Strategies for Robust Chromatographic Methods: From Fundamental Principles to Regulatory Compliance

This comprehensive article addresses the critical need for robust chromatographic methods in pharmaceutical development and quality control.

Strategies for Robust Chromatographic Methods: From Fundamental Principles to Regulatory Compliance

Abstract

This comprehensive article addresses the critical need for robust chromatographic methods in pharmaceutical development and quality control. Covering foundational concepts of method robustness, advanced methodological approaches including in-silico modeling and controlled flow reversal, systematic troubleshooting protocols, and validation strategies compliant with FDA/EPA standards, it provides researchers and drug development professionals with practical frameworks to safeguard method performance against parameter variations and operational uncertainties. The content integrates recent advances in chromatographic science to deliver actionable insights for developing reliable, trouble-free analytical methods that ensure data integrity and regulatory compliance.

Understanding Chromatographic Robustness: Fundamental Principles and Surface Interaction Dynamics

In the context of chromatographic methods, robustness is defined as the capacity of an analytical procedure to remain unaffected by small, deliberate variations in method parameters listed in the documentation [1]. It provides an indication of the method's reliability and consistency during normal use. Robustness is distinct from ruggedness, which refers to the degree of reproducibility of test results obtained under a variety of normal conditions such as different laboratories, analysts, instruments, and days [1]. A simple rule of thumb distinguishes them: if a parameter is written into the method (e.g., 30°C, 1.0 mL/min), it is a robustness issue. If it is not specified in the method (e.g., which analyst runs the method or on which specific instrument), it is a ruggedness issue [1].

Core Parameters Affecting Chromatographic Robustness

The robustness of a liquid chromatography (LC) method is typically evaluated by intentionally varying key method parameters within a small but realistic range [1] [2]. The table below summarizes the core parameters commonly investigated and their typical variation ranges.

Table 1: Key Parameters for Robustness Evaluation in HPLC

| Parameter Category | Specific Parameter | Example Variations | Impact on Method Performance |

|---|---|---|---|

| Mobile Phase | pH [1] [2] | ±0.1 - 0.2 units [2] | Affects analyte ionization, retention time, and selectivity |

| Buffer Concentration [1] [2] | ±5-10% [2] | Influences retention time and peak shape | |

| Organic Solvent Composition [1] | ±2-3% absolute [1] | Directly impacts retention factor (k) and resolution (Rs) | |

| Chromatographic Hardware | Column Temperature [1] [2] | ±5°C [2] | Affects column efficiency, retention, and selectivity |

| Flow Rate [1] [2] | ±0.1 mL/min [2] | Alters retention time, pressure, and can impact resolution | |

| Detection Wavelength [1] | ±2-3 nm [1] | Affects sensitivity and signal-to-noise ratio | |

| Column Characteristics | Column Lot/Brand [1] | Different batches/suppliers | Can cause significant shifts in selectivity and efficiency |

| Gradient Profile | Gradient Time/Slope [1] | ±1-2% relative | Impacts the elution profile and resolution of all analytes |

Experimental Protocols for Assessing Robustness

A systematic approach to robustness testing is crucial for generating meaningful data. The following protocol outlines a standard methodology.

Preliminary Steps and Factor Selection

- Identify Critical Parameters: Based on method development knowledge, select the parameters to be varied. These typically include the most influential factors from Table 1 [1] [3].

- Define Ranges of Variation: Establish realistic ranges for each parameter that represent expected minor fluctuations in a routine laboratory environment (e.g., flow rate of 1.0 mL/min ± 0.1 mL/min) [2].

- Set Acceptance Criteria: Before the experiment, define the acceptable limits for key performance metrics such as resolution (Rs), tailing factor (Tf), retention time (tR), and plate number (N). A common criterion is that all critical peak pairs must maintain Rs > 2.0 throughout the variations [4].

Experimental Designs: From Univariate to Multivariate

While the univariate approach (changing one factor at a time) is intuitive, multivariate experimental designs are more efficient and can reveal interactions between variables [1].

- Screening Designs: These are highly efficient for identifying which factors have a significant impact on robustness [1].

- Plackett-Burman Designs: Ideal for screening a large number of factors (e.g., 5-11) with a minimal number of experimental runs (e.g., 12 runs for up to 11 factors) [1]. They are used when you primarily need to know which factors are important.

- Full Factorial Designs: In a full factorial design, all possible combinations of factors at their high and low levels are measured. For

kfactors, this requires2^kruns (e.g., 4 factors require 16 runs) [1]. This design can estimate all main effects and interaction effects but becomes impractical for many factors. - Fractional Factorial Designs: A carefully chosen subset (fraction) of the full factorial combinations is used. This is a practical compromise that allows for the evaluation of multiple factors with fewer runs, though some interactions may be "confounded" or aliased [1].

The following diagram illustrates the decision-making process for selecting an appropriate experimental design for a robustness study.

Data Analysis and Interpretation

After executing the experimental design, analyze the data to determine the method's robustness.

- Calculate Performance Metrics: For each experimental run, calculate the critical performance metrics (Resolution, Tailing, Retention Time, etc.) [4].

- Statistical Evaluation: Use statistical tools like Analysis of Variance (ANOVA) to determine which parameter variations have a statistically significant effect on the results [3].

- Establish System Suitability Tests: The results of the robustness study should be used to define appropriate system suitability test (SST) limits that will ensure the validity of the system throughout its use [1] [4]. For instance, if robustness testing shows resolution drops below 2.0 when the flow rate is too high, the SST can include a minimum resolution requirement of 2.0 to catch this failure mode.

Key Performance Metrics for System Suitability

System suitability testing serves as a quality control check to ensure the chromatographic system is performing adequately at the time of the test. The following metrics are fundamental [4].

Table 2: Key System Suitability Performance Metrics and Recommendations

| Metric | Definition & Calculation | Recommended Minimum | Role in Robustness |

|---|---|---|---|

| Retention Factor (k) | ( k = (tR - t0) / t0 ) ( tR ): analyte retention time; ( t_0 ): column dead-time | k > 2 for the first peak of interest [4] | Ensures peaks are sufficiently retained away from the solvent front, reducing susceptibility to minor variations. |

| Resolution (Rs) | ( Rs = [2(t{R2} - t{R1})] / (w1 + w2) ) ( t{R1}, t{R2} ): retention times; ( w1, w_2 ): peak widths | Rs > 2.0 between critical pairs [4] | A higher Rs value provides a "safety margin" against peak coalescence due to small changes in conditions. |

| Tailing Factor (Tf) | ( Tf = w{0.05} / (2f) ) ( w_{0.05} ): peak width at 5% height; ( f ): front half-width | Tf ≤ 2.0 [4] | Tailing peaks reduce resolution and are more sensitive to changes in column condition and mobile phase. |

| Theoretical Plates (N) | ( N = 16 (t_R / w)^2 ) ( w ): peak width at base | As specified based on column performance (e.g., >10,000 for a 150mm column) [4] | A measure of column efficiency. A drop in 'N' can indicate column degradation or other issues affecting robustness. |

Troubleshooting Guides and FAQs

Frequently Asked Questions on Method Robustness

Q1: Why is my method sensitive to very small changes in mobile phase pH, even though the robustness study said it was acceptable? A1: Your method may be operating near the pKa of the analyte. When the pH is close to the pKa, the ionization state of the compound is highly sensitive to minor pH shifts, causing significant retention time changes. During method development, it is best to select a mobile phase pH at least 1-2 units away from the analyte's pKa for more robust performance [2].

Q2: How can I improve the robustness of a method that fails system suitability due to low resolution when transferred to another lab? A2: First, use an experimental design (e.g., a fractional factorial) to identify the most critical factors affecting resolution. Then, re-optimize the method to increase the resolution between the critical peak pair to well above the minimum requirement (e.g., Rs > 2.5 instead of 2.0). This provides a larger safety margin. Finally, ensure the method documentation includes strict system suitability tests and clear instructions for preparing critical reagents like buffers [1] [4].

Q3: What is the most efficient way to test robustness for a method with many (e.g., 7) critical parameters? A3: A full factorial design for 7 factors would require 128 experiments, which is impractical. Use a Plackett-Burman design or a fractional factorial design, which can efficiently screen all 7 factors for their effect on robustness in as few as 12 to 16 experimental runs. This approach helps you identify the 1 or 2 most critical parameters that require tighter control [1].

Q4: How do I handle a situation where a new column lot causes a failure in resolution? A4: Column lot-to-lot variability is a common ruggedness issue. To safeguard your method, during validation, test columns from at least two different lots. If a new lot causes failure, consider implementing a column equivalency test protocol in your method. This may involve making minor adjustments to the gradient or temperature to restore the original separation, followed by validation to demonstrate equivalent performance [1].

Troubleshooting Common Robustness Issues

Table 3: Troubleshooting Guide for Robustness Failures

| Observed Problem | Potential Causes | Corrective & Preventive Actions |

|---|---|---|

| Drifting Retention Times | - Unstable mobile phase pH- Fluctuating column temperature- Inadequate mobile phase equilibration | - Prepare fresh buffer and mobile phase daily- Use a column oven with precise temperature control- Allow sufficient equilibration time between runs |

| Loss of Resolution | - Changes in mobile phase organic % or pH- Column degradation (loss of efficiency)- Interaction with active sites on aged column | - Tighten tolerances for mobile phase preparation- Implement guard column and monitor system suitability- Consider using a more selective column chemistry |

| Peak Tailing | - Secondary interactions with active silanols on column- Incompatibility between sample solvent and mobile phase- Column voiding | - Use a mobile phase with a competing base (e.g., triethylamine)- Ensure sample solvent is close to mobile phase in strength- Replace the column if damaged |

The Scientist's Toolkit: Essential Reagents and Materials

Table 4: Key Research Reagent Solutions for Robust Methods

| Item | Function & Role in Robustness |

|---|---|

| High-Purity Buffering Salts | Provides consistent pH control, which is critical for the reproducibility of retention times for ionizable compounds. |

| HPLC-Grade Solvents & Water | Minimizes UV-absorbing impurities that cause baseline noise and drift, leading to more accurate and precise integration. |

| Characterized Column Heater | Maintains a stable column temperature, a key parameter that affects retention, efficiency, and resolution. |

| Certified Reference Standards | Allows for accurate calculation of performance metrics like retention factor, resolution, and tailing during method development and validation. |

| Guard Column of the Same Phase | Protects the expensive analytical column from contaminants, extending its lifetime and maintaining consistent performance. |

Theoretical Background and Troubleshooting FAQs

What is surface heterogeneity and why does it matter in my chromatographic methods?

Surface heterogeneity refers to the presence of different types of adsorption sites on the stationary phase surface, each with distinct binding energies for analytes [5]. This is a critical consideration because it directly impacts the reproducibility of retention times and can cause a rapid loss of efficiency, especially when sample sizes are increased [5]. In method development, failing to account for heterogeneity can lead to poor robustness, as the presence of even a small number of high-energy sites can significantly skew results at different concentration levels.

How does the Bi-Langmuir model differ from the classic Langmuir model?

The classic Langmuir adsorption model assumes a perfectly homogeneous surface with all adsorption sites being energetically equivalent [6] [7]. In contrast, the Bi-Langmuir model explicitly accounts for surface heterogeneity by proposing two distinct types of independent adsorption sites. Each site type has its own characteristic Langmuir parameters, representing a surface with a bimodal energy distribution [5]. This makes the model more complex but far more accurate for describing real-world chromatographic surfaces.

I observe a significant decrease in retention time as I increase sample concentration. Is this normal?

Yes, this is a classic symptom of a heterogeneous stationary phase. The phenomenon occurs because at low concentrations, analyte molecules preferentially occupy the high-energy binding sites, leading to longer retention times. As the concentration increases, these high-energy sites become saturated, and a greater proportion of molecules interact with lower-energy sites, resulting in an overall decrease in retention time [5]. The magnitude of this effect varies with the degree of surface heterogeneity.

What are the practical limits for linear chromatographic behavior on a heterogeneous surface?

The upper concentration limit for linear behavior is highly dependent on the specific stationary phase. The table below summarizes experimental data for two different C18 adsorbents, illustrating how surface heterogeneity drastically affects the linear range [5].

Table 1: Impact of Stationary Phase Heterogeneity on Linear Chromatographic Range

| Commercial Adsorbent | Best-Fit Isotherm Model | Adsorption Energy Distribution | Upper Limit for Linear Behavior (Caffeine) | Observed Retention Time Decrease |

|---|---|---|---|---|

| Non-end-capped Resolve-C18 | Tetra-Langmuir | Quadrimodal | 1 x 10⁻⁴ g/L | 40% decrease (from 10⁻⁵ to 10 g/L) |

| End-capped XTerra-C18 | Bi-Langmuir | Bimodal | 0.01 g/L | 10% decrease (from 10⁻⁵ to 10 g/L) |

Key Experimental Protocols

Protocol: Determination of Adsorption Isotherms via Frontal Analysis

Frontal analysis is a highly accurate method for acquiring adsorption isotherm data.

- Preparation: Continuously pump a solution of the analyte in the mobile phase at a known, constant concentration, ( C ), through the chromatographic column.

- Saturation: The detector response will show a breakthrough curve as the stationary phase becomes saturated and the concentration at the column outlet reaches ( C ).

- Mass Balance Calculation: The amount of analyte adsorbed, ( q ), at concentration ( C ) is calculated from the breakthrough time, the void time of the column, the flow rate, and the concentration of the solution.

- Data Acquisition: Repeat this procedure for a series of increasing analyte concentrations to build a full adsorption isotherm, ( q = f(C) ) [5].

Protocol: Measuring the Dependence of Retention Time on Sample Size

This is a straightforward experiment to probe for surface heterogeneity.

- Sample Preparation: Prepare a series of solutions of your analyte with a constant injection volume but varying concentrations (e.g., from 1 x 10⁻⁵ g/L to 10 g/L) [5].

- Chromatographic Analysis: Inject each solution onto the column under isocratic elution conditions.

- Data Analysis: Precisely measure the retention time for each injection.

- Interpretation: Plot the retention time against the sample concentration (or mass). A significant decrease in retention time with increasing concentration is a clear indicator of surface heterogeneity and a non-linear adsorption isotherm [5].

Research Reagent Solutions

Table 2: Essential Materials for Investigating Adsorption and Surface Heterogeneity

| Item | Function / Explanation |

|---|---|

| Heterogeneous Stationary Phases (e.g., Non-end-capped C18) | Used to study the pronounced effects of high-energy sites. Resolve-C18 is an example that exhibited quadrimodal energy distribution [5]. |

| Homogeneous-Model Stationary Phases (e.g., End-capped C18) | Used as a comparative control. End-capping reduces the number of high-energy silanol sites, leading to a more homogeneous surface [5]. |

| Model Analytes (e.g., Caffeine) | A well-characterized compound useful for probing surface energy distributions, as used in foundational studies [5]. |

| In Silico Modeling Software | Computational tools used to predict retention times, model isotherms, and accelerate method development by reducing laboratory experiments [8] [9]. |

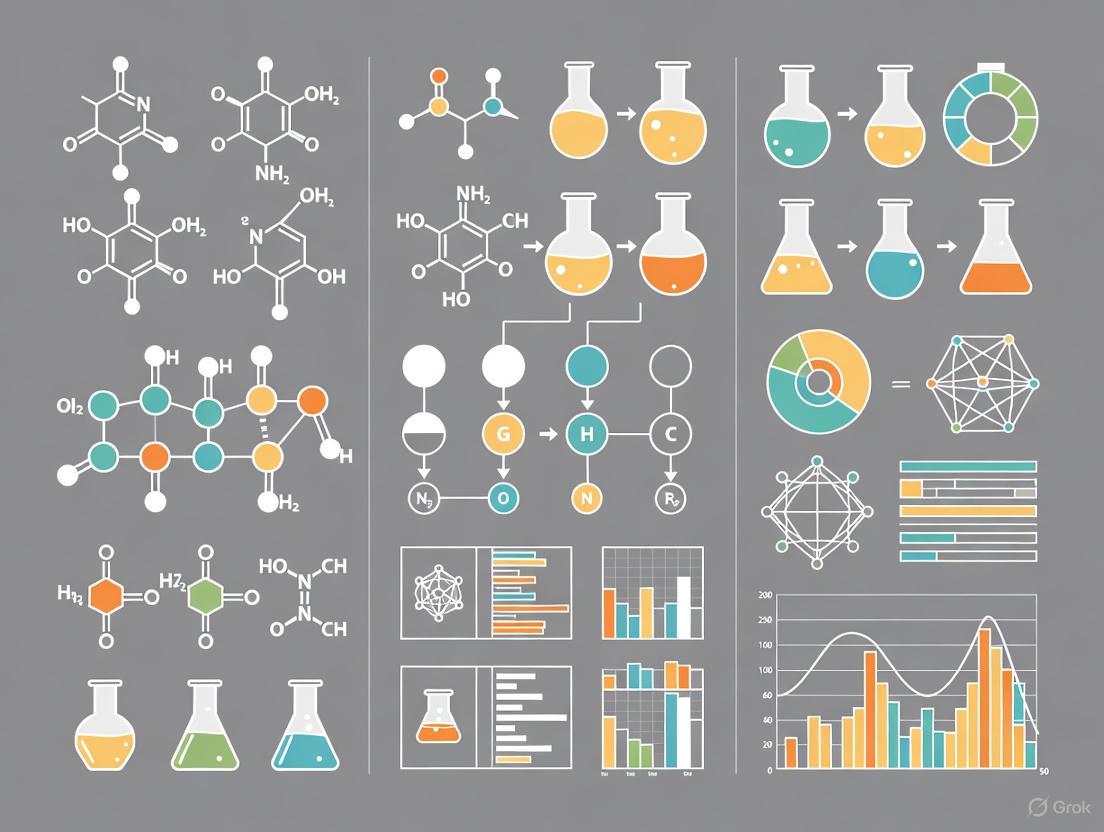

Workflow and Conceptual Diagrams

Surface Heterogeneity Impact

Isotherm Modeling Workflow

Adsorption Energy Distribution (AED) Analysis for Stationary Phase Characterization

In liquid chromatography, the surface of stationary phases is not uniform. Adsorption heterogeneity arises from the distribution of adsorption sites with varying interaction energies, which significantly affects retention behavior and separation performance [10]. Traditional adsorption isotherms often fail to accurately describe these complex interactions because they operate on the assumption of uniform adsorption energies across the chromatographic surface [10].

The Adsorption Energy Distribution (AED) framework provides a powerful alternative by modeling adsorption as a sum of independent homogeneous sites, each characterized by a specific energy level [10]. This approach offers a more realistic representation of heterogeneous adsorption systems, moving beyond the limitations of simplistic models like the Langmuir isotherm, which cannot account for the energy diversity present on real chromatographic surfaces [11]. The AED method was first introduced to the chromatography field by Brett Stanley and Georges Guiochon in the early 1990s, utilizing mathematical inversion techniques to extract energy distributions from experimental isotherms [11].

Fundamental Principles of AED

Understanding Surface Heterogeneity

Chromatographic stationary phases exhibit surface heterogeneity, meaning they contain a variety of adsorption sites with different interaction strengths. This heterogeneity can be particularly pronounced in certain phases, such as protein-based chiral stationary phases, which consist of a large number of weak, non-selective sites alongside only a few strong, chiral-discriminating ones [11]. This distribution of site energies directly impacts chromatographic performance, often causing peak tailing and distorted elution profiles, especially under overloaded conditions common in preparative chromatography [10] [11].

The AED approach reveals that what might appear as a simple retention mechanism often masks a complex distribution of interactions. For example, in chiral separations, the true chiral contribution is frequently obscured by dominant non-selective retention, emphasizing the need to separate and quantify both mechanisms through advanced modeling techniques [11].

Mathematical Foundation

The AED framework employs sophisticated mathematical approaches to deconvolute the overall adsorption behavior into its underlying energy components. Rather than assuming one or two distinct types of adsorption sites—as traditional models such as Langmuir or bi-Langmuir do—AED reveals the full spectrum of binding strengths, providing a detailed energetic "fingerprint" of the chromatographic surface [11].

The calculation of AED requires raw adsorption isotherm data, which can be obtained through various experimental methods. Recent advancements have extended AED calculations to work with the raw tangential slope data provided by the perturbation peak method, expanding the experimental approaches available for AED characterization [12].

Experimental Protocols for AED Analysis

Workflow for AED Determination

A structured four-step workflow has been developed to identify the correct physical adsorption model using AED analysis [11]:

- Visual Classification: The shape of the adsorption isotherm (linear, convex, or concave) is visually examined for initial assessment.

- Scatchard Analysis: This exploratory step examines interaction patterns—linear Scatchard plots suggest Langmuir behavior, while curved plots indicate heterogeneity.

- AED Calculation: The energy distribution is computed, distinguishing unimodal from bimodal distributions to narrow down candidate models.

- Model Fitting and Statistical Testing: Parameter estimation and Fisher analysis are performed to confirm the best-fit model.

This systematic approach ensures that the selected adsorption model accurately represents the underlying physicochemical processes governing the separation.

Data Collection Considerations

When planning AED experiments, several practical factors must be carefully considered to ensure reliable results:

- Concentration Range: The adsorption isotherm must be measured across an appropriate range of concentrations to adequately capture the system's behavior [10].

- Kernel Selection: A suitable mathematical kernel function must be selected for the AED calculation [10].

- Computational Parameters: The number of iterations and grid points in the AED analysis must be optimized for accuracy and efficiency [10].

- Temperature Control: Adsorption behavior is often exothermic, with adsorbate-adsorbate interaction strength typically decreasing with increasing temperature [13].

The following diagram illustrates the complete experimental workflow for AED analysis, from initial data collection to final model validation:

AED in Practice: Troubleshooting Guides and FAQs

Frequently Asked Questions

Q1: What analytical challenges can AED help resolve? AED is particularly valuable for diagnosing and addressing peak tailing and asymmetric elution profiles that result from heterogeneous adsorption. By quantifying the distribution of adsorption energies, AED provides mechanistic insights that help explain why traditional peak-shape corrections may be ineffective for certain stationary phase-analyte combinations [10] [11].

Q2: How does AED differentiate between thermodynamic and kinetic peak tailing? Peak tailing can originate from either thermodynamic or kinetic sources. In thermodynamic heterogeneity, tailing occurs when strong binding sites become saturated, while in kinetic heterogeneity, tailing arises when some adsorption sites have slower exchange rates. A simple test can distinguish these: if tailing decreases at lower flow rates, the origin is kinetic; if tailing decreases at lower sample concentrations, the cause is thermodynamic [11].

Q3: Can AED be applied to chiral separations? Yes, AED has proven particularly valuable in chiral separations. Research has revealed that chiral stationary phases, especially protein-based phases, are not uniform but consist of numerous weak, non-selective sites with only a few strong, chiral-discriminating sites. This heterogeneity explains why enantioselectivity can diminish at higher concentrations as the selective sites become saturated [11].

Q4: How does AED complement robustness testing? AED strengthens robustness testing by identifying the fundamental adsorption properties most likely to affect method performance when parameters fluctuate. For instance, AED can reveal how surface heterogeneity changes with pH, explaining why basic solutes may exhibit tailing at low pH but not at high pH [11]. This understanding helps focus robustness studies on the most critical method parameters.

Troubleshooting Common AED Challenges

Problem: Inconsistent AED results across replicate experiments Solution: Verify the stability of your chromatographic system, including precise temperature control, as adsorption processes are often temperature-dependent and exothermic [13]. Ensure consistent mobile phase preparation and degassing, as minor variations can affect adsorption equilibria.

Problem: AED indicates heterogeneity but traditional models appear adequate Solution: Consider whether you're operating in linear or nonlinear conditions. Under linear (analytical) conditions, peak broadening is primarily kinetic, while under nonlinear (preparative) conditions, broadening is governed by thermodynamics [11]. AED provides the greatest value when working near or in nonlinear conditions.

Problem: Difficulty interpreting multimodal energy distributions Solution: Reference case studies with similar distributions. For example, research on alkaline-stable C18 columns showed a strongly bimodal AED distribution at low pH that transformed to a more uniform distribution at high pH for basic solutes like metoprolol [11]. Such examples provide context for interpretation.

Connection to Method Robustness

Robustness Testing Fundamentals

Method robustness is formally defined as "a measure of the capacity of an analytical procedure to remain unaffected by small but deliberate variations in procedural parameters" [1]. Unlike ruggedness (recently termed "intermediate precision"), which addresses external factors like different laboratories or analysts, robustness focuses on internal method parameters specified in the documentation [1].

Robustness studies in liquid chromatography typically investigate the impact of variations in:

- Mobile phase composition (organic percentage, buffer concentration, pH)

- Flow rate and temperature

- Detection wavelength

- Column characteristics (different lots, aging) [1]

Integrating AED with Robustness Assessment

AED analysis significantly enhances robustness assessment by identifying the fundamental adsorption characteristics that underlie a method's sensitivity to parameter changes. The quantitative data provided by AED helps establish meaningful system suitability tests and method operable design regions.

Table: AED Parameters Relevant to Robustness Assessment

| AED Parameter | Impact on Robustness | Related Method Variables |

|---|---|---|

| Energy Distribution Width | Wider distributions increase sensitivity to mobile phase changes | Organic solvent %, pH, temperature |

| Presence of High-Energy Sites | Increases risk of tailing with injection volume changes | Injection volume, sample solvent |

| Bimodal vs. Unimodal Distribution | Bimodal distributions may show distinct behavior with pH changes | Mobile phase pH, buffer type |

| Temperature Dependence of Sites | Affects retention time stability | Column temperature control |

Experimental Design for Robustness Studies

Proper experimental design is crucial for effective robustness testing. Rather than the traditional univariate approach (changing one variable at a time), modern robustness studies employ multivariate screening designs that efficiently identify critical factors [1]. Common approaches include:

- Full Factorial Designs: All possible combinations of factors at two levels (high/low). Suitable for up to 5 factors [1].

