform |

Detailed Optimized Protocol for Simultaneous Drug Extraction

This section provides a step-by-step experimental protocol adapted from a research study that successfully optimized the simultaneous extraction of efavirenz and levonorgestrel from wastewater [10].

Materials and Reagents

- Sorbent: Oasis HLB cartridges (60 mg/3 mL) [10].

- Analytes: Efavirenz and Levonorgestrel standard solutions.

- Solvents: Methanol (HPLC grade), Acetonitrile (HPLC grade), Ultrapure water [10].

- Equipment: HPLC system with photodiode array detector (PDA), vacuum manifold, pH meter, nitrogen evaporator [10].

Step-by-Step Procedure

- Cartridge Conditioning: Condition the HLB cartridge with 5 mL of 10% methanol, followed by 5 mL of ultrapure water. Maintain a flow rate of approximately 1 mL/min and do not let the sorbent bed run dry [10].

- Sample Pretreatment: Adjust the pH of the 100 mL aqueous sample to the optimal value of 2.0 using 0.1 M HCl or NaOH [10].

- Sample Loading: Load the pH-adjusted sample onto the conditioned cartridge at a controlled flow rate not exceeding 1 mL/min [10] [17].

- Cartridge Washing: Wash the cartridge with 5 mL of 10% methanol and 5 mL of ultrapure water to remove weakly retained matrix interferences [10].

- Analyte Elution: Elute the target analytes using 4 mL of 100% methanol. Using two aliquots of 2 mL can improve elution efficiency [10] [17].

- Sample Reconstitution: Evaporate the eluate to dryness under a gentle stream of nitrogen at 50°C. Reconstitute the dried sample in 1 mL of methanol, and filter it through a 0.22 µm nylon syringe filter prior to HPLC analysis [10].

Method Validation

The optimized method was validated with the following performance characteristics [10]:

- Linearity: Correlation coefficient (R²) > 0.98.

- Limit of Detection (LOD): 0.705 µg/L for efavirenz and 0.061 µg/L for levonorgestrel.

- Limit of Quantification (LOQ): 0.14 µg/L for efavirenz and 0.199 µg/L for levonorgestrel.

SPE Parameter Optimization Workflow

The following diagram illustrates the systematic approach to optimizing critical SPE parameters, from problem identification to final method validation.

Troubleshooting Guides and FAQs

Frequently Asked Questions

Q: My analyte recovery is low. What are the primary parameters to investigate?

- A: Low recovery most commonly stems from incomplete elution or inadequate sorbent retention. First, check your elution solvent strength and volume; a stronger solvent or larger volume may be needed. Second, review the sample pH, as an improper pH can prevent proper retention of ionic analytes on the sorbent [16] [17].

Q: How can I reduce matrix effects in my LC-MS analysis?

- A: Matrix effects are caused by co-eluting interferences. Optimize your wash step by using a solvent strong enough to remove impurities but weak enough to not displace your analytes. Sorbents specifically designed for phospholipid removal (e.g., Oasis PRiME HLB) can also significantly reduce common matrix effects [16].

Q: What is the most critical step in the SPE procedure to ensure reproducibility?

- A: Controlling the flow rate during sample loading and elution is crucial. High or variable flow rates can lead to inconsistent extraction and poor reproducibility. Always ensure the flow rate does not exceed 1-2 mL/min for cartridge-based SPE [17].

Q: Are there greener alternatives to traditional SPE solvents?

- A: Yes. The principles of Green Analytical Chemistry (GAC) encourage solvent replacement. For example, ethanol can sometimes be used as a safer alternative to methanol or acetonitrile in certain applications [18] [19]. Furthermore, micro-extraction techniques like µSPE or DLLME use significantly smaller solvent volumes [20].

Troubleshooting Common Problems

Problem: Poor Recovery

- Possible Causes:

- Incomplete Elution: The elution solvent is too weak or the volume is insufficient.

- Analyte Not Retained: The sample solution's pH or solvent strength prevents optimal binding to the sorbent.

- Sorbent Drying: The sorbent bed dried out completely during the conditioning or loading steps.

- Solutions:

Problem: High Background/Interferences

- Possible Causes:

- Ineffective Washing: The wash step is too weak to remove matrix interferences.

- Overloading: The sample contains too much matrix relative to the sorbent capacity.

- Solutions:

Problem: Irreproducible Results

- Possible Causes:

- Variable Flow Rates: Manually applied vacuum or pressure is inconsistent.

- Channeling: The sample flows through cracks in the sorbent bed instead of evenly.

- Clogging: Particulates in the sample clog the cartridge frits.

- Solutions:

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials and Reagents for SPE Method Development

This table lists critical components used in advanced SPE research, providing a foundation for setting up and optimizing your own experiments.

| Item | Function & Application | Example Use-Case |

|---|---|---|

| Oasis HLB Sorbent | A hydrophilic-lipophilic balanced copolymer for the broad-spectrum retention of acids, bases, and neutrals; ideal for multi-analyte methods [10] [16]. | Simultaneous extraction of pharmaceuticals like efavirenz and levonorgestrel from wastewater [10]. |

| Mixed-Mode Ion Exchange Sorbents (e.g., MCX, MAX) | Provide mixed-mode retention (reversed-phase + ion exchange) for superior selectivity and clean-up of acidic/basic analytes from complex matrices [16]. | Extraction of basic drugs (e.g., benzodiazepines, opioids) or tryptic peptides from biological fluids [20] [16]. |

| Loofah Sponge (LS) Sorbent | A novel, low-cost, and green biosorbent with functional groups (e.g., hydroxyl, carboxyl) for extracting polar contaminants [21]. | Analysis of bisphenols in environmental water samples, offering an efficient and sustainable alternative [21]. |

| Methanol & Acetonitrile (HPLC Grade) | Standard organic solvents used for elution in reversed-phase SPE. Methanol is often preferred for its elution strength and lower toxicity [10] [18]. | Optimal elution solvent (100% Methanol) for efavirenz and levonorgestrel from HLB cartridges [10]. |

| µElution Plates | A specialized SPE format for processing low-volume samples with minimal elution volume (often 25-50 µL), maximizing analyte concentration and minimizing solvent use [16]. | Ideal for bioanalytical assays where sample volume is limited and high sensitivity is required [16]. |

Troubleshooting Guide

This guide addresses common problems you might encounter during the simultaneous Solid Phase Extraction (SPE) of pharmaceuticals like efavirenz and levonorgestrel from wastewater.

Problem 1: Low Analyte Recovery Low recovery is a frequent challenge in SPE, manifesting as unexpectedly low analyte signals in the final extract [4].

- Causes and Solutions:

- Sorbent/Polarity Mismatch: The sorbent's retention mechanism may not match the analyte's chemistry [4].

- Fix: For simultaneous extraction of multiple pharmaceuticals, use a sorbent with a balanced retention mechanism. Hydrophilic-Lipophilic Balance (HLB) cartridges are recommended as they offer better retention for both polar and non-polar compounds [10].

- Insufficient Eluent Strength or Volume: The solvent may not be strong enough to desorb the analytes, or the volume may be insufficient [4].

- Sorbent/Polarity Mismatch: The sorbent's retention mechanism may not match the analyte's chemistry [4].

Problem 2: Irregular or Slow Flow Rate Flow rate variations can affect the interaction between the solvent and sorbent, leading to inconsistent results [4].

- Causes and Solutions:

- Clogging or Particulate Matter: Sample debris can clog the sorbent bed [4].

- Fix: Always filter wastewater samples before loading. Using a 0.22 µm nylon syringe filter is an effective practice [10].

- High Sample Viscosity: This can drastically slow the flow rate [4].

- Fix: Dilute the sample with a matrix-compatible solvent to lower its viscosity [4].

- Packing Density Variations: Differences in sorbent packing can cause flow rate inconsistencies between cartridges [4].

- Fix: Use a controlled vacuum manifold to maintain a reproducible flow rate, typically below 5 mL/min for critical steps [4].

- Clogging or Particulate Matter: Sample debris can clog the sorbent bed [4].

Problem 3: Poor Reproducibility High variability between replicate extractions undermines the reliability of your data [4].

- Causes and Solutions:

- Inconsistent Cartridge Conditioning: If the sorbent bed dries out before sample loading, it can lead to poor and variable recovery [4].

- Fix: Ensure cartridges are consistently preconditioned. A standard method involves wetting with 5 mL of methanol (e.g., 10% concentration) followed by equilibration with 5 mL of ultra-pure water [10].

- Overloaded Cartridge: Exceeding the sorbent's capacity causes analyte breakthrough and loss [4].

- Fix: Reduce the sample load or use a cartridge with a higher sorbent mass. The adsorption capacity for a polymeric HLB sorbent can be up to 15% of its mass [4].

- Flow Rate Too High: A fast flow rate during sample application reduces contact time and can lead to incomplete retention [4].

- Fix: Control and lower the loading flow rate to allow sufficient equilibrium time [4].

- Inconsistent Cartridge Conditioning: If the sorbent bed dries out before sample loading, it can lead to poor and variable recovery [4].

Problem 4: Unsatisfactory Cleanup The sample extract may still contain interfering compounds from the complex wastewater matrix.

- Causes and Solutions:

- Suboptimal Washing: The wash solvent may be too strong, eluting your analytes, or too weak, leaving behind interferents [4].

- Fix: Re-optimize the wash conditions. A common protocol is to rinse with 5 mL of 10% Methanol after sample loading to remove untargeted compounds without eluting the analytes of interest [10].

- Incorrect Purification Strategy: The selected SPE mode may not provide sufficient selectivity for your analytes versus the matrix [4].

- Fix: For targeted analysis, a strategy that retains the analyte and selectively washes out interferents often provides the best cleanup [4].

- Suboptimal Washing: The wash solvent may be too strong, eluting your analytes, or too weak, leaving behind interferents [4].

Frequently Asked Questions (FAQs)

Q1: What is the most critical parameter to optimize for simultaneous SPE of efavirenz and levonorgestrel? The solution pH is paramount, especially for ionizable compounds. For the simultaneous extraction of efavirenz and levonorgestrel, an acidic pH of 2 was identified as optimal, enabling recoveries of 67-83% for efavirenz and 70-95% for levonorgestrel [10]. The pH affects the charge state of the molecules and their subsequent retention on the sorbent.

Q2: Why are HLB cartridges recommended for this application? Oasis HLB cartridges are recommended because they contain a hydrophilic-lipophilic balanced copolymer. This structure provides better retention capabilities for a wide range of compounds, which is essential when dealing with pharmaceuticals of differing polarities, such as efavirenz and levonorgestrel, in a single method [10] [4].

Q3: How can I break a persistent emulsion during liquid-liquid extraction if I use it as a pre-treatment? Emulsions are a common issue in LLE. Several techniques can help:

- Salting Out: Add brine or salt to increase the ionic strength of the aqueous layer, which helps break the emulsion [22] [23].

- Filtration: Pass the emulsion through a glass wool plug or a specialized phase separation filter paper [23].

- Centrifugation: Use centrifugation to isolate the emulsion material in the residue [23].

- Solvent Adjustment: Add a small amount of a different organic solvent to adjust the solvent properties and break the emulsion [23].

Q4: How do I validate my HPLC method for this analysis? Method validation is critical for generating reliable data. For the simultaneous quantification of efavirenz and levonorgestrel, the method was validated by [10]:

- Linearity: Achieving a correlation coefficient (R²) greater than 0.98 from a seven-point calibration curve.

- Sensitivity: Calculating the Limit of Detection (LOD) and Limit of Quantification (LOQ). For example, LOD for levonorgestrel was 0.061 µg/L.

- Accuracy: Comparing results with a confirmatory technique like Ultra-High-Performance Liquid Chromatography (UHPLC).

Experimental Protocol: Optimized SPE for Efavirenz and Levonorgestrel

The following methodology is adapted from research aimed at optimizing SPE parameters for the simultaneous extraction of efavirenz (EFA) and levonorgestrel (LVG) from wastewater, followed by analysis with High-Performance Liquid Chromatography (HPLC) [10].

1. Reagents and Materials

- Analytes: Efavirenz (EFA) and Levonorgestrel (LVG) standards.

- SPE Cartridges: 60 mg/3 mL Oasis HLB (Hydrophilic-Lipophilic Balance).

- Solvents: Methanol, Acetonitrile (HPLC grade).

- Others: Hydrochloric acid (HCl), Sodium Hydroxide (NaOH), Nylon Syringe Filters (0.22 µm).

2. Sample Preparation

- Prepare individual stock solutions of 1,000 ppm in 80% Methanol. Store in amber bottles to prevent degradation.

- For wastewater samples, adjust the pH to 2 using 0.1 M HCl or NaOH [10].

3. Solid Phase Extraction Procedure

- Conditioning: Pre-condition the HLB cartridge with 5 mL of 10% Methanol, followed by 5 mL of ultra-pure water at a flow rate of ~1 mL/min [10].

- Loading: Load 100 mL of the pH-adjusted sample onto the cartridge under vacuum.

- Washing: Rinse the cartridge with 5 mL of 10% Methanol to remove impurities [10].

- Elution: Elute the adsorbed analytes with 4 mL of 100% Methanol [10].

- Post-Elution: Evaporate the eluent to dryness under a gentle stream of nitrogen at 50°C. Reconstitute the dry residue with 1 mL of Methanol and filter through a 0.22 µm nylon syringe filter before HPLC analysis [10].

4. Instrumental Analysis (HPLC)

- System: LC-20 Prominence HPLC with a Photodiode Array (PDA) detector.

- Column: C18 column (e.g., 250 mm x 4.6 mm, 5 µm).

- Mobile Phase: Use a gradient elution with water and acetonitrile.

- Detection: Monitor efavirenz and levonorgestrel at their specific wavelengths (e.g., 258 nm and 241 nm, respectively) [10].

Optimized SPE Workflow for Simultaneous Extraction

The table below consolidates the key quantitative data from the optimization study, providing a clear reference for method implementation [10].

Table 1: Optimized SPE Parameters and Analytical Performance

| Parameter | Optimized Condition for EFA & LVG | Note / Function |

|---|---|---|

| SPE Sorbent | Oasis HLB (60 mg/3 mL) | Retains both polar & non-polar compounds |

| Solution pH | 2 | Critical for retention of both analytes |

| Elution Solvent | 100% Methanol | Provides optimal elution strength |

| Elution Volume | 4 mL | Sufficient for complete desorption |

| Recovery (EFA) | 67% - 83% | - |

| Recovery (LVG) | 70% - 94.6% | - |

| LOD (EFA) | 0.705 µg/L | - |

| LOD (LVG) | 0.061 µg/L | - |

| LOQ (EFA) | 0.14 µg/L | - |

| LOQ (LVG) | 0.199 µg/L | - |

| Linearity (R²) | > 0.98 | For calibration curve |

Table 2: Concentrations Found in Wastewater (Example Data)

| Analyte | Influent Concentration (µg/L) | Effluent Concentration (µg/L) |

|---|---|---|

| Efavirenz (EFA) | 0.36 - 8.10 | 2.88 - 8.11 |

| Levonorgestrel (LVG) | 2.64 - 32.31 | 2.32 - 12.35 |

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents and Materials for SPE of Pharmaceuticals

| Item | Function / Role in the Experiment |

|---|---|

| Hydrophilic-Lipophilic Balance (HLB) Cartridge | A polymeric sorbent for broad-spectrum retention of acidic, basic, and neutral compounds from water. Ideal for simultaneous extraction. |

| Methanol (HPLC Grade) | Used as an elution solvent and for preparing stock solutions. Its strength and polarity are effective for desorbing a wide range of pharmaceuticals. |

| Hydrochloric Acid (HCl) | Used to adjust the pH of the sample solution to the optimal value (e.g., pH 2), which is crucial for stabilizing the charge of ionizable analytes for effective SPE retention. |

| Nylon Syringe Filter (0.22 µm) | Used to remove particulate matter from the reconstituted sample extract before injection into the HPLC, protecting the column from clogging. |

| Efavirenz & Levonorgestrel Standards | High-purity reference materials used to prepare calibration standards for quantifying the analytes in unknown wastewater samples. |

SPE Troubleshooting Decision Tree

The complexity of modern analytical challenges, particularly in environmental and pharmaceutical research, often exceeds the capability of any single solid-phase extraction (SPE) sorbent. Utilizing a combination of sorbents in a single extraction protocol significantly expands the "chemical space coverage"—the range of analytes with diverse physical and chemical properties that can be effectively extracted from a single sample [24]. This approach is especially critical for non-targeted analysis (NTA), where the goal is to detect and identify hundreds to thousands of chemicals simultaneously, rather than focusing on a predefined list of target analytes [24].

While single sorbents like hydrophilic-lipophilic balanced (HLB) polymers provide broad-range extraction, they can miss certain polar or ionic compounds. Research has demonstrated that stacking or mixing different sorbent materials in a single cartridge can improve the retention of a wider spectrum of analytes, from non-polar organics to polar ionic compounds [24]. This guide provides detailed methodologies and troubleshooting for developing these multi-sorbent protocols to optimize extraction efficiency.

Research Reagent Solutions: Essential Sorbents and Their Functions

Selecting the appropriate sorbents is the foundation of a successful multi-sorbent method. The table below details sorbents commonly used in combination protocols.

Table 1: Key Sorbent Chemistries for Combined Protocols

| Sorbent Type | Primary Retention Mechanism | Ideal For Compound Classes | Function in a Mixed Bed |

|---|---|---|---|

| HLB (Hydrophilic-Lipophilic Balanced) | Reversed-phase adsorption | Broad range of non-polar to polar neutral molecules [24] | The foundational sorbent for capturing the widest "chemical space" [24]. |

| WAX (Weak Anion Exchange) | Ion-exchange (anionic) | Strong and weak acids, polar anions [24] | Retains acidic compounds that may be poorly captured by HLB alone. |

| WCX (Weak Cation Exchange) | Ion-exchange (cationic) | Strong and weak bases, polar cations [24] | Retains basic compounds that may be poorly captured by HLB alone. |

| MCX (Mixed-Mode Cation Exchange) | Reversed-phase & Cation Exchange | Basic compounds and cations [24] | Provides a stronger, more selective retention for bases. |

| Graphitized Carbon Black (GCB) | Dispersive interactions | Very polar planar molecules and pigments [25] | Used for selective cleanup and retention of specific planar compounds. |

Detailed Experimental Protocol: A Four-Method Comparison

The following protocol is adapted from a comprehensive study that evaluated four different SPE methods with varying complexity to assess their chemical space coverage in environmental water analysis [24].

Materials and Reagents

- Water Samples: Surface water with wastewater influence was used. Samples should be filtered (e.g., 0.7 µm glass fiber filter) to remove particulate matter prior to extraction [24].

- Surrogate Standards: A set of 231 analytical-grade reference standards representing a range of chemical classes and properties is recommended for method optimization and evaluation [24].

- Sorbent Cartridges: The study specifically evaluated the following setups [24]:

- Method A: Oasis HLB alone (200 mg).

- Method B: A stacked cartridge of WAX (150 mg) over HLB (200 mg).

- Method C: A stacked cartridge of WCX (150 mg) over HLB (200 mg).

- Method D: A complex mixed sorbent cartridge.

- Solvents: HPLC-grade or better methanol, water, acetonitrile, and appropriate buffers (e.g., ammonium acetate, ammonium formate).

Step-by-Step Procedure

- Sample Pre-treatment: Acidify all water samples to pH 2 with hydrochloric acid or formic acid. Pass samples through a 0.7 µm glass fiber filter [24].

- Conditioning: Condition the mixed sorbent cartridge with 5-10 mL of methanol followed by 5-10 mL of reagent water at a controlled flow rate of 1-2 mL/min. Do not let the sorbent bed run dry [26] [4].

- Sample Loading: Load the acidified sample onto the cartridge. The study used a large sample volume (0.5 - 1.0 L). Maintain a slow, controlled flow rate of 1-2 mL/min to ensure adequate interaction time, especially for ion-exchange mechanisms [24] [27].

- Rinsing/Washing: Wash the cartridge with 5-10 mL of a weak solvent (e.g., 5% methanol in water acidified to pH 2) to remove weakly retained matrix interferences without eluting analytes [26].

- Drying: Apply a high vacuum (up to 25 in. Hg) for 5-10 minutes to dry the sorbent bed completely. This step is crucial when switching to organic elution solvents [27].

- Elution: Elute analytes using two separate aliquots of a strong organic solvent (e.g., 5 mL of methanol followed by 5 mL of acetonitrile). Incorporate a 1-5 minute "soak step" after adding the elution solvent to allow it to penetrate the sorbent pores fully before applying pressure or vacuum [26] [27].

- Post-Processing: Combine the eluates and evaporate to near-dryness under a gentle stream of nitrogen. Reconstitute the extract in a solvent compatible with the final analysis (e.g., 100 µL of methanol/water mixture for LC-MS) [24].

Workflow Diagram

The following diagram illustrates the logical decision-making process for selecting and executing a multi-sorbent SPE method.

Diagram: Sorbent Selection and Method Workflow

Performance Data and Comparison

The quantitative evaluation of the four methods revealed clear performance differences, as summarized below.

Table 2: Comparative Performance of Multi-Sorbent SPE Methods [24]

| Method Configuration | Relative Complexity | Key Strengths / Recovered Compound Classes | Considerations |

|---|---|---|---|

| HLB Alone | Low | Broad range of neutral and moderately polar compounds; simple and cost-effective. | The benchmark method; may miss very polar ionic species. |

| HLB + WAX | Medium | Excellent for acidic compounds (e.g., pharmaceuticals, PFAS); complements HLB coverage. | Adds steps for specific pH adjustments during elution. |

| HLB + WCX | Medium | Superior for basic compounds and polar cations (e.g., specific pharmaceuticals). | Adds steps for specific pH adjustments during elution. |

| Complex Mixed Bed | High | Maximum theoretical chemical space coverage; captures a wide array of ionic and neutral compounds. | Most complex and expensive method; requires careful optimization. |

Troubleshooting Guide: FAQs

Q1: I am getting low recovery for my target analytes even with a multi-sorbent method. What could be wrong?

- Cause 1: Improper Conditioning. The sorbent bed was not fully activated or equilibrated, or it dried out before sample loading [26] [4].

- Fix: Ensure the cartridge is conditioned with a strong solvent (e.g., methanol) followed by an equilibration solvent that matches the sample matrix. Do not let the bed run dry between steps [26].

- Cause 2: Weak Elution Conditions. The elution solvent is not strong enough to disrupt analyte-sorbent interactions, or the volume is insufficient [26] [4].

- Cause 3: Flow Rate Too High. A high flow rate during sample loading or elution does not allow sufficient time for equilibration, reducing retention or elution efficiency [4] [27].

- Fix: Reduce the flow rate to 1-2 mL/min for loading and washing. For elution, allow the solvent to seep into the sorbent bed before applying pressure [26].

Q2: My results show poor reproducibility between replicates. How can I improve this?

- Cause 1: Variable Flow Rates. Inconsistent flow rates during critical steps lead to varying interaction times with the sorbent [4].

- Fix: Use a vacuum manifold or positive pressure system that allows for precise and consistent flow control across all samples [4].

- Cause 2: Incomplete Drying or Soaking. Residual water can dilute organic elution solvents, and a lack of soak time can lead to incomplete elution [27].

- Fix: Implement a consistent, thorough drying step (e.g., high vacuum for 2-5 min) after the wash step. Consistently use soak steps after eluent addition [27].

- Cause 3: Sorbent Overload. The mass of interfering compounds in the sample exceeds the capacity of the sorbent [26] [4].

- Fix: Reduce the sample volume or mass, or switch to a cartridge with a larger sorbent mass or higher capacity [26].

Q3: When should I consider a multi-sorbent approach over a single sorbent like HLB?

- Answer: A multi-sorbent protocol is recommended when your analysis requires a comprehensive profile of a complex sample, especially if the compounds of interest span a wide range of polarities and include ionizable species (acids or bases) [24]. If a targeted analysis shows that key polar ionic compounds are being missed with HLB alone, adding a WAX or WCX sorbent is a logical next step [24].

Q4: The extraction is taking too long. How can I speed it up without sacrificing performance?

- Answer: While slower flow rates are often necessary, you can optimize other aspects. Ensure samples are properly filtered to prevent clogging [26] [4]. For some steps where equilibrium is quickly reached (like strong wash steps), a slightly faster flow may be acceptable. However, do not compromise on the recommended slow flow rates for sample loading and elution, as this is critical for high recovery [27].

Troubleshooting Guide: Common D-µ-SPE and Magnetic Extraction Issues

This section addresses specific experimental problems encountered with Dispersive Micro-Solid Phase Extraction (D-µ-SPE) and magnetic sorbents, providing causes and practical solutions.

Symptom: Low Analyte Recovery

Problem: Unexpectedly low analyte signals in the final extract.

| Potential Cause | Recommended Solution |

|---|---|

| Insufficient Sorbent-Analyte Interaction | Choose a sorbent with a complementary retention mechanism (reversed-phase for nonpolar, ion-exchange for charged species). For ionic analytes, adjust sample pH to ensure proper charge [4]. |

| Weak Elution Solvent | Increase organic solvent percentage or use a stronger eluent. For ionizable analytes, adjust elution solvent pH to convert analyte to its neutral form [4]. |

| Inadequate Elution Volume | Increase the volume of elution solvent. Collect multiple fractions to monitor recovery [4]. |

| Sorbent Overload | Reduce sample volume or switch to a cartridge with higher sorbent capacity. Silica-based sorbents capacity is ~5% of sorbent mass; polymeric sorbents can be up to ~15% [4]. |

Symptom: Poor Reproducibility

Problem: High variability between replicate extractions.

| Potential Cause | Recommended Solution |

|---|---|

| Inconsistent Sorbent Dispersion | Use assisted dispersion methods (vortex, ultrasound, mechanical stirring) to ensure uniform contact between sorbent and analyte [28]. |

| Variable Flow Rates | For cartridge-based D-µ-SPE, control loading and elution flow rates (often below 5 mL/min). Avoid excessive vacuum/pressure [4]. |

| Sorbent Bed Drying | Ensure the sorbent bed does not dry out before or during sample loading. Re-condition the cartridge if drying occurs [4]. |

| Carryover or Contamination | Wash magnetic sorbents thoroughly between uses. For reusable sorbents, establish a regeneration protocol and monitor performance [29]. |

Symptom: Inadequate Sample Cleanup

Problem: Co-extraction of matrix interferences, leading to poor selectivity.

| Potential Cause | Recommended Solution |

|---|---|

| Non-Selective Wash Step | Optimize the wash solvent composition. Use the strongest solvent that will not elute the target analyte to remove interferences [7]. |

| Incorrect Sorbent Selectivity | Switch to a more selective sorbent. Selectivity generally follows: Ion-exchange > Normal-phase > Reversed-phase [4]. |

| Complex Sample Matrix | For biological samples, consider dilution or protein precipitation. Magnetic sorbents with restricted access properties can exclude proteins [29]. |

Symptom: Slow or Clogged Flow

Problem: Sample passes through the cartridge too slowly or not at all.

| Potential Cause | Recommended Solution |

|---|---|

| Particulate Clogging | Filter or centrifuge samples with high particulate matter before loading. Use a pre-filter or glass fiber filter on the cartridge [4]. |

| High Sample Viscosity | Dilute the sample with a weak, matrix-compatible solvent to reduce viscosity [4]. |

| Nano-sorbent Packing | If using nanoscale sorbents in a cartridge, the high backpressure may be inherent. Consider a dispersive approach instead of a packed cartridge [28]. |

Frequently Asked Questions (FAQs)

Q1: What are the main advantages of using magnetic sorbents in D-µ-SPE? Magnetic sorbents simplify the most challenging step in D-µ-SPE: the separation of the sorbent from the sample solution after extraction. By applying an external magnetic field, the sorbent can be easily and rapidly collected without the need for centrifugation or filtration [30] [29]. This leads to a simpler workflow, higher throughput, and the ability to handle large sample volumes efficiently.

Q2: My analytes are not being retained. What should I check first? First, verify the compatibility between your sorbent's chemistry and the analyte's properties (polarity, charge) [4]. Next, check the sample solution's pH, especially for ionizable compounds; adjusting pH can ensure the analyte is in a form that interacts strongly with the sorbent [31]. Also, ensure the sorbent was properly conditioned and that the sample loading flow rate was not too high, which can reduce interaction time [4].

Q3: How can I improve the selectivity of my D-µ-SPE method? Improving selectivity can be achieved by:

- Using a more selective sorbent: Molecularly Imprinted Polymers (MIPs) provide cavities tailored to your specific analyte [32]. Metal-Organic Frameworks (MOFs) and Covalent Organic Frameworks (COFs) offer tunable pore sizes and surfaces for steric and chemical recognition [31] [32].

- Optimizing the wash protocol: Implement a selective wash step that removes interferences without displacing the target analyte [7].

- Functionalizing sorbents: Modify sorbents with specific groups (e.g., antibodies, ionic liquids) that have a high affinity for your target analyte [33] [32].

Q4: Can D-µ-SPE sorbents be reused? Yes, some sorbents, particularly stable magnetic composites, can be reused. For example, a novel magnetic humic acid sorbent (Magn-Humic) was successfully reused for eight extraction cycles from human plasma without significant performance loss [29]. However, reusability depends on the sorbent's chemical and physical stability and the complexity of the sample matrix. A rigorous cleaning/regeneration protocol must be validated.

Detailed Experimental Protocols

Protocol 1: Magnetic µ-SPE for Pharmaceutical Analysis in Water

This protocol is adapted from a study analyzing Ibuprofen (IBP) in water samples using tea waste impregnated with magnetic nanoparticles (MNP-TW) [30].

Workflow Overview:

Materials & Reagents:

- Sorbent: Magnetic Tea Waste (MNP-TW). Function: Biodegradable, low-cost adsorbent with functional groups that bind IBP [30].

- Sample: Water samples (e.g., wastewater, surface water).

- Chemicals: IBP standard, Methanol (HPLC grade), HCl/NaOH for pH adjustment, NaCl.

- Equipment: UV-Vis spectrophotometer, vortex mixer, ultrasonic bath, neodymium magnet, pH meter.

Step-by-Step Procedure:

- Sorbent Preparation: Synthesize MNP-TW by co-precipitation of Fe₃O₄ nanoparticles onto washed and dried tea waste [30].

- Sample Preparation: Adjust the pH of the water sample to 2 using HCl. Add NaCl to achieve a final concentration of 5% (w/v) to increase ionic strength and enhance extraction.

- Extraction: Add 25 mg of MNP-TW sorbent to a 15 mL sample. Vortex the mixture for 45 minutes to ensure complete dispersion and interaction.

- Separation: Place the sample vial against an external neodymium magnet. Allow the magnetic sorbent to be pulled to the side of the vial (approximately 2-5 minutes). Carefully decant the clear supernatant.

- Desorption: Add 150 µL of methanol to the collected sorbent. Ultrasonicate the mixture for 20 minutes to release the bound IBP.

- Analysis: Separate the eluent magnetically and transfer it for analysis via UV-Vis spectrophotometry at 222 nm.

Protocol 2: Magnetic µ-SPE for Multi-Steroid Analysis in Human Plasma

This protocol summarizes a robust method for extracting 16 different steroids from human plasma using a novel Magn-Humic sorbent [29].

Workflow Overview:

Materials & Reagents:

- Sorbent: Magn-Humic (Silica-coated magnetite with a pyrolyzed humic acid carbon phase). Function: Provides mixed-mode interactions (reversed-phase and π-π) and exhibits protein exclusion properties [29].

- Sample: Human plasma.

- Chemicals: Phosphate Buffered Saline (PBS), Formic Acid, Acetonitrile (HPLC-MS grade), Methanol (HPLC-MS grade).

- Equipment: HPLC-MS/MS system, rotating mixer, neodymium magnet, centrifugal evaporator.

Step-by-Step Procedure:

- Sample Dilution: Dilute 250 µL of human plasma with 750 µL of PBS to reduce matrix viscosity and protein binding.

- Extraction: Add 50 mg of Magn-Humic sorbent to the diluted plasma. Place the mixture on a rotating plate and agitate for 10 minutes.

- Separation: Isolate the sorbent using a magnet.

- Washing: Add 2 mL of a 2% (v/v) formic acid solution to the sorbent. Agitate briefly to remove weakly adsorbed matrix interferences. Separate and discard the wash solution.

- Elution: Add 0.5 mL of a 1:1 (v/v) mixture of acetonitrile and methanol, followed by 0.5 mL of pure methanol. Agitate to ensure complete desorption of the steroids.

- Concentration: Combine the eluates and evaporate the solvent under a gentle stream of nitrogen or using a centrifugal evaporator until the volume is reduced to 250 µL.

- Analysis: Inject the concentrated extract into the HPLC-MS/MS system for separation and quantification.

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function / Application in D-µ-SPE |

|---|---|

| Magnetic Nanoparticles (Fe₃O₄) | The core magnetic material enabling easy separation. Often requires surface functionalization for stability and selectivity [30] [29]. |

| Carbon Nanotubes (CNTs) | High-surface-area sorbents that extract analytes via non-polar and π-π interactions. Used for pesticides, PAHs, and pharmaceuticals [33] [28]. |

| Metal-Organic Frameworks (MOFs) | Crystalline, porous materials with ultra-high surface area and tunable chemistry. Provide selectivity based on pore size and functional groups [31] [32]. |

| Molecularly Imprinted Polymers (MIPs) | "Lock-and-key" sorbents with synthetic cavities designed for a specific target molecule, offering high selectivity in complex matrices [31] [32]. |

| Graphene/Oxide (GO) | Two-dimensional sorbent with a large surface area. Excellent for aromatic compounds via π-π stacking. Can be functionalized with ionic liquids or magnetic particles [33] [32]. |

| Ionic Liquids (ILs) | Can be used as functional modifiers for sorbents or as solvents. Enhance dispersion and selectivity for specific analytes [34] [32]. |

| Polymeric Sorbents (e.g., HLB) | Hydrophilic-Lipophilic Balanced copolymers. Versatile for a wide range of analytes, with higher capacity (~15% of sorbent mass) than silica-based sorbents [4]. |

SPE Troubleshooting: Diagnosing and Solving Common Problems for Robust Methods

FAQs: Troubleshooting Low Recovery in Solid-Phase Extraction

Question: My analyte recovery is lower than expected. How can I determine if the problem is with my eluent strength or volume?

Answer: Low recovery can be attributed to either insufficient eluent strength or inadequate elution volume. To diagnose the issue, first, try increasing your elution volume incrementally (for example, from 3 mL to 4, 5, and 6 mL) and monitor the recovery after each increment [10]. If recovery improves, the initial volume was too low. If recovery remains poor, the elution solvent is likely too weak to disrupt the interaction between the analyte and the sorbent [6]. You should then evaluate stronger solvents or adjust the pH to ensure a greater affinity for the analytes [6].

Question: What specific adjustments can I make to the elution solvent to improve recovery?

Answer: Optimizing the elution solvent is a multi-faceted process. You should consider the following adjustments:

- Solvent Strength: For reversed-phase SPE, increase the organic percentage (e.g., from 50% to 80% or 100% methanol) [10] [4].

- pH Adjustment: For ionizable analytes, adjust the pH of the eluting solvent to convert the analyte into its neutral form, which has less affinity for the sorbent. For example, using a solvent containing 2-5% ammonium hydroxide can effectively elute basic compounds [35] [27].

- Solvent Type: Evaluate different solvent types. Methanol and acetonitrile are common, but sometimes switching from one to the other or adding small amounts of modifiers can improve desorption [36] [4].

- Soak Time: Introduce a "soak" period of 30 seconds to several minutes after adding the elution solvent, allowing it time to fully penetrate the sorbent bed and disrupt analyte interactions before applying vacuum or pressure [37] [38] [27].

Question: Beyond elution, what other fundamental issues could be causing low recovery?

Answer: While elution is a common culprit, other steps in the SPE protocol can also lead to analyte loss:

- Incorrect Sorbent Choice: The sorbent's retention mechanism may not match the analyte's chemistry (e.g., using a reversed-phase cartridge for a very polar analyte) [4]. Selecting a more appropriate sorbent, such as a mixed-mode phase, can provide the necessary selectivity [27].

- Improper Conditioning: Inadequate conditioning or equilibration of the SPE cartridge can lead to poor recovery by failing to fully activate the sorbent bed [36] [6]. Always follow the manufacturer's recommended conditioning procedure.

- Column Overloading: If the sample mass exceeds the cartridge's capacity, analyte breakthrough will occur, leading to loss [36] [6]. Reduce the sample load volume or switch to a cartridge with a higher sorbent mass.

- Overly Strong Wash Solvent: A wash solvent that is too strong can accidentally elute your target analytes along with the interferences [6] [27]. Optimize the wash strength to remove impurities while retaining the analytes.

Experimental Protocols: Optimizing Elution for Simultaneous Drug Quantification

The following table summarizes a validated experimental protocol for the simultaneous extraction of the pharmaceuticals efavirenz and levonorgestrel from wastewater, demonstrating the optimization of elution parameters [10].

Table 1: Optimized SPE Method for Efavirenz and Levonorgestrel

| Parameter | Optimized Condition | Experimental Details |

|---|---|---|

| Sorbent Cartridge | Oasis HLB (60 mg/3 mL) | Hydrophilic-Lipophilic Balance copolymer for broad-spectrum retention [10]. |

| Conditioning | 5 mL of 10% Methanol, then 5 mL ultra-pure water | Flow rate of 1 mL/min [10]. |

| Sample Loading | 100 mL at pH 2 | Sample pH adjusted using 0.1 M HCl [10]. |

| Washing | 5 mL of 10% Methanol, then 5 mL ultra-pure water | To remove untargeted compounds [10]. |

| Elution Solvent | 100% Methanol | Methanol provided higher recoveries compared to acetonitrile in this study [10]. |

| Elution Volume | 4 mL | Found to be sufficient for complete desorption of both analytes [10]. |

| Post-Elution | Dried under nitrogen at 50°C, reconstituted in 1 mL Methanol | Concentrates the sample for analysis [10]. |

| Results: Recovery | Efavirenz: 67-83%; Levonorgestrel: 70-94.61% | Demonstrates the method's effectiveness [10]. |

The logical workflow for this optimization process, from problem identification to resolution, can be summarized as follows:

The Scientist's Toolkit: Essential Reagents and Materials

Table 2: Key Research Reagents and Materials for SPE Optimization

| Item | Function/Explanation | Example from Literature |

|---|---|---|

| HLB SPE Cartridge | A hydrophilic-lipophilic balanced copolymer sorbent that effectively retains a wide range of both polar and non-polar analytes from aqueous matrices. | Oasis HLB, 60 mg/3 mL cartridge [10]. |

| Elution Solvents (Methanol, Acetonitrile) | Organic solvents used to disrupt the hydrophobic interactions between the analyte and the sorbent, thereby desorbing (eluting) the analyte. | 100% Methanol provided optimal recovery for efavirenz and levonorgestrel [10]. |

| pH Modifiers (HCl, NaOH, NH₄OH) | Acids and bases used to adjust the sample and solvent pH. This is critical for ionizable analytes, as pH controls their charge state and affinity for the sorbent. | Sample pH adjusted to 2 with HCl; Elution with 5% NH₄OH in methanol for basic drugs [10] [35]. |

| Syringe Filters | Used to remove particulate matter from the final extract before injection into the analytical instrument, preventing column clogging. | 0.22 µm nylon syringe filters [10]. |

| Mixed-Mode Sorbents | Sorbents that combine two retention mechanisms (e.g., reversed-phase and ion-exchange), offering superior selectivity, especially for complex matrices. | Strata-X-C (strong cation exchange) provided >98% recovery for basic drugs [35]. |

Managing Flow Rate and Preventing Clogging from Particulate Matter

Troubleshooting Guides

Why is the flow rate too slow or the cartridge appears clogged?

