UV-Vis vs. UFLC-DAD: A Strategic Guide for Analytical Method Selection in Pharmaceutical Analysis

This article provides a comprehensive framework for researchers, scientists, and drug development professionals to strategically select between UV-Vis spectrophotometry and UFLC-DAD (Ultra-Fast Liquid Chromatography with Diode Array Detection) for their...

UV-Vis vs. UFLC-DAD: A Strategic Guide for Analytical Method Selection in Pharmaceutical Analysis

Abstract

This article provides a comprehensive framework for researchers, scientists, and drug development professionals to strategically select between UV-Vis spectrophotometry and UFLC-DAD (Ultra-Fast Liquid Chromatography with Diode Array Detection) for their analytical needs. It covers the foundational principles of both techniques, explores their specific methodological applications in pharmaceutical analysis, offers troubleshooting and optimization strategies, and details validation protocols. By synthesizing key performance indicators and practical considerations, this guide empowers professionals to make informed decisions that enhance accuracy, efficiency, and regulatory compliance in method development and quality control.

Core Principles: Demystifying How UV-Vis Spectrophotometry and UFLC-DAD Work

Ultraviolet-Visible (UV-Vis) spectroscopy is an analytical technique that measures the amount of discrete wavelengths of UV or visible light that are absorbed by or transmitted through a sample in comparison to a reference or blank sample [1]. This property is influenced by the sample composition, providing information on what is in the sample and at what concentration [1]. The technique covers light wavelengths in the ultraviolet (190-400 nm) and visible (400-800 nm) regions of the electromagnetic spectrum [2]. When light at these wavelengths interacts with molecules, electrons in the molecules become excited and move to higher energy states, resulting in characteristic absorption patterns that serve as fingerprints for identifying substances and determining their concentrations [2].

The fundamental principle underlying UV-Vis spectroscopy is the Beer-Lambert Law, which relates the attenuation of light to the properties of the material through which light is traveling [3]. This law enables the transition of UV-Vis spectroscopy from a qualitative identification technique to a powerful quantitative analytical method applicable across chemistry, pharmacy, environmental science, and food and beverage quality control [2]. This technical guide explores the core principles of UV-Vis spectroscopy and provides a comparative framework for researchers deciding between UV-Vis and Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) for analytical applications.

Fundamental Principles of Light-Matter Interaction

Electronic Transitions

The core mechanism of UV-Vis spectroscopy involves electronic transitions within molecules. When photons of UV or visible light encounter a molecule, they can be absorbed if their energy precisely matches the energy difference between a ground state and an excited state orbital of electrons in that molecule [2]. Molecules that absorb light in the UV-Vis range are called chromophores and typically contain π-electrons, unsaturated bonds, or atoms with non-bonding orbitals [2].

The specific amount of energy required for electronic transitions depends on the molecular structure and bonding environment [1]. Different molecules therefore absorb different wavelengths, creating unique absorption spectra that can be used for identification [2]. The energy of light is inversely proportional to its wavelength, meaning shorter wavelengths carry more energy and are more effective at promoting electrons to higher energy states [1].

Transmittance and Absorbance

When light passes through a sample, its intensity decreases due to absorption. This attenuation is quantified through two fundamental parameters:

Transmittance (T) is defined as the ratio of the transmitted intensity (I) over the incident intensity (Iâ‚€) [4]:

- ( T = \frac{I}{I_0} )

- Commonly expressed as percentage transmittance: ( \%T = \frac{I}{I_0} \times 100 )

Absorbance (A) has a logarithmic relationship to transmittance [4]:

- ( A = \log{10} \left( \frac{I0}{I} \right) = -\log_{10} T )

The relationship between absorbance and transmittance means that an absorbance of 0 corresponds to 100% transmittance (no absorption), while an absorbance of 1 corresponds to 10% transmittance (90% absorption) [4]. This logarithmic scale makes absorbance more practical for quantitative measurements across a wide range of concentrations.

Table 1: Relationship Between Absorbance and Transmittance

| Absorbance | Transmittance | Light Absorbed | Light Transmitted |

|---|---|---|---|

| 0 | 100% | 0% | 100% |

| 0.3 | 50% | 50% | 50% |

| 1 | 10% | 90% | 10% |

| 2 | 1% | 99% | 1% |

| 3 | 0.1% | 99.9% | 0.1% |

The Beer-Lambert Law

Mathematical Formulation

The Beer-Lambert Law (also known as Beer's Law) establishes a quantitative relationship between absorbance and the properties of an absorbing solution [3]. The law states that absorbance is directly proportional to both the concentration of the absorbing species and the path length of light through the solution [3]. This relationship is mathematically expressed as:

A = εlc

Where:

- A is the absorbance (unitless)

- ε is the molar absorptivity or molar extinction coefficient (L·molâ»Â¹Â·cmâ»Â¹)

- l is the path length of light through the solution (cm)

- c is the concentration of the absorbing species (mol·Lâ»Â¹)

The molar absorptivity (ε) is a measure of how strongly a chemical species absorbs light at a particular wavelength [3]. A larger molar absorptivity indicates a greater probability of the electronic transition occurring, making the substance a more effective light absorber at that wavelength [3].

Historical Context and Theoretical Foundation

The Beer-Lambert Law represents a combination of two historical discoveries. Lambert's Law, formulated by Johann Heinrich Lambert, states that absorbance and path length are directly proportional [5]. Beer's Law, developed by August Beer, establishes that concentration and absorbance are directly proportional [5]. The modern formulation merges these two relationships into a single comprehensive law [6].

The theoretical foundation begins with the observation that the rate of decrease in light intensity with material thickness is proportional to the incident light intensity [5]. This leads to a differential equation that, when solved, yields the logarithmic relationship formalized in the Beer-Lambert Law [6] [5]. Although the law is widely applied, it's important to recognize that it represents an approximation that neglects certain electromagnetic effects and light scattering phenomena [6].

Practical Applications and Examples

The primary utility of the Beer-Lambert Law in analytical chemistry is the determination of unknown concentrations. By measuring the absorbance of a solution at a specific wavelength and knowing the molar absorptivity and path length, the concentration can be calculated as:

c = A / (εl)

For example, if a sample has an absorbance of 1 at a specific wavelength, this means that 90% of the light at that wavelength has been absorbed, and only 10% is transmitted [3]. This quantitative relationship enables researchers to create calibration curves using standard solutions of known concentrations, then use these curves to determine concentrations of unknown samples [4].

Table 2: Beer-Lambert Law Components and Their Significance

| Component | Symbol | Units | Physical Significance |

|---|---|---|---|

| Absorbance | A | Unitless | Measure of light absorbed by sample |

| Molar Absorptivity | ε | L·molâ»Â¹Â·cmâ»Â¹ | Measure of how strongly a species absorbs light at specific wavelength |

| Path Length | l | cm | Distance light travels through sample |

| Concentration | c | mol·Lâ»Â¹ | Amount of absorbing species in solution |

Instrumentation and Measurement

Components of a UV-Vis Spectrophotometer

A UV-Vis spectrophotometer consists of four essential components that work together to measure light absorption [1] [2]:

Light Source: Provides broad-spectrum UV and visible light. Common configurations include:

- Single xenon lamp for both UV and visible ranges

- Two-lamp system: deuterium lamp for UV (190-400 nm) and tungsten or halogen lamp for visible light (400-800 nm) [1]

Wavelength Selector: Monochromators containing diffraction gratings are most common, separating light into narrow wavelength bands [1]. Typical systems have 1200-2000 grooves per mm, providing a balance between resolution and usable wavelength range [1].

Sample Container: Holds the sample in a cuvette with standard path length of 1 cm. Quartz cuvettes are essential for UV measurements as glass and plastic absorb UV light [1].

Detector: Converts transmitted light intensity into an electrical signal. Photomultiplier tubes (PMTs) are common for their sensitivity to low light levels, while photodiodes and charge-coupled devices (CCDs) are also used [1].

Measurement Process

The measurement process involves comparing light intensity through a sample to that through a reference solution (blank) [3] [1]. In double-beam instruments, the light beam is split, passing simultaneously through sample and reference cuvettes for immediate comparison [2]. The instrument electronics then calculate absorbance using the relationship ( A = \log{10} \left( \frac{I0}{I} \right) ), where Iâ‚€ is the reference intensity and I is the sample intensity [3].

Diagram 1: UV-Vis spectrophotometer workflow in double-beam configuration

Experimental Protocols and Method Validation

Standard Quantitative Analysis Protocol

Materials and Reagents:

- UV-Vis spectrophotometer with deuterium and tungsten lamps

- Quartz cuvettes (1 cm path length)

- Analytical balance (±0.0001 g accuracy)

- Volumetric flasks (appropriate volumes)

- High-purity solvents

- Standard reference material of analyte

Procedure:

- Preparation of Standard Solutions: Create a series of standard solutions with known concentrations covering the expected sample concentration range.

Blank Measurement: Fill a cuvette with solvent alone and measure baseline absorbance across desired wavelength range.

Spectrum Acquisition: Scan each standard solution to identify wavelength of maximum absorption (λ_max).

Calibration Curve: Measure absorbance of standard solutions at λ_max and plot absorbance versus concentration.

Sample Measurement: Measure absorbance of unknown samples at the same λ_max.

Quantification: Calculate sample concentration using the linear regression equation from the calibration curve.

Validation Parameters:

- Linearity: Coefficient of determination (R²) should exceed 0.995

- Precision: Relative standard deviation (RSD) of replicate measurements <2%

- Accuracy: Recovery of spiked standards should be 95-105%

- Limit of Detection (LOD): Typically 3×signal-to-noise ratio

- Limit of Quantification (LOQ): Typically 10×signal-to-noise ratio

Research Reagent Solutions

Table 3: Essential Research Reagents and Materials for UV-Vis Spectroscopy

| Reagent/Material | Specification | Function | Application Notes |

|---|---|---|---|

| Quartz Cuvettes | 1 cm path length, UV-transparent | Sample container | Essential for UV measurements (<350 nm) |

| Deuterium Lamp | 190-400 nm spectral range | UV light source | Typical lifetime 1000 hours |

| Tungsten/Halogen Lamp | 350-800 nm spectral range | Visible light source | More stable than xenon lamps |

| Methanol/Acetonitrile | HPLC grade | Solvent | Low UV cutoff, minimal interference |

| Buffer Salts | Analytical grade | pH control | Phosphate buffer common for biomolecules |

| Standard Reference Materials | Certified purity | Calibration | NIST-traceable standards recommended |

Comparative Analysis: UV-Vis Spectroscopy vs. UFLC-DAD

Technical Comparison

The choice between UV-Vis spectroscopy and UFLC-DAD depends on analytical requirements, sample complexity, and available resources [7]. Both techniques utilize the Beer-Lambert Law and light absorption principles but differ significantly in implementation and application.

Table 4: Technical Comparison Between UV-Vis Spectroscopy and UFLC-DAD

| Parameter | UV-Vis Spectroscopy | UFLC-DAD |

|---|---|---|

| Principle | Absorption of light by chromophores | Separation followed by absorption detection |

| Analysis Time | Minutes | 10-30 minutes |

| Sample Volume | 0.5-3 mL (cuvette); µL-range for microvolume systems | 1-100 µL injection |

| Concentration Range | Limited by Beer-Lambert linearity (typically A<2) | Wider dynamic range through dilution |

| Sample Complexity | Limited resolution for mixtures | High resolution for complex mixtures |

| Specificity | Lower, unless unique chromophores present | High, due to retention time + spectrum |

| Equipment Cost | $3,000-$60,000 [2] | Significantly higher |

| Operational Cost | Low (minimal solvents) | Higher (solvent consumption, column replacement) |

| Method Development | Simple and rapid | Complex and time-consuming |

Pharmaceutical Application Case Study

A recent comparative study of metoprolol tartrate (MET) quantification in pharmaceuticals demonstrated the practical implications of technique selection [7]. The UV-Vis method recorded absorbance at λ_max = 223 nm, while UFLC-DAD employed chromatographic separation before detection [7].

Key Findings:

- Both methods were validated for specificity, sensitivity, linearity, accuracy, precision, and robustness

- UFLC-DAD offered advantages in speed and simplicity for complex formulations

- UV-Vis provided simplicity, precision, and lower cost but had limitations regarding sample volume and higher concentration detection

- Statistical analysis (ANOVA) showed no significant difference in determined MET concentrations between techniques at 95% confidence level

- Greenness assessment using Analytical GREEnness (AGREE) metric favored UV-Vis spectroscopy

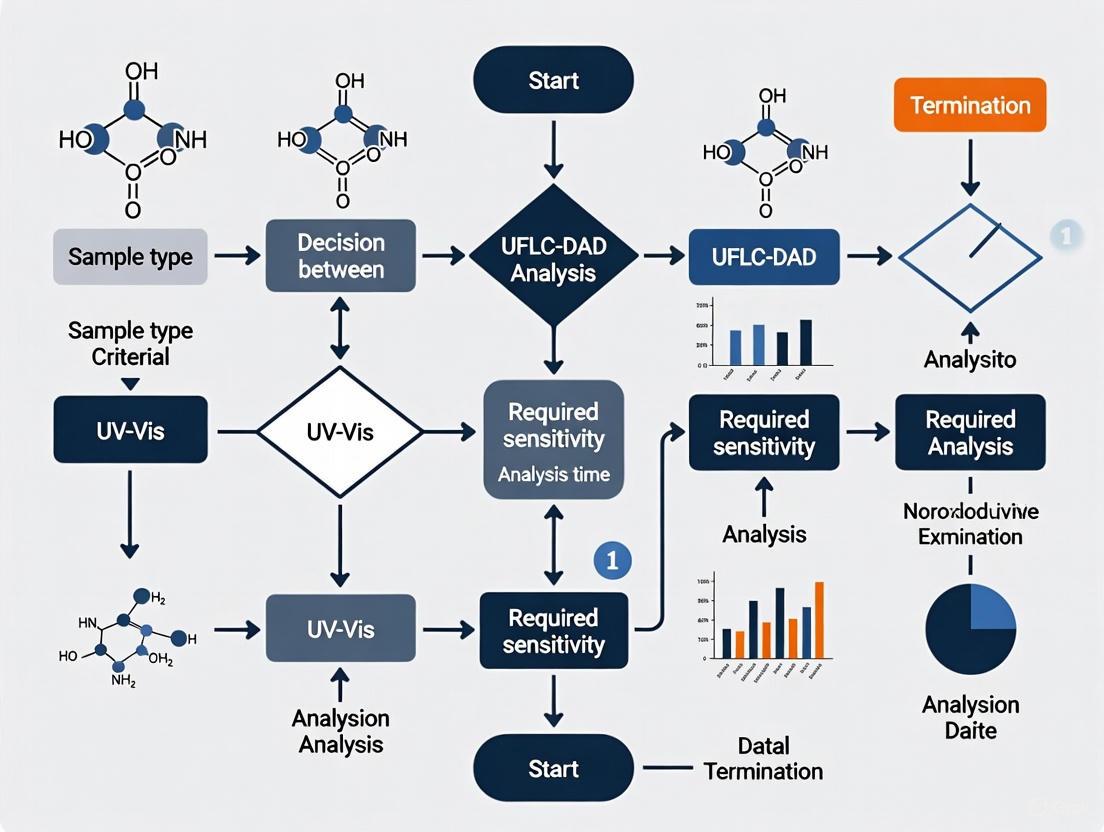

Diagram 2: Method selection guide for UV-Vis versus UFLC-DAD

Application-Specific Considerations

Choose UV-Vis Spectroscopy when:

- Analyzing pure compounds or simple mixtures

- High-throughput analysis is priority

- Resources are limited (budget, training)

- Sample amounts are not constrained

- Method development time must be minimized

- Green chemistry principles are important [7]

Choose UFLC-DAD when:

- Analyzing complex mixtures without unique chromophores

- Specificity is critical (e.g., isomers, co-eluting compounds)

- Sample is limited or precious

- Wider dynamic range is required

- Confirmation of compound identity is essential through retention time and spectrum

The complementary nature of these techniques is evident in comprehensive studies, such as wine aging research, where UV-Vis absorption spectroscopy provides rapid screening while HPLC-DAD delivers specific compound identification and quantification [8].

UV-Vis spectroscopy, grounded in the Beer-Lambert Law, remains a cornerstone analytical technique due to its simplicity, cost-effectiveness, and broad applicability. The principle of electronic transitions induced by UV-Vis light provides both qualitative identification through spectral fingerprints and quantitative analysis through absorbance-concentration relationships.

For researchers and drug development professionals, technique selection between UV-Vis and UFLC-DAD represents a strategic decision balancing analytical needs with practical constraints. UV-Vis excels in simplicity, speed, and cost-efficiency for appropriate applications, while UFLC-DAD provides superior resolution and specificity for complex samples. Understanding the fundamental principles outlined in this guide enables informed methodological choices that optimize analytical outcomes within project constraints.

The continued relevance of UV-Vis spectroscopy in modern laboratories is evidenced by its widespread application across quality control, pharmaceutical analysis, environmental monitoring, and research, where its operational principles continue to make it an indispensable tool in the analytical sciences.

Ultra-Fast Liquid Chromatography (UFLC) represents a significant evolution in separation science, enabling dramatically reduced analysis times and enhanced resolution compared to conventional High-Performance Liquid Chromatography (HPLC). When coupled with a Diode-Array Detector (DAD), also known as a Photodiode-Array Detector (PDA), this integrated system provides not only superior separation power but also comprehensive spectral data for each analyte. This architecture is particularly valuable in pharmaceutical analysis, food safety testing, and environmental monitoring where both the identity and quantity of compounds must be determined with high confidence [9] [10].

The core innovation of UFLC-DAD technology lies in its ability to simultaneously deliver high-speed separations through columns packed with sub-2-micron particles operating at elevated pressures, while collecting full ultraviolet-visible (UV-Vis) spectra for each eluting peak. This dual capability addresses a critical need in modern analytical laboratories: the requirement for methods that are both fast and information-rich. Unlike single-wavelength UV detectors that merely confirm presence based on retention time, DAD detection adds a second dimension of spectral confirmation, enabling researchers to perform peak purity assessment and identify unknown compounds within a single chromatographic run [11] [12].

Core Components and Operating Principles

UFLC Separation Module

The UFLC subsystem is engineered for high-pressure operation, typically up to 1000 bar or more, which enables the use of columns packed with stationary phases of 1.7-1.9 μm particle size. These smaller particles provide enhanced efficiency according to the Van Deemter equation, maintaining optimal performance at higher linear velocities and thereby allowing faster separations without sacrificing resolution [10]. The pumping system must deliver precise, pulse-free flow rates even at elevated pressures, with typical analytical-scale flow rates ranging from 0.1-2.0 mL/min. The autosampler must introduce samples with minimal dispersion while maintaining precision at low injection volumes (often 1-10 μL), and the column oven provides precise temperature control to ensure retention time stability [13].

Compared to conventional HPLC systems limited to approximately 400 bar, UFLC systems can reduce analysis times by 3-5 times while improving resolution by approximately 70% [10]. This separation power is particularly valuable for complex samples such as herbal supplements, pharmaceutical formulations, and biological matrices where multiple analytes with similar structural characteristics must be resolved [9]. The ability to rapidly separate complex mixtures makes UFLC the foundation upon which the comprehensive detection capabilities of the DAD can be fully utilized.

Diode-Array Detection Technology

The DAD represents a significant advancement over conventional UV-Vis detectors through its ability to monitor the entire UV-Vis spectrum simultaneously. While a variable wavelength detector (VWD) uses a monochromator to select a single wavelength before the light passes through the flow cell, the DAD employs a fundamentally different optical design: light from the source passes through the flow cell first, then is dispersed by a diffraction grating onto an array of photodiodes [12]. This reversed optical path enables the detector to capture the full absorption spectrum (typically 190-800 nm) for each data point throughout the chromatographic run.

The key components of a modern DAD system include:

- Light Source: A deuterium lamp for the UV region (190-400 nm), often supplemented with a tungsten lamp for the visible range (400-800 nm) [12] [1].

- Flow Cell: Typically with a pathlength of 10 mm but significantly reduced volume (0.5-1 μL for UHPLC applications) to minimize post-column band broadening [12].

- Diffraction Grating: Usually a blazed holographic grating with 300-2000 grooves per mm that disperses the light after it passes through the flow cell [1].

- Photodiode Array: Consisting of 512-1024 individual diodes, each measuring the intensity at a specific wavelength (approximately 1 nm resolution) [12].

This configuration enables the detector to collect up to 80 spectra per second, providing comprehensive spectral information for even the narrowest peaks generated by UFLC systems, which can have peak widths of just 1-2 seconds [13].

Figure 1: Optical pathway in a Diode-Array Detector (DAD)

Comparative Technical Specifications

Performance Comparison: UFLC-DAD vs. HPLC-UV

The combination of UFLC with DAD detection provides significant advantages over conventional HPLC with single-wavelength UV detection across multiple performance parameters. The following table summarizes these key differences based on data from validation studies and technical specifications:

Table 1: Performance comparison between UFLC-DAD and conventional HPLC-UV systems

| Parameter | HPLC-UV | UFLC-DAD | Improvement |

|---|---|---|---|

| Operating Pressure | 200-400 bar [10] | 600-1000 bar [10] | 2.5x increase |

| Analysis Time | 10-30 min [10] | 1-5 min [10] | 5-10x reduction |

| Detection | Single wavelength [12] | Full spectrum (190-800 nm) [11] | Spectral confirmation |

| Peak Capacity | 100-200 [14] | 200-500 [14] | 2x increase |

| Solvent Consumption | 5-10 mL/run [14] | 1-2 mL/run [14] | 5x reduction |

| Data Collection Rate | 5-20 Hz [13] | 20-80 Hz [13] | 4x increase |

The enhanced performance of UFLC-DAD systems is particularly evident in method validation parameters. In a study comparing methods for anticancer guanylhydrazones, UFLC-DAD demonstrated superior precision with RSD values ≤1.27% compared to ≤2.81% for HPLC-UV, while maintaining excellent linearity (r²>0.999) for all compounds [14]. Similar results were reported in a study of posaconazole analysis, where UHPLC achieved a run time of just 3 minutes compared to 11 minutes for HPLC, with equivalent sensitivity and linearity [10].

Research Reagent Solutions for UFLC-DAD Analysis

Successful implementation of UFLC-DAD methods requires careful selection of reagents and consumables compatible with the high-pressure environment and detection requirements. The following table outlines essential materials and their functions:

Table 2: Essential research reagents and materials for UFLC-DAD applications

| Item | Function/Application | Technical Specifications |

|---|---|---|

| C18 Reverse Phase Column | Stationary phase for separation [9] | Sub-2μm particles, 50-100mm length, 2.1-3.0mm ID [10] |

| Acetonitrile (HPLC Grade) | Organic mobile phase component [9] | Low UV cutoff (<200nm), high purity for sensitivity [9] |

| Formic Acid/Acetic Acid | Mobile phase modifier [9] | 0.1% concentration for peak symmetry [14] |

| Methanol (HPLC Grade) | Alternative organic modifier [14] | For less hydrophobic compounds [14] |

| Ammonium Acetate | Buffer for mass spectrometry compatibility [9] | 1-10mM concentration [9] |

| Quartz Flow Cells | DAD detection path [12] | 10mm pathlength, <1μL volume [12] |

The selection of appropriate mobile phase components is particularly critical for DAD detection, as these must provide both satisfactory chromatographic separation and UV transparency at the wavelengths of interest. Acetonitrile with 0.1% formic acid is a frequently employed mobile phase in UFLC-DAD methods for pharmaceutical analysis, as evidenced by multiple methods for PDE-5 inhibitors and related compounds [9]. The acidic modifier improves peak shape while maintaining compatibility with both the separation and detection systems.

Operational Methodologies and Experimental Protocols

Standard UFLC-DAD Method Development Workflow

Developing a robust UFLC-DAD method requires systematic optimization of both separation and detection parameters. The following workflow represents a generalized approach applicable to most small molecule analyses:

Sample Preparation: Implement appropriate extraction and clean-up procedures. For complex matrices such as dietary supplements or biological fluids, liquid-liquid extraction (LLE) or solid-phase extraction (SPE) may be necessary. In the analysis of PDE-5 inhibitors in illicit products, simple extraction with water/acetonitrile containing 1% formic acid followed by sonication and centrifugation provided satisfactory results [9].

Column Selection: Choose a appropriate UHPLC column based on analyte characteristics. Reverse-phase C18 columns (50-100 mm × 2.1 mm, 1.7-1.9 μm) are most commonly employed for small molecules. The column temperature is typically maintained at 40°C to ensure retention time stability [9].

Mobile Phase Optimization: Develop gradient elution conditions. A typical initial approach employs a binary gradient with 0.1% formic acid in water (Mobile Phase A) and 0.1% formic acid in acetonitrile (Mobile Phase B). The gradient might begin at 5-10% B, increasing to 90-95% B over 3-10 minutes depending on analyte hydrophobicity [9].

DAD Spectral Collection: Configure spectral acquisition parameters. Set the wavelength range to 190-400 nm for most UV-absorbing compounds, with a spectrum acquisition rate of 10-20 Hz (higher for very fast separations). Select appropriate monitoring wavelengths for quantification based on analyte spectra [11].

System Suitability Testing: Establish criteria for retention time stability, peak symmetry, resolution, and signal-to-noise ratio before implementing the method for routine analysis [14].

Figure 2: UFLC-DAD method development workflow

Peak Purity Assessment Protocol

One of the most powerful applications of DAD detection is peak purity assessment, which helps determine if a chromatographic peak represents a single compound or multiple co-eluting substances. The standard protocol involves:

Spectral Acquisition: Collect full UV-Vis spectra (typically 190-400 nm) throughout the elution of the chromatographic peak at multiple points: upslope, apex, and downslope [11].

Spectral Comparison: Normalize the spectra and compare them using the instrument software. Modern DAD systems automatically calculate a peak purity index or purity angle based on the spectral similarity [12].

Threshold Determination: Establish acceptance criteria for peak purity. A purity angle less than the purity threshold (as determined by analysis of a standard) indicates a pure peak, while a larger value suggests potential co-elution [11].

Advanced Deconvolution: For partially resolved peaks, utilize advanced software features such as Shimadzu's i-PDeA function, which employs spectral data to mathematically resolve overlapping peaks without physical separation [11].

This peak purity assessment capability is particularly valuable in pharmaceutical analysis where it is necessary to demonstrate method specificity and the absence of interfering peaks near the analyte of interest, as required by ICH guidelines [12].

Decision Framework: When to Select UV-Vis vs. UFLC-DAD

Application-Based Selection Criteria

The choice between a conventional UV-Vis detector and a UFLC-DAD system depends on multiple factors related to the analytical requirements, sample characteristics, and operational constraints. The following decision framework provides guidance for selecting the appropriate technology:

Figure 3: Detector selection decision framework

Specific Application Scenarios

Choose UFLC-DAD when:

- Method Development and Unknown Screening: The full spectral capability enables compound identification through library matching and peak purity assessment [11].

- Regulated Pharmaceutical Analysis: ICH Q3A guidelines require demonstration of specificity and peak purity for stability-indicating methods [12].

- Complex Natural Product Analysis: Herbal supplements and botanical extracts often contain multiple compounds with similar retention times but different spectra [9].

- Impurity Profiling: The combination of high separation efficiency and spectral data facilitates identification and quantification of low-level impurities [9].

Choose HPLC-UV when:

- Routine Quality Control: For well-characterized compounds where only quantification is needed, single-wavelength detection suffices [15].

- Budget Constraints: UV detectors are more cost-effective than DAD systems, both in initial investment and maintenance [16].

- Limited Technical Expertise: UV detectors are simpler to operate and maintain [12].

- Methods with Established Specificity: When interference has been ruled out through previous validation studies [14].

A hybrid approach employing HPLC with DAD detection may be appropriate when separation requirements are modest but spectral confirmation is desirable. Similarly, UFLC with UV detection may be optimal when speed is essential but the analytes are well-characterized [13].

UFLC-DAD architecture represents the convergence of high-efficiency separation technology with comprehensive spectroscopic detection, providing an powerful analytical tool for modern laboratories. The integration of sub-2-micron particle chromatography with full-spectrum UV-Vis detection enables researchers to not only separate complex mixtures rapidly but also obtain critical spectral data for compound identification, confirmation, and purity assessment within a single analysis.

The decision to implement UFLC-DAD versus conventional HPLC-UV involves careful consideration of analytical requirements, sample complexity, and operational constraints. For applications demanding the highest level of confidence in compound identity or dealing with unknown components, the additional information provided by DAD detection is invaluable. For routine analysis of well-characterized compounds where throughput and cost-efficiency are primary concerns, UV detection may remain sufficient. As analytical challenges continue to evolve toward more complex samples and shorter turnaround times, UFLC-DAD technology offers a robust solution that balances separation power with comprehensive detection capabilities.

Selecting the appropriate analytical technique is a critical decision in research and drug development. The choice between Ultraviolet-Visible (UV-Vis) spectroscopy and Ultra-Fast Liquid Chromatography with a Diode Array Detector (UFLC-DAD) hinges on a fundamental understanding of their core components and how these components dictate the capabilities and limitations of each system. This guide provides an in-depth technical comparison of the light sources, wavelength selectors, and detectors that form the foundation of both instruments. By framing this comparison within the context of specific analytical needs—from rapid, pure compound analysis to the separation and identification of complex mixtures—this guide empowers scientists to make informed, strategic decisions for their research.

Core Component Comparison

The analytical performance of UV-Vis and UFLC-DAD systems is directly determined by their core optical components. The table below provides a detailed, quantitative comparison of these subsystems.

Table 1: Technical Comparison of Core Components in UV-Vis Spectrophotometers and UFLC-DAD Systems

| Component | UV-Vis Spectrophotometer | UFLC-DAD System |

|---|---|---|

| Light Sources | • Deuterium (D₂) lamp: Covers UV range (∼190–400 nm) [1].• Tungsten-Halogen (W) lamp: Covers visible range (∼350–1000 nm) [1].• Xenon lamp: Single, high-intensity source for both UV and visible ranges; more expensive and less stable [1]. | • Typically uses a Deuterium (D₂) lamp and a Tungsten (W) lamp to cover the UV-Vis spectrum [17].• Lamps are integrated into a single detector module. |

| Wavelength Selectors | • Monochromator: Most common; uses a diffraction grating (often ≥1200 grooves/mm) for wavelength selection [1].• Filters: Absorption, interference, cutoff, and bandpass filters are used to narrow wavelengths or for specific applications [1]. | • Incorporates a monochromator (e.g., with a diffraction grating) after the sample flow cell [17].• This allows polychromatic light to pass through the sample first. |

| Detectors | • Photomultiplier Tube (PMT): Common; high sensitivity for low-light detection [1].• Photodiodes & CCDs: Semiconductor-based detectors [1]. | • Utilizes a Photo Diode Array (PDA) consisting of multiple diodes (e.g., 512 or 1024), each measuring a specific wavelength simultaneously [17]. |

| Key Operational Characteristics | • Sequential wavelength measurement.• Requires a reference (blank) measurement for baseline correction [1]. | • Simultaneous, full-spectrum acquisition at every data point during the chromatographic run [18].• Provides a three-dimensional data output: retention time, absorbance, and wavelength [17]. |

Experimental Protocols

The distinct configurations of these components lead to different standard operating procedures. The following workflows, derived from recent research, illustrate the application-specific protocols for each technique.

Protocol 1: Rapid Contamination Detection in Microalgae Cultures using UV-Vis and Machine Learning

This protocol highlights the use of UV-Vis for rapid, in-vivo analysis of complex biological samples without the need for separation [19].

- Sample Preparation: Grow cultures of the microalgae of interest (e.g., Chlorella vulgaris). Introduce potential biological contaminants, such as the flagellate Poterioochromonas malhamensis or the rotifer Brachionus plicatilis. For robustness testing, culture samples under different stress conditions, such as salt-stressed media [19].

- Instrument Setup: Configure a UV-Vis spectrophotometer with a light source covering 200–1000 nm and a 10-mm path length cuvette holder. A handheld spectrometer can be used for portability [19].

- Data Acquisition: Collect UV-Vis absorption spectra of both uncontaminated and contaminated cultures. The distinct spectral fingerprints of chlorophylls, carotenoids, and other pigments serve as the analytical signal [19].

- Data Analysis: Employ machine learning for data analysis. Use Principal Component Analysis (PCA) to classify the spectral data and distinguish between uncontaminated and contaminated cultures, even under challenging salt-stress conditions that alter pigment profiles [19].

Protocol 2: Comprehensive Analysis of Wine Aging Markers using UFLC-DAD

This protocol demonstrates the use of UFLC-DAD for separating, identifying, and quantifying specific compounds within a complex mixture [8].

- Sample Collection: Obtain a set of sweet botrytized wine samples with a known and wide age range (e.g., 3 to 60 years) [8].

- Chromatographic Separation:

- Column: Use a reversed-phase C18 column.

- Mobile Phase: Employ a binary gradient, typically consisting of water (with acid modifier) and an organic solvent like acetonitrile or methanol.

- Injection: Automatically inject a precise volume of filtered wine sample.

- DAD Detection & Data Acquisition:

- Set the DAD to acquire full spectra (e.g., from 190–400 nm) for every data point during the chromatographic run.

- Set the data acquisition rate to at least 5–20 Hz to ensure sufficient data points across narrow UHPLC peaks [20].

- Use a narrow bandwidth (e.g., 1–4 nm) for high spectral resolution and a small step size (e.g., 1 nm) for smooth spectral curves [20].

- Compound Identification & Quantitation:

- Identify phenolic compounds (e.g., catechin, gallic acid, caftaric acid) by matching their retention times and UV-Vis spectra against those of authentic standards analyzed under identical conditions [8].

- Quantify the compounds using calibration curves built from standards.

- Chemometric Analysis: Perform statistical analysis (e.g., Spearman correlation) to establish a high correlation between the concentration of specific markers (e.g., caftaric acid, catechin, gallic acid) and the chronological age of the wine [8].

System Workflows and Logical Relationships

The fundamental difference in data acquisition between the two techniques—sequential versus simultaneous—dictates their analytical workflows and applications. The following diagram visualizes the operational logic of each system.

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful execution of the protocols depends on the use of specific, high-quality materials. The following table lists key reagents and their functions in the featured experiments.

Table 2: Essential Research Reagents and Materials

| Item Name | Function / Analytical Role |

|---|---|

| Microalgae Cultures (e.g., Chlorella vulgaris) | Serves as the model biological system for developing rapid contamination screening methods using its natural pigment fingerprints [19]. |

| Phenolic Compound Standards (Catechin, Gallic Acid, etc.) | Used for compound identification and creating quantitative calibration curves in HPLC-DAD analysis of complex samples like wine [8]. |

| HPLC/DAD Solvents (Acetonitrile, Methanol, Acidified Water) | Form the mobile phase for chromatographic separation; purity is critical to maintain low background noise and ensure peak resolution [8]. |

| Quartz Cuvettes | Essential for UV range measurements in spectrophotometry, as quartz is transparent down to ~190 nm, unlike plastic or glass [1]. |

| Syringe Filters (0.45 µm or 0.22 µm) | Used to clarify and particulate-free liquid samples (e.g., wine, culture media) prior to injection into the HPLC system to prevent column damage [8]. |

| BAY-179 | BAY-179, MF:C23H21N5OS, MW:415.5 g/mol |

| DS88790512 | DS88790512, MF:C22H29N3O2, MW:367.5 g/mol |

Decision Framework: UV-Vis vs. UFLC-DAD

The choice between UV-Vis and UFLC-DAD is not a matter of which instrument is superior, but which is more appropriate for the specific analytical question. The following framework guides this decision.

Choose UV-Vis Spectroscopy when:

- The analytical goal is rapid quantification of a known compound in a pure or simple mixture [21].

- The sample is a simple solution and does not require separation of components [21].

- You need to monitor reaction kinetics or time-dependent processes in real-time [1].

- Cost-effectiveness, speed, and ease of use are primary concerns, and the necessary information can be derived from a bulk absorption measurement [21].

Choose UFLC-DAD when:

- The sample is a complex mixture requiring high-resolution separation of multiple components before detection [21].

- Peak purity assessment and identification of co-eluting compounds is necessary, as the DAD's full-spectrum capability can reveal impurities invisible to a single-wavelength detector [18].

- Spectral confirmation of identity is required, as the UV-Vis spectrum of a peak provides a additional identification point alongside its retention time [17] [18].

- The analysis involves unknown compounds or impurities, and you need to retrospectively extract chromatograms at different wavelengths without reinjecting the sample [18].

This technical guide provides an in-depth examination of three fundamental parameters in ultraviolet-visible (UV-Vis) spectroscopy and ultra-fast liquid chromatography with diode array detection (UFLC-DAD): spectral bandwidth, pathlength, and molar absorptivity. Understanding the interplay between these parameters is crucial for researchers and drug development professionals when selecting appropