Peak Purity Testing with PDA and MS: A Comprehensive Guide for Robust Analytical Methods

This article provides researchers, scientists, and drug development professionals with a complete guide to peak purity assessment, a critical technique for ensuring accurate quantification and method specificity in HPLC.

Peak Purity Testing with PDA and MS: A Comprehensive Guide for Robust Analytical Methods

Abstract

This article provides researchers, scientists, and drug development professionals with a complete guide to peak purity assessment, a critical technique for ensuring accurate quantification and method specificity in HPLC. Covering foundational principles, step-by-step methodologies for Photodiode Array (PDA) and Mass Spectrometry (MS) detection, advanced troubleshooting, and validation strategies, it delivers practical insights for developing reliable, stability-indicating methods compliant with ICH and other regulatory standards.

Understanding Peak Purity: Principles, Importance, and Regulatory Context

Defining Peak Purity and Its Critical Role in Accurate Quantification

Accurate quantification in High-Performance Liquid Chromatography (HPLC) is a cornerstone of reliable analytical data, particularly in fields like pharmaceutical development where it directly impacts product quality and patient safety. The foundation of this accuracy is peak purity—the assurance that a chromatographic peak represents a single chemical entity. This guide explores the definition of peak purity, its pivotal role in quantification, and provides a comparative analysis of the primary techniques and software tools used for its assessment.

What is Peak Purity?

Peak purity is an assessment of the spectral homogeneity of a chromatographic peak. A "pure" peak demonstrates that the UV-visible spectrum (or mass spectrum) does not change significantly throughout the peak's elution, providing strong evidence that the peak originates from a single compound. Conversely, an "impure" peak shows spectral variation, indicating the co-elution of two or more substances that the chromatographic method could not fully separate [1] [2].

The most common tool for this assessment is the Photodiode Array (PDA) detector, which captures full spectra at multiple points across a peak—typically at the start, apex, and end [1] [2]. The software then calculates two key metrics [3] [2]:

- Purity Angle: A numerical value representing the degree of spectral variation across the peak. A larger angle suggests greater variation and potential impurity.

- Purity Threshold: A reference value derived from the baseline noise, representing the maximum acceptable spectral variation for a peak to be considered pure.

The peak is considered spectrally pure if the Purity Angle is less than the Purity Threshold [2]. It is crucial to understand that peak purity analysis can only prove that a peak is impure; it cannot definitively prove that a peak is pure. It can only conclude that no co-eluted compounds were detected given the limitations of the technique [4] [5].

Why Peak Purity is Critical for Accurate Quantification

Relying solely on retention time and peak area for quantification is risky. Without purity assessment, analytical data is vulnerable to significant error.

- Prevention of Inaccurate Quantification: Co-elution of an impurity with the main analyte peak leads to an inflated peak area. This results in over-reporting the concentration of the target compound, compromising data integrity [1].

- Essential for Stability-Indicating Methods: In pharmaceutical development, analytical methods must be "stability-indicating," meaning they can accurately measure the active ingredient in the presence of its degradation products. Peak purity assessment is a central part of Forced Degradation Studies to validate that degradants do not co-elute with the main drug peak, ensuring accurate stability monitoring throughout the product's shelf life [4].

- Enhanced Confidence in Results: Using peak purity as an orthogonal check alongside retention time provides a higher level of confidence in analytical results, ensuring that reported concentrations are reliable and not skewed by hidden impurities [1].

Techniques for Peak Purity Assessment

The two most prevalent techniques for peak purity analysis are PDA-based and Mass Spectrometry (MS)-based detection, each with distinct strengths and limitations.

| Feature | PDA (Photodiode Array) Detection | MS (Mass Spectrometry) Detection |

|---|---|---|

| Principle | Compares UV-visible spectral shapes across the peak [1] [2]. | Detects co-elution based on mass-to-charge ratio (m/z) differences [1] [4]. |

| Primary Metric | Purity Angle vs. Purity Threshold [3] [2]. | Consistency of precursor ions, product ions, or adducts across the peak [4]. |

| Strengths | Non-destructive; cost-effective; widely available and well-understood [4]. | Highly selective and sensitive; can identify impurities; superior for unknowns [1] [4]. |

| Limitations | Cannot distinguish impurities with nearly identical UV spectra; limited sensitivity for low-concentration impurities [1] [4]. | Higher cost and operational complexity; not universal (depends on ionizability) [4] [5]. |

| Ideal for | Routine quality control, method development for compounds with distinct chromophores [4]. | Advanced research, biomarker discovery, and resolving complex co-elution issues [6] [4]. |

Detailed Experimental Protocols

PDA-Facilitated Peak Purity Analysis

This protocol is fundamental for demonstrating the specificity of chromatographic methods in regulated environments [4] [7].

- Sample Preparation:

- Analyze a high-purity reference standard of the target compound.

- Analyze stressed or real-world samples (e.g., from forced degradation studies) where impurities are expected.

- Instrumentation and Data Acquisition:

- Use an HPLC system coupled with a PDA detector.

- The DAD method must acquire full spectra across a defined wavelength range (e.g., 210-400 nm or wider, considering solvent cutoff) [7].

- Ensure the absorbance remains within the linear range of the detector, typically below 1.0 AU, to avoid skewed purity results [7].

- Optimize data acquisition settings: a faster sampling rate provides more data points across the peak for a more robust assessment [5].

- Data Processing and Analysis:

- Process data using a Chromotography Data System (CDS) with peak purity algorithms (e.g., Waters Empower, Agilent OpenLab CDS, Shimadzu LabSolutions).

- Perform a background correction to subtract the mobile phase or matrix contribution, using automatic or manual baseline reference points [5].

- The software compares all spectra within the peak to the spectrum at the peak apex, calculating the Purity Angle and Purity Threshold.

- Visually inspect the overlaid, normalized spectra and the purity plot. A pure peak will have overlapping spectra and a Purity Angle below the threshold line across the entire peak [3] [2].

MS-Facilitated Peak Purity Analysis

This technique provides orthogonal confirmation and is especially valuable when PDA results are inconclusive [4].

- Sample Preparation: Similar to the PDA protocol.

- Instrumentation and Data Acquisition:

- Use an HPLC system coupled to a mass spectrometer (e.g., single quadrupole, tandem MS, or high-resolution MS).

- For nominal mass instruments, monitor the Total Ion Chromatogram (TIC) and specific Extracted Ion Chromatograms (XICs) for the target analyte and potential impurities [4].

- Data Processing and Analysis:

- Examine the mass spectra at different points across the chromatographic peak (front, apex, tail).

- A pure peak will show consistent mass spectra, with the same precursor ions, product ions (in MS/MS), and adducts present throughout the elution [4].

- Any significant change in the mass spectral profile indicates a co-eluting impurity.

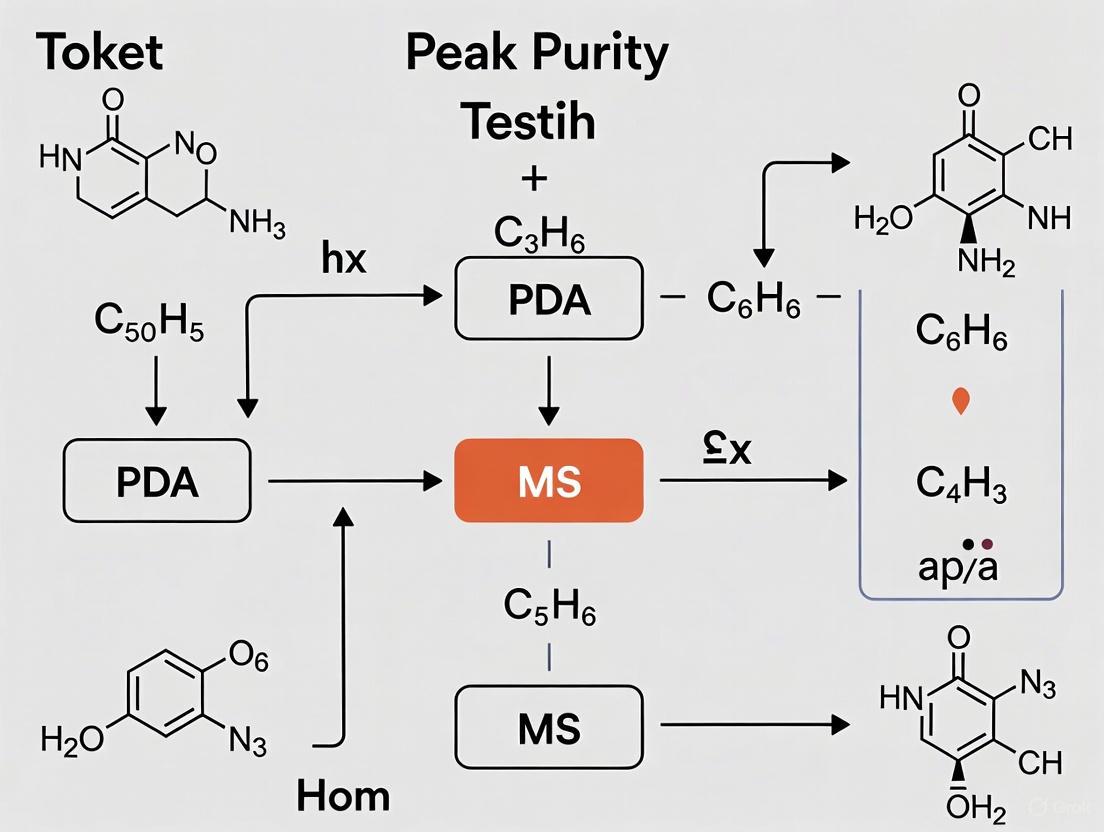

The following diagram illustrates the logical decision pathway for conducting a peak purity analysis, integrating both PDA and MS techniques.

A Comparison of CDS Software for Peak Purity

Different Chromatography Data Systems (CDS) implement peak purity algorithms with varying terminology, though the underlying principles are consistent. The table below compares the approaches of three major platforms.

| Software Platform | Calculation Method | Key Output Metrics | Notable Features |

|---|---|---|---|

| Waters Empower | Spectral contrast angle between vectors in n-dimensional space [4]. | Purity Angle and Purity Threshold; Peak is pure if Purity Angle < Threshold [3]. | Multi-component peak purity analysis to determine the number of spectrally different components [3]. |

| Agilent OpenLab CDS | Comparison of spectra to the apex spectrum after baseline correction [7]. | UV Purity Value (Match Factor); a low value indicates potential co-elution [7]. | Adjustable sensitivity settings to control the threshold for purity flags [7]. |

| Shimadzu LabSolutions | Uses cosθ values derived from spectral contrast angles [4]. | Purity Factor based on cosθ [4]. | Intelligent Peak Deconvolution Analysis (i-PDeA II) using MCR-ALS algorithm to mathematically resolve co-eluting peaks [4]. |

The Scientist's Toolkit: Essential Research Reagent Solutions

The following table details key materials and instruments essential for performing reliable peak purity assessments.

| Item | Function |

|---|---|

| PDA (Photodiode Array) Detector | The primary hardware for UV-based peak purity; captures full spectra during peak elution [1]. |

| Mass Spectrometer (e.g., SQD, TQ) | Provides orthogonal confirmation of purity by detecting co-elution based on mass differences [4]. |

| Chromatography Data System (CDS) | Software that controls the instrumentation, processes data, and runs algorithms for peak purity calculation [3] [7]. |

| High-Purity Reference Standards | Critical for establishing the spectral signature of a pure analyte and for system suitability testing [7]. |

| Biocompatible or Inert HPLC Flow Path | For analyzing sensitive molecules (e.g., biologics), prevents adsorption and degradation, ensuring the peak observed is truly the analyte [6]. |

| Real-Time Spectral Deconvolution Software | Advanced software that can mathematically resolve (deconvolute) overlapping peaks in real-time, providing another layer of purity assurance [6]. |

| Cobalt(III) oxide black | Cobalt(III) Oxide Black | High Purity | For Research |

| 3-(2-Chloroethoxy)prop-1-ene | 3-(2-Chloroethoxy)prop-1-ene|CAS 1462-39-1 |

Practical Considerations and Best Practices

- Optimize Detector Settings: For PDA, select an appropriate bandwidth and slit width. A narrower slit width improves spectral resolution, aiding in detecting subtle spectral differences, while a wider bandwidth can improve the signal-to-noise ratio [5].

- Understand the Limitations: Be aware that PDA cannot detect impurities with nearly identical UV spectra or those present at very low concentrations (<0.1%) [4]. It also cannot identify impurities that lack a chromophore [5].

- Manual Review is Essential: Never rely solely on software-generated purity scores. Always visually inspect the overlaid normalized spectra and the purity plot for signs of spectral variation, especially at the peak edges [1].

- Employ Orthogonal Techniques: For critical applications, use a combination of PDA and MS to maximize confidence. MS is particularly effective for identifying low-level contaminants that PDA might miss [1] [4].

The Science Behind Co-elution and Its Impact on Data Integrity

Co-elution, the phenomenon where two or more compounds exit a chromatographic column simultaneously, represents a critical vulnerability in analytical chemistry. For researchers and drug development professionals, undetected co-elution compromises data integrity, leading to inaccurate quantification, misidentification, and potentially serious consequences in pharmaceutical quality control [1] [8]. This guide examines the science of co-elution and objectively compares the performance of primary detection and resolution technologies: Photodiode Array (PDA) detectors, Mass Spectrometry (MS), and Two-Dimensional Liquid Chromatography (2D-LC).

The Critical Challenge of Co-elution

Co-elution occurs when analytes have nearly identical retention times under a given set of chromatographic conditions. A peak that appears symmetrical may, in fact, be a composite, obscuring impurities or related substances [8]. The core problem is that retention time alone is insufficient to confirm peak purity [1]. The impact on data integrity is direct:

- Inaccurate Quantification: The area of a co-eluted peak is the sum of all contributing compounds, overstating the concentration of the target analyte.

- Misidentification: A co-eluted peak might be incorrectly identified as a pure substance, leading to false conclusions about sample composition.

- Undetected Impurities: In pharmaceutical analysis, this can allow harmful degradants or process-related impurities to go undetected, risking product safety and efficacy [9].

Comparison of Peak Purity Assessment Technologies

The following table summarizes the core principles, strengths, and limitations of the main technologies used for peak purity analysis.

Table 1: Comparison of Peak Purity Assessment Technologies

| Technology | Principle of Detection | Key Strengths | Inherent Limitations |

|---|---|---|---|

| PDA/DAD | Compares UV-Vis absorbance spectra across a peak to identify spectral inconsistencies [1] [10]. | - Widely available and cost-effective.- Non-destructive.- Provides spectral confirmation.- Excellent for detecting impurities with different chromophores. | - Cannot distinguish compounds with nearly identical spectra (e.g., structurally similar impurities or isomers) [1] [9].- Limited sensitivity for low-level impurities [9].- Purity assessments can be skewed by baseline noise and solvent effects [1] [10]. |

| Mass Spectrometry (MS) | Detects co-elution based on differences in mass-to-charge ratio (m/z) [1]. | - Highly selective and sensitive.- Capable of identifying unknown impurities.- Orthogonal detection principle to PDA. | - Cannot differentiate stereoisomers with identical mass [9].- Susceptible to ion suppression effects, which can mask low-level impurities [9].- Destructive technique.- Higher operational cost and complexity. |

| Two-Dimensional LC (2D-LC) | Separates compounds in two distinct chromatographic dimensions [9]. | - Highest resolving power for complex mixtures.- Can separate isomers and impurities with similar spectra or mass.- Directly addresses the separation challenge at its core. | - Technically complex method development.- Requires sophisticated instrumentation.- Longer analysis times compared to 1D-LC. |

Performance Analysis in Critical Scenarios

- Detecting Structurally Similar Impurities: PDA performance declines when impurities share the parent compound's chromophore. A case study found 2D-LC detected an 11% impurity that was completely missed by DAD-based purity assessment due to spectral similarity [9]. MS would likely detect this impurity unless it was an isomer.

- Resolving Isomers: This is a classic challenge. MS often fails as isomers have identical mass. PDA may also fail if their spectra are indistinguishable. 2D-LC, by employing two different separation mechanisms (e.g., different stationary phases or pH), provides the highest probability of resolution [9].

- Low-Level Impurities: MS generally offers superior sensitivity for trace-level co-eluting substances. While modern PDAs are highly sensitive, very low-level impurities may not cause a statistically significant change in the spectral match angle, allowing them to go undetected [1] [10].

Advanced Solutions and Methodologies

Spectral Deconvolution with Chemometrics

Advanced software algorithms can mathematically resolve co-eluted peaks using PDA data. Techniques like Multivariate Curve Resolution-Alternating Least Squares (MCR-ALS) can deconvolve a single peak into its contributing components, providing pure spectra and chromatograms for each, even for some isomers [11]. This approach, implemented in tools like Shimadzu's i-PDeA II, leverages the full three-dimensional (time, absorbance, wavelength) data from the PDA [11].

A Standardized 2D-LC Screening Platform

Research demonstrates that a standardized 2D-LC screening platform can effectively address the weaknesses of 1D-LC. By using a set of different stationary phases (e.g., C18, PFP, Biphenyl, Cyano) and mobile phase pH values in the second dimension, this platform maximizes orthogonality to resolve difficult-to-separate mixtures, providing a powerful walk-up tool for peak purity determination [9].

Experimental Protocols for Robust Peak Purity

Protocol 1: HPLC-PDA-MS/MS for Compound Characterization and Quantification

This protocol, used for characterizing pigments in microalgae, exemplifies the synergy between PDA and MS [12].

- 1. Instrumentation: HPLC system coupled to a Photodiode Array Detector and a Tandem Mass Spectrometer with an electrospray ionization (ESI) source [12].

- 2. Chromatographic Conditions:

- Column: Suitable C18 or similar reversed-phase column.

- Mobile Phase: Typically, a gradient of water or aqueous buffer and an organic solvent like acetonitrile or methanol.

- Flow Rate & Temperature: Optimized for separation (e.g., 0.5 mL/min, 40°C) [13].

- 3. Data Acquisition:

- PDA: Scan from 190–400 nm or a wider range to capture full spectral data [1].

- MS/MS: Operate in Multiple Reaction Monitoring (MRM) mode for quantification or full-scan mode for identification.

- 4. Peak Purity Analysis:

- PDA Workflow: The software (e.g., Empower) compares spectra from the upslope, apex, and downslope of the peak, calculating a purity angle and purity threshold. A purity angle less than the purity threshold suggests a pure peak [10]. Analysts must manually review spectral overlays for subtle differences [1].

- MS Confirmation: Check the extracted ion chromatograms (XICs) for other m/z values at the same retention time.

Protocol 2: Forced Degradation Study with LC-PDA

This stability-indicating method, used for drugs like glycerol phenylbutyrate, validates method specificity by intentionally degrading a sample [13].

- 1. Sample Preparation: Subject the active pharmaceutical ingredient (API) to stress conditions: acid, base, oxidation, heat, and light, as per ICH guidelines Q1A(R2) [13].

- 2. Instrumentation: LC system with a PDA detector.

- 3. Analysis: Inject stressed samples and analyze using the developed method.

- 4. Specificity Assessment:

- Chromatographic Separation: Ensure baseline separation of the API from all degradation products.

- Peak Purity: Perform a PDA peak purity assessment on the main API peak in the stressed sample chromatogram. A pure peak (purity angle < threshold) confirms that degradants are not co-eluting with the API, proving the method's stability-indicating property [13].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Materials for Peak Purity and Method Development Experiments

| Item | Function & Importance |

|---|---|

| Core-Shell Particle Columns | Provide high-efficiency separations with lower backpressure compared to fully porous sub-2-μm particles, improving resolution and speeding up analysis [13] [9]. |

| High-Purity Mobile Phase Solvents | Essential for minimizing baseline noise and UV absorbance, especially at low wavelengths, which is critical for sensitive PDA detection [13]. |

| Buffers (Ammonium Acetate, Formic Acid) | Control mobile phase pH, which is critical for separating ionizable compounds and achieving orthogonal selectivity in 2D-LC [13] [9]. |

| Stationary Phase Library (C18, C8, PFP, Biphenyl, etc.) | A collection of columns with different selectivities is vital for troubleshooting co-elution and developing orthogonal 2D-LC methods [9] [8]. |

| PDA Detector with High Spectral Resolution | A detector with a narrow slit width provides higher spectral resolution, allowing for more sensitive peak purity analysis by capturing finer spectral details [5]. |

| Methyl penta-2,4-dienoate | Methyl penta-2,4-dienoate | High-Purity Reagent |

| 2-Diethylamino-5-phenyl-2-oxazolin-4-one | 2-Diethylamino-5-phenyl-2-oxazolin-4-one|CAS 1214-73-9 |

Troubleshooting Co-elution: A Practical Workflow

This logical workflow, derived from expert recommendations [8], provides a systematic approach to diagnosing and resolving co-elution.

Ensuring data integrity in chromatography requires moving beyond the assumption that a single peak represents a single compound. While PDA detectors are a vital first line of defense for identifying spectral inconsistencies, they have blind spots, particularly with structurally similar compounds. Mass spectrometry provides a powerful orthogonal technique based on mass but struggles with isomers and ion suppression. Two-dimensional LC and advanced chemometric deconvolution represent the cutting edge, offering the highest confidence in peak purity by tackling the separation challenge directly.

A robust analytical method leverages the strengths of these technologies in combination. The most reliable strategies for critical applications like pharmaceutical development involve using PDA and MS complementarily and employing 2D-LC or algorithmic deconvolution when the highest level of certainty is required.

In the pharmaceutical industry, ensuring the purity of a drug substance is paramount for patient safety and product efficacy. Peak purity assessment is a critical analytical task that helps determine if a chromatographic peak is attributable to a single component or if co-elution with impurities has occurred. Among the various techniques available, Photodiode Array (PDA) detection is the most widely used tool for this purpose. Its effectiveness hinges on two fundamental metrics: the Purity Angle and the Purity Threshold. This guide explores the core principles of these concepts, detailing how they are calculated and interpreted within commercial software like Empower, while also objectively comparing PDA performance with mass spectrometric (MS) and two-dimensional liquid chromatography (2D-LC) alternatives.

Core Principles of PDA-Based Peak Purity

The Concept of Spectral Contrast Angle

At the heart of PDA-based peak purity assessment is the principle of spectral contrast. The underlying assumption is that different chemical compounds will have unique ultraviolet (UV) absorbance spectra. To assess the purity of a chromatographic peak, the waveform of the spectrum at the peak's apex is compared to the waveform of every other spectrum acquired across the entire peak [10].

The core mathematical approach treats each spectrum as a vector in n-dimensional space, where 'n' is the number of data points (wavelengths) in the spectrum [14]. The similarity between two spectra is then quantified by the angle between their corresponding vectors:

- An angle of 0 degrees indicates that the spectral shapes are identical, even if their overall intensities differ.

- An angle of 90 degrees indicates that there is no spectral overlap whatsoever [4].

This "spectral contrast angle" is the direct predecessor of the Purity Angle calculated in software algorithms.

Defining Purity Angle and Purity Threshold

Commercial chromatographic data systems use the principles of spectral contrast to compute two key values.

- Purity Angle: This is a weighted average of the angles between each spectrum in the peak and the spectrum at the peak's apex [10]. In simpler terms, it represents the overall spectral heterogeneity within the peak. A smaller purity angle suggests the spectra are more consistent throughout the peak.

- Purity Threshold (or Threshold Angle): This is an index value that represents the combined effect of spectral noise and solvent contributions. It establishes a limit above which the observed spectral differences can be considered statistically significant, rather than just a result of background noise [10] [15]. The threshold is typically calculated as the sum of a Noise Angle and a Solvent Angle [16].

The relationship between these two values determines the software's peak purity conclusion:

- If Purity Angle < Purity Threshold: There is no spectral evidence of co-elution. The peak is considered "spectrally pure" within the noise limitations of the data [10] [16].

- If Purity Angle > Purity Threshold: There are spectral differences that exceed what can be attributed to noise. It is highly likely that components with different spectra are co-eluting [10].

Table 1: Key Parameters for Peak Purity Assessment in Empower Software

| Parameter | Description | Role in Purity Calculation |

|---|---|---|

| Purity Angle | Weighted average of spectral angles within a peak | Quantifies the degree of spectral variation inside the peak. |

| Purity Threshold | Sum of Noise Angle and Solvent Angle | Sets a statistical limit to distinguish real spectral differences from noise. |

| Noise Angle | Angle contribution calculated from a user-defined noise interval | Accounts for the impact of baseline noise on spectral fidelity. |

| Solvent Angle | Angle contribution from the mobile phase background | Compensates for solvent background absorption, especially at low UV wavelengths. |

| Active Peak Region | Percentage of the peak area (from start to end) used in the calculation | Allows exclusion of noisy baseline sections near peak edges [15]. |

Practical Implementation and Experimental Protocols

Configuring the Purity Method in Software

Setting up a robust peak purity method requires careful configuration. The following workflow outlines the key steps, particularly for Waters Empower software, which is widely used in the industry.

A critical choice in the method setup is the Threshold Criteria. The AutoThreshold setting is recommended as a starting point, as it automatically calculates the Solvent Angle for each peak based on its Maximum Spectral Absorbance (MSA) [15] [16]. However, AutoThreshold must be validated and has limitations: it is not suitable for peaks with an MSA greater than 1.0 Absorbance Unit (AU) due to increased photometric error, and the MSA of unknown samples must be less than five times the MSA of the standard used for validation [16]. If validation fails, the user must select the Noise+Solvent option and manually determine the Solvent Angle using a chemically pure standard [16].

Essential Research Reagent Solutions

Successful peak purity analysis relies on more than just software settings. The following reagents and materials are fundamental to obtaining reliable data.

Table 2: Key Reagents and Materials for PDA Peak Purity Analysis

| Item | Function / Role | Best Practice Considerations |

|---|---|---|

| Chemically Pure Standard | To validate the purity method and establish baselines. | Must be of highest available purity; used to determine/validate the Solvent Angle [16]. |

| Optical Grade Solvents | Form the mobile phase (e.g., Acetonitrile, Methanol). | Use high-purity solvents with low UV absorbance, especially at low wavelengths [16] [17]. |

| PDA Detector | Captures full UV-Vis spectra across the chromatographic peak. | Ensure linearity; avoid signal saturation by keeping MSA < 1.0 AU [10] [16]. |

| Analytical Column | Provides chromatographic separation of components. | Select a column with selectivity appropriate for the analyte and potential impurities. |

Comparison with Orthogonal Purity Assessment Techniques

While PDA is the most common tool for peak purity, it is not the only one. Other techniques offer different strengths and weaknesses, and a holistic strategy often combines multiple approaches.