A slow or blocked flow rate is one of the most frequent issues in Solid Phase Extraction (SPE). The table below summarizes the common causes and their solutions.

| Cause | Solution and Preventive Measure |

|---|---|

| Clogging from particulate matter [39] [5] | Filter (e.g., 0.45 µm) or centrifuge the sample before loading it onto the SPE cartridge to remove insoluble particles. Using cartridges with a prefilter can also be effective. [4] [40] |

| High sample viscosity [4] [40] | Dilute the sample with a matrix-compatible solvent (e.g., water or a weak buffer) to reduce its viscosity. [4] |

| Use of incorrectly sized sorbent particles [40] [41] | Select a sorbent with a larger particle size for faster flow. Smaller particles (e.g., 40-60 µm) create more resistance and slower flow than larger ones (e.g., 75-150 µm). [41] |

| Improper cartridge conditioning [39] [41] | Ensure the cartridge is activated and equilibrated with the correct solvents in the proper order. For reversed-phase sorbents, activate with a strong solvent like methanol before equilibrating with water or buffer. [39] |

| Air bubbles in the sorbent bed [39] [41] | Carefully load samples to minimize air introduction. Apply positive pressure or a vacuum to drive out trapped air. Visually inspect the bed for cracks or faults. [39] |

| Incompatible solvents between steps [39] [41] | When switching between immiscible solvents (e.g., from dichloromethane to water), use a transition solvent (e.g., methanol) that is miscible with both to maintain a consistent flow. [39] |

Why is the flow rate too fast, and how does it affect my results?

An excessively fast flow rate reduces the contact time between the analytes and the sorbent, leading to poor retention and low recovery. The solutions are often the inverse of those for a slow flow rate.

| Cause | Solution and Preventive Measure |

|---|---|

| Overly large sorbent particles [40] [41] | Select a sorbent with a smaller particle size to increase flow resistance and slow the rate. [40] |

| Excessive vacuum or pressure [40] | Use a controlled manifold or a check valve to adjust and maintain a stable, recommended flow rate. A typical target flow rate for sample loading is around 1 mL/min. [4] [5] |

| Inadequate sorbent bed mass for sample volume [39] | Use a cartridge with a larger bed mass (e.g., 500 mg vs. 100 mg) or a larger volume to provide more flow resistance and increase interaction time. [39] |

Frequently Asked Questions (FAQs)

How can I prevent clogging from particulate matter in my samples?

Proactive sample preparation is the most effective strategy. These steps are critical for complex matrices like biological tissues, environmental samples, or soil extracts.

- Filtration: Pass the sample through a membrane filter (0.2 µm or 0.45 µm) before loading it onto the SPE cartridge. [42]

- Centrifugation: Use a benchtop centrifuge to pellet particulate matter, and carefully transfer the clarified supernatant to the cartridge. [41]

- Cartridge with Prefilter: Select SPE cartridges that include a built-in glass fiber or depth filter at the top to capture particulates before they reach the sorbent bed. [4]

What is the ideal flow rate for an SPE procedure?

While the optimal flow rate can vary by method, a common guideline is 1-2 mL/min for many manual SPE procedures. [4] [5] A useful rule of thumb is to aim for approximately one drop per second. [41] A flow rate that is too slow prolongs the experiment, while one that is too fast does not allow sufficient time for the analyte to interact with the sorbent, resulting in breakthrough and low recovery. [4] [41] For critical steps like sample loading and elution, a slower, controlled flow is recommended. [4]

My cartridge started with a good flow rate but slowed down significantly during the run. Why?

This typically indicates that the sorbent bed is becoming blocked by material from the sample. This can occur if the sample contains fine particulates that were not removed during pre-filtration, or if components in the sample itself (such as proteins or lipids) precipitate onto the sorbent bed upon contact with the solvent or due to pH changes. [42] Ensuring robust sample pre-treatment, including protein precipitation or lipid removal, is essential for preventing this issue. [5]

Experimental Protocol for Flow Rate Optimization

This protocol provides a method to systematically investigate and establish the optimal flow rate for your specific SPE application to maximize recovery.

1. Objective: To determine the effect of sample loading flow rate on the recovery of target analytes and to identify the maximum flow rate that does not compromise recovery.

2. Materials and Reagents:

- Standard solution of the target analyte(s)

- Appropriate SPE cartridges (e.g., 100 mg/1 mL bed)

- SPE vacuum manifold or positive pressure system

- Solvents for conditioning, washing, and elution as per the method

- HPLC or LC-MS system for analysis

3. Methodology:

- Sample Preparation: Prepare a standard solution of the analyte in the sample loading solvent. Ensure it is properly filtered.

- Conditioning: Condition and equilibrate the SPE cartridges identically.

- Sample Loading at Varied Flow Rates: Load an identical volume of the standard solution onto multiple cartridges. Use a controlled manifold or pump to apply the sample at different, precisely measured flow rates (e.g., 0.5, 1.0, 2.0, and 5.0 mL/min). Collect the load-through fraction from each cartridge.

- Washing and Elution: Wash and elute the cartridges using identical, optimized methods and solvents, controlling the flow rate at ~1 mL/min for these steps.