Ultimate Guide to Troubleshooting and Optimizing Peak Resolution in UFLC-DAD Analysis

This comprehensive guide addresses the critical challenge of peak resolution in Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) systems, providing researchers and pharmaceutical professionals with foundational principles, methodological applications,...

Ultimate Guide to Troubleshooting and Optimizing Peak Resolution in UFLC-DAD Analysis

Abstract

This comprehensive guide addresses the critical challenge of peak resolution in Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) systems, providing researchers and pharmaceutical professionals with foundational principles, methodological applications, systematic troubleshooting protocols, and validation frameworks. Drawing from current chromatographic science and real-world case studies, we explore column selection strategies, mobile phase optimization, detector configuration, and method validation techniques to resolve common issues including peak tailing, fronting, broadening, and co-elution. The article synthesizes practical solutions for maintaining system performance while ensuring regulatory compliance through robust analytical methods suitable for pharmaceutical compounds, natural products, and clinical samples.

Understanding UFLC-DAD Fundamentals: Principles of Separation and Detection

Core Components of UFLC-DAD Systems and Their Impact on Resolution

Ultra-Fast Liquid Chromatography (UFLC) coupled with Diode-Array Detection (DAD) represents a significant advancement in analytical separation science. This technology enables researchers to achieve rapid, high-resolution analysis of complex mixtures, which is particularly valuable in pharmaceutical development and quality control. The core of UFLC's performance lies in its ability to operate at higher pressures than conventional HPLC while using columns packed with smaller stationary phase particles, typically below 2μm. This combination dramatically enhances separation speed and efficiency, allowing analysts to resolve complex mixtures up to ten times faster than traditional methods while maintaining robust performance without the extreme pressure requirements of specialized UHPLC systems [1].

The UFLC system's design incorporates several optimized components that collectively contribute to its resolution capabilities. The SIL-20A autosampler, for instance, enables a remarkably fast 10-second injection cycle while maintaining precision. The LC-20AD solvent-delivery system features a micro-plunger design that provides exceptional gradient resolution and reproducibility across a wide flow rate range from 100 nL/min to 10 mL/min. When paired with specialized columns such as the Shim-pack XR Series with inner diameters of 2, 3, or 4.6 mm and lengths ranging from 30 to 100 mm, the system achieves high-speed, high-resolution analysis at pressures below 30 MPa (300 kgf/cm²) [1]. For applications demanding even greater resolution, the system can be converted to a UFLC-XR configuration capable of handling system pressures up to 9500 psi (66MPa) through fully re-engineered components in the injection valve [1].

Core System Components and Their Functional Roles

UFLC-DAD System Configuration

Diagram 1: UFLC-DAD system workflow and critical components for resolution.

A UFLC-DAD system consists of several integrated components that collectively determine its separation capabilities and resolution performance. The mobile phase reservoir contains the solvents that will be pumped through the system. The high-pressure pump delivers mobile phase at controlled, stable flow rates with exceptional precision, a critical factor for maintaining retention time consistency and peak sharpness. The injector or autosampler introduces the sample into the mobile phase stream; in UFLC systems, this component can achieve injection cycle times as low as 10 seconds while maintaining injection volume accuracy. The chromatographic column, packed with stationary phase material, is where the actual separation occurs based on differential partitioning of analytes between mobile and stationary phases. The DAD detector converts eluted compounds into measurable signals across multiple wavelengths simultaneously, providing both quantitative and qualitative information about each peak. Finally, the data system records and displays chromatograms for analysis, interpretation, and reporting [2].

The resolution in UFLC-DAD is fundamentally governed by the interactions between these components. The quality of separation between adjacent peaks depends on factors including column efficiency (theoretical plate count), selectivity (relative retention of components), and retention factor (how long components are retained on the column). The DAD component contributes to effective resolution by enabling peak purity assessment through spectral comparison across the peak profile, which is crucial for detecting co-eluting compounds that may appear as a single chromatographic peak [3].

Research Reagent Solutions for Optimal UFLC-DAD Performance

Table 1: Essential research reagents and materials for UFLC-DAD experiments

| Reagent/Material | Function/Purpose | Application Example |

|---|---|---|

| Reference Standards | Compound identification and quantification | Geniposide, paeoniflorin, liquiritin for quality control of traditional medicine formulations [4] |

| HPLC-grade Solvents | Mobile phase preparation; sample dissolution | Acetonitrile, methanol, water for carotenoid analysis in soybean oil [5] |

| Buffer Salts & Modifiers | Mobile phase pH and ionic strength control | Formic acid, ammonium acetate, phosphate buffers for improving peak shape [4] [6] |

| Derivatization Reagents | Enhancing detection of poorly-absorbing compounds | 2,4-dinitrophenylhydrazine (2,4-DNPH) for carbonyl compound analysis in oils [5] |

| Stationary Phases | Analytical separation | C18, C8, phenyl, polar-embedded phases for different selectivity needs [1] [6] |

UFLC-DAD Methodologies and Experimental Protocols

Standard UFLC-DAD Analytical Method for Natural Product Analysis

Table 2: Quantitative UFLC-DAD method parameters from published research

| Parameter | Fuling Decoction Analysis [4] | J. isabellei Analysis [7] | Carbonyl Compounds in Oils [5] |

|---|---|---|---|

| Column | Not specified | C18, 100 mm × 2.1 mm, 2.6 μm | Not specified |

| Mobile Phase | Gradient with water/acetonitrile | Water and acetonitrile (no modifiers) | Not specified |

| Flow Rate | Not specified | 0.3 mL/min (column) or 1 mL/min (tubing) | Not specified |

| Analysis Time | <7 minutes | Not specified | Not specified |

| Detection | DAD with ESI-MS | DAD | DAD with ESI-MS |

| Key Compounds | Genipingentiobioside, geniposide, paeoniflorin, liquiritin | Jatrophone | Acrolein, 4-hydroxy-2-nonenal (HNE) |

| Sample Prep | Direct injection after filtration | Partitioning with dichloromethane | Derivatization with 2,4-DNPH |

The development of robust UFLC-DAD methods requires careful optimization of multiple parameters. A study profiling principal components in Fuling Decoction demonstrated that most analytes could be eluted with satisfactory resolution within 7 minutes using an optimized UFLC approach [4]. The method successfully identified fourteen constituents and quantified four major compounds (genipingentiobioside, geniposide, paeoniflorin, and liquiritin), showcasing the technique's capability for rapid analysis of complex botanical samples.

For quantitative analysis, researchers developing a method for jatrophone quantification in Jatropha isabellei implemented a validated UFLC-DAD approach that allowed precise measurement of this diterpene at approximately 90 μg/mg of fraction [7]. The methodology employed a Kinetex EVO C18 column (100 mm × 2.1 mm, 2.6 μm particle size) with isocratic elution using HPLC grade water and gradient grade acetonitrile without modifiers. The system was maintained at 25°C with an injection volume of 1 μL and flow rates of 0.3 mL/min for the column or 1 mL/min when using tubing to simulate perfect co-elution conditions [7].

Sample Preparation and Derivatization Protocols

Sample preparation represents a critical step in UFLC-DAD analysis that directly impacts resolution and detection sensitivity. For the analysis of carbonyl compounds in soybean oil, researchers developed a liquid-liquid extraction protocol followed by derivatization with 2,4-dinitrophenylhydrazine (2,4-DNPH) [5]. This approach enabled the selective extraction and enhanced detection of toxic aldehydes like acrolein and 4-hydroxy-2-nonenal formed during oil heating. The method demonstrated good selectivity, precision, sensitivity, and accuracy for monitoring these degradation products in the liquid fraction of edible oils.

In natural product analysis, sample preparation often involves extraction and fractionation. The dichloromethane fraction of J. isabellei was obtained by macerating powdered underground parts with 70% (v/v) ethanol for 10 days at room temperature, followed by filtration, evaporation under reduced pressure, and partitioning with dichloromethane [7]. The resulting fraction was taken to dryness under reduced pressure, yielding 3.7% of the original plant material, which was then resuspended in appropriate vehicles for analysis.

Troubleshooting Peak Resolution Issues in UFLC-DAD

Comprehensive Troubleshooting Guide for Resolution Problems

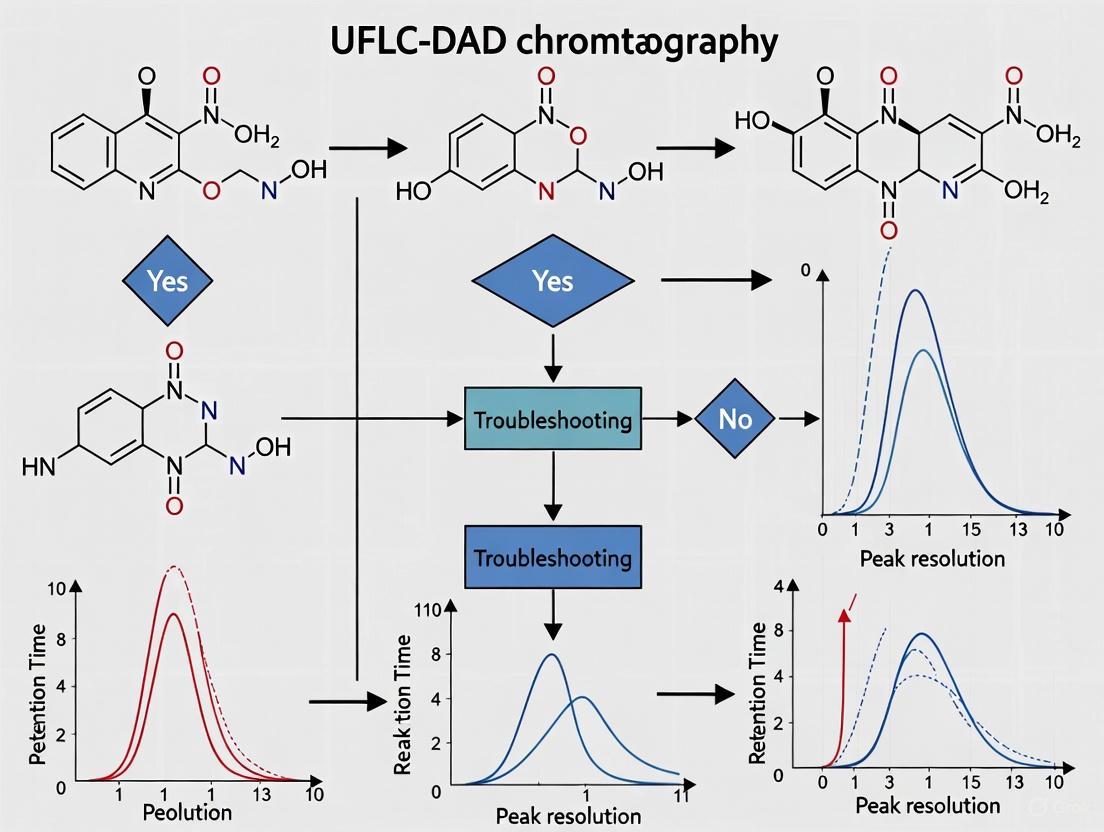

Diagram 2: Systematic troubleshooting approach for resolution issues.

Common Resolution Problems and Solutions

Symptom: Peak Tailing or Broadening

Possible Causes:

Solutions:

- Use high-purity silica (type B) or shielded phases with polar-embedded groups for basic compounds [6]

- Add competing bases like triethylamine to the mobile phase [6]

- Use short capillary connections with appropriate inner diameter (0.13 mm for UHPLC, 0.18 mm for conventional HPLC) [6]

- Ensure flow cell volume does not exceed 1/10 of the smallest peak volume [6]

- Replace degraded column; avoid pressure shocks and aggressive pH conditions [6]

Symptom: Poor Resolution Between Peaks

Possible Causes:

Solutions:

- Optimize mobile phase composition (organic modifier percentage, pH, buffer strength) [2]

- Reduce sample amount or injection volume [6]

- Consider alternative column chemistry (C8 instead of C18, different bonded phases) [6]

- Use efficient sample cleanup techniques such as solid-phase extraction [6]

- For isocratic separations with long retention times, switch to gradient elution or use a less retaining stationary phase [6]

Symptom: Retention Time Shifts

Possible Causes:

Solutions:

- Prepare mobile phases consistently with precise measurements [2]

- Allow sufficient column equilibration before analysis [2]

- Service pumps regularly to maintain flow accuracy [2]

- Use column ovens to maintain stable temperature [6]

- For methods with extreme pH, check compatibility of injector seal polymers [6]

FAQs: Addressing Common UFLC-DAD Challenges

Q1: What are the primary advantages of UFLC over conventional HPLC systems?

UFLC systems provide analysis speeds up to ten times faster than conventional HPLC that uses 5-μm particle columns while maintaining high-quality analytical results. This performance is achieved without the design concessions required for extreme pressure requirements in specialized systems. The key advantage is the combination of high-speed analysis with resolution that is maintained through optimized system components including low-dispersion tubing, rapid injection cycles, and detectors with appropriate flow cell volumes [1].

Q2: How can I improve the peak shape for basic compounds in my UFLC-DAD analysis?

Basic compounds often exhibit tailing due to interactions with acidic silanol groups on the stationary phase surface. To address this, use high-purity silica (type B) columns or shielded phases containing polar-embedded groups. Adding a competing base such as triethylamine to the mobile phase can reduce these interactions. Alternatively, consider using polymeric columns or buffers with high ionic strength (though note that high ionic strength buffers are not compatible with LC/MS applications) [6].

Q3: Why do I observe broader peaks with later retention times, and how can I address this?

This phenomenon often indicates high longitudinal dispersion in the system. For isocratic separations, the retention time may be excessively long; switching to gradient elution or using a stronger isocratic mobile phase can help. Alternatively, consider using a less retaining stationary phase (C8 instead of C18). Also verify that the linear velocity (flow rate) is appropriate for the column dimensions [6].

Q4: What steps can I take when facing pressure abnormalities in my UFLC system?

High pressure often results from clogged columns, salt precipitation, or blocked inlet frits. Address this by gradually flushing the column with pure water at 40-50°C, followed by methanol or other organic solvents. Low pressure typically indicates leaks in tubing, fittings, or pump seals; inspect and tighten connections (without overtightening) and replace damaged seals. Pressure fluctuations are commonly caused by air bubbles due to insufficient degassing or malfunctioning pump/check valves; thoroughly degas mobile phases and purge air from the pump [2].

Q5: How does the DAD detector contribute to peak purity assessment?

The DAD detector enables peak purity assessment by collecting full spectra throughout the peak elution. The similarity between spectra acquired at different points across the peak is measured using algorithms based on vector comparison in n-dimensional space (where n is the number of wavelengths). The cosine of the angle between vectors or the correlation coefficient between spectra provides a measure of spectral similarity. A pure peak exhibits high spectral similarity (cosine θ ≈ 1), while a contaminated peak shows spectral variations [8] [3]. This assessment is particularly valuable for detecting co-eluting impurities in pharmaceutical analysis and method validation.

Troubleshooting Peak Resolution in UFLC-DAD Chromatography Research

Theoretical Principles: Resolution Equation, Selectivity, and Efficiency Factors

Chromatographic resolution (Rs) is quantitatively described by the fundamental resolution equation, which defines the separation capability between two adjacent peaks. This equation integrates the critical factors of column efficiency (N), selectivity (α), and retention (k) [9]:

Rs = ¼ * √N * (α - 1)/α * k/(k + 1)

- Efficiency (N), or plate number, represents the column's ability to produce narrow peaks. It is primarily improved by using columns packed with smaller particles or longer columns, which increases the number of theoretical plates and sharpens peaks [10] [9].

- Selectivity (α), or the separation factor, is the ratio of the retention factors of two peaks. It is the most powerful factor for adjusting resolution, achieved by changing the chemical interaction between analytes and the stationary or mobile phases [9] [11].

- Retention (k), the capacity factor, measures how long an analyte is retained on the column. It can be optimized by adjusting the strength of the mobile phase [9].

The following diagram illustrates the logical relationship between these factors and the common parameters you can adjust in the lab to control them.

Troubleshooting Guides & FAQs

How do I resolve overlapping or co-eluting peaks?

Checklist for Addressing Poor Resolution:

- Adjust Selectivity (α): This is the most effective approach [9].

- Change the organic modifier (e.g., from acetonitrile to methanol or tetrahydrofuran) [12] [9].

- Modify the mobile phase pH to alter the ionization state of ionizable compounds [12] [9].

- Use a different stationary phase (e.g., C8 vs. C18, or a polar-embedded phase) to change the chemical interaction mechanism [12] [11].

- Increase Efficiency (N): This sharpens peaks to improve separation [9].

- Optimize Retention (k): Ensure analytes have adequate retention.

Why are my peaks tailing or fronting, and how can I fix them?

Tailing and fronting peaks indicate non-ideal chromatographic behavior, which reduces resolution.

- For Tailing Peaks:

- Chemical Causes: Silanol interaction for basic compounds is a common cause. Solutions include using high-purity silica columns, adding a competing base like triethylamine to the mobile phase, or using a stationary phase designed for basic compounds [6].

- Physical Causes: A void at the column inlet or a bad connection in the flow path can cause tailing. Check capillary connections for dead volume and consider replacing the column if it has degraded [6] [13].

- For Fronting Peaks:

- Chemical Causes: Sample solvent is stronger than the mobile phase, or column is overloaded with too much sample. Re-dissolve the sample in the starting mobile phase or reduce the injection volume [6] [12].

- Physical Causes: Channeling in the column bed due to a poorly packed or damaged column. The solution is typically to replace the column [13].

A previously resolved peak has disappeared from my chromatogram. What should I do?

This problem requires a systematic investigation to isolate the cause [14].

- Step 1: Verify the Solution. Inject the standard solution of the "missing" impurity by itself. If the peak appears, the issue is not with the solution. If it does not appear, the analyte may have degraded in the standard mixture due to instability or interaction with other components [14].

- Step 2: Check for Adsorption. If the single-analyte standard shows a peak but the mixture does not, the analyte may be adsorbing onto the stationary phase of the column, especially if the problem is specific to certain columns. This can be related to active silanol sites [14].

- Step 3: Inspect Method Conditions. Ensure that the buffer concentration is adequate and that no precipitation of components is occurring. Check if the column pressure has changed significantly, which could indicate column failure [14].

| Parameter | Effect on Resolution | Practical Adjustment | Advantage | Limitation |

|---|---|---|---|---|

| Efficiency (N) | Increases with √N; sharper peaks | Smaller particle size; longer column | Can resolve moderately overlapped peaks | Increased backpressure; longer analysis time |

| Selectivity (α) | Most powerful effect; changes relative spacing | Change solvent type, pH, or stationary phase | Can resolve severely co-eluting peaks | Requires re-optimization; new method conditions |

| Retention (k) | Increases with k/(k+1) up to a point | Reduce solvent strength (%B) | Simple to implement | Limited effect if k is already >10; long analysis times |

Common Peak Shape Issues and Solutions

| Symptom | Likely Cause | Recommended Solution | |

|---|---|---|---|

| Peak Tailing | Silanol interactions (basic compounds) | Use high-purity silica; add competing amine to mobile phase [6] | |

| Column void or bad connection | Replace column; check fittings for dead volume [6] [13] | ||

| Peak Fronting | Sample solvent too strong | Dissolve sample in starting mobile phase [6] [12] | |

| Column overload | Reduce sample mass or injection volume [6] [13] | ||

| Channeling in column | Replace the column [13] | ||

| Split Peaks | Occluded column frit | Reverse and flush column (short-term fix) [13] | |

| Broader Peaks (General) | Extra-column volume too large | Use shorter, narrower capillaries; ensure detector cell volume is appropriate [6] [10] |

Experimental Protocols

Protocol 1: Measuring System Dispersion (Instrument Bandwidth)

Purpose: To quantify the band-broadening contribution of the instrument itself (tubing, detector cell, injector), which is critical for maintaining the efficiency of high-performance columns, especially in UHPLC [10].

Methodology:

- Remove the analytical column from the system and connect a zero-dead-volume union in its place.

- Prepare a dilute standard solution of a stable, UV-active analyte (e.g., uracil or caffeine).

- Set a fast detector response time (e.g., 0.1 s) and a high data acquisition rate (≥10 Hz).

- Inject a very small volume (≤ 1 μL) of the standard and record the resulting peak.

- Calculate the Instrument Bandwidth (IBW) as the peak width at base (in volume units, μL). This can be estimated as 4σ, where σ is the standard deviation of the peak, calculated from the efficiency report: N = (tR/σ)², and tR is converted to volume using the flow rate [10].

Protocol 2: Systematic Approach to Improve Selectivity

Purpose: To methodically explore different selectivity options when initial chromatographic conditions yield insufficient resolution [9].

Methodology:

- Change Organic Modifier: Using the solvent strength chart (see Figure 4 in [9]), replace acetonitrile with methanol or tetrahydrofuran at a concentration that provides equivalent elution strength. For example, 50% acetonitrile is roughly equivalent to 57% methanol or 35% tetrahydrofuran in water.

- Adjust Mobile Phase pH: For ionizable compounds, adjust the buffer pH to values at least 1 unit above or below the analyte's pKa to change its ionization state and retention. Use a buffer with sufficient capacity (typically 10-50 mM) [12].

- Change Stationary Phase: Switch to a column with different surface chemistry (e.g., from C18 to CN, phenyl, or polar-embedded phases) to alter the primary molecular interactions [9] [11].

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in UFLC-DAD Analysis |

|---|---|

| Type B High-Purity Silica Columns | Minimizes peak tailing for basic compounds by reducing metal impurities and silanol activity [6]. |

| Solid-Core (Fused-Core) Particles | Provides high efficiency and lower backpressure compared to fully porous particles, improving resolution and speed [10] [11]. |

| Triethylamine (TEA) | A competing base added to the mobile phase to passivate active silanol sites on the silica surface, improving peak shape for basic analytes [6]. |

| Buffers (e.g., Phosphate, Ammonium Formate) | Control the pH of the mobile phase, which is critical for reproducible retention of ionizable compounds [12] [15]. |

| HPLC-Grade Solvents & Water | Prevents baseline noise and ghost peaks caused by UV-absorbing contaminants in the mobile phase [6] [2]. |

| Guard Columns | Protects the expensive analytical column from particulate matter and irreversibly adsorbed sample components, extending its lifetime [2]. |

Frequently Asked Questions: DAD Fundamentals

What is the core advantage of a DAD over a conventional UV-Vis detector? While a conventional UV-Vis detector measures only a few user-selected wavelengths, a Diode Array Detector (DAD) or Photo Diode Array (PDA) captures the entire ultraviolet-visible spectrum (190-900 nm) in real time for every data point during the peak's elution [16]. This enables two critical functions: spectral confirmation of analyte identity and assessment of chromatographic peak purity [16].

When should I use peak purity analysis in my work? Peak purity assessment is crucial in method development and validation, particularly in the pharmaceutical industry for developing stability-indicating methods [3]. It is used to provide evidence that the method can monitor the main analyte without interference from impurities or degradation products, which is essential for ensuring drug product quality and patient safety [3].

Can I definitively prove a peak is pure using DAD? No, you can only prove that a peak is impure [17]. A peak purity result indicating a "pure" peak means that no spectral differences were detected across the peak; it does not guarantee that a co-eluting impurity is absent. The impurity might have a nearly identical spectrum, be at a very low concentration, or not possess a chromophore in the monitored range [17].

Troubleshooting Guide: Peak Purity and Spectral Analysis

Problem 1: Poor Peak Purity Results or Failed Purity Tests

| Potential Cause | Diagnostic Steps | Solution |

|---|---|---|

| True Co-elution | Check method resolution. Analyze stressed samples to see if a new peak appears under the main peak. | Adjust chromatographic conditions (mobile phase pH, gradient, column temperature) or switch to a column with different selectivity [3]. |

| Insufficient Spectral Contrast | The impurity and analyte have highly similar UV spectra. | Use mass spectrometric (MS) detection for orthogonal confirmation if DAD is inconclusive [3]. |

| Incorrect Purity Analysis Parameters | Review the settings for background correction and wavelength range. | Apply proper background correction to remove mobile phase effects and set an appropriate wavelength range that excludes high-noise regions [17]. |

| Low Concentration Impurity | The impurity is below the detection limit of the DAD. | Concentrate the sample or use a detection method with higher sensitivity for the suspected impurity [17]. |

Problem 2: Poor Spectral Quality for Confirmation

| Potential Cause | Diagnostic Steps | Solution |

|---|---|---|

| Insufficient Signal-to-Noise (S/N) | Inspect the baseline noise in the chromatogram and spectrum. | Increase sample concentration or injection volume. Use a higher sampling rate (slower scan speed) to improve S/N, but balance with having enough data points across the peak [17]. |

| Incorrect Detector Settings | Check the configured bandwidth and slit width. | Increase bandwidth to improve S/N, or decrease it to improve selectivity. Use a narrower slit width to maintain high spectral resolution, which is critical for distinguishing similar spectra [17]. |

| Mobile Phase Background | Run a blank gradient and observe the baseline absorbance. | Use high-purity HPLC-grade solvents. Employ background correction during data processing to subtract the changing mobile phase background [17]. |

Experimental Protocol: Conducting a Peak Purity Assessment

A reliable peak purity assessment requires a well-designed experiment from sample preparation to data processing.

Step 1: Method Development and Sample Preparation

- Develop a Stability-Indicating Method: The chromatographic method must be able to resolve the main analyte from its potential impurities and degradation products. This involves screening columns of different selectivity (e.g., C8, C18, phenyl) and mobile phases at different pH values [3].

- Use Stressed Samples: Subject the analyte to stress conditions (acid, base, oxidation, heat, light) to generate degradation products. A good method should be able to resolve these degradation products from the main peak [3].

- Ensure Proper Data Acquisition:

- Data Rate: The acquisition rate must be fast enough to provide sufficient data points across a peak (e.g., 20-30 points per peak) to accurately define its shape and spectrum [17] [13].

- Spectral Range: Collect data over a UV-Vis range that includes the absorbance maxima of your analyte and potential impurities.

Step 2: Data Collection and Processing

- Apply Background Correction: During data processing, subtract the spectral background from the mobile phase. This can be done automatically by the software using baseline points before and after the peak or manually with reference spectra [17].

- Normalize Spectra: Normalize the spectra collected from the upslope, apex, and downslope of the peak to correct for concentration differences. This allows for a direct comparison of spectral shape [3] [17].

- Set an Absorbance Threshold: Apply a minimum absorbance threshold to exclude the noisy regions at the very beginning and end of the peak from the purity calculation [17].

Step 3: Interpret the Results The software calculates a purity angle and purity threshold [3]. If the purity angle is less than the purity threshold, the peak is considered "pure" (i.e., no spectral differences were detected). If the purity angle exceeds the purity threshold, the peak is impure, indicating the presence of a co-eluting compound with a different spectral signature [3].

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function & Importance |

|---|---|

| Type B (High-Purity) Silica Columns | Minimizes interaction of basic compounds with acidic silanol groups on the silica surface, reducing peak tailing and improving peak shape for more accurate purity analysis [6]. |

| Polar-Embedded or Shielded Phases | Provides alternative selectivity for challenging separations and can improve the retention and peak shape of polar compounds [6]. |

| HPLC-Grade Solvents & Buffers | Essential for a clean, low-UV background baseline. Contaminated solvents or buffers are a common source of noise, ghost peaks, and baseline drift, which interfere with spectral analysis [6] [17]. |

| Competing Additives (e.g., TEA) | Added to the mobile phase to sativate active sites on the stationary phase, improving peak shape for susceptible compounds like amines [6]. |

| Stressed Sample Solutions | Samples subjected to acid, base, oxidative, thermal, or photolytic stress are critical for validating that a method is "stability-indicating" and can detect degradation products [3]. |

Common Resolution Challenges in Pharmaceutical and Biomedical Analysis

Troubleshooting Guides

Why are my peaks tailing or fronting?

Symptom: Peaks exhibit asymmetric shape, with the tail (or front) of the peak dragging, rather than forming a symmetric Gaussian profile.

| Possible Cause | Diagnostic Steps | Solution |

|---|---|---|

| Column Degradation | Check system pressure history for increases; inspect for column voids [6]. | Replace column; avoid pH and temperature conditions outside column specifications [6]. |

| Silanol Interactions (Basic Compounds) | Observe if tailing affects only specific peaks, often basic compounds [6]. | Use high-purity silica columns; add competing bases like triethylamine to mobile phase [6]. |

| Inappropriate Detector Settings | Check detector response time and data acquisition rate [6] [12]. | Set response time to ≤1/4 the width of the narrowest peak; ensure sufficient data points per peak [6] [12]. |

| Dead Volumes in Flow Path | Check all capillary connections and fittings [6] [13]. | Use short capillaries with correct inner diameter; ensure fittings are properly tightened [6]. |

| Mass Overload | Reduce injection amount; if peak shape improves, mass overload is confirmed [13]. | Reduce sample mass injected or dilute sample [13]. |

| Channeling in Column Bed | Tailing or fronting affects all peaks in the chromatogram [6] [13]. | Replace the column [6] [13]. |

Experimental Protocol for Diagnosis:

- Inject a test mixture containing known compounds that previously showed good peak shape.

- Reduce the injection volume by 50-75%. If the peak shape corrects, the issue is likely mass overload.

- Check system pressure and compare to the column's pressure specification and historical data for the same method.

- Connect the column outlet directly to the waste (bypassing the detector cell) and inject again. If tailing persists, the issue is column- or chemistry-based.

- Use a fresh, certified reference column to isolate if the problem is specific to the column in use.

Why is my signal-to-noise ratio (S/N) too low, affecting detection limits?

Symptom: The baseline is noisy, and peaks for trace analytes are difficult to distinguish from the background, leading to poor Limit of Detection (LOD) and Limit of Quantification (LOQ).

| Possible Cause | Diagnostic Steps | Solution |

|---|---|---|

| Contaminated Mobile Phase or System | Run a blank gradient; observe baseline profile and noise [6] [18]. | Use HPLC-grade solvents; flush system and detector flow cell; clean or replace guard column [6] [18]. |

| Insufficient Detector Settings | Check data acquisition rate and time constant (response time) settings [19] [20]. | Optimize wavelength for maximum analyte absorption; adjust acquisition rate and time constant for a balance of noise and peak fidelity [20] [12]. |

| Air in Detector Cell or Pump | Observe baseline for very high-frequency, sharp spikes or erratic drift [6]. | Purge detector and pump according to manufacturer instructions; degas mobile phases thoroughly [6]. |

| Temperature Fluctuations | Monitor laboratory environment for drafts or cycling temperatures [18]. | Use a column heater; insulate tubing between column and detector; shield instrument from drafts [18]. |

| Sample-Related Issues | Check if noise increases with sample injection versus blank injection. | Implement sample clean-up techniques like solid-phase extraction (SPE) [6]. |

Quantitative Guidelines for S/N, LOD, and LOQ:

- Limit of Detection (LOD): Generally accepted at S/N between 2:1 and 3:1, though ICH Q2(R2) specifies 3:1 [19] [21].

- Limit of Quantification (LOQ): Typically defined at S/N of 10:1 [19] [18].

- Method Precision Relationship: A rough rule of thumb is %RSD ≈ 50 / (S/N). Therefore, for a method requiring 2% RSD, an S/N of approximately 25 is needed [18].

Experimental Protocol for S/N Improvement:

- Increase Signal:

- Reduce Noise:

Why are my peaks broader than expected, reducing resolution?

Symptom: Peaks appear wider and shorter than usual, leading to co-elution and poor separation between adjacent peaks.

| Possible Cause | Diagnostic Steps | Solution |

|---|---|---|

| Extra-Column Volume | Problem is worse for early-eluting, sharp peaks. Check connection tubing [6] [13]. | Use short, narrow-bore connection capillaries; ensure inner diameter is appropriate for column type (e.g., 0.13 mm for UHPLC) [6]. |

| Column Overload | Check injection volume and sample concentration [6] [12]. | Reduce injection volume or sample concentration; ensure sample solvent is not stronger than the mobile phase [6] [12]. |

| Insufficient Data Acquisition Rate | Zoom in on a peak; calculate data points across the peak [13] [20]. | Increase data acquisition rate to ensure a minimum of 20-40 data points across a peak [20] [12]. |

| Longitudinal Dispersion | Retention times are excessively long in isocratic runs [6]. | Use gradient elution or a stronger isocratic mobile phase; consider a less retaining stationary phase [6]. |

| Void at Column Inlet | Peak broadening affects all peaks; a significant pressure drop may be observed [6]. | Replace the column. Prevent by avoiding pressure shocks and operating within pH specifications [6]. |

Frequently Asked Questions (FAQs)

How can I tell if a peak is pure or a co-elution of multiple compounds?

Assessing peak purity is critical in pharmaceutical and biomedical analysis, as co-elution can lead to inaccurate quantification and missed impurities [3].

Principles: Modern software, especially with Diode Array Detectors (DAD), uses spectral comparison to assess purity. It compares spectra taken at different points across the peak (up-slope, apex, down-slope). If the spectra are identical, the peak is considered "spectrally pure." A significant difference in spectral shape suggests a co-eluting impurity [3].

Limitations: This method primarily detects impurities with different UV spectra. Structurally similar impurities (like many degradation products) often have nearly identical spectra and may not be detected by this method. Mass spectrometry (MS) is a more powerful detector for confirming peak purity in these cases [3].

Experimental Protocol for Peak Purity with DAD:

- Obtain Good Spectra: Ensure the peak has a high enough signal-to-noise ratio for reliable spectral comparison.

- Set Appropriate Peak Limits: The software must correctly identify the start and end of the peak to define the baseline.

- Review the Purity Report: The software provides a purity angle and threshold. If the purity angle is less than the purity threshold, the peak is considered spectrally pure.

- Corroborate with Other Data: Use orthogonal methods like changing the column chemistry, mobile phase pH, or gradient to see if the peak splits, indicating co-elution.

What are the most critical DAD settings to optimize for better resolution and sensitivity?

The Diode Array Detector (DAD) has several key settings that directly impact data quality [20].

| Setting | Function & Impact | Best Practice Recommendation |

|---|---|---|

| Wavelength | Selects the optimal energy for analyte absorption [20] [12]. | Set at the absorbance maximum for the target analyte. Use a wavelength spectrum to choose, avoiding slopes [12]. |

| Bandwidth | The range of wavelengths averaged around the target wavelength [20]. | A narrower bandwidth (e.g., 4 nm) increases selectivity. A wider bandwidth can reduce noise but may decrease signal [20]. |

| Data Acquisition Rate | How often data points are collected per second (Hz) [20]. | Higher rates (e.g., 20 Hz) provide more data points per peak for accurate integration but create larger files. Use a rate that yields >20 points per peak [20] [12]. |

| Response Time (Time Constant) | An electronic filter that smooths the signal [19] [18]. | Set to ~1/10 the width of the narrowest peak. Too high a value can broaden peaks and lose data; too low increases noise [6] [18]. |

| Reference Wavelength | Compensates for background drift and lamp fluctuations [20]. | Set to a wavelength where the analytes have minimal absorption. Use an isoabsorbance plot for optimization [20]. |

How do I systematically improve resolution when developing or optimizing a method?

Improving resolution (Rs) is a multi-factorial process. The resolution equation is Rs = (1/4)√N * (α-1/α) * (k'/k'+1), where N is efficiency, α is selectivity, and k' is the retention factor. Target each term systematically [12].

1. Improve Efficiency (N) - Get Tighter Peaks:

- Column: Use columns packed with smaller particles (e.g., sub-2µm for UHPLC) [12].

- Flow Rate: Find the optimal flow rate for your column. Often, slightly lower flow rates improve efficiency but increase run time [12].

- Temperature: Increase column temperature to reduce mobile phase viscosity, which can improve efficiency (provided the sample is stable) [12].

- Extra-System Volume: Minimize all tubing volumes between the injector and detector [6].

2. Improve Selectivity (α) - Increase Space Between Peaks:

- Mobile Phase pH: This is the most powerful tool for ionizable compounds. A small change can drastically alter retention times of acids and bases relative to each other [12].

- Solvent Strength & Type: Change the organic modifier (e.g., acetonitrile vs. methanol) or the gradient profile [12].

- Column Chemistry: Switch to a column with different selectivity (e.g., C18 to phenyl, cyano, or pentafluorophenyl) [12].

3. Adjust Retention (k') - Move Peaks to a Better Location:

- Gradient/Isocratic Strength: Weaken the mobile phase to increase retention (k') and move peaks away from the solvent front, where resolution is poor [6].

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function in UFLC-DAD Analysis | Key Considerations |

|---|---|---|

| High-Purity Silica Columns (Type B) | Stationary phase for compound separation. | Reduces peak tailing for basic compounds by minimizing metal impurities and silanol activity [6]. |

| Polar-Embedded Phase Columns | Stationary phase for challenging separations. | Provides alternative selectivity; can improve peak shape for a wider range of compounds [6]. |

| HPLC-Grade Solvents | Constituents of the mobile phase. | Minimizes UV-absorbing contaminants that cause high background noise and baseline drift [6] [18]. |

| Buffers & Ion-Pair Reagents | Modifies mobile phase to control pH and ionic strength. | Essential for reproducible retention of ionizable compounds. Ensure buffer capacity is sufficient and compatibility with DAD/MS [6]. |

| Triethylamine (TEA) | Mobile phase additive. | Acts as a competing base to mask acidic silanol groups on the silica surface, improving peak shape of basic analytes [6]. |

| Guard Column | Small cartridge placed before the analytical column. | Protects the expensive analytical column from particulate matter and strongly retained contaminants, extending its lifetime [6]. |

| Solid-Phase Extraction (SPE) Cartridges | For sample clean-up. | Removes interfering matrix components (e.g., proteins, salts) from biological samples, reducing baseline noise and column fouling [6] [18]. |

This guide provides troubleshooting support for researchers and scientists working with UFLC-DAD systems, focusing on how instrumental parameters impact chromatographic separation and peak resolution.

Troubleshooting Guides

Flow Cell-Related Issues

| Symptom | Possible Cause | Solution |

|---|---|---|

| Early peaks broader than later eluting ones | Detector cell volume too large relative to peak volume [6] | Use a flow cell with a volume not exceeding 1/10 of the smallest peak volume; select micro or semi-micro flow cells for UHPLC or microbore columns [6]. |

| Low signal-to-noise (S/N) ratio | Dirty detector flow cell [22] | Perform cleaning procedures as specified in the user documentation; regular maintenance prevents contamination buildup [22]. |

| Baseline drift and noise | Contaminated flow cell; air bubbles; lamp issues [2] | Clean flow cell regularly; ensure mobile phases are degassed; replace UV lamps approaching end of life (typically ~2000 hours) [2] [23]. |

| Reduced UV sensitivity | Inappropriate flow cell pathlength or configuration [6] | Select appropriate flow cell (e.g., 10 mm vs. 60 mm Lightpipe) based on application requirements to optimize signal [6]. |

Tubing and Extracolumn Volume Issues

| Symptom | Possible Cause | Solution |

|---|---|---|

| Poor efficiency (low plate count), especially for early peaks | Excessive extracolumn volume (ECV) from connecting capillaries [6] | Use short capillary connections with appropriate internal diameters: 0.13 mm (0.005 in.) for UHPLC and 0.18 mm (0.007 in.) for conventional HPLC. Ensure total ECV is <1/10 of the smallest peak volume [6]. |

| Peak tailing or broadening | Improper capillary connections causing dead volume [6] [22] | Check fittings for correct ferrule placement; use fingertight fitting systems to ensure zero-dead-volume connections; replace ferrules when changing columns [6] [22]. |

| System pressure issues or leaks | Tubing blockages or fractures; material incompatibility [23] | Use pressure-rated PEEK tubing; avoid solvents that degrade PEEK (THF, DMSO, acetone); document normal system pressure to quickly identify anomalies [23] [22]. |

| Peak fronting | Tubing connections with incorrect stop depth or volume [22] | Verify all connections use fittings and ferrules matched to the column and system specifications to minimize dead volume [22]. |

Data System and Acquisition Issues

| Symptom | Possible Cause | Solution |

|---|---|---|

| Peak broadening | Detector response time (time constant) setting too long [6] | Set response time to less than 1/4 of the peak width at half-height of the narrowest peak. Use data system wizards to optimize settings [6]. |

| Irreproducible peak integration | Improper data acquisition rate [6] | Avoid automatic data rate settings; use a fixed data rate. For accurate integration, ensure sufficient data points are captured across each peak (typically 20-30 points per peak). |

| Irreproducible integration | Pump pulsation or mixing ripple affecting baseline [6] | Address the root cause of baseline instability; refer to pump and mixer maintenance protocols [6]. |

Frequently Asked Questions (FAQs)

1. How does detector cell volume directly impact my chromatographic results? An overly large flow cell volume causes peak broadening as the analyte band disperses within the cell before detection. This effect is most detrimental to early, sharp peaks. The cell volume should not exceed one-tenth of the volume of your narrowest peak to preserve separation efficiency [6].

2. What is the single most critical factor regarding tubing for UHPLC methods? Internal diameter (i.d.) is paramount. For UHPLC, use 0.13 mm i.d. tubing to minimize extracolumn band broadening. Larger i.d. tubing creates significant dead volume, causing peak spreading and loss of resolution, which defeats the purpose of UHPLC's high efficiency [6].

3. My data rate is sufficient (>20 pts/sec), but peaks still look broadened. What else should I check? Beyond the data rate, check the detector response time (or time constant) setting. A slow response time acts as an electronic filter that smears the peak signal. Ensure this setting is faster than 1/4 of the narrowest peak's width at half-height [6].

4. How can I systematically identify the source of a sudden pressure increase? Document your system's baseline pressure with and without columns. When pressure spikes, disconnect components stepwise [22]:

- First, open the connection at the column inlet. If pressure remains high, the issue is in the pump, autosampler, or inlet tubing.

- If pressure normalizes, the column is likely blocked.

- If pressure is normal at the column outlet but high after the detector, the detector cell or outlet tubing is obstructed.

5. Are gold-plated fittings or special ferrule systems necessary for UHPLC? This is a common misconception. While robust, leak-free connections are critical, modern fingertight fitting systems (e.g., Viper or nanoViper) are engineered for UHPLC pressures and provide zero-dead-volume connections without requiring gold plating or complex double-ferrule assemblies [6] [24].

Research Reagent Solutions and Essential Materials

| Item | Function in UFLC-DAD Analysis |

|---|---|

| Micro Flow Cell | Minimizes post-column peak broadening for high-efficiency UHPLC separations by reducing the volume in which detection occurs [6]. |

| UHPLC-Grade Capillary Tubing (0.13 mm i.d.) | Connects system components with minimal dead volume, preserving the separation efficiency generated by the column [6]. |

| Inert Guard Column Cartridges | Protects the expensive analytical column from particulates and contaminants that can clog frits and degrade performance [25]. |

| High-Purity Solvents & Buffers | Reduces baseline noise and UV background absorption; prevents salt crystallization and microbial growth that can damage pump seals and block tubing [2] [23]. |

| PEEK Tubing | Provides a biocompatible, inert flow path for analyzing metal-sensitive compounds; however, it requires careful solvent compatibility checks [23]. |

Experimental Protocols

Protocol 1: System Suitability and Extracolumn Volume Assessment

Purpose: To establish a performance baseline and quantify the band-broadening contribution of your instrument's flow cell, tubing, and detector.

Methodology:

- Baseline Pressure Documentation: With the column installed and under standard operating conditions, record the system pressure. Repeat this measurement with the column bypassed (connect inlet tubing directly to detector or waste). This provides a reference for troubleshooting pressure issues [22].

- Peak Narrowness Profiling: Inject a small volume (1-2 µL) of a stable, low-dispersity test compound (e.g., toluene, uracil) without a column installed. Directly connect the injector to the detector using a zero-dead-volume union.

- Data Acquisition: Use a high data rate (e.g., 50-100 Hz) and the fastest instrument response time setting. The resulting peak represents the minimum possible peak width your system can generate, defining the extracolumn volume effect [6].

- Calculation: The observed peak volume from the column-less injection is your system's effective extracolumn volume. Compare subsequent column performance tests against this baseline.

Protocol 2: Methodical Troubleshooting of Peak Shape Anomalies

Purpose: To systematically diagnose the root cause of peak tailing, fronting, or broadening.

Workflow Logic: The following diagram outlines the logical decision process for diagnosing peak shape problems.

Diagnostic Steps:

- If all peaks show tailing/broadening, the issue is likely system-wide (e.g., excessive extracolumn volume from tubing, large detector cell, slow data acquisition) [6].

- If only specific peaks are distorted, the problem is often specific to the column chemistry or analyte interaction (e.g., column voiding, blocked frit, silanol interaction for basic compounds, sample solvent mismatch) [6].

- For specific peak issues:

- Tailing: Often indicates active sites. For basic compounds, use high-purity silica, polar-embedded phases, or add a competing base like triethylamine to the mobile phase [6].

- Fronting: Can be caused by a blocked frit, channeling in the column bed, or sample overload. Check for particles, reduce injection volume, or dissolve sample in a weaker solvent [6].

Method Development Strategies for Optimal UFLC-DAD Performance

Core Principles of Column Selection

How Particle Size and Pore Size Influence Your Separation

The physical characteristics of your HPLC column, primarily particle size and pore size, are fundamental determinants of separation efficiency, resolution, and speed [26].

- Particle Size refers to the average diameter of the spherical particles that make up the stationary phase packing within the column [26].

- Pore Size refers to the average diameter of the channels within each particle, which determines the accessibility of the stationary phase surface to your analytes [26].

The following table summarizes the effects and typical applications for different particle and pore sizes.

| Parameter | Typical Sizes | Impact on Chromatography | Recommended Application |

|---|---|---|---|

| Particle Size | 5 µm, 3.5 µm, 3 µm | Larger: Higher mass transfer resistance, lower backpressure, slower analysis [26]. | Standard HPLC for routine analysis [26]. |

| < 2 µm (for UHPLC) | Smaller: Higher efficiency (theoretical plates, N), sharper peaks, higher resolution, faster analysis, but significantly higher backpressure [26] [12]. | UHPLC for high-resolution, fast, or complex mixture analysis [26]. | |

| Pore Size | 6 - 15 nm (60 - 150 Å) | Smaller surface area; suitable for molecules < 1000 Da [26]. | Analysis of small molecules (e.g., active pharmaceutical ingredients, geniposide, paeoniflorin) [4] [26]. |

| ≥ 30 nm (300 Å) | Larger surface area; allows large molecules to access the pores [26]. | Analysis of large biomolecules (e.g., proteins, antibodies, peptides) [26]. |

Stationary Phase Chemistry: C18 and Beyond

The chemical nature of the stationary phase dictates the selectivity and retention of your analytes through hydrophobic, polar, ionic, and other interactions.

| Phase Type | Key Characteristics | Primary Interaction Mechanism | Ideal For Separating |

|---|---|---|---|

| C18 (ODS) | High hydrophobicity, versatile, most common | Hydrophobic (van der Waals) | Non-polar to moderately polar compounds [6]. |

| C8 (Octyl) | Moderate hydrophobicity | Hydrophobic | Medium to large molecules; often provides different selectivity than C18 [6]. |

| Phenyl | Aromatic ring structure | π-π interactions | Compounds with aromatic rings; can offer unique selectivity [6]. |

| Polar-Embedded | Polar group (e.g., amide) embedded in alkyl chain | Mixed-mode (hydrophobic and polar) | Prevents retention collapse with high aqueous mobile phases; useful for polar compounds [6]. |

| Cyano (CN) | Low hydrophobicity, moderate polarity | Hydrophobic and dipole-dipole | Rapid analysis; can be used in both reversed-phase and normal-phase modes. |

| HILIC | Hydrophilic stationary phase | Partitioning & polar interactions | Very polar and hydrophilic compounds that are not retained in standard reversed-phase HPLC [12]. |

Troubleshooting Guide: Peak Resolution Issues

Common Symptoms and Solutions

| Symptom | Possible Cause | Experimental Verification & Solution |

|---|---|---|

| Broad Peaks | - Extra-column volume too large [6].- Detector flow cell volume too large [6].- Column degradation or void [6] [2]. | Verify: Check capillary connections (use 0.13 mm I.D. for UHPLC). Ensure flow cell volume is ≤1/10 of the smallest peak volume [6].Solve: Use shorter, narrower capillaries. Replace column [6]. |

| Peak Tailing | - Secondary interactions (e.g., basic compounds with silanol groups) [6].- Column voiding [6].- Blocked frit or channels in column [6]. | Verify & Solve: Use high-purity silica (Type B) or polar-embedded phases [6]. Add a competing base like triethylamine to mobile phase [6]. Replace column or frit [6] [2]. |

| Poor Resolution (Peaks Co-elute) | - Incorrect mobile phase composition/pH [12].- Column chemistry not selective for analytes [12].- Flow rate too high [12].- Column temperature too high [12]. | Verify & Solve: Optimize organic solvent ratio, buffer pH, and ionic strength [12]. Test a different stationary phase (e.g., Phenyl vs. C18) [12]. Lower flow rate to improve efficiency [12]. Lower column temperature to increase retention and resolution [12]. |

| Variable Retention Times | - Inconsistent mobile phase preparation [2].- Column aging or damage [2].- Temperature fluctuations [2]. | Verify & Solve: Prepare mobile phases consistently and use fresh buffers [2]. Ensure column is properly equilibrated [2]. Use a column oven for stable temperature control [2]. |

Systematic Protocol for Optimizing Peak Resolution

When developing or adapting a method for improved resolution, follow this systematic protocol, changing only one parameter at a time [12].

Sample Preparation

Method Parameters (Liquid Phase)

- Mobile Phase Composition: Systematically adjust the organic-to-aqueous solvent ratio to modify elution strength. A weaker eluent (more aqueous) increases retention [12].

- Mobile Phase pH: Adjust the pH to alter the ionization state of ionizable analytes, significantly changing retention and selectivity. Ensure the pH is within the stability range of your column [12].

- Buffer Concentration: Use a buffer with sufficient capacity (typically 10-50 mM) to maintain a stable pH, especially when analyzing ionizable compounds [6].

Method Parameters (Hardware & Solid Phase)

- Flow Rate: In most cases, lowering the flow rate will improve efficiency and resolution by allowing more time for mass transfer, though it increases run time [12].

- Column Temperature: Lower temperatures generally increase retention and can improve resolution, but will lengthen analysis time. Use a column oven for stability [12].

- Injection Volume: Avoid mass overload. As a rule, the injection volume should be 1-2% of the total column volume for a sample concentration of 1 µg/µL [12].

Detection

- Wavelength: For DAD detectors, select the optimal wavelength based on the analyte's absorption spectrum to maximize sensitivity and minimize interference [12].

- Data Acquisition Rate: Ensure a high enough acquisition rate to capture at least 20-40 data points across the narrowest peak of interest for accurate integration and quantification [12].

Frequently Asked Questions (FAQs)

What is the most critical factor when selecting a column for a new application? The chemical compatibility between your analytes and the stationary phase chemistry is paramount for achieving selectivity and resolution. The particle size primarily affects efficiency and speed. Always base your initial selection on the chemical nature of your compounds (e.g., use C18 for non-polar, HILIC for very polar) [26] [12].

My peaks were sharp but now they are tailing. What should I check first? Peak tailing is most often caused by column degradation, such as a void forming at the inlet, or by secondary interactions. First, check the system pressure for unusual changes. Then, try flushing the column with a strong solvent according to the manufacturer's instructions. If tailing persists, the column may be damaged and need replacement [6] [2].

Can I use a column packed with sub-2µm particles on my standard HPLC system? It is possible but not always ideal. Standard HPLC systems may not be able to handle the very high backpressures generated by these columns and may have excessive extra-column volume, which broadens peaks and reduces the efficiency gains [26]. Verify that your system's pressure limit is sufficient and consider using a column with solid-core particles, which can offer similar efficiency at lower pressures.

How does mobile phase pH affect my separation on a C18 column? pH critically influences the ionization state of acidic and basic compounds. An ionized compound will be much less retained on a hydrophobic C18 surface than its neutral form. For example, controlling pH is essential for separating compounds like geniposide and paeoniflorin in complex mixtures [4]. Always use a buffered mobile phase to control pH precisely [12].

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function in UFLC-DAD Analysis |

|---|---|

| UFLC/DAD System | The core instrument for ultra-fast separation and diode-array detection, enabling rapid profiling of complex samples [4]. |

| C18 Column (1.8-3µm) | The workhorse reversed-phase column for high-efficiency separation of small molecules; common in pharmaceutical and natural product analysis [4] [26]. |

| Solid-Core Particle Columns | Provide high efficiency and sharp peaks with lower backpressure compared to fully porous sub-2µm particles, a good compromise for many systems [12]. |

| HPLC-Grade Solvents (Acetonitrile, Methanol) | High-purity mobile phase components to minimize baseline noise and prevent system contamination [6] [2]. |

| Volatile Buffers (e.g., Formate, Acetate) | Used to control mobile phase pH for reproducible retention of ionizable compounds, especially when hyphenating with mass spectrometry (MS) [4]. |

| Guard Column | A small cartridge placed before the analytical column to protect it from particulate matter and chemically irreversibly adsorbed sample components, extending its lifespan [2]. |

| Vial Inserts & Low-Volume Vials | Maximize recovery of precious samples and minimize dead volume for accurate autosampler injections, crucial for high-sensitivity analysis [12]. |

Frequently Asked Questions (FAQs)

Q1: How does mobile phase pH fundamentally affect my separation? Mobile phase pH is a powerful tool for controlling separation selectivity, especially for ionogenic compounds (acids and bases). Changing the pH alters the analyte's ionization state, which dramatically affects its retention in reversed-phase chromatography. For instance, a protonated basic compound is more hydrophilic and less retained, while its deprotonated form is more hydrophobic and has longer retention. The optimal buffering capacity is achieved when the mobile phase pH is within ±1 unit of the buffer's pKa [27].

Q2: Should I adjust the pH of the aqueous buffer before or after adding the organic modifier? You should always adjust the pH of the aqueous portion only, before mixing it with the organic solvent. A standard pH meter is calibrated for aqueous solutions and does not give accurate or meaningful readings in water-organic solvent mixtures [28]. The key to reproducibility is strict consistency; once a method is established, the mobile phase must always be prepared in the exact same way.

Q3: My peaks are tailing. Could the mobile phase buffer be the cause? Yes. Poor peak shape, especially for basic compounds, can result from insufficient buffer concentration or a pH that is too far from the buffer's pKa. This reduces buffer capacity, leading to localized pH shifts within the column that cause tailing. To resolve this, ensure you are using an adequate concentration of a buffering agent whose pKa is within one unit of your target mobile phase pH [27].

Q4: What is the impact of data acquisition rate on my peak appearance in DAD detection? The data acquisition rate (in Hz) determines the number of data points collected per second. A higher rate provides more data points across a peak, resulting in a sharper, more true-to-form peak shape. However, it also increases baseline noise and data file size. A lower rate applies more filtering, smoothing the baseline but potentially leading to a distorted, broader peak if too few points are collected. For optimal quantification, ensure you have at least 20-40 data points across the narrowest peak of interest [20] [12].

Q5: How does buffer concentration affect my method beyond just controlling pH? Buffer concentration determines your method's buffer capacity—its ability to resist pH changes. If the concentration is too low, the buffer can be overwhelmed by the sample or by residual silanols on the column, leading to poor retention time reproducibility and peak shape. A general rule is to use the lowest buffer concentration that provides robust performance, typically in the 5-50 mM range, depending on the sample load and column characteristics [27] [28].

Troubleshooting Guides

Common Mobile Phase-Related Issues and Solutions

| Symptom | Possible Cause | Recommended Solution |

|---|---|---|

| Peak Tailing | Low buffer capacity; wrong buffer pH [27] | Increase buffer concentration; adjust pH to be within ±1 of buffer pKa [27]. |

| Irreproducible Retention Times | Inadequate buffering; pH mismatch [27] | Use a buffer with sufficient capacity at the working pH; prepare mobile phase consistently [27] [28]. |

| Broad Peaks | High column temperature; mismatch between sample and mobile phase solvents [6] [12] | Lower column temperature; ensure sample is dissolved in the starting mobile phase composition [6] [12]. |

| Low Peak Resolution | Non-optimal pH or organic modifier ratio; high flow rate [12] | Re-optimize mobile phase composition (pH and organic %); reduce flow rate to improve efficiency [12]. |

| High Backpressure | Buffer precipitation; clogged frit [12] | Ensure buffer is soluble in the water-organic mixture; replace or flush column inlet frit [12]. |

| Noisy Baseline (DAD) | Data acquisition rate too high; high bandwidth setting [20] | Slightly decrease the acquisition rate; use a narrower bandwidth if selectivity allows [20]. |

Optimizing Detector (DAD) Settings for Better Data Quality

| Setting | Effect on Chromatogram | Optimization Guideline |

|---|---|---|

| Acquisition Rate | Higher rate: sharper peaks, more noise. Lower rate: smoother baseline, potential peak distortion [20]. | Use a higher rate (e.g., 20-80 Hz) for fast, narrow peaks; a lower rate (e.g., 1-5 Hz) for broader peaks [20]. |

| Bandwidth | Narrow BW: increased selectivity. Wide BW: lower noise, higher signal-to-noise for some compounds [20]. | Set bandwidth based on the spectral feature of the analyte; typically 4-16 nm is a good starting point [20]. |

| Wavelength | Directly impacts sensitivity according to Lambert-Beer's law [20]. | Choose a wavelength where the analyte absorbs strongly, avoiding regions of signal saturation [20] [12]. |

| Reference Wavelength | Compensates for background fluctuations and lamp noise [20]. | Use a wavelength where the analyte has minimal absorption; can be used for peak suppression [20]. |

| Step Setting (for Spectra) | Smaller step: smoother spectral peaks, larger file. Larger step: coarse spectra, smaller file [20]. | Use a 1-2 nm step for investigative work; a 4-8 nm step may suffice for routine analysis [20]. |

Systematic Optimization Strategy

A systematic approach to mobile phase optimization involves understanding the logical relationship between parameters and the desired outcomes. The following workflow diagrams a robust strategy for method development.

Step-by-Step Experimental Protocol

1. Define Initial Conditions: Begin with a scouting gradient using a wide pH range (e.g., pH 3, 5, 7, and 9) and a common buffer like phosphate or ammonium formate/acetate to identify the most promising pH window for your analytes [27].

2. Optimize pH for Selectivity: Prepare a series of isocratic or shallow gradient methods with the buffer pH varying in 0.2-0.3 unit increments around the promising region identified in Step 1. Monitor the resolution (Rs) between the most critical peak pair. The goal is to find a pH that provides maximum resolution and where the separation is robust against minor pH variations [27].

3. Optimize Buffer Type and Strength:

- Buffer Type: Choose a buffer appropriate for your detector (e.g., volatile formate/acetate for MS, phosphate for UV) with a pKa within ±1 of your target pH [27].

- Buffer Strength: Test buffer concentrations (e.g., 5, 10, 20, 50 mM) at the optimal pH. Inject your sample and look for consistent retention times and minimal peak tailing. Select the lowest concentration that provides stable performance [27] [28].

4. Optimize Organic Modifier and Gradient:

- Modifier Type: Acetonitrile often provides sharper peaks, while methanol can offer different selectivity.

- Gradient/Isocratic: For complex samples, optimize the gradient profile (slope, initial and final % organic) to balance resolution and analysis time. For simple mixtures, an isocratic method may be sufficient [12].

5. Fine-Tune Detector Settings: Set the DAD acquisition rate to ensure at least 20-40 data points across the narrowest peak. Select the optimal wavelength and bandwidth for best sensitivity and selectivity [20] [12].

The Scientist's Toolkit: Key Reagents and Materials

| Reagent/Material | Critical Function in Mobile Phase Optimization |

|---|---|

| Ammonium Formate/Acetate | Volatile buffering agents, essential for LC-MS compatibility. Effective in low pH (formate) and mid-range pH (acetate) applications [27]. |

| Potassium/Sodium Phosphate | Provides high buffering capacity in the UV-transparent range for HPLC-UV/DAD applications. Useful across a wide pH range (pKa₂ ~7.2) [27]. |

| Trifluoroacetic Acid (TFA) | A common ion-pairing agent and pH modifier for controlling the retention and peak shape of peptides and proteins [27]. |

| Type B Silica C18 Column | The standard workhorse column for reversed-phase chromatography. High-purity silica minimizes peak tailing for basic compounds [6]. |

| Acetonitrile & Methanol | The two most common organic modifiers. Acetonitrile offers low viscosity and high elution strength, while methanol provides different selectivity and is less expensive [12]. |

| pH Meter with ATC Probe | Crucial for the accurate and reproducible preparation of aqueous buffer solutions. Automatic Temperature Compensation (ATC) is vital for accuracy [28]. |

Detailed Experimental Protocol: A DoE Approach for Rapid Optimization

Factorial design is a superior alternative to the "one-factor-at-a-time" approach, as it reveals interactions between factors and reduces the total number of experiments required [29].

Protocol:

- Identify Critical Factors: Select the factors you wish to optimize. For mobile phase optimization, these are typically:

- Factor A: pH of the buffer

- Factor B: Concentration of the buffer (mM)

- Factor C: Percentage of organic modifier (%B)

- Define Ranges: Set a high and low level for each factor based on preliminary experiments or literature (e.g., pH: 3.0 and 4.0; Buffer: 10 mM and 30 mM; %B: 40% and 60%).

- Create and Execute Design: Use software to generate a randomized experimental design (e.g., a Full Factorial or Central Composite Design). Prepare mobile phases and run the analyses according to the randomized list to minimize bias.

- Analyze Responses: For each chromatogram, measure key responses like Resolution (Rs) of the critical peak pair, peak symmetry, and analysis time.

- Build Model and Predict: Input the responses into the software to build a mathematical model. Use the model's prediction function to find the combination of factor settings that maximizes resolution and peak symmetry while maintaining a desirable run time.

- Verify Experimentally: Prepare the mobile phase at the predicted optimal conditions and perform a confirmation run. The experimental results should closely match the model's prediction [29].

Why does my baseline drift during a gradient run, and how can I fix it?

Baseline drift is a common issue in gradient elution, primarily when using UV detection, especially at lower wavelengths (<220 nm). It occurs when the mobile phase solvents (A and B) have different UV absorbance at the detection wavelength. As the proportion of the solvents changes during the gradient, the baseline signal shifts [30].

Troubleshooting Steps:

- Identify the Cause: Determine if the drift is due to a difference in UV absorbance between your solvents. This is the most frequent cause. A rising baseline often means solvent B has stronger UV absorbance than A, while a falling baseline suggests the opposite [30].

- Change the Detection Wavelength: Increasing the detection wavelength (e.g., to 254 nm or higher) can often minimize or eliminate drift, as most organic solvents have lower UV absorbance at higher wavelengths [30].

- Match Solvent Absorbance: Modify the mobile phase to make the UV absorbance of solvents A and B more similar.

- For water-methanol gradients at low UV: Use a UV-absorbing buffer (e.g., 10 mM potassium phosphate) as solvent A instead of pure water to match methanol's absorbance [30].

- For acetonitrile gradients: Acetonitrile often has low UV absorbance relative to water, making it a preferred solvent for low-wavelength UV detection. Using additives like trifluoroacetic acid (TFA) (e.g., 0.1% in both A and B solvents) can also help produce a flat baseline at 215 nm [30].

- Check for Temperature Instability: Ensure your column temperature is stable by using a column oven, as temperature fluctuations can also cause baseline drift [30].

Table: Common Mobile Phase Combinations and Their Baseline Drift Potential at Low UV Wavelengths

| Solvent A | Solvent B | Typical Drift at <220 nm | Recommended Fix |

|---|---|---|---|

| Water | Methanol | Strong positive drift (rising) | Use phosphate buffer as A; or increase wavelength [30] |

| Water | Acetonitrile | Low drift (often flat) | Ideal for low-wavelength UV [30] |

| 25 mM Ammonium Acetate | 80% Methanol | Strong negative drift (falling) | Increase detection wavelength; or add buffer to B solvent [30] |

| 0.1% TFA in Water | 0.1% TFA in Acetonitrile | Very low drift | Excellent for peptides/proteins at 215 nm [30] |

How can I improve resolution between closely eluting peaks?

Resolution (Rs) is governed by three factors in the fundamental resolution equation: efficiency (N), retention (k), and selectivity (α) [9]. The equation is: Rs = 1/4 * (α - 1) * √N * (k / (1 + k))

Troubleshooting Steps:

- Increase Efficiency (N): This sharpens the peaks, improving separation.

- Use a column with smaller particles: Columns packed with smaller particles (e.g., sub-2μm) provide higher plate numbers and better resolution [9] [12].

- Use a longer column: Doubling the column length can increase peak capacity and resolution, which is especially useful for complex samples like protein digests [9].

- Optimize flow rate: Lowering the flow rate can improve efficiency but increases run time. Find the optimal balance [12].

- Increase temperature: Elevated column temperature reduces mobile phase viscosity and increases diffusion rates, enhancing efficiency [9].

- Adjust Retention (k): Ensure peaks are not eluting too early (k < 2). You can do this by reducing the strength of the mobile phase (e.g., a lower percentage of organic solvent, %B) in reversed-phase HPLC [9].

- Change Selectivity (α): This is the most powerful way to improve resolution as it changes the relative spacing of peaks.

- Change the organic solvent: If you started with acetonitrile, try methanol or tetrahydrofuran. Use solvent strength charts to estimate the new %B required for similar retention times [9].

- Adjust mobile phase pH: This dramatically impacts the ionization and retention of acidic or basic compounds. A change of just 0.1 pH units can alter selectivity [31].

- Change the column chemistry: Switching to a different stationary phase (e.g., from C18 to a phenyl or polar-embedded phase) can significantly alter selectivity and resolve co-eluting peaks [9].

Table: Methods for Changing Peak Resolution [9]

| Method | Mechanism | Advantages | Limitations |

|---|---|---|---|

| Smaller Particle Size | Increases efficiency (N) | Sharper peaks, better resolution | Higher backpressure |

| Longer Column | Increases efficiency (N) | Higher peak capacity for complex mixtures | Much higher backpressure, longer run times |

| Change Organic Solvent | Alters selectivity (α) | Powerful effect on peak spacing | Requires re-method development |

| Adjust pH | Alters selectivity (α) | Very effective for ionizable compounds | Limited by column pH stability |

| Change Stationary Phase | Alters selectivity (α) | Can resolve structurally similar compounds | Requires column purchase and testing |

The following diagram illustrates a systematic workflow for troubleshooting peak resolution issues:

What causes peak tailing, and how can I achieve symmetrical peaks?

Peak tailing (asymmetry factor, As > 1.2) primarily occurs due to secondary, unwanted interactions of the analyte with the stationary phase [31] [32]. For basic compounds, this is often an ionic interaction with ionized silanol groups on the silica surface [31].

Troubleshooting Steps:

- For Basic Compounds:

- Use a lower mobile phase pH: Operating at pH ≤ 3.0 ensures silanol groups are protonated (non-ionized) and basic analytes are fully ionized, minimizing ionic interactions [31]. Ensure your column is stable at low pH.

- Use a highly deactivated column: Select columns that are heavily end-capped (e.g., Agilent ZORBAX Eclipse Plus) to minimize the number of accessible silanol groups [31].

- Use a sterically protected column: Columns like Agilent ZORBAX Extend can operate at higher pH (up to 11), where basic analytes are non-ionized, thus avoiding silanol interactions [31].

- Check for Mass Overload: If all peaks in the chromatogram are tailing, the column might be overloaded with sample. Dilute your sample 10-fold and re-inject. If peak shape improves, you need to reduce the injection volume or concentration [31].

- Check for Column Damage:

- Column Voids: A void at the column inlet can cause peak tailing or splitting for all peaks. Reverse the column and flush it with a strong solvent (check manufacturer's instructions), or replace the column [33].

- Blocked Inlet Frit: Sample matrix components can clog the frit. Using an in-line filter and/or a guard column can prevent this [31] [33].

My peaks were separating well, but the peak shape has degraded over many injections. What should I do?

This is typically a sign of column degradation or contamination from the sample matrix [33] [32].

Troubleshooting Steps:

- Replace the Guard Column: If you are using one, this is the first and easiest step. If peak shape is restored, the guard column has absorbed the contamination and protected the analytical column [33].

- Clean the Analytical Column: Follow the manufacturer's instructions for flushing the column with strong solvents to remove adsorbed contaminants.

- Check for Column Voiding: If the column has been used under high pH conditions (>7) or exposed to rapid pressure changes, the silica bed can form a void. Replacing the column is the only solution [33].

- Improve Sample Cleanup: If column contamination is a recurring issue, implement or optimize a sample preparation step such as solid-phase extraction (SPE) to remove proteins, lipids, and other interfering matrix components before injection [31] [33].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table: Key materials and their functions in gradient elution method development and troubleshooting.

| Item | Function | Example Use Case |

|---|---|---|

| High-Purity Acetonitrile | Low-UV absorbance organic solvent | Gradient elution with detection <220 nm [30] |

| Trifluoroacetic Acid (TFA) | Ion-pairing agent and pH modifier; volatile | Peptide/protein separations; LC-MS compatibility [30] |

| Potassium Phosphate Buffer | UV-absorbing buffer | Compensate for baseline drift in methanol-water gradients [30] |

| Heavily End-capped C18 Column | Reduced secondary silanol interactions | Improve peak shape for basic compounds [31] |

| Guard Column | Pre-column filter | Protects analytical column from contamination, extending its life [33] |

| In-line Filter | Protects the column and system | Prevents particulates from blocking the column inlet frit [31] |

In UFLC-DAD chromatography research, achieving optimal peak resolution is critically dependent on effective sample preparation. Matrix effects, caused by co-eluting sample components, can significantly compromise data accuracy, method robustness, and instrument performance [34] [35]. This technical support center article focuses on solid-phase extraction (SPE) and filtration as two foundational techniques to mitigate these interferences, providing troubleshooting guides and FAQs tailored for researchers and drug development professionals.

Understanding Matrix Interference and Its Impact