- Fractional Factorial Designs: A carefully chosen subset of factor combinations that reduces experimental runs while maintaining information quality [1].

- Plackett-Burman Designs: Economical designs in multiples of four, ideal when only main effects are of interest [1].

A case study on warfarin analysis demonstrated the effectiveness of fractional factorial design for robustness testing, examining factors including aqueous content, acetic acid concentration, flow rate, and wavelength [14]. The study found aqueous content had a significant effect on capacity factor and analysis time, illustrating how robustness studies identify critical parameters [14].

Research Reagent Solutions

Table: Essential Materials for AED Characterization

| Material/Reagent | Function in AED Analysis | Application Notes |

|---|---|---|

| Stationary Phase Test Columns | Provides surface for adsorption studies | Characterize multiple lots for consistency [1] |

| Probe Solute Mixture | Measures adsorption isotherms | Select solutes with diverse interaction capabilities [15] |

| Mobile Phase Components | Control elution strength | Vary composition systematically for isotherms [10] |

| Buffer Systems | Control pH and ionic strength | Include in robustness testing [1] [14] |

| Reference Standards | Quantify retention and selectivity | Use for Tanaka or Abraham characterization [15] |

Advanced Applications and Case Studies

Case Study: Chiral Stationary Phase Characterization

Research on racemic methyl-mandelate separation on a tris-(3,5-dimethylphenyl) carbamoyl cellulose chiral stationary phase revealed an unusual adsorption behavior [13]. The overloaded band of the more retained enantiomer exhibited a peculiar shape indicating a Type V adsorption isotherm, while the less retained enantiomer showed normal Type I behavior [13]. Through AED analysis combined with Scatchard plots, researchers determined that the less retained enantiomer was best described by a Tóth adsorption isotherm, while the more retained enantiomer required a bi-Moreau model accounting for non-ideal adsorbate-adsorbate interactions [13].

Case Study: Alkaline-Stable C18 Columns

AED analysis has demonstrated its practical value in explaining the pH-dependent behavior of stationary phases. In a study of alkaline-stable C18 columns, AED revealed how surface heterogeneity changes with pH, explaining why basic solutes like metoprolol tail at low pH but not at high pH [11]. The AED showed a strongly bimodal distribution at low pH that transformed to a more uniform distribution at high pH, enabling appropriate model selection and quantification of site differences that standard isotherm fits could not resolve [11].

Cross-Technique Validation with Biosensors

Interestingly, research has revealed strong connections between AED in chromatography and interaction analysis using biosensors [11]. Techniques like surface plasmon resonance (SPR) and quartz crystal microbalance (QCM) provide real-time binding data that complement chromatographic studies. The development of the Adaptive Interaction Distribution Algorithm (AIDA) for biosensor data analysis is conceptually similar to AED in chromatography but focuses on kinetic rather than thermodynamic distributions [11]. This cross-technique approach provides more comprehensive characterization of molecular interactions.

Adsorption Energy Distribution analysis represents a significant advancement in stationary phase characterization, moving beyond the limitations of traditional homogeneous surface models. By providing a detailed "fingerprint" of the energy landscape on chromatographic surfaces, AED offers profound insights into the fundamental mechanisms governing retention and separation behavior. When integrated with systematic robustness testing and proper experimental design, AED becomes a powerful tool for developing reliable, predictable chromatographic methods capable of withstanding normal operational variations in pharmaceutical and analytical laboratories. The continued refinement of AED methodologies and their integration with complementary techniques like biosensor analysis promises to further enhance our ability to design robust separation methods based on fundamental understanding rather than empirical observation.

Troubleshooting Guides

Guide to Resolving Broad Peaks

| Symptom | Possible Cause | Recommended Solution |

|---|---|---|

| Broad Peaks | System not equilibrated [16] | Equilibrate the column with 10 volumes of mobile phase [16]. |

| Injection solvent too strong [16] | Ensure injection solvent is the same or weaker strength than the mobile phase [16]. | |

| Injection volume or mass too high [16] | Reduce injection volume or sample concentration to avoid column overload [16]. | |

| Extra column volume too high [16] | Reduce diameter and length of connecting tubing and flow cell volume [16]. | |

| Temperature fluctuations [16] | Use a thermostatically controlled column oven [16]. | |

| Old or contaminated column [16] | Wash or replace the column; do not use columns degraded by ion-pair reagents [16]. |

Guide to Resolving Tailing Peaks

| Symptom | Possible Cause | Recommended Solution |

|---|---|---|

| Tailing Peaks | Old guard cartridge [16] | Replace the guard cartridge [16]. |

| Injection solvent too strong [16] | Ensure injection solvent is the same or weaker strength than the mobile phase [16]. | |

| Injection volume or mass too high [16] | Reduce injection volume or sample concentration to avoid column overload [16]. | |

| Old or voided column [16] | Replace the column; do not use outside the recommended pH range [16]. | |

| Blocked column or active sites [17] | Reverse-phase flush column or replace it; consider a different stationary phase [17]. |

Guide to Resolving Varying Retention Times

| Symptom | Possible Cause | Recommended Solution |

|---|---|---|

| Varying Retention Times | System not equilibrated [16] | Equilibrate the column with 10 volumes of mobile phase [16]. |

| Temperature fluctuations [16] [17] | Use a thermostatically controlled column oven [16] [17]. | |

| Leak in the system [16] | Check for and replace any leaking tubing or fittings [16]. | |

| Pump not mixing solvents properly [16] | Ensure proportioning valve is working; for isocratic methods, blend solvents manually [16]. | |

| Mobile phase composition changed [17] | Prepare fresh mobile phase and ensure it is degassed [17]. |

Fundamental Principles: Kinetic vs Thermodynamic Control

The concepts of kinetic and thermodynamic control explain product distribution in competing reactions, which is fundamental to understanding peak profiles and identities in chromatography [18].

Characteristic Comparison Table

| Property | Kinetic Product | Thermodynamic Product |

|---|---|---|

| Reaction Conditions | Low temperature (≤ 0°C) [18] | High temperature (≥ 40°C) [18] |

| Formation Rate | Fast [18] | Slow [18] |

| Product Stability | Less stable (higher energy) [18] | More stable (lower energy) [18] |

| Double Bond | Terminal (less substituted) [18] | Internal (more substituted) [18] |

| Reaction Type | Irreversible [18] | Reversible [18] |

| Primary Factor | Lower activation energy [18] | Greater product stability [18] |

Frequently Asked Questions (FAQs)

FAQ 1: To what degree can a chromatographic procedure be modified and still be in compliance with USP <621>?

Chromatography General Chapter <621> contains a list of allowed adjustments to chromatographic systems. However, the user must verify the suitability of the method under the new conditions by assessing the relevant analytical performance characteristics potentially affected by the change [19].

FAQ 2: My method shows extra peaks. What are the most common causes?

Extra peaks can arise from a degraded sample, contaminated solvents or column, "ghost peaks" in gradient methods, or carry-over from previous injections [16] [17]. Prepare a fresh sample and fresh mobile phase of HPLC grade. Flush the system with a strong organic solvent and use/replace the guard column [16] [17].

FAQ 3: How much deviation is allowed from a relative retention time prescribed in a monograph?

According to USP <621>, deviations of relative retention time values should not exceed the reliability estimates determined statistically from replicate assays. Note that relative retention times may be provided in monographs for informational purposes only, in which case no acceptance criteria are applied [19].

FAQ 4: How can I manipulate reaction conditions to favor the thermodynamic product?

To ensure the greatest possible yield of thermodynamic products, the reaction should be carried out at a temperature of 40°C or greater with longer reaction times. This provides sufficient energy to overcome the higher activation energy barrier and allows the system to reach the more stable equilibrium state [18].

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function |

|---|---|

| Guard Cartridge | Protects the analytical column from particulate matter and chemically irreversibly adsorbed compounds from the sample [16]. |

| HPLC-Grade Solvents | Ensure purity and prevent contamination, baseline noise, and ghost peaks [16] [17]. |

| Column Oven | Provides thermostatic control to prevent retention time drift and peak broadening due to temperature fluctuations [16] [17]. |

| Mobile Phase Buffers | Control pH to ensure consistent ionization of analytes, preventing peak tailing and varying retention times [16] [17]. |

| Strong Organic Solvent | Used for flushing the system and column to remove contamination and resolve issues like carry-over and extra peaks [17]. |

The Impact of Surface Heterogeneity on Chiral Recognition and Separation Performance

FAQs: Surface Heterogeneity and Chiral Separation

1. What is surface heterogeneity in chiral separation, and why is it a problem? Surface heterogeneity refers to the atomic-scale variations and irregularities on the surface of a chiral stationary phase. These variations create adsorption sites with different binding energies for enantiomers. While some heterogeneity can provide selective binding pockets, excessive or uncontrolled heterogeneity often leads to reduced enantioselectivity due to inconsistent molecular interactions. This is a significant problem because it can cause broadening of chromatographic peaks, poor resolution between enantiomers, and low reproducibility in separation performance, ultimately compromising the robustness of analytical methods and purification processes [20].

2. How can I tell if my chiral separation problems are caused by surface heterogeneity? Several experimental observations can indicate issues related to surface heterogeneity:

- Irreproducible retention times for the same enantiomer across multiple runs

- Variable enantioselectivity (α value) between different batches of the same chiral stationary phase

- Asymmetric or tailing peaks in your chromatograms, suggesting multiple, non-uniform adsorption mechanisms

- Inconsistent performance when scaling methods from analytical to preparative scale [20]

3. What new materials show promise for more robust chiral surfaces? Recent research has identified medium-entropy ceramics (MECs) as promising materials for chiral recognition. For example, (CrMoTa)Si2 with a C40 hexagonal crystal structure demonstrates exceptional thermal stability and consistent chiral recognition capability. Unlike traditional metal surfaces that can lose chirality within 30 minutes under operating conditions, MECs maintain structural integrity due to higher coordination numbers and stronger chemical bonds, preventing the atomic ejection and diffusion that lead to surface heterogeneity [20].

4. How does the Analytical Quality by Design (AQbD) approach address robustness? The AQbD methodology systematically builds robustness into chromatographic methods by:

- Identifying Critical Method Parameters (CMPs) through risk assessment

- Analyzing their effects on Critical Method Attributes (CMAs) using Design of Experiments

- Defining a Design Space where method robustness is confirmed

- Applying Monte Carlo simulations to propagate error and ensure defined quality levels are met despite parameter variations [21]

Troubleshooting Guides

Problem: Declining Enantioselectivity Over Time

Symptoms: Gradual decrease in separation factor (α) and resolution (Rs) with repeated use of the chiral stationary phase.

Root Cause: Surface evolution and atomic roughness on chiral surfaces, particularly problematic with high-Miller-index metal surfaces where kink atoms have low coordination numbers and high surface energy [20].

Solutions:

- Switch to more stable chiral materials: Implement medium-entropy ceramics like (CrMoTa)Si2 which have higher adatom formation energy (1.13 eV vs. ~0.9 eV for high-index metals), making structural evolution more difficult [20].

- Optimize operating conditions: Reduce temperature and pressure extremes that accelerate surface degradation.

- Implement regular column regeneration protocols: Use prescribed cleaning procedures to maintain surface integrity.

Problem: Irreproducible Separation Performance

Symptoms: Inconsistent retention times and variable enantiomeric resolution between different batches or columns.

Root Cause: Inconsistent surface heterogeneity due to variations in manufacturing processes or material composition.

Solutions:

- Adopt robust optimization methodologies: Utilize alternating optimization approaches that separate nominal optimization from robustification steps [22].

- Implement comprehensive characterization: Use techniques like Transmission Electron Microscopy (TEM) and Circular Dichroism (CD) spectra to verify chiral nature and surface uniformity before use [20].

- Apply quality control measures: Establish strict specifications for chiral stationary phase procurement, including performance verification tests.

Problem: Poor Peak Shape in Chiral Separations

Symptoms: Tailing, fronting, or broad peaks that reduce resolution and quantification accuracy.

Root Cause: Heterogeneous adsorption energy distribution across the chiral surface, where enantiomers experience multiple different interaction energies rather than a uniform binding environment [20].

Solutions:

- Material selection: Choose chiral stationary phases with well-defined, uniform surface chemistry.

- Mobile phase optimization: Adjust pH, ionic strength, and organic modifier content to minimize secondary interactions.

- Temperature control: Maintain consistent column temperature to ensure reproducible kinetics.

Experimental Data and Performance Metrics

Table 1: Performance Comparison of Chiral Surfaces for Serine Separation

| Material | Enantiomeric Excess (e.e.) | Adsorption Ratio (L/D) | Thermal Stability | Structural Evolution Barrier |

|---|---|---|---|---|

| Medium-Entropy Ceramic (CrMoTa)Si2 | 42% | 1.58 | High (adatom formation: 1.13 eV) | 1.34 eV (atomic diffusion) |

| High-Miller-Index Cu Surfaces | Not specified | Not specified | Low (loses chirality in 30 min) | 0.67 eV (atomic diffusion) |

| Natural Quartz | 1.0-1.8% | Not specified | Moderate | Not specified |

| Calcite Crystal | Up to 10% | Not specified | Moderate | Not specified |

Table 2: Key Experimental Parameters for Chiral Surface Evaluation

| Parameter | Measurement Technique | Target Values | Significance |

|---|---|---|---|

| Enantioselectivity | Quartz Crystal Microbalance (QCM) | Adsorption ratio >1.5 (L/D) | Quantifies chiral recognition capability |

| Surface Chirality | Circular Dichroism (CD) spectra | Distinct CD signals | Confirms chiral nature of surface |

| Crystal Structure | Grazing Incidence X-ray Diffraction (GIXRD) | C40 hexagonal structure | Verifies proper phase formation |

| Elemental Distribution | Energy Dispersive X-ray Spectroscopy (EDS) | Uniform Cr/Mo/Ta/Si distribution | Confirms homogeneous composition |

| Thermal Stability | Adatom Formation Energy Calculation | >1.0 eV | Predicts operational lifetime |

Experimental Protocols

Protocol 1: Evaluating Chiral Recognition Using QCM

Purpose: To quantitatively measure the enantioselective adsorption capability of chiral surfaces.

Materials and Equipment:

- Quartz Crystal Microbalance (QCM) system

- Chiral stationary phase (e.g., MEC film-coated electrode)

- D- and L-enantiomer solutions (e.g., serine, 0-60 mM concentration range)

- Buffer solutions for maintaining pH

Procedure:

- Deposit chiral film (e.g., 92.8 nm thick MEC) on QCM electrode using non-reactive magnetron sputtering.

- Pre-treat the surface with appropriate conditioning protocol.

- Introduce D-enantiomer solution at known concentration (e.g., 10 mM) and monitor frequency shift.

- Thoroughly rinse system with pure solvent until baseline frequency stabilizes.

- Introduce L-enantiomer solution at identical concentration and monitor frequency shift.

- Repeat across concentration range (0-60 mM) to establish adsorption isotherms.

- Calculate adsorption ratio as: α = Adsorptionamount-L-serine / Adsorptionamount-D-serine [20]

Expected Outcome: A robust chiral surface should show consistent preferential adsorption for one enantiomer (e.g., α = 1.58 for L-serine over D-serine on MEC).

Protocol 2: Surface Stability Assessment

Purpose: To evaluate the thermal and operational stability of chiral surfaces.

Materials and Equipment:

- Chiral stationary phase material

- High-temperature incubation system

- Surface analysis tools (TEM, X-ray diffraction)

- Computational modeling software for DFT calculations

Procedure:

- Subject chiral material to accelerated aging conditions (elevated temperatures).

- Periodically sample material and evaluate chiral performance using QCM or chromatographic testing.

- Characterize surface morphology changes using TEM.

- Calculate adatom formation energy using Density-Functional Theory (DFT).

- Determine energy barriers for atomic diffusion using climbing image nudged elastic band (CI-NEB) method [20].

Interpretation: Materials with higher adatom formation energy (>1.0 eV) and diffusion barriers (>1.3 eV) demonstrate superior stability for long-term applications.

Workflow Diagrams

Research Reagent Solutions

Table 3: Essential Materials for Robust Chiral Separation Studies

| Material/Reagent | Function | Application Notes |

|---|---|---|

| Medium-Entropy Ceramics (MECs) | Chiral stationary phase with enhanced thermal stability | (CrMoTa)Si2 with C40 structure; superior to metal surfaces [20] |

| Chiral Model Compounds | Evaluation of enantioselectivity performance | D- and L-serine (0-60 mM) as prototype molecules [20] |

| Ammonium Acetate Buffer | Mobile phase component for pH control | 15 mM concentration at pH 5.5 used in RP-HPLC optimization [21] |

| Acetonitrile (HPLC Grade) | Organic mobile phase modifier | 34% content in mobile phase for optimal separation [21] |

| Xterra RP18 Column | Analytical chromatography column | 150 × 4.6 mm, 3.5 µm particle size for impurity separation [21] |

Advanced Method Development: In-Silico Modeling, Flow Reversal, and Green Chemistry Approaches

In-silico chromatography utilizes computational models and simulations to accelerate and refine the development of liquid chromatography (LC) methods. This approach is revolutionizing a field traditionally reliant on time-consuming and material-intensive trial-and-error experiments. By leveraging techniques like machine learning (ML) and physicochemical modeling, researchers can now predict chromatographic behavior, optimize separation parameters, and troubleshoot issues digitally before stepping into the laboratory.

This paradigm shift aligns with the broader industry movement toward digitalization and Quality by Design (QbD). The core promise of in-silico methods is to enhance the robustness of analytical procedures by providing a deeper, model-based understanding of the method's operational space and its critical parameters. This technical support center provides practical guidance for integrating these computational tools into your research workflow.

Core Computational Methodologies

Key Machine Learning Approaches

In-silico chromatography employs several data-driven strategies to predict retention behavior. The table below summarizes the primary computational methodologies in use.

Table 1: Key Computational Methodologies for In-Silico Chromatography

| Methodology | Description | Primary Application |

|---|---|---|

| Quantitative Structure–Property Relationships (QSPR) | Uses molecular descriptors (MDs) derived from a molecule's structure (e.g., from a SMILES string) to predict its physicochemical properties [23] [24]. | Predicting solute-dependent parameters for retention models. |

| Linear Solvation Energy Relationships (LSER) | A partially physics-based model that relates retention to a set of solute parameters describing molecular interactions (e.g., hydrogen bonding, polarity) [23]. | Modeling the complex interactions between a solute, the stationary phase, and the mobile phase. |

| Linear Solvent Strength (LSS) Theory | A simple, widely used theory describing how a solute's retention factor ((k)) changes with the mobile phase composition ((\phi)) [23]. | Predicting how changes in the organic modifier concentration will affect elution times. |

| Quantitative Structure-Retention Relationships (QSRR) | A subtype of QSPR that relates molecular descriptors directly to retention behavior (e.g., retention factor, time) [23]. | Directly predicting a molecule's retention time based on its structure. |

| In-Silico Fragmentation | Uses tools like MetFrag or CFM-ID to predict tandem mass spectrometry (MS²) spectra from a chemical structure [25]. | Structural annotation of unknowns in non-targeted screening. |

A powerful emerging approach combines these methods. For instance, one can use QSPR to predict the LSER solute parameters, which are then fed into the LSS theory to forecast retention factors across different mobile phase compositions, all without running a single experiment [23] [24].

The In-Silico Prediction Workflow

The following diagram illustrates the integrated workflow for predicting retention time using molecular structure and chromatographic conditions.

Computational Troubleshooting & FAQs

This section addresses specific challenges researchers face when developing and using in-silico chromatography models.

FAQ 1: My in-silico model's predictions are inaccurate for my specific analyte class. How can I improve it?

- Cause: Generic models are often trained on broad chemical spaces and may lack specificity for particular compound classes (e.g., certain heteroatoms) [25].

- Solution: Implement transfer learning or fine-tuning.

- Experimental Protocol: Collect a small, high-quality dataset of retention times for your specific analyte class under your standard chromatographic conditions.

- Use this targeted dataset to retrain or fine-tune the final layers of a pre-existing, general-purpose ML model. This allows the model to adapt its general knowledge to your specific domain, significantly improving prediction accuracy without requiring a massive amount of new data [25].

FAQ 2: The retention time predictions are good, but my peaks still show tailing or fronting in the lab. What's the digital solution?

- Cause: Peak shape issues are often related to secondary interactions with the stationary phase or column overload, which are not directly captured by retention time prediction models.

- Solution: Use in-silico modeling to guide parameter optimization.

- Protocol:

- Use your in-silico tool to identify the initial mobile phase composition that provides adequate resolution.

- Digitally probe the effect of adding a buffer (e.g., 10-20 mM ammonium formate or acetate) to the mobile phase. The model can help predict how this changes the ionization state and interaction of analytes, mitigating silanol interactions that cause tailing [26].

- Model the effect of injection volume and sample solvent strength. In-silico simulations can help identify conditions that prevent peak fronting or splitting due to solvent mismatch [26].

- Protocol:

FAQ 3: The structural annotations from my in-silico MS/MS library search have low confidence. How can I prioritize candidates?

- Cause: Relying solely on spectral matching can be ambiguous, especially for isomers or novel compounds not in libraries [25].

- Solution: Implement a multi-dimensional prioritization strategy.

- Protocol:

- Obtain a list of candidate structures from in-silico fragmentation tools (e.g., MetFrag, CFM-ID) [25].

- For each candidate, use a QSRR model to predict its retention time (RT) and an ion mobility model to predict its collision cross section (CCS) value.

- Prioritize the candidate structures based on a combined score that weighs the similarity of the predicted RT and CCS values against the experimentally measured values, in addition to the spectral match score [25]. This orthogonal verification greatly increases annotation confidence.

- Protocol:

FAQ 4: My model works well for isocratic methods but fails with complex gradients. Why?

- Cause: Simple models like the basic LSS theory may not accurately capture retention behavior across the entire range of a gradient, especially at high organic modifier concentrations where the relationship can become nonlinear [23].

- Solution: Employ a mechanistic transport model.

- Protocol: Couple your data-driven predictions with first-principle-based models like the equilibrium dispersive model or the general rate model [23]. These models simulate the entire chromatographic process. Your predicted retention parameters (e.g., from QSPR-LSER) serve as inputs for the adsorption isotherms within these more complex simulations, enabling accurate in-silico replication and optimization of full gradient elution programs.

Experimental Validation & Robustness

A Framework for Validating In-Silico Methods

Before replacing conventional experiments, in-silico predictions must be rigorously validated. The following workflow outlines a robust validation process integrated within the analytical procedure lifecycle.

Establishing Acceptance Criteria

Validation requires clear, quantitative metrics. The table below suggests key parameters to assess when validating an in-silico developed method.

Table 2: Key Validation Parameters for an In-Silico Developed LC Method

| Performance Characteristic | Typical Acceptance Criteria | Rationale |

|---|---|---|

| Peak Resolution (Rs) | Rs ≥ 1.5 between all critical pairs | Ensures baseline separation for accurate quantification [27]. |

| Retention Time Accuracy | ≤ ±5% deviation from prediction | Validates the core accuracy of the in-silico retention model. |

| Peak Asymmetry (As) | 0.8 - 1.8 | Indicates healthy column-solute interactions and proper method conditions [26]. |

| Precision (%RSD) | %RSD of RT ≤ 1-2% (Intra-day) | Demonstrates the method's robustness and repeatability. |

| Automated Integration Rate | > 90% of peaks integrated without manual intervention | A key metric for the robustness of the method and its associated AI/ML integration rules [27]. |

Regulatory & Practical Considerations (FAQs)

FAQ 5: What is the regulatory stance on using AI/ML for analytical methods in drug development?

Regulatory guidance is evolving. The FDA and EMA have published draft frameworks, but they are not fully aligned [27].

- FDA Draft Guidance: Encourages early engagement with the agency and proposes a "credibility assessment framework" to evaluate the context of use and reliability of AI models supporting regulatory decisions [27].

- EMA Reflection Paper & Draft Annex 22: Discusses the use of AI in the medicinal product lifecycle but is more cautious, potentially discouraging the use of generative AI and probabilistic models for Good Manufacturing Practice (GMP)-critical applications without full justification [27].

- Key Action: Implement strong AI governance within your Pharmaceutical Quality System (PQS) and be prepared to provide extensive documentation on model training, testing data, and performance metrics [27].

FAQ 6: What are the fundamental limitations of in-silico chromatography?

While powerful, these tools are not a panacea.

- Computational Demand: Simulating complex molecular dynamics, like protein folding, can be computationally intensive and time-consuming, sometimes leading to inadequate sampling [28].

- Dependence on Quality Data: The predictive power of ML models is directly tied to the volume and quality of the training data. "No amount of AI input can resurrect poor chromatography" [27].

- Inaccurate Scoring Functions: Methods like molecular docking rely on scoring functions that can sometimes be inaccurate, though post-processing techniques are being developed to mitigate this [28].

- Incomplete Chemical Space: Spectral and structural databases, while growing, still cover only a fraction of known chemicals, leaving many compounds in the "unknown chemical space" unannotated [25].

The Scientist's Toolkit

Table 3: Essential Research Reagents & Computational Tools for In-Silico Chromatography

| Item / Solution | Function / Explanation | Example/Note |

|---|---|---|

| LC-MS Grade Solvents & Additives | High-purity solvents are critical for generating consistent experimental data for model training and validation, especially in mass spectrometry [26]. | Prevents contamination that leads to peak shape issues and noisy baselines. |

| Buffers (Ammonium Formate/Acetate) | Buffers block active silanol sites on the stationary phase, improving peak shape for ionizable compounds [26]. | Use a buffer matched to your acid (e.g., Formic Acid/Ammonium Formate). |

| In-Line Filters & Guard Columns | Protects the analytical column from particulates, extending its life and maintaining consistent backpressure—a key for robust, long-term method performance [26] [29]. | A 0.5-µm porosity frit for columns with particles >2 µm. |

| Molecular Descriptor Software | Calculates numerical representations of molecular structures from SMILES strings, which are the inputs for QSPR/QSRR models [23] [24]. | Tools like RDKit or PaDEL-Descriptor. |

| In-Silico Fragmentation Tools | Predicts theoretical MS² spectra from a candidate structure for comparison with experimental data in non-targeted screening [25]. | MetFrag, CFM-ID, GrAFF-MS. |

| Spectral & Structural Databases | Provides the reference data for structural annotation via spectral matching or for training machine learning models [25]. | MassBank, NIST, PubChem, ZINC. |

Controlled Flow Reversal Techniques for Enhanced Separation Efficiency

This technical support resource is designed for researchers and scientists in drug development who are implementing Controlled Flow Reversal Techniques to improve the robustness of their chromatographic methods. The content is framed within a broader thesis on enhancing method resilience against operational and parameter variations. Below you will find detailed troubleshooting guides, frequently asked questions, and essential experimental protocols to help you achieve consistent, high-efficiency separations.

This guide synthesizes advanced research on using flow reversal as an additional control degree of freedom to safeguard product purity against uncertainties in process conditions and model parameters [30].

Frequently Asked Questions (FAQs)

Q1: What is the fundamental principle behind using controlled flow reversal to improve separation robustness?

Controlled flow reversal introduces a periodic switching of the flow direction as an additional time-dependent control parameter. This manipulation of the concentration profile helps maintain separation performance even in the presence of perturbations, such as altered buffer salt concentrations or other process variations. By periodically reversing the flow, the technique mitigates the effects of non-ideal behavior and parameter uncertainties, leading to more robust and reliable separation processes [30].

Q2: During robustness testing, which method parameters are most critical to investigate for a flow reversal method?

Robustness tests should deliberately vary internal method parameters written into your procedure. For a liquid chromatography method involving flow reversal, the most critical parameters typically include [1]:

- Mobile phase composition: Number, type, and proportion of organic solvents; buffer composition and concentration; pH.

- System operational parameters: Flow rate (during forward and reverse cycles), temperature, column oven temperature, and detection wavelength.

- Column parameters: Different column lots, stationary phase characteristics.

- Flow reversal specific parameters: Cycle timing, duration of forward and reverse phases, slope of flow rate changes.

Q3: What are the primary indicators that my flow reversal process requires troubleshooting or optimization?

Key indicators of performance issues include:

- Changes in chromatogram peak shape, symmetry, or retention time consistency [31].

- Drifting pressure profiles or unexpected pressure increases across the column.

- Reduced resolution between critical analyte pairs.

- Inconsistent purity levels of collected fractions despite unchanged method parameters.

- Evidence of increased back-mixing or band broadening in the separation profile [30].

Q4: What experimental design is most efficient for testing the robustness of a new flow reversal method?

For robustness testing with multiple factors, screening designs are highly efficient. While a univariate approach (changing one variable at a time) is traditional, multivariate approaches allow you to study multiple variables simultaneously and detect important interactions [1].

- Full Factorial Designs: Measure all possible combinations of factors but become impractical with many factors (2^k runs for k factors).

- Fractional Factorial Designs: A carefully chosen subset of factor combinations that is more efficient for investigating larger numbers of factors.

- Plackett-Burman Designs: Extremely economical designs in multiples of four, ideal for screening many factors to identify which are most significant [1].

Q5: How can I use chromatogram analysis for early detection of performance issues in my flow reversal process?

Implement a robust chromatogram shape analysis routine. This involves:

- Pre-processing: Aligning chromatograms from different runs and patching together different chromatogram phases.

- Multivariate Analysis: Using techniques like Principal Component Analysis (PCA) on standardized chromatograms to identify batches affected by process changes.

- Predictive Modeling: Correlating changes in chromatogram peaks with critical quality attributes like impurity clearance for early problem detection [31].

Troubleshooting Guides

Problem 1: Deteriorating Peak Resolution

Symptoms: Decreasing resolution between target compounds, peak tailing, or broadening over successive cycles.

| Possible Cause | Investigation Steps | Corrective Actions |

|---|---|---|

| Suboptimal flow reversal timing | Analyze peak shapes at the column outlet during reversal cycles. Measure resolution metrics. | Adjust flow reversal cycle frequency. Optimize switch times based on actual peak migration, not just theoretical values. |

| Insufficient column equilibration | Check system pressure stability after flow direction changes. | Increase equilibration time after flow reversal. Implement a graduated return to forward flow conditions. |

| Column degradation | Compare performance with a new column of the same type. Test with standard mixtures. | Implement guard columns. Establish column cleaning protocols. Monitor column performance metrics systematically. |

Problem 2: System Pressure Fluctuations

Symptoms: Irregular pressure spikes or gradual pressure increase during flow reversal cycles.

| Possible Cause | Investigation Steps | Corrective Actions |

|---|---|---|

| Particulate accumulation | Inspect inlet frits. Check for increased pressure at constant flow rate. | Implement more stringent sample cleanup. Use in-line filters. Regularly replace guard columns. |

| Buffer precipitation | Review buffer composition, especially with pH-sensitive salts. | Ensure mobile phase compatibility. Incorporate regular system flushing protocols. |

| Hardware limitation | Check pump performance specifications for rapid flow direction changes. | Adjust ramp rates for flow direction changes. Ensure check valves are functioning properly. |

Problem 3: Inconsistent Inter-Batch Separation

Symptoms: Variable separation efficiency between different production batches despite identical method parameters.

| Possible Cause | Investigation Steps | Corrective Actions |

|---|---|---|

| Uncontrolled parameter variations | Conduct a robustness study using Plackett-Burman design to identify influential factors [1]. | Implement tighter control on critical parameters identified in robustness testing. |

| Stationary phase variations | Test method with columns from different manufacturing lots. | Establish column qualification protocols. Incorporate system suitability tests with broader acceptance criteria. |

| Sample matrix effects | Analyze sample composition variations between batches. | Adjust sample preparation consistency. Implement in-process monitoring of critical sample properties. |

Experimental Protocols

Protocol 1: Robustness Testing for Flow Reversal Methods

Objective: To identify critical method parameters and establish a robust operating window for flow reversal chromatography.

Materials:

- Chromatography system capable of controlled flow reversal

- Appropriate analytical column

- Standard test mixture representing critical separations

- Mobile phase components

Methodology:

- Identify Factors: Select 5-7 critical method parameters for investigation (e.g., mobile phase pH, flow rate, temperature, reversal cycle time, gradient slope).

- Define Ranges: Set appropriate high (+) and low (-) values for each factor based on expected operational variations.

- Experimental Design: Implement a Plackett-Burman screening design to efficiently evaluate all factors [1].

- Execution: Run experiments according to the design matrix, measuring critical responses (resolution, retention time, peak area, pressure).

- Analysis: Use statistical analysis to identify factors significantly affecting method performance.

- Define Control Limits: Establish system suitability criteria based on robustness study outcomes.

Protocol 2: Chromatogram Shape Analysis for Performance Monitoring

Objective: To implement PAT tools for early detection of column performance issues in flow reversal processes [31].

Materials:

- Historical chromatogram data from successful runs

- Statistical software capable of multivariate analysis

- New production batch data

Methodology:

- Data Collection: Gather raw chromatographic data from multiple successful batches.

- Pre-processing:

- Align chromatograms to correct for minor retention time shifts

- Normalize data to account for concentration variations

- Patch together different chromatogram phases for complete analysis

- Multivariate Model Development:

- Perform Principal Component Analysis (PCA) on standardized chromatograms

- Establish a control model based on successful historical batches

- Monitoring:

- Project new batch chromatograms onto the established PCA model

- Use statistical control limits (e.g., Hotelling's T²) to detect deviations

- Investigate any batches outside established control limits

Protocol 3: Optimization of Flow Reversal Timing

Objective: To determine optimal flow reversal cycle parameters for specific separation challenges.

Materials:

- Chromatography system with programmable flow reversal capability

- Test mixture with known adsorption characteristics

- Detection system (UV/VIS or other appropriate detector)

Methodology:

- Baseline Establishment: Run separation with conventional unidirectional flow to establish baseline performance.

- Initial Reversal Parameters: Implement flow reversal based on theoretical calculations of wave propagation velocities.

- Systematic Variation: Methodically vary:

- Cycle time (duration between flow reversals)

- Relative duration of forward vs. reverse flow phases

- Transition steepness between flow directions

- Performance Measurement: Quantify separation efficiency (number of theoretical plates), resolution, and product purity for each condition.

- Model Validation: Compare experimental results with predicted outcomes from mathematical models of the process [30].

Table 1: Robustness Study Factors and Typical Variation Ranges

This table outlines key parameters to investigate during robustness testing of chromatographic methods, with typical variation ranges based on regulatory guidance and industry practice [1].

| Parameter Category | Specific Factor | Typical Variation Range | Recommended Testing Level |

|---|---|---|---|

| Mobile Phase | pH | ±0.1-0.2 units | Low/High |

| Organic Solvent % | ±1-2% absolute | Low/High | |

| Buffer Concentration | ±5-10% | Low/High | |

| System Parameters | Flow Rate | ±5-10% | Low/High |

| Temperature | ±2-5°C | Low/High | |

| Detection Wavelength | ±1-3 nm | Low/High | |

| Flow Reversal | Cycle Time | ±5-10% | Low/High |

| Forward:Reverse Ratio | ±5-10% | Low/High |

| Problem Area | Key Performance Indicators | Target Values | Corrective Action Timeline |

|---|---|---|---|

| Peak Shape | Asymmetry factor | 0.8-1.5 | Immediate |

| Theoretical plates | >2000 | Next batch | |

| Resolution | Resolution between critical pairs | >1.5 | Immediate |

| Selectivity factor | Consistent ±5% | Next batch | |

| Pressure | System pressure | <200 bar | Immediate |

| Pressure fluctuation | <±5% | Immediate |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Flow Reversal Chromatography Experiments

| Item | Function | Application Notes |

|---|---|---|

| C18-Bonded Silica Column | Reversed-phase separation of low-molecular-weight analytes [32] | Tightly packed with coating material; withstands high pressure |

| High-Pressure Pump | Sustain constant liquid flow at high pressure through column [32] | Essential for UPLC applications (operating pressure up to 15,000 psi) |

| Mobile Phase Buffers | Control pH and ionic strength of eluent | Phosphate, acetate, or formate buffers commonly used |

| Organic Modifiers | Adjust solvent strength for gradient elution | Acetonitrile, methanol, or tetrahydrofuran typically used [32] |

| Index Matching Solutions | For refractive index matching in flow visualization | Used in particle image velocimetry setups [33] |

| Standard Test Mixtures | System suitability testing and performance monitoring | Should represent critical separations in your application |

Experimental Workflow and Relationship Diagrams

Flow Reversal Robustness Testing

Flow Reversal Process Monitoring

Frequently Asked Questions (FAQs) on Sustainable Chromatography

FAQ 1: What are the core principles of Green Analytical Chemistry (GAC) I should consider for my chromatographic methods?

The 12 principles of Green Analytical Chemistry (GAC) provide a foundational guideline for making analytical methods more environmentally friendly [34]. When applied to liquid chromatography, this primarily involves:

- Reducing solvent and energy consumption: This can be achieved by using smaller particle columns, monolithic or core–shell columns, shorter columns, and reducing analysis time [34].

- Using safer solvents: A primary focus is substituting toxic organic solvents in the mobile phase with greener alternatives [34] [35].

- Minimizing waste: Employing biodegradable solvents and considering waste generation throughout the method's lifecycle are key aspects [34].

- Prioritizing operator safety: This involves choosing solvents with lower toxicity and safer environmental profiles [36].

FAQ 2: How do I choose a "green" solvent for my HPLC method?

Selecting a green solvent involves evaluating its environmental, health, and safety (EHS) profile. Tools like the CHEM21 Solvent Selection Guide are excellent resources, ranking solvents as "recommended," "problematic," or "hazardous" based on criteria aligned with the Globally Harmonized System (GHS) [36]. The guide scores solvents on:

- Safety: Considering flash point, boiling point, and potential for peroxide formation.

- Health: Based on GHS classification and exposure limits.

- Environment: Accounting for toxicity to aquatic life and overall environmental impact [36].

A general guide for transitioning from classical solvents to greener alternatives in reversed-phase liquid chromatography is summarized in the table below.

Table 1: Guide to Greener Solvent Substitutions in Reversed-Phase Liquid Chromatography

| Classical Solvent | Recommended Greener Alternative | Key Considerations |

|---|---|---|

| Acetonitrile | Ethanol, methanol | Higher viscosity may require pressure adjustment; check UV cutoff [34]. |

| n-Hexane | Heptane, ethanol | Heptane is often preferred over n-hexane in green chemistry guides [36]. |

| Dichloromethane (DCM) | Ethyl acetate, methyl tert-butyl ether (MTBE), 2-methyltetrahydrofuran (2-MeTHF) | DCM is highly hazardous; alternatives are much safer and often bio-based [34] [36]. |

| Chloroform | - | No ideal green substitute; requires significant method redevelopment [34]. |

| Dimethylformamide (DMF) | Cyrene (dihydrolevoglucosenone) | Cyrene is a bio-based solvent with promising applications in chromatography [34]. |

FAQ 3: What is the difference between Green, Blue, and White Analytical Chemistry?

These terms represent an evolving understanding of sustainable analytical methods:

- Green Analytical Chemistry (GAC): Focuses primarily on the environmental impact of the method, aiming to reduce its ecological footprint [34].

- Blue Analytical Chemistry (BAC): Extends the concept to include the practicality and cost-effectiveness of the method. A green method is not sustainable if it is too expensive or complex for routine use [34].

- White Analytical Chemistry (WAC): This is a holistic approach that balances three equally weighted components: the greenness (environmental aspect), the redness (analytical efficiency and reliability), and the blueness (practicality and economic aspect) of a method. The goal is a "white" method that excels in all three areas [34].

The relationship between these concepts is illustrated below.

FAQ 4: My new "green" method has broad peaks and poor resolution. What could be the cause?

Transferring a method to a greener solvent often requires re-optimization. Broad peaks and poor resolution are common challenges with several potential causes [16] [17]:

- System not equilibrated: Equilibrate the column with 10-20 column volumes of the new mobile phase.

- Injection solvent mismatch: Ensure the sample is dissolved in a solvent that is the same or weaker strength than your new green mobile phase.

- Column overload: Reduce the injection volume or sample concentration.

- Insufficient buffer capacity: If analyzing ionizable compounds, increase the buffer concentration in the aqueous mobile phase component.

- High extra-column volume: Ensure all connection tubing is of the correct internal diameter and as short as possible.

HPLC Troubleshooting Guide for Sustainable Methods

This guide addresses common issues you might encounter when developing or transferring to greener chromatographic methods.

Table 2: Troubleshooting Common HPLC Problems in Method Development

| Symptom | Potential Causes | Solutions |

|---|---|---|

| Broad Peaks | - High extra-column volume [16]- Column overload (mass or volume) [16] [17]- Strong injection solvent [16] [17]- System not equilibrated [16] | - Use shorter, narrower internal diameter tubing [37].- Reduce injection volume/sample concentration [16].- Dissolve sample in mobile phase or a weaker solvent [17].- Equilibrate column with more mobile phase [16]. |

| Tailing Peaks | - Active sites on column (e.g., for basic compounds) [37]- Column voiding [16]- Inappropriate mobile phase pH [17] | - Use high-purity silica or polar-embedded stationary phases [37].- Replace the column [16].- Adjust mobile phase pH to suppress analyte ionization [17]. |

| Varying Retention Times | - Temperature fluctuations [16]- Pump not mixing solvents properly [16]- System not equilibrated [16] | - Use a thermostatically controlled column oven [16].- Check proportioning valve function; for isocratic methods, pre-mix solvents manually [16].- Ensure full column equilibration, especially after mobile phase change [16]. |

| High Backpressure | - Blocked column frit [17]- Mobile phase precipitation (e.g., with salts) [37]- Increased viscosity of green solvent (e.g., ethanol) [34] | - Replace guard column or reverse-flush analytical column [17].- Flush system with strong solvent and prepare fresh mobile phase [37].- Reduce flow rate, use a higher column temperature, or blend with a less viscous solvent [34]. |