UFLC-DAD in Pharmaceutical Analysis: Practical Applications, Method Development, and Validation for Modern Labs

This article provides a comprehensive overview of the practical applications of Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) in pharmaceutical analysis.

UFLC-DAD in Pharmaceutical Analysis: Practical Applications, Method Development, and Validation for Modern Labs

Abstract

This article provides a comprehensive overview of the practical applications of Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) in pharmaceutical analysis. Tailored for researchers, scientists, and drug development professionals, it explores the foundational principles of UFLC-DAD, details its methodological use in quantifying active ingredients and studying drug release, addresses common troubleshooting and optimization strategies, and establishes its validity through comparative analysis with other techniques. The content synthesizes current research and case studies to offer a actionable guide for implementing robust, efficient, and compliant UFLC-DAD methods in quality control and research laboratories.

UFLC-DAD Fundamentals: Principles, Advantages, and Core Components for Pharmaceutical Scientists

Core Principles of Ultra-Fast Liquid Chromatography (UFLC) and Diode Array Detection (DAD)

Core Principles and Instrumentation

Ultra-Fast Liquid Chromatography (UFLC) represents an advanced evolution of High-Performance Liquid Chromatography (HPLC), engineered to achieve superior speed and resolution through operational pressures that can exceed conventional HPLC limits. When integrated with Diode Array Detection (DDA), this technique becomes a powerful tool for the comprehensive analysis of complex pharmaceutical mixtures.

Table 1: Key Operational Principles of UFLC and DAD

| Principle | Technical Description | Impact on Pharmaceutical Analysis |

|---|---|---|

| Reduced Particle Size | Utilization of sub-2-micron particle packing in analytical columns [1]. | Dramatically enhances chromatographic efficiency and resolution, enabling separation of structurally similar impurities and degradation products. |

| Increased Pressure Tolerance | System capability to withstand pressures up to 1300 bar (approx. 19,000 psi) [1]. | Facilitates the use of longer columns or faster flow rates for separating complex samples, such as protein digests or synthetic intermediates. |

| High-Speed Scanning DAD | Simultaneous acquisition of spectra across a range of wavelengths (e.g., 190-800 nm) [2]. | Provides spectral confirmation of analyte identity and checks peak purity, which is critical for method specificity in regulatory submissions. |

| Binary Pumps & Low-Dispersion Flow Paths | Advanced pumping systems that deliver highly accurate mobile phase compositions with minimal delay volume [1]. | Essential for achieving sharp peaks and reproducible retention times in fast, shallow gradients, improving throughput in quality control (QC) labs. |

| Biocompatible Flow Paths | Use of MP35N, gold, ceramic, and special polymers in the fluidic path [1]. | Allows for the direct analysis of biomolecules like proteins and peptides without sample degradation or metal adsorption, streamlining biopharmaceutical analysis. |

Experimental Protocol: Method Development for Pharmaceutical Mixtures

The following protocol details a streamlined approach for developing a UFLC-DAD method suitable for separating a mixture of small molecule pharmaceuticals or their metabolites, incorporating both automated and manual screening strategies.

Materials and Reagents

- Analytical Standards: Target analytes (e.g., drug substance and known impurities).

- Mobile Phase A: High-purity water with 0.1% (v/v) formic acid.

- Mobile Phase B: HPLC-grade acetonitrile with 0.1% (v/v) formic acid.

- Columns: A selection of 3-5 reversed-phase C18 columns (e.g., 50-100 mm length, 2.1 mm internal diameter, 1.7-1.8 µm particle size) from different manufacturers to assess selectivity.

- Equipment: UFLC system equipped with a binary pump, autosampler, thermostatted column compartment, and DAD.

Procedure

Initial Automated Scouting (Optional but Recommended)

- Employ automated method development software if available. Tools like ChromSword can automate column and mobile phase screening [3].

- The software uses an AI-based algorithm to perform iterative injections, automatically adjusting the gradient based on previous results to rapidly identify the optimal starting conditions for selectivity and resolution [3].

Manual Column and Mobile Phase Screening

- If automated screening is not available, systematically screen the different C18 columns.

- For each column, perform an initial fast generic gradient (e.g., 5% B to 95% B over 10 minutes) at a flow rate of 0.4-0.6 mL/min and a column temperature of 40°C.

- Monitor the separation using the DAD, acquiring spectra from 200 nm to 400 nm for all peaks.

Gradient Optimization

- Based on the best separation from the initial screen, use computer-assisted retention modeling or empirical testing to fine-tune the gradient slope, temperature, and mobile phase pH.

- The goal is to achieve baseline resolution for all critical peak pairs (resolution, Rs > 1.5) in the shortest possible runtime. A feedback-controlled optimization strategy can significantly reduce the time required for this step [3].

DAD-Specific Method Setup

- After establishing the separation, select the most appropriate wavelength for quantification based on the absorbance spectra of each analyte to maximize sensitivity.

- Implement peak purity analysis by comparing spectra across the peak (at the upslope, apex, and downslope) to ensure each peak represents a single, pure compound [2].

Method Validation

- Validate the final method according to ICH guidelines, assessing parameters including linearity, precision, accuracy, limit of detection (LOD), and limit of quantification (LOQ) [2].

| Validation Parameter | Result for SCFA Analysis |

|---|---|

| Precision (Coefficient of Variance) | ≤ 2.5% |

| Linearity (Determination Coefficient, R²) | > 0.997 |

| Limit of Detection (LOD) | 0.01 - 0.80 mmol/kg |

| Limit of Quantification (LOQ) | 0.04 - 2.64 mmol/kg |

| Recovery | 90 ± 2% to 106 ± 2% |

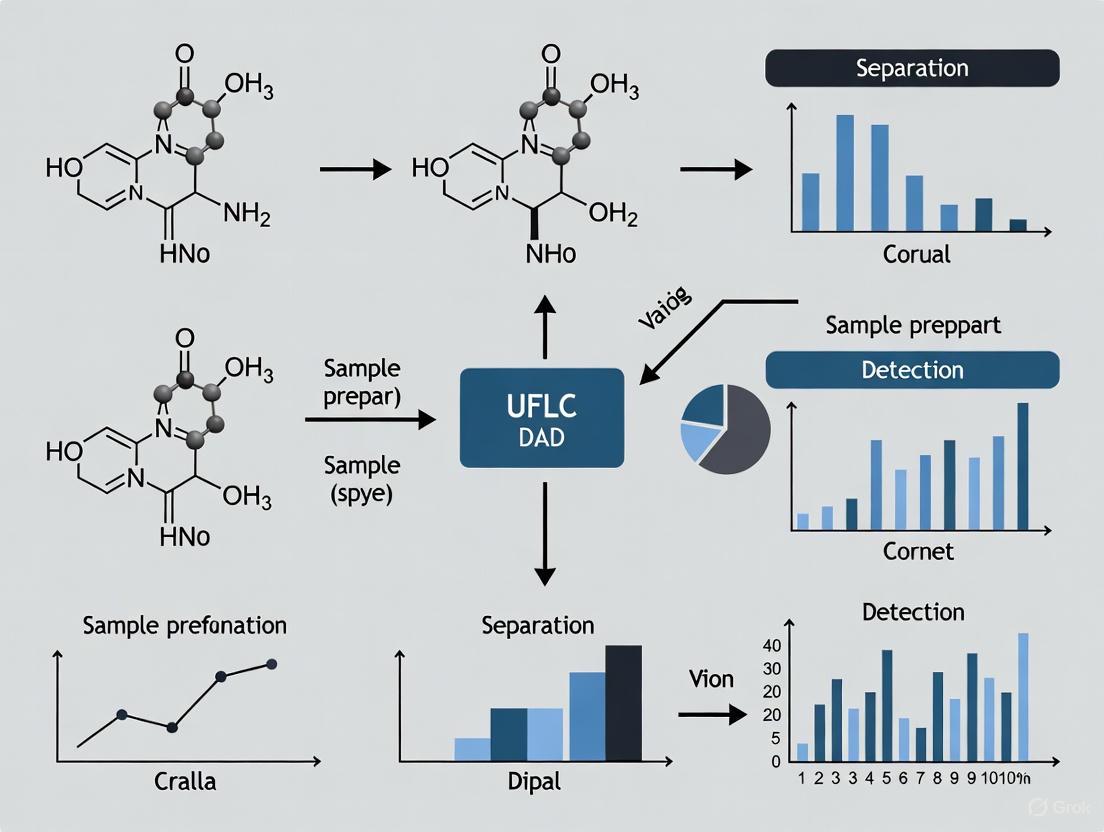

Workflow Visualization

UFLC-DAD Method Development Workflow

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials and Reagents for UFLC-DAD Analysis

| Item | Function & Importance | Example/Specification |

|---|---|---|

| UHPLC Columns | The stationary phase where chemical separation occurs. Small, solid particles are critical for achieving high efficiency and fast separations [1]. | Reversed-phase C18, 50-100 mm long, 1.7-1.8 µm particle size. |

| Mass Spectrometry-Grade Solvents | Form the mobile phase. High purity is essential to minimize baseline noise and prevent detector contamination, ensuring high sensitivity. | Acetonitrile and Water with low UV cutoff and minimal particulate matter. |

| Ion-Pairing & pH Modifiers | Additives that modify mobile phase properties to control ionization of analytes, improving peak shape and selectivity for ionizable compounds. | Trifluoroacetic Acid (TFA), Formic Acid, Ammonium Formate/Bicarbonate. |

| System Suitability Standards | A mixture of known compounds used to verify that the entire chromatographic system is performing adequately before sample analysis. | USP standards or custom mixes of APIs and related compounds. |

| Biocompatible Seal Kits | Replacement seals and components designed for use with high-pH mobile phases or to prevent leaching of metal ions when analyzing biomolecules. | MP35N, gold-pled, or ceramic components [1]. |

Ultra-Fast Liquid Chromatography (UFLC) coupled with Diode Array Detection (DAD) represents a significant technological evolution in analytical chromatography, offering substantial improvements over traditional High-Performance Liquid Chromatography (HPLC) for pharmaceutical analysis. UFLC systems achieve enhanced performance primarily through the use of columns packed with smaller particles (typically sub-2 µm) and instrumentation capable of operating at significantly higher pressures [4]. This configuration, combined with the versatile detection capabilities of DAD, provides pharmaceutical researchers with a powerful tool for method development, quality control, and regulatory compliance.

The core principle of UFLC builds upon the van Deemter equation, which describes the relationship between flow rate and plate height (HETP). By utilizing smaller stationary phase particles, UFLC minimizes the contributions of eddy diffusion (A-term) and mass transfer resistance (C-term), resulting in a flatter van Deemter curve [4]. This theoretical foundation enables operation at higher linear velocities without sacrificing efficiency, directly translating to the key practical advantages of speed, sensitivity, and solvent economy that form the focus of this application note.

Core Advantages: Quantitative Comparison

The operational benefits of UFLC-DAD can be quantitatively demonstrated through direct comparison with conventional HPLC systems. The following table summarizes key performance metrics that highlight these advantages.

Table 1: Quantitative Performance Comparison: UFLC vs. Traditional HPLC

| Performance Parameter | Traditional HPLC | UFLC Systems | Advantage Factor |

|---|---|---|---|

| Operating Pressure | Typically < 600 bar | Up to 1300 bar [1] | ~2x increase |

| Particle Size | 3–5 µm | 1.7–2.5 µm [4] | ~2-3x reduction |

| Analysis Time | Baseline (e.g., 30 min) | Up to 9x reduction [5] | 3x to 9x faster |

| Solvent Consumption | Baseline | Up to 90% reduction [5] | Significant saving |

| Flow Rate Range | Broader ranges | Optimized for low flow (e.g., 0.2–0.5 mL/min) [6] | Enhanced efficiency |

Enhanced Speed and Throughput

The reduction in analysis time is one of the most impactful advantages of UFLC. By using sub-2 µm particles and higher pressures, UFLC systems can achieve separations 3 to 9 times faster than chromatographic systems using 5 µm particle-size packed columns [5]. This dramatic increase in speed directly enhances laboratory throughput, enabling a significantly higher number of analyses per unit time. This is crucial in pharmaceutical development for applications like high-throughput screening, dissolution testing, and stability studies, where rapid method execution accelerates decision-making and reduces time-to-market for new therapeutics.

Superior Sensitivity and Resolution

The smaller particle size and optimized flow path in UFLC systems contribute to narrower and sharper chromatographic peaks [5]. This peak shape results in a higher signal-to-noise ratio and lower detection limits, thereby improving overall method sensitivity. The DAD detector further augments this by acquiring full UV-Vis spectra for each peak, providing a second dimension of data for peak purity assessment and identity confirmation. This combination is invaluable for detecting and quantifying low-abundance impurities and degradation products in complex pharmaceutical matrices.

Significant Solvent Economy

The shift to UFLC brings substantial reductions in solvent consumption, often cited as up to 90% compared to conventional HPLC methods [5]. This economy is achieved through shorter run times, narrower-bore columns, and optimized low flow rates (e.g., 0.2–0.5 mL/min) [6]. This aligns with the principles of Green Analytical Chemistry (GAC), minimizing environmental impact and waste generation while also reducing operational costs associated with solvent purchase and disposal [7].

Experimental Protocol: Determination of Active Pharmaceutical Ingredients and Related Substances

This protocol details a representative method for the simultaneous assay and impurity determination of a drug substance using UFLC-DAD, adaptable for various small-molecule pharmaceuticals.

Research Reagent Solutions

Table 2: Essential Materials and Reagents

| Item | Specification / Function |

|---|---|

| UFLC System | Binary or quaternary pump capable of ≥ 1000 bar pressure [1]. |

| DAD Detector | Capable of scanning 200-400 nm; configured for low-volume flow cells. |

| Analytical Column | C18, 100 x 2.1 mm, 1.7–1.8 µm particle size [4]. |

| Mobile Phase A | 0.1% Formic acid or appropriate buffer in high-purity water. |

| Mobile Phase B | 0.1% Formic acid in acetonitrile (HPLC grade). |

| Standard Solution | Accurate weight of reference standard dissolved in diluent. |

| Sample Solution | Test sample prepared at appropriate concentration. |

Chromatographic Conditions and Sample Preparation

- Chromatographic System: Shimadzu i-Series UFLC or equivalent, equipped with DAD.

- Column Temperature: 40 °C.

- Mobile Phase: Gradient elution using Water:Acetonitrile with 0.1% Formic Acid [6].

- Gradient Program: Time (min) / %B: 0/5, 1.0/5, 8.0/95, 9.0/95, 9.1/5, 12.0/5.

- Flow Rate: 0.4 mL/min.

- Injection Volume: 2 µL.

- DAD Settings: Acquisition range: 200-400 nm; Primary monitoring wavelength: 254 nm.

- Sample Preparation:

- Standard Solution: Accurately weigh about 10 mg of drug reference standard into a 10 mL volumetric flask. Dissolve and dilute to volume with a mixture of water and acetonitrile (50:50, v/v) to obtain a 1 mg/mL stock solution. Further dilute as needed.

- Test Solution: Prepare the sample (tablet powder, capsule content, or drug substance) at a concentration of approximately 1 mg/mL in the same diluent.

System Suitability and Analysis

- System Equilibration: Stabilize the system with initial mobile phase conditions for at least 10 column volumes or until a stable baseline is achieved.

- System Suitability Test: Make six replicate injections of the standard solution. The relative standard deviation (RSD) for the peak area of the active ingredient should be ≤ 1.0%. The number of theoretical plates should be > 10,000.

- Sample Analysis: Inject the standard solution followed by the test solution. Record the chromatograms and spectra for the active peak and any impurity peaks.

- Data Processing: Integrate the peaks and calculate the assay content using the formula:

- Assay (%) = (AT / AS) x (CS / CT) x 100

- Where AT and AS are the peak areas of the analyte in the test and standard solutions, respectively, and CT and CS are their concentrations.

The workflow for this analytical procedure is outlined below.

Advanced Application: Forced Degradation Studies

Forced degradation (stress testing) is a critical application of UFLC-DAD in pharmaceutical development, used to elucidate the stability profile of a drug substance.

Protocol for Stress Testing

- Sample Preparation: Subject the drug substance to various stress conditions:

- Acidic Hydrolysis: Expose to 0.1M HCl at 60°C for 1-4 hours.

- Basic Hydrolysis: Expose to 0.1M NaOH at 60°C for 1-4 hours.

- Oxidative Degradation: Expose to 3% H₂O₂ at room temperature for 1-4 hours.

- Thermal Degradation: Heat solid sample at 80°C for 24 hours.

- Photodegradation: Expose to UV light as per ICH guidelines [8].

- Analysis: After neutralizing or quenching the reactions, prepare samples at appropriate concentrations and analyze using the UFLC-DAD method described in Section 3.2.

- Data Interpretation: Use the DAD's spectral capabilities to compare the UV spectra of the main peak and all degradation peaks. This helps in identifying potential degradation products and assessing peak purity, which is vital for establishing the stability-indicating power of the method.

UFLC-DAD technology provides a robust, efficient, and environmentally conscious platform for modern pharmaceutical analysis. The demonstrated advantages of speed, sensitivity, and solvent economy directly address the core needs of drug development laboratories striving for higher productivity, superior data quality, and sustainable practices. The protocols outlined herein provide a practical framework for scientists to implement this powerful technique for routine quality control and advanced research applications, contributing significantly to the overarching goal of ensuring drug safety and efficacy.

Ultra-Fast Liquid Chromatography coupled with Diode Array Detection (UFLC-DAD) represents a significant advancement in analytical technology for pharmaceutical research and development. This instrumentation enables researchers to achieve superior separation efficiency, faster analysis times, and comprehensive spectral data collection for compound identification and quantification. The integration of high-pressure fluidics, advanced separation columns, and multi-wavelength detection provides a powerful platform for analyzing complex pharmaceutical compounds, from active pharmaceutical ingredients (APIs) to impurities and degradation products. The practical application of UFLC-DAD has become indispensable in modern drug development, quality control, and stability studies, offering the robustness, sensitivity, and reproducibility required to meet stringent regulatory standards. This deep dive explores the critical hardware components that constitute a UFLC-DAD system and their specific roles in pharmaceutical analysis, providing researchers with the foundational knowledge necessary to optimize analytical methods and troubleshoot instrumental challenges.

Core UFLC-DAD System Architecture

A UFLC-DAD system is an integrated instrument comprising several specialized components that work in concert to separate, detect, and quantify chemical compounds. The system operates with significantly higher pressure capabilities (typically up to 1300 bar or 18,850 psi) compared to conventional High-Performance Liquid Chromatography (HPLC), enabling the use of smaller particle size columns (<2 μm) for improved resolution and faster separations. The fundamental workflow involves the mobile phase transporting the sample through the system under high pressure, separation of components on the chromatographic column, and subsequent detection across a range of wavelengths in the DAD. Each hardware component plays a critical role in ensuring the accuracy, precision, and reliability of pharmaceutical analysis, from method development and stability studies to quality control of finished drug products and bioavailability studies. Understanding the specific function, operational parameters, and technical specifications of each component is essential for researchers to fully leverage the capabilities of UFLC-DAD technology in addressing complex analytical challenges in pharmaceutical sciences.

Table 1: Core UFLC-DAD System Components and Their Pharmaceutical Applications

| System Component | Key Function | Technical Specifications | Pharmaceutical Application Relevance |

|---|---|---|---|

| Solvent Delivery Pump | Generates high pressure for mobile phase delivery | Pressure up to 1300 bar; flow rate precision <0.1% RSD; programmable composition | Enables fast separations with sub-2μm particles; critical for high-throughput analysis of multiple samples |

| Autosampler | Introduces precise sample volumes into mobile phase stream | Injection volume precision <0.5% RSD; temperature control (4-40°C); carryover <0.05% | Ensures reproducible sample introduction for quantitative analysis; maintains sample integrity |

| Column Oven | Maintains stable temperature for separation column | Temperature range: ambient-100°C; stability ±0.1°C | Improves retention time reproducibility; optimizes separation efficiency for temperature-sensitive compounds |

| DAD Detector | Simultaneous multi-wavelength detection with spectral scanning | Wavelength range: 190-800 nm; resolution: 1-4 nm; sampling rate: up to 100 Hz | Provides spectral confirmation of compound identity; peak purity assessment; method specificity |

Critical Hardware Components and Their Technical Specifications

Solvent Delivery System

The solvent delivery system, typically a binary or quaternary high-pressure pump, is the cornerstone of any UFLC-DAD instrument. Modern systems like the Shimadzu i-Series and Agilent Infinity III LC series incorporate advanced pumping technologies capable of maintaining stable flow rates against back-pressures up to 1300 bar, which is essential for utilizing columns packed with sub-2μm particles. These systems feature dual piston in-series or parallel designs with active damper chambers to minimize flow and pressure pulsations, ensuring a stable baseline for sensitive detection. The pumping systems include degassing capabilities, either inline or through built-in membrane degassers, to prevent bubble formation that can disrupt detection stability. For pharmaceutical applications requiring high precision in gradient elution, the dwell volume (delay between gradient formation and arrival at column) is minimized (typically 100-500 μL) to improve method transferability between different systems. Modern pumps also incorporate leak detection sensors, pressure monitoring with automatic shutdown capabilities, and corrosion-resistant materials (e.g., MP35N, titanium, or ceramic) for compatibility with a wide range of mobile phases including high-salt buffers and acidic conditions commonly used in pharmaceutical analysis [1].

Autosampler Technology

Modern UFLC autosamplers, such as the Knauer Analytical Liquid Handler LH 8.1, are engineered for high precision and minimal carryover, which is critical for quantitative pharmaceutical analysis. These systems employ various injection mechanisms including flow-through needle, fixed-loop, and dynamic loading designs. Key technical considerations include injection volume accuracy (typically <0.5% RSD for volumes from 0.1-100 μL), temperature-controlled sample compartments (4-40°C) to maintain sample stability, and wash protocols to minimize carryover between injections (<0.005%). Advanced systems feature multiple sample tray configurations accommodating vials, microplates, and deep-well plates for high-throughput applications. For regulated pharmaceutical laboratories, compliance features including sample tracking (barcode/RFID readers), audit trails, and integration with chromatography data systems (CDS) are essential. The autosampler's ability to maintain sample integrity, provide precise injection volumes, and minimize cross-contamination directly impacts the quality and reliability of pharmaceutical analytical data, particularly for low-dose compounds and trace impurity analysis [1].

Separation Column Technology

The chromatographic column is where actual separation of pharmaceutical compounds occurs, making its selection critical for method development. UFLC columns are typically shorter (50-100 mm) with smaller internal diameters (2.1-3.0 mm) packed with sub-2μm particles to maximize efficiency under ultra-high pressure conditions. Stationary phase chemistry selection depends on the analytical application: reversed-phase C18 columns are most common for neutral and moderately polar compounds; phenyl-hexyl phases offer alternative selectivity for aromatic compounds; HILIC columns separate polar compounds; and charged surface hybrid (CSH) technology provides improved peak shape for basic compounds. Column materials include stainless steel for high-pressure compatibility, and titanium or PEEK-lined for bio-compatibility or ion analysis. Column oven technology maintains stable temperature (±0.1°C) to ensure retention time reproducibility, with some systems offering active pre-heating of mobile phase before it enters the column. For pharmaceutical laboratories analyzing multiple compounds, switching valves enable method-specific column selection or two-dimensional chromatography for complex separations [9] [10].

Diode Array Detector (DAD) Optics and Flow Cells

The DAD represents a significant advancement over single-wavelength UV detectors by simultaneously capturing full UV-Vis spectra for each data point across the chromatogram. Key components include a deuterium lamp (190-400 nm) and tungsten lamp (400-800 nm) as light sources, a diffraction grating to disperse light across the diode array (typically 512-1024 diodes), and a flow cell where detection occurs. Technical specifications critical for pharmaceutical applications include wavelength accuracy (±1 nm), photometric accuracy (±5 mAU), baseline noise (<±0.1 mAU), and stray light (<0.02%). Flow cell design balances path length (typically 10-60 mm) against pressure tolerance and dispersion volume, with modern cells featuring bubble traps, reduced volume (≤500 nL) to maintain chromatographic efficiency, and high-pressure ratings (>200 bar). The DAD's ability to collect full spectra enables peak purity analysis through spectral overlay, identification of unknown peaks by library matching, and selection of optimal wavelengths for quantification post-analysis. These capabilities are particularly valuable for method development, forced degradation studies, and impurity profiling in pharmaceutical analysis [9] [10] [11].

Experimental Protocol: Multi-Component Analysis of Antihypertensive Drugs

Background and Pharmaceutical Context

The quantitative analysis of antihypertensive drug combinations exemplifies the application of UFLC-DAD in pharmaceutical quality control and bioequivalence studies. This protocol details the simultaneous determination of amlodipine and valsartan, commonly prescribed in combination for hypertension management, using green analytical chemistry principles. The method emphasizes practical considerations for pharmaceutical researchers, including sample preparation, chromatographic separation, detection parameters, and method validation according to ICH guidelines. The protocol incorporates recent advancements in green analytical chemistry, utilizing metrics such as Analytical GREEnness (AGREE) and Blue Applicability Grade Index (BAGI) to evaluate environmental impact and practical applicability, aligning with the pharmaceutical industry's increasing focus on sustainable analytical practices [9].

Materials and Reagents

Table 2: Research Reagent Solutions for Antihypertensive Drug Analysis

| Reagent/Material | Specification | Function in Analysis | Handling Considerations |

|---|---|---|---|

| Amlodipine besylate reference standard | USP reference standard; ≥98.5% purity | Primary standard for quantification | Light-sensitive; store in amber glass at 2-8°C |

| Valsartan reference standard | USP reference standard; ≥99.0% purity | Primary standard for quantification | Hygroscopic; store in desiccator at room temperature |

| Acetonitrile (ACN) | LC-MS grade; ≥99.9% purity | Mobile phase component (organic modifier) | Use with adequate ventilation; flammable |

| Ammonium acetate | Analytical grade; ≥98% purity | Mobile phase buffer component | Prepares 10 mM buffer solution in purified water |

| Purified water | HPLC grade; 18.2 MΩ·cm resistance | Aqueous mobile phase component | Freshly prepared or stored <24 hours |

| Phosphoric acid | Analytical grade; 85% solution | pH adjustment of mobile phase | Corrosive; handle with appropriate PPE |

| Methanol | HPLC grade; ≥99.9% purity | Sample extraction solvent | Use with adequate ventilation; flammable |

Instrumentation and Conditions

This analysis employs a UFLC-DAD system configured for high-pressure operation with low-dispersion fluidics to maintain separation efficiency. The specific conditions have been optimized for the simultaneous determination of amlodipine and valsartan, incorporating green chemistry principles by minimizing organic solvent consumption and analysis time [9].