Strengths and Limitations of PDA

Strengths:

- Efficiency and Cost-Effectiveness: PDA analysis is integrated into the HPLC run with minimal additional cost or time [4].

- Well-Understood: It is a widely accepted and well-understood technique within the pharmaceutical analytical community [4].

- Direct Detection: It directly detects compounds based on their UV chromophores, without the need for ionization.

Limitations and Potential for False Results: PDA-based purity assessment cannot definitively prove a peak is pure; it can only report whether co-eluted compounds were detected [4]. Its main limitations stem from the nature of UV spectroscopy.

Causes of False Negatives (Purity test passes, but the peak is impure):

- The co-eluting impurity has a nearly identical UV spectrum [4] [14].

- The impurity has a very poor UV response [4].

- The impurity co-elutes at a very low concentration [4].

- The impurity perfectly and uniformly co-elutes with the main peak, resulting in a constant spectral ratio from peak start to finish [10].

Causes of False Positives (Purity test fails, but the peak is pure):

Orthogonal Techniques: MS and 2D-LC

Mass Spectrometry (MS) MS detects compounds based on their mass-to-charge ratio (m/z), providing a different selectivity compared to UV detection.

- Strengths: Up to 37 times more sensitive than PDA for some compounds like lycopene and carotenoids; can detect co-eluting compounds with similar UV spectra but different masses [19]. It can also identify unknown impurities.

- Weaknesses: Subject to matrix suppression or enhancement effects [19]; requires internal standards for accurate quantitation; higher instrument cost and operational complexity.

Two-Dimensional Liquid Chromatography (2D-LC) 2D-LC separates compounds using two independent separation mechanisms, dramatically increasing resolving power.

- Strengths: The most powerful technique for separating complex mixtures; can physically resolve co-eluting peaks that are inseparable by 1D-LC, providing definitive purity assessment.

- Weaknesses: Method development is more complex; requires sophisticated instrumentation.

Table 3: Technique Comparison for Peak Purity Assessment

| Technique | Detection Principle | Key Advantage | Key Limitation | Ideal Use Case |

|---|---|---|---|---|

| PDA (UV Spectral) | UV-Vis Absorbance Spectrum | Efficient, low-cost, well-established | Cannot detect impurities with identical UV spectra | First-line assessment, method development, impurity screening |

| Mass Spectrometry (MS) | Mass-to-Charge Ratio (m/z) | High sensitivity, selective for mass differences | Matrix effects, higher cost | Confirming UV-invisible impurities, identifying unknowns |

| Two-Dimensional LC (2D-LC) | Orthogonal Separation | Highest resolving power, physically separates co-elutions | Complex method development | Definitive proof of purity for complex samples |

Best Practices for Reliable PDA Peak Purity

- Control Absorbance: Keep the maximum spectral absorbance (MSA) of the analyte peak below 1.0 AU to avoid detector non-linearity and spectral distortion [10] [16].

- Optimize Wavelength Range: Avoid using the low UV range (<210 nm) if it is noisy or dominated by mobile phase absorption. Restricting the range to 210-400 nm can reduce false positives [18] [17].

- Validate the Threshold: Always validate the

AutoThresholdsetting or manually determine the Solvent Angle using six replicates of a pure standard [15] [16]. - Inspect Spectral Overlays: Never rely solely on numerical purity and threshold angles. Manually review the overlaid spectra from the peak start, apex, and end to visually confirm homogeneity or identify subtle differences [1] [18].

- Use Orthogonal Confirmation: For critical assessments, such as stability-indicating methods, confirm pivotal purity results with an orthogonal technique like MS or 2D-LC [4].

The concepts of Purity Angle and Purity Threshold provide a powerful, mathematically grounded framework for assessing peak purity using PDA detectors. When properly configured and validated, this tool is an efficient and robust first line of defense against undetected co-elution in HPLC analysis. However, it is crucial for researchers to understand its intrinsic limitations. A modern, scientifically rigorous approach to peak purity does not rely on PDA alone but leverages it as part of a broader toolkit. Combining PDA with the superior sensitivity of MS or the unmatched separation power of 2D-LC provides the highest possible confidence in the purity of chromatographic peaks, ultimately ensuring the quality and safety of pharmaceutical products.

In pharmaceutical analysis and quality control for drug development, demonstrating that a chromatographic peak represents a single, pure compound is a fundamental requirement. This process, known as peak purity assessment, is critical for validating stability-indicating methods, profiling impurities, and ensuring product safety [4]. While Photodiode Array (PDA) UV detection has historically been the most common tool for this purpose, its limitations in detecting co-eluting compounds with similar UV spectra can compromise accuracy [4] [1]. Mass spectrometry (MS) has emerged as a powerful orthogonal technique, offering superior selectivity based on mass differences rather than spectral contrasts [4] [20]. This guide provides an objective comparison of MS-based purity assessment, focusing on the interpretation of mass chromatograms and spectral comparisons, and details the experimental protocols for implementation.

Fundamental Principles of MS-Based Purity Assessment

Mass spectrometry facilitates peak purity assessment by detecting ions based on their mass-to-charge ratio (m/z). This provides a different dimension of selectivity compared to UV detection. The core principle involves examining the spectral homogeneity of a chromatographic peak by comparing mass spectra acquired across its front, apex, and tail [4].

In a pure peak, the mass spectral data—including precursor ions, product ions, and adduct profiles—remain consistent throughout the peak's elution. Conversely, variations in these mass spectral features across the peak indicate the presence of a co-eluting impurity [4] [20]. MS detection can be applied in several modes for this purpose:

- Total Ion Chromatogram (TIC): Represents the total MS response versus time.

- Extracted Ion Chromatogram (XIC/EIC): Plots the intensity of a specific

m/zvalue over time, allowing investigators to trace ions characteristic of the main compound or potential impurities [4]. - Mass Spectral Comparison: Direct overlay and mathematical comparison of spectra from different time points across the peak.

Comparative Analysis: MS vs. PDA for Peak Purity

The following table summarizes the key performance characteristics of MS-based purity assessment compared to the traditional PDA approach.

Table 1: Performance Comparison of PDA and MS for Peak Purity Assessment

| Feature | PDA (UV Spectroscopic) | Mass Spectrometry (MS) |

|---|---|---|

| Basis of Discrimination | UV spectral shape contrast [4] | Mass-to-charge ratio (m/z) differences [4] |

| Primary Metrics | Purity Angle, Purity Threshold, Spectral Contrast [4] | Spectral similarity scores, ion intensity profiles, extracted ion chromatograms [4] [21] |

| Sensitivity | Limited for low-abundance impurities and impurities with poor UV response [4] | High sensitivity; can detect low-level impurities even at <0.1% of main peak [4] |

| Specificity | Can fail for impurities with nearly identical UV spectra (high risk of false negatives) [4] | High specificity; can distinguish co-eluting compounds with different molecular masses [4] [20] |

| False Negative Risk | Higher (e.g., co-eluting impurities with minimal spectral difference) [4] | Lower, but dependent on mass difference and sensitivity |

| False Positive Risk | Higher (e.g., from baseline shifts, noise, suboptimal processing) [4] | Lower, though can occur from background ions or signal-dependent noise [20] |

| Data Complexity | Lower | Higher; requires expertise in MS data interpretation |

| Instrument Cost & Operation | Lower | Higher |

Experimental Protocols for MS-Based Purity Assessment

Protocol 1: Peak Purity Assessment Using Spectral Comparisons

This is the most direct method for evaluating peak purity with MS.

1. Instrument Setup and Data Acquisition:

- Utilize an LC-MS system, typically with a single quadrupole or similar mass analyzer [4].

- Acquire data in full-scan mode (

scanning MS) across a suitablem/zrange to capture the parent ion and potential fragment ions [20]. - Ensure a sufficient data acquisition rate (e.g., 5-10 points across the peak) for reliable spectral comparison.

2. Data Processing and Analysis:

- Extract mass spectra from at least three points across the chromatographic peak: the leading edge, the apex, and the trailing edge [4].

- Visually compare the overlaid spectra for consistency in the ion pattern.

- Alternatively, use software algorithms to calculate a spectral similarity score [21]. A pure peak will exhibit a high similarity score (e.g., close to 1.000 for cosine correlation) across all compared spectra.

Protocol 2: Assessment via Extracted Ion Chromatograms (XICs)

This method is highly effective for targeting known or suspected impurities.

1. Data Interrogation:

- Process the acquired full-scan MS data to generate XICs for key ions.

- Generate an XIC for the primary ion of the main analyte (e.g.,

[M+H]+). - Generate XICs for ions characteristic of potential impurities or degradation products. This can be based on prior knowledge or generated by examining the mass spectrum at the peak apex for unexpected ions.

2. Result Interpretation:

- A pure peak will show that the XIC of the main analyte perfectly co-elutes with the TIC peak.

- The XICs for impurity ions should show a flat baseline with no co-eluting peaks. The presence of a peak in an impurity XIC that overlaps with the main peak in the TIC provides strong evidence of co-elution [20].

Protocol 3: Chemometric Analysis for Complex Data

For complex samples or subtle impurities, advanced data analysis techniques can be employed.

1. Data Matrix Formation:

- The LC-MS data is organized into a bilinear data matrix D, where rows represent mass spectra and columns represent mass chromatograms [20].

2. Factor Analysis:

- Apply chemometric techniques like Fixed-Size Moving Window Evolving Factor Analysis (FSMW-EFA) or Principal Component Analysis (PCA) to this data matrix [20].

- These methods can automatically identify the number of components within a chromatographic peak cluster by detecting changes in the data structure that are not apparent visually. An eigenvalue plot from FSMW-EFA, for instance, will show a significant value when a new component emerges within the moving window [20].

Visual Workflows for MS-Based Purity Analysis

The following diagram illustrates the logical workflow for applying these techniques.

Figure 1: Workflow for MS-based peak purity assessment, showing three parallel analytical pathways.

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful implementation of MS-based purity methods requires specific tools and reagents. The following table lists key solutions used in the featured experiments.

Table 2: Key Research Reagent Solutions for MS-Based Purity Assessment

| Item | Function / Description | Example Use Case |

|---|---|---|

| Qualified LC-MS System | A system with a mass spectrometer (e.g., single quadrupole, QDa) coupled to an HPLC. Must be qualified for GMP use if required [4] [22]. | Foundation for all analytical data generation. |

| Chromatographic Data System (CDS) with MS Purity Algorithms | Software for instrument control, data acquisition, and processing. Includes algorithms for spectral comparison and XIC generation [4]. | Calculating spectral similarity scores; generating XICs for impurity tracking. |

| Stable Isotope-Labeled Standards | Internal standards with identical chemical properties but different mass. Used for accurate quantification. | Spiking studies to demonstrate method accuracy and distinguish artifacts [23]. |

| Forced Degradation Samples | Stressed drug substance/product samples that generate relevant impurities and degradation products [4]. | Used during method development and validation to challenge the method's selectivity. |

| Well-Characterized Reference Material | A high-purity sample of the main analyte [23]. | Serves as a benchmark for spectral comparison and system suitability testing. |

| 2,3-Dimethyl-1,3-pentadiene | 2,3-Dimethyl-1,3-pentadiene, CAS:1113-56-0, MF:C7H12, MW:96.17 g/mol | Chemical Reagent |

| 4-Methyl-2,1,3-benzothiadiazole | 4-Methyl-2,1,3-benzothiadiazole|CAS 1457-92-7 | High-purity 4-Methyl-2,1,3-benzothiadiazole for organic electronics and materials science research. For Research Use Only. Not for human use. |

Mass spectrometry provides a definitive and highly selective approach to peak purity assessment, overcoming critical limitations of PDA-based techniques. By leveraging mass chromatograms (XICs) and sophisticated spectral comparisons, MS enables researchers to detect and identify co-eluting impurities with high confidence, even at low levels and with structurally similar compounds. While the initial investment and operational complexity are higher, the resulting data offers unparalleled robustness for regulatory submissions and ensures the highest standards in drug development and quality control. The experimental protocols outlined here provide a clear roadmap for scientists to implement this powerful technology effectively.

In pharmaceutical development, demonstrating that an analytical method can accurately measure a drug substance while distinguishing it from its degradation products is a fundamental regulatory requirement. This capability is established through forced degradation studies, which are guided by the foundational principles of ICH Q1A(R2) for stability testing [24]. The resulting analytical methods must then be formally validated per ICH Q2(R1) to prove their reliability and, more recently, developed following the enhanced, science-based approaches described in ICH Q14 [25] [26]. Within this framework, peak purity assessment is a critical analytical endpoint, providing direct evidence of a method's ability to detect co-eluting impurities. This guide compares the performance of two primary detection technologies—Photo-Diode Array (PDA) and Mass Spectrometry (MS)—for this purpose, using supporting experimental data to highlight their respective advantages and limitations in a regulated environment.

Unpacking the Regulatory Guidelines: Q2(R1) and Q14

ICH Q2(R1): Validation of Analytical Procedures

ICH Q2(R1) outlines the validation of analytical procedures, defining the key performance characteristics that must be demonstrated to prove a method is suitable for its intended purpose [26]. For stability-indicating methods, specificity is the paramount validation parameter. The guideline requires that specificity be demonstrated by accurately measuring the analyte in the presence of components like impurities and degradation products [24]. This is typically achieved by analyzing samples from forced degradation studies and proving that the analytical method can successfully separate the active pharmaceutical ingredient (API) from all its degradants [24].

ICH Q14: Analytical Procedure Development

ICH Q14 describes a more modern, science and risk-based approach for developing and maintaining analytical procedures [25]. It encourages a deeper understanding of how method parameters impact performance, potentially leading to more robust methods. This guideline also supports the establishment of an Analytical Procedure Control Strategy and lifecycle management, facilitating continuous improvement post-approval. The enhanced understanding promoted by ICH Q14 is particularly beneficial when designing forced degradation studies and developing the associated peak purity methods, as it encourages a systematic investigation of variables affecting the separation and detection of degradants.

The Role of Forced Degradation Studies

Forced degradation studies intentionally degrade the drug substance under harsh conditions (e.g., acid/base hydrolysis, oxidation, thermal stress, and photolysis) to identify degradation pathways and products [24]. The primary objectives are to:

- Identify degradation products and understand the API's intrinsic stability.

- Generate samples for validating the stability-indicating power of analytical methods.

- Provide data that supports formulation development, packaging, and shelf-life decisions [27].

A critical best practice is to aim for 5–20% degradation of the API. This range generates sufficient degradants for meaningful analysis without causing over-degradation, which can produce irrelevant secondary impurities [24].

Comparative Performance: PDA vs. MS in Peak Purity Analysis

Peak purity assessment determines whether a chromatographic peak corresponds to a single entity or contains co-eluting impurities. PDA and MS detectors operate on fundamentally different principles, leading to significant differences in their performance.

Table 1: Fundamental Comparison of PDA and MS Detectors

| Feature | Photo-Diode Array (PDA) | Mass Spectrometry (MS) |

|---|---|---|

| Detection Principle | Ultraviolet-Visible (UV-Vis) absorbance spectroscopy | Mass-to-charge ratio (m/z) of ions |

| Primary Measurable | Spectral homogeneity (absorbance spectrum across the peak) | Mass homogeneity (ion signal across the peak) |

| Key Performance Metric | Purity Factor / Spectral Match Angle | Mass chromatographic profile for individual ions |

| Specificity | Moderate (compounds with similar spectra may co-elute) | High (distinguishes compounds by molecular mass and fragmentation pattern) |

| Sensitivity | Good for UV-absorbing compounds | Excellent, capable of detecting trace-level impurities |

Supporting Experimental Data from a GPB Case Study

A 2025 study on Glycerol Phenylbutyrate (GPB) provides quantitative data comparing LC-PDA and LC-MS/MS methods, illustrating their performance in a real-world pharmaceutical analysis context [13].

Table 2: Experimental Performance Data from GPB Analysis

| Parameter | LC-PDA Method | LC-MS/MS Method |

|---|---|---|

| Linear Range (bulk) | 1.40 – 55.84 ng/mL | 2.79 – 111.68 µg/mL |

| Recovery in Plasma | 94.27% | 98.20% |

| Detection Wavelength/Mode | 200 nm | ESI+ and ESI– with MRM |

| Application Note | Successfully identified a novel degradation product formed under acid, alkali, and oxidative stress. | Used to characterize the novel degradation product via high-resolution LC-MS-IT-TOF. |

This data demonstrates that while both methods can be validated per ICH Q2(R1), they offer different strengths. The LC-PDA method showed a wider linear range for bulk analysis at low concentrations, while the LC-MS/MS method demonstrated superior recovery in a complex biological matrix like plasma [13]. The study also highlighted the complementary role of both techniques: PDA was used for the quantitative analysis of the drug, while MS was essential for characterizing the structure of the novel degradation product [13].

Experimental Protocols for Peak Purity Assessment

Peak Purity Using Photo-Diode Array (PDA)

Protocol Summary:

- Chromatographic Separation: The analysis is performed using a suitable HPLC system. The cited study used a core–shell particle column (Ascentis Express F5, 2.7 µm, 100 x 4.6 mm) with a mobile phase of 1 mM ammonium acetate buffer (pH ≈5.30) and acetonitrile (25:75, v/v) at a flow rate of 0.5 mL/min and a column temperature of 40°C [13].

- Spectral Acquisition: The PDA detector is set to continuously acquire full UV spectra across a defined range (e.g., 190-380 nm) throughout the chromatographic run [13].

- Data Analysis: Software algorithms compare spectra from the upslope, apex, and downslope of the peak of interest. A high spectral match (or low purity threshold) indicates a pure peak, while significant spectral differences suggest co-elution of an impurity.

Peak Purity Using Mass Spectrometry (MS)

Protocol Summary:

- LC-MS Setup: The HPLC system is coupled to a mass spectrometer. The same chromatographic conditions used for PDA analysis can often be applied, though mobile phases must be MS-compatible (e.g., volatile buffers like ammonium acetate) [13].

- MS Data Acquisition: The MS is set to scan a relevant mass range (e.g., m/z 100-800). Electrospray Ionization (ESI) in positive or negative mode is typical [13].

- Data Interrogation:

- Extracted Ion Chromatograms (XIC): Generate chromatograms for specific m/z values. A pure API peak will show all relevant ions (e.g., [M+H]+, adducts, fragments) co-eluting with the same profile.

- Advanced Software Tools: Solutions like Mnova MSChrom can automate purity assessment using features like Multivariate Curve Resolution (MCR-ALS), which deconvolves overlapping signals, and molecule matching, which verifies structures by comparing experimental and theoretical isotope patterns [28].

The following workflow diagrams illustrate the application of these detectors within the regulated stability testing environment.

Diagram 1: The role of forced degradation and peak purity in developing a stability-indicating method according to ICH guidelines.

Diagram 2: A comparative workflow for peak purity assessment using PDA and MS detectors.

The Scientist's Toolkit: Essential Reagents and Software

Table 3: Key Reagents and Software for Forced Degradation and Purity Analysis

| Item | Function | Example from Literature |

|---|---|---|

| Core-Shell HPLC Column | Provides high-efficiency chromatographic separation of APIs from degradants. | Ascentis Express F5 (2.7 µm, 100 x 4.6 mm) [13] |

| Ammonium Acetate | MS-compatible buffer for the mobile phase, maintaining pH and ionic strength. | 1 mM solution, pH ≈5.30 [13] |

| Stress Reagents | To induce specific degradation pathways for forced degradation studies. | HCl (Acid), NaOH (Base), Hâ‚‚Oâ‚‚ (Oxidation) [24] |

| Mnova MSChrom Software | A unified platform for LC/MS data analysis, including peak purity assessment, molecule matching, and isotope prediction [28] | |

| Zeneth Software | An in silico prediction tool for identifying potential degradation pathways and products, aiding in study design [27] | |

| Dioleyl hydrogen phosphate | Dioleyl Hydrogen Phosphate | High-Purity Reagent | Dioleyl hydrogen phosphate for RUO. A key surfactant & extractant for metal separation & lipid membrane research. For research use only. Not for human use. |

| 9-Thiabicyclo[6.1.0]non-4-ene | 9-Thiabicyclo[6.1.0]non-4-ene|CAS 13785-73-4 |

Both PDA and MS detectors are indispensable in modern pharmaceutical analysis for ensuring peak purity and method specificity in compliance with ICH Q2(R1) and Q14. PDA offers a cost-effective, straightforward, and quantitative approach for assessing spectral homogeneity and is fully capable of serving as a validated stability-indicating method. MS, while more expensive, provides superior specificity and sensitivity, making it the unequivocal choice for identifying and characterizing unknown degradation products, especially at trace levels. The most robust analytical control strategy often leverages the complementary strengths of both techniques: using PDA for routine testing and stability monitoring, and deploying MS for method development, troubleshooting, and structural elucidation during forced degradation studies.

A Step-by-Step Guide to Implementing PDA and MS Peak Purity Methods

In high-performance liquid chromatography (HPLC), the photodiode array (PDA) detector is a critical tool for assessing peak purity, a fundamental requirement in pharmaceutical analysis where undetected coelution can compromise data quality and lead to misleading results [1]. Proper configuration of a PDA detector is not merely an operational formality but a scientific necessity to unlock its full potential for reliable impurity detection. The parameters of wavelength range, slit width, and scan speed directly determine the balance between analytical sensitivity and spectral fidelity, impacting the confidence of peak purity assessments [29]. This guide explores the configuration of PDA detectors, objectively comparing their performance capabilities with complementary techniques like Mass Spectrometry (MS) to frame their role within a comprehensive peak purity strategy.

Core Principles: How a PDA Detector Functions

A photodiode array detector operates on the principle of reversed optics. After light from the source passes through the flow cell, it is dispersed by a diffraction grating onto an array of diodes, typically containing 1024 elements [29]. This allows for the simultaneous detection of absorbance across a spectrum of wavelengths, generating a three-dimensional data cube (absorbance, wavelength, and time). It is this rich spectral and temporal data that enables the comparison of spectra across different segments of a chromatographic peak—the foundational process for software-driven peak purity algorithms that calculate metrics like Purity Angle and Purity Threshold [1] [30].

Parameter Deep Dive: Configuration and Experimental Impact

Optimizing PDA settings is a strategic exercise in balancing competing demands: signal-to-noise ratio (sensitivity) versus spectral resolution (qualitative confidence). The table below summarizes the key parameters, their functions, and their qualitative impacts.

Table 1: Core PDA Detector Parameters and Their Effects on Data Quality

| Parameter | Function & Definition | Impact on Sensitivity | Impact on Spectral Resolution |

|---|---|---|---|

| Wavelength Range | The span of wavelengths recorded (e.g., 200-400 nm) [29]. | A narrower range reduces file size but can compromise method robustness. | A wider range is essential for collecting full spectra for purity assessment [1]. |

| Slit Width | The physical width controlling the amount of light entering the optical path [29]. | Wider slits allow more light, reducing noise and improving detection limits [29] [11]. | Narrower slits provide better wavelength discrimination, preserving fine spectral features for purity checks [29]. |

| Spectral Bandwidth/Resolution | The wavelength width over which data is averaged, often tied to slit width [29]. | Larger bandwidths average more signal, improving signal-to-noise [29]. | Smaller bandwidths provide higher spectral resolution, crucial for identifying coeluting compounds with similar spectra [29]. |

| Scan Speed/Data Rate | The frequency at which full spectra are captured [29]. | A slower data rate can smooth noise but may miss narrow peaks. | A faster rate captures more data points across a peak, improving peak modeling and purity assessment accuracy; ≥25 points per peak is recommended [29]. |

Experimental Data on Parameter Optimization

Research provides quantitative evidence for the impact of parameter optimization. A study using a Waters Alliance iS HPLC System with a PDA detector demonstrated that moving from default settings to an optimized configuration—adjusting data rate, filter time constant, slit width, and resolution—resulted in a 7-fold increase in the USP signal-to-noise (S/N) ratio for the analysis of organic impurities in ibuprofen tablets [31]. This dramatic improvement in sensitivity directly enhances the ability to detect low-level impurities that could otherwise go unnoticed.

Furthermore, a robust HPLC-PDA method for quantifying short-chain fatty acids achieved complete separation of six analytes in under 8 minutes, a significant speed improvement over existing methods. This was accomplished without derivatization, highlighting how careful optimization of parameters like mobile phase composition, flow rate, and temperature can deliver high throughput, sensitivity, and simplicity simultaneously [32].

Comparative Analysis: PDA vs. MS for Peak Purity

While PDA is a powerful and accessible tool, its position must be understood in relation to the mass spectrometer (MS), another cornerstone of orthogonal detection.

Table 2: Objective Comparison of PDA and MS Detectors for Peak Purity Analysis

| Feature | PDA Detector | MS Detector (e.g., QDa) |

|---|---|---|

| Principle of Detection | Ultraviolet-Visible (UV-Vis) light absorbance [1]. | Mass-to-charge ratio (m/z) of ions [1]. |

| Peak Purity Basis | Spectral homogeneity across a peak via cosine matching (Purity Angle vs. Threshold) [1] [30]. | Mass spectral homogeneity; detection of different ions [30]. |

| Primary Strength | Detects impurities with differing UV spectra, even if same molecular weight [1]. | Unambiguous detection of coelution based on mass difference; superior for trace-level impurities [1]. |

| Key Limitation | Cannot distinguish impurities with nearly identical UV spectra [1]. | Cannot distinguish isomers with identical mass and fragmentation patterns. |

| Optimal Use Case | First-line purity assessment, method development, and stability-indicating assays where UV spectra differ. | Definitive confirmation of coelution, identifying unknown impurities, and analyzing compounds with low UV absorbance. |

The most robust analytical workflows integrate both techniques. Empower CDS software, for example, allows for the combined reporting of purity results from both PDA and a QDa Mass Detector, providing a multi-faceted view of chromatographic purity [30].

Advanced Techniques and Future Directions

Beyond basic spectral comparison, advanced software leverages the full power of 3D PDA data. Shimadzu's i-PDeA II uses multivariate curve resolution alternating least squares (MCR-ALS) to deconvolve coeluted peaks, providing both the spectrum and chromatographic profile for individual components within an unresolved peak. This powerful approach can even separate and quantify coeluted isomers, which are indistinguishable by MS alone [11].

Future directions point toward greater automation and intelligence. The concept of "Analytical Intelligence" involves systems that automatically assess data quality and instrument conditions, simulating expert decision-making to ensure reliability and compensate for differences in user experience [11].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials and Reagents for HPLC-PDA Method Development

| Item | Function/Description | Example Application/Note |

|---|---|---|

| SPD-M40 PDA Detector | Advanced PDA detector with stray light elimination for a wide dynamic range (linearity up to 2.5 AU) [11]. | Ideal for impurity analysis in pharmaceuticals where main component and impurities have vastly different concentrations [11]. |

| C18 Column | A standard reversed-phase stationary phase for separating a wide range of analytes. | Used in the separation of folic acid and methotrexate with a methanol and formic acid mobile phase [33]. |

| LabSolutions / Empower CDS | Chromatography Data Software for instrument control, data processing, and peak purity calculation [30] [11]. | Critical for automating purity calculations (Purity Angle/Threshold) and generating reports [30]. |

| 0.1% Formic Acid in Water | A common aqueous mobile phase component providing acidity for protonation and improved chromatography. | Used in a 69:31 ratio with methanol for the separation of folic acid and methoxsalene [33]. |

| Methanol (HPLC Grade) | A common organic modifier in reversed-phase mobile phases. | Optimized at 31% in a mobile phase for a rapid 8-minute separation of six short-chain fatty acids [32]. |

| Azane;hydroiodide | Azane;hydroiodide, CAS:12027-06-4, MF:H4IN, MW:144.943 g/mol | Chemical Reagent |

| 1,3-Dibromo-2,4,6-trinitrobenzene | 1,3-Dibromo-2,4,6-trinitrobenzene, CAS:13506-78-0, MF:C6HBr2N3O6, MW:370.9 g/mol | Chemical Reagent |

Configuring a PDA detector by strategically selecting wavelength range, slit width, and scan speed is a foundational step toward achieving reliable peak purity data. While PDA offers an indispensable, cost-effective tool for spectral-based impurity detection, its limitations mean that for definitive results—especially in regulated environments—it should be viewed as part of an orthogonal strategy that includes mass spectrometry. The future of peak purity lies in the intelligent integration of these techniques, enhanced by advanced deconvolution algorithms and automated systems, empowering scientists to ensure the highest data quality in drug development.

Step-by-Step Workflow for PDA Peak Purity Analysis in Empower and Other CDS

Peak purity assessment is a critical analytical procedure in pharmaceutical analysis that determines the spectral homogeneity of a chromatographic peak, providing evidence that a peak represents a single chemical compound rather than multiple co-eluting substances [34]. It is essential to understand that peak purity is not equivalent to chemical purity but rather demonstrates spectral consistency across different regions of a chromatographic peak [34]. This analysis is particularly valuable in forced degradation studies during method development for stability-indicating methods, where it helps demonstrate that the method can adequately separate parent drug compounds from their degradation products [4].

Photodiode Array (PDA) detectors have become the primary tool for peak purity assessment in liquid chromatography due to their ability to collect full spectral data across defined wavelength ranges in real-time [35]. The fundamental principle behind PDA-based peak purity is the comparison of normalized UV absorbance spectra extracted from different regions across a chromatographic peak (typically leading edge, apex, and trailing edge) [34]. If the normalized spectra overlay perfectly, the peak is considered spectrally pure; spectral differences suggest potential co-elution [34]. Major Chromatography Data Systems (CDS) platforms, including Waters Empower, Agilent OpenLab, and Shimadzu LabSolutions, implement proprietary algorithms to calculate and report peak purity metrics, though their fundamental principles share common mathematical foundations in vector analysis [4] [14].

Theoretical Foundations of PDA Peak Purity

The Vector-Based Mathematical Model

PDA peak purity algorithms in commercial CDS software are predominantly based on treating UV spectra as vectors in n-dimensional space, where n represents the number of data points in the spectrum [14]. In this model, each spectrum is represented as a vector whose terminal point has coordinates corresponding to absorbance values at each wavelength [4]. Spectral similarity is quantified by calculating the angle between vectors representing spectra from different regions of the chromatographic peak [4] [14].

The core calculation involves determining the purity angle and purity threshold. The purity angle represents a weighted average of all calculated angles between spectra across the peak compared to the apex spectrum, while the purity threshold (or threshold angle) represents the degree of uncertainty based on solvent contributions and spectral noise [4]. A chromatographic peak is considered spectrally pure when the purity angle is less than the purity threshold [4]. The mathematical relationship for spectral similarity is expressed through the cosine of the angle θ between two spectral vectors a and b:

[ \cos \theta = \frac{\mathbf{a} \cdot \mathbf{b}}{\|\mathbf{a}\|\|\mathbf{b}\|} ]

Where the numerator represents the dot product of the two vectors, and the denominator contains the product of their norms (lengths) [14]. This calculation generates a value independent of signal amplitude, depending only on spectral shape [14].

Figure 1: Algorithmic workflow for PDA-based peak purity assessment, showing the sequence from spectral collection to purity determination [4].

Commercial CDS Platform Implementations

While the core principles of peak purity assessment are consistent across platforms, major CDS vendors implement slightly different algorithms and terminology [4]:

- Waters Empower: Utilizes purity angle and purity threshold terminology, with spectral contrast measured as the angle between baseline-corrected spectral vectors [4].

- Agilent OpenLab: Employs a similarity factor expressed as 1000 × r², where r is equivalent to cosθ (θ = purity angle in Empower) [4].

- Shimadzu LabSolutions: Uses cosθ values to quantify peak purity and features i-PDeA II (Intelligent Peak Deconvolution Analysis II) for deconvolving co-eluted peaks using multivariate curve resolution-alternating least squares (MCR-ALS) algorithm [4] [35].

Comparative Experimental Protocols

Waters Empower Peak Purity Workflow

Method Development and Data Collection

To obtain reliable peak purity results in Empower, specific parameters must be properly configured in the PDA instrument method [34]:

- Wavelength Range: Start above the UV cutoff of the mobile phase and end at a wavelength that encompasses all absorbance areas. Avoid ranges where mobile phase components absorb strongly, as this reduces the linear dynamic range [34].

- Spectral Resolution: Select 1.2nm for optimal spectral resolution [34].

- Sampling Rate: Choose a rate that provides at least 12 spectra across the narrowest peak of interest, with 15-20 spectra being optimal [34].

- Absorbance Control: Maintain absorbance of all peaks less than 1 AU according to MaxPlot to minimize photometric error that can cause spectral inhomogeneity [34].

Data Processing and Peak Purity Parameters

The Empower processing method requires specific configuration on the 'Purity' tab [15] [36]:

- Enable Purity Calculation: Check the 'Purity Enabled' box to activate peak purity calculations [15] [36].

- Active Peak Region: Defaults to 100.0%, meaning all spectra from 'peak liftoff' to 'peak touchdown' are used. Reduce this value with noisy baselines to exclude noisy baseline spectra from calculations [15] [36].

- Threshold Angle Determination: Typically the sum of Noise Angle (based on selected noise interval) plus Solvent Angle. Begin with AutoThreshold, which automatically determines Solvent Angle as a function of Maximum Spectral Absorbance (MSA) [15] [36].

AutoThreshold Validation

AutoThreshold requires validation before use with unknown samples [15] [36]:

- Make six injections of standard

- Create PDA Processing Method with enabled purity and determined Noise Interval

- Set Threshold Angle to 'AutoThreshold'

- Process all six injections

- If Purity Angle is less than Purity Threshold for all peaks in all injections, AutoThreshold is validated

- The validated AutoThreshold can be used for unknown samples, provided their maximum spectral absorbance is <1.0 AU and less than five times the MSA of the standard used for validation [15] [36]

Reporting Peak Purity Results

Empower provides flexible reporting of numerical and graphical peak purity results [30]:

- Report Method Setup: Copy default Report Methods from PDA Defaults project to working project

- PDA Purity Plot: Displays one purity plot for each peak with Purity Angle and Purity Threshold values

- Mass Analysis Integration: Add QDa Mass Detector purity results by adding Mass Analysis Plot to report and selecting 'Purity' on Mass Analysis tab

- Multi-Component Reporting: For multi-component peak purity, use '4 Pass Peak Purity Report' from PDA Defaults project

- Tabular Data: Purity Angles and Thresholds can be added to existing report tables under PDA Peak section [30]

Shimadzu LabSolutions Workflow

Shimadzu's implementation includes proprietary deconvolution capabilities [35]:

- Spectral Collection: Collect full spectral data across the peak using appropriate sampling rate

- Similarity Calculation: Calculate cosθ values to quantify spectral similarity

- Peak Deconvolution: Apply i-PDeA II (Intelligent Peak Deconvolution Analysis II) utilizing multivariate curve resolution-alternating least squares (MCR-ALS) algorithm to deconvolve co-eluting peaks when detected [4] [35]

- Purity Reporting: Generate purity reports with similarity indices and deconvolution results when applicable

Agilent OpenLab Approach

Agilent's platform employs a different reporting metric [4]:

- Data Collection: Follow similar principles for spectral acquisition

- Similarity Calculation: Compute similarity factor as 1000 × r², where r equals cosθ (equivalent to purity angle in Empower)

- Threshold Application: Establish and apply appropriate thresholds for purity determination

- Result Interpretation: Interpret results based on similarity factors relative to thresholds

Critical Comparison of CDS Platforms

Table 1: Comparative analysis of peak purity algorithms and reporting across major CDS platforms

| Parameter | Waters Empower | Agilent OpenLab | Shimadzu LabSolutions |

|---|---|---|---|

| Core Algorithm | Vector angle comparison in n-dimensional space [4] | Vector angle comparison in n-dimensional space [4] | Vector angle comparison in n-dimensional space [4] |

| Primary Metric | Purity Angle vs. Purity Threshold [4] | Similarity Factor (1000 × r²) [4] | cosθ values [4] |

| Deconvolution Capability | Limited | Limited | Advanced (i-PDeA II with MCR-ALS) [4] [35] |

| MS Integration | Direct QDa Mass Detector integration [30] | MSD detector compatibility [4] | Compatible with MS systems |

| Multi-Component Purity | 4 Pass Peak Purity Report [30] | Standard approaches | Standard approaches |

| Baseline Handling | Active Peak Region adjustment for noisy baselines [15] [36] | Standard approaches | Standard approaches |

| Threshold Determination | AutoThreshold with validation protocol [15] [36] | Vendor-recommended approaches | Vendor-recommended approaches |

Analytical Performance Metrics

Table 2: Performance characteristics and limitations of PDA-based peak purity assessment

| Performance Aspect | Experimental Findings | Platform Considerations |

|---|---|---|

| Detection Limits | Reliable detection ~0.1% co-elution under optimal conditions [4] | Consistent across platforms when properly configured |

| False Negative Risk | High when: co-eluting impurities have minimal spectral differences, poor UV response, elute near apex, or present at very low concentrations [4] | Platform-independent limitation of PDA technology |

| False Positive Risk | Occurs with: significant baseline shifts, suboptimal processing settings, integration issues, extreme wavelengths (<210 nm or >800 nm), low concentration impurities (<0.1%), excipient interference [4] | All platforms susceptible; proper method development critical |

| Linear Dynamic Range | Optimal performance with Max Spectral Absorbance <1.0 AU [34] [15] | Consistent across platforms |

| Spectral Range Considerations | Challenges below 210 nm due to mobile phase absorption and noise [17] | Affects all platforms; recommend working >210 nm when possible |

| Structural Similarity Impact | Limited discrimination for structurally similar compounds with nearly identical UV spectra [4] | Fundamental limitation of UV-based purity assessment |

Advanced Applications and Complementary Techniques

Mass Spectrometry as a Complementary Technique

Mass spectrometry-facilitated peak purity assessment provides orthogonal data to PDA-based approaches [4]. This technique is typically performed using nominal mass resolution single quadrupole mass spectrometers (such as Waters QDa or Agilent MSD detectors) [4]. Peak purity is verified by demonstrating consistent precursor ions, product ions, and/or adducts across the chromatographic peak in total ion chromatograms (TIC) or extracted ion chromatograms (EIC/XIC) [4]. The Waters Empower platform enables direct integration of MS-based purity assessment by adding Mass Analysis Plot to reports and selecting 'Purity' on the Mass Analysis tab, allowing simultaneous review of UV and MS spectra from leading edge, apex, and trailing edge for each peak [30].

2D-LC for Complex Purity Challenges

Two-dimensional liquid chromatography (2D-LC) provides enhanced peak capacity for resolving complex mixtures where conventional purity assessment indicates potential co-elution [4]. This approach is particularly valuable when: (1) co-eluting compounds have nearly identical UV spectra, (2) impurities are present at very low concentrations, or (3) exactly co-eluting peaks require resolution through orthogonal separation mechanisms [4].

Essential Research Reagents and Materials

Table 3: Key reagents, materials, and instrumentation for robust peak purity assessment

| Item Category | Specific Examples | Functional Role in Purity Assessment |

|---|---|---|

| Chromatography Columns | Ascentis Express F5 2.7 μm, 100 × 4.6 mm i.d. [13] | Provides chromatographic separation with core-shell particles for enhanced efficiency |

| Mobile Phase Components | LC-MS grade acetonitrile [13], Ammonium acetate buffer [13] | Creates separation environment while minimizing UV background interference |

| PDA Detectors | ACQUITY PDA Detector [34], SPD-M20A PDA detector [13] | Captures full UV spectral data across peaks for purity analysis |

| Mass Detectors | ACQUITY QDa Mass Detector [34] [4], LC-MS-IT-TOF [13] | Provides orthogonal purity assessment through mass spectral data |

| Data Systems | Waters Empower [30], Agilent OpenLab [4], Shimadzu LabSolutions [4] | Processes spectral data and calculates purity metrics using proprietary algorithms |

| Validation Standards | Company-specific drug substance standards [15] | Validates peak purity method performance and threshold settings |

PDA-based peak purity analysis represents a powerful, widely implemented approach for assessing spectral homogeneity in chromatographic methods across major CDS platforms. While Waters Empower, Agilent OpenLab, and Shimadzu LabSolutions employ slightly different algorithms and reporting metrics, they share common fundamental principles based on vector comparison of spectral similarity. The effectiveness of these systems depends heavily on proper method development, including optimal wavelength selection, appropriate sampling rates, controlled absorbance levels, and validated threshold settings. Researchers should recognize that PDA-based purity assessment alone cannot unequivocally prove a peak is pure but rather indicates whether co-eluting compounds with different UV spectra were detected. For comprehensive purity assessment, particularly with structurally similar compounds, orthogonal techniques such as mass spectrometry or 2D-LC provide valuable complementary data to strengthen method validity and regulatory submissions.

Implementing MS Peak Purity with Single Quadrupole and QDa Detectors

Peak purity assessment is a critical analytical procedure in pharmaceutical development and other scientific fields to determine whether a chromatographic peak represents a single, pure compound or contains co-eluting impurities. Peak purity is spectral purity or spectral homogeneity, not chemical purity [34]. The fundamental principle involves extracting spectra across different points of a chromatographic peak—typically at the leading edge, apex, and trailing edge—and comparing them. If the normalized spectra overlay perfectly, chances are there is one component under the peak; if not, multiple components are likely present [34].

While Photodiode Array (PDA) ultraviolet detection has been the traditional workhorse for peak purity assessments, Mass Spectrometric (MS) detection provides enhanced specificity and is increasingly implemented using accessible mass detectors like single quadrupole and QDa systems. MS-facilitated PPA verifies purity by demonstrating that the same precursor ions, product ions, and/or adducts attributed to the parent compound are present consistently across the entire peak in the total ion chromatogram (TIC) or extracted ion chromatogram (EIC/XIC) [4]. This guide objectively compares the performance of these MS detection platforms for peak purity analysis within the broader context of analytical techniques, providing the experimental data and methodologies needed for informed implementation.

Comparison of Detection Technologies

The choice of detection technology significantly impacts the reliability, cost, and analytical scope of peak purity determinations. The table below summarizes the core characteristics of the primary detection modalities.

Table 1: Comparison of Peak Purity Detection Technologies

| Feature | PDA/UV Detection | Single Quadrupole MS | QDa Mass Detector |

|---|---|---|---|

| Primary Principle | Spectral contrast of UV absorbance spectra [4] | Mass-to-charge (m/z) ratio filtering and analysis [37] [38] | Compact, purpose-built single quadrupole mass detection [39] [4] |

| Key Strength | Efficient, well-understood, minimal extra cost [4] | Molecular weight confirmation, high specificity for different masses | Ease of use, simplified integration with LC systems [39] |

| Key Limitation | Cannot distinguish impurities with nearly identical UV spectra [4] [5] | Lower resolution than high-end MS; cannot distinguish isobaric species [40] | Limited to nominal mass resolution [4] |

| False Negative Risk | High (when impurities have similar UV spectra or poor UV response) [4] | Low for impurities with different m/z, but high for isomers | Low for impurities with different m/z, but high for isomers |

| Ideal For | Initial method development, compounds with good chromophores | Labs requiring molecular weight confirmation for purity | Routine QC labs adding mass confirmation to existing methods |