Strategic Method Development for 2D-LC: A Guide from Foundations to Advanced Applications in Pharmaceutical and Biomedical Research

This article provides a comprehensive guide to two-dimensional liquid chromatography (2D-LC) method development, tailored for researchers, scientists, and drug development professionals.

Strategic Method Development for 2D-LC: A Guide from Foundations to Advanced Applications in Pharmaceutical and Biomedical Research

Abstract

This article provides a comprehensive guide to two-dimensional liquid chromatography (2D-LC) method development, tailored for researchers, scientists, and drug development professionals. It covers foundational principles, including the strengths of comprehensive (LC×LC) and heart-cut (LC-LC) modes for complex mixture analysis and peak purity assessment. The guide details systematic methodologies for selecting orthogonal stationary phases and mobile phases, with applications ranging from small molecule impurities to biopharmaceutical characterization. It addresses critical troubleshooting aspects, such as managing mobile-phase mismatch with techniques like Active Solvent Modulation (ASM), and explores validation strategies that demonstrate the superior peak capacity and compound identification power of 2D-LC compared to 1D-LC, cementing its value in quality control and complex sample analysis.

Understanding 2D-LC: Core Principles, Modes, and Orthogonality for Complex Separations

For decades, one-dimensional liquid chromatography (1D-LC) has served as the workhorse for analytical separations. However, when analyzing complex samples such as natural products, biologics, and pharmaceutical formulations, conventional 1D-LC systems reach their fundamental limitations. The extremely low resolution of 1D-LC results in only a limited number of compounds being separated and determined, even when coupled with advanced mass spectrometry [1]. The evolution to ultra-high performance liquid chromatography (UHPLC) with higher-pressure systems and smaller particle size columns represented a significant improvement, increasing detected compounds from tens to hundreds, yet this still proves insufficient for truly complex matrices where co-elution, minor components, and numerous isomers create an "insurmountable mountain" for 1D separation approaches [1].

Two-dimensional liquid chromatography (2D-LC) emerges as a powerful solution to these challenges. Originally conceptualized by Giddings, 2D-LC operates on the principle that analytes are first separated by a first dimension (1D) column, after which eluted fractions are systematically transferred to a second dimension (2D) separation [1]. The theoretical peak capacity of an ideal 2D-LC system becomes the product of the individual dimensions' peak capacities, rather than their sum, enabling unprecedented resolution for complex samples [2]. This transformative approach has demonstrated superior capabilities in peak capacity, resolution, and sensitivity compared to 1D-LC, making it particularly valuable for quantitative analysis where accurate characterization and quantification of individual components are essential [1] [3].

Technical Foundations of 2D-LC Separation

Fundamental Principles and System Configurations

The separation power of 2D-LC stems from its ability to leverage two different separation mechanisms, significantly increasing the total peak capacity. While 1D-LC might achieve peak capacities of a few hundred, comprehensive 2D-LC (LC×LC) can achieve peak capacities of several thousand, with 10,000 being within reasonable reach [2]. This creates substantially more "room" in the chromatogram to separate complex mixtures. The peak-production rate (peak capacity divided by analysis time) of LC×LC reaches approximately 1 peak per second, compared to about 1 peak per minute for typical high-resolution 1D-LC [2].

2D-LC systems are implemented in three primary operational modes, each with distinct characteristics and applications:

- Heart-cutting 2D-LC (LC-LC): Transfers one or a few specific fractions from the 1D separation to the 2D dimension [2]. This approach is ideal for targeted applications such as peak purity assessment or purification of specific analytes [4].

- Comprehensive 2D-LC (LC×LC): Transfers all 1D effluent to the 2D column in consecutive fractions, providing complete two-dimensional separation of the entire sample [1] [2]. This mode is essential for untargeted analysis and complete sample characterization.

- Multiple heart-cutting 2D-LC: Occupies the middle ground, transferring multiple discrete fractions from across the 1D chromatogram to the 2D dimension [2].

Table 1: Comparison of 2D-LC Operational Modes

| Feature | Heart-cutting (LC-LC) | Comprehensive (LC×LC) |

|---|---|---|

| Fractions Analyzed | Selective fractions | All fractions |

| Peak Capacity | High for targeted analytes | Very high (1,000-10,000) |

| Analysis Time | Moderately increased | Longer (30 min - 2+ hours) |

| Primary Applications | Peak purity assessment, target analysis | Complete sample characterization, untargeted analysis |

| Data Complexity | Moderate | High, requires specialized software |

| Method Development | Relatively straightforward | More complex and time-consuming |

Orthogonality and Separation Mechanism Selection

The effectiveness of any 2D-LC separation depends critically on the concept of orthogonality – the degree to which the two separation dimensions employ different retention mechanisms. True orthogonality occurs when the retention times in the two dimensions are completely independent, maximizing the separation space utilization [2]. In practice, selecting complementary separation modes is essential for achieving high orthogonality.

The most frequently used online 2D-LC system is two-dimensional reversed-phase LC (RPLC×RPLC), valued for its high separation efficiency and better mobile phase compatibility compared to other configurations [3]. However, this approach may result in relatively low orthogonality and peak capacity. To address this limitation, modified RP stationary phases with different selectivity are continually being developed [3].

Other effective orthogonal combinations include:

- HILIC-RPLC: Combines hydrophilic interaction chromatography with reversed-phase separation, offering high orthogonality for certain compound classes [3].

- RPLC-Strong Cation Exchange (SCX): Particularly valuable for separating ionic compounds and biomolecules [3].

- Normal Phase (NP)-RPLC: Potentially offers high orthogonality but is constrained by significant solvent incompatibility issues [1].

Table 2: Common 2D-LC Column Combinations and Their Characteristics

| Combination | Orthogonality | Solvent Compatibility | Typical Applications |

|---|---|---|---|

| RPLC×RPLC | Low to Moderate | High | Broad applicability, natural products, pharmaceuticals |

| HILIC×RPLC | High | Moderate | Polar compounds, metabolites, natural products |

| NP×RPLC | High | Low | Complex natural products, isomers |

| SCX×RPLC | High | Moderate | Peptides, ionic compounds, biologics |

| SEC×RPLC | High | Low | Biopolymers, protein aggregates |

Critical Application Protocols

Protocol: Peak Purity Assessment for Pharmaceutical QC

This protocol details the application of heart-cutting 2D-LC for peak purity testing of drug products, a critical quality control requirement in pharmaceutical development [4].

Application Context: Demonstrating specificity during method validation requires confirming that the active pharmaceutical ingredient (API) peak is pure and free from co-eluting impurities or degradants [4].

Materials and Reagents:

- Agilent 1290 Infinity II 2D-LC system or equivalent

- First dimension column: C18, 150 × 2.1 mm, 1.8 μm

- Second dimension columns: Multiple with different selectivities (e.g., different C18 ligands, phenyl, polar-embedded)

- Mobile phases: A) Water with 0.1% formic acid; B) Acetonitrile with 0.1% formic acid

- Alternative mobile phases: Different pH (neutral and acidic) with different organic modifiers (acetonitrile and methanol)

- Reference standards: API and potential impurities

- Forced degradation samples: Acid, base, peroxide, and light stress conditions

Experimental Procedure:

First Dimension Separation:

- Inject forced degradation sample onto 1D column

- Apply gradient elution: 5-95% B over 30 minutes

- Monitor separation at 220 nm and 254 nm

- Identify retention time of main API peak

Heart-Cutting Method:

- Program fraction collection to cut the entire API peak from 1D

- For comprehensive purity assessment, cut peak into several pieces (beginning, middle, end) to examine potential co-elution in different peak regions [4]

- Transfer fractions to 2D loops using an 8- or 10-port 2-position valve

Second Dimension Separation:

- Apply orthogonal separation conditions on 2D column

- Use isocratic or shallow gradient elution for rapid separation

- Employ different separation mechanisms (varying pH, organic modifiers, stationary phases)

Quantitative Analysis:

- For quantitative determination, utilize software features that combine different fractions from one 1D peak into a single 2D injection to maintain sensitivity [4]

- Compare peak areas in 1D and 2D to calculate recovery

- Confirm absence of additional peaks in 2D chromatogram indicating impurities

Method Optimization:

- Systematically test different 2D mobile phases and columns

- Evaluate 12 different conditions (2 pH × 2 organic modifiers × 3 gradient slopes) for robustness [4]

- Verify sensitivity with limit of quantitation solutions (e.g., 0.05% of main compound)

Data Interpretation: A pure API peak will show a single peak in the second dimension with no additional peaks present. Co-eluting impurities will appear as distinct peaks in the 2D separation, enabling their identification and quantification.

Protocol: Comprehensive Analysis of Natural Products

This protocol describes the application of comprehensive 2D-LC (LC×LC) for the quantitative analysis of complex natural products, such as herbal medicines [1] [3].

Application Context: Complete characterization of complex chemical compositions in natural products where extremely low concentration compounds, co-elutions, and numerous isomers exceed 1D-LC capabilities [1].

Materials and Reagents:

- Comprehensive 2D-LC system with active modulation capability

- First dimension column: C18, 100 × 3.0 mm, 1.7 μm

- Second dimension column: Modified C18 (e.g., pentafluorophenyl), 30 × 2.1 mm, 1.7 μm

- Mobile Phase A1 (1D): Water with 0.1% formic acid

- Mobile Phase B1 (1D): Acetonitrile with 0.1% formic acid

- Mobile Phase A2 (2D): Water

- Mobile Phase B2 (2D): Methanol

- Standard solutions: Target analytes at known concentrations

- Natural product extract samples: Appropriately diluted in initial mobile phase

Experimental Procedure:

System Configuration:

- Implement active solvent modulation (ASM) to address solvent incompatibility between dimensions [2]

- Set modulation time to 4× the 2D cycle time (typically 0.1-0.5 minutes per 2D analysis)

- Use two 20-μL storage loops for fraction collection and transfer

First Dimension Separation:

- Apply slow gradient elution: 5-50% B1 over 60 minutes

- Maintain low flow rate: 0.1 mL/min to accommodate 2D analysis time

- Use column temperature: 40°C for retention stability

Comprehensive Modulation:

- Transfer 1D effluent continuously to 2D via modulation interface

- Apply ASM to dilute strong 1D effluent with weak 2D solvent [2]

- Maintain comprehensive operation (≥3 fractions per 1D peak)

Second Dimension Separation:

- Implement fast gradient elution: 5-95% B2 in 0.2 minutes

- Use high flow rate: 2.0 mL/min for rapid separation

- Maintain column temperature: 50°C

Detection and Data Collection:

- Use diode array detector (DAD) with high acquisition rate (80 Hz)

- Alternatively, couple to mass spectrometer for structural identification

- Collect data in centroid mode to reduce file size

Data Processing and Analysis:

- Use specialized 2D-LC software for data visualization and analysis

- Generate contour plots for visual representation of separation

- Apply chemometric algorithms for peak detection and integration [1]

- Construct calibration curves using reference standards for quantification

Advanced Technical Considerations

Modulation Strategies and Solvent Incompatibility

The modulation interface represents the heart of any 2D-LC system, responsible for transferring fractions from the 1D to the 2D separation. The most common implementation uses a 2-position 8- or 10-port valve equipped with two identical storage loops that alternately sample the 1D effluent [2]. However, this "passive" modulation approach creates a fundamental challenge: the 1D effluent becomes the injection solvent for the 2D separation, potentially leading to significant solvent incompatibility issues.

The pursuit of maximal orthogonality often necessitates combining two incompatible solvent systems. Key incompatibility challenges include:

Solvent Strength Mismatch: When the 1D effluent is a relatively strong injection solvent compared to the 2D eluent, the intended retention mechanism may be compromised as analytes are not strongly retained by the 2D stationary phase [2]. For example, combining organic size-exclusion chromatography (SEC) with RPLC results in fully organic 1D effluent that can prevent hydrophobic analytes from being retained on the 2D RP column.

Viscosity Contrast: Significant differences in viscosity between the two solvent systems may result in flow instabilities and viscous fingering, where a low-viscosity 2D mobile phase penetrates a high-viscosity injection plug in finger-shaped cones, potentially causing peak deformation and splitting [2].

Advanced modulation techniques have been developed to address these challenges:

Active Solvent Modulation (ASM): Dilutes the 1D effluent with a weak solvent before transfer to the 2D column, reducing the solvent strength mismatch [2].

Stationary Phase-Assisted Modulation: Uses trapping columns or cartridges to focus analytes while allowing strong solvents to pass through.

Vacuum Evaporation Interfaces: Remove the 1D mobile phase before 2D analysis, effectively addressing incompatibility but adding complexity [1].

Method Development and Optimization Strategy

Developing robust 2D-LC methods requires systematic optimization of multiple parameters. An effective strategy includes:

Orthogonality Screening: Evaluate different column combinations using representative samples to assess practical orthogonality.

Modulation Condition Optimization: Determine optimal modulation time, fraction volume, and dilution factors when using ASM.

Separation Synchronization: Balance 1D and 2D analysis times to ensure adequate sampling of 1D peaks (≥3 fractions per peak) while maintaining reasonable total analysis time.

Detection Sensitivity Enhancement: Address potential sensitivity loss from sample dilution by optimizing injection volume, using pathlength extension flow cells, or implementing analyte focusing techniques.

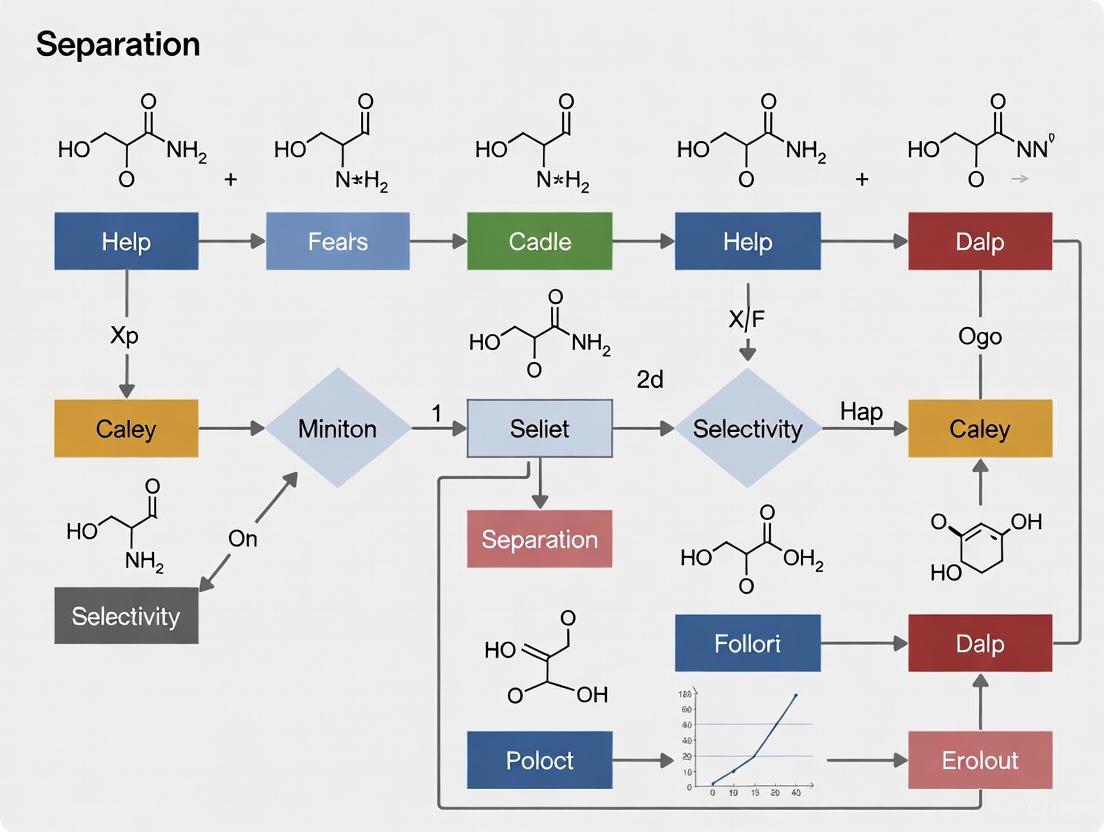

Diagram 1: 2D-LC Method Development Workflow

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential Research Reagents and Materials for 2D-LC Applications

| Item | Function | Application Notes |

|---|---|---|

| Different Selectivity Columns | Provide orthogonal separation mechanisms | Include C18, phenyl, polar-embedded, HILIC, cyano, pentafluorophenyl |

| High-Purity Mobile Phase Modifiers | Control retention and selectivity | Formic acid, ammonium formate, ammonium acetate, trifluoroacetic acid |

| Multiple Organic Modifiers | Vary solvent strength and selectivity | Acetonitrile, methanol, isopropanol in various combinations |

| Active Solvent Modulation Kit | Address solvent incompatibility between dimensions | Essential for NP-RPLC and other incompatible phase combinations |

| Reference Standards | Method development and quantification | Target analytes, potential impurities, and internal standards |

| Forced Degradation Samples | Method validation and specificity demonstration | Acid, base, peroxide, heat, and light stress conditions |

| Specialized 2D-LC Software | Data processing, visualization, and analysis | Essential for handling complex comprehensive 2D-LC datasets |

Operational Workflow and System Configuration

Diagram 2: Comprehensive 2D-LC System Configuration

2D-LC has firmly established itself as a powerful separation technology that effectively overcomes the fundamental limitations of 1D-LC for complex sample analysis. With its high peak capacity and superior resolution, 2D-LC enables researchers to address analytical challenges that were previously intractable with conventional approaches, particularly in pharmaceutical quality control, natural products analysis, and complex mixture characterization [1] [3] [4].

Despite its demonstrated capabilities, the field continues to evolve with several important developments on the horizon. Advanced modulation interfaces represent a critical area of innovation, with new approaches needed to solve persistent solvent incompatibility problems when combining highly orthogonal separation mechanisms [1]. Similarly, the development of more accurate and efficient data processing algorithms and software will enhance the reliability and convenience of 2D-LC for both qualitative and quantitative analysis of complex samples [1] [3]. As these technical advances mature and method development strategies become more streamlined, 2D-LC is positioned to transition from a specialized technique to a mainstream analytical tool capable of addressing the growing demands for characterization of increasingly complex samples across diverse scientific fields.

Two-dimensional liquid chromatography (2D-LC) has become a powerful analytical technique for the separation of complex samples that exceed the resolving power of conventional one-dimensional liquid chromatography (1D-LC) [5]. By combining two separate separation mechanisms with different selectivities, 2D-LC provides significantly enhanced peak capacity and resolution [6] [7]. The fundamental principle involves transferring part or all of the effluent from a first dimension (1D) separation to a second dimension (2D) column for further separation [8]. This transfer is typically automated using switching valves and sampling loops, enabling reproducible, online analysis [6] [8].

Two primary operational modes dominate 2D-LC: comprehensive (LC×LC) and heart-cutting (LC-LC). In comprehensive 2D-LC, the entire effluent from the first dimension is sequentially sampled and analyzed in the second dimension within the runtime of the 1D method [9] [8]. Conversely, in heart-cutting 2D-LC, only selected fractions from regions of interest in the 1D separation are transferred to the 2D for further analysis [9] [8]. A further development, multiple heart-cutting (MHC) 2D-LC, allows for the heart-cutting of multiple specific regions from a single 1D run [9]. Understanding the capabilities, requirements, and limitations of each mode is essential for selecting the optimal strategy for specific analytical challenges in pharmaceutical, biopharmaceutical, environmental, and food analysis [10] [11] [7].

Key Characteristics and Comparison of LC×LC and LC-LC

The choice between comprehensive and heart-cutting 2D-LC involves careful consideration of analytical goals, sample complexity, and available instrument capabilities.

Table 1: Core Characteristics of Comprehensive and Heart-Cutting 2D-LC

| Feature | Comprehensive (LC×LC) | Heart-Cutting (LC-LC) |

|---|---|---|

| Principle | The entire 1D effluent is cut into small sections and analyzed in the 2D [9] [8]. | Only selected sections (heart-cuts) from the 1D are analyzed in the 2D [9] [8]. |

| Peak Capacity | Very high (the product of the peak capacities of both dimensions) [7]. | Moderate (applicable only to the transferred regions) [5]. |

| Analysis Time | 2D runtime is limited by the 1D sampling time; requires very fast 2D separations [9]. | 2D runtime is independent of the 1D sampling time, allowing for longer, more resolved 2D runs [9]. |

| Ideal Sample Type | Highly complex, unknown samples requiring maximum resolution (e.g., proteomics, natural products) [8] [12]. | Samples requiring targeted, in-depth analysis of specific regions/peaks (e.g., impurity identification, chiral separations) [9] [13]. |

| Modulation & Interface | Requires a dedicated interface (valve with loops) for continuous, high-speed fraction transfer [6]. | Less demanding interface; typically a valve with one or more loops for storing heart-cuts [9]. |

| Data Complexity | High; generates complex three-dimensional data sets requiring specialized software [10] [5]. | Lower; data interpretation is more straightforward, similar to comparing multiple 1D chromatograms [9]. |

Table 2: Comparative Applications and Practical Considerations

| Aspect | Comprehensive (LC×LC) | Heart-Cutting (LC-LC) |

|---|---|---|

| Primary Application Goal | Untargeted analysis and full sample characterization [6] [8]. | Targeted analysis of specific compounds or regions (e.g., co-eluting peaks) [9] [5]. |

| Handling Mobile Phase Incompatibility | Challenging due to continuous transfer; requires strategies like Active Solvent Modulation (ASM) [10] [5]. | More straightforward, as dilution or trapping can be applied to specific cuts [9] [8]. |

| Quantification | Possible but can be challenging due to peak deformation from modulation and high dilution [6]. | Well-suited for quantification, especially of low-level impurities, via single complete heart-cutting [5]. |

| Instrumentation & Cost | Often requires specialized, high-end commercial systems to achieve fast 2D cycles and handle data [10]. | Can be implemented on in-house modified 1D-LC systems or commercial systems, offering more flexibility [10] [8]. |

| Example Applications | Analysis of protein digests [12], complex polymer mixtures [5], foodomics [11]. | Impurity profiling in pharmaceuticals [9], peak purity assessment [5], chiral separations [13]. |

Strategic Selection and Method Development

Decision Workflow for Mode Selection

The following diagram outlines the key decision points for selecting the appropriate 2D-LC mode based on the analytical goal.

Critical Method Development Considerations

Successful implementation of either 2D-LC mode requires careful optimization of several parameters:

- Orthogonality: The two separation dimensions must employ different retention mechanisms to maximize the peak capacity of the 2D system [6] [7]. Common orthogonal combinations include Reversed-Phase LC (RPLC) with Hydrophilic Interaction Liquid Chromatography (HILIC), Ion-Exchange Chromatography (IEC), or Size-Exclusion Chromatography (SEC) [6] [7]. Even different selectivities within the same mode (e.g., RPLC×RPLC with different stationary phases or pH) can be effective [5] [12].

- Mobile Phase Compatibility: A significant challenge in 2D-LC is the potential incompatibility between the mobile phases used in the two dimensions [10] [8]. For example, transferring a highly organic HILIC effluent to a RPLC column can cause severe peak broadening due to the strong elution strength [10] [8]. Strategies to mitigate this include:

- Active Solvent Modulation (ASM): A valve-based approach that online-dilutes the 1D effluent with a weak solvent before transfer to the 2D column [10] [5].

- Trapping Columns: The heart-cut is diluted and focused on a small trap column before being eluted to the analytical 2D column [10] [8].

- In-Line Mixing Modulation (ILMM): Using an in-line mixer to dilute the transferred fraction [8].

- Modulation Period (LC×LC): In comprehensive 2D-LC, the modulation period—the time at which fractions are transferred from the 1D to the 2D—is critical. To preserve the resolution achieved in the first dimension, 3-4 samplings across the base of a 1D peak are generally recommended [6]. This necessitates very fast 2D separations, often completed in seconds to a few minutes [6] [9].

- Column Dimensions and Flow Rates: The first dimension typically uses a long column operated at a low flow rate, while the second dimension uses a short column (e.g., 2-5 cm) operated at a high flow rate to enable fast separations [6]. The internal diameter of the second column is often equal to or larger than that of the first to minimize extra-column band broadening [6].

Detailed Experimental Protocols

Protocol 1: Multiple Heart-Cutting (MHC) 2D-LC for Impurity Identification

This protocol, adapted from applications at LEO Pharma, is designed for identifying and characterizing low-level impurities co-eluting with a main active pharmaceutical ingredient (API) or in a complex matrix [9].

I. Goals and Setup

- Primary Goal: To isolate and achieve high-resolution separation of a target impurity from a co-eluting API or matrix components for subsequent identification by UV and/or MS [9].

- Instrument Configuration: An Agilent 1290 Infinity 2D-LC system or equivalent, equipped with two binary pumps, two column ovens, two photodiode array (PDA) detectors, and a multiple heart-cutting valve interface with 12x 40µL loops. A Q-TOF mass spectrometer is attached to the outlet of the 2D-PDA [9].

- Research Reagent Solutions:

- 1D Column: A column with the same chemistry as the original method (e.g., C18, 150 x 2.1 mm, 1.8 µm), downsized to 2 mm ID to adjust flow rates for better compatibility with the 2D system [9].

- 2D Column: An orthogonal column selected for maximum resolution of the target compounds (e.g., a different C18 ligand, phenyl, or pentafluorophenylpropyl (PFPP) column, 50-100 x 3.0 mm, sub-2µm or core-shell particles) [9] [14].

- Mobile Phases: 1D mobile phase replicates the original method. 2D mobile phase is MS-compatible (e.g., formic acid and acetonitrile) [9].

II. Procedure

- 1D Method Development: Recreate the original chromatographic conditions where the impurity was observed. Optimize the 1D gradient to achieve the best possible separation before the heart-cut, using a flow rate of 0.1-0.2 mL/min for a 2 mm ID column [9].

- 2D Method Development: Develop a fast, orthogonal, and MS-compatible gradient on the 2D column. The goal is to separate the impurity from the API and other closely eluting compounds. A flow rate of 0.5 mL/min for a 3 mm ID column is a typical starting point [9].

- Valve Programming: Program the MHC interface to perform time-based or peak-based cuts around the region of interest from the 1D separation. Each cut (typically 40 µL) is stored in a dedicated loop [9].

- Method Synchronization: Synchronize the timelines of the 1D and 2D methods. The 2D system analyzes the heart-cuts sequentially once the 1D run is complete. Program the MS to send the initial flow-through (containing non-volatile salts if present) to waste [9].

- Data Analysis: Correlate the 2D chromatograms with the 1D run. Use the orthogonal separation in the 2D to obtain a clean UV spectrum and high-quality MS spectrum of the isolated impurity for identification [9].

Protocol 2: Comprehensive RPLC×RPLC (LC×LC) for Peptide Mapping

This protocol details the setup for a comprehensive 2D-LC separation of a complex peptide digest using parallel gradients to enhance sensitivity, based on the work described by [12].

I. Goals and Setup

- Primary Goal: To achieve maximum peak capacity for the separation of a complex protein digest, enabling a higher number of peptide and protein identifications compared to 1D-LC [12].

- Instrument Configuration: An Agilent 1290 Infinity 2DLC system or equivalent, comprising two binary pumps, an autosampler, a thermostated column compartment, a 2DLC valve, and a diode-array detector. The system is coupled to a high-resolution Q-Exactive Plus mass spectrometer [12].

- Research Reagent Solutions:

- 1D Column: Agilent InfinityLab Poroshell 120 HPH-C18 (150 x 2.1 mm, 1.9 µm) [12].

- 2D Column: Agilent ZORBAX Eclipse Plus C18 (50 x 2.1 mm, 1.8 µm) [12].

- Modulation Strategy: Two Phenomenex SecurityGuard ULTRA C18 Cartridges (2 x 2.1 mm) for stationary-phase-assisted modulation (SPAM) [12].

- Mobile Phases: 1D: Water (A) and Acetonitrile (B), both with 20 mM ammonium formate at pH 10. 2D: Water (A) and Acetonitrile (B), both with 0.1% formic acid [12].

II. Procedure

- 1D Separation Conditions: Inject 2 µL of the digested peptide sample. Use a column temperature of 50°C and a flow rate of 0.16 mL/min. Employ a gradient from 2% to 38% B over 60 minutes [12].

- Modulation Setup: Implement SPAM using the trap cartridges. Set a modulation time of 10-30 seconds. The fast, parallel gradient in the second dimension focuses the transferred fractions on the trap cartridges before elution [12].

- 2D Separation Conditions (Parallel Gradient): Use a parallel gradient in the 2D, where the gradient slope is correlated to the 1D gradient throughout the analysis. This maximizes the usage of the 2D separation space without requiring extremely high flow rates. A 2D flow rate of 0.7 mL/min is used, which is directly compatible with the MS, eliminating the need for flow splitting and improving sensitivity [12].

- MS Data Acquisition: Operate the Q-Exactive Plus in data-dependent acquisition (DDA) mode. The high scan speed of the MS allows for multiple MS/MS events within the very narrow peaks produced by the fast 2D separation [12].

- Data Processing: Use specialized 2D-LC software for data visualization and processing. The identification of peptides and proteins is performed using standard database search algorithms against the appropriate proteome database [12].

Research Reagent Solutions

The following table lists key materials and their functions for setting up a 2D-LC experiment, as derived from the cited protocols.

Table 3: Essential Research Reagent Solutions for 2D-LC Method Development

| Item Category | Specific Examples | Function & Importance in 2D-LC |

|---|---|---|

| 1D Separation Column | Poroshell 120 HPH-C18 (150 x 2.1 mm, 1.9 µm) [12]; ZORBAX SB-CN [12] | Provides the first dimension of separation. Long and narrow columns are typical for high peak capacity. |

| 2D Separation Column | ZORBAX Eclipse Plus C18 (50 x 2.1 mm, 1.8 µm) [12]; Short columns with sub-2µm particles [6] | Provides the fast second dimension separation. Short columns are essential for achieving the required rapid analysis times in LC×LC. |

| Modulation Interface | Dual-loop valve [6]; Multiple heart-cutting valve with loop deck [9]; ASM (Active Solvent Modulation) kit [10] | The heart of the 2D-LC system; enables the automated transfer and temporary storage of fractions from the 1D to the 2D. |

| Solvent Modulator | Trap columns (e.g., SecurityGuard ULTRA Cartridges) [12]; In-line mixers (Jet Weaver) [8] | Manages mobile phase incompatibility by focusing analytes (trapping) or diluting the strong eluent from the 1D before it enters the 2D column. |

| Mobile Phase Additives | Ammonium formate (pH 10) [12]; Formic Acid [12]; Phosphate buffers [9] | Control retention and selectivity. High-pH in 1D and low-pH in 2D for RPLC×RPLC can enhance orthogonality. MS-compatible additives are preferred. |

In the separation of complex samples, one-dimensional liquid chromatography (1D-LC) often provides insufficient resolving power. Comprehensive two-dimensional liquid chromatography (LC×LC) addresses this limitation by combining two distinct separation mechanisms, with the overall peak capacity being the product of the peak capacities in each dimension when the separations are truly orthogonal [15]. Orthogonality, defined as the degree to which two separation mechanisms are independent of each other, is therefore the critical factor determining the success of a 2D-LC method [15]. When separations are orthogonal, sample components spread across the two-dimensional separation space based on different physicochemical properties, dramatically increasing the number of components that can be resolved in a single analysis [15] [16]. This application note details the theoretical principles, practical measurement approaches, and optimized protocols for achieving maximum orthogonality in 2D-LC separations, with a specific focus on pharmaceutical and environmental applications.

Theoretical Foundations and Metrics

Peak Capacity and Practical Performance

The theoretical maximum peak capacity in comprehensive 2D-LC is expressed as the product of the peak capacities in the first (1nc) and second (2nc) dimensions: nc,2D = 1nc × 2nc [17]. However, this theoretical maximum is never achieved in practice due to two primary factors: the inability to fully utilize the entire separation space (surface coverage) and the undersampling effect when transferring effluent from the first to the second dimension [17].

The effective peak capacity is calculated by applying correction factors for these practical limitations, as shown in the equations below:

Equation 1: ( n{c,2D}^{eff} = {}^{1}n{c} \times {}^{2}n{c} \times f{coverage} \times \frac{1}{\langle\beta\rangle} )

Equation 2: ( \langle\beta\rangle = 1 + 0.21(^{2}t_{s}/^{1}\sigma)^{2} )

Where ( f{coverage} ) represents the fractional surface coverage correction, ( \langle\beta\rangle ) is the undersampling correction factor, ( ^{2}t{s} ) is the second dimension cycle time, and ( ^{1}\sigma ) is the first dimension peak standard deviation [17]. These relationships highlight that even with high individual dimension peak capacities, poor orthogonality and excessive undersampling can severely compromise the overall separation power.

Quantifying Orthogonality

Several mathematical approaches have been developed to quantify orthogonality, including bin-counting methods, ecological home-range theory, fractal mathematics, and the Asterisk Equation metric [17]. The Asterisk Equation metric is particularly valuable as it is less sample-dependent and adequately considers peak spreading in both dimensions while being practically implementable through standard software tools [17].

Table 1: Orthogonality Metrics and Their Applications

| Metric | Principle | Advantages | Limitations |

|---|---|---|---|

| Bin-Counting | Divides 2D space into bins and counts occupied bins | Intuitive calculation | Sensitive to bin size selection |

| Asterisk Equation | Measures peak distribution across separation space | Less sample-dependent; accounts for peak spreading | Requires specialized software |

| Geometric Approach | Calculates practical peak capacity based on correlation | Directly relates to separation power | Requires retention data for standards |

Orthogonal Separation Mechanisms

Successful orthogonal separations are achieved when the two dimensions operate based on different physicochemical principles. Common separation mechanisms used in 2D-LC include reversed-phase (RPLC), hydrophilic interaction liquid chromatography (HILIC), size-exclusion chromatography (SEC), and ion exchange chromatography (IEX), each exploiting different molecular properties [15]. The degree of orthogonality between different mode combinations varies significantly, with SCX-RP, HILIC-RP, and RP-RP (with significantly different pH in both dimensions) demonstrating particularly useful orthogonality for peptide separation [16].

Practical Implementation and Method Development

Selecting Orthogonal Separation Modes

The selection of orthogonal separation modes requires careful consideration of the sample's physicochemical properties and the complementary nature of the separation mechanisms. While completely different mechanisms (e.g., HILIC × RPLC) offer high theoretical orthogonality, they often present significant mobile phase incompatibility challenges [15]. Recent work has demonstrated that RPLC × RPLC using significantly different pH in both dimensions can provide excellent orthogonality while avoiding solvent compatibility issues [18] [16].

Table 2: Orthogonal Mode Combinations and Their Applications

| Mode Combination | Separation Mechanisms | Orthogonality | Typical Applications |

|---|---|---|---|

| SCX × RPLC | Charge → Hydrophobicity | High | Peptides, pharmaceuticals |

| HILIC × RPLC | Polarity → Hydrophobicity | High | Metabolomics, natural products |

| RPLC × RPLC | Hydrophobicity (different pH) | Moderate to High | Complex industrial samples |

| SEC × RPLC | Size → Hydrophobicity | Moderate | Proteins, polymers |

Method Development Workflow

A systematic approach to 2D-LC method development significantly enhances the likelihood of achieving optimal orthogonality. The following diagram illustrates a comprehensive workflow for method development, incorporating both theoretical considerations and practical optimization steps:

Instrumentation and Modulation Strategies

Modern 2D-LC systems typically employ two-position switching valves with multiple loops for continuous fraction transfer between dimensions [15]. The most critical considerations in interface design include:

- Minimizing extra-column band broadening through reduced tubing volumes and optimized connections

- Managing mobile phase incompatibility through active solvent modulation or flow splitting

- Ensuring compatibility between flow rates in both dimensions, often using micro- or narrow-bore columns in the first dimension [15]

When mobile phase incompatibility cannot be avoided, active solvent modulation (ASM) has emerged as a powerful solution. ASM employs additional pumps and mixing tees to modify the composition of the first dimension effluent before it enters the second dimension column, preventing strong solvents from disrupting the second dimension separation [15].

Case Study: Pharmaceutical Analysis in Hospital Wastewater

Experimental Protocol

Objective: Develop and optimize an online LC×LC method for the identification of pharmaceutical residues in hospital wastewater.

Materials and Reagents:

- Water samples: Collected from hospital wastewater effluent

- Standards: Pharmaceutical compounds of various therapeutic classes

- Solvents: LC-MS grade water, acetonitrile, methanol

- Additives: Formic acid, ammonium formate

Instrumentation:

- 2D-LC system: Agilent 1290 Infinity II 2D-LC system or equivalent

- Columns: Various combinations tested (RPLC, HILIC)

- Detection: Diode array detector coupled to Q-TOF mass spectrometer

- Software: Python-based 2D combination selector (PCS) tool for method prediction

Procedure:

Sample Preparation:

- Solid-phase extraction (SPE) of wastewater samples

- Reconstitution in compatible mobile phase

- Filtration through 0.22 μm membrane

Initial Screening:

- Evaluate multiple column combinations using PCS tool

- Assess orthogonality using 12 different orthogonality metrics

- Predict peak capacities for each combination

Method Optimization:

- Optimize gradient profiles in both dimensions

- Adjust flow rates for compatibility (1D: low flow; 2D: high flow)

- Implement active solvent modulation to address mobile phase incompatibility

- Fine-tune modulation time to balance resolution and analysis time

Validation:

- Analyze spiked samples for recovery assessment

- Determine linearity, precision, and detection limits

- Apply to real hospital wastewater samples

Results and Discussion

The systematic screening approach identified three promising combinations for further optimization: RPLC × RPLC, HILIC × RPLC, and RPLC × HILIC. After optimization, the RPLC × RPLC method demonstrated the best 2D-peak shapes and highest effective peak capacity (1877), consistent with predictions from the PCS tool [19]. This method successfully identified 36 pharmaceuticals of various classes in real hospital wastewater, demonstrating the practical utility of orthogonality-optimized 2D-LC methods for complex environmental samples [19].

The following diagram illustrates the solvent modulation strategy that was critical to the success of the RPLC × RPLC method:

Research Reagent Solutions

Successful implementation of orthogonal 2D-LC methods requires careful selection of research reagents and materials. The following table details essential components and their functions:

Table 3: Essential Research Reagents and Materials for Orthogonal 2D-LC

| Category | Specific Examples | Function in 2D-LC |

|---|---|---|

| Stationary Phases | C18, Pentafluorophenyl (F5), PAH, HILIC, SCX | Provide complementary separation mechanisms for orthogonality |

| Mobile Phase Additives | Formic acid, ammonium formate, phosphate buffers | Modulate selectivity and ensure MS compatibility |

| Modulation Solutions | Weak solvents matching 2D starting conditions | Focus analytes at head of 2D column via ASM |

| Reference Standards | Pharmaceutical mixtures, peptide standards | System suitability testing and orthogonality measurement |

Achieving orthogonality is fundamental to maximizing peak capacity in comprehensive 2D-LC separations. While theoretical principles provide guidance, practical implementation requires systematic method development that considers both the degree of orthogonality between separation mechanisms and the technical aspects of coupling dimensions, particularly mobile phase compatibility. The case study presented demonstrates that through careful optimization, even seemingly similar mechanisms such as RPLC × RPLC can provide excellent orthogonality when operated under significantly different conditions. As 2D-LC continues to evolve, advances in predictive tools, stationary phase design, and modulation techniques will further enhance our ability to achieve orthogonal separations for increasingly complex samples in pharmaceutical, environmental, and biological analysis.

Two-dimensional liquid chromatography (2D-LC) has emerged as a powerful analytical technique to address complex separation challenges that overwhelm the capabilities of conventional one-dimensional liquid chromatography. The fundamental principle of 2D-LC involves subjecting a sample to two independent separation mechanisms, significantly enhancing overall resolving power. This technique has gained substantial traction in pharmaceutical and biopharmaceutical industries where analysts routinely encounter both difficult-to-resolve samples (containing structurally similar impurities, isomers, or degradation products) and complex mixtures (containing hundreds or even thousands of unique molecular entities) [20].

The expanding adoption of 2D-LC methodologies stems from significant advances in commercial instrumentation and column technologies that have transformed 2D-LC from a niche technique using "home-built" instruments to a robust, integrated solution suitable for regulated environments. Modern 2D-LC systems offer flexible operational modes, enhanced software control, and improved visualization of multidimensional data, making the technology more accessible and applicable to a wider range of analytical challenges [20]. This analysis examines the strengths, weaknesses, opportunities, and threats of 2D-LC technology to provide researchers and drug development professionals with a comprehensive framework for evaluating its implementation in method development.

Comprehensive SWOT Analysis of 2D-LC

The following table presents a structured SWOT analysis of two-dimensional liquid chromatography, summarizing key internal and external factors influencing its application and development.

| Strengths | Weaknesses |

|---|---|

| • Enhanced Peak Capacity & Resolution: Combines two orthogonal separation mechanisms, dramatically increasing peak capacity over 1D-LC for complex mixtures [20]. | • Technical Complexity: Method development requires optimization of two separate dimensions and their coupling, demanding significant expertise [20] [21]. |

| • Orthogonal Selectivity: Enables separation of critical pairs (e.g., impurities, isomers) that are unresolvable with a single mechanism through modes like achiral-chiral 2D-LC [20]. | • Interface & Compatibility Challenges: Mobile phase from the 1D can negatively impact the 2D separation (solvent strength mismatch); interfaces can be complex, especially when coupling to SFC [21]. |

| • Automated Online Sample Processing: Heart-cutting and related modes can automate tedious offline sample preparation (e.g., protein removal for ADC analysis), saving time and improving reproducibility [22]. | • Instrumentation Cost & Accessibility: Commercial 2D-LC systems represent a significant capital investment over 1D-LC, potentially limiting access [20]. |

| • Multiple Operational Modes: Offers flexibility with comprehensive (LCxLC), heart-cutting (LC-LC), and hybrid modes (mLC-LC, sLCxLC) to tailor the analysis to the problem [20]. | • Data Complexity: Generates large, multidimensional datasets that require specialized software for visualization, interpretation, and data analysis [20]. |

| Opportunities | Threats |

| :--- | :--- |

| • Biopharmaceutical Characterization: Tremendous potential for analyzing complex biomolecules like mAbs, ADCs, and oligonucleotides, where 1D-LC peak capacity is often insufficient [20] [22]. | • Limited Orthogonality for Neutral Compounds: RPLCxRPLC offers poor orthogonality, and RPLCxHILIC, while more orthogonal, remains limited for neutral species [21]. |

| • Hybrid Mode Development: Innovations like mLC-LC and sLCxLC offer new ways to balance analysis time, resolution, and sensitivity for specific regions of interest [20]. | • Competition from Alternative Techniques: Other multidimensional separation techniques (e.g., LC-SFC, SFCxSFC) may offer better solutions for specific application niches [21]. |

| • Hyphenation with Novel Separation Mechanisms: Coupling LC with techniques like Supercritical Fluid Chromatography (SFC) shows promise for extending the range of analyzable compounds, particularly neutrals [21]. | • Pace of Column Technology Development: The speed and performance of 2D-LC, especially in the second dimension, can be limited by the availability of stationary phases designed for ultrafast separations [20]. |

| • Advanced Column Technologies: New columns with sub-2-µm particles and superficially porous particles for various modes (SEC, RPLC) promise faster and more efficient 2D separations [20]. | • Standardization and Knowledge Gaps: As a relatively advanced technique, a lack of standardized methods and widespread expertise can hinder its adoption in some laboratories. |

Experimental Protocols and Applications

Protocol 1: Analysis of Free Drug in Antibody-Drug Conjugates (ADCs) using 2D-LC/Q-TOF

This protocol details a heart-cutting 2D-LC method coupled to Q-TOF mass spectrometry for identifying free cytotoxic drug content in ADC samples, a critical quality attribute (CQA) [22].

The following diagram illustrates the automated workflow for analyzing free drug in ADCs, integrating size-based separation with reversed-phase analysis and mass spectrometric detection.

Materials and Reagents

- ADC Sample: Desalted and dissolved in 100 mM ammonium acetate buffer (pH 7.0) at a concentration of 5 mg/mL [22].

- Standards: Free drug (e.g., DM1) and linker-drug (e.g., SMCC-DM1) standards for spiking and identification.

- Mobile Phase Components:

- Water and ACN: LC/MS grade.

Instrumentation and Parameters

Table 2: Liquid Chromatography Parameters for ADC Analysis

| Parameter | First Dimension (SEC) | Second Dimension (RP) |

|---|---|---|

| Column | AdvanceBio SEC 200 Å, 4.6 × 150 mm, 1.9 µm | Poroshell C18, 3.0 × 50 mm, 1.9 µm |

| Mobile Phase | 100 mM Ammonium Acetate + 40% ACN (Isocratic) | 0.1% Formic Acid in H₂O (A) / 0.1% FA in 95% ACN (B) (Gradient) |

| Flow Rate | 0.25 mL/min | 0.5 mL/min |

| Column Temperature | 25 °C | 40 °C |

| Injection Volume | 10 µL | Via heart-cut valve and loops |

| UV Detection | 252 nm | 252 nm |

| Heart-Cut Timing | 9.0 min (Time-based, capturing low MW species) | - |

| 2D Gradient | - | 38% B to 65% B in 5 min |

Mass Spectrometry Parameters (Q-TOF)

- Ionization: Agilent Jet Stream Electrospray Ionization (ESI), Positive polarity.

- Gas Temperatures: Drying Gas: 300 °C; Sheath Gas: 350 °C.

- Voltages: Capillary: 3,500 V; Fragmentor: 135 V.

- Mass Range: m/z 100 to 1,700 [22].

Method Development Notes

- SEC Mobile Phase Optimization: ACN concentration in the SEC mobile phase was optimized to mitigate hydrophobic interactions of the ADC and small molecule drugs with the stationary phase. A concentration of 40% ACN was found to provide the best peak shape for the free drug (DM1) while remaining within the column's tolerance limits [22].

- Automated Protein Removal: This online 2D-LC approach eliminates the need for manual, offline protein precipitation or solid-phase extraction, enhancing operational efficiency and reproducibility [22].

Protocol 2: Peak Purity Assessment using Selective Comprehensive 2D-LC (sLCxLC)

This protocol uses sLCxLC as an orthogonal technique to UV-vis or MS detection for demonstrating peak purity in method validation for small-molecule pharmaceuticals [20].

The following diagram outlines the process of using multiple, small-volume fraction transfers to retain first-dimension retention information for high-resolution peak purity analysis.

Key Advantages of sLCxLC for Peak Purity

- Retained Retention Information: Unlike single heart-cutting (LC-LC), transferring multiple fractions across the peak of interest preserves the first-dimension elution profile, allowing visualization of partially co-eluting impurities [20].

- Manageable Fraction Volumes: Dividing the target peak into several smaller fractions reduces the volume transferred to the second dimension in each cycle, minimizing potential negative effects (e.g., peak broadening) on the 2D separation compared to transferring one large fraction [20].

The Scientist's Toolkit: Essential Materials for 2D-LC

Table 3: Key Research Reagent Solutions and Materials

| Item | Function / Application | Example Specifications / Notes |

|---|---|---|

| SEC Columns (1D) | Separates by hydrodynamic volume; ideal for separating proteins/aggregates from small molecules in 1D (e.g., ADC analysis) [22]. | AdvanceBio SEC 200 Å, 4.6 × 150 mm, 1.9 µm; Mobile Phase: 100 mM Ammonium Acetate with organic modifier (e.g., 40% ACN). |

| RP Columns (2D) | Provides separation based on hydrophobicity; workhorse for 2D separation of small molecules and peptides [20] [22]. | Poroshell C18, 3.0 × 50 mm, 1.9 µm (short, narrow-bore columns with superficially porous particles for fast 2D analysis). |

| Chiral Columns | Enables resolution of enantiomers in one dimension; ultrafast chiral columns (< 3 µm particles) are key for 2D-LC [20]. | Used in achiral x chiral 2D-LC configurations for pharmaceutical impurity and enantiomeric excess analysis. |

| MS-Compatible Buffers | Volatile salts for mobile phases enable seamless hyphenation of 2D-LC with mass spectrometry [22]. | Ammonium Acetate, Ammonium Formate; preferred over non-volatile phosphate buffers. |

| Heart-Cutting Valve & Loops | Interface for capturing effluent from the 1D and injecting it into the 2D; essential for LC-LC and mLC-LC modes [20] [22]. | Biocompatible Multiple Heart-Cutting Valves with 40 µL loops; number of loops determines how many cuts can be stored and analyzed. |

Two-dimensional liquid chromatography represents a paradigm shift in separation science, offering unparalleled resolving power for the most challenging analytical problems in pharmaceutical and biopharmaceutical research. While the technique demands significant expertise and investment, its strengths in providing orthogonal selectivity and automating complex analyses, coupled with emerging opportunities in hybrid modes and column technologies, make it an indispensable tool for modern laboratories. As instrumentation and methodologies continue to mature, 2D-LC is poised to become a more standardized and accessible technique, ultimately accelerating drug development and ensuring product quality by providing insights that are simply unattainable through one-dimensional analysis.

Building Your 2D-LC Method: A Step-by-Step Guide to Column Selection and Real-World Applications

The analysis of complex samples, such as those encountered in biopharmaceuticals, foodomics, and environmental monitoring, presents a significant challenge for one-dimensional liquid chromatography (1D-LC) due to insufficient peak capacity. Comprehensive two-dimensional liquid chromatography (LC×LC) addresses this limitation by coupling two separate separation mechanisms, resulting in a multiplicative peak capacity that enables the resolution of hundreds or even thousands of components [23] [24]. However, the widespread adoption of LC×LC has been hampered by the complexity of method development, particularly the selection of orthogonal stationary phase combinations that maximize the separation power of the two-dimensional system [24].

Traditional column selection approaches rely heavily on empirical testing and chromatographer experience, which is both time-consuming and resource-intensive. The Hydrophobic Subtraction Model (HSM) has emerged as a powerful predictive tool to streamline this process by enabling in-silico screening of column selectivity based on physicochemical properties [25]. This application note details a systematic protocol for leveraging the HSM and selectivity databases to facilitate rational column selection for LC×LC method development, framed within the broader context of creating robust, orthogonal separation systems for complex sample analysis.

Theoretical Foundation of the Hydrophobic Subtraction Model

The Hydrophobic Subtraction Model, developed by Snyder and Dolan, provides a quantitative framework for characterizing reversed-phase LC column selectivity based on five specific interaction parameters [25] [26]. The model posits that retention of a solute under reversed-phase conditions is determined primarily by its hydrophobicity, with secondary contributions from other molecular interactions. The HSM equation is expressed as:

log(α) = log(kanalyte/kref) = η'H - σ'S* + β'A + α'B + κ'C

Where:

- H: Hydrophobicity of the analyte

- S*: Steric resistance of the stationary phase

- A: Hydrogen-bond acidity of the stationary phase

- B: Hydrogen-bond basicity of the stationary phase

- C: Ion-exchange capacity of the stationary phase (at pH 2.8)

The model uses a set of probe compounds with known interaction parameters to characterize the five interaction parameters (H, S*, A, B, C) for hundreds of commercially available stationary phases [25] [26]. This extensive database of column selectivity parameters forms the foundation for computational screening of column orthogonality in LC×LC systems.

Computational Screening Protocol for Column Selection

Data Preparation and Analyte Set Generation

The first step in systematic column selection involves defining the chemical space of analytes to be separated. When authentic standards are unavailable, virtual analyte sets can be generated computationally to represent the expected chemical diversity of the sample.

Table 1: Required Parameters for HSM-Based Column Selection

| Parameter | Description | Source |

|---|---|---|

| Column H, S*, A, B, C values | Physicochemical interaction parameters for stationary phases | Pre-characterized HSM database [25] |

| Analyte H, S*, A, B, C values | Physicochemical interaction parameters for target compounds | Experimental measurement or computational prediction |

| Virtual analyte set | Representative molecular structures covering expected chemical space | Combinatorial generation from known molecular fragments [26] |

| Chromatographic conditions | Mobile phase composition, temperature, gradient profile | Method requirements or standard operating conditions |

Protocol Steps:

- Define Analyte Chemical Space: Identify 20-50 representative compounds that span the chemical diversity of your sample, including variations in molecular weight, polarity, functional groups, and acid-base characteristics.

- Obtain HSM Parameters: For each representative compound, obtain or calculate the five HSM interaction parameters (H, S*, A, B, C). For novel compounds, these can be predicted using quantitative structure-retention relationship (QSRR) models.

- Generate Virtual Analyte Set (Optional): To enhance statistical significance, computationally combine physicochemical properties from known compounds to create a larger virtual analyte set (e.g., 1,000-10,000 compounds) [26].

- Select Column Database: Utilize the HSM database containing approximately 565 commercially available reversed-phase columns with pre-determined interaction parameters [25].

Orthogonality Assessment and Column Pair Ranking

The core of the computational screening involves predicting retention times for all analytes across all possible column combinations and assessing their orthogonality.

Figure 1: Computational screening workflow for systematic column selection in 2D-LC.

Protocol Steps:

- Calculate Retention Parameters: For each column pair combination (319,225 pairs for 565 columns), compute predicted retention times for all analytes in both dimensions using the HSM equation [25].

- Generate Virtual Chromatograms: Create simulated 2D chromatograms for each column combination using the predicted retention times [26].

- Quantify Orthogonality: Apply orthogonality metrics, such as the new geometric approach described by Mommers et al. (2019), to quantify the practical separation space utilization [27].

- Rank Column Pairs: Sort column combinations based on their ability to resolve the largest number of analytes, giving preference to pairs with:

- High orthogonality scores

- Even distribution of peaks across the separation space

- Minimal correlation between first and second dimension retention times

Interpretation of Computational Results

The computational screening typically reveals clear patterns in optimal column combinations. Research by Lindsey et al. (2019) analyzing 319,225 column pairs demonstrated distinct preferences:

Table 2: Optimal Column Characteristics Based on HSM Screening

| Dimension | Recommended Stationary Phase | Rationale | Performance Notes |

|---|---|---|---|

| First Dimension | C18 or phenyl columns | Provides robust hydrophobicity-based separation with well-understood retention mechanisms | Relatively weak preference observed; multiple options viable [25] |

| Second Dimension | Embedded polar groups (e.g., amide, ether) | Enhanced selectivity for specific polar interactions; complementary to first dimension | Strong preference observed; critical for overall separation power [25] [26] |

| Alternative Combinations | Ion-exchange, HILIC, or mixed-mode | Maximum orthogonality for specific analyte classes (e.g., biopharmaceuticals) | Particularly effective when coupled with RPLC in the other dimension [28] |

Experimental Validation Protocol

Method Translation and Optimization

Computational predictions require experimental validation to account for real-world factors not captured in the HSM, such as mobile phase compatibility and instrumental effects.

Protocol Steps:

- Select Top Candidates: Choose 3-5 top-ranked column pairs from the computational screening for experimental testing.

- Address Mobile Phase Compatibility: Ensure compatibility between dimensions, particularly when using different separation modes (e.g., RPLC/HILIC). Consider at-column dilution or active solvent modulation if necessary [27] [24].

- Optimize Operating Conditions:

- First Dimension: Use longer columns (e.g., 100-150 mm) with smaller particle sizes (1.7-2.7 μm) for higher peak capacity at lower flow rates (0.1-0.3 mL/min) [23].

- Second Dimension: Implement short, efficient columns (e.g., 20-50 mm) with small particles (1.7-2.7 μm) for rapid separations at higher flow rates (1-3 mL/min) [23].

- Establish Modulation Parameters: Set modulation time to ensure each first-dimension peak is sampled 3-4 times across its width [23].

Performance Assessment and Method Fine-tuning

Protocol Steps:

- Analyze Standard Mixtures: Inject test mixtures containing representative analytes to generate actual 2D chromatograms.

- Compare Experimental vs. Predicted Results: Assess correlation between predicted and observed retention times and orthogonality.

- Quantify System Performance: Calculate practical peak capacity, orthogonality metrics, and resolution of critical pairs.

- Fine-tune Operating Conditions: Adjust gradient profiles, temperature, and flow rates to optimize separation for the specific sample matrix.

Research Reagent Solutions and Materials

Table 3: Essential Materials for HSM-Guided 2D-LC Method Development

| Category | Specific Items | Function/Purpose | Examples/Notes |

|---|---|---|---|

| Stationary Phases | C18, phenyl, embedded polar (e.g., amide), HILIC, ion-exchange | Provide complementary separation mechanisms for orthogonal 2D separation | Select based on HSM screening results; prefer columns with characterized HSM parameters [25] |

| Mobile Phase Components | Acetonitrile, methanol, water, volatile buffers (ammonium formate/acetate), acidic modifiers (TFA, FA) | Create gradient elution conditions compatible with MS detection | Ensure compatibility between dimensions; consider pH and ionic strength effects [24] |

| Modulation Hardware | Two-position/10-port switching valves, sampling loops, active solvent modulation (ASM) interfaces | Transfer effluent from 1D to 2D system with minimal breakthrough and distortion | Loop volume should suit 1D flow rate and modulation period [27] |

| Reference Standards | Pharmacopeial standards, custom analyte mixtures, quality control samples | System suitability testing and method validation | Should represent chemical diversity of actual samples |

| Software Tools | HSM-based column selection tools, 2D-LC simulation software, orthogonality calculation algorithms | In-silico method development and prediction of separation performance | Freely available tools emerging (e.g., from Stoll group) [24] |

Applications in Pharmaceutical Analysis

The systematic column selection approach has demonstrated particular utility in challenging pharmaceutical applications:

Antibody-Drug Conjugates (ADCs) Characterization:

- First Dimension: Hydrophobic interaction chromatography (HIC) for separation based on drug loading

- Second Dimension: Reversed-phase chromatography with embedded polar groups for separation of drug species and impurities

- Detection: MS-compatible conditions enable comprehensive characterization [28]

Therapeutic Monoclonal Antibodies:

- First Dimension: Ion-exchange chromatography (IEX) for charge variant analysis

- Second Dimension: RPLC with C18 or phenyl phases for hydrophobic interaction profiling

- Applications: Purity assessment, degradation product monitoring, and comparability studies [28]

Complex Natural Product Mixtures:

- First Dimension: HILIC for polar compound separation

- Second Dimension: RPLC for hydrophobicity-based separation

- Results: Enhanced resolution of structurally similar compounds in traditional medicine extracts [27] [28]

Implementation Workflow and Future Perspectives

Figure 2: Complete implementation workflow for systematic column selection with future development directions.

The field of 2D-LC method development continues to evolve rapidly. Future directions include:

- Integration of Machine Learning: Advanced simulation tools informed by larger datasets will enhance prediction accuracy and reduce experimental validation requirements [24].

- Expanded Selectivity Databases: Incorporation of HSM parameters for non-reversed-phase separation modes (HILIC, ion-exchange, SEC) to enable comprehensive multi-modal method development [29].

- Automated Optimization Algorithms: Bayesian optimization and other chemometric approaches for automated method fine-tuning after initial column selection [27] [24].

- Open-Access Computational Tools: Freely available simulation tools are emerging to make HSM-guided column selection accessible to a wider range of laboratories [24].

Systematic column selection using the Hydrophobic Subtraction Model and selectivity databases represents a paradigm shift in 2D-LC method development, moving from empirical trial-and-error to rational, predictive approaches. The computational screening protocol detailed in this application note enables researchers to identify highly orthogonal column combinations with maximal separation power for specific analytical challenges. When coupled with appropriate experimental validation, this approach significantly reduces method development time while improving separation performance, particularly for complex samples in pharmaceutical research and development. As computational tools continue to advance and selectivity databases expand, this systematic approach promises to make comprehensive 2D-LC more accessible and routine across diverse application areas.

Comprehensive two-dimensional liquid chromatography (LC×LC) has emerged as a powerful analytical technique for separating complex mixtures encountered in pharmaceutical, biological, and environmental analyses. Its superior separation power stems from the combination of two independent separation mechanisms, a concept known as orthogonality [2]. When two separation modes with fundamentally different retention mechanisms are combined, the achievable peak capacity becomes the product of the peak capacities of each dimension, enabling the resolution of thousands of individual components in a single analysis [30] [2].

The most effective pairings are those that exploit different physicochemical properties of analytes. Reversed-phase liquid chromatography (RPLC), which separates compounds based on hydrophobicity, demonstrates high orthogonality with hydrophilic interaction liquid chromatography (HILIC), which separates based on compound polarity and hydrophilicity [31]. The integration of ion-exchange chromatography (IEX) and mixed-mode chromatography (MMC), which can simultaneously utilize multiple interaction mechanisms, further expands the possibilities for creating highly orthogonal 2D-LC systems [32] [33] [34].

This application note provides a structured overview of effective phase pairings, supported by experimental protocols and practical implementation guidelines for developing robust 2D-LC methods.

Effective Mode Pairings and Their Characteristics

The selection of separation modes for the two dimensions is paramount to achieving high orthogonality. The table below summarizes the most effective pairings and their key characteristics.

Table 1: Effective Pairings of Separation Modes in 2D-LC

| 1D Mode | 2D Mode | Orthogonality Basis | Key Applications | Critical Considerations |

|---|---|---|---|---|

| HILIC | RPLC | Hydrophilicity vs. Hydrophobicity [31] | Peptides, pharmaceuticals, natural products [35] | Solvent strength mismatch requires active modulation [2] |

| Mixed-Mode | RPLC | Multiple mechanisms (e.g., IEX, HILIC) vs. Hydrophobicity [32] | Ionic and neutral analytes, pharmaceuticals with counterions [34] | Mobile phase compatibility; often requires tandem columns in 1D [32] |

| IEX | RPLC | Ionic charge vs. Hydrophobicity [30] | Proteins, peptides, charged biomolecules [30] | High salt buffers in 1D require desalting before 2D |

| RPLC | HILIC | Hydrophobicity vs. Hydrophilicity [31] | Complex samples with wide polarity range [35] | Aqueous 1D effluent is a weak solvent in 2D HILIC |

The Gold Standard: HILIC × RPLC

The combination of HILIC in the first dimension and RPLC in the second is one of the most orthogonal and popular setups [35] [31]. The retention order in HILIC is roughly the reverse of that in RPLC, providing excellent orthogonality by separating analytes based on their polarity and hydrophilicity in the first dimension and their hydrophobicity in the second [31]. This pairing is particularly powerful for the analysis of peptides and pharmaceutical compounds [35].

A key challenge in this setup is the solvent strength mismatch: the highly organic effluent from the HILIC dimension (1D) is a very strong solvent for the RPLC dimension (2D), which can lead to peak deformation and poor retention in the second dimension [2]. Solutions to this problem include:

- Active Solvent Modulation (ASM): Diluting the 1D effluent with a weak solvent before its transfer to the 2D column [2].

- Using "Reversed HILIC" (revHILIC) in 1D: Applying a water-rich mobile phase on a polar stationary phase, which improves compatibility with the RPLC second dimension [35].

Diagram: HILIC x RPLC Workflow with Active Moderation

Leveraging Versatility: Mixed-Mode × RPLC

Mixed-mode phases, which are purposefully engineered to incorporate multiple separation mechanisms such as RPLC, IEX, and HILIC, provide a unique and powerful selectivity for the first dimension [36] [34]. When coupled with RPLC in the second dimension, they enable the comprehensive analysis of complex mixtures containing both ionic and hydrophobic compounds in a single run [32] [37].

Key Implementation Considerations:

- Stationary Phase: Mixed-mode phases can be a single column with multi-functional ligands (e.g., Acclaim Trinity series) or a tandem column set-up [32] [37].

- Mobile Phase Optimization: The balance between organic modifier and buffer concentration/pH can be tuned to emphasize different retention mechanisms (e.g., HILIC vs. IEX) [33] [34].

- Applications: This pairing is exceptionally suited for the simultaneous analysis of active pharmaceutical ingredients (APIs) and their counterions, as well as peptides and impurities with varying charge and hydrophobicity [36] [37].

Diagram: Mixed-mode x RPLC Separation Mechanism

Detailed Experimental Protocols

Protocol 1: HILIC × RPLC for Pharmaceutical Analysis

This protocol is adapted from applications separating complex mixtures of pharmaceuticals and peptides [35].

Research Reagent Solutions:

- Mobile Phase A1 (HILIC): 5 mM Ammonium Acetate in Water, pH 5.0

- Mobile Phase B1 (HILIC): Acetonitrile with 0.1% Formic Acid

- Mobile Phase A2 (RPLC): Water with 0.1% Formic Acid

- Mobile Phase B2 (RPLC): Acetonitrile with 0.1% Formic Acid

- Modulation Diluent: 20:80 Water/Acetonitrile (v/v)

Instrumental Setup:

- System: Comprehensive 2D-LC system with an automated two-loop modulator and active solvent modulation capability.

- 1D Column: BEH HILIC Column (150 mm × 1.0 mm, 1.7 μm).

- 2D Column: C18 Column (50 mm × 3.0 mm, 1.7 μm).

Chromatographic Conditions:

- 1D HILIC Gradient:

- Initial: 98% B1

- Gradient: 98% → 60% B1 over 30 min

- Flow Rate: 0.05 mL/min

- Temperature: 40°C

- Modulation:

- Modulation Period: 30 s

- ASM: 1D effluent diluted 3:1 with modulation diluent

- 2D RPLC Gradient:

- Initial: 5% B2

- Gradient: 5% → 95% B2 in 0.4 min (re-equilibration: 0.2 min)

- Flow Rate: 1.0 mL/min

- Temperature: 50°C

Method Notes:

- The use of volatile buffers (ammonium acetate, formic acid) ensures MS compatibility [31].

- The active solvent modulation step is critical to overcome the solvent strength mismatch, ensuring proper focusing and separation in the second dimension [2].

Protocol 2: Mixed-Mode (SAX-RP Tandem) × RPLC for Phenolic Acids

This protocol is based on a published study analyzing phenolic and polar compounds in wine and herbal medicine [32].

Research Reagent Solutions:

- Mobile Phase A1 (MM): 20 mM Ammonium Bicarbonate (pH 7.8)

- Mobile Phase B1 (MM): Methanol

- Mobile Phase A2 (RPLC): Water with 0.1% Formic Acid

- Mobile Phase B2 (RPLC): Acetonitrile

Instrumental Setup:

- System: Comprehensive 2D-LC system.

- 1D Column Setup: Tandem column (SAX + PFP, each 150 mm × 2.1 mm, 3 μm) to create a mixed-mode separation environment.

- 2D Column: C18 Column (30 mm × 3.0 mm, 1.8 μm).

Chromatographic Conditions:

- 1D Mixed-Mode Gradient:

- Initial: 100% A1

- Gradient: 0% → 40% B1 over 40 min

- Flow Rate: 0.1 mL/min

- Modulation:

- Modulation Period: 60 s (Two 60 μL loops)

- No active modulation required due to aqueous-rich 1D eluent.

- 2D RPLC Gradient:

- Initial: 5% B2

- Gradient: 5% → 80% B2 in 0.8 min (re-equilibration: 0.4 min)

- Flow Rate: 1.5 mL/min

Method Notes:

- The tandem 1D column setup provides a broader selectivity than single-mode columns, leading to higher orthogonality with the 2D RPLC separation [32].

- The aqueous-rich 1D effluent is directly compatible with the 2D RPLC system, simplifying the instrumental setup.

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions and Materials

| Category | Item | Typical Specification/Example | Function/Purpose |

|---|---|---|---|

| Columns | HILIC | BEH Amide, ZIC-cHILIC, Diol | Separation of polar compounds by hydrophilicity [31] |

| RPLC | C18, C8, PFP | Separation based on hydrophobicity [35] | |

| Mixed-Mode | Acclaim Trinity P1/P2, WCX-1, WAX-1 | Simultaneous separation of ionic, polar, and hydrophobic analytes [34] [37] | |

| IEX | SAX, SCX, WAX, WCX | Separation based on ionic charge [30] | |

| Buffers & Additives | Volatile Salts | Ammonium Acetate, Ammonium Formate (5-50 mM) | Provides ionic strength for HILIC/IEX; MS-compatible [31] |

| Volatile Acids | Formic Acid, Trifluoroacetic Acid (0.05-0.1%) | pH control and ion-pairing; promotes protonation in ESI-MS [33] | |

| Organic Solvents | Acetonitrile (ACN) | LC-MS Grade | Primary organic modifier for HILIC and RPLC [31] |

| Methanol | LC-MS Grade | Alternative organic modifier, weaker eluting strength than ACN | |

| Instrumentation | Modulator | 2-Position 8-/10-Port Valve with Dual Loops | Heart of the 2D-LC system; transfers fractions from 1D to 2D [2] |

The strategic combination of RPLC, HILIC, IEX, and Mixed-Mode phases provides a powerful framework for tackling the most challenging separation problems in complex sample analysis. The HILIC × RPLC pairing offers exceptional orthogonality for samples spanning a wide polarity range, while Mixed-Mode × RPLC leverages multiple retention mechanisms for unparalleled selectivity towards ionic and hydrophobic compounds. Success in 2D-LC relies not only on selecting orthogonal phases but also on carefully managing critical parameters such as solvent compatibility through techniques like active modulation and on employing volatile, MS-compatible buffers. The protocols and guidelines provided here serve as a robust foundation for researchers to develop and optimize advanced 2D-LC methods for pharmaceutical and biomolecular analysis.

Within pharmaceutical quality control (QC), demonstrating that an analytical method can accurately and reliably report the purity of a drug substance in the presence of its potential impurities is paramount. This capability, known as specificity, is a cornerstone of stability-indicating methods. Traditional one-dimensional liquid chromatography (1D-LC) coupled with diode array detection (DAD) or mass spectrometry (MS) often encounters challenges with complex samples, where co-eluting impurities can remain undetected due to spectral similarity or ion suppression effects [38]. Two-dimensional liquid chromatography (2D-LC) has emerged as a powerful solution, providing the separation power necessary to resolve these challenging mixtures and offer unambiguous peak purity assessment [39] [38]. Furthermore, the role of forced degradation studies is to intentionally stress a drug to generate these impurities, validating the method's specificity and providing insight into the molecule's intrinsic stability [40] [41]. This application note details the integration of 2D-LC within pharmaceutical QC workflows for peak purity and forced degradation analysis, providing validated protocols and illustrative case studies.

The Critical Role of Forced Degradation Studies

Forced degradation, or stress testing, involves exposing a drug substance or product to conditions more severe than accelerated storage to identify likely degradation products, elucidate degradation pathways, and establish the stability-indicating properties of analytical methods [40] [41]. A well-designed forced degradation study is foundational to developing a validated QC method.

Recommended Stress Conditions and Endpoints

A scientific rationale for stress endpoints has been established to ensure comprehensive coverage of pharmaceutically-relevant degradation pathways without applying overly drastic conditions. The recommended endpoint can be either a target of 5-20% total degradation for "reactive" drugs or the application of a specified amount of stress (e.g., a specific concentration of oxidant or duration of heating) even in the absence of degradation for "stable" drugs [41]. Abnormal degradation, typically considered as exceeding 20%, should be investigated [42].

Table 1: Standard Conditions for Forced Degradation Studies

| Stress Condition | Typical Parameters | Purpose | Key Considerations |

|---|---|---|---|