Table 3: UFLC-DAD Instrumental Conditions for Antihypertensive Analysis

| Parameter | Specification | Rationale |

|---|---|---|

| UFLC System | Shimadzu i-Series or equivalent | High-pressure capability (up to 1300 bar) with low dwell volume |

| Column | C18 (100 × 2.1 mm, 1.8 μm) | Provides efficient separation of both polar and non-polar compounds |

| Column Temperature | 35°C | Optimizes retention time reproducibility and separation efficiency |

| Mobile Phase | A: 10 mM ammonium acetate (pH 4.5) B: Acetonitrile | Volatile buffer compatible with MS detection; pH optimized for compound ionization |

| Gradient Program | 0 min: 20% B; 5 min: 50% B; 6 min: 90% B; 7 min: 90% B; 7.1 min: 20% B; 10 min: 20% B | Efficient separation with runtime under 10 minutes for high throughput |

| Flow Rate | 0.4 mL/min | Balances separation efficiency with back-pressure and solvent consumption |

| Injection Volume | 2 μL | Provides adequate sensitivity while minimizing column overloading |

| DAD Wavelengths | 237 nm (amlodipine); 250 nm (valsartan) | Wavelengths of maximum absorbance for each compound |

| Spectral Acquisition | 200-400 nm | Enables peak purity assessment and spectral confirmation |

Sample Preparation Protocol

Standard Solution Preparation: Accurately weigh 25 mg of amlodipine besylate and 50 mg of valsartan reference standards into separate 50 mL volumetric flasks. Dissolve and dilute to volume with methanol to create stock solutions of 500 μg/mL amlodipine and 1000 μg/mL valsartan. Prepare working standard solutions by appropriate dilution with the mobile phase initial composition (20% acetonitrile in 10 mM ammonium acetate, pH 4.5) to cover the concentration range of 1-50 μg/mL for amlodipine and 5-200 μg/mL for valsartan.

Pharmaceutical Formulation Preparation: Randomly select and accurately weigh not less than 20 tablets. Calculate the average tablet weight and finely powder the tablets. Transfer an accurately weighed portion of the powder equivalent to one tablet to a 100 mL volumetric flask. Add approximately 70 mL of methanol, sonicate for 30 minutes with occasional shaking, and dilute to volume with methanol. Filter through a 0.45 μm PVDF membrane, discarding the first 5 mL of filtrate. Dilute the filtrate appropriately with the mobile phase initial composition to obtain concentrations within the working range of the calibration curve.

Validation Parameters: Establish method validation according to ICH Q2(R1) guidelines including specificity (peak purity >990), linearity (r²>0.999), precision (RSD<2%), accuracy (98-102% recovery), and robustness (deliberate variations in pH, temperature, and mobile phase composition) [9].

Advanced UFLC-DAD Configurations for Pharmaceutical Applications

Two-Dimensional Liquid Chromatography (2D-LC)

Comprehensive two-dimensional liquid chromatography configurations represent a significant advancement for analyzing complex pharmaceutical samples. 2D-LC systems incorporate two separate separation mechanisms with complementary selectivity, such as reversed-phase coupled with hydrophilic interaction chromatography (HILIC) or ion-exchange chromatography. Advanced systems like the Agilent InfinityLab 2D-LC solution utilize multiple pumps, a two-position/four-port duo valve for heart-cutting or comprehensive analysis, and a high-speed second dimension separation to maintain resolution from the first dimension. This configuration is particularly valuable for pharmaceutical impurity profiling, forced degradation studies, and analysis of complex biological matrices where single-dimension separation proves insufficient. The DAD detector in 2D-LC systems provides spectral data for peaks from both dimensions, aiding in compound identification. For regulated environments, compatible chromatography data systems (CDS) manage the complex instrument control and data processing requirements, with recent advancements focusing on automated method development and real-time data processing for increased laboratory efficiency [1].

Coupled UFLC-DAD-MS Systems

The hyphenation of UFLC-DAD with Mass Spectrometry (MS) creates a powerful analytical platform combining separation efficiency, spectral identification, and mass confirmation. Modern triple quadrupole mass spectrometers like the Sciex 7500+ MS/MS and Shimadzu LCMS-TQ series provide complementary detection with high sensitivity and selectivity for pharmaceutical applications. In such configurations, the flow is typically split post-column with approximately 5-10% directed to the DAD and 90-95% to the MS, or alternatively, the DAD is placed before the MS with minimal extra-column volume. The DAD provides UV-spectral data and quantitative information, while the MS offers molecular weight and structural information through fragmentation patterns. This configuration is particularly valuable for metabolite identification, impurity characterization, and degradation product studies in pharmaceutical development. Interface technology, including electrospray ionization (ESI) and atmospheric pressure chemical ionization (APCI) sources, enables efficient transfer of analytes from the liquid phase to the gas phase for mass analysis. Recent systems incorporate additional detectors such as corona charged aerosol detection (CAD) or evaporative light scattering detection (ELSD) for compounds with poor UV chromophores [10] [1].

System Suitability and Quality Control Protocols

Performance Verification Tests

Regular performance verification ensures UFLC-DAD systems operate within specified parameters for pharmaceutical analysis. Key tests include pump flow rate accuracy and precision verification using a calibrated flow meter or gravimetric method (acceptance criteria: ±1% accuracy, <0.1% RSD precision). Autosampler injection volume accuracy and carryover assessment using appropriate standards (acceptance criteria: ±2% accuracy, <0.1% carryover). DAD wavelength accuracy verification using holmium oxide or caffeine standards (acceptance criteria: ±2 nm accuracy). Photometric accuracy assessment using potassium dichromate solutions at specific concentrations (acceptance criteria: ±2% accuracy). Baseline noise and drift evaluation over a 30-minute period with mobile phase isocratic conditions (acceptance criteria: <±0.1 mAU noise, <1 mAU/hr drift). These verification tests should be performed during installation, after major repairs, and periodically (typically every 6-12 months) as part of a preventive maintenance program in regulated pharmaceutical laboratories [9] [10].

Quality Control in Routine Pharmaceutical Analysis

For daily system suitability testing in pharmaceutical quality control environments, specific test mixtures are chromatographed to verify resolution, efficiency, sensitivity, and reproducibility. The United States Pharmacopeia (USP) system suitability tests provide standardized protocols and acceptance criteria for various analytical applications. A typical system suitability protocol for UFLC-DAD includes evaluation of retention time reproducibility (<0.5% RSD for n=6 injections), theoretical plate count (>5000 for the analyte peak), tailing factor (<2.0 for the analyte peak), resolution (>1.5 between critical pair), and signal-to-noise ratio (>10 for the lowest concentration of interest). These parameters confirm that the entire UFLC-DAD system—from solvent delivery through separation to detection—is performing appropriately for its intended analytical application. Documentation of system suitability results provides evidence of instrument performance for regulatory audits and ensures the validity of generated analytical data [9] [10].

Workflow Diagram: UFLC-DAD Pharmaceutical Analysis Pathway

Diagram 1: UFLC-DAD Pharmaceutical Analysis Workflow

The sophisticated hardware components of UFLC-DAD systems provide pharmaceutical researchers with powerful tools for drug development, quality control, and regulatory compliance. Understanding the technical specifications, operational principles, and performance characteristics of each component—from high-pressure pumping systems and precision autosamplers to efficient separation columns and multi-wavelength detection—enables scientists to maximize instrumental capabilities and develop robust analytical methods. The continuing evolution of UFLC-DAD technology, including higher pressure limits, reduced extra-column volume, enhanced detection sensitivity, and improved integration with mass spectrometry, promises to further expand pharmaceutical applications. As demonstrated in the antihypertensive drug analysis protocol, proper method development combined with instrumental expertise delivers accurate, precise, and reliable results that meet stringent regulatory requirements while incorporating green analytical chemistry principles. For pharmaceutical researchers, this deep understanding of UFLC-DAD instrumentation translates to improved method development efficiency, enhanced troubleshooting capabilities, and ultimately, higher quality analytical data supporting drug development and manufacturing.

The evolution of liquid chromatography has been marked by a continuous pursuit of higher efficiency, speed, and sensitivity. Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) represents a significant advancement over traditional High-Performance Liquid Chromatography (HPLC), particularly for pharmaceutical analysis where throughput, resolution, and method robustness are critical. UFLC, also referred to as UHPLC (Ultra-High Performance Liquid Chromatography), utilizes columns packed with smaller particles (typically below 2μm) and systems capable of operating at significantly higher pressures compared to conventional HPLC [12]. This technological progression bridges the gap between demanding performance requirements and practical laboratory constraints, enabling researchers and pharmaceutical analysts to achieve superior separations in a fraction of the time. Within drug development and quality control, this translates to faster method development, more precise quantification of active pharmaceutical ingredients (APIs), and more efficient screening of impurities and degradation products [13] [14].

Comparative Performance: UFLC-DAD vs. Traditional HPLC

The fundamental differences between UFLC-DAD and traditional HPLC systems lie in their operational parameters, which directly impact their analytical performance. Table 1 provides a direct comparison of key technical characteristics.

Table 1: Technical and Performance Comparison between Traditional HPLC and UFLC-DAD

| Parameter | Traditional HPLC | UFLC-DAD |

|---|---|---|

| Operating Pressure | Typically 200-400 bar | 600-1300 bar [12] [1] |

| Particle Size | 3-5 μm | Often below 2.2 μm, commonly 1.3-1.7 μm [12] [14] |

| Analysis Time | Longer (e.g., 11 minutes for Posaconazole) | Shorter (e.g., 3 minutes for Posaconazole) [12] |

| Solvent Consumption | Higher (e.g., 1.5 mL/min flow rate) | Lower (e.g., 0.4 mL/min flow rate) [12] |

| Injection Volume | Higher (e.g., 20-50 μL) | Lower (e.g., 5 μL) [12] |

| Peak Capacity/Resolution | Standard | Enhanced due to smaller particle size and higher efficiency [14] |

| Detection | Variable Wavelength (VWD) or DAD | Primarily DAD, enabling spectral confirmation [15] |

The practical benefits of UFLC are demonstrated in direct application studies. A comparative study on the analysis of Posaconazole in a suspension dosage form developed methods for both HPLC-DAD and UHPLC-UV. The UHPLC method provided a run time of only 3 minutes, a stark contrast to the 11 minutes required for the HPLC method, while maintaining equivalent linearity (r² > 0.999) and precision [12]. This four-fold reduction in analysis time is coupled with a significant decrease in solvent consumption, from 1.5 mL/min in HPLC to 0.4 mL/min in UHPLC, making the UFLC approach more economical and environmentally friendly [12] [14]. Similarly, in the analysis of anticancer guanylhydrazones, the UHPLC-DAD method demonstrated a 20-fold reduction in injection volume and a four-fold decrease in solvent usage compared to the HPLC method, all while achieving the required specificity, accuracy, and precision [14].

The Diode Array Detector (DAD) is a critical component that complements the separation power of UFLC. Unlike a single-wavelength UV detector, the DAD simultaneously captures the entire UV-Vis spectrum (e.g., 190-800 nm) for each data point during the chromatographic run [15]. This capability allows for peak purity assessment by comparing spectra across the peak, as well as method specificity verification by ensuring that analytes are free from co-elution [13] [14]. The DAD's ability to acquire spectra in multiple channels and provide 3D data (time-absorbance-wavelength) makes it invaluable for method development and the analysis of complex pharmaceutical matrices where interference is a concern [15].

Experimental Protocols

Protocol 1: Quantification of Metoprolol Tartrate in Tablets using UFLC-DAD

This protocol is adapted from a study that optimized and validated a UFLC-DAD method for quantifying the active component metoprolol tartrate (MET) in commercial tablets, comparing it favorably to a spectrophotometric method [13].

1. Scope and Application: This method is suitable for the extraction and quantification of metoprolol tartrate in 50 mg and 100 mg commercial tablets for quality control purposes.

2. Apparatus and Reagents:

- UFLC-DAD System: Configured with a quaternary pump, autosampler, column thermostat, and diode array detector.

- Analytical Column: Reverse-phase C18 column (e.g., 50 mm x 2.1 mm, 1.7 μm particle size or equivalent).

- Reagents: Metoprolol tartrate (≥98%) reference standard, HPLC-grade acetonitrile, ultrapure water, phosphoric acid.

3. Methodology:

- Mobile Phase Preparation: Prepare a mixture of acetonitrile and 15 mM potassium dihydrogen phosphate buffer. The exact pH and gradient elution profile must be optimized during method development. An example isocratic mobile phase for similar applications is acetonitrile:phosphate buffer (45:55, v/v) [12].

- Standard Solution Preparation: Accurately weigh an appropriate amount of MET reference standard. Dissolve and dilute with the mobile phase or a compatible solvent to prepare a stock solution. Subsequently, prepare a series of working standard solutions for constructing the calibration curve.

- Sample Preparation (Tablet Extraction): Weigh and finely powder not less than 20 tablets. Transfer an accurately weighed portion of the powder, equivalent to about 50 mg of MET, to a suitable container. Add approximately 30 mL of ultrapure water and sonicate for 15-20 minutes with occasional shaking. Cool, dilute to volume with the same solvent, and mix well. Filter a portion of the solution, discarding the first few mL of the filtrate. Further dilute the filtrate quantitatively with the mobile phase to obtain a final concentration within the linear range of the assay.

- Chromatographic Conditions:

- Column Temperature: 40 °C

- Flow Rate: 0.4 - 0.5 mL/min

- Injection Volume: 5 μL

- Detection Wavelength: 223 nm (with spectral confirmation via DAD from 200-400 nm)

- Run Time: Optimized to approximately 3-5 minutes.

- System Suitability: The chromatographic system should meet predefined suitability criteria prior to analysis. Parameters include retention time reproducibility (%RSD < 2%), theoretical plate count (e.g., > 2000), and tailing factor (e.g., < 2.0).

4. Method Validation: The method was validated according to ICH guidelines, demonstrating acceptable parameters for specificity/selectivity, sensitivity, linearity (e.g., R² > 0.999), accuracy (recovery 80-110%), precision (intra-day and inter-day RSD < 2%), and robustness [13].

Protocol 2: Simultaneous Determination of Guanylhydrazones by UFLC-DAD

This protocol outlines the use of UFLC-DAD for the simultaneous quantification of multiple guanylhydrazone compounds with anticancer activity, showcasing the application of experimental design (DoE) for method optimization [14].

1. Scope and Application: This method is designed for the simultaneous quantification of guanylhydrazones LQM10, LQM14, and LQM17 in synthetic mixtures and raw materials for quality control during drug synthesis.

2. Apparatus and Reagents:

- UFLC-DAD System

- Analytical Column: Kinetex-C18 (2.1 x 50 mm, 1.3 μm) or equivalent.

- Reagents: LQM10, LQM14, LQM17 reference standards, HPLC-grade methanol, acetonitrile, and ultrapure water. Acetic acid for pH adjustment.

3. Methodology:

- Mobile Phase Preparation: The study employed a design of experiments (DoE) approach to optimize the mobile phase. An optimized isocratic elution system can consist of a mixture of acetonitrile and water with acid modifier (e.g., 0.1% formic acid). The final proportion is determined via DoE.

- Standard and Sample Preparation: Prepare stock and working standard solutions of each guanylhydrazone in methanol. For synthetic raw material samples, dissolve an accurately weighed sample in methanol and dilute to an appropriate volume.

- Chromatographic Conditions:

- Column Temperature: 40 °C

- Flow Rate: 0.4 mL/min

- Injection Volume: 2 μL

- Detection Wavelength: 290 nm (with DAD spectral acquisition from 220-400 nm for peak purity).

- Run Time: ~5 minutes.

- Method Optimization via DoE: Critical method parameters (e.g., mobile phase composition, pH, temperature, gradient profile) are varied simultaneously according to a factorial design. The chromatographic responses (resolution, peak symmetry, run time) are measured, and a statistical model is built to identify the optimal robust conditions.

5. Method Validation: The validated method demonstrated high specificity with peak purity index > 999, linearity (R² > 0.999), accuracy (recoveries 99.07% - 101.62%), and precision (intra-day RSD < 1.27%) for all three analytes [14].

Workflow and Logical Diagrams

The following diagram illustrates the strategic decision-making workflow for selecting and implementing a chromatographic method for pharmaceutical analysis, integrating the comparative advantages of UFLC-DAD and HPLC.

Method Selection Workflow

The Scientist's Toolkit: Essential Research Reagent Solutions

Successful implementation of UFLC-DAD methods relies on the selection of appropriate materials and reagents. Table 2 lists key components and their functions in the analytical process.

Table 2: Essential Research Reagents and Materials for UFLC-DAD Analysis

| Item | Function/Description | Application Example |

|---|---|---|

| Reverse-Phase C18 Column (Sub-2μm particles, e.g., 1.3-1.7 μm) | The core separation component; high-efficiency columns with small particles are essential for achieving the high resolution and speed of UFLC [12]. | Separation of metoprolol tartrate, guanylhydrazones, and posaconazole from their respective matrices [13] [12] [14]. |

| HPLC-Grade Acetonitrile & Methanol | High-purity organic modifiers for the mobile phase to prevent baseline noise, ghost peaks, and system damage. | Used as the organic component in the mobile phase for eluting analytes from the reverse-phase column [13] [14]. |

| High-Purity Water (e.g., 18.2 MΩ·cm) | The aqueous component of the mobile phase. Must be free of organics and particles. | Used in mobile phase preparation, often with a buffer or acid modifier [12]. |

| Buffer Salts & Acid Modifiers (e.g., Potassium dihydrogen phosphate, Formic acid, Acetic acid) | Control the pH and ionic strength of the mobile phase, which critically affects analyte ionization, retention, and peak shape. | Phosphate buffer for posaconazole; acetic acid for guanylhydrazones to improve peak symmetry [12] [14]. |

| Reference Standards | Highly characterized, pure substances used for peak identification and quantitative calibration. | Metoprolol tartrate (≥98%), Posaconazole, and guanylhydrazone compounds for method development and validation [13] [12] [14]. |

UFLC-DAD unequivocally bridges the gap between high performance and practicality in modern pharmaceutical analysis. The documented evidence demonstrates its superior capabilities in speed, resolution, and solvent economy compared to traditional HPLC, without compromising on accuracy, precision, or reliability. The integration of diode array detection further empowers this technique by providing spectral confirmation and peak purity assessment, which is indispensable for method specificity. As the pharmaceutical industry continues to strive for greater efficiency and greener methodologies, the adoption of UFLC-DAD represents a strategic advancement. It enables faster drug development cycles, more robust quality control, and the ability to tackle increasingly complex analytical challenges, solidifying its role as a cornerstone technique in the analytical scientist's arsenal.

Practical UFLC-DAD Workflows: From Method Development to Real-World Pharma Applications

In the field of pharmaceutical analysis, the demand for robust, precise, and efficient analytical methods is paramount. Systematic method development for liquid chromatography ensures reliable quantification of active pharmaceutical ingredients and impurities. This document outlines a structured approach to optimizing column selection, mobile phase composition, and gradient parameters, specifically within the context of Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD). The principles discussed support critical pharmaceutical applications, from raw material testing to stability studies, aligning with regulatory requirements for method validation [16].

Systematic Optimization Strategy

A systematic approach to method development significantly enhances efficiency, reduces solvent consumption, and leads to more robust methods compared to univariate (trial-and-error) experimentation [14].

Critical Method Attributes (CMAs) and Analytical Target Profile (ATP)

Begin by defining the Analytical Target Profile (ATP)—a pre-defined objective that outlines the method's purpose. The ATP specifies requirements for critical method attributes such as resolution, analysis time, and sensitivity.

- Key CMAs: Resolution (Rs ≥ 1.5), peak asymmetry (0.8 - 1.2), runtime, and signal-to-noise ratio [17].

- Define Scope: Determine the number of analytes, their chemical properties, and the required detection limits.

Factor Screening and Optimization

Utilize Design of Experiments (DoE) to efficiently identify and optimize critical factors.

- Screening Designs: Use fractional factorial or Plackett-Burman designs to identify significant factors (e.g., % organic, pH, temperature) from a wide range of variables [14].

- Optimization Designs: Apply Response Surface Methodology (RSM), such as Central Composite Design, to model the relationship between factors and responses (e.g., resolution) and locate the optimal operational region [14].

Table 1: Key Factors to Evaluate in Chromatographic Method Development

| Factor Category | Specific Factors | Impact on Separation |

|---|---|---|

| Stationary Phase | Column chemistry (C18, C8, PFP), particle size (e.g., 1.7-5 µm), column dimensions | Selectivity, efficiency, backpressure [18] [16] |

| Mobile Phase | % Organic modifier (ACN/MeOH), buffer pH, buffer concentration, additive (e.g., TFA) | Retention, selectivity, peak shape [17] [14] |

| Gradient Profile | Initial/Final %B, gradient time (tG), flow rate | Resolution, analysis time [16] |

| System Parameters | Temperature, flow rate, detection wavelength | Efficiency, retention, sensitivity [17] |

Experimental Protocols

Protocol 1: Column and Mobile Phase Scouting

Objective: To rapidly identify the most promising column and mobile phase combination for a given separation [18].

Materials:

- UFLC-DAD System: Equipped with quaternary pump, autosampler, DAD, and column oven.

- Columns: A suite of 3-5 columns with different selectivities (e.g., C18, C8, Phenyl, PFP).

- Chemical Reagents: HPLC-grade water, acetonitrile, methanol, and buffer salts (e.g., potassium phosphate).

- Analytes: Standard solution of target analytes at a known concentration.

Procedure:

- Condition Setting: Maintain a constant column temperature (e.g., 30 °C) and flow rate (e.g., 1.0 mL/min).

- Mobile Phase Preparation: Prepare at least two different mobile phase systems:

- Scouting Run: For each column, perform a fast, wide-range gradient (e.g., 5% to 95% organic in 10 minutes).

- Data Analysis: Evaluate chromatograms for retention of all analytes, general peak shape, and early resolution assessment. Select the column/mobile phase combination that provides the best overall performance for further optimization.

Protocol 2: Gradient Optimization via DoE

Objective: To systematically optimize the gradient profile and temperature for maximum resolution and minimal runtime [14].

Procedure:

- Define Factors and Ranges: Based on scouting results, select factors such as:

- Initial %B (e.g., 5% - 20%)

- Final %B (e.g., 80% - 95%)

- Gradient Time (tG) (e.g., 5 - 15 min)

- Temperature (e.g., 25 - 45 °C)

- Experimental Design: Create a Central Composite Design (CCD) using statistical software. The design will specify the experimental conditions for each run.

- Execution: Perform the chromatographic runs in a randomized order to minimize bias.

- Response Modeling: Input the measured responses (e.g., resolution between critical pair, total runtime) into the software to generate a mathematical model and contour plots.

- Optimization and Prediction: Use the software's optimizer to find the parameter set that maximizes resolution while maintaining an acceptable runtime. Verify the predicted optimal conditions with a confirmatory experiment.

Diagram 1: Systematic Method Development Workflow. This flowchart outlines the sequential and iterative stages of developing a robust chromatographic method, from initial scouting to final validation.

Case Study & Data Presentation

Separation of Guanylhydrazones by HPLC-DAD and UHPLC-DAD

A study developing methods for anticancer guanylhydrazones (LQM10, LQM14, LQM17) demonstrates the systematic approach [14].

- HPLC Method (Empirical): Optimized via one-factor-at-a-time, using a C18 column, isocratic elution with methanol-water (60:40, pH 3.5 with acetic acid) at 1.5 mL/min. Total runtime was ~7 minutes [14].

- UHPLC Method (DoE): A faster method was developed using a factorial design to optimize the gradient and temperature, resulting in a method with 4x less solvent consumption and a 20x smaller injection volume [14].

Table 2: Validation Parameters for HPLC and UHPLC Methods for Guanylhydrazones [14]

| Validation Parameter | HPLC Method (LQM10) | UHPLC Method (LQM10) |

|---|---|---|

| Linearity (R²) | 0.9995 | 0.9994 |

| Precision (Intra-day RSD%) | 1.48% | 0.53% |

| Accuracy (% Recovery) | 99.49 - 100.46% | 99.32 - 101.62% |

| Injection Volume | 20 µL | 1 µL |

| Solvent Consumption per Run | ~10.5 mL | ~2.6 mL |

The superior precision and significantly reduced solvent consumption/injection volume of the UHPLC method, developed via DoE, highlight the benefits of a systematic approach [14].

Overcoming Co-elution: Derivatization for Tocol Analysis

A common challenge in pharmaceutical analysis is separating structurally similar compounds. A study on tocopherols and tocotrienols (collectively "tocols") faced this with the β- and γ-forms, which co-elute on standard C18 columns [18].

- Optimized Solution: A pre-column derivatization step was introduced, esterifying the tocols' hydroxyl group with trifluoroacetic anhydride. This chemical modification altered their hydrophobicity sufficiently to allow for satisfactory separation on a conventional C18 column [18].

- Method Performance: The optimized C18-UFLC method was precise, accurate, and offered low limits of detection (<10 ng/mL) and quantification (<27 ng/mL) [18].

This case underscores that systematic development includes not just physical parameters but also chemical modification of analytes to achieve selectivity.

Diagram 2: DoE Optimization Logic. This diagram illustrates the use of a statistical model to balance often conflicting goals, such as maximum resolution and minimum runtime, to find a optimal compromise.

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for UFLC-DAD Method Development

| Reagent / Material | Function / Explanation |

|---|---|

| C18 Chromatographic Column | The most common reversed-phase stationary phase; a versatile starting point for method development [18] [17]. |

| Trifluoroacetic Anhydride | Derivatization agent used to chemically modify compounds with hydroxyl groups (e.g., tocols) to improve separation and resolution on a C18 column [18]. |

| Acetonitrile & Methanol (HPLC Grade) | Organic modifiers for the mobile phase; scouting both is crucial as they can impart different selectivity for various analytes [14]. |

| Buffer Salts (e.g., Phosphate) | Used to prepare aqueous mobile phase components to control pH, which critically impacts ionization, retention, and peak shape of ionizable compounds [17]. |

| Acetic Acid / Trifluoroacetic Acid | Acidic mobile phase additives which suppress silanol activity on the stationary phase, improving peak symmetry for acidic and basic analytes [14]. |

| Design of Experiments (DoE) Software | Statistical software used to create efficient experimental designs, model results, and pinpoint optimal chromatographic conditions, saving time and resources [14]. |

Systematic method development, grounded in structured scouting and statistical optimization via DoE, is the most efficient path to creating robust, transferable, and high-quality chromatographic methods for pharmaceutical analysis. The integration of UFLC-DAD with these principles provides a powerful platform for meeting the demanding timelines and regulatory standards of modern drug development. As demonstrated, this approach consistently yields methods that are not only analytically superior but also more sustainable and economical due to reduced solvent consumption and waste generation.

The demand for robust, efficient, and reliable analytical methods for the simultaneous quantification of multiple active pharmaceutical ingredients (APIs) is paramount in modern drug development and quality control. This application note details the development and validation of an Ultra-Fast Liquid Chromatography (UFLC) method with Diode Array Detection (DAD) for the simultaneous determination of multiple active ingredients, framed within a broader thesis on the practical applications of this technique in pharmaceutical analysis. The protocols described herein are designed to provide researchers, scientists, and drug development professionals with a detailed framework for implementing this methodology in their own laboratories, emphasizing practical considerations for method development, validation, and application to complex matrices such as dietary supplements.

Method Development and Optimization

Chromatographic Conditions

The development of a precise and accurate chromatographic method requires careful optimization of critical parameters to achieve optimal separation, sensitivity, and peak shape.

- Stationary Phase: A UPLC CSH column (100 mm × 2.1 mm, 1.7 μm particle size) is recommended for its superior reproducibility with challenging matrices compared to classical C18 columns [19]. The use of columns with sub-2 μm particles is a cornerstone of UHPLC/UFLPC, enabling higher efficiency, resolution, and shorter analysis times [14].

- Mobile Phase: A binary solvent system is employed [19].

- Solvent A: 0.1% Formic acid in water.

- Solvent B: Methanol.

- Flow Rate and Run Time: The total run time is 4 minutes, consuming only 1.2 mL of liquid, which underscores the method's efficiency and alignment with green chemistry principles by reducing solvent waste [19].

- Detection: DAD is initially favored for its cost-effectiveness and because it does not require expensive stable isotope-labeled reference standards, which are necessary for mass spectrometric detection [19]. The wavelength for detection should be set based on the maximum absorbance of the target analytes; for example, 290 nm was used for a class of guanylhydrazones [14]. The use of a DAD also allows for peak purity assessment by comparing ultraviolet spectral characteristics [19].

Sample Preparation

The sample preparation protocol varies depending on the sample matrix. For solid dosage forms like tablets or capsules, content uniformity should be assessed, and an average weight powder should be dissolved and sonicated in a suitable solvent (e.g., methanol). The resulting solution should be centrifuged, filtered (e.g., through a 0.22 μm syringe filter), and diluted to an appropriate concentration within the linear range of the method before injection [19].

Method Validation

The method was rigorously validated according to international guidelines, such as ICH Q2(R2), to ensure its suitability for the intended purpose. The table below summarizes key validation parameters for a model analysis of guanylhydrazones, demonstrating the method's performance [14].

Table 1: Method Validation Parameters for Simultaneous Determination of Guanylhydrazones (LQM10, LQM14, LQM17) via HPLC-DAD

| Validation Parameter | LQM10 | LQM14 | LQM17 |

|---|---|---|---|

| Linearity (R²) | 0.9995 | 0.9999 | 0.9994 |

| Accuracy (Recovery % at 10 μg/mL) | 100.46% | 101.47% | 99.71% |

| Precision (RSD%, n=6) | |||

| Intra-day | 1.48% | 2.00% | 1.24% |

| Inter-day | 2.81% | 1.56% | 2.20% |

| Robustness (Variation in Flow Rate) | RSD: 2.07% | RSD: 2.34% | RSD: 2.54% |

| Robustness (Variation in pH) | RSD: 1.76% | RSD: 1.64% | RSD: 1.61% |

Validation Protocols

- Selectivity and Specificity: The method's selectivity is demonstrated by the absence of interfering peaks at the retention times of the target analytes in representative blank matrices. Peak identification is confirmed by comparing both the retention time and the ultraviolet spectrum of the sample with those of a reference standard. For complex herbal matrices (e.g., containing passionflower, hop, or hemp), the peak purity should be verified to ensure the absence of co-eluting compounds [19].

- Linearity: Prepare at least five standard solutions of the target analytes at concentrations spanning the expected range (e.g., 8-12 μg/mL). Inject each solution in triplicate and plot the peak area versus the concentration. The correlation coefficient (R²) should be greater than 0.999 [14].

- Accuracy (Recovery): Spike a known amount of the reference standard into a placebo or a pre-analyzed sample matrix at multiple concentration levels (e.g., 80%, 100%, 120% of the target concentration). Analyze these samples (n=5 per level) and calculate the percentage recovery of the known added amount. Recovery rates should be close to 100% [14].

- Precision:

- Intra-day Precision: Analyze six independent sample preparations from a homogeneous sample at 100% of the test concentration on the same day and calculate the relative standard deviation (RSD%) of the peak areas.

- Inter-day Precision: Repeat the intra-day precision assay over three different days and calculate the RSD% of the results [14].

- Robustness: Deliberately introduce small, deliberate variations in method parameters (e.g., mobile phase flow rate ±0.05 mL/min, pH ±0.05 units). The RSD% of the peak areas and retention times under these varied conditions should remain low, indicating the method's resilience [14].

Application to Real-World Samples: Melatonin in Dietary Supplements

To demonstrate its applicability, the UFLC-DAD methodology was applied to analyze 50 dietary supplements claiming to contain melatonin [19]. The findings confirmed reports of high melatonin content, particularly in products purchased from online sources. The study highlighted compliance issues, finding that 12% of samples from legal supply chains violated legislation through unauthorized health claims or by containing at least triple the permitted melatonin amount.

Table 2: System Suitability Parameters for UHPLC-DAD Method for Melatonin Quantification

| Parameter | Description/Value |

|---|---|

| Chromatographic Column | Acquity UPLC CSH (100 x 2.1 mm, 1.7 μm) |

| Mobile Phase | 0.1% Formic Acid (A) / Methanol (B) |

| Analysis Time | 4 minutes |

| Solvent Consumption | 1.2 mL per run |

| Detection | Diode Array Detector (DAD) |

| Key Advantage | Cost-effective; suitable for medicines and most dietary supplements |

For complex herbal supplements containing ingredients like passionflower, hop, hemp, lime tree, or lavender, UFLC-DAD may face selectivity issues due to overlapping peaks from the complex matrix. In such cases, coupling chromatography to high-resolution accurate mass spectrometry (HRAM MS) is recommended for unambiguous identification and quantification [19].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Research Reagent Solutions and Essential Materials

| Item | Function/Application |

|---|---|

| UHPLC/UFLC System | High-pressure chromatographic system for efficient separation. |

| Diode Array Detector (DAD) | Detection and peak purity verification via UV spectrum. |

| CSH C18 Column (1.7 μm) | Advanced stationary phase for challenging matrices. |

| Melatonin Reference Standard | Primary standard for identification and quantification. |

| Formic Acid (MS Grade) | Mobile phase modifier to improve peak shape and ionization. |

| Methanol (HPLC Grade) | Organic solvent for mobile phase and sample preparation. |

| Syringe Filters (0.22 μm) | Clarification of samples prior to injection. |

| Stable Isotope-Labeled Melatonin | Internal standard for mass spectrometry-based methods. |

Workflow and Signaling Pathway Diagrams

The following diagrams outline the logical workflow for method development and application, as well as the decision pathway for detection system selection.

Method Development Workflow

Detection System Selection

Application in Drug Release and In-Vitro Digestion Studies

Ultra-Fast Liquid Chromatography coupled with Diode Array Detection (UFLC-DAD) has become a cornerstone technique in modern pharmaceutical analysis, offering rapid, precise, and reliable quantification of active pharmaceutical ingredients and nutraceuticals in complex matrices. This technology is particularly vital for advancing pre-clinical research in two critical areas: understanding drug release profiles from novel formulations and predicting human bioavailability through in-vitro digestion models. These applications are fundamental to the development of safe and effective pharmaceutical products, enabling researchers to simulate and analyze a drug's journey from ingestion to absorption. This application note details specific, validated protocols utilizing UFLC-DAD for studying the release of B-complex vitamins from gummy formulations and for assessing the bioaccessibility of bioactive compounds from natural products, providing a practical framework for scientists in drug development.

UFLC-DAD in Vitamin Release from Pharmaceutical Gummies

The release profile of vitamins from advanced dosage forms, such as gummies, can be significantly influenced by dietary co-consumption. A recent study developed and validated a robust HPLC-DAD method to investigate the impact of different fluids on the in-vitro digestion of B-complex vitamins from pharmaceutical gummies [20].

Key Quantitative Findings

The table below summarizes the key validation parameters and findings for the UFLC-DAD method used in the gummy vitamin study [20].

Table 1: Method Validation and Application Data for Vitamin Analysis in Gummies and GI Fluids

| Parameter | Result / Value | Application Finding |

|---|---|---|

| Analytical Method | HPLC-DAD/FLD | Simultaneous analysis of B1, B2, B6 in gummies & GI fluids. |

| Chromatographic Column | Aqua column (250 mm × 4.6 mm, 5 µm) | Effective separation of target vitamins. |

| Linearity (R²) | > 0.999 | Excellent correlation across the calibrated range. |

| Accuracy (% Mean Recovery) | 100 ± 3% | High accuracy for quantitative analysis. |

| Precision (% RSD) | < 3.23% | High repeatability of the method. |

| Gummy Extraction (% Recovery) | > 99.8% (Liquid/Solid Extraction) | Efficient recovery from the gummy matrix. |

| GI Fluid Extraction (% Recovery) | 100 ± 5% (Solid Phase Extraction) | Efficient and clean recovery from complex biological fluids. |

| Superior Release Medium for B2 & B6 | Water | Slightly better release compared to milk or orange juice. |

| Superior Release Medium for B1 | Orange Juice | Slightly better release compared to water or milk. |

Detailed Experimental Protocol

Method Title: UFLC-DAD Analysis of Vitamins B1, B2, and B6 in Pharmaceutical Gummies and Gastrointestinal Fluids During In-Vitro Digestion [20].

1. Scope: This protocol describes the simultaneous determination of thiamine (B1), riboflavin (B2), and pyridoxine (B6) in pharmaceutical gummies and simulated gastric/intestinal fluids using UFLC-DAD. For B1 analysis via fluorometry (FLD), a separate pre-column derivatization step is required.

2. Equipment and Reagents:

- UFLC-DAD System: Configured with a DAD detector.

- Chromatography Column: Aqua column (250 mm × 4.6 mm, 5 µm particle size).

- Chemicals: HPLC-grade methanol, sodium dihydrogen phosphate (NaH₂PO₄), potassium ferricyanide, sodium hydroxide.

- Solvents and Buffers: Ultrapure water, NaH₂PO₄ buffer (pH 4.95).

- Simulated Fluids: Simulated gastric and intestinal fluids, optionally prepared with water, milk, or orange juice as diluents.

- Standards: Certified reference standards of Vitamin B1, B2, and B6.

3. Sample Preparation:

- Gummy Extraction: Accurately weigh a homogenized gummy sample. Perform liquid/solid extraction using a suitable solvent. Vortex and centrifuge, then filter the supernatant through a 0.45 µm membrane prior to injection [20].

- GI Fluid Extraction (SPE): After in-vitro digestion, acidify the gastrointestinal fluid sample. Condition a dedicated Solid Phase Extraction (SPE) cartridge. Load the sample, wash interfering compounds, and elute the target vitamins. Evaporate the eluent to dryness and reconstitute in the mobile phase for analysis [20].

4. UFLC-DAD Analysis:

- Mobile Phase: 70% NaH₂PO₄ buffer (pH 4.95) and 30% methanol (isocratic elution).

- Flow Rate: 0.9 mL/min.

- Column Temperature: 40 °C.

- Injection Volume: 10 µL.

- DAD Detection: Set wavelengths for simultaneous detection of B2 and B6. Typical wavelengths are 265 nm for B1 (pre-derivatization), 270 nm for B2, and 290 nm for B6.

- Pre-column Derivatization for B1/FLD: For fluorometric detection of B1, oxidize an aliquot of the prepared sample with potassium ferricyanide under alkaline conditions to convert it to fluorescent thiochrome. The FLD detection can be set at Ex: 375 nm, Em: 430 nm [20].

5. In-Vitro Digestion Procedure: A three-phase in-vitro digestion protocol simulating the human gastrointestinal tract was applied [20].

- Phase I - Oral Digestion: Mix the gummy sample with simulated salivary fluid for a defined period.

- Phase II - Gastric Digestion: Combine the oral bolus with simulated gastric fluid and incubate with agitation to simulate stomach conditions.

- Phase III - Intestinal Digestion: Transfer the gastric chyme to simulated intestinal fluid and incubate further. Samples should be collected at the end of the gastric and intestinal phases for UFLC-DAD analysis to determine the release profile.

Diagram 1: In-vitro digestion and analysis workflow for gummy vitamins.

Assessment of Bioactive Compound Bioaccessibility

UFLC-DAD is equally powerful for evaluating the bioaccessibility of bioactive compounds from natural products and herbal medicines during simulated digestion, a key step in predicting their bioavailability. A study on fruit residues demonstrated this application, showing that gastrointestinal digestion and probiotic fermentation can significantly increase the bioaccessibility of phenolic compounds [21]. Another study on Gardenia jasminoides Ellis (GJE) utilized advanced UFLC-MS/MS for comprehensive multi-component analysis, highlighting how geographical origin affects chemical composition, an important consideration for standardizing herbal medicines [10]. The principles of sample preparation and digestion are directly transferable to UFLC-DAD analysis.

Table 2: Key Findings from Bioaccessibility Studies of Natural Products

| Study Material | Analytical Technique | Key Finding on Bioaccessibility | Implication for Drug Development |

|---|---|---|---|

| Cashew Apple & Soursop Residues | UFLC-DAD & Biochemical Assays | Increased bioaccessibility of total phenolics (up to 475%) and flavonoids after digestion/fermentation [21]. | Probiotic fermentation can enhance the release and potential absorption of antioxidants. |

| Gardenia jasminoides Ellis (GJE) | UFLC-MS/MS & PCA | Significant regional variations (P < 0.05) in content of iridoid glycosides, flavonoids, and phenolic acids [10]. | Critical for quality control and standardization of herbal medicine sources. |

Detailed Experimental Protocol

Method Title: UFLC-DAD Analysis of Bioactive Compounds Following In-Vitro Gastrointestinal Digestion and Fermentation [21].

1. Scope: This protocol determines the bioaccessibility of phenolic compounds and other antioxidants from a plant-based matrix after simulated digestion and probiotic fermentation.

2. Equipment and Reagents:

- UFLC-DAD System

- Chromatography Column: C18 column (e.g., 4.6 mm × 100 mm, 3.5 µm).

- Chemicals: HPLC-grade methanol, acetonitrile, formic acid, acetic acid.

- Simulated Digestion Fluids: Simulated salivary, gastric, and intestinal fluids (with electrolytes and enzymes).

- Probiotic Strains: Lactobacillus species (e.g., L. rhamnosus), Bifidobacterium longum.

- Standards: Reference standards for target bioactive compounds (e.g., gallic acid, catechin, quercetin).

3. In-Vitro Digestion and Fermentation:

- Simulated Digestion: Subject the sample to a sequential 3-phase (oral, gastric, intestinal) in-vitro digestion model. Centrifuge the final intestinal digesta to obtain the soluble fraction (serum), which represents the bioaccessible compounds [21].

- Probiotic Fermentation: Inoculate the digested sample or its insoluble fraction with a probiotic culture in an anaerobic chamber. Incubate for 24-48 hours while monitoring pH. Stop the fermentation by heating or centrifugation [21].

4. Sample Preparation for UFLC-DAD:

- Liquid-Liquid Extraction: Acidify the digested/fermented sample and extract bioactive compounds with a mixture of methanol/ethyl acetate/water.

- Solid Phase Extraction (SPE): For cleaner extracts, use C18 or similar SPE cartridges. Condition, load, wash, and elute as described in Section 2.2.

- Filtration: Before injection, pass the final extract through a 0.22 µm syringe filter.

5. UFLC-DAD Analysis:

- Mobile Phase: (A) 0.1% Formic acid in water; (B) 0.1% Formic acid in acetonitrile.

- Gradient Elution: Program from 98% A to 60% A over 4 min, then to 5% A, hold, and re-equilibrate.

- Flow Rate: 0.8 mL/min.

- Column Temperature: 40 °C.

- Injection Volume: 2-5 µL.

- DAD Detection: Acquire spectra from 200 nm to 400 nm. Monitor specific wavelengths for compounds of interest (e.g., 280 nm for phenolic acids, 360 nm for flavonoids).

6. Data Analysis:

- Calculate the Bioaccessibility Index using the formula:

(Concentration in soluble digest fraction / Total concentration in undigested sample) × 100%.

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful execution of these protocols relies on specific, high-quality materials. The following table catalogs the essential reagent solutions and their functions.

Table 3: Essential Research Reagents and Materials for UFLC-DAD Drug Release Studies

| Reagent / Material | Function / Application | Example from Protocols |

|---|---|---|

| Simulated Gastrointestinal Fluids | To mimic the chemical environment (pH, enzymes, ions) of the human GI tract for in-vitro digestion. | Salivary, gastric, and intestinal fluids with enzymes like pepsin and pancreatin [20] [21]. |

| Stable Isotope-Labeled Internal Standards | To correct for analyte loss during sample preparation and matrix effects in mass spectrometry; enables precise quantification. | Use of deuterated analogs (e.g., DTX-d5 for Docetaxel) in drug release assays [22]. |

| Solid Phase Extraction (SPE) Cartridges | To purify and pre-concentrate analytes from complex biological matrices like GI fluids, reducing matrix interference. | C18 or dedicated cartridges for cleaning up vitamin samples from digested fluids [20]. |

| UFLC-QTRAP-MS System | For high-sensitivity, high-selectivity simultaneous quantification of multiple analytes in complex mixtures. | Used for simultaneous determination of 21 target compounds in Gardenia jasminoides [10]. |

| Certified Reference Standards | To provide absolute identification and enable accurate quantification of target analytes via calibration curves. | Certified standards of vitamins (B1, B2, B6) or phenolic compounds (gallic acid, quercetin) [20] [21]. |

| Molecular Cut-Off Filters | To separate free/unencapsulated drug from encapsulated drug in plasma during drug release studies. | 10-30 kDa molecular weight cut-off (MWCO) filters for ultrafiltration [22]. |