UV-Vis Spectroscopy for Active Component Quantification: Principles, Methods, and Pharmaceutical Applications

This comprehensive article explores the critical role of Ultraviolet-Visible (UV-Vis) spectroscopy in quantifying active components, with a specific focus on pharmaceutical applications.

UV-Vis Spectroscopy for Active Component Quantification: Principles, Methods, and Pharmaceutical Applications

Abstract

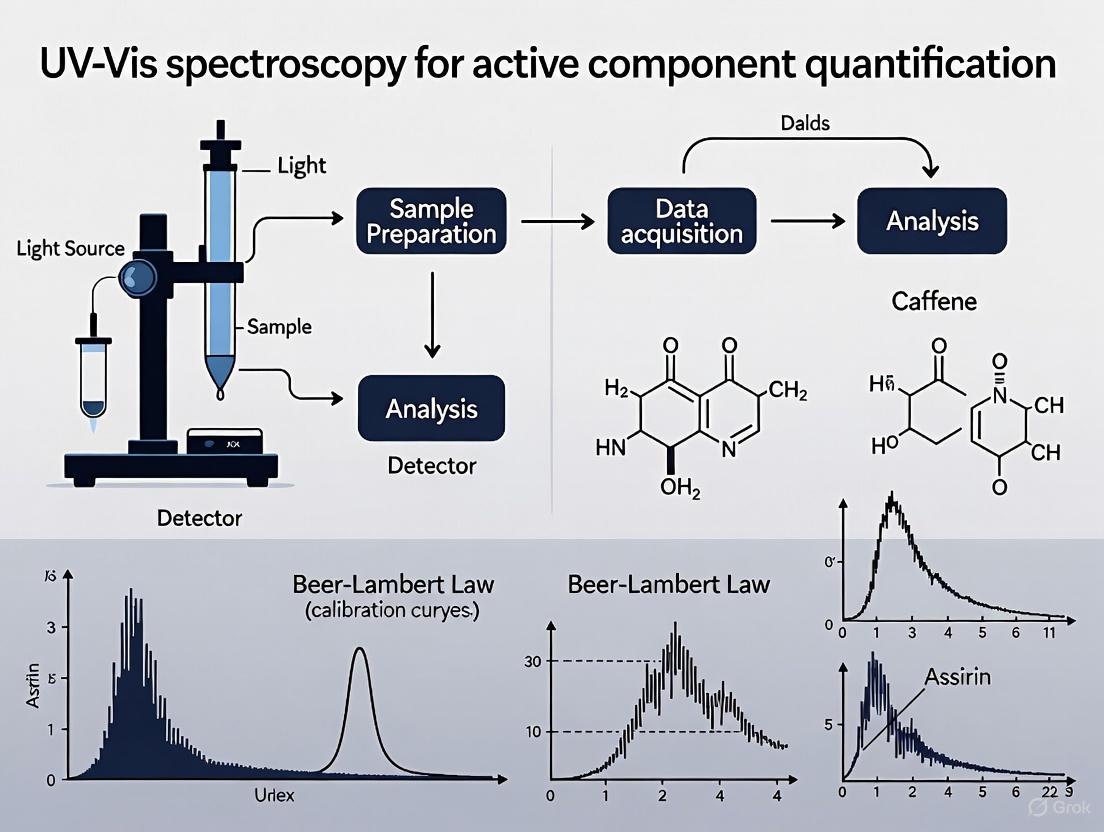

This comprehensive article explores the critical role of Ultraviolet-Visible (UV-Vis) spectroscopy in quantifying active components, with a specific focus on pharmaceutical applications. It covers foundational principles from light absorption to Beer-Lambert's law, details methodological approaches for drug stability testing, dissolution analysis, and content uniformity, provides practical troubleshooting guidance for common instrumentation and sample issues, and examines validation protocols and comparative analyses with other spectroscopic techniques. Tailored for researchers, scientists, and drug development professionals, this review synthesizes current advancements and practical implementations of UV-Vis spectroscopy in ensuring drug quality, safety, and efficacy from development through quality control.

UV-Vis Spectroscopy Fundamentals: From Light Absorption to Quantitative Analysis

Core Principles of UV-Vis Spectroscopy and Light-Matter Interactions

Ultraviolet-Visible (UV-Vis) spectroscopy is an analytical technique that measures the attenuation of a beam of light after it passes through a sample or after reflection from a sample surface. This technique operates on the principle of light absorption in the ultraviolet and visible regions of the electromagnetic spectrum, typically between 190 nm and 800 nm [1]. The core importance of UV-Vis spectroscopy in modern laboratories stems from its ability to both identify and quantify molecular components in a sample based on their characteristic absorption patterns [1] [2]. For researchers in drug development, this technique provides a cost-effective, simple, versatile, and non-destructive analytical method suitable for a broad spectrum of organic compounds and some inorganic species [2].

In pharmaceutical research and active component quantification, UV-Vis spectroscopy serves as an indispensable tool for drug discovery, impurity quantification, and quality control [1]. The technique is particularly valuable because it can determine concentrations of specific molecules in solution through application of the Beer-Lambert law, enabling precise quantitative analysis essential for formulation development and compliance with regulatory standards such as the Fair Packaging and Labeling Act [1] [2].

Theoretical Foundations

Light-Matter Interactions and Electronic Transitions

The fundamental principle of UV-Vis spectroscopy centers on the interaction between ultraviolet/visible light and matter, resulting in the absorption of specific wavelengths by electrons in the sample molecules [1]. When a molecule absorbs light energy in the UV-Vis range, electrons are promoted from their ground state to a higher energy excited state—a process known as an electronic transition [1]. The specific wavelength absorbed depends on the energy difference between molecular orbitals, which is uniquely determined by the molecular structure [1].

In organic molecules, three distinct types of electrons are involved in these transitions [3]:

- σ electrons: Involved in single bonds

- π electrons: Found in double and triple bonds

- n electrons: Non-bonding electrons (lone pairs)

The energy required for promoting electrons follows the order: σ > π > n [3]. Different electronic transitions require different energy amounts, which correspond to specific wavelength ranges in the electromagnetic spectrum.

Chromophores: The Color-Bearing Groups

Chromophores are molecular regions responsible for light absorption in the UV-Vis range [1] [4]. These are functional groups within molecules that contain valence electrons of low excitation energy, typically found in conjugated π-electron systems [2] [4]. The term "chromophore" derives from the Greek words "chroma" (color) and "phoros" (carrier), literally meaning "color carrier" [4].

In conjugated chromophore systems, electrons jump between energy levels that are extended π orbitals created by electron clouds similar to those in aromatic systems [4]. The degree of conjugation significantly affects the absorption characteristics—longer conjugated systems (more adjacent double bonds) absorb longer wavelengths of light [4]. For example, β-carotene, with its extensive conjugated system, absorbs at 452 nm, appearing orange [4]. Common biological chromophores include retinal (used in vision), chlorophyll, hemoglobin, and various food colorings [4].

Table 1: Common Chromophores and Their Absorption Characteristics

| Chromophore/Compound | Absorption Wavelength | Structural Features |

|---|---|---|

| Bromophenol blue (yellow form) | 591 nm | Aromatic structure with extended conjugation |

| Malachite green | 617 nm | Triarylmethane dye with conjugated system |

| β-carotene | 452 nm | Extended polyene chain with 11 conjugated double bonds |

| Cyanine dyes | Varies with chain length | Conjugated polymethine bridge between heterocycles |

Electronic Transition Types

The four primary electronic transitions in UV-Vis spectroscopy are:

σ → σ* transition: Requires the highest energy, occurring in saturated compounds with only single bonds. For example, methane absorbs at 125 nm [3].

n → σ* transition: Occurs in saturated compounds containing heteroatoms (O, N, S, halogens) with lone pair electrons. These transitions typically occur in the 150-250 nm range [3].

π → π* transition: Requires less energy than σ transitions, observed in compounds with multiple bonds like alkenes, alkynes, carbonyls, nitriles, and aromatic compounds. Alkenes generally absorb between 170-205 nm [3].

n → π* transition: Requires the least energy, occurring in compounds containing double bonds involving heteroatoms (C=O, C≡N, N=O). These transitions typically show absorption at longer wavelengths around 300 nm [3].

The Beer-Lambert Law: Quantitative Foundation

The quantitative aspect of UV-Vis spectroscopy is governed by the Beer-Lambert Law, which forms the mathematical foundation for concentration determination [1] [5]. This law states that when a beam of monochromatic light passes through a solution of an absorbing substance, the rate of decrease of radiation intensity with thickness of the absorbing solution is proportional to both the incident radiation and the solution concentration [3].

The mathematical expression of the Beer-Lambert law is:

A = εbc

Where:

- A = Absorbance (unitless)

- ε = Molar absorptivity or extinction coefficient (M⁻¹cm⁻¹)

- b = Path length of the sample cell (cm)

- c = Concentration of the solute (mol/L) [5]

According to this relationship, absorbance is directly proportional to concentration when the path length and molar absorptivity remain constant [1]. This linear relationship enables researchers to determine unknown concentrations by measuring absorbance and comparing to standards of known concentration.

Two main factors affect light absorption as described by the Beer-Lambert law: the sample's concentration and the path length of the absorbing medium [1]. Higher molecule concentrations and longer path lengths through the sample result in greater absorbance, evident from the decreased light intensity reaching the detector [1].

Table 2: Beer-Lambert Law Parameters and Their Significance in Quantitative Analysis

| Parameter | Symbol | Units | Significance in Pharmaceutical Analysis |

|---|---|---|---|

| Absorbance | A | Unitless | Measured value indicating how much light is absorbed at specific wavelength |

| Molar Absorptivity | ε | M⁻¹cm⁻¹ | Molecular property indicating how strongly a compound absorbs at specific wavelength; constant for each compound |

| Path Length | b | cm | Fixed by cuvette dimensions; typically 1 cm in standard measurements |

| Concentration | c | mol/L | Target variable in quantitative analysis; calculated from measured absorbance |

Instrumentation and Measurement

UV-Vis Spectrometer Components

A typical UV-Vis spectrometer consists of four essential components that enable precise light absorption measurement and facilitate data analysis [1]:

Light Source: Emits a broad range of wavelengths in the UV-Vis spectrum. Common configurations include:

- Single xenon lamps for both UV and visible ranges

- Dual-lamp systems: deuterium lamp for UV light and tungsten/halogen lamp for visible light [1]

Wavelength Selector: Narrow down the broad wavelength range to specific wavelengths needed for analysis. Monochromators containing prisms are typically used, though various filters can serve the same function [1].

Sample Container: Holds the sample during analysis. Cuvettes with standard path lengths (typically 1 cm) are most common. Instruments may be single-beam (measuring sample and reference separately) or double-beam (simultaneously comparing sample and reference) [1].

Detector: Converts transmitted light into electrical signals readable by analytical software. The information is typically presented as a graph with peaks representing wavelengths of maximum absorption [1].

The Scientist's Toolkit: Essential Research Reagent Solutions

Successful implementation of UV-Vis spectroscopy for active component quantification requires specific reagents and materials carefully selected for each application. The following table details essential research reagent solutions and their functions in pharmaceutical analysis:

Table 3: Essential Research Reagent Solutions for UV-Vis Spectroscopy in Pharmaceutical Analysis

| Reagent/Material | Function/Application | Technical Specifications |

|---|---|---|

| Deuterium Lamp | UV light source for wavelengths 190-400 nm | Typical lifespan: 1000 hours; requires warm-up time for stability |

| Halogen/Tungsten Lamp | Visible light source for wavelengths 400-800 nm | Longer lifespan than deuterium lamps; stable output |

| Quartz Cuvettes | Sample containers for UV range measurements | Transparent down to 190 nm; standard path length 1.0 cm |

| Glass Cuvettes | Sample containers for visible range measurements | Lower cost than quartz; usable from 340-2500 nm |

| Solvent-Grade Water | Blank and solvent for water-soluble compounds | UV-transparent; purified to eliminate organic impurities |

| HPLC-Grade Solvents | Blanks and solvents for organic compounds | Low UV absorption; high purity to prevent interference |

| Standard Reference Materials | Calibration standards for quantitative analysis | Certified concentrations; traceable to reference standards |

| Buffer Solutions | pH control for ionizable analytes | Maintain consistent ionization state of analyte |

Experimental Protocols for Active Component Quantification

Protocol 1: Standard Calibration Curve Method for API Quantification

Purpose: To establish a quantitative relationship between absorbance and concentration of an Active Pharmaceutical Ingredient (API) for unknown sample determination.

Materials and Equipment:

- UV-Vis spectrophotometer with matched quartz cuvettes

- Analytical balance (±0.0001 g precision)

- Volumetric flasks (10 mL, 25 mL, 50 mL)

- Micropipettes with appropriate volume ranges

- Reference standard of API (>98% purity)

- Appropriate solvent (water, buffer, or HPLC-grade organic solvent)

Procedure:

Standard Stock Solution Preparation:

- Accurately weigh 25 mg of API reference standard using analytical balance

- Transfer quantitatively to 25 mL volumetric flask using solvent

- Dissolve completely and dilute to mark with solvent (concentration: 1 mg/mL)

- Mix thoroughly by inverting flask 10 times

Working Standard Solutions Preparation:

- Prepare dilution series according to table below using volumetric flasks

- Ensure thorough mixing after each dilution step

Table 4: Example Calibration Standard Preparation Scheme

| Standard Solution | Volume of Stock Solution (mL) | Final Volume (mL) | Final Concentration (μg/mL) |

|---|---|---|---|

| Blank | 0.0 | 10.0 | 0.0 |

| STD 1 | 0.5 | 10.0 | 50.0 |

| STD 2 | 1.0 | 10.0 | 100.0 |

| STD 3 | 1.5 | 10.0 | 150.0 |

| STD 4 | 2.0 | 10.0 | 200.0 |

| STD 5 | 2.5 | 10.0 | 250.0 |

Spectrophotometer Setup and Measurement:

- Turn on instrument and allow 15-20 minutes for lamp stabilization

- Set appropriate wavelength based on API absorbance maximum (determined from preliminary scan)

- Zero instrument with blank solution containing only solvent

- Measure absorbance of each standard solution in triplicate

- Record average absorbance values for each concentration

Calibration Curve Construction:

- Plot average absorbance (y-axis) versus concentration (x-axis)

- Perform linear regression analysis to obtain equation: y = mx + c

- Verify correlation coefficient (R²) ≥ 0.995 for acceptable linearity

Unknown Sample Analysis:

- Prepare unknown sample solution within linear range of calibration curve

- Measure absorbance following same procedure as standards

- Calculate concentration using linear regression equation

Validation Parameters:

- Linearity: R² ≥ 0.995 across working range

- Precision: Relative Standard Deviation (RSD) ≤ 2% for replicate measurements

- Accuracy: Recovery of 98-102% for spiked samples

- Limit of Quantification (LOQ): Signal-to-noise ratio ≥ 10:1

Protocol 2: Method for Chromophore Maturation Kinetics in Fluorescent Proteins

Purpose: To analyze the temperature-dependent chromophore maturation kinetics of fluorescent protein reporters used in pharmaceutical research.

Background: Chromophore maturation refers to the process where expressed fluorescent proteins form their functional light-absorbing structures, requiring molecular oxygen as an external reagent [6]. This process is crucial when using fluorescent proteins as reporters in cell-free expression systems for drug screening applications.

Materials and Equipment:

- Cell-free protein expression system (E. coli based)

- Expression vectors for target fluorescent proteins (EGFP, EYFP, mCherry)

- Thermocycler or temperature-controlled incubation blocks

- UV-Vis spectrophotometer with temperature control

- Microcentrifuge tubes and appropriate pipettes

Procedure:

Protein Expression:

- Mix DNA template with cell-free expression solution according to manufacturer protocol

- Incubate synthesis reaction at room temperature for 2-4 hours

- Stop reaction by adding 0.1% RNase A to degrade RNA templates

- Centrifuge at 18,000 × g for 20 minutes to remove large particles

Temperature-Dependent Maturation Kinetics:

- Divide expressed protein solution into aliquots for different temperature conditions

- Incubate aliquots at temperatures ranging from 20°C to 37°C

- Monitor fluorescence intensity increase over time at protein-specific wavelengths:

- EGFP: Excitation 488 nm / Emission 507 nm

- EYFP: Excitation 514 nm / Emission 527 nm

- mCherry: Excitation 587 nm / Emission 610 nm

Data Collection:

- Record fluorescence intensity at regular intervals (e.g., every 5-10 minutes)

- Continue measurements until fluorescence plateaus (typically 2-6 hours depending on temperature)

- Perform triplicate measurements for each temperature condition

Kinetic Analysis:

- Fit fluorescence versus time data to equation: F(t) = F₀ + ΔF(1 - e^(-t/τ))

- Where τ is maturation time constant at each temperature

- Plot maturation rates (1/τ) versus temperature to determine temperature dependence

- Apply transition state theory to calculate activation parameters

Applications in Drug Development:

- Optimization of fluorescent reporter systems for high-throughput screening

- Characterization of protein folding under different physiological conditions

- Assessment of compound effects on protein expression and maturation

Pharmaceutical Applications and Case Studies

UV-Vis spectroscopy finds diverse applications throughout drug development processes, from discovery through manufacturing quality control. The technique's versatility, sensitivity, and quantitative capabilities make it indispensable in modern pharmaceutical analysis.

Key Application Areas

Pharmaceutical Analysis: UV-Vis spectroscopy facilitates drug discovery and development through impurity quantification, component identification, and stability testing [1]. The technique serves as an effective quality control method with minimal impact on drug samples being analyzed [1]. Specific applications include:

- Identity confirmation of raw materials and active ingredients

- Determination of potency and content uniformity in dosage forms

- Dissolution testing of solid oral dosage forms

- Detection and quantification of degradation products

DNA and RNA Analysis: In genetic medicine and biopharmaceutical development, UV-Vis spectroscopy quickly verifies purity and concentration of nucleic acid samples [1]. This is particularly critical when preparing DNA for sequencing, where samples must be contamination-free [1]. The A260/A280 ratio provides a reliable purity indicator, with values of ~1.8 indicating pure DNA and ~2.0 indicating pure RNA.

Impurity Profiling: UV-Vis spectroscopy can detect and quantify impurities in pharmaceutical compounds through difference spectroscopy techniques. By comparing absorbance spectra of test samples against reference standards, even minor impurities with distinct chromophores can be identified and quantified.

Case Study: Caffeine Quantification in Formulations

Background: Regulatory requirements mandate accurate caffeine quantification in pharmaceutical formulations, with legal limits on caffeine content that must be accurately represented on product labels [1].

Methodology:

- Extraction of caffeine from matrix using appropriate solvent

- Scanning from 200-400 nm to identify caffeine absorbance maximum (~273 nm)

- Preparation of caffeine standards in concentration range 2-20 μg/mL

- Measurement of unknown samples against calibration curve

Results Interpretation:

- Absorbance values of unknown samples fitted to linear regression equation

- Concentration calculation considering appropriate dilution factors

- Comparison against regulatory limits with ±5% accuracy requirement

Quality Control Application:

- Routine analysis of production batches for compliance verification

- Stability testing to monitor potency over shelf life

- Formulation development to optimize caffeine concentration

Troubleshooting and Method Validation

Successful implementation of UV-Vis spectroscopy for active component quantification requires awareness of potential limitations and implementation of appropriate validation protocols.

Common Limitations and Solutions

Sample Limitations: UV-Vis spectroscopy works optimally with liquids and solutions, while suspensions of solid particles can scatter light more than absorb it, skewing data [5]. Solutions include:

- Filtration or centrifugation to remove particulate matter

- Use of integrating sphere accessories for scattering samples

- Appropriate sample dilution to minimize inner filter effects

Solvent Selection: Solvents must be transparent in the spectral region of interest. Common solvent cutoffs include:

- Water: 190 nm

- Acetonitrile: 190 nm

- Methanol: 205 nm

- Chloroform: 240 nm

- Dimethyl sulfoxide: 260 nm

Stray Light Effects: Stray light reaching the detector without passing through the sample causes deviation from Beer-Lambert law at high absorbances (>1.5 AU). Maintenance of instrument optical components and proper wavelength calibration minimize these effects.

Method Validation Parameters

For regulatory compliance in pharmaceutical analysis, UV-Vis methods require comprehensive validation including:

- Linearity: Demonstrated across specified concentration range with R² ≥ 0.995

- Accuracy: Recovery of 98-102% for quality control samples

- Precision: Relative Standard Deviation ≤ 2% for repeatability

- Specificity: Ability to unequivocally assess analyte in presence of expected impurities

- Limit of Detection (LOD): Typically signal-to-noise ratio of 3:1

- Limit of Quantification (LOQ): Typically signal-to-noise ratio of 10:1 with precision ≤ 5% RSD

- Robustness: Capacity to remain unaffected by small, deliberate variations in method parameters

UV-Vis spectroscopy remains a cornerstone analytical technique in pharmaceutical research and development, providing crucial data for active component quantification from discovery through quality control. The fundamental principles of electronic transitions, chromophore absorption, and the Beer-Lambert law create a robust foundation for quantitative analysis. When implemented with proper experimental protocols, calibration procedures, and validation protocols, UV-Vis spectroscopy delivers reliable, accurate, and precise results essential for drug development.

The continuing relevance of UV-Vis spectroscopy in modern laboratories is assured by its unique combination of simplicity, cost-effectiveness, and versatility. For researchers and drug development professionals, mastery of both the theoretical principles and practical applications contained in this document provides an essential skill set for successful pharmaceutical analysis. As technology advances, the integration of UV-Vis spectroscopy with automated platforms and data analytics continues to expand its utility in the rapidly evolving pharmaceutical landscape.

Ultraviolet-Visible (UV-Vis) spectroscopy serves as a fundamental analytical technique in pharmaceutical research and drug development, providing a robust means for the identification and quantification of active pharmaceutical ingredients (APIs). This technique operates on the principle of measuring the absorption of light in the ultraviolet (190-400 nm) and visible (400-800 nm) regions of the electromagnetic spectrum, which corresponds to the excitation of electrons to higher energy states [7]. The instrumentation's core components work in concert to deliver precise, reproducible data essential for compliance with rigorous regulatory standards. The quantification capability stems primarily from the Beer-Lambert Law (A = εcl), which establishes a linear relationship between absorbance (A) and the concentration (c) of the analyte in a solution [8] [7]. This application note provides a detailed breakdown of the key instrumental components—light sources, monochromators, and detection systems—and outlines standardized protocols for their application in quantifying active components, framed within the context of analytical research for drug development.

Core Instrumentation Components

The performance, accuracy, and sensitivity of a UV-Vis spectrophotometer are determined by the integrated operation of its three key subsystems: the light source, the wavelength selection system, and the detector.

A stable light source capable of emitting consistent intensity across a broad wavelength range is fundamental. Spectrophotometers typically use multiple lamps to cover the entire UV-Vis spectrum effectively [9] [8].

Table 1: Characteristics of Common UV-Vis Light Sources

| Light Source | Spectral Range | Key Characteristics | Pharmaceutical Application Suitability |

|---|---|---|---|

| Deuterium Lamp | 190 - 350 nm [9] | Intense, continuous spectrum in the UV region; lifetime is a key consideration. | Ideal for quantifying APIs with chromophores absorbing in the deep UV range. |

| Tungsten-Halogen Lamp | 330 - 2500 nm [9] [10] | Robust, long-lasting, and cost-effective for the visible to NIR region. | Suitable for colored compounds or formulation assays using visible wavelengths. |

| Xenon Lamp | 190 - 800 nm [10] [8] | Covers both UV and Vis with a single lamp; higher cost and can be less stable. | Useful for rapid scanning across a wide range but may require more frequent calibration. |

Modern instruments automatically switch between the deuterium and tungsten-halogen lamps during a scan, with the transition typically engineered to occur smoothly between 300 and 350 nm where their light emission is comparable [8] [7].

Wavelength Selection: Monochromators

The monochromator is critical for selecting discrete wavelengths from the broad-spectrum light source to probe specific electronic transitions of a sample's chromophores. Its primary function is to disperse the light and select a narrow band of wavelengths to irradiate the sample [9] [10]. The core components include an entrance slit, a collimating mirror, a dispersing element (usually a diffraction grating), a focusing mirror, and an exit slit [9].

The diffraction grating, characterized by its groove frequency (grooves per mm), is rotated to select specific wavelengths. A higher groove frequency (e.g., 1200 grooves/mm or more) provides better optical resolution [8]. The width of the exit slit determines the Spectral Bandwidth (SBW), defined as the full width at half maximum (FWHM) of the light intensity distribution [9]. A narrower SBW provides better resolution, allowing for the differentiation of sharp absorption peaks, which is crucial for identifying specific APIs in a mixture. Conversely, a wider SBW allows more light to reach the detector, improving the signal-to-noise ratio, which can be beneficial for measuring highly scattering samples or low concentrations [9]. The optimal bandwidth is typically set to 1/10 of the natural width of the sample's absorption peak [9].

Detection Systems

The detector converts the transmitted light intensity into an electrical signal, which is then processed to generate the absorption spectrum. The choice of detector impacts the sensitivity, wavelength range, and signal-to-noise ratio of the measurement [9] [8].

Table 2: Comparison of UV-Vis Spectrophotometer Detectors

| Detector Type | Operating Principle | Wavelength Range | Advantages | Limitations |

|---|---|---|---|---|

| Photomultiplier Tube (PMT) | Photoelectric effect with amplification via dynodes [9] [10] | UV-Vis | Very high sensitivity and low noise; excellent for low-light applications [9]. | Can be damaged by intense light; limited dynamic range [10]. |

| Silicon Photodiode | Semiconductor generates current when photons are absorbed [9] | ~190 - 1100 nm [10] | Robust, fast response time, wide dynamic range, and cost-effective [9]. | Generally less sensitive than PMT [9]. |

| Photodiode Array (PDA) | Array of individual photodiodes allowing simultaneous multi-wavelength detection [10] | UV-Vis | Extremely fast acquisition, enabling real-time monitoring of reactions [10]. | Resolution and sensitivity can be lower than a PMT-based system. |

Experimental Protocols for Active Component Quantification

Protocol: Quantification of an Active Pharmaceutical Ingredient (API)

This protocol details the use of UV-Vis spectrophotometry for the absolute quantification of a single API in a standard solution.

1. Principle: The concentration of an API in solution is determined by measuring its absorbance at a wavelength of maximum absorption (λmax) and applying the Beer-Lambert Law. A calibration curve of absorbance versus concentration is constructed using standard solutions of known concentration [7].

2. Research Reagent Solutions: Table 3: Essential Materials for API Quantification

| Item | Specification | Function |

|---|---|---|

| UV-Vis Spectrophotometer | Double-beam configuration recommended | Compensates for source drift and solvent absorption [9]. |

| Cuvettes | Quartz, 1 cm path length | Transparent across the entire UV-Vis range [8]. |

| API Standard | Certified Reference Material (CRM), high purity | Used to prepare calibration standards for accurate quantification. |

| Solvent | UV-grade (e.g., methanol, water, buffer) | Dissolves the analyte and must not absorb significantly at the λmax [7]. |

| Volumetric Flasks | Class A | For accurate preparation of standard and sample solutions. |

| Micropipettes | Calibrated | For precise liquid handling. |

3. Methodology:

- Instrument Setup and Blank Measurement: Turn on the instrument and allow the lamps to stabilize for at least 30 minutes. Set the desired instrumental parameters (e.g., wavelength range, SBW). Fill a cuvette with the pure solvent and place it in the reference cell holder. Place an identical empty cuvette in the sample holder and run a baseline correction to account for solvent absorption [8].

- Preparation of Standard Solutions: Accurately weigh the API standard. Dissolve and dilute to prepare a stock standard solution. Serially dilute the stock solution with the solvent to prepare at least five standard solutions covering a concentration range where absorbance remains linear (typically Abs < 1.0) [8].

- Determination of λmax: Scan one of the standard solutions (e.g., a mid-range concentration) over a suitable wavelength range to obtain its absorption spectrum. Identify the wavelength of maximum absorption (λmax).

- Measurement of Standards and Sample: Set the spectrophotometer to the fixed λmax. Measure the absorbance of each standard solution and the unknown sample solution in triplicate. Always use the solvent blank to zero the instrument before measurements.

- Data Analysis and Calculation: Plot the average absorbance of the standard solutions against their known concentrations to generate a calibration curve. Perform linear regression analysis. The equation of the line (y = mx + c, where y is absorbance and x is concentration) is used to calculate the concentration of the API in the unknown sample based on its measured absorbance.

Protocol: Purity Assessment of Nucleic Acids for Biopharmaceuticals

In the development of nucleic acid-based therapeutics, assessing the purity of DNA or RNA preparations is a critical quality control step.

1. Principle: The concentration and purity of nucleic acid samples are determined by measuring their absorbance at specific wavelengths. The absorbance at 260 nm is proportional to the concentration of nucleic acids. The ratio of absorbance at 260 nm to 280 nm (A260/A280) is used to assess protein contamination, while the A260/A230 ratio indicates contamination by solvents or salts [7].

2. Methodology:

- Instrument Preparation: Use a double-beam spectrophotometer. Zero the instrument using a cuvette filled with the dilution buffer (e.g., Tris-EDTA buffer).

- Sample Preparation: Dilute the nucleic acid sample appropriately with the same buffer. A typical dilution for DNA is 1:100 to ensure the A260 reading is between 0.1 and 1.0.

- Measurement: Measure the absorbance of the diluted sample at 230 nm, 260 nm, and 280 nm.

- Data Analysis and Interpretation:

- Concentration: For double-stranded DNA, Concentration (ng/μL) = A260 × 50 × Dilution Factor.

- Purity Ratios: Interpret the results as follows:

- Significant deviation from these ratios suggests contamination that may interfere with downstream enzymatic processes or analytical methods.

Instrumental Workflow and Signaling Pathways

The following diagram illustrates the logical sequence and component interaction within a standard double-beam UV-Vis spectrophotometer, which is the preferred configuration for high-precision quantitative analysis.

Diagram 1: Logical workflow of a double-beam UV-Vis spectrophotometer.

Critical Considerations for Analytical Performance

Stray Light and Photometric Linearity

Stray light, defined as any light reaching the detector that is outside the selected wavelength band, is a primary factor compromising photometric accuracy, particularly at high absorbances [9]. It causes a negative deviation from the Beer-Lambert Law, resulting in measured absorbances that are lower than the true value. This directly impacts the photometric linearity of the instrument—the range over which absorbance readings are accurately proportional to concentration [9]. For assays requiring high accuracy at elevated concentrations, instruments with double monochromators can be employed to minimize stray light.

Solvent and Cuvette Selection

The choice of solvent and cuvette material is critical:

- Solvents must be transparent in the spectral region of interest. Common solvents for UV-Vis include water, hexane, 95% ethanol, and methanol [7].

- Cuvettes must be selected based on the wavelength range. Standard quartz or fused silica cuvettes are required for UV work (down to 190 nm), while glass or plastic may be suitable for visible-only measurements [8].

A detailed understanding of UV-Vis instrumentation—from the characteristics of light sources and the resolution of monochromators to the sensitivity of detection systems—is paramount for researchers and scientists engaged in the quantification of active components. The precise and robust protocols outlined for API quantification and nucleic acid purity analysis provide a framework for generating reliable, reproducible data essential for drug development pipelines. By adhering to these standardized methodologies and being mindful of critical factors such as spectral bandwidth and stray light, professionals can ensure the integrity of their analytical results, thereby supporting the development of safe and effective pharmaceutical products.

Ultraviolet-Visible (UV-Vis) spectroscopy is an instrumental analytical technique that measures the absorption of light by a chemical substance in the ultraviolet (typically 100-400 nm) and visible (400-800 nm) regions of the electromagnetic spectrum [11] [12]. This measurement occurs when valence electrons in molecules are promoted from their ground state to higher energy excited states by absorbing specific wavelengths of light [12]. The technique is widely employed across scientific disciplines due to its relative simplicity, cost-effectiveness, non-destructive nature, and rapid analysis capabilities [2].

The quantitative application of UV-Vis spectroscopy fundamentally relies on the Beer-Lambert Law (also known as Beer's Law) [13] [14]. This law establishes the foundational relationship between the amount of light absorbed by a solution and the concentration of the absorbing species within it, thereby enabling researchers to precisely quantify analytes [15]. The combined Beer-Lambert Law provides the mathematical basis for modern spectrophotometric analysis, making it indispensable for drug development and analytical research.

Theoretical Foundation of the Beer-Lambert Law

The Beer-Lambert Law synthesizes two historical observations: Lambert's law, which states that absorbance is proportional to the path length of the light through the sample, and Beer's law, which states that absorbance is proportional to the concentration of the absorbing species [14] [15]. The unified law is expressed by the equation:

A = ε * c * l

Where:

- A is the Absorbance (also known as optical density), a dimensionless quantity defined as A = log₁₀(I₀/I) [14] [11]. Here, I₀ is the intensity of the incident light, and I is the intensity of the transmitted light.

- ε is the Molar Absorptivity (or molar extinction coefficient), with typical units of L·mol⁻¹·cm⁻¹ [15]. This is a characteristic constant for a given substance at a specific wavelength, measuring the probability of electronic transitions [14].

- c is the Molar Concentration of the absorbing solute in the solution, with units of mol·L⁻¹ [15].

- l is the Path Length, representing the distance (in cm) the light travels through the sample [15].

Mathematical Derivation and Key Relationships

The derivation of the Beer-Lambert Law begins with the observation that the decrease in light intensity (-dI) across an infinitesimally thin layer of solution (dx) is proportional to the incident intensity (I), the concentration of the absorber (c), and the thickness of the layer [14].

- This relationship is expressed as: -dI/dx = α * I * c, where α is a proportionality constant.

- Integrating this differential equation and applying the boundary condition that I = I₀ when x = 0 yields: ln(I₀/I) = α * c * x.

- Converting the natural logarithm to base-10 gives: log₁₀(I₀/I) = (α/2.303) * c * x.

- By defining Absorbance A = log₁₀(I₀/I) and substituting the molar absorptivity ε for (α/2.303), the final form is obtained: A = ε * c * l [14] [15].

This derivation confirms the linear relationship between absorbance and concentration, which is the cornerstone of quantitative analysis.

Quantitative Data and Units

The following table summarizes the core components and their standard units in the Beer-Lambert equation.

Table 1: Core Components of the Beer-Lambert Law and Their Standard Units

| Quantity | Symbol | Formula | Units |

|---|---|---|---|

| Absorbance | A | A = log₁₀(I₀/I) | None (dimensionless) |

| Molar Absorptivity | ε | In A = ε c l | L·mol⁻¹·cm⁻¹ |

| Concentration | c | In A = ε c l | mol·L⁻¹ |

| Path Length | l | In A = ε c l | cm |

Applications in Analytical Research

The Beer-Lambert Law is the driving principle behind countless quantitative analyses in research and industry. Its primary application is determining the concentration of an unknown sample by measuring its absorbance and applying the law, either directly or via a calibration curve [12].

DNA and RNA Quantification

In molecular biology and genetics, quantifying nucleic acids is a critical step. The concentration of pure double-stranded DNA (dsDNA) can be determined directly using its absorbance at 260 nm. An absorbance of 1.0 at 260 nm corresponds to approximately 50 µg/mL of dsDNA [16]. The calculation is:

Concentration (µg/mL) = A₂₆₀ reading × Dilution Factor × 50 µg/mL

Purity is assessed using absorbance ratios. For pure DNA, the A₂₆₀/A₂₈₀ ratio should be between 1.8 and 2.0. A lower ratio suggests protein contamination (as proteins absorb at 280 nm). The A₂₆₀/A₂₃₀ ratio, which should be greater than 1.5, indicates contamination by organic compounds or chaotropic salts [16].

Protein Quantification via A₂₈₀ Absorbance

Protein concentration can be estimated by measuring absorbance at 280 nm, which is primarily due to the aromatic amino acids tryptophan and tyrosine [17]. This method is quick and simple, as it requires no additional reagents. The measurable concentration range for Bovine Serum Albumin (BSA) using this direct absorbance method is approximately 125-1000 µg/mL [17]. While convenient, this method's accuracy can be affected by the specific aromatic amino acid composition of the protein.

Determination of Unknown Concentrations Using a Calibration Curve

For most accurate results, especially with complex matrices or when the exact molar absorptivity is unknown, a calibration curve is constructed [12]. This procedure involves:

- Preparing a series of standard solutions with known concentrations of the analyte.

- Measuring the absorbance of each standard at a specific wavelength (preferably at λ_max, the wavelength of maximum absorption).

- Plotting absorbance versus concentration to create a scatter plot.

- Fitting a straight line (using linear regression) to the data points.

The equation of this line (y = mx + b, where y is absorbance and x is concentration) is then used to calculate the concentration of an unknown sample from its measured absorbance [18]. This approach empirically accounts for the specific experimental conditions and is considered more reliable than relying on a literature value for ε.

Detailed Experimental Protocols

Protocol 1: Quantifying DNA Concentration and Purity by UV Absorbance

This protocol is used for the rapid quantification and purity assessment of purified DNA samples [16].

The Scientist's Toolkit: Research Reagent Solutions

- DNA Sample: The nucleic acid to be quantified.

- TE Buffer or Nuclease-Free Water: A blank solution to dilute the DNA and serve as the reference. It must be UV-transparent.

- Quartz Cuvette: For holding the sample during measurement. Quartz is required for UV light transmission.

- UV-Vis Spectrophotometer: The instrument capable of generating and measuring light in the UV range.

Procedure:

- Blank Measurement: Pipette an appropriate volume of the blank solution (e.g., TE buffer) into a quartz cuvette and place it in the spectrophotometer. Perform a blank measurement to calibrate the instrument to 100% transmittance / 0.000 absorbance.

- Sample Preparation: Dilute the DNA sample with the same blank solution. A typical dilution factor for concentrated DNA is 1:50 or 1:100.

- Absorbance Measurement: Measure the absorbance of the diluted DNA sample at 230 nm, 260 nm, and 280 nm.

- Data Analysis:

- Concentration Calculation: dsDNA Concentration (ng/µL) = A₂₆₀ × Dilution Factor × 50.

- Purity Assessment: Calculate the A₂₆₀/A₂₈₀ and A₂₆₀/A₂₃₀ ratios.

DNA Quantification Workflow

Protocol 2: Determining Protein Concentration by A₂₈₀ Absorbance

This protocol is suitable for a quick estimation of protein concentration, provided the sample is pure and the buffer does not contain strong UV-absorbing additives [17].

The Scientist's Toolkit: Research Reagent Solutions

- Protein Sample: The protein solution to be quantified.

- Reference Buffer: The exact buffer the protein is dissolved in, used for blanking.

- Quartz Cuvette: Essential for UV measurements at 280 nm.

- UV-Vis Spectrophotometer: The instrument for absorbance measurement.

Procedure:

- Blank Measurement: Pipette the reference buffer into a quartz cuvette and blank the spectrophotometer at 280 nm.

- Sample Measurement: Replace the blank with the protein sample and measure the absorbance at 280 nm. Ensure the absorbance reading is within the linear range of the instrument (preferably between 0.1 and 1.5 AU). If it is too high, dilute the sample and re-measure.

- Concentration Calculation: Use the protein-specific molar absorptivity (ε) or the general approximation for IgG antibodies (A₂₈₀ of 1.4 ≈ 1 mg/mL). Alternatively, construct a calibration curve using a standard like BSA for greater accuracy.

Table 2: Comparison of Absorbance-Based Protein Quantification Methods

| Method | Principle | Wavelength (nm) | Typical Range (µg/mL) | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Direct A₂₈₀ | Absorption by Trp/Tyr residues | 280 | 125 - 1000 [17] | Fast, no reagents, sample recoverable | Affected by buffer composition; less accurate |

| Bradford Assay | Coomassie dye binding shift | 595 (from 465) [17] | 62.5 - 1000 [17] | Sensitive, simple protocol | Non-linear response; dye interference |

| BCA Assay | Cu²⁺ reduction by peptides | 562 [17] | 15.6 - 1500 [17] | Tolerant to some detergents; sensitive | Time-consuming (30 min incubation) |

Critical Considerations and Limitations

Despite its widespread utility, the Beer-Lambert Law is subject to deviations under non-ideal conditions. Researchers must be aware of these limitations to ensure accurate data interpretation.

Fundamental Conditions for Valid Application

For the Beer-Lambert Law to hold true, several conditions must be met [14] [15]:

- Monochromicity of Light: The incident light should be monochromatic. The use of polychromatic light can lead to negative deviations from the law [11].

- Low Concentration: The absorbing species must be at a relatively low concentration. At high concentrations (>0.01 M), electrostatic interactions between molecules can alter the absorptivity [14] [15].

- Chemical Independence: The absorbers must act independently of one another. Chemical phenomena such as association, dissociation, or polymerization in response to concentration changes will cause deviations [15].

- Homogeneous Sample: The sample must be a homogeneous solution without turbidity. Scattering due to particles, bubbles, or colloids will falsely increase the measured absorbance [12].

- Stray Light: Stray light within the spectrophotometer, which is light of wavelengths outside the band selected by the monochromator, can cause significant errors, particularly at high absorbances, leading to a plateau in the calibration curve [11].

Real-World Deviations and Nonlinearity

In practice, deviations from the linear Beer-Lambert relationship are common. A 2022 study highlighted the widespread misuse of calibration curves, emphasizing that the classical method of regressing concentration on absorbance is statistically incorrect; the proper inverse regression (absorbance on concentration) should be used for predicting unknown concentrations [18]. Furthermore, a 2021 empirical investigation found that while high concentrations of lactate (up to 600 mmol/L) did not introduce significant nonlinearities, highly scattering media (like whole blood) did justify the use of more complex, nonlinear models [19]. This underscores the importance of matching the analytical method to the sample matrix.

Ultraviolet-visible (UV-Vis) spectroscopy is a fundamental analytical technique in research and drug development for the identification and quantification of active components. Its operation is grounded in the Beer-Lambert Law, which establishes that the absorbance of a solution is directly proportional to the concentration of the absorbing species (the analyte), its molar absorptivity, and the path length of light through the sample [12]. The accurate quantification of any analyte therefore hinges on the precise understanding and control of three essential parameters: the wavelength of measurement, the molar absorptivity of the analyte, and the path length of the sample container. This document provides detailed application notes and protocols to guide researchers in optimizing these parameters for robust and reliable quantitative analysis.

Core Principles and the Beer-Lambert Law

The foundational relationship for quantitative UV-Vis spectroscopy is the Beer-Lambert Law, expressed as:

A = εcl

Where:

- A is the measured Absorbance (dimensionless) [8]

- ε is the Molar Absorptivity (or molar extinction coefficient) with units of L·mol⁻¹·cm⁻¹ [20] [12]

- c is the Molar Concentration of the absorber (mol·L⁻¹)

- l is the Path Length of the light through the sample (cm) [12]

This linear relationship allows for the direct determination of an unknown concentration once the absorbance, path length, and molar absorptivity are known [12] [11]. The following sections delve into the critical considerations for each of these parameters.

Parameter 1: Wavelength Selection

The choice of wavelength is critical for achieving maximum sensitivity, selectivity, and adherence to the Beer-Lambert Law.

Optimal Wavelength Criteria

The primary criterion for quantitative analysis is to select the wavelength at which the analyte has the highest molar absorptivity, known as λmax (lambda max) [21] [22]. Measuring at λmax provides the greatest analytical sensitivity, as the largest absorbance signal is obtained for a given concentration, which improves the signal-to-noise ratio. Furthermore, the absorption spectrum is typically flattest near the peak, meaning that the molar absorptivity changes least with small, inevitable drifts in the instrument's wavelength calibration. This minimizes errors in concentration calculations [11].

Table 1: Characteristic Absorption Maxima for Common Chromophores

| Chromophore / Functional Group | Electronic Transition | Typical λ_max Range (nm) | Molar Absorptivity (ε) Range (L·mol⁻¹·cm⁻¹) |

|---|---|---|---|

| Carbonyl (C=O) | n → π* | 270 - 300 | 10 - 100 [20] |

| Aromatic Systems | π → π* | 250 - 280 | ~200 - 10,000 [20] |

| Conjugated Dienes | π → π* | 220 - 250 | ~10,000 - 25,000 [20] |

| Highly Conjugated Systems | π → π* | >300 | Can exceed 50,000 [20] |

Protocol for Wavelength Selection and Verification

Methodology:

- Preliminary Scan: Prepare a standard solution of the pure analyte within the concentration range expected for your samples. Using a spectrophotometer, perform a full wavelength scan (e.g., from 200 nm to 800 nm, or a relevant range for the analyte) against a solvent blank [22].

- Identify λmax: From the resulting absorption spectrum, identify the wavelength corresponding to the highest absorbance peak. This is the preliminary λmax [22].

- Check for Interferences: Prepare a blank matrix that mimics the sample but lacks the analyte. Scan this solution over the same wavelength range. If the blank shows significant absorption at the chosen λ_max, consider using an alternative, secondary absorption peak where interference is minimal, even if the molar absorptivity is lower [21].

- Final Method Validation: The selected wavelength must be validated as part of the overall analytical method to ensure specificity, accuracy, and precision.

Parameter 2: Molar Absorptivity

Molar absorptivity (ε) is an intrinsic property of a chemical species at a given wavelength and temperature, representing its ability to absorb light [20].

Factors Influencing Molar Absorptivity

The value of ε is primarily determined by the electronic structure of the molecule. Key influencing factors include:

- Chromophore Type: Different functional groups and their associated transitions (e.g., π→π* vs. n→π) have characteristic and vastly different absorptivities. For instance, π→π transitions are typically "allowed" and have high ε values (often >10,000), whereas n→π* transitions are "forbidden" and have low ε values (typically 10-100) [20] [22].

- Conjugation: Extending conjugation in a molecule (e.g., in polyenes or aromatic systems) delocalizes electrons, lowers the energy required for electronic transition, and results in a bathochromic (red) shift to longer wavelengths along with a hyperchromic effect (increase in ε) [20]. This is a key design principle for creating highly sensitive assays.

- Solvent and Environment: Solvent polarity can cause shifts in λ_max and changes in ε, particularly for transitions involving non-bonding electrons (n→π). Protic solvents can hydrogen-bond to n electrons, stabilizing the ground state and increasing the energy required for an n→π transition, leading to a hypsochromic (blue) shift and potential change in ε [20]. pH can also dramatically affect the absorption profile of ionizable chromophores [21].

Protocol for Determining Molar Absorptivity

Methodology:

- Prepare Standard Solutions: Accurately prepare a series of at least five standard solutions of the analyte with known concentrations, spanning the expected working range. The concentrations should be chosen such that the measured absorbance values fall within the linear range of the instrument, ideally between 0.1 and 1.0 AU [22].

- Measure Absorbance: Measure the absorbance of each standard solution at the predetermined λ_max, using the appropriate solvent as a blank. Ensure a fixed, known path length (e.g., 1 cm) [22].

- Construct Calibration Curve: Plot the measured absorbance (y-axis) against the corresponding concentration (x-axis).

- Calculate Molar Absorptivity: Perform linear regression on the data. The slope of the resulting calibration curve is equal to the product of the molar absorptivity and the path length (slope = εl). Since the path length (l) is known (e.g., 1 cm), the molar absorptivity (ε) can be calculated directly from the slope [12] [22].

Parameter 3: Path Length

The path length (l) is the distance the light travels through the sample solution. According to the Beer-Lambert Law, absorbance is directly proportional to path length for a given concentration [12].

Path Length Considerations and Linearity

Standard cuvettes have a path length of 1.0 cm. However, a variety of path lengths are available and can be selected based on the sample concentration:

- High Concentration Samples: For highly absorbing samples, a shorter path length (e.g., 0.1 cm or 1 mm) can be used to bring the absorbance reading back into the optimal range of 0.1-1.0 AU, thereby avoiding deviations from the Beer-Lambert Law [8].

- Low Concentration Samples: For very dilute solutions, a longer path length (e.g., 2 cm, 5 cm, or 10 cm) can be used to increase the absorbance signal and improve detection limits.

- Linearity Verification: A key test for the validity of the Beer-Lambert Law for a given system is to demonstrate that absorbance is linearly proportional to path length. This can be tested by measuring the same sample in cuvettes of different path lengths; a plot of absorbance vs. path length should yield a straight line [11].

Integrated Workflow for Method Development

The following diagram and protocol outline a systematic approach for developing a quantitative UV-Vis method, integrating the three essential parameters.

Diagram 1: UV-Vis Quantification Method Workflow

Comprehensive Experimental Protocol for Active Component Quantification

Objective: To quantify the concentration of an active pharmaceutical ingredient (API) in a solution.

Materials:

- The Scientist's Toolkit: Key Research Reagent Solutions

- High-Purity Reference Standard: The authentic, high-purity analyte for preparing calibration standards [11].

- Appropriate Solvent: A solvent that dissolves the analyte and does not absorb significantly in the spectral region of interest (e.g., water, methanol, acetonitrile) [8] [22].

- Volumetric Flasks: For accurate preparation and dilution of standard and sample solutions.

- Matched Cuvettes: A pair of spectrometric cuvettes with a known, fixed path length (e.g., 1 cm). For UV work, quartz cuvettes are required; glass or plastic may be used for visible light only [8].

- Micropipettes: For accurate and precise liquid handling.

- UV-Vis Spectrophotometer: A calibrated instrument with a scanning capability.

Procedure:

- Solution Preparation:

- Stock Standard Solution: Accurately weigh the reference standard and dissolve it in the chosen solvent to prepare a stock solution of known concentration.

- Calibration Standards: Serially dilute the stock solution with solvent to prepare at least five standard solutions covering a concentration range that will produce absorbances between 0.1 and 1.0 AU.

- Sample Solution: Prepare the unknown sample by dissolving or diluting it in the same solvent to bring its expected concentration within the range of the calibration standards.

Spectrophotometric Analysis:

- Turn on the UV-Vis spectrophotometer and allow it to warm up as per the manufacturer's instructions.

- Set the instrument to measure absorbance.

- Fill a cuvette with the pure solvent (the "blank"), place it in the sample holder, and perform a blank correction.

- For wavelength selection (Diagram 1, Box P1), replace the blank with an intermediate standard solution and perform a full wavelength scan to identify and confirm the λ_max for the analyte.

- For quantification (Diagram 1, Boxes P2 & P3), set the instrument to the fixed λ_max. Measure the absorbance of each calibration standard and the unknown sample solution against the solvent blank. Ensure all measurements are performed using the same cuvette or matched cuvettes with the same path length.

Data Analysis and Calculation:

- Plot a calibration curve with absorbance on the y-axis and standard concentration on the x-axis.

- Perform a linear regression analysis to obtain the equation of the line (y = mx + b, where y is absorbance and x is concentration) and the correlation coefficient (R²).

- The slope (m) of the line is equal to εl. If the path length (l) is 1 cm, the slope is the molar absorptivity (ε).

- Substitute the absorbance of the unknown sample (y) into the linear equation and solve for the concentration (x).

Troubleshooting and Best Practices

- Deviations from Beer-Lambert Law: Non-linearity can occur at high concentrations (>0.01 M) due to electrostatic interactions or changes in refractive index [20]. It can also be caused by instrumental factors such as stray light, which becomes significant at high absorbances (typically >1.0 AU) and leads to a false lower absorbance reading [11].

- Stray Light Mitigation: Use a spectrophotometer with a low stray light specification and ensure concentrations/path lengths are chosen to keep absorbance readings below 1.0-1.5 AU for quantitative work [11].

- Sample Preparation Errors: Ensure samples are fully dissolved and free of bubbles or particulate matter that can scatter light and cause erroneously high absorbance readings [12] [22]. Always use clean, scratch-free cuvettes.

By systematically applying these principles and protocols, researchers can develop validated, robust, and reliable UV-Vis spectroscopic methods for the accurate quantification of active components in pharmaceutical research and development.

Ultraviolet-visible (UV-Vis) spectroscopy is a cornerstone analytical technique in pharmaceutical laboratories due to its inherent advantages in speed, cost-effectiveness, and accuracy. This application note details how these benefits are realized in the quantification of active pharmaceutical ingredients (APIs), supported by structured experimental protocols. Framed within broader research on API quantification, this document provides scientists and drug development professionals with validated methodologies that align with regulatory standards, including United States (USP), European (EP), and Japanese (JP) pharmacopeias [23].

UV-Vis spectroscopy measures the absorption of discrete wavelengths of ultraviolet or visible light by a sample. The fundamental principle is governed by the Beer-Lambert Law (A = εlc), which states that absorbance (A) is proportional to the concentration (c) of the analyte, its molar absorptivity (ε), and the path length (l) of light through the sample [8] [24]. This direct relationship provides the foundation for its quantitative use in pharmaceutical analysis. The technique is versatile, supporting applications from drug discovery and development to quality control (QC) and impurity profiling [23]. Its compliance with international pharmacopeias makes it an indispensable tool for regulated laboratories.

Core Advantages in Pharmaceutical Analysis

The deployment of UV-Vis spectroscopy in the pharmaceutical industry is driven by three principal advantages, summarized in the table below.

Table 1: Key Advantages of UV-Vis Spectroscopy in Pharmaceutical Analysis

| Advantage | Description | Impact in Pharmaceutical Context |

|---|---|---|

| Speed | Delivers results in minutes or even seconds; requires minimal sample preparation [24]. | Accelerates high-throughput screening in drug discovery and enables rapid quality control (QC) release of finished products [23]. |

| Cost-Effectiveness | Lower initial instrument cost and maintenance compared to techniques like HPLC or MS; minimal consumable use (e.g., quartz cuvettes) [24]. | Reduces overall analytical costs for both research and development (R&D) and QC laboratories, making it accessible for various levels of operation. |

| Accuracy & Precision | Provides highly accurate and precise quantitative results when properly calibrated and validated; compliant with pharmacopeial standards for identity, assay, and purity [23]. | Ensures reliability of data for regulatory submissions and guarantees that APIs and finished products meet stringent quality specifications. |

These advantages are synergistic. The speed and low cost allow for frequent testing and monitoring, while the inherent accuracy ensures the data generated is reliable for critical decision-making throughout the drug development lifecycle.

Essential Research Toolkit

Successful implementation of UV-Vis protocols requires specific instrumentation and reagents. The following table lists the essential components for a pharmaceutical analysis laboratory.

Table 2: Key Research Reagent Solutions and Essential Materials

| Item | Function/Description |

|---|---|

| UV-Vis Spectrophotometer | An instrument with a deuterium (UV) and tungsten/halogen (Vis) lamp source, capable of scanning from ~190 nm to 800 nm. Models with regulated software (e.g., for 21 CFR Part 11 compliance) are essential for QC [23]. |

| Quartz Cuvettes | Sample holders transparent to UV light. Glass or plastic cuvettes are unsuitable for UV range measurements as they absorb UV light [8]. |

| Reference Solvent | A high-purity solvent (e.g., the same buffer used to dissolve the sample) to zero the instrument and establish a baseline absorbance [8]. |

| Pharmaceutical Standards | Certified Reference Materials (CRMs) of the target Active Pharmaceutical Ingredient (API) with known purity and concentration for calibration [23]. |

| Volumetric Glassware | Precise flasks and pipettes for accurate sample and standard solution preparation. |

Application Notes & Experimental Protocols

Protocol 1: Quantitative Analysis of an Active Pharmaceutical Ingredient (API)

This protocol outlines the steps for quantifying the concentration of an API, such as ibuprofen, in a solution using a direct absorbance measurement [23].

Workflow Overview:

Materials:

- API reference standard

- Appropriate solvent (e.g., phosphate buffer, methanol)

- Volumetric flasks (e.g., 10 mL, 25 mL, 100 mL)

- Pipettes

- UV-Vis spectrophotometer with quartz cuvettes

Procedure:

- Solution Preparation:

- Prepare a stock solution of the API reference standard at a known concentration (e.g., 100 µg/mL).

- Using serial dilution, prepare a series of at least five standard solutions covering a concentration range where absorbance is linear (e.g., 5, 10, 20, 30, 40 µg/mL). Ensure absorbance values remain below 1.0 for reliability [8].

- Instrument Setup:

- Turn on the UV-Vis spectrophotometer and allow the lamps to warm up for the time specified by the manufacturer (typically 15-30 minutes).

- Set the instrument to the wavelength of maximum absorption (λmax) for the API, which can be determined from a preliminary scan or literature (e.g., 221 nm for ibuprofen in alkaline medium as per USP) [23].

- Blank Measurement:

- Fill a quartz cuvette with the pure solvent used to prepare the standards and place it in the sample holder.

- Use this measurement to zero the instrument (set absorbance to 0.0).

- Calibration Curve:

- Measure the absorbance of each standard solution in sequence.

- Record the absorbance values and plot a graph of absorbance (y-axis) versus concentration (x-axis). The software typically generates a linear regression equation (y = mx + c).

- Sample Analysis:

- Prepare a sample solution of the unknown API concentration within the linear range of the calibration curve.

- Measure its absorbance at the same λmax.

- Use the regression equation from the calibration curve to calculate the concentration of the unknown sample.

Protocol 2: Dissolution Testing of Solid Oral Dosage Forms

Dissolution testing is critical for evaluating the release of a drug from its dosage form. UV-Vis is the standard method for analyzing the dissolved concentration in the medium [23].

Workflow Overview:

Materials:

- Dissolution test apparatus (paddles or baskets)

- Dissolution medium (e.g., buffer at pH 1.2, 4.5, or 6.8)

- Syringe filters (e.g., 0.45 µm)

- UV-Vis spectrophotometer

Procedure:

- Apparatus Setup:

- Fill the dissolution vessel with a specified volume of pre-warmed (e.g., 37°C ± 0.5°C) dissolution medium.

- Place the tablet or capsule into the apparatus and start the rotation at the specified speed (e.g., 50 rpm for paddles).

- Sampling:

- At predetermined time intervals (e.g., 10, 15, 20, 30, 45, and 60 minutes), withdraw a small aliquot (e.g., 5-10 mL) from the vessel.

- Immediately replace the withdrawn volume with fresh, pre-warmed medium to maintain a constant volume.

- Sample Preparation:

- Filter the withdrawn aliquot through a syringe filter to remove any undissolved particles.

- Analysis:

- Measure the absorbance of the filtered solution at the API's λmax.

- Calculate the concentration of dissolved drug at each time point using a pre-established calibration curve (as developed in Protocol 1).

- Report the percentage of drug released versus time to generate a dissolution profile.

Advanced Techniques: Extending Analytical Capabilities

For complex matrices, advanced UV-Vis techniques enhance the method's power and accuracy.

- Multivariate Analysis: Techniques like Principal Component Analysis (PCA) and Partial Least Squares (PLS) regression are used to extract quantitative information from spectra of complex mixtures, resolving issues like overlapping peaks from multiple analytes or excipients [24].

- Hyphenated Techniques: Coupling UV-Vis detection with High-Performance Liquid Chromatography (HPLC) creates the powerful HPLC-UV-Vis platform. Here, HPLC separates the components of a complex mixture, and the UV-Vis detector provides quantitative analysis of each separated peak, which is crucial for impurity profiling and stability-indicating methods [24].

Method Validation and Quality Assurance

To ensure data accuracy and regulatory compliance, UV-Vis methods must be validated. Key performance characteristics include:

- Linearity: Demonstrated by a high correlation coefficient (R² > 0.999) of the calibration curve.

- Accuracy: Typically confirmed through recovery studies (e.g., 98-102%).

- Precision: Evaluated as repeatability (multiple measurements of the same sample) and intermediate precision (different days, different analysts).

- Specificity: The ability to unequivocally assess the analyte in the presence of other components like impurities or excipients. This can be confirmed by comparing spectra of pure and sample solutions [23].

Regular instrument performance verification using certified reference materials (e.g., holmium oxide filters for wavelength accuracy, neutral density filters for photometric accuracy) is mandatory in pharmacopeia-compliant laboratories [23].

UV-Vis spectroscopy remains a vital analytical technique in pharmaceutical analysis due to its compelling combination of speed, cost-effectiveness, and accuracy. From straightforward API quantification to complex dissolution testing, its principles, governed by the Beer-Lambert law, provide a robust foundation for generating reliable data. When coupled with proper method validation and quality control practices, UV-Vis spectroscopy meets the stringent requirements of modern drug development and quality assurance, making it an indispensable tool in the scientist's toolkit.

Pharmaceutical Applications: From API Quantification to Dissolution Testing

Active Pharmaceutical Ingredient (API) Quantification and Purity Assessment

Ultraviolet-Visible (UV-Vis) spectroscopy serves as a cornerstone analytical technique in pharmaceutical development and quality control, enabling precise quantification of Active Pharmaceutical Ingredients (APIs) and critical assessment of their purity [25]. The technique operates on the principle of the Beer-Lambert law, which relates the absorption of light to the properties of the material through which the light is traveling [26] [24]. Its simplicity, speed, sensitivity, and cost-effectiveness make it indispensable for ensuring drug identity, potency, and stability across research, development, and manufacturing workflows [24] [27]. This application note details established protocols and methodologies for leveraging UV-Vis spectroscopy in API analysis, framed within a rigorous Analytical Quality by Design (AQbD) and method validation framework [28].

Core Principles and Method Selection

UV-Vis spectroscopy measures the absorption of light in the ultraviolet (190–380 nm) and visible (380–800 nm) regions of the electromagnetic spectrum, resulting from electronic transitions in molecules [25] [27]. The fundamental relationship between absorbance and analyte concentration is described by the Beer-Lambert Law: [A = \epsilon l c] where (A) is the measured absorbance, (\epsilon) is the molar absorptivity (a molecule-specific constant), (l) is the path length of the cuvette (cm), and (c) is the analyte concentration (mol/L) [24].

The choice of methodology depends on the analytical goal and the complexity of the sample. The table below summarizes the primary techniques used for API analysis.

Table 1: Overview of UV-Vis Techniques for API Analysis

| Technique | Principle | Best Suited For | Key Advantages |

|---|---|---|---|

| Direct Quantification | Measurement of absorbance at the λₘₐₓ of a single, isolated API. | Standardized assay of pure API solutions; content uniformity [25]. | Simplicity and speed. |

| Baseline Manipulation (Difference) Spectroscopy | Using a solution of one analyte as a blank to eliminate its spectral contribution, allowing direct measurement of a second analyte [26]. | Binary mixtures in combined dosage forms without prior separation. | Eliminates need for complex separation steps; cost-effective [26]. |

| Multivariate Analysis & Spectral Deconvolution | Application of statistical models (e.g., PLS, PCA) to extract concentration information from complex, overlapping spectra [28] [24]. | Complex formulations with severe spectral overlap; in-line Process Analytical Technology (PAT) [28]. | Handles complex data; enables real-time, in-line monitoring. |

| Hyphenated Techniques (e.g., HPLC-UV-Vis) | Coupling separation power of HPLC with the detection capability of UV-Vis [24]. | Purity assessment and impurity profiling in complex mixtures. | High specificity and sensitivity; can separate and quantify multiple components. |

Experimental Protocols

Protocol 1: Direct API Quantification in a Standard Solution

This fundamental protocol is used to determine the concentration of an API in a simple solution and forms the basis for many pharmacopeial methods [25].

The Scientist's Toolkit:

- UV-Vis Spectrophotometer: A double-beam instrument is preferred for stability. Must be equipped with matched quartz cuvettes (typically 1 cm path length) [26].

- High-Purity Solvent: Spectroscopic grade methanol, water, or buffer as appropriate. Must be transparent in the spectral region of interest [25].

- Analytical Balance: For precise weighing of the API standard (e.g., Shimadzu AUW-220D) [26].

- Volumetric Flasks: Class A glassware for accurate preparation of standard and sample solutions.

Step-by-Step Methodology:

- Standard Stock Solution: Accurately weigh about 100 mg of API reference standard and transfer to a 100 mL volumetric flask. Dissolve and dilute to volume with the chosen solvent to obtain a stock solution of approximately 1000 µg/mL [26].

- Working Standard Solutions: Prepare a series of working standards (e.g., 5-25 µg/mL) by precise serial dilution of the stock solution.

- Spectral Scan: Scan one of the mid-range working standards from 200 nm to 400 nm to identify the wavelength of maximum absorption (λₘₐₓ).

- Blank Preparation: Prepare a blank consisting of the pure solvent.

- Calibration Curve: Measure the absorbance of each working standard solution at the predetermined λₘₐₓ against the solvent blank. Construct a calibration curve by plotting absorbance versus concentration.

- Sample Analysis: Prepare the sample solution (e.g., from a dissolved tablet) to fall within the calibration range and measure its absorbance. Calculate the API concentration using the regression equation from the calibration curve.

Protocol 2: Purity Assessment and Contaminant Screening

UV-Vis spectroscopy can provide a rapid initial assessment of sample purity by examining the spectral profile beyond a single wavelength [29] [30].

Step-by-Step Methodology:

- Sample Preparation: Prepare a solution of the test sample at an appropriate concentration.

- Broad-Range Scanning: Record the full UV-Vis spectrum of the sample from 240 nm to 350 nm (or higher if colored) using the solvent as a blank [29].

- Spectral Analysis:

- Check for Nucleic Acid Contamination: A distinct "bump" or elevated absorbance at ~260 nm indicates potential nucleic acid contamination. The 260/280 nm absorbance ratio should be approximately 0.57 for a pure protein; significant deviation suggests contamination [29].

- Check for Scattering/Insolubles: A rising baseline towards lower wavelengths (particularly in the visible region) can indicate light scattering from insoluble particles or API oversaturation in a polymer matrix, as seen in Hot Melt Extrusion [28] [27].

- Examine Peak Shape and Fine Structure: The unique microenvironment of aromatic residues in a protein confers a unique UV spectrum. Deviations from the expected spectral fine structure can indicate conformational changes or the presence of impurities [30].

Diagram: Workflow for API Analysis and Purity Assessment

Method Validation as per ICH Guidelines

For any analytical method to be used in a regulatory environment, it must be validated according to international guidelines, such as ICH Q2(R1) [26] [25]. The following table outlines key validation parameters and typical acceptance criteria for a UV-Vis method.

Table 2: Method Validation Parameters and Acceptance Criteria

| Validation Parameter | Protocol Description | Typical Acceptance Criteria |

|---|---|---|

| Linearity & Range | Analyze a minimum of 5 concentrations in triplicate across the intended range [26]. | Correlation coefficient (r) > 0.999. Fischer variance ratio test for linearity [26]. |

| Accuracy | Perform recovery studies by spiking a placebo or pre-analyzed sample with known amounts of API at 50%, 100%, and 150% levels [26]. | Mean recovery between 98.0–102.0%. |

| Precision | Repeatability: Six replicate analyses of a single homogenous sample [26]. Intermediate Precision: Analysis by a second analyst on a different day [26]. | RSD ≤ 1.0% for repeatability. RSD ≤ 2.0% for intermediate precision. |

| Specificity | Demonstrate that the method can unequivocally assess the analyte in the presence of potential interferents like excipients, degradation products, or impurities [26] [25]. | No interference from blank or placebo at the analyte's λₘₐₓ. |

| Robustness | Deliberately introduce small, purposeful variations in method parameters (e.g., wavelength ±2 nm, sonication time ±5 min) [26]. | The method remains unaffected by small variations (RSD remains within specified limits). |

| LOD & LOQ | Calculate based on the standard deviation of the response (σ) and the slope of the calibration curve (b): LOD = 3.3σ/b; LOQ = 10σ/b [26]. | Signal-to-noise ratio of 3:1 for LOD and 10:1 for LOQ. |

Advanced Applications in Pharmaceutical Development

In-line Monitoring Using Process Analytical Technology (PAT)

UV-Vis spectroscopy is a powerful PAT tool for real-time monitoring of Critical Quality Attributes (CQAs) during continuous manufacturing processes like Hot Melt Extrusion (HME) [28] [27]. AQbD principles are applied to develop robust in-line methods, where an Analytical Target Profile (ATP) is established upfront. For example, in-line UV-Vis has been successfully used to monitor the API content and color (as lightness, L*) of piroxicam in a polymer melt during HME, enabling real-time release testing (RTRT) [28]. The method's validation, based on accuracy profile strategy, showed that 95% β-expectation tolerance limits were within the ±5% acceptance limits, proving its suitability for in-process control [28].

Drug Stability Testing

UV-Vis spectrophotometry is extensively used in forced, accelerated, and real-time stability studies to predict the commercial viability of drug products [31]. By subjecting drugs to stressors like light, temperature, and pH changes, scientists can track decreases in API potency (via reduced absorbance at λₘₐₓ) and the formation of degradation products (via new absorbance peaks or shifts in the spectrum) [31]. This provides critical data for establishing shelf-life and appropriate storage conditions.

Diagram: AQbD-based Method Development Workflow

UV-Vis spectroscopy remains a versatile, robust, and indispensable technique for the quantification and purity assessment of APIs. From simple direct assays to advanced in-line PAT applications, its utility spans the entire drug development and manufacturing lifecycle. By adhering to systematic method development principles and rigorous validation protocols as outlined in this application note, researchers and quality control professionals can ensure the generation of reliable, high-quality data. This, in turn, guarantees the identity, strength, quality, purity, and stability of pharmaceutical products, ultimately ensuring patient safety and regulatory compliance.

Drug Stability Testing and Shelf-Life Determination Under Stress Conditions