UFLC-DAD-ESI-MS Fundamentals: A Comprehensive Guide for Pharmaceutical and Biomedical Analysis

This article provides a comprehensive exploration of Ultra-Fast Liquid Chromatography coupled with Diode Array and Electrospray Ionization Mass Spectrometry (UFLC-DAD-ESI-MS), a powerful hyphenated technique pivotal in modern analytical laboratories.

UFLC-DAD-ESI-MS Fundamentals: A Comprehensive Guide for Pharmaceutical and Biomedical Analysis

Abstract

This article provides a comprehensive exploration of Ultra-Fast Liquid Chromatography coupled with Diode Array and Electrospray Ionization Mass Spectrometry (UFLC-DAD-ESI-MS), a powerful hyphenated technique pivotal in modern analytical laboratories. Tailored for researchers, scientists, and drug development professionals, the content covers foundational principles from chromatographic separation to ionization mechanisms and mass analysis. It details method development, showcases diverse applications in pharmaceutical and food safety analysis, and offers practical troubleshooting guidance for optimizing sensitivity and resolving common issues. The guide also addresses rigorous method validation and provides a comparative analysis with related techniques like UHPLC-MS/MS and SFC-MS/MS, serving as an essential resource for leveraging this technology in complex sample analysis.

Core Principles: Understanding UFLC-DAD-ESI-MS Components and Mechanisms

Ultra-Fast Liquid Chromatography (UFLC) represents a significant evolution in liquid chromatography, engineered to deliver dramatically reduced analysis times and enhanced chromatographic resolution. The core technological advancement enabling UFLC is the systematic optimization of column packing materials, most notably through the use of sub-2-micron particles. Traditional High-Performance Liquid Chromatography (HPLC) typically utilizes columns with 3-5 µm particles and operates at lower pressures, resulting in moderate analysis speeds [1]. In contrast, UFLC leverages particles with diameters ≤2 micrometers, which create a more uniform and efficient chromatographic bed. This foundational shift in particle size directly enhances the kinetics of mass transfer, allowing analytes to move more quickly and efficiently between the mobile and stationary phases [2] [3]. The result is a system capable of performing high-resolution separations in a fraction of the time required by conventional HPLC, making it indispensable for modern high-throughput laboratories in drug development and complex sample analysis [1].

The operational context of UFLC is often framed within a broader methodology that includes sophisticated detection systems. When coupled with Diode Array Detection and Electrospray Ionization Mass Spectrometry (UFLC-DAD-ESI-MS), the technique provides a powerful platform for the rapid separation, identification, and quantification of complex mixtures [4] [5] [6]. This guide details the fundamental role of sub-2-micron particles in achieving the performance characteristics that define UFLC.

The Fundamental Impact of Particle Size on Performance

The relationship between particle size and chromatographic efficiency is quantitatively described by the van Deemter equation, which models the contributions to band broadening. The equation is expressed as:

- H = A + B/μ + Cμ Where H is the height equivalent to a theoretical plate (HETP, a measure of efficiency), and μ is the linear velocity. The A term represents eddy diffusion, the B term represents longitudinal diffusion, and the C term represents the resistance to mass transfer [2].

The use of sub-2-micron particles directly optimizes the C term in the van Deemter equation. Smaller particles drastically shorten the diffusion path that analytes must travel within the particle pores, accelerating the mass transfer process between the mobile and stationary phases [2] [3]. This results in two key performance advantages, as shown in Figure 1:

- Lower Minimum Plate Height: The van Deemter curve for smaller particles reaches a lower minimum, indicating higher efficiency (a greater number of theoretical plates, N) can be achieved.

- Extended Efficiency at High Velocity: The curve is flatter at higher linear velocities, meaning that high efficiency can be maintained at faster flow rates, enabling rapid separations without a significant loss of resolution [2].

Figure 1: Conceptual Van Deemter Curve Comparing Particle Sizes

Furthermore, a narrow Particle Size Distribution (PSD) is critical for packing a homogeneous column bed. A tight PSD, often reported as a D90/10 value below 1.2, minimizes flow path inconsistencies (the A term in van Deemter), contributing to sharper peaks and superior resolution [2]. While superficially porous particles (core-shell) around 2.7 µm can approach the performance of sub-2 µm fully porous particles, the smallest particles consistently provide the highest theoretical plate counts and fastest separations, provided the instrument can handle the required pressure [7].

Comparative Analysis: UFLC vs. HPLC vs. UPLC

UFLC occupies a distinct position in the landscape of modern liquid chromatography techniques. Its performance is best understood through a direct comparison with its technological predecessor, HPLC, and its close relative, UPLC (Ultra-Performance Liquid Chromatography). The defining differences lie in the particle size of the columns and the resulting operational parameters, as detailed in Table 1.

Table 1: Quantitative Performance Comparison of HPLC, UFLC, and UPLC

| Parameter | HPLC (High Performance Liquid Chromatography) | UFLC (Ultra Fast Liquid Chromatography) | UPLC (Ultra Performance Liquid Chromatography) |

|---|---|---|---|

| Column Particle Size | 3 – 5 µm [1] | ≤ 2 µm (typically 1.7-1.8 µm) [1] [5] | ≤ 2 µm (typically 1.7 µm) [1] |

| Operating Pressure Limit | Up to ~400 bar (6000 psi) [1] | Up to ~600 bar (8700 psi) [1] | Up to ~1000 bar (15,000 psi) [1] [3] |

| Typical Analysis Speed | Moderate (10–30 minutes) [1] | Faster (5–15 minutes) [1] | Very Fast (1–10 minutes) [1] [3] |

| Chromatographic Resolution | Moderate [1] | High [3] | Very High [1] [3] |

| Detection Sensitivity | Moderate | High (due to narrower peaks) [1] [3] | Very High [1] |

| Instrument and Column Cost | Lower | Moderate | Higher [1] |

As the table illustrates, UFLC's use of sub-2-micron particles at intermediate pressures (up to ~600 bar) provides a crucial balance between performance and practicality. It offers a significant leap in speed and resolution over traditional HPLC without demanding the extreme pressure tolerance and associated instrument cost of a full UPLC system [1]. This makes UFLC a particularly cost-effective and versatile strategy for laboratories seeking to enhance throughput and resolution for routine analysis and method development.

Essential Methodologies for UFLC-DAD-ESI-MS

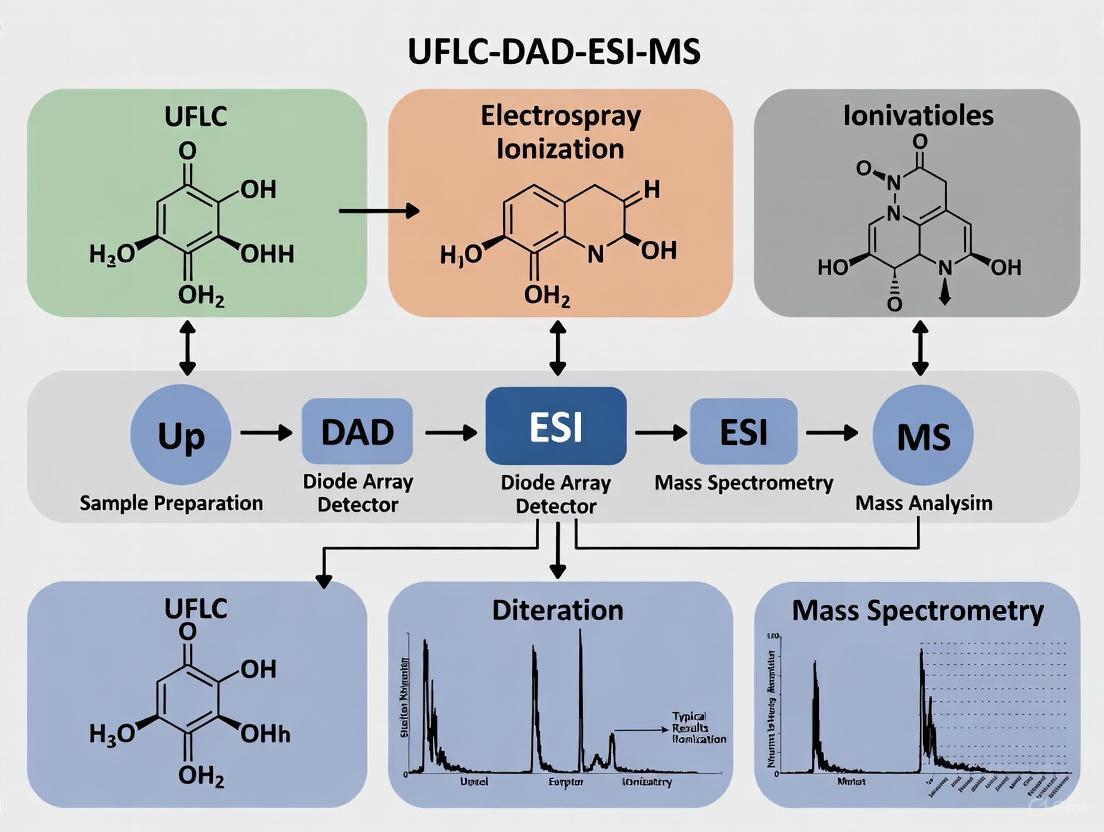

The integration of sub-2-micron particle technology with advanced detection systems forms the basis of the powerful UFLC-DAD-ESI-MS methodology. A typical experimental workflow is outlined in Figure 2, showcasing the process from sample preparation to data analysis.

