UFLC-DAD in High-Throughput Screening: Accelerating Drug Discovery and Bioanalysis

Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) has emerged as a pivotal analytical technique for high-throughput screening (HTS) in modern drug discovery and development.

UFLC-DAD in High-Throughput Screening: Accelerating Drug Discovery and Bioanalysis

Abstract

Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) has emerged as a pivotal analytical technique for high-throughput screening (HTS) in modern drug discovery and development. This article explores the integral role of UFLC-DAD in providing rapid, sensitive, and reliable analytical data crucial for evaluating pharmacokinetic properties, screening compound libraries, and ensuring the quality and safety of pharmaceutical agents. Tailored for researchers, scientists, and drug development professionals, we cover the foundational principles of UFLC-DAD, its methodological applications in biomimetic chromatography and ADMET profiling, strategies for troubleshooting and system optimization, and its comparative validation against other HTS platforms. By synthesizing current methodologies and practical applications, this review provides a comprehensive framework for leveraging UFLC-DAD to significantly accelerate compound screening and streamline the drug development pipeline.

UFLC-DAD Fundamentals: Principles and Its Role in Modern High-Throughput Screening

Core Principles of Ultra-Fast Liquid Chromatography and Diode Array Detection

Ultra-Fast Liquid Chromatography (UFLC) coupled with Diode Array Detection (DAD) represents a powerful analytical technique that has revolutionized high-throughput screening in modern drug development. This synergy provides researchers with the capability to achieve rapid separations while obtaining rich spectral data for compound identification and purity assessment. The core principle of UFLC lies in the use of columns packed with smaller particles (typically sub-2μm or superficially porous particles around 2.7μm) operated at higher pressures, which dramatically enhances separation efficiency and speed compared to conventional High-Performance Liquid Chromatography (HPLC) [1]. When integrated with a DAD detector, which simultaneously captures absorbance spectra across a wide wavelength range, this technique becomes an indispensable tool for accelerating analytical workflows in pharmaceutical research. The application of UFLC-DAD is particularly valuable in therapeutic drug monitoring, metabolite profiling, and quality control of pharmaceutical formulations, where speed, resolution, and reliable characterization are paramount [2] [3].

Core Principles of UFLC-DAD

The Chromatographic Foundation of UFLC

The exceptional speed and efficiency of UFLC are fundamentally grounded in the van Deemter equation, which describes the relationship between linear velocity and theoretical plate height. UFLC systems minimize plate height by utilizing stationary phases with reduced particle sizes (1.6-2.7μm), which creates a flatter van Deemter curve and allows operation at higher optimal linear velocities without significant loss of efficiency [4] [1]. This principle enables separations that are up to 10 times faster than conventional HPLC while maintaining or improving resolution.

The practical implementation of these principles requires specialized equipment designed to withstand elevated system pressures (often exceeding 400 bar) and to minimize extra-column volume that could degrade separation efficiency. Modern UFLC systems incorporate low-dispersion tubing, specialized injectors, and reduced flow cell volumes to preserve the separation efficiency achieved within the column [1]. When coupled with the DAD detector, this configuration provides not only rapid separation but also comprehensive spectral information for each analyte, creating a robust platform for complex sample analysis.

Diode Array Detection Technology

The DAD detector operates on the principle of parallel wavelength detection, where a polychromatic light source passes through the sample flow cell, and the transmitted light is dispersed onto an array of photodiodes [4] [5]. This design enables simultaneous monitoring of multiple wavelengths during a single analysis, providing complete UV-Vis spectra for each chromatographic peak. This capability is crucial for peak purity assessment as analysts can compare spectra from different regions of a chromatographic peak to detect potential co-elution.

For method development, the DAD allows retrospective data analysis without reinjection, as the complete spectral data is stored for all compounds eluting from the column. Researchers can optimize detection wavelengths after data acquisition to maximize sensitivity for specific analytes [6]. The typical wavelength range for UFLC-DAD systems spans 190-800 nm, with photodiode arrays containing 512 to 1024 individual elements providing spectral resolution of approximately 1-2 nm [5]. This high spectral resolution enables the distinction between compounds with similar absorption characteristics but subtle spectral differences.

Advanced Applications in High-Throughput Research

Pharmaceutical Compound Analysis

UFLC-DAD has proven particularly valuable in the analysis of pharmaceutical compounds with narrow therapeutic windows, where precise quantification is critical for patient safety. A representative application is the simultaneous determination of tyrosine kinase inhibitors (afatinib and ibrutinib) in human plasma, which achieved precise quantification over a range of 5-400 ng/mL using an Acquity UPLC BEH C18 column with gradient elution [2]. The method employed a mobile phase combining ammonium formate buffer and acetonitrile at a flow rate of 0.4 mL/min, with the DAD providing the necessary selectivity for reliable detection in complex biological matrices.

Another significant application involves the analysis of erectile dysfunction therapeutics, where researchers developed a method for simultaneous determination of seven drugs (phosphodiesterase-5 inhibitors and serotonin reuptake inhibitors) using a C8 column with isocratic elution [7]. The method successfully resolved all compounds within 14 minutes with detection at 225 nm, demonstrating the efficiency of UFLC-DAD for multi-component pharmaceutical analysis. The validation results showed excellent linearity across concentration ranges of 2-500 μg/mL, with limits of detection between 0.18-0.38 μg/mL, highlighting the method's robustness for quality control applications [7].

Table 1: Application of UFLC-DAD in Pharmaceutical Analysis

| Analytes | Matrix | Column | Analysis Time | Linear Range | LOD |

|---|---|---|---|---|---|

| Afatinib, Ibrutinib [2] | Human plasma | Acquity UPLC BEH C18 | Not specified | 5-250 ng/mL (afatinib), 5-400 ng/mL (ibrutinib) | Not specified |

| Seven PDE5 inhibitors and SSRIs [7] | Tablet formulations | Waters C8 | 14 min | 2-500 μg/mL | 0.18-0.38 μg/mL |

| Paclitaxel, Lapatinib [8] | Polymeric micelles | C18 MZ-Analytical | 30 min (including re-equilibration) | 5-80 μg/mL | 1 μg/mL |

Food and Nutraceutical Analysis

The determination of tocopherols and tocotrienols in diverse food matrices exemplifies the application of UFLC-DAD in nutraceutical research. A recently developed method addressed the challenging separation of β- and γ-isomers of tocopherols and tocotrienols using a conventional C18 column with optimized pre-column sample treatment [4]. The research emphasized that while specialized columns (C30, pentafluorophenyl) can achieve this separation, properly optimized C18 methods provide a more accessible alternative for routine analysis. The UFLC-DAD method employed both fluorescence (excitation 290 nm, emission 327 nm) and DAD detection, leveraging the native fluorescence of tocochromanols for enhanced sensitivity and selectivity.

The analysis of orotic acid in milk samples further demonstrates the versatility of UFLC-DAD for food component analysis [5]. The method utilized two serially connected Kinetex C18 columns (1.7 μm, 150 mm × 2.1 mm) with UV detection at 278 nm, achieving excellent separation of orotic acid from interfering milk components in approximately 6.4 minutes. The validation data showed average recoveries of 96.7-105.3% with inter- and intra-assay coefficients of variation below 1.3%, confirming the method's reliability for routine quality control applications in dairy products [5].

Table 2: Application of UFLC-DAD in Food and Nutraceutical Analysis

| Analytes | Matrix | Column | Detection | Key Separation Achievement |

|---|---|---|---|---|

| Tocopherols, Tocotrienols [4] | Plant oils, fish oils, milk | Luna Omega C18 (1.6μm) | DAD (190-500 nm), FLD (290/327 nm) | Separation of β- and γ- isomers using conventional C18 |

| Orotic Acid [5] | Sheep and cow milk | Two Kinetex C18 (1.7μm) | DAD (278 nm) | Complete separation from milk interferents in 6.44 min |

Experimental Protocols

Protocol 1: Simultaneous Determination of Tyrosine Kinase Inhibitors in Human Plasma

This protocol adapts the method described by [2] for the quantification of afatinib and ibrutinib in human plasma using UFLC-DAD with solid-phase extraction.

Materials and Reagents:

- Afatinib and ibrutinib reference standards

- Diclofenac sodium (internal standard)

- Ammonium formate

- Acetonitrile (HPLC grade)

- Formic acid

- Human plasma samples

- Oasis MCX μElution solid-phase extraction plates

Equipment:

- UFLC system with DAD detector

- Acquity UPLC BEH C18 column (1.7 μm, 2.1 × 50 mm)

- Centrifuge

- Vortex mixer

- pH meter

Sample Preparation:

- Add 50 μL of internal standard working solution (diclofenac sodium, 100 ng/mL) to 500 μL of plasma sample.

- Vortex mix for 30 seconds.

- Load samples onto Oasis MCX μElution plates preconditioned with 1 mL methanol followed by 1 mL water.

- Wash with 1 mL of 2% formic acid in water, followed by 1 mL of methanol.

- Elute with 2 × 25 μL of 5% ammonium hydroxide in acetonitrile.

- Dilute eluate with 150 μL of water and vortex mix for 30 seconds.

- Transfer to autosampler vials for analysis.

Chromatographic Conditions:

- Column: Acquity UPLC BEH C18 (1.7 μm, 2.1 × 50 mm)

- Mobile Phase A: 10 mM ammonium formate buffer (pH 3.0)

- Mobile Phase B: Acetonitrile

- Gradient: 0-2 min: 10-30% B, 2-4 min: 30-50% B, 4-5 min: 50-90% B, 5-6 min: 90% B, 6-6.5 min: 90-10% B, 6.5-8 min: 10% B

- Flow Rate: 0.4 mL/min

- Column Temperature: 40°C

- Injection Volume: 5 μL

- Detection: DAD, 254 nm for afatinib and ibrutinib

Validation Parameters:

- Calibration range: 5-250 ng/mL for afatinib, 5-400 ng/mL for ibrutinib

- Accuracy and precision evaluated using quality control samples

- Extraction recovery assessed by comparing extracted samples with post-extraction spiked samples

Protocol 2: High-Throughput Screening of Cytochrome P450 Inhibitors

This protocol implements a cutting-edge high-throughput approach using segmented flow injection for rapid LC analysis, based on the methodology described by [1].

Materials and Reagents:

- Cytochrome P450 reaction components

- Potential inhibitor compounds

- Thiourea, acetophenone, propiophenone (test analytes)

- Acetonitrile (LC-MS grade)

- Water (LC-MS grade)

- Formic acid

Equipment:

- UFLC system with DAD and MS capability

- Poroshell 120 StableBond C18 column (2.7 μm, 2.1 mm i.d. × 5 mm)

- Droplet microfluidic injection system

- PTFE tubing (0.8 mm i.d. × 1.6 mm o.d.)

- Syringe pump

Sample Introduction via Segmented Flow:

- Prepare samples in 96-well plate format.

- Load samples into PTFE tubing using droplet microfluidics: submerge tubing tip into sample well for 1 second, move to next well while withdrawing air (1 second travel time).

- Maintain segmented flow with sample droplets (∼4 μL) separated by air segments.

- Connect tubing outlet to injection valve with fixed sample loop.

- Automatically inject each sample droplet as it fills the sample loop.

Chromatographic Conditions:

- Column: Poroshell 120 StableBond C18 (2.7 μm, 2.1 mm i.d. × 5 mm)

- Mobile Phase: Isocratic, acetonitrile/water with 0.1% formic acid (premixed)

- Flow Rate: 5 mL/min

- Column Temperature: 25°C

- Injection Volume: ∼4 μL (droplet volume)

- Detection: DAD (210 nm or 254 nm) and MS

- Analysis Time: 1 second per sample

Method Performance:

- Throughput: 96-well plate analyzed in 1.6 minutes

- Carryover: Minimized by including wash droplets of organic solvent between sample droplets

- Precision: <2% RSD for peak areas

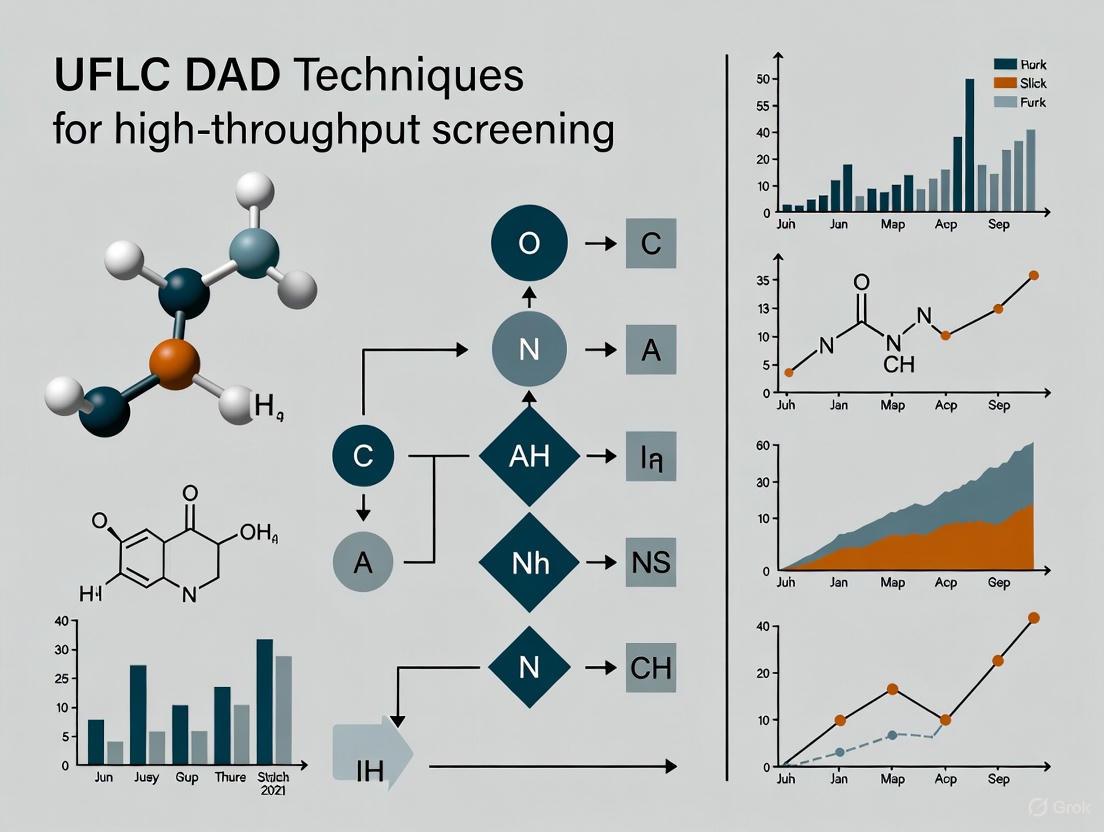

Visualization of UFLC-DAD Workflows

Diagram 1: Comprehensive UFLC-DAD Analytical Workflow

Diagram 2: High-Throughput Screening Workflow with UFLC-DAD

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential Research Reagent Solutions for UFLC-DAD Method Development

| Category | Specific Examples | Function in UFLC-DAD |

|---|---|---|

| Stationary Phases | Acquity UPLC BEH C18 [2], Kinetex C18 [5], Luna Omega C18 [4] | Core separation media; selection depends on required selectivity, efficiency, and pressure limits |

| Mobile Phase Components | Ammonium formate buffer [2], Phosphoric acid [5], Acetonitrile/Methanol [7] [8] | Creates elution environment; buffer controls pH and ionization, organic modifier strength controls retention |

| Reference Standards | Afatinib, Ibrutinib [2], Tocopherol/Tocotrienol isomers [4], Orotic acid [5] | Method development and validation, calibration curves, identification and quantification |

| Sample Preparation Materials | Oasis MCX μElution plates [2], Acetonitrile for protein precipitation [5], Derivatization reagents | Extract, concentrate, and clean up samples; improve sensitivity and column lifetime |

| System Suitability Tools | Thiourea (void marker), Test mixtures for efficiency and peak symmetry [1] | Verify system performance before sample analysis |

UFLC-DAD technology represents a cornerstone analytical methodology for high-throughput screening in pharmaceutical research and development. The core principles of enhanced separation efficiency through reduced particle size columns, combined with the comprehensive spectral information provided by diode array detection, create a powerful synergy for accelerating drug discovery workflows. As research continues to push the boundaries of analytical speed and sensitivity, further innovations in column technology, detection systems, and data analysis algorithms will continue to expand the capabilities of UFLC-DAD platforms. The ongoing development of integrated approaches, such as coupling with high-resolution mass spectrometry and implementing advanced data mining workflows [9] [3], ensures that UFLC-DAD will remain an essential tool in the analytical scientist's arsenal for addressing the complex challenges of modern drug development.

High-Throughput Screening (HTS) represents a foundational paradigm in modern drug discovery, enabling the rapid testing of hundreds of thousands of chemical, genetic, or pharmacological compounds against biological targets [10]. This approach leverages robotics, automated liquid handling, and miniaturized assays to identify novel lead compounds with unprecedented speed compared to traditional rational drug design methods [10]. The evolution of HTS technologies has progressively transformed pharmaceutical research from a labor-intensive, low-throughput process to an automated, data-rich science capable of generating millions of data points in a single campaign [11] [10]. Within this context, analytical techniques like Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) provide critical support for compound analysis and validation, offering satisfactory precision, accuracy, and repeatability with low limits of detection and quantification for assayed compounds [4].

The Technological Evolution of HTS

From Traditional Methods to Automated Screening

The transition from traditional drug screening to contemporary HTS represents one of the most significant technological shifts in pharmaceutical science. Traditional methods were characterized by low-throughput capabilities, requiring extensive manual manipulation and offering limited capacity for testing compound libraries. These approaches typically involved individualized testing protocols that were time-consuming, resource-intensive, and poorly suited to systematic exploration of chemical space.

The emergence of HTS technologies in the late 20th century introduced a new paradigm based on automation, miniaturization, and parallel processing. This shift was driven by several key developments:

- Robotics and Automation: The integration of robotic systems enabled continuous, high-speed operation with minimal human intervention, significantly increasing throughput while reducing operational variability [10].

- Miniaturization: The transition from standard laboratory vessels to microtiter plates (96-well, 384-well, and 1536-well formats) dramatically reduced reagent consumption and processing times while increasing data output density [10].

- Advanced Detection Technologies: The development of sensitive, high-speed detection systems, including fluorescence, luminescence, and mass spectrometry-based methods, enabled rapid readout of biological interactions even in miniaturized formats [10].

The Advent of Ultra-High-Throughput Screening (uHTS)

The continuous progression toward higher throughput capabilities has culminated in the development of Ultra-High-Throughput Screening (uHTS), which can process over 300,000 compounds per day compared to the 10,000-100,000 compounds typical of conventional HTS [10]. This advancement has been enabled by further miniaturization to 1536-well plates and beyond, with typical assay volumes of 1-2 μL, alongside sophisticated fluid handling systems and enhanced data processing capabilities [10].

Table 1: Comparison of HTS and uHTS Capabilities

| Attribute | HTS | uHTS | Comments |

|---|---|---|---|

| Speed (assays/day) | < 100,000 | >300,000 | uHTS offers significantly higher throughput |

| Complexity | Moderate | High | uHTS requires more sophisticated infrastructure |

| Cost | Lower | Significantly higher | uHTS involves greater capital investment |

| Data Analysis Requirements | Moderate | High | uHTS often requires AI/ML for data processing |

| Ability to Monitor Multiple Analytes | Limited | Enhanced | uHTS benefits from multiplexed sensor systems |

Key Technological Components of Modern HTS

Modern HTS platforms integrate several core technological components that work in concert to enable efficient screening operations:

- Automated Liquid Handling: Robotic systems capable of accurately dispensing nanoliter aliquots of samples and reagents, minimizing assay setup times while ensuring reproducibility [10].

- Compound Management: Highly automated systems for compound storage, retrieval, solubilization, and quality control, typically utilizing miniaturized microwell plates [10].

- Detection Technologies: Diverse detection methods including fluorescence, luminescence, mass spectrometry, and differential scanning fluorimetry that provide sensitive measurement of biological interactions [10].

- Data Management and Analysis: Advanced computational infrastructure and algorithms for processing large datasets, identifying false positives, and triaging results based on probability of success [10].

Current Applications and Methodologies in HTS

Primary Applications in Drug Discovery

HTS has established itself as a critical technology across multiple domains of pharmaceutical research and development:

Drug Discovery and Development: HTS serves as a primary approach for identifying starting compounds for small molecule drug design programs, particularly when limited information is available about the pharmacological target, which precludes structure-based drug design approaches [10]. The methodology enables rapid lead identification and supports "fast to failure" strategies that quickly eliminate unsuitable candidates from the development pipeline [10].

Toxicology Assessment: Cell-based HTS methodologies have increasingly replaced traditional animal studies for predicting chemical toxicity, offering enhanced predictive value for human toxicity while addressing ethical concerns associated with animal testing [10]. Initiatives such as the Tox21 program leverage HTS to identify toxicity issues of novel molecules in a high-throughput, concentration-responsive manner using in vitro assays [10].

Genomic and Functional Screening: HTS enables comprehensive analysis of large gene sets to identify those affecting specific diseases or biological pathways, facilitating functional genomics research and supporting the analysis of extensive genomic datasets [10]. Applications include RNA sequencing, chromatin immunoprecipitation sequencing, and various microarray technologies [10].

HTS Assay Development and Validation

The development of robust, reproducible, and sensitive assays represents a critical foundation for successful HTS campaigns. HTS assays require comprehensive validation according to predefined statistical concepts to ensure pharmacological and biological relevance [10]. Key considerations include:

- Miniaturization Compatibility: Assays must be suitable for miniaturization to reduce reagent consumption while maintaining performance characteristics in 96-, 384-, and 1536-well formats [10].

- Automation Suitability: Assay protocols must be compatible with automated liquid handling and signal detection systems, with minimal manual intervention requirements [10].

- Transferability: Methods transferred between different laboratories or facilities require appropriate validation to ensure consistent performance across sites [10].

Table 2: HTS Assay Formats and Characteristics

| Assay Format | Throughput | Well Formats | Volume Range | Primary Applications |

|---|---|---|---|---|

| Biochemical Assays | High | 96-1536 well | 1-100 μL | Enzyme targets, receptor binding |

| Cell-Based Assays | Moderate-High | 96-384 well | 10-200 μL | Functional responses, phenotypic screening |

| uHTS Formats | Very High | 1536-3456 well | 1-10 μL | Primary screening of large libraries |

UFLC-DAD Techniques in HTS Research

Analytical Applications in Compound Analysis

Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) provides powerful analytical capabilities that support various aspects of HTS campaigns. The technique enables high-separation efficiency combined with comprehensive spectral data collection, making it particularly valuable for compound characterization and validation [4]. Specific applications include:

- Compound Identification and Purity Assessment: UFLC-DAD facilitates the identification of bioactive compounds from complex mixtures and assesses their purity following primary screening, with detection limits below 10 ng/mL and quantification limits below 27 ng/mL for various analytes [4].

- Metabolite Screening: The technique supports the identification and quantification of metabolites in biological samples, providing critical information about compound stability and metabolic fate [4].

- Separation of Complex Mixtures: UFLC-DAD enables the separation of structurally similar compounds that may be present in screening libraries or biological samples, including challenging separations such as β- and γ-forms of tocopherols and tocotrienols through derivatization approaches [4].

UFLC-DAD Protocols for Compound Validation

The following protocol outlines a standardized approach for compound analysis using UFLC-DAD within HTS workflows:

Protocol 1: UFLC-DAD Analysis of Bioactive Compounds

Principle: This method describes the quantification of chemical compounds in diverse biological matrices using C18-UFLC with photodiode array (DAD) and fluorescence detection (FLD) [4].

Materials and Reagents:

- C18 Chromatography Column: Conventional C18 column with microparticulate stationary phases [4]

- Mobile Phase A: Water or aqueous buffer

- Mobile Phase B: Acetonitrile or methanol

- Reference Standards: Target compounds dissolved in appropriate solvents

- Derivatization Reagent: Trifluoroacetic anhydride (for selective compound separation) [4]

- Biological Samples: Plant, algae, or fish oils; milk; animal tissues [4]

Instrumentation:

- UFLC system with binary or quaternary pump

- Diode Array Detector (DAD)

- Optional: Fluorescence Detector (FLD)

- Autosampler with temperature control

- Column compartment with temperature control

Procedure:

- Sample Preparation:

- For oils: Direct analysis without saponification permits quantification of tocopherols and tocotrienols [4].

- For milk and animal tissues: Employ gentle saponification followed by C18-chromatography [4].

- For challenging separations (e.g., β- and γ-forms): Implement esterification of hydroxyl groups with trifluoroacetic anhydride [4].

Chromatographic Conditions:

- Column: C18 column (specify dimensions and particle size)

- Mobile Phase: Binary gradient elution program

- Flow Rate: 0.5-2.0 mL/min (optimize for specific column)

- Column Temperature: 25-40°C

- Detection: DAD monitoring at 278 nm and 205 nm for tocopherols and tocotrienols [4]

- Injection Volume: 1-20 μL (depending on concentration)

System Operation:

- Equilibrate column with initial mobile phase composition

- Implement gradient elution program optimized for target compounds

- Monitor separation using DAD with spectral acquisition from 200-400 nm

- Quantify compounds based on calibration curves from reference standards

Data Analysis:

- Identify compounds based on retention time and spectral matching

- Quantify using peak areas or heights relative to calibration standards

- Generate reports including compound identity, concentration, and purity assessment

Validation Parameters:

- Precision: Satisfactory precision demonstrated for tocopherol and tocotrienol analysis [4]

- Accuracy: Confirmed through recovery studies

- Repeatability: Established through multiple injections

- Limit of Detection: <10 ng/mL for target compounds [4]

- Limit of Quantification: <27 ng/mL for target compounds [4]

Essential Research Reagents and Materials

Successful implementation of HTS campaigns requires carefully selected reagents and materials that ensure assay robustness and reproducibility. The following table outlines key research reagent solutions employed in HTS workflows:

Table 3: Essential Research Reagent Solutions for HTS

| Reagent/Material | Function | Application Examples | Considerations |

|---|---|---|---|

| Combinatorial Libraries | Source of structurally diverse compounds for screening | Primary hit identification, lead discovery | Quality control for enhanced clinical exposure and safety [10] |

| Fluorescence Probes | Enable detection of molecular interactions | Enzymatic assays, binding studies, cellular imaging | Sensitivity to environmental conditions; potential interference [10] |

| Cell Culture Reagents | Support maintenance of cellular assay systems | Cell-based screening, toxicity assessment, functional genomics | Batch-to-batch consistency; impact on cellular responses |

| Enzyme Preparations | Catalyze specific biochemical reactions | Target-based screening, mechanistic studies | Purity, specific activity, stability under assay conditions [10] |

| Microplates | Platform for miniaturized assay formats | All HTS applications | Well geometry, surface treatment, compatibility with detection systems [10] |

| UFLC-DAD Mobile Phases | Enable chromatographic separation | Compound analysis, purity assessment, metabolite identification | HPLC-grade solvents; degassing to prevent bubble formation [4] |

Integrated Workflow for HTS in Drug Discovery

The successful implementation of HTS in drug discovery requires the integration of multiple technological components into a seamless workflow. The following diagram illustrates the comprehensive process from library preparation to hit validation:

Emerging Trends in HTS Technology

The field of High-Throughput Screening continues to evolve with several emerging trends shaping its future development:

Artificial Intelligence and Machine Learning: The integration of AI/ML technologies is revolutionizing HTS data analysis, enabling predictive modeling of compound activity, optimization of screening strategies, and reduction of false positive rates through advanced pattern recognition [12] [10]. These approaches facilitate more effective triage of HTS output by ranking compounds based on their probability of success [10].

Advanced Automation and Robotics: Next-generation robotic systems are enhancing screening efficiency through improved speed, accuracy, and reliability while reducing operational costs [12]. These systems support increasingly complex assay protocols and enable continuous operation with minimal human intervention.

Miniaturization and Microfluidics: The ongoing trend toward further miniaturization, including the development of lab-on-a-chip systems and microfluidic devices, continues to reduce reagent consumption and increase throughput while enabling novel assay formats [12] [10]. These technologies facilitate high-throughput analysis while minimizing the required sample material and reagents, thereby lowering overall screening costs [12].

Integration of Real-Time Data Analytics: The incorporation of real-time data analytics and cloud computing into HTS platforms allows researchers to process vast amounts of data more effectively, driving faster decision-making and improving the success rate of drug discovery efforts [12].

The evolution of High-Throughput Screening from traditional methods to automated screening platforms has fundamentally transformed drug discovery, enabling unprecedented throughput and efficiency in identifying novel therapeutic compounds. The continued advancement of HTS technologies, including the emergence of uHTS and the integration of artificial intelligence, promises to further accelerate this field. Within this context, analytical techniques such as UFLC-DAD provide critical support for compound validation and characterization, offering the precision, accuracy, and sensitivity required for modern drug discovery pipelines. As HTS continues to evolve, its integration with complementary technologies and analytical methods will remain essential for addressing the increasing complexity of pharmaceutical research and delivering innovative therapies to patients.

Ultra-Fast Liquid Chromatography coupled with Diode-Array Detection (UFLC-DAD) represents a powerful analytical platform that effectively balances speed, sensitivity, and versatility for high-throughput screening (HTS) applications in drug discovery and development. This application note details the core advantages of UFLC-DAD technology, provides validated experimental protocols for HTS workflows, and presents quantitative performance data demonstrating its utility in complex matrix analysis. The integration of rapid separation capabilities with comprehensive spectral information makes UFLC-DAD particularly valuable for the screening of natural products, metabolite profiling, and quality control of complex samples.

The demand for rapid analytical techniques in modern high-throughput screening laboratories has driven the adoption of Ultra-Fast Liquid Chromatography systems capable of delivering high-resolution separations in significantly reduced timeframes. When coupled with Diode-Array Detection (DAD), which provides simultaneous multi-wavelength monitoring and spectral confirmation, this platform offers a unique combination of separation efficiency and compound characterization ability. Within drug discovery pipelines, particularly in natural product screening and metabolomics, UFLC-DAD serves as an indispensable tool for the initial rapid identification of bioactive compounds before more resource-intensive characterization using mass spectrometry.

Key Technical Advantages of UFLC-DAD in HTS

Enhanced Separation Speed and Efficiency

UFLC systems utilize columns packed with smaller particles (typically 1.7-2.7 μm) and higher operating pressures to achieve dramatic improvements in separation speed without compromising resolution. The reduction in analysis time directly translates to increased throughput in screening campaigns.

Table 1: Comparison of UFLC Performance in Various Applications

| Application Context | Analysis Time | Flow Rate | Resolution Achieved | Key Benefit | Reference |

|---|---|---|---|---|---|

| PDE-5 Inhibitor Screening | <30 min | 0.2-0.5 mL/min | Baseline separation of multiple analogs | Rapid screening of complex mixtures | [13] |

| Tea Metabolite Profiling | 35 min (conventional HPLC: >60 min) | 0.3-0.4 mL/min | Quantification of 22 metabolites | High-resolution pattern recognition | [14] |

| Phenolic Compound Analysis | <20 min | Not specified | Resolution ≥7.12 between critical pairs | Fast quality control screening | [15] |

Detection Sensitivity and Spectral Verification

The DAD component provides critical advantages for compound identification through continuous spectral acquisition. Unlike single-wavelength detectors, DAD captures the full UV-Vis spectrum for each eluting peak, enabling peak purity assessment and preliminary compound classification through spectral matching.

Table 2: Sensitivity Performance Metrics of DAD Detection

| Analytic Class | Limit of Detection (LOD) | Limit of Quantification (LOQ) | Linear Range | Detection Wavelength | Reference |

|---|---|---|---|---|---|

| Phenolic Compounds | Not specified | Not specified | R² > 0.995 | 280 nm, 320 nm | [15] |

| PDE-5 Inhibitors & Analogs | 0.09-8.55 ng/mL | 0.24-17.10 ng/mL | R² > 0.997 | 220, 290, 360 nm | [13] |

| Anti-impotence Compounds | 0.005-0.50 μg/g | 0.02-1.24 μg/g | R² > 0.9973 | Multi-wavelength | [13] |

The sensitivity of DAD systems can be optimized through proper flow cell selection. While extended pathlength cells (e.g., 60 mm) enhance sensitivity, conventional spring-type flow cells offer greater reliability for high-throughput applications where system robustness is prioritized [16].

Versatility in Complex Matrix Applications

UFLC-DAD demonstrates particular strength in analyzing complex biological and botanical matrices where component identification and purity assessment are challenging:

- Natural Product Screening: Successfully applied to identify PDE-5 inhibitors in herbal matrices with minimal sample cleanup [13]

- Metabolite Profiling: Enables simultaneous quantification of multiple metabolite classes in plant extracts [14]

- Bioactive Compound Analysis: Provides rapid antioxidant screening when coupled with electrochemical detection [15]

Experimental Protocols for HTS Workflows

Protocol 1: Rapid Screening of Natural Products for PDE-5 Inhibitors

This protocol adapts methodologies from multiple sources for high-throughput screening of potential phosphodiesterase-5 (PDE-5) inhibitors in natural product libraries [13].

Materials and Reagents

- UFLC System: Shimadzu Prominence UFLC or equivalent with DAD detector

- Chromatography Column: Reversed-phase C18 column (150 mm × 2.1 mm, 1.7-2.7 μm)

- Mobile Phase A: 0.1% formic acid in deionized water

- Mobile Phase B: 0.1% formic acid in acetonitrile

- Standards: PDE-5 inhibitor reference compounds (sildenafil, tadalafil, vardenafil)

- Samples: Natural product extracts dissolved in appropriate solvent

Chromatographic Conditions

- Flow Rate: 0.3-0.4 mL/min

- Injection Volume: 1-5 μL

- Column Temperature: 40°C

- Gradient Program:

- 0-2 min: 5% B

- 2-15 min: 5-95% B (linear gradient)

- 15-17 min: 95% B

- 17-17.5 min: 95-5% B

- 17.5-20 min: 5% B (re-equilibration)

- DAD Parameters: Monitoring at 220 nm, 290 nm, and 360 nm with full spectrum acquisition (200-800 nm) for peak purity assessment

Sample Preparation

- Weigh 100 mg of natural product extract into 10 mL centrifuge tube

- Add 5 mL of extraction solvent (methanol:water 70:30, v/v)

- Sonicate for 15 minutes at 40°C

- Centrifuge at 10,000 × g for 10 minutes

- Filter supernatant through 0.22 μm membrane prior to injection

Data Analysis

- Identify compounds of interest by comparison of retention times with standards (±2%)

- Confirm identity by spectral matching using built-in library (minimum match factor of 995)

- Perform peak purity assessment using DAD spectra

- Quantify using external calibration curve (5-point minimum)

Protocol 2: Metabolite Profiling for Quality Control Screening

This protocol is adapted from Wuyi rock tea analysis [14] and optimized for general metabolite screening in natural products.

Materials and Reagents

- Extraction Solvent: Methanol (HPLC grade)

- Ultrasonication Bath: With temperature control

- Centrifuge: Capable of 10,000 × g

- Syringe Filters: 0.22 μm PTFE

Optimized Extraction Procedure

- Weigh 50 mg of finely powdered sample into 15 mL conical tube

- Add 5 mL of 75% methanol in water (optimized using response surface methodology [14])

- Sonicate at 160 W for 14 minutes at room temperature

- Centrifuge at 10,000 × g for 10 minutes

- Collect supernatant and filter through 0.22 μm membrane

- Dilute 1:10 with mobile phase A prior to analysis

UFLC-DAD Analysis Parameters

- Column: C18 (100 mm × 2.1 mm, 2.7 μm)

- Flow Rate: 0.4 mL/min

- Temperature: 40°C

- Injection Volume: 2 μL

- Gradient:

- 0-1 min: 5% B

- 1-10 min: 5-60% B

- 10-12 min: 60-95% B

- 12-13 min: 95% B

- 13-14 min: 95-5% B

- 14-16 min: 5% B

- Detection: 210-800 nm full scan with specific monitoring at 280 nm (phenolics) and 320 nm (flavonoids)

Diagram 1: HTS Workflow Using UFLC-DAD

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for UFLC-DAD HTS Workflows

| Item | Function | Application Notes |

|---|---|---|

| Reversed-phase C18 Columns (50-150 mm length, 1.7-2.7 μm) | High-resolution separation | Core component for fast separations; sub-2μm particles for maximum efficiency [13] |

| Formic Acid (MS-grade) | Mobile phase additive | Improves peak shape and ionization; typically used at 0.1% concentration [13] |

| Acetonitrile (HPLC-grade) | Mobile phase organic modifier | Preferred for low UV cutoff and compatibility with MS detection [13] |

| Methanol (HPLC-grade) | Extraction solvent & mobile phase component | Effective for extraction of medium-polarity compounds; used in optimized 75% concentration for metabolites [14] |

| Reference Standards | Compound identification and quantification | Essential for retention time alignment and quantitative analysis [13] [15] |

Critical Method Validation Parameters

For reliable HTS implementation, UFLC-DAD methods require comprehensive validation. Key parameters adapted from EMA guidelines include [15]:

- System Suitability: Retention time RSD <1.0%, peak area RSD <1.0%, symmetry factor 0.82-1.20

- Linearity: Correlation coefficient R² >0.995 for calibrated compounds

- Detection Limits: Substance-dependent but typically in low ng/mL range for DAD detection [13]

- Precision: Intra-day and inter-day RSD ≤6.5% for robust screening methods [13]

Diagram 2: Method Validation Parameters

Integration in Broader Drug Discovery Workflow

UFLC-DAD serves as a critical bridge between initial biological screening and definitive structural elucidation in modern drug discovery pipelines, particularly in natural product research [17]. The technology enables:

- Rapid Triage: Quick assessment of compound libraries to identify promising leads for further investigation

- Purity Assessment: Evaluation of sample complexity and potential for isolation

- Spectral Libraries: Building of searchable databases for compound classification

- Method Transfer: Seamless transition to LC-MS methods for definitive identification

The compatibility of UFLC-DAD methods with mass spectrometry facilitates a hierarchical screening approach where large numbers of samples can be rapidly processed with UFLC-DAD, with only hits progressing to more resource-intensive MS-based characterization.

UFLC-DAD technology provides an optimal balance of speed, sensitivity, and informational content for high-throughput screening applications. The capacity for rapid separations coupled with comprehensive spectral data enables efficient triage of compound libraries, quality assessment of natural products, and metabolite profiling in drug discovery pipelines. The experimental protocols and performance metrics detailed in this application note demonstrate the robust capabilities of UFLC-DAD as a cornerstone analytical technology in modern pharmaceutical research.

Integration with Biomimetic Chromatography for Predicting Physicochemical Properties

The integration of Ultra-Fast Liquid Chromatography (UFLC) with Diode Array Detection (DAD) and biomimetic stationary phases represents a transformative advancement in high-throughput screening for drug discovery. This synergy enables the rapid profiling of chemical constituents and prediction of in vivo distribution behavior based on calibrated retention parameters. Biomimetic chromatography utilizes stationary phases containing proteins and phospholipids to mimic the biological environment encountered in the human body, providing a powerful platform for predicting physicochemical properties critical to drug absorption, distribution, and toxicity. When operated with aqueous organic mobile phases at physiological pH 7.4, these systems effectively model a compound's affinity for proteins and phospholipids—key determinants of their biological fate [18]. This Application Note details protocols for leveraging UFLC-DAD systems with biomimetric columns to accelerate compound characterization and selection in pharmaceutical development.

Theoretical Foundations

Principles of Biomimetic Chromatography

Biomimetic chromatography functions as a dynamic in vitro system that models passive biological distribution processes. The retention factor (k) is directly proportional to the compound's distribution between the biomimetic stationary phase and the aqueous mobile phase, described by the equation:

k = (tR - t0) / t_0

where tR is the compound's retention time and t0 is the column dead time [19]. The logarithmic retention factor (log k) shows a linear relationship with the logarithmic partition coefficient (log K), enabling quantitative prediction of membrane permeability and protein binding [18] [19].

Unlike traditional octanol/water partition systems, biomimetic chromatography incorporates charged groups and exhibits shape selectivity, more closely resembling biological membranes where distribution occurs on large surfaces through dynamic equilibrium processes [18]. This provides superior prediction accuracy for in vivo distribution behavior, particularly for charged compounds where octanol/water systems show significant limitations [18].

UFLC-DAD System Configuration for High-Throughput Analysis

UFLC systems provide superior performance for biomimetic screening through the use of fine stationary phase particles (typically 1.7-2.2 μm) that enable extremely high resolution with significantly reduced analytical time. When coupled with DAD detection, these systems facilitate the rapid identification and quantification of multiple analytes in complex mixtures with enhanced sensitivity [20]. The system configuration typically includes:

- Low-dispersion binary or quaternary pumps capable of operating at high pressures (≥ 6000 psi)

- Thermostatted auto-sampler with sample pre-conditioning capabilities

- Column oven with precise temperature control (±0.5°C)

- DAD detector with high sampling rates and spectral acquisition capabilities

- Optional MS interface for compound identification and confirmation

Experimental Protocols

Protocol 1: Biomimetic Lipophilicity Measurement Using IAM Chromatography

Purpose: To determine the chromatographic hydrophobicity index (CHI) as a measure of membrane partitioning using Immobilized Artificial Membrane (IAM) stationary phases.

Materials:

- IAM.PC.DD2 column (e.g., Regis Technologies, 10-50 mm length, 2.1-4.6 mm i.d.)

- Mobile Phase A: 10-50 mM ammonium acetate buffer, pH 7.4

- Mobile Phase B: Acetonitrile or methanol (HPLC grade)

- Standard compounds for calibration (corticosteroids, β-blockers, nonsteroidal anti-inflammatories)

- Test compounds dissolved in DMSO (1-10 mM stock solutions)

Method:

- System Equilibration: Equilibrate column with 5% mobile phase B for at least 20 column volumes at flow rate of 0.5-1.5 mL/min (UFLC) or 0.2-0.5 mL/min (nano-LC).

- Gradient Program: Employ a linear gradient from 5% to 100% B over 5-15 minutes.

- Column Re-equilibration: Return to initial conditions and equilibrate for 5 column volumes between runs.

- Detection: Monitor elution at 220-280 nm using DAD; acquire full spectra from 200-600 nm.

- Calibration: Inject CHI calibration mix containing compounds with known CHI values (0-100 scale).

- Sample Analysis: Inject test compounds (0.5-5 μL, 1-50 μM final concentration).

- Data Analysis: Calculate CHI values using the linear relationship between gradient retention time and CHI of calibration standards [19].

Notes: For isocratic measurements, determine retention factors (k) at 3-5 different organic modifier concentrations and extrapolate to 0% organic to obtain log k_w values [19].

Protocol 2: High-Throughput Protein Binding Assessment

Purpose: To predict human serum albumin (HSA) and α-1-acid glycoprotein (AGP) binding using biomimetic columns.

Materials:

- HSA column (e.g., ChiralPak-HSA, 5 μm, 50 × 2.1 mm)

- AGP column (e.g., ChiralPak-AGP, 5 μm, 50 × 2.1 mm)

- Mobile Phase: 10-50 mM ammonium acetate or phosphate buffer, pH 7.4

- Organic Modifier: Isopropanol (0-20%)

- Reference compounds with known protein binding (warfarin, diazepam, propranolol)

Method:

- System Setup: Equilibrate HSA or AGP column with initial mobile phase (typically 5-10% isopropanol in buffer).

- Gradient Elution: Apply shallow gradient from 0% to 20% isopropanol over 10 minutes.

- Detection: Monitor at 220, 254, and 280 nm with spectral acquisition.

- Calibration: Inject reference compounds with known protein binding values to establish correlation between retention time and binding affinity.

- Quantification: Calculate protein binding potential using the calibrated retention parameters [18].

Notes: For neutral compounds, retention on biomimetic stationary phases correlates well with lipophilicity and octanol/water partition coefficients, while for ionizable compounds, the charged groups on biomimetic phases provide superior prediction accuracy [18].

Protocol 3: Rapid Profiling of Complex Mixtures

Purpose: To simultaneously identify and quantify principal components in complex botanical extracts or synthetic mixtures.

Materials:

- UFLC system with DAD and MS compatibility

- C18, IAM, or HSA columns (50-100 mm length, 2.1 mm i.d., sub-2μm particles)

- Mobile Phase: Acidified water (0.1% formic acid) and acidified acetonitrile

- Reference standards for target compounds

Method (Adapted from Fuling Decoction Analysis):

- Chromatographic Conditions:

- Column: C18 (100 × 2.1 mm, 1.8 μm)

- Mobile Phase: Water (0.1% formic acid) and acetonitrile (0.1% formic acid)

- Gradient: 5% to 95% acetonitrile over 7 minutes

- Flow Rate: 0.4 mL/min

- Column Temperature: 40°C

- Detection: 235 nm, 250 nm, and 280 nm

- Sample Preparation: Dissolve extracts in methanol or mobile phase (1-5 mg/mL), filter through 0.22 μm membrane

- Injection Volume: 2-5 μL

- Identification: Compare retention times and UV spectra with reference standards

- Quantification: Use external calibration curves for target compounds [21] [20]

Notes: This UFLC method enabled identification of 14 constituents in Fuling Decoction within 7 minutes, with simultaneous quantification of four major components: genipingentiobioside, geniposide, paeoniflorin, and liquiritin [21] [20].

Data Analysis and Interpretation

Retention-Pproperty Relationships

Biomimetic chromatographic retention parameters show strong correlation with key physicochemical and ADME properties:

Table 1: Correlation of Biomimetic Chromatographic Data with Physicochemical Properties

| Chromatographic Parameter | Stationary Phase | Correlated Property | Application Domain |

|---|---|---|---|

| CHI (Chromatographic Hydrophobicity Index) | IAM.PC.DD2 | Membrane partitioning, Lipophilicity | Absorption prediction, Blood-brain barrier penetration |

| log k(HSA) | Human Serum Albumin | Plasma protein binding | Volume of distribution, Free drug concentration |

| log k(AGP) | α-1-acid glycoprotein | Acute phase protein binding | Drug-drug interactions, Disease state adjustments |

| CHI log D | C18 with acetonitrile/water | Octanol-water distribution | Traditional lipophilicity estimation |

| PFI (Property Forecast Index) | C18 + aromatic ring count | ADME optimization | Compound selection and design |

The relationship between biomimetic retention and in vivo distribution can be modeled using the following equation for volume of distribution (Vd):

log Vd = a × log k(IAM) + b × log k(HSA) + c

where a, b, and c are coefficients determined by multivariate regression analysis of known drug molecules [18].

Quantitative Structure-Retention Relationships

The solvation parameter model provides a mechanistic basis for interpreting biomimetic retention data:

log k = c + eE + sS + aA + bB + vV

where capital letters represent solute descriptors (excess molar refraction, polarity/polarizability, hydrogen-bond acidity/basicity, McGowan volume) and lower-case letters are system constants reflecting complementary properties of the chromatographic system [19]. This model helps deconstruct the specific molecular interactions governing biological distribution.

Research Reagent Solutions

Table 2: Essential Materials for Biomimetic Chromatography Studies

| Reagent/Column | Supplier Examples | Function in Biomimetic Chromatography |

|---|---|---|

| IAM.PC.DD2 Column | Regis Technologies | Mimics phosphatidylcholine-rich cell membranes for phospholipid binding assessment |

| IAM.SPH Column | Regis Technologies | Sphingomyelin-based phase for modeling blood-brain barrier and neuronal tissue distribution |

| ChiralPak-HSA | Chiral Technologies (Daicel) | Human serum albumin column for plasma protein binding prediction |

| ChiralPak-AGP | Chiral Technologies (Daicel) | α-1-acid glycoprotein column for acute phase protein binding studies |

| Phosphatidylethanolamine (PE) Monolith | Academic sources [18] | Models lung tissue distribution (under development) |

| Ammonium acetate buffer | Various | Maintains physiological pH (7.4) in mobile phase |

| Formic acid | Various | Mobile phase additive for improved peak shape in LC-MS |

Workflow Visualization

Biomimetic Chromatography Screening Workflow

UFLC-DAD System Configuration

Applications in Drug Discovery

Property-Based Optimization

The integration of UFLC-DAD with biomimetic chromatography enables high-throughput characterization of critical drug properties early in discovery. By measuring CHI values on IAM columns and protein binding on HSA/AGP columns, researchers can:

- Predict volume of distribution using multivariate models incorporating IAM and HSA binding data [18]

- Estimate unbound drug fraction for PK/PD modeling

- Optimize blood-brain barrier penetration using sphingomyelin (SPH) stationary phases [18]

- Predict tissue-specific distribution using specialized phospholipid phases (e.g., PE columns for lung tissue) [18]

Toxicity Prediction

Recent applications extend to toxicity assessment, where biomimetic chromatographic data has been used to predict:

- Phospholipidosis potential through IAM retention parameters

- Cardiotoxicity risk via hERG channel binding correlations

- Aquatic toxicity for environmental impact assessment of pharmaceuticals and agrochemicals [18]

Natural Products Screening

UFLC-DAD systems with biomimetic columns facilitate rapid screening of complex natural product extracts, as demonstrated in studies of Fuling Decoction and Scutellaria baicalensis [21] [20] [22]. The method enables simultaneous identification, quantification, and property prediction of multiple constituents in significantly reduced analysis times compared to conventional HPLC.

The integration of biomimetic chromatography with UFLC-DAD technology provides a powerful, high-throughput platform for predicting physicochemical properties critical to drug discovery. The protocols outlined in this Application Note enable rapid characterization of membrane partitioning, protein binding, and lipophilicity using minimal compound quantities. As new biomimetic stationary phases continue to emerge—including sphingomyelin and phosphatidylethanolamine phases—the application scope continues to expand toward increasingly specific tissue distribution and toxicity predictions. This methodology represents a paradigm shift in early drug discovery, enabling property-based optimization that reduces late-stage attrition while aligning with the principles of the 3Rs (Replacement, Reduction, Refinement) in animal testing.

Methodological Applications: Implementing UFLC-DAD in ADMET Screening and Bioanalysis

Protocol Development for High-Throughput Lipophilicity (LogP/LogD) Assessment

Lipophilicity, quantified as the partition coefficient (Log P) for neutral compounds or the distribution coefficient (Log D) at a specific pH for ionizable species, is a fundamental physicochemical property in drug discovery. It profoundly influences a compound's absorption, distribution, metabolism, excretion, and toxicity (ADMET) profile [23] [24]. The gold standard for its experimental determination is the shake-flask method, which measures the equilibrium concentration of a solute between n-octanol and water phases [23] [24]. However, this method is labor-intensive, time-consuming, and requires relatively large amounts of pure compounds, making it unsuitable for modern high-throughput screening paradigms [25] [23].

To address these limitations, this application note details the development of a high-throughput protocol for lipophilicity assessment. The method is adapted from a published procedure that utilizes a 96-well format with a plasticized poly(vinyl chloride) polymer phase, offering a robust, resource-sparing, and automatable alternative to traditional methods [25]. This protocol is specifically framed within the context of employing Ultra-Fast Liquid Chromatography with a Diode Array Detector for quantitative analysis, aligning with the needs of high-throughput screening research.

High-Throughput Lipophilicity Measurement Principle

This protocol replaces the conventional n-octanol/water system with a biphasic system consisting of an aqueous phase and a plasticized poly(vinyl chloride) film phase [25]. The composition of the polymer phase is 2:1 (w/w) dioctyl sebacate plasticizer and PVC. The logarithmic polymer-water partition coefficient (Log P_pw) is determined by measuring the depletion of the solute from the aqueous phase after equilibration.

A key advantage of this method is the strong linear correlation established between Log Ppw and the conventional n-octanol/water partition coefficient (Log Pow). Studies have shown a correlation coefficient of 0.979, with a slope and intercept statistically indistinguishable from 1 and 0, respectively [25]. This correlation allows the measured Log Ppw values to be used for predicting Log Pow, effectively extending the method's applicability to predict the standard lipophilicity metric. Furthermore, the protocol can be straightforwardly adapted to determine the distribution coefficient (Log D) and the pKa of charged solutes by conducting experiments at different pH values [25].

Experimental Workflow

The diagram below illustrates the high-throughput workflow for the polymer-water partition coefficient assay.

The Scientist's Toolkit: Research Reagent Solutions

The following table lists the essential materials and reagents required to execute the high-throughput lipophilicity protocol.

Table 1: Essential Research Reagents and Materials for High-Throughput Log P Assessment

| Item | Function / Role in the Protocol | Exemplary Specifications / Notes |

|---|---|---|

| Poly(vinyl chloride) (PVC) | Polymer matrix forming the solid film phase. | High molecular weight, Selectophore grade [25]. |

| Dioctyl Sebacate (DOS) | Plasticizer for PVC; forms the lipophilic environment for partitioning. | Selectophore grade [25]. |

| Tetrahydrofuran (THF) | Solvent for dissolving PVC and DOS for film preparation. | HPLC grade [25]. |

| Polypropylene 96-Well Microplates | Platform for polymer film formation and the partitioning experiment. | Flat-bottom, chemical resistant [25]. |

| UV-Transparent 96-Well Microplates | Used for UV absorbance measurement of the aqueous phase. | Compatible with microplate reader [25]. |

| Microplate Sealing Film | Seals plates during equilibration to prevent solvent evaporation and contamination. | Adhesive, heat-sealing [25]. |

| UFLC System with DAD | For method development and analysis of samples from alternative Log P methods (e.g., shake-flask). | Enables fast analysis and quantification [26] [27]. |

| Microplate Shaker/Incubator | Provides controlled agitation and temperature during the equilibration step. | Capable of ~500 rpm, temperature control (e.g., 25°C) [25]. |

| Microplate Reader | Measures UV absorbance of the aqueous phase before and after equilibration. | Equipped with monochromators or filters for specific wavelengths [25]. |

Detailed Experimental Methodology

Preparation of Plasticized PVC Films

- Polymer Solution Preparation: Dissolve 1.67 g of PVC and 3.33 g of DOS in 200 mL of THF in a volumetric flask. This yields a 2:1 (w/w) DOS:PVC solution [25].

- Film Dispensing: Using a multi-channel pipette, dispense 100 µL of the PVC/DOS/THF solution into each well of a polypropylene 96-well microplate. The volume of the resulting film is approximately 2.5 µL per well [25].

- Solvent Evaporation: Place the microplate in a fume hood for approximately 6 hours to allow the THF to evaporate completely, leaving a solid, plasticized PVC film at the bottom of each well [25].

Sample Loading and Equilibration

- Solute Solution Preparation: Prepare aqueous solutions of the test compounds at a suitable concentration (e.g., 0.5 mM). Filter the solutions if necessary [25].

- Loading: Dispense 200 µL of the solute solution into each well containing the prepared PVC film.

- Sealing and Equilibration: Seal the microplate with an adhesive sealing film. Incubate the plate in a microplate shaker with controlled temperature (e.g., 25°C) and agitation (e.g., 500 rpm) for 4 hours to reach partitioning equilibrium [25].

Quantitative Analysis using UFLC-DAD

While the original protocol uses a microplate reader for direct UV measurement, the supernatant can also be analyzed by UFLC-DAD for enhanced specificity, particularly for complex mixtures or compounds with overlapping UV spectra. The workflow and parameters for UFLC-DAD analysis are summarized below.

Table 2: Key Validation Parameters for the Analytical Method (HPLC/UPLC-DAD) [26] [27]

| Validation Parameter | Target Acceptance Criteria | Application Note |

|---|---|---|

| Specificity | No interference from blank or other analytes; Peak purity > 950 (Similarity Index) [27]. | Ensures the analyte peak is unequivocally attributed to the target compound. |

| Linearity | Correlation coefficient (R²) > 0.999 [26] [27]. | Demonstrates a proportional relationship between concentration and detector response across the working range. |

| Accuracy | Recovery of 80-110% [26] [27]. | Measures the closeness of the measured value to the true value. |

| Precision (Repeatability) | Relative Standard Deviation (RSD) < 2% for intra-day [27]. | Assesses the agreement under the same operating conditions over a short interval. |

| LOD / LOQ | Signal-to-noise ratio of 3:1 for LOD and 10:1 for LOQ [26]. | Defines the lowest amount of analyte that can be detected or quantified with acceptable accuracy and precision. |

Data Processing and Calculation

- Concentration Determination: For the direct UV method, measure the UV absorbance of the initial solution (C₀) and the equilibrium supernatant (C₁) at the compound's λ_max. For the UFLC-DAD method, use the peak area from the chromatogram and a pre-established calibration curve to determine C₁.

Partition Coefficient Calculation: Calculate the polymer-water partition coefficient (P_pw) for each well using the following formula [25]:

P_pw = (C₀ - C₁) / C₁ × ΦWhere:

C₀= Initial solute concentration in the aqueous phase.C₁= Solute concentration in the aqueous phase at equilibrium.Φ= Phase ratio (Volume of aqueous phase / Volume of polymer film). For 200 µL aqueous phase and 2.5 µL film, Φ = 80.

Log Pow Prediction: Convert Ppw to its logarithm (Log Ppw). The Log Pow can be predicted from the established linear correlation: Log Pow ≈ Log Ppw [25]. For a more precise prediction, a calibration curve can be constructed using standard compounds with known Log P_ow values.

Discussion

Advantages of the High-Throughput Protocol

The described protocol offers significant advantages over traditional methods. Its primary benefit is dramatically increased throughput; with six replicates, Log P_pw values for 15 solutes can be determined in a single 96-well microplate within 4 hours [25]. The method is also resource-sparing, consuming minimal amounts of both the test compound and reagents, which is critical in early drug discovery [25] [28]. The entire process, from film preparation to quantification, is amenable to full automation using standard liquid handling systems and robotic platforms [25]. Furthermore, the method is highly flexible, as it can be easily adapted to measure distribution coefficients (Log D) at various pH levels and to determine the pKa of ionizable compounds [25].

Limitations and Considerations

Despite its advantages, researchers must be aware of certain limitations. The method relies on an empirical correlation between Log Ppw and Log Pow. While demonstrated to be statistically robust for a range of compounds, the correlation should be verified for novel chemical entities [25]. The method also depends on accurate UV absorbance or chromatographic quantification, which requires the analyte to possess a chromophore and be stable in aqueous solution during the equilibration period. Finally, the kinetics of partitioning must be established for new compound classes to ensure equilibrium is reached within the designated 4-hour incubation time [25].

Concluding Remarks

This application note provides a detailed protocol for a high-throughput method to assess lipophilicity, framed within the context of UFLC DAD techniques. By leveraging a 96-well format and a plasticized polymer phase, this approach effectively addresses the need for speed, efficiency, and minimal compound consumption in modern drug discovery screening campaigns. The method is robust, viable, and represents a significant advancement over the classical shake-flask technique, facilitating the rapid prioritization of lead compounds based on a critical ADMET-related property.

In modern drug discovery, the early screening of pharmacokinetic properties is paramount for identifying viable candidate molecules. Among these properties, plasma protein binding (PPB) and metabolic stability are critical determinants of a drug's fate in vivo [29]. High PPB can significantly reduce the concentration of free, pharmacologically active drug available to diffuse into tissues, while rapid metabolic clearance can lead to poor oral bioavailability and a short duration of action [30]. The integration of Ultra-Fast Liquid Chromatography (UFLC) with diode array detection (DAD) and mass spectrometry (MS) has revolutionized high-throughput screening for these parameters. These automated, robust, and sensitive platforms enable the efficient handling of large compound sets, providing the high-quality data necessary for advanced computational modeling and informed decision-making in lead optimization [31] [32]. This application note details standardized protocols for the assessment of PPB and metabolic stability, framed within the context of UFLC-DAD for high-throughput screening research.

Experimental Design and Workflow

A streamlined workflow is essential for the successful high-throughput screening of pharmacokinetic properties. The following diagram illustrates the integrated experimental workflow for simultaneous assessment of plasma protein binding and metabolic stability.

Detailed Experimental Protocols

Protocol 1: Plasma Protein Binding (PPB) via Equilibrium Dialysis

Plasma protein binding determines the fraction of unbound drug available for pharmacological activity and is typically assessed using equilibrium dialysis [29] [30].

3.1.1 Materials and Reagents

- Control human, rat, or dog plasma (EDTA-K2 anticoagulant) [29]

- Test compound and internal standard (e.g., vardenafil) [29]

- Equilibrium dialysis membranes (molecular mass cut-off: 0.8–14 kDa) [29]

- Potassium phosphate buffer (100 mM, pH 7.4) [29]

- UPLC/MS-grade acetonitrile, methanol, and formic acid [31] [29]

3.1.2 Procedure

- Preparation of Solutions: Prepare stock solutions of the test compound at 10 mM in DMSO. Subsequently, dilute the compound in acetonitrile:water (1:1, v/v) to create working solutions [29].

- Spiking of Plasma: Spike 450 µL of blank plasma with 50 µL of the working solution to achieve the desired final concentration (e.g., 1-5 µM) [29].

- Dialysis Setup: Load the spiked plasma into one chamber of the dialysis apparatus, separated by a semi-permeable membrane from the other chamber containing an equal volume of phosphate buffer.

- Incubation: Incubate the dialysis apparatus at 37°C with gentle agitation for a predetermined period (typically 4-24 hours) to reach equilibrium [29].

- Sample Collection: Post-incubation, collect aliquots from both the plasma and buffer chambers.

- Sample Processing: Precipitate proteins in the plasma aliquot by adding a chilled solution of acetonitrile containing an internal standard (e.g., albendazole). Centrifuge the samples at 3000 rpm for 20 minutes at 6°C to remove precipitated proteins [31] [29].

- Analysis: Inject the supernatant (or a dilution thereof) into the UFLC-DAD/MS system for quantification of the compound in both matrices.

3.1.3 Data Calculation The fraction of unbound drug (( fu )) is calculated using the formula: ( fu = \frac{C{buffer}}{C{plasma}} ) where ( C{buffer} ) and ( C{plasma} ) are the measured concentrations of the drug in the buffer and plasma chambers, respectively, after equilibrium has been reached. The percentage of plasma protein binding is then calculated as: ( \%PPB = (1 - f_u) \times 100 ).

Protocol 2: Metabolic Stability in Liver Microsomes

The metabolic stability assay measures the innate stability of a compound with respect to hepatic metabolism, most commonly using the substrate depletion method to determine intrinsic clearance (( CL_{int} )) [31] [30].

3.2.1 Materials and Reagents

- Pooled human, rat, or dog liver microsomes (e.g., BD Gentest) [31] [29]

- NADPH regenerating solution (Solution A/B) [31]

- Potassium phosphate buffer (100 mM, pH 7.4) [31]

- Test compounds and control compounds (e.g., ketoconazole, buspirone) [31]

- UPLC/MS-grade water, acetonitrile, and formic acid [31]

3.2.2 Automated Incubation Procedure The following procedure can be efficiently handled by a robotic system (e.g., Tecan EVO 200) in a 384-well format [31].

- Pre-incubation: Pipette 82.73 µL of diluted liver microsomes (e.g., 3 pmol of CYP3A4) into the incubation plate pre-heated to 37°C.

- Time Zero (T0) Sample Preparation: Aspirate 40 µL of chilled acetonitrile containing the internal standard into a fresh T0 plate. After the 5-minute pre-incubation, add 2.27 µL of the test compound (50 µM in ACN) to the microsomal mixture. Immediately after mixing, transfer a 7.5 µL aliquot to the T0 plate to quench the reaction at time zero [31].

- Initiation of Reaction: Add 25 µL of NADPH regenerating solution to the incubation plate to initiate the metabolic reaction. The final concentration of the test compound is typically 1 µM [31].

- Sampling at Multiple Time Points: At predetermined time points (e.g., 5, 10, 15, 30, and 60 minutes), transfer a 9.92 µL aliquot of the incubation mixture to fresh plates containing 40 µL of chilled acetonitrile with internal standard to stop the reaction [31].

- Sample Cleanup: Seal all plates, centrifuge at 3000 rpm for 20 minutes at 6°C to pellet precipitated proteins, and prepare the supernatant for analysis [31].

3.2.3 UFLC-DAD/MS Analysis

- Chromatography: Utilize a UHPLC system (e.g., Waters Acquity) with a reversed-phase column (e.g., BEH Shield RP18, 1.7 µm, 2.1 × 50 mm). The mobile phase typically consists of (A) water with 0.1% formic acid and (B) acetonitrile with 0.1% formic acid. A gradient elution is employed at a flow rate of 0.6 mL/min [31] [33].

- Detection: For metabolic stability, tandem mass spectrometry (MS/MS) with a triple quadrupole mass analyzer operating in Multiple Reaction Monitoring (MRM) mode is recommended for its high sensitivity and selectivity [31] [33]. Electrospray ionization (ESI) in positive mode is commonly used.

- Data Acquisition: Monitor the depletion of the parent compound over time. The percent remaining at each time point is calculated by comparing the peak area ratio (analyte/internal standard) to the T0 sample [31].

3.2.4 Data Analysis and Calculation of ( CL{int} ) The natural logarithm of the percent remaining is plotted against time. The slope (( k )) of the linear regression represents the *in vitro* depletion rate constant. The *in vitro* half-life (( t{1/2} )) is calculated as: ( t{1/2} = \frac{ln(2)}{k} ). Intrinsic clearance (( CL{int} )) is then derived as: ( CL{int} = \frac{ln(2)}{t{1/2}} \times \frac{incubation\ volume}{microsomal\ protein} ) [31].

Table 1: Key Parameters for UFLC-DAD/MS Analysis of Metabolic Stability and PPB

| Parameter | Specification | Application Notes |

|---|---|---|

| Chromatographic System | UFLC/UHPLC (e.g., Waters Acquity) | Enables rapid separation with high resolution [31] |

| Analytical Column | C18 column (e.g., 1.7-1.8 µm, 2.1 x 50 mm) | Provides efficient separation for small molecules [31] [33] |

| Mobile Phase | (A) Water + 0.1% Formic Acid; (B) ACN + 0.1% Formic Acid | Formic acid enhances ionization in positive ESI mode [31] [33] |

| Flow Rate | 0.3 - 0.6 mL/min | Optimized for speed and backpressure [31] [33] |

| Mass Spectrometer | Triple Quadrupole (TQD) | Preferred for high-sensitivity quantification in MRM mode [31] [33] |

| Ion Source | Electrospray Ionization (ESI) | Suitable for a wide range of drug-like molecules [32] |

| Ionization Mode | Positive Ion Mode | Commonly used for basic and neutral compounds [33] |

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful execution of these assays relies on a suite of specialized reagents and materials.

Table 2: Essential Research Reagents and Materials for PPB and Metabolic Stability Studies

| Reagent/Material | Function | Examples & Specifications |

|---|---|---|

| Liver Microsomes | Source of metabolic enzymes (CYPs, UGTs) for stability assays | Pooled human, rat, or dog liver microsomes (e.g., BD Gentest); stored at -70°C [31] [29] |

| NADPH Regenerating System | Cofactor for cytochrome P450-mediated oxidation reactions | Contains NADP+, isocitrate, and isocitrate dehydrogenase to maintain constant NADPH levels [31] [29] |

| Equilibrium Dialysis Device | Physically separates protein-bound and free drug for PPB assessment | Membranes with a molecular cut-off of 0.8-14 kDa [29] |

| Biological Matrices | Provide the physiological environment for in vitro tests | Control plasma (e.g., from Bioreclamation) and liver microsomes from relevant species [29] |

| Internal Standards | Correct for variability in sample processing and ionization | Stable isotope-labeled internal standards (SIL-IS) are ideal; others like albendazole or flavopiridol are also used [31] [33] |

| Protein Precipitation Solvents | Denature and precipitate proteins to clean up samples | Chilled acetonitrile or methanol, often spiked with an internal standard [31] |

Data Interpretation and Application

The data generated from these assays are used to rank-order compounds and predict in vivo performance.

Table 3: Interpretation of Metabolic Stability and Plasma Protein Binding Data

| Parameter | Value Range | Interpretation | Reported Example |

|---|---|---|---|

| In Vitro Half-Life (( t_{1/2} )) | ( t_{1/2} < 10\ min ) | High clearance, short-lived in vivo [31] | Buspirone, Loperamide [31] |

| ( 10 < t_{1/2} < 30\ min ) | Moderate clearance [31] | Ketoconazole [31] | |

| ( t_{1/2} > 30\ min ) | Low clearance, favorable for once-daily dosing [31] | Carbamazepine, Antipyrine [31] | |

| Intrinsic Clearance (( CL_{int} )) | High ( CL_{int} ) | Low predicted oral bioavailability | Dog microsomes: 0.1204 mL/min/mg (NHPPC) [29] |

| Low ( CL_{int} ) | High predicted oral bioavailability | Human microsomes: 0.0214 mL/min/mg (NHPPC) [29] | |

| Plasma Protein Binding (PPB) | ( PPB > 95\% ) | Low free drug concentration; may limit efficacy or drive drug-drug interactions | NHPPC: 99.4% in human, 99.6% in dog [29] |

| ( PPB < 90\% ) | Generally sufficient free drug for pharmacological activity | -- |

The relationship between assay data and downstream decision-making is summarized in the following workflow:

The integration of robust, high-throughput UFLC-DAD/MS methods for assessing plasma protein binding and metabolic stability is a cornerstone of modern drug discovery. The automated protocols described herein, capable of handling thousands of compounds as demonstrated for CYP3A4 [31], provide critical early-stage data on key pharmacokinetic parameters. This data directly fuels lead optimization cycles, enabling medicinal chemists to design compounds with improved drug-like properties. By applying these standardized workflows, researchers can significantly de-risk the development pipeline, increase the likelihood of clinical success, and ultimately deliver more effective and safer therapeutics to patients.

Ultra-Fast Liquid Chromatography (UFLC) coupled with Diode Array Detection (DAD) represents a powerful analytical platform for the quantification of bioactive compounds in complex matrices. This technique is indispensable in modern phytochemical analysis, quality control of herbal medicines, and drug discovery research, where it enables rapid separation and reliable quantification of target analytes amidst intricate sample backgrounds. The need for robust, high-throughput methods is particularly critical given the expanding market for plant-based food supplements and the increasing demand for natural products in drug development [34] [35]. This application note details standardized protocols for UFLC-DAD method development, validation, and application across diverse sample types, providing researchers with executable methodologies for their analytical workflows.

Analytical Techniques and Instrumentation

Core Principles of UFLC-DAD

UFLC-DAD combines the superior separation efficiency of ultra-fast liquid chromatography with the versatile detection capabilities of diode array technology. The system operates with core-shell particle columns (typically 100-150 mm × 2.1-3.0 mm, 1.7-2.7 μm particle size) that provide enhanced efficiency at lower back pressures compared to fully porous particles [34] [35]. The DAD detector simultaneously records absorbance across a broad wavelength spectrum (190-800 nm), enabling peak purity assessment and compound identification through spectral matching.

The technique's robustness stems from its ability to maintain resolution while significantly reducing analysis time. For instance, conventional HPLC methods for curcuminoid analysis require 20-60 minutes, whereas optimized UFLC-DAD methods achieve complete separation of curcuminoids and piperine in under 12 minutes [34]. This efficiency makes UFLC-DAD particularly valuable for high-throughput screening environments where analytical speed and reliability are paramount.

UFLC-DAD Workflow for Bioactive Compound Analysis

The following diagram illustrates the complete analytical workflow from sample preparation to data analysis:

Experimental Protocols

Protocol 1: Analysis of Curcuminoids and Piperine in Food Supplements