Figure 2: UFLC-DAD-ESI-MS Experimental Workflow

Critical Experimental Protocols

A. Sample and Mobile Phase Preparation

The small pore sizes in sub-2-micron particle columns are highly susceptible to clogging. To prevent elevated backpressure and column damage, rigorous preparation is mandatory.

- Sample Filtration: All sample solutions must be filtered through a 0.22 µm membrane prior to injection [5] [3].

- Mobile Phase Filtration: All aqueous and organic mobile phases must be filtered through a 0.22 µm or 0.45 µm membrane and thoroughly degassed [3]. This is a non-negotiable step for stable baseline and column longevity.

B. Chromatographic Separation Conditions (Example)

A validated method for analyzing active components in a complex matrix (e.g., traditional Chinese medicine) exemplifies standard UFLC conditions [5]:

- Column: Agilent ZORBAX SB-C18 (3.0 mm × 100 mm, 1.8 µm) or equivalent.

- Mobile Phase: (A) 0.2% aqueous formic acid; (B) 0.2% formic acid in acetonitrile.

- Gradient Elution: 0–2 min (90–70% B); 3–7 min (70–50% B); 7–10 min (50–20% B); 10–14.5 min (20–90% B); 14.5–17 min (10% B).

- Flow Rate: 0.2 mL/min to 0.3 mL/min [4] [5].

- Column Temperature: Maintained at a constant temperature, often between 25-40°C.

- Injection Volume: Typically 1-5 µL, optimized for the specific detector and column capacity.

C. Detection via DAD and ESI-MS/MS

- DAD Analysis: Simultaneously monitors multiple wavelengths (e.g., 254 nm, 280 nm) to capture UV-Vis spectra for each peak, aiding in compound characterization and purity assessment [8].

- ESI-MS/MS Parameters: The effluent from the DAD is directed into the ESI source. A typical setup for small molecules uses positive or negative ion mode with a Multiple Reaction Monitoring (MRM) scan type for high sensitivity and selective quantification [5]. Key parameters include capillary voltage, cone voltage, source temperature, and desolvation gas flow, which are optimized for the target analytes.

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful implementation of UFLC-DAD-ESI-MS relies on a set of high-purity materials and reagents, as cataloged in Table 2.

Table 2: Essential Research Reagent Solutions for UFLC-DAD-ESI-MS

| Item | Function & Importance | Technical Specification |

|---|---|---|

| Sub-2µm U/HPLC Column | The core component enabling high-speed, high-resolution separations. | C18 bonded phase on 1.7-1.8 µm fully porous silica particles; Dimensions: 2.1-3.0 mm x 50-100 mm [5]. |

| High-Purity Solvents | Form the mobile phase; impurities cause high background noise and baseline drift. | LC-MS grade water, acetonitrile, and methanol [5]. |

| Volatile Additives | Modify mobile phase pH and improve ionization efficiency for ESI-MS. | Mass spectrometry-grade formic acid, ammonium formate, or ammonium acetate (e.g., 0.1% formic acid) [4] [5]. |

| Membrane Filters | Protect the column and instrument from particulate matter. | 0.22 µm pore size, compatible with both aqueous and organic solvents [3]. |

| Reference Standards | Essential for method development, calibration, and peak identification. | Certified reference materials of target analytes with purity ≥ 98% [5]. |

Challenges and Practical Considerations

Despite its advantages, the use of sub-2-micron particles in UFLC presents specific challenges that require careful management.

- Hardware Requirements: UFLC instruments need pumps capable of sustaining stable flows at pressures up to 600 bar and autosamplers/injection systems with minimal delay volume to preserve separation efficiency [1] [7].

- Frictional Heating: Operation at high pressures can generate significant heat within the column due to friction, potentially affecting retention times and selectivity. Using narrower I.D. columns (e.g., 2.1 mm) helps dissipate this heat more effectively [7].

- Method Transferability: Methods developed on UFLC systems using sub-2-micron columns may not be directly transferable to conventional HPLC systems with larger particles without re-validation, due to differences in selectivity and system dwell volume [7].

The integration of sub-2-micron particle technology is the definitive factor that unlocks the high speed and enhanced resolution of UFLC. By fundamentally improving the kinetics of chromatographic separation, these particles enable the rapid and precise analysis essential for modern scientific applications, from pharmaceutical development to metabolomics. When coupled with DAD and ESI-MS detection within a rigorously controlled methodological framework, UFLC provides researchers and drug development professionals with a powerful and robust analytical platform for tackling complex separation challenges.

The Diode Array Detector (DAD), also referred to as Photo Diode Array (PDA), represents a pivotal advancement in detection technology for high-performance liquid chromatography (HPLC) and ultra-fast liquid chromatography (UFLC). As a component of the comprehensive UFLC-DAD-ESI-MS methodology, the DAD provides a critical dimension of analytical data through its capacity to simultaneously capture full ultraviolet and visible (UV-Vis) spectra. This capability fundamentally enhances compound identification and purity assessment prior to mass spectrometric analysis.

Unlike conventional UV-Vis detectors that measure at limited, preselected wavelengths, the DAD employs an array of photodiodes—typically hundreds to thousands—enabling the capture of complete absorption spectra for each data point during chromatographic separation [9]. This simultaneous multi-wavelength detection occurs across a broad spectrum, generally from 190 to 900 nm, utilizing both deuterium (D₂) and tungsten (W) lamps as light sources to cover the UV and visible regions, respectively [10] [9]. The resulting three-dimensional data (absorbance, wavelength, and time) provides a rich information matrix that is indispensable for method development and validation within integrated analytical workflows.

Fundamental Operating Principles of DAD

Optical System and Design

The optical configuration of a DAD differs significantly from that of a traditional UV-Vis detector. In a conventional UV-Vis system, light from the source is first dispersed by a monochromator, and a specific wavelength is selected to pass through the flow cell containing the sample [9]. In contrast, a DAD utilizes a reverse optics design. As illustrated in Figure 1, polychromatic light from the source lamps passes directly through the flow cell, and the transmitted light is then dispersed onto a photodiode array [9].

This design comprises several key stages:

- Broad-Spectrum Illumination: The deuterium lamp (for UV range) and tungsten lamp (for visible range) provide continuous light across the operational wavelength spectrum [10].

- Sample Interaction: The light beam traverses the flow cell, where sample compounds absorb specific wavelengths according to their electronic structures.

- Spectral Dispersion: After passing through the flow cell, the transmitted light is focused onto a diffraction grating, which disperses it into its constituent wavelengths.

- Parallel Detection: The dispersed light is projected onto a photodiode array, where hundreds of individual diodes simultaneously measure the light intensity at their specific wavelengths [10] [9]. This process allows for the instantaneous capture of a full spectrum without the need for wavelength scanning.

Data Acquisition and Output

The detector measures the light intensity at each wavelength, and the system software calculates the absorbance according to the Beer-Lambert law. The result is a three-dimensional data set where absorbance is recorded as a function of both retention time and wavelength [11]. This data can be visualized and interrogated in multiple formats:

- Chromatograms: Extracted at a single wavelength for quantification.

- Spectra: Absorbance spectra at any point in time (e.g., at the peak apex) for identification.

- Contour Plots: A two-dimensional map showing absorbance as a function of retention time and wavelength, providing a comprehensive overview of the separated components [9].

Figure 1: Optical Path and Data Flow in a Diode Array Detector

Comparative Advantages: DAD vs. Conventional UV-Vis Detection

The fundamental design of the DAD confers several critical advantages in the context of UFLC-DAD-ESI-MS methodology, particularly for method development and validation.

Comprehensive Spectral Information

The most significant advantage of the DAD is its ability to collect full spectral data for every point in the chromatogram. A conventional UV-Vis detector is typically set to monitor one or a few specific wavelengths chosen based on known analyte properties [11]. If an unexpected compound elutes that does not absorb significantly at the monitored wavelengths, it may be missed entirely. The DAD, by contrast, records all UV-Vis active compounds, providing an unsurpassed capability for method development and the detection of unknown or unexpected impurities [12].

Peak Purity and Homogeneity Assessment

Peak purity analysis is a cornerstone application of DAD technology. By comparing spectra extracted from the upslope, apex, and downslope of a chromatographic peak, the software can determine with high probability whether the peak represents a single, pure compound or a co-eluting mixture [11]. A pure compound will have identical spectra across the entire peak, while a co-eluting impurity will cause spectral shifts. This is vital for validating chromatographic methods and ensuring the accuracy of quantitative results before MS analysis.

Spectral-Based Identification and Confirmation

While mass spectrometry is the primary tool for definitive identification, UV-Vis spectra from a DAD provide a valuable second dimension of confirmation. The absorption spectrum of a compound is a function of its chromophores and overall structure. For instance, in cannabinoid analysis, DAD can readily distinguish between neutral cannabinoids (e.g., THC, CBD) and their acidic forms (e.g., THCA, CBDA) based on their distinct spectral profiles, even before they enter the mass spectrometer [11]. This spectral library matching adds confidence to identifications based on retention time alone.

Table 1: Key Performance and Application Differences Between Detector Types

| Feature | Conventional UV-Vis Detector | Diode Array Detector (DAD) |

|---|---|---|

| Wavelength Operation | Single or few sequential wavelengths [11] | Full spectrum simultaneously (190-900 nm) [10] [9] |

| Spectral Data | Limited to set wavelengths | Complete spectrum for every data point [11] |

| Peak Purity Analysis | Not possible, or requires multiple injections | Robust, via spectral comparison across a peak [11] |

| Identification Confidence | Based on retention time only | Retention time plus spectral match [11] [9] |

| Method Development | Requires prior knowledge of λ_max | Ideal for characterizing unknowns and optimizing λ [12] |

| Sensitivity | Generally high at a fixed wavelength | Slightly lower due to light splitting, but modern systems are highly improved [9] |

Critical Applications in Pharmaceutical and Bioanalysis

The DAD is an indispensable tool within the UFLC-DAD-ESI-MS framework, providing specific functionalities that complement mass spectrometric detection.

Peak Purity Assessment for Method Validation

In pharmaceutical quality control, demonstrating that a chromatographic peak is pure and free from co-eluting impurities is a regulatory requirement. The DAD is the standard tool for this purpose. The experimental protocol involves:

- Chromatographic Separation: Execute the UFLC method to elute the target analyte.

- Spectral Acquisition: The DAD continuously collects spectra throughout the elution of the peak.

- Spectral Comparison: Software algorithms automatically compare the spectrum at the peak apex against spectra from the peak's leading and trailing edges.

- Purity Index Calculation: A numerical value (purity index or match threshold) is generated. A value above a set threshold (e.g., 99.9%) indicates a pure peak, while a lower value suggests co-elution [11].

Spectral Deconvolution of Overlapping Peaks

Even with optimized chromatography, complete resolution of all peaks is not always achievable. Advanced DAD software, such as Shimadzu's i-PDeA function, can mathematically deconvolute overlapping peaks based on their unique spectral profiles [11]. This "virtual separation" allows for the quantification of individual analytes in an unresolved peak pair, provided their spectra are sufficiently distinct. The protocol relies on extracting the pure spectrum of each component from the regions where they are less overlapped and using this information to resolve the combined signal.

Identity Confirmation in Complex Matrices

In bioanalysis (e.g., pharmacokinetic studies), biological matrices are complex and can contain interfering compounds with similar retention times. The DAD provides a powerful orthogonal check to MS detection. The protocol involves:

- Library Building: Creating a spectral library of target analytes and known metabolites under controlled conditions.

- Sample Analysis: Running the UFLC-DAD-ESI-MS method on the biological sample.

- Data Correlation: For a peak with a matching retention time, its spectrum is automatically compared against the library entry. A high spectral match factor confirms the identity, adding a layer of certainty to the MS identification [13].

The Scientist's Toolkit: Essential Reagents and Components for DAD Systems

Maintaining optimal performance of a DAD within a UFLC-DAD-ESI-MS system requires specific consumables and reagents.

Table 2: Key Research Reagent Solutions and Consumables for HPLC-DAD

| Item | Function / Purpose | Example / Specification |

|---|---|---|

| Mobile Phase Solvents | Liquid carrier for chromatographic separation; must be high purity ("HPLC grade") to minimize UV background noise [12] | High-purity water, acetonitrile, methanol |

| D₂ Lamp | Light source providing continuous emission in the ultraviolet (UV) range (~190-380 nm) [10] [9] | SCION LC20210125 [10] |

| W Lamp | Light source providing continuous emission in the visible (VIS) range (~380-900 nm) [10] [9] | SCION LC20210094 [10] |

| Flow Cell | Transparent container where the eluent passes through the optical path for absorbance measurement [10] | SCION LC20200036 [10] |

| Hg Lamp (Optional) | Lamp used for automated wavelength calibration verification to ensure spectral accuracy [9] | SCION LC20210108 [10] / Built-in for Shimadzu [9] |

| Certified Standards | For system qualification, method validation, and quantification of target analytes. | USP/Ph.Eur. standards for pharmaceuticals; Bisphenol A, Aflatoxins for food/environmental [12] |

Integrated Workflow: The Role of DAD in UFLC-DAD-ESI-MS Methodology

The power of the DAD is fully realized when it is integrated with mass spectrometry, as each technique addresses the limitations of the other. The typical analytical workflow and the specific role of the DAD at each stage are outlined below.

Figure 2: Integrated Analytical Workflow in UFLC-DAD-ESI-MS

As shown in Figure 2, the DAD acts as a non-destructive, information-rich detector placed in-line after the chromatographic column and prior to the ESI-MS. The eluent can be split, with one portion going to the DAD and the other to the MS, or it can pass through the DAD flow cell first. The DAD provides:

- Peant Purity Flagging: Alerts the analyst to potential co-elution that could compromise MS quantification or lead to misidentification.

- Orthogonal Confirmation: Adds a UV-Vis spectral match to the mass spectral data for higher-confidence identification.

- Compound Class Distinction: Easily differentiates between compounds with similar masses but different chromophores (e.g., the cannabinoid example) [11].

While LC-MS is more sensitive and capable of identifying unknowns based on molecular mass and fragmentation pattern, HPLC-DAD is often chosen as a more straightforward and cost-effective method for quantifying known compounds where spectral information provides sufficient selectivity [12]. The combination of both techniques in a single platform provides the most comprehensive analytical picture.

Electrospray Ionization (ESI) is a foundational soft ionization technique that has fundamentally reshaped modern mass spectrometry by enabling the efficient analysis of large, non-volatile, and thermally labile biomolecules [14] [15]. Its core innovation lies in the ability to gently convert analytes from a liquid solution into intact gas-phase ions, making it perfectly suited for direct coupling with liquid-phase separation techniques like Liquid Chromatography (LC) [16]. This synergy is the bedrock of the powerful UFLC-DAD-ESI-MS methodology, a comprehensive platform for separation, detection, and identification.

The transformative impact of ESI was recognized with the 2002 Nobel Prize in Chemistry, awarded to John B. Fenn for its development [15] [16]. Within the context of UFLC-DAD-ESI-MS research, ESI serves as the critical bridge. The Ultra-Fast Liquid Chromatography (UFLC) system separates complex mixtures, the Diode Array Detector (DAD) provides spectral data for chromophore-containing compounds, and the ESI source efficiently transports the separated analytes into the mass spectrometer for mass analysis [17] [18]. This guide details the core principles and processes that underpin this essential technology.

The ESI Process: A Step-by-Step Mechanism

The transformation of a sample in solution to a gas-phase ion in the mass spectrometer is a multi-stage process occurring at atmospheric pressure. It involves the application of a strong electric field to a liquid, leading to the creation of a fine aerosol and culminating in the release of free ions [14] [16].

Formation of the Taylor Cone and Charged Droplets

The process begins when the sample solution, typically comprising a polar volatile solvent like water, methanol, or acetonitrile, is introduced through a metal capillary needle (electrospray tip) held at a high voltage (typically 2–6 kV) [19] [14]. A fine mist of highly charged droplets with the same polarity as the capillary voltage is generated. The strong electric field induces a charge accumulation at the tip of the capillary, deforming the liquid into what is known as a Taylor cone [15] [16]. When the electrostatic repulsion overcomes the surface tension of the liquid, the tip of this cone emits a fine jet that disintegrates into a mist of charged droplets [15].

Solvent Evaporation and Coulomb Fission

The charged droplets are then directed towards the mass spectrometer's inlet. As they travel, a stream of heated drying gas (often nitrogen) and the application of heat aid in the evaporation of the solvent [19] [14]. This evaporation reduces the droplet size while the charge remains constant, leading to a dramatic increase in charge density at the droplet surface [16]. The electrostatic repulsion between like charges within the droplet intensifies until it surpasses the cohesive force of the surface tension, a threshold known as the Rayleigh limit [19] [15]. At this point, the droplet becomes unstable and undergoes Coulomb fission, disintegrating into smaller, progeny droplets [19] [15]. This cycle of solvent evaporation and Coulomb fission repeats iteratively, producing progressively smaller and more highly charged droplets [16].

Production of Gas-Phase Ions

The final stage is the release of gas-phase ions from these highly charged, desolvated droplets. Two primary models explain this for different types of analytes:

- Charge Residue Model (CRM): Proposed by Malcolm Dole, this model suggests that repeated droplet fission continues until a droplet is formed that contains only a single analyte molecule. The eventual evaporation of the last solvent molecules leaves the analyte with the residual charge, producing a gas-phase ion [15]. This mechanism is generally accepted for large biomolecules like folded proteins.

- Ion Evaporation Model (IEM): This model posits that for smaller ions, the electric field at the surface of a very small, charged droplet becomes strong enough to directly desorb or "evaporate" the solvated ion into the gas phase before the droplet reaches the theoretical Rayleigh limit [15].

A critical feature of ESI is its tendency to produce ions with multiple charges [15]. This is particularly common for large molecules like proteins, which can accommodate many protons at various sites. The multiple charging phenomenon effectively extends the mass range of mass spectrometers, allowing the measurement of molecules with masses tens or hundreds of thousands of Daltons on instruments with a limited m/z range [15] [16].

The following diagram illustrates the complete workflow of the UFLC-DAD-ESI-MS system, integrating the ESI process into the broader analytical context.

Essential Components and Optimization in UFLC-DAD-ESI-MS

Successful implementation of the integrated UFLC-DAD-ESI-MS methodology requires careful consideration of both the sample preparation and the operational parameters of the ESI source. These factors directly impact sensitivity, reproducibility, and data quality.

Samples for ESI-MS are typically purified to remove non-volatile salts and contaminants that can suppress ionization or deposit on the instrument, causing signal instability [19]. Common online purification techniques coupled directly to the ESI source include High-Performance Liquid Chromatography (HPLC) and Capillary Electrophoresis [19] [14]. The choice of solvent is critical; optimal solvents are polar and volatile, such as mixtures of water with methanol or acetonitrile, often modified with small concentrations (e.g., 0.1%) of acids (formic or acetic acid) or volatile buffers (ammonium formate/acetate) to enhance conductivity and promote protonation or deprotonation [20] [15].

Key ESI Parameters and Their Influence

Optimizing the ESI source parameters is crucial for robust performance. The table below summarizes the core parameters and their typical optimization ranges.

Table 1: Key ESI Source Parameters for Method Optimization

| Parameter | Typical Range/Value | Influence on Ionization Process |

|---|---|---|

| Capillary Voltage | 2.5 – 6.0 kV [14] | Applied to the spray needle to generate the Taylor cone and charged droplets. Too low: no spray; too high: discharge instability. |

| Drying Gas (N₂) Flow & Temperature | Variable, often 100-300°C [19] | Aids in solvent evaporation from charged droplets, facilitating droplet shrinkage and Coulomb fissions. |

| Nebulizing Gas (N₂) Pressure | Variable | Shears the eluted solution to enhance the formation of a finer mist of droplets, improving ionization efficiency [14]. |

| Capillary Inlet Temperature | 100 – 300 °C [19] | Heats the capillary leading to the MS vacuum, ensuring complete desolvation of ions before analysis. |

| Sample Flow Rate | 1 – 20 µL/min (conventional) [19]; Nano-liter scales for nano-ESI [15] | Lower flow rates produce smaller initial droplets, which can increase ionization efficiency and sensitivity [15]. |

The Scientist's Toolkit: Research Reagents and Materials

The experimental workflow in UFLC-DAD-ESI-MS relies on a suite of specialized reagents, solvents, and materials. The following table details essential components for preparing and analyzing samples, drawing from validated methodologies in the literature.

Table 2: Essential Research Reagents and Materials for UFLC-DAD-ESI-MS

| Reagent/Material | Function/Purpose | Example from Literature |

|---|---|---|

| Mobile Phase Additives | Adjust pH and provide protons for ionization; must be volatile for MS compatibility. | 10 mM Ammonium Formate (pH 3 with HCOOH) or 10 mM Ammonium Bicarbonate (pH 9 with NH₃) [20]. |

| Solid-Phase Extraction (SPE) Cartridges | Sample clean-up to remove matrix interferents and reduce ion suppression. | Oasis HLB (for urine) and Oasis MAX (for herbal extracts) [20]. |

| Organic Solvents (HPLC/MS Grade) | Mobile phase components; extraction solvents. | Acetonitrile, Methanol [20] [17]. |

| Analytical Standards | For instrument calibration, method validation, and compound identification/quantification. | Commercially available pure standards (e.g., digoxin, oleandrin, chlorogenic acid, rutin) [20] [17]. |

| Internal Standards (IS) | Correct for variability in sample preparation and ionization efficiency; essential for quantification. | Isotopically labeled analogs of the analyte (e.g., Digoxin-d3) [20]. |

| UHPLC Columns | High-efficiency separation of complex mixtures under high pressure. | C18 BEH column [20]; RP-C18 column [17]. |

Advanced Applications in Pharmaceutical and Bioanalytical Research

The UFLC-DAD-ESI-MS platform, with ESI at its core, is indispensable in modern laboratories. Its "soft ionization" nature preserves non-covalent interactions and provides a robust tool for quantitative and qualitative analysis.

Quantification of Bioactive Compounds and Toxins

The methodology excels at sensitive and precise quantification. A validated UHPLC-ESI-MS/MS method was developed for five cardiac glycosides (e.g., oleandrin, digoxin) in complex matrices like culinary herbs and human urine [20]. The method achieved impressive limits of quantification (1.5–15 ng/g for herbs and 0.025–1 ng/mL for urine), with mean recoveries of 70–120% and excellent linearity (R² > 0.997) [20]. Another study simultaneously quantified six bioactive phenolics (e.g., chlorogenic acid, rutin, quercetin) in Sambucus formosana extracts, demonstrating high recovery (86.5–93.1%) and good reproducibility (RSD 1.7–3.1%) [17].

Detection of Illicit Substances and Impurity Profiling

ESI-MS is a powerful tool for forensic and pharmaceutical quality control. It has been used to screen cosmetic creams for illegally added pharmaceuticals like sildenafil, tadalafil, and testosterone [18]. Furthermore, ESI's compatibility with various chromatographic modes, including Hydrophilic Interaction Liquid Chromatography (HILIC), makes it vital for profiling polar impurities in pharmaceutical products that are poorly retained by reversed-phase chromatography [21].

"Omics" Sciences and Biomarker Discovery

In proteomics and metabolomics, ESI's ability to handle complex mixtures and generate multiply charged ions from large biomolecules is unrivaled. It is routinely used for the large-scale identification and quantification of proteins, metabolites, and lipids, facilitating the discovery of novel biomarkers for diseases and the understanding of biological pathways [22] [16].

Electrospray Ionization has unequivocally demystified the challenge of moving from liquid samples to gas-phase ions, establishing itself as a cornerstone of modern analytical chemistry. Its integration into the UFLC-DAD-ESI-MS workflow provides a comprehensive and powerful platform that leverages high-resolution separation, multi-mode detection, and sensitive, information-rich mass analysis. As mass spectrometry continues to advance with innovations in nano-flow systems, ion source design, and high-resolution instrumentation, the fundamental principles of ESI will continue to underpin new breakthroughs in drug development, clinical research, and the life sciences.

Mass spectrometry (MS) stands as a cornerstone analytical technique in modern scientific research, enabling the precise determination of molecular mass and structure. Within a mass spectrometer, the mass analyzer is the critical component responsible for separating ions based on their mass-to-charge ratio (m/z). The choice of mass analyzer directly impacts key performance parameters such as mass resolution, accuracy, sensitivity, and speed. This technical guide provides an in-depth examination of two prevalent mass analyzer technologies: the quadrupole and time-of-flight (TOF), with specific focus on their integration within Ultra-Fast Liquid Chromatography-Diode Array Detector-Electrospray Ionisation-Mass Spectrometry (UFLC-DAD-ESI-MS) methodology. This hyphenated technique is indispensable in pharmaceutical research and drug development, allowing for the high-throughput separation, detection, and characterization of complex mixtures.

Fundamental Principles of Operation

The Quadrupole Mass Analyzer

The quadrupole mass analyzer functions as a mass filter utilizing dynamic electric fields. It consists of four precisely parallel metal rods. Opposite rod pairs are connected electrically, and a combination of a direct current (DC) voltage and a radio frequency (RF) alternating current voltage is applied to them [23] [24] [25].

Principle of Operation: The applied electromagnetic fields create a oscillating path for ions traveling through the quadrupole. For given DC and RF voltages, only ions of a specific mass-to-charge ratio (m/z) will maintain a stable trajectory and successfully traverse the entire length of the rods to reach the detector. Ions with unstable trajectories will collide with the rods and be neutralized [24] [25]. To acquire a full mass spectrum, the DC and RF potentials are scanned, which sequentially allows ions of different m/z values to pass through [23].

The Time-of-Flight (TOF) Mass Analyzer

The Time-of-Flight (TOF) mass analyzer separates ions based on their velocity over a known distance. In this system, all ions are accelerated by the same electric field, imparting them with identical kinetic energy [26] [27].

Principle of Operation: According to the fundamental physical relationship ( v = d/t ), ions of lower mass achieve higher velocities, while heavier ions of the same charge travel more slowly. The flight time from the ion source to the detector is measured and converted into an m/z value using the equation ( t = \frac{d}{\sqrt{2U}} \sqrt{\frac{m}{q}} ), where t is time, d is the flight path length, U is the accelerating voltage, m is mass, and q is charge [27]. This demonstrates that the flight time is proportional to the square root of the mass-to-charge ratio [26] [27]. Unlike the quadrupole, the TOF analyzer is a nonscanning instrument; it measures all ions from each ionization pulse simultaneously [23].

Critical Performance Characteristics and Comparison

The fundamental differences in the operation of quadrupole and TOF mass analyzers lead to distinct performance profiles, which determine their suitability for specific applications.

Table 1: Comparison of Quadrupole and Time-of-Flight Mass Analyzer Performance

| Characteristic | Quadrupole Mass Analyzer | Time-of-Flight (TOF) Mass Analyzer |

|---|---|---|

| Operating Principle | Mass filtering via stable/unstable trajectories in EM fields [24] | Velocity-based separation over a known distance [26] [27] |

| Acquisition Mode | Scanning (sequential) [23] | Nonscanning (simultaneous) [23] |

| Acquisition Speed | Limited by scan speed; typically up to ~10,000 u/s [23] | Very fast; up to 500 spectra/s, independent of mass range [23] |

| Sensitivity | High in Selected Ion Monitoring (SIM) mode, but limited in full-scan mode [26] [23] | Inherently high in full-spectrum mode due to simultaneous analysis of all ions [26] [23] |

| Mass Resolution | Unit mass resolution typically sufficient for targeted analysis [25] | High resolution (can reach tens of thousands) [27] |

| Mass Accuracy | Moderate | High (low ppm range) [23] |

| Dynamic Range | ~3 orders of magnitude [23] | ~4 orders of magnitude or greater [23] |

| Spectral Skew | Present due to sequential scanning of changing ion concentrations [23] | Absent; nonscanning nature provides spectral continuity [23] |

Integration in UFLC-DAD-ESI-MS Methodology

The combination of Ultra-Fast Liquid Chromatography (UFLC), a Diode Array Detector (DAD), Electrospray Ionisation (ESI), and a Mass Spectrometer forms a powerful platform for comprehensive sample analysis.

1. System Synergy: In a UFLC-DAD-ESI-MS system, the UFLC component rapidly separates complex mixtures. The DAD detects analytes based on their UV-Vis absorption spectra, providing information on chromophores and enabling peak purity assessment [10]. The ESI source gently converts liquid-phase analytes into gas-phase ions, making it ideal for thermally labile molecules and large biomolecules [14]. Finally, the mass analyzer (Quadrupole or TOF) provides mass-specific detection.

2. The ESI Process and Analyzer Interface: ESI works by creating a fine spray of highly charged droplets at the tip of a capillary held at high voltage. Through solvent evaporation and Coulombic repulsion, gas-phase ions are produced from these droplets [14]. TOF analyzers are often coupled to continuous ion sources like ESI via orthogonal acceleration (oa-TOF), where ions are pulsed at 90 degrees into the flight tube. This technique, combined with collisional cooling, separates ion production from mass analysis, allowing for high resolution without sacrificing sensitivity [27].

3. Application Context: A representative application of this methodology is illustrated by a study screening for topoisomerase I inhibitors in a medicinal plant extract. The researchers used bioaffinity ultrafiltration combined with UFLC-ESI-Q/TOF-MS/MS [28]. This approach highlights the utility of the Q/TOF hybrid instrument, which combines the mass-filtering capability of a quadrupole with the high mass accuracy and resolution of a TOF analyzer for identifying bioactive compounds in complex matrices.

Essential Research Reagents and Materials

Successful implementation of UFLC-DAD-ESI-MS experiments requires specific reagents and consumables. The following table details key materials used in the featured bioaffinity screening application [28] and general system operation.

Table 2: Key Research Reagent Solutions and Essential Materials

| Item | Function / Application |

|---|---|

| DNA Topoisomerase I (Human) | Biological target enzyme used in bioaffinity ultrafiltration screening to identify binding ligands from a complex extract [28]. |

| Amicon Ultra-0.5 Centrifugal Filters | Ultrafiltration devices (e.g., 3 kDa MWCO) used to separate ligand-enzyme complexes from unbound compounds [28]. |

| HPLC-grade Solvents (Methanol, Acetonitrile) | Essential for mobile phase preparation in UFLC, ensuring low UV background and minimal ion suppression in ESI-MS [28]. |

| SRB Assay Kit | Sulforhodamine B (SRB) assay used for in vitro cell viability and cytotoxicity assessment of active compounds [28]. |

| Electrospray Ionization Source Consumables | Includes capillary tubes, and in some designs, nebulizing and drying gas (e.g., Nitrogen), for stable and efficient ion production [14]. |

| D2 and W Lamps for DAD | Light sources for the Diode Array Detector, providing a broad spectrum in the UV (Deuterium) and visible (Tungsten) range [10]. |

| Mobile Phase Additives | Volatile buffers (e.g., ammonium acetate/formate) and modifiers (e.g., formic acid) to enhance chromatographic separation and ESI efficiency. |

Detailed Experimental Protocol: Bioaffinity Screening via UFLC-ESI-Q/TOF-MS

The following protocol is adapted from a study investigating topoisomerase I inhibitors from a plant extract, demonstrating a key application of the Q/TOF technology in pharmaceutical analysis [28].

1. Sample Preparation:

- Extraction: Subject dried plant powder to ultrasonic-assisted extraction using 50% ethanol. Concentrate the combined extracts under reduced pressure.

- Fractionation: Partition the crude extract using ethyl acetate saturated with water. Collect the ethyl acetate fraction and concentrate it for analysis.

2. Bioaffinity Ultrafiltration Screening:

- Incubation: Incubate the plant extract (e.g., 20 µL of 10 mg/mL) with the target enzyme, Topoisomerase I (e.g., 20 µL, 12.5 U), in an appropriate buffer (pH 7.9) at 37°C for 30 minutes.

- Ultrafiltration: Transfer the mixture to an Amicon Ultra-0.5 centrifugal filter unit (3 kDa molecular weight cut-off). Centrifuge to remove unbound compounds.

- Washing: Wash the filter with buffer to remove any non-specifically bound compounds.

- Elution: Elute the potent ligands bound to the enzyme using a denaturing solvent (e.g., methanol-water). The eluate contains compounds with high affinity to the target enzyme.

- Control: Run a control experiment without the enzyme in parallel to identify compounds that bind non-specifically to the filter device.

3. UFLC-ESI-Q/TOF-MS/MS Analysis:

- Chromatography: Separate the eluted ligands using a UHPLC system with a C18 reverse-phase column. Employ a gradient elution with water and acetonitrile, both containing a small percentage of formic acid.

- Detection: First, acquire UV spectra using the DAD.

- Mass Spectrometry:

- Ionization: Introduce the LC effluent into the ESI source operating in positive or negative ion mode.

- Data Acquisition (TOF MS): Use the TOF analyzer to acquire high-resolution full-scan mass spectra over a defined m/z range (e.g., 50-1000 m/z) for both the control and the enzyme-binding sample. This allows for accurate mass measurement of potential inhibitors.

- Data Acquisition (MS/MS): For structural elucidation, use the tandem MS capability. The first quadrupole (Q1) selects the precursor ion of interest, which is then fragmented in the collision cell (q2) using an inert gas like argon. The resulting product ions are analyzed by the TOF mass analyzer to generate a characteristic fragmentation spectrum.

4. Data Analysis:

- Ligand Identification: Compare the full-scan MS data of the enzyme-binding sample with the control to pinpoint the specific ligands that bound to the target.

- Structural Confirmation: Interpret the MS/MS spectra of the identified ligands and match them against spectral libraries or databases for confirmation.

Quadrupole and Time-of-Flight mass analyzers offer complementary strengths that make them suitable for different phases of pharmaceutical analysis within a UFLC-DAD-ESI-MS framework. The quadrupole excels in targeted, quantitative applications such as therapeutic drug monitoring and pharmacokinetic studies, particularly when operated in Selected Ion Monitoring (SIM) or Multiple Reaction Monitoring (MRM) mode on a triple-quadrupole platform [23] [14]. In contrast, TOF analyzers are the superior choice for untargeted analyses, rapid screening, and high-resolution accurate mass measurement, which is essential for identifying metabolites, characterizing impurities, and deconvoluting complex mixtures like natural product extracts [26] [23] [28]. The combination of these technologies in hybrid systems like the Q-TOF provides an even more powerful tool, merging quantitative precision with qualitative comprehensive analysis, thereby accelerating drug discovery and development processes.

Hyphenated techniques represent a paradigm shift in modern analytical chemistry, developed from the on-line coupling of a separation technique with one or more spectroscopic detection technologies [29]. The term "hyphenation" was introduced to describe this seamless integration, which combines the superior separation power of techniques like chromatography with the selective identification capabilities of spectrometry [29]. This synergy creates analytical tools with capabilities far exceeding those of their individual components. The fundamental principle involves using chromatography to produce pure or nearly pure fractions of chemical components in a mixture, while spectroscopy generates selective information for identification using standards or library spectra [29]. The remarkable improvements in hyphenated analytical methods over recent decades have significantly broadened their applications across numerous fields, including biomaterial analysis, natural product research, drug development, food chemistry, and metabolomic studies [29] [30].

The core value proposition of hyphenation lies in its ability to provide comprehensive analytical information from a single experimental run. Where traditional approaches required time-consuming fraction collection followed by separate analysis, modern hyphenated systems perform separation, detection, and identification in a continuous, automated workflow [29]. This integrated approach is particularly valuable for analyzing complex mixtures found in natural products, biological samples, pharmaceuticals, and environmental samples, where individual components may be present at low concentrations within challenging matrices [29].

The Fundamental Synergy in UFLC-DAD-ESI-MS

Conceptual Framework of Technique Integration

The power of UFLC-DAD-ESI-MS emerges from the sequential application of complementary analytical principles, where each component addresses specific challenges in complex mixture analysis. Ultra-Fast Liquid Chromatography (UFLC) provides the initial separation dimension, utilizing advanced column packing materials (typically 1.8-5 µm particles) and high-pressure systems (up to 1000 bar) to achieve rapid and efficient separation of complex mixtures [31] [32]. The separation mechanism is based on differential interaction between sample components, the stationary phase (column material), and mobile phase (solvent), resulting in the temporal separation of analytes as they elute from the column [32].

The Diode Array Detector (DAD) serves as the first detection point, providing UV-Vis spectral data for preliminary compound characterization [29]. This non-destructive detection method records complete absorbance spectra across a wavelength range (typically 200-400 nm or broader), enabling compound classification based on chromophore characteristics and purity assessment of chromatographic peaks [33]. The DAD data is particularly valuable for identifying compound classes with characteristic UV profiles, such as phenolic compounds, aromatic systems, and conjugated double bonds [33].

The analytical workflow then transitions to mass spectrometric detection through the Electrospray Ionization (ESI) interface, which serves as the critical bridge between the liquid-based separation and the gas-phase mass analysis [32]. In the ESI source, the separated components are nebulized into fine droplets under the influence of a high voltage applied to a capillary (typically 2000-5000 V), while a neutral carrier gas (e.g., nitrogen) assists in solvent evaporation [32] [34]. As the droplets disintegrate, charged analyte molecules are released into the gas phase through mechanisms that may involve charge residue or ion evaporation models [32].

The final detection occurs in the Mass Spectrometer (MS), where the ionized molecules are separated according to their mass-to-charge ratio (m/z) in an analyzer under high vacuum, before striking a detector that registers and counts the ions [32]. This generates a mass spectrum that displays signal intensity versus m/z, providing molecular weight information and, through fragmentation patterns, structural characteristics [29]. The combination of these technologies creates an analytical system capable of separating complex mixtures and providing extensive structural information on the separated components.

Technical Synergy and Information Complementarity

The synergy between these techniques creates a comprehensive analytical system where the whole is significantly greater than the sum of its parts. The complementary data generated through this hyphenation provides multiple dimensions of information for each component in a mixture: retention time from chromatography, UV spectrum from DAD, and mass spectrum from MS [29] [33]. This multi-parameter detection greatly enhances the confidence in compound identification, as each identifier provides orthogonal verification.

The hyphenated system exhibits remarkable sensitivity derived from the focusing effect of chromatographic separation combined with selective mass detection. By separating analytes from matrix interferences before introduction to the mass spectrometer, chemical noise is dramatically reduced, thereby enhancing signal-to-noise ratios and lowering detection limits [35] [34]. This is particularly important for analyzing trace components in complex samples like biological fluids, environmental samples, or natural product extracts [29].

Another key advantage lies in the analytical efficiency achieved through automation and continuous operation. Early methods required manual fraction collection followed by separate spectral analysis, which was time-consuming, prone to sample loss or degradation, and limited in reproducibility [29]. The hyphenated system transforms this into a seamless automated process where separation, detection, and data collection occur in a unified workflow, significantly enhancing throughput, reproducibility, and data quality [32] [29].

Table 1: Complementary Information Provided by Components of UFLC-DAD-ESI-MS

| Technique | Primary Information | Analytical Value | Limitations Addressed by Hyphenation |

|---|---|---|---|

| UFLC | Retention time, separation efficiency | Purity assessment, relative hydrophobicity | Limited compound identification capability |

| DAD | UV-Vis spectrum, chromophore characteristics | Compound class identification, purity assessment | Limited structural information, coelution issues |

| ESI-MS | Molecular mass, fragmentation pattern | Structural elucidation, exact mass determination | Matrix effects, isobaric interferences |

| Hyphenated System | Comprehensive dataset with retention time, UV spectrum, and mass spectrum | Confident compound identification, unknown characterization | All limitations of individual techniques |

Core Components and Operating Principles

Ultra-Fast Liquid Chromatography (UFLC) Separation Mechanics

UFLC represents an evolution of traditional High-Performance Liquid Chromatography (HPLC), with significant advancements in separation efficiency and analysis speed. The key technological improvements include reduced particle sizes in stationary phases (often sub-2µm), specialized instrumentation capable of withstanding higher pressures (up to 1000 bar), and optimized fluidic systems that minimize extra-column volume [31]. These developments enable faster separations without compromising resolution, making UFLC particularly valuable in high-throughput analytical environments where time efficiency is critical [31].

The separation process occurs within the chromatographic column, where analytes interact with the stationary phase (typically C18-modified silica) through mechanisms such as hydrophobic interactions, hydrogen bonding, and π-π interactions [32]. A solvent mixture (e.g., water and acetonitrile, often with modifiers like formic acid) is passed over the column in varying proportions, creating a mobile phase gradient that elutes compounds based on their polarity and affinity for the stationary phase [32] [35]. Components with greater affinity for the stationary phase are retained longer, while those with higher compatibility with the mobile phase elute more quickly [32]. This differential migration results in the temporal separation of mixture components before they enter the detection systems.

Diode Array Detection (DAD) Fundamentals

The DAD detector provides the first dimension of spectroscopic information following chromatographic separation. Operating on the principles of the Beer-Lambert law, DAD measures the absorbance of UV or visible light as analytes pass through a flow cell [29]. Unlike single-wavelength detectors, DAD simultaneously captures absorbance across a spectrum of wavelengths (typically 200-600 nm), generating complete UV-Vis profiles for each point in the chromatogram [33].

The resulting three-dimensional data (absorbance × wavelength × time) enables several critical analytical functions: peak purity assessment through spectral comparison across a chromatographic peak, compound classification based on characteristic chromophores and absorption maxima, and method development assistance by identifying optimal detection wavelengths for specific compounds [33]. For example, phenolic compounds like chlorogenic acid display maximum absorption around 325-330 nm, while flavonoids such as quercetin derivatives show distinctive band I and band II absorption between 240-280 nm and 330-380 nm [33]. This spectral information serves as valuable preliminary evidence for compound identity and characteristics.

Electrospray Ionization (ESI) Interface Mechanisms

The ESI interface represents one of the most significant technological advancements enabling robust LC-MS coupling, particularly for its ability to handle high flow rates (typically 0.1-1.0 mL/min) while efficiently transferring non-volatile and thermally labile compounds from solution to the gas phase [32] [29]. The ionization process begins when the liquid effluent from the DAD cell is introduced through a capillary to which a high voltage (2000-5000 V) is applied, creating a Taylor cone that disperses the liquid into a fine mist of charged droplets [32] [34].

As these droplets travel toward the mass analyzer entrance, a countercurrent flow of drying gas (typically nitrogen) facilitates solvent evaporation, causing droplet shrinkage and increasing charge density [32]. When electrostatic repulsion overcomes surface tension, droplets undergo Coulombic fission, eventually leading to the release of desolvated, charged analyte ions into the gas phase [32]. Two primary mechanisms explain final ion formation: the charge residue model (CRM) where evaporation continues until a single charged analyte remains, and the ion evaporation model (IEM) where direct ion emission occurs from highly curved droplet surfaces [29].

ESI is particularly valued as a soft ionization technique, generating predominantly molecular ions with minimal fragmentation, which is ideal for molecular weight determination [29]. It efficiently handles a broad mass range and is especially effective for polar and ionic compounds. A notable characteristic of ESI is its propensity to generate multiply charged ions for larger molecules (e.g., proteins, peptides), effectively extending the mass range of analyzers by reducing the m/z ratio [32] [29]. This multiple charging phenomenon makes ESI indispensable for biomacromolecule analysis.

Mass Spectrometric Analysis and Detection

The mass analyzer represents the final component where separated ions are discriminated based on their mass-to-charge ratio (m/z). Various analyzer types can be employed in UFLC-DAD-ESI-MS systems, each with distinct characteristics and applications. Triple quadrupole systems operate by selectively transmitting ions through sequential mass filters, enabling highly sensitive targeted analysis and multiple reaction monitoring (MRM) experiments ideal for quantification [35]. Time-of-flight (TOF) analyzers separate ions based on velocity measurements in a field-free drift region, providing high mass accuracy and resolution valuable for unknown identification and elemental composition determination [33]. Quadrupole-time-of-flight (Q-TOF) hybrid instruments combine the ion selection capability of quadrupoles with the high resolution and mass accuracy of TOF analyzers, making them exceptionally powerful for structural elucidation and metabolomic studies [33].

The detection process culminates when separated ions strike an electron multiplier or similar detection device, generating electrical signals proportional to ion abundance [32]. Sophisticated data systems process these signals to produce mass spectra (intensity versus m/z) at regular intervals throughout the chromatographic separation, creating a comprehensive three-dimensional dataset (intensity × m/z × retention time) that forms the basis for qualitative and quantitative analysis [32] [29].

Table 2: Mass Analyzer Configurations in Hyphenated Systems

| Analyzer Type | Mass Accuracy | Resolving Power | Primary Applications | Key Advantages |

|---|---|---|---|---|

| Triple Quadrupole | Medium (100-500 ppm) | Unit resolution | Targeted quantification, MRM studies | Excellent sensitivity, robust quantification |

| Time-of-Flight (TOF) | High (1-5 ppm) | High (20,000-60,000) | Untargeted screening, unknown identification | High mass accuracy, fast acquisition |

| Quadrupole-TOF (Q-TOF) | High (1-5 ppm) | High (20,000-60,000) | Structural elucidation, metabolomics | MS/MS capability with high resolution |

| Ion Trap | Medium (100-500 ppm) | Unit to medium | Multiple-stage MS, fragmentation studies | Multiple MS^n capability, compact design |

Experimental Methodology and Optimization

Comprehensive Workflow for UFLC-DAD-ESI-MS Analysis

A robust analytical method using UFLC-DAD-ESI-MS involves multiple critical steps, each requiring careful optimization to ensure reliable results. The complete workflow encompasses sample preparation, chromatographic separation, multi-detection data acquisition, and comprehensive data analysis.

Sample Preparation represents a crucial initial step that significantly impacts final data quality. For plant material analysis, samples are typically harvested, frozen in liquid nitrogen, and finely ground using a mortar and pestle [35]. Precise weighing (typically 50-100 mg) is followed by extraction with appropriate solvents (e.g., methanol, acetonitrile, or dichloromethane), often assisted by vortex mixing and sonication [35] [36]. After centrifugation (13,000 ×g for 5-15 minutes at 4°C), the supernatant is collected, filtered through 0.45 μm or 0.22 μm membrane filters, and transferred to autosampler vials for analysis [35]. For complex matrices, additional cleanup steps such as solid-phase extraction (SPE) may be incorporated to reduce matrix effects and enhance sensitivity [29].

Chromatographic Separation requires careful optimization of multiple parameters. Typical UFLC conditions employ reversed-phase C18 columns (150 × 4.6 mm, 2.5-5 μm particle size) maintained at 40°C to ensure retention time stability [35]. Mobile phase systems commonly consist of aqueous (A: 0.1% formic acid in water) and organic (B: acetonitrile or methanol) components delivered according to optimized gradient programs [35]. For example, a representative gradient might progress from 0-40% B over 0.01-2 minutes, 40-60% B from 2-5 minutes, 100% B from 5-13 minutes, and re-equilibration at 20% B from 13-15 minutes, with a flow rate of 0.5 mL/min [35]. Injection volumes typically range from 1-20 μL, depending on concentration and detection sensitivity requirements [35].

Mass Spectrometric Detection parameters must be optimized for each analyte class. ESI source conditions typically include: nebulizer gas flow (2-3 L/min), drying gas flow (10-15 L/min), desolvation line temperature (250-300°C), heat block temperature (400-500°C), and interface voltage (2000-5000 V, depending on polarity mode) [35]. For targeted analysis, Multiple Reaction Monitoring (MRM) transitions are established by direct infusion of standard solutions, identifying precursor ions and characteristic product ions for each compound [35]. Data acquisition and instrument control are managed by dedicated software (e.g., LabSolutions) that also processes the generated data [35].

Method Validation and Quality Assurance

To ensure analytical reliability, comprehensive method validation is essential. Key validation parameters include linearity, sensitivity, precision, accuracy, and robustness. Linearity is established through calibration curves spanning relevant concentration ranges, with correlation coefficients (r²) typically exceeding 0.995 [35]. Sensitivity is expressed as Limit of Detection (LOD) and Limit of Quantification (LOQ), determined from signal-to-noise ratios of 3:1 and 10:1, respectively [35]. Precision is evaluated through repeated injections (n≥3) at different concentration levels, with relative standard deviation (RSD) values for retention times and peak areas ideally below 5% [35]. Accuracy is assessed through recovery studies by spiking samples with known amounts of standards, with acceptable recovery ranges typically between 80-120% [35]. Robustness testing examines method resilience to minor, deliberate variations in operational parameters.

Table 3: Typical Validation Parameters for UFLC-DAD-ESI-MS Methods

| Validation Parameter | Experimental Approach | Acceptance Criteria | Example Values from Literature |

|---|---|---|---|

| Linearity | Calibration curves at 5-7 concentration levels | r² > 0.995 | r² = 0.9973-0.999 for anti-impotence compounds [31] |

| LOD | Signal-to-noise ratio = 3:1 | Compound-dependent | 0.005-0.50 μg/g for dietary supplement analysis [31] |

| LOQ | Signal-to-noise ratio = 10:1 | Compound-dependent | 0.02-1.24 μg/g for herbal supplements [31] |

| Precision (Intra-day) | Repeated injections (n=3-6) same day | RSD < 5% | RSD ≤ 4.2% at 5 μg/g level [31] |

| Precision (Inter-day) | Repeated injections over 3 days | RSD < 10% | RSD ≤ 5.2% at 0.25 μg/g level [31] |

| Accuracy | Spike recovery experiments | 80-120% recovery | 82-118% for plant hormone analysis [35] |

| Matrix Effects | Comparison of standards in solvent vs. matrix | Signal suppression/enhancement < 20% | Evaluated for plant hormones in Arabidopsis [35] |

Essential Research Reagent Solutions

Successful implementation of UFLC-DAD-ESI-MS methodology requires careful selection of reagents and materials that meet stringent quality standards to ensure reproducible results and prevent instrument contamination.

Table 4: Essential Research Reagents for UFLC-DAD-ESI-MS

| Reagent/Material | Specifications | Function/Purpose | Application Notes |

|---|---|---|---|

| HPLC-grade Water | 18.2 MΩ·cm resistivity, < 5 ppb TOC | Mobile phase component | Baseline for aqueous mobile phase, minimizes background interference |

| HPLC-grade Acetonitrile | Low UV cutoff (< 190 nm), high purity | Organic mobile phase component | Strong elution power, low viscosity, compatible with MS detection |

| HPLC-grade Methanol | Low UV cutoff (< 205 nm), high purity | Organic mobile phase component | Alternative to acetonitrile, different selectivity |

| Formic Acid | LC-MS grade, ≥99% purity | Mobile phase additive (0.05-0.1%) | Promotes protonation in positive ion mode, improves chromatography |

| Ammonium Acetate | LC-MS grade, ≥99% purity | Mobile phase additive (1-10 mM) | Volatile buffer for pH control, MS-compatible |

| C18 Chromatography Column | 50-150 mm length, 2.1-4.6 mm ID, 1.8-5 μm particles | Stationary phase for separation | Core separation component, sub-2μm for UHPLC applications |

| Syringe Filters | Nylon or PTFE, 0.22 μm or 0.45 μm pore size | Sample clarification | Removes particulates that could damage columns or instrumentation |

| Reference Standards | Certified purity (>95%), MS-compatible | Method development and quantification | Essential for compound identification and method validation |

Applications in Scientific Research

Analysis of Edible Oil Oxidation

UFLC-DAD-ESI-MS has proven invaluable for evaluating the oxidation degree of edible oils, a critical parameter for quality control and food safety assessment [37]. During oil oxidation, fatty acids undergo auto-oxidation processes involving chain initiation, propagation, and termination stages, producing primary oxidation products (mainly lipid hydroperoxides) that further degrade into secondary oxidation products including small-molecule aldehydes, ketones, carboxylic acids, and hydrocarbons [37]. These oxidation products negatively impact oil quality, nutrition, and safety, with potential health implications including inflammation, aging, cardiovascular disease, and cancer [37].

A specific method developed for carbonyl compounds (CCs) in soybean oil employed UFLC-DAD-ESI-MS with optimized extraction parameters: 1.5 mL of acetonitrile as extraction solvent, manual stirring for 3 minutes, and 30 minutes of sonication time [38]. The validated method demonstrated detection limits ranging from 0.03 to 0.1 μg·mL⁻¹ and quantification limits of 0.2 μg·mL⁻¹ for all compounds [38]. When applied to soybean oil heated to 180°C, the method identified concerning carbonyl compounds including 4-hydroxy-2-nonenal, 2,4-decadienal, 2,4-heptadienal, 4-hydroxy-2-hexenal, acrolein, 2-heptenal, 2-octenal, 4,5-epoxy-2-decadal, 2-decenal, and 2-undecenal [38]. The first three compounds presented the highest mean concentrations after heating (36.9, 34.8, and 22.6 μg·g⁻¹ of oil, respectively), highlighting the method's capability to quantify potentially harmful oxidation products [38].

Phytochemical Characterization of Natural Products

The hyphenated technique has become indispensable for comprehensive phytochemical analysis of natural products, enabling simultaneous qualification and quantification of diverse secondary metabolites. In studies of Salvia hispanica L. (chia) aerial parts, UPLC-ESI-MS/MS analysis tentatively identified 42 compounds in non-polar fractions, including steroids, diterpenes, triterpenoids, and fatty acids [36]. The analysis revealed compounds such as β-sitosterol-O-glucoside (identified by molecular ion [M+H]+ at m/z 577 and fragment ion at m/z 415 [M+H-Glu]+), sugiol (precursor ion [M+H]+ at m/z 301), and various triterpenoids including betulinic acid and oleanolic acid (both showing [M+H]+ at m/z 457) [36].

Similarly, research on Eleutherococcus senticosus fruits employed UHPLC-DAD-ESI-TOF-MS to quantify metabolites including oleanolic acid (16.01 ± 1.3 μg/g), ursolic acid (2.21 ± 0.17 μg/g), and various phenolic compounds [33]. The DAD detection provided characteristic UV spectra for compound classification, with caffeic acid derivatives showing maximum absorbance between 322-327 nm, while the MS detection enabled precise identification based on mass accuracy and fragmentation patterns [33]. This comprehensive phytochemical profiling provides crucial data for standardizing herbal preparations and understanding their pharmacological activities.

Targeted Analysis of Plant Hormones

UFLC-DAD-ESI-MS methods have been successfully developed for simultaneous analysis of multiple plant hormones, which are challenging to quantify due to their low concentrations and complex matrix effects. A validated method for five major plant hormones (zeatin, abscisic acid, jasmonic acid, salicylic acid, and brassinolide) employed optimized extraction procedures and MRM detection with a triple quadrupole mass spectrometer [35]. The method demonstrated excellent sensitivity with instrumental LODs ranging from 5-100 ng mL⁻¹ depending on the compound, and provided good recovery rates (82.2-109.3%) when applied to Arabidopsis thaliana samples [35]. The analytical capability to simultaneously quantify these signaling molecules with divergent chemical properties has significantly advanced plant stress physiology research, enabling investigations of hormonal crosstalk during abiotic stress responses [35].

Technical Visualizations

The synergy created by hyphenating chromatography and spectrometry represents one of the most significant advancements in modern analytical science. UFLC-DAD-ESI-MS exemplifies this powerful integration, combining exceptional separation capability with comprehensive detection and identification technologies. The continuous evolution of hyphenated techniques continues to expand their applications across diverse scientific disciplines, from food chemistry and natural products research to pharmaceutical development and clinical analysis [37] [29] [30]. As analytical challenges grow increasingly complex, requiring the detection and identification of trace components in intricate matrices, the role of hyphenated techniques becomes ever more indispensable. Future developments will likely focus on enhancing sensitivity, improving data processing algorithms, increasing automation, and developing even more sophisticated hyphenated systems capable of addressing the most demanding analytical requirements across scientific research and industrial applications.

Method Development and Real-World Applications in Pharmaceutical and Food Analysis

Ultra-Fast Liquid Chromatography (UFLC) represents a significant advancement in chromatographic science, enabling dramatic reductions in analysis time while maintaining or improving separation efficiency compared to conventional HPLC. The core principle of UFLC utilizes columns packed with smaller particles (typically sub-2µm) and chromatographic systems capable of operating at significantly higher pressures (often exceeding 600 bar). This combination facilitates faster separations by improving mass transfer kinetics and reducing band broadening, allowing for sharper peaks and lower detection limits. When coupled with Diode Array Detection (DAD) and Electrospray Ionization Mass Spectrometry (ESI-MS), UFLC becomes a powerful analytical platform capable of providing high-resolution separations with comprehensive compound characterization in significantly reduced timeframes.

The strategic development of UFLC methods requires careful consideration of three interdependent components: the column stationary phase, mobile phase composition, and gradient profile. These elements must be optimized in concert to achieve the desired separation, sensitivity, and throughput for specific analytical challenges. For researchers working within UFLC-DAD-ESI-MS methodology, this optimization must also account for the specific requirements of the detection systems, including MS-compatibility of mobile phases and the influence of operational parameters on both ionization efficiency and spectral quality.

Column Chemistry Selection for UFLC Separations

Stationary Phase Properties and Selectivity

The selection of an appropriate column chemistry forms the foundation of any robust UFLC method. The stationary phase dictates the primary interaction mechanism with analytes, thereby governing selectivity, retention, and ultimately, the success of the separation.

Reversed-Phase C18 Columns: The workhorse for most UFLC applications, C18 columns provide hydrophobicity-based separation ideal for a wide range of semi-polar to non-polar compounds. Modern C18 phases, including those based on charged-surface hybrid (CSH) technology, offer improved peak shape for basic compounds and greater retention time stability, especially when switching between mobile phases of different pH [39]. For example, a CSH C18 column (2.1 × 30 mm, 1.7 µm) has been successfully employed in a rapid 3-minute screening protocol for pharmaceutical compounds [39].

Hydrophilic Interaction Liquid Chromatography (HILIC) Columns: For the separation of highly polar compounds that show little retention in reversed-phase mode, HILIC columns provide a strong alternative. The BEH HILIC column (1.7 µm × 2.1 mm × 100 mm) has demonstrated effective separation of challenging polar analytes like streptomycin and dihydrostreptomycin in honey samples, which would otherwise elute near the void volume on C18 phases [40].

Column Dimensions: UFLC typically utilizes columns with shorter lengths (50-100 mm) and narrower internal diameters (2.1 mm) compared to standard HPLC, packed with sub-2µm particles. This configuration reduces analysis time and solvent consumption while maintaining separation efficiency. A column volume (Vm) of approximately 1.5 mL can be expected for a 150 mm × 4.6 mm column, which influences gradient re-equilibration times [41].

Table 1: Guide to UFLC Column Selection Based on Analyte Properties

| Analyte Characteristics | Recommended Stationary Phase | Typical Column Dimensions | Application Example |

|---|---|---|---|

| Non-polar to medium polarity | C18 or C8 reversed-phase | 50-100 mm × 2.1 mm, 1.7-1.8 µm | Pharmaceutical impurities [39] |

| Basic compounds | Charged Surface Hybrid (CSH) C18 | 30-100 mm × 2.1 mm, 1.7 µm | Basic drug screening at high/low pH [39] |

| Highly polar, hydrophilic | HILIC | 100 mm × 2.1 mm, 1.7 µm | Aminoglycoside antibiotics [40] |

| Broad polarity range in single run | C18 with wide pH stability | 50-150 mm × 2.1 mm, 1.7-2.6 µm | Multi-residue pesticide analysis [42] |

Matching Column Chemistry to Analytical Goals

The selection process must align with overall analytical objectives. For method development screening, columns with wide pH stability (e.g., CSH technology) allow evaluation of both high and low pH conditions without damaging the column or compromising performance [39]. This approach facilitates rapid identification of optimal separation conditions, as pH switching can significantly impact selectivity for ionizable compounds. For bioanalytical applications involving complex matrices like serum or breast milk, columns with robust surface chemistry that withstands extensive sample cleaning are essential, as matrix effects can substantially impact detection sensitivity [42].

Mobile Phase Optimization for UFLC-DAD-ESI-MS

Solvent Selection and MS-Compatibility

The mobile phase in UFLC serves not only as the carrier that elutes analytes from the column but also as the medium that introduces them into the ESI source. Therefore, optimization must consider both separation efficiency and ionization efficiency.

Organic Modifier Choice: Acetonitrile is generally preferred over methanol for UFLC-ESI-MS applications due to its lower viscosity (contributing to lower backpressure), better UV transparency, and enhanced desolvation and ionization efficiency in the ESI source. However, methanol may offer different selectivity for challenging separations.

Aqueous Phase Modifiers: The addition of volatile buffers and acidic/basic modifiers is often necessary to control ionization, improve peak shape, and enhance sensitivity. Ammonium formate (0.05 mM) and formic acid (0.1%) are commonly used additives that are MS-compatible. The choice of modifier can dramatically affect sensitivity; in the analysis of gingerols and shogaols, the use of 0.05 mM ammonium formate as a mobile phase modifier decreased sodium adduct formation and increased protonated ions, improving sensitivity by 4.5- to 15.7-fold compared to negative ion mode [43].

pH Considerations: Mobile phase pH significantly impacts the ionization state of analytes, thereby affecting retention and peak shape. For reversed-phase separations, low pH (2-4) is commonly used to suppress silanol activity and protonate basic compounds. The ability to screen both high and low pH conditions using stable column chemistries like CSH C18 provides a powerful strategy for method development [39].

Mitigating Matrix Effects in Complex Samples

Matrix effects pose significant challenges in quantitative UFLC-ESI-MS analysis, particularly for complex biological samples. The sample matrix can cause ion suppression or enhancement, leading to quantification inaccuracies. Several strategies can mitigate these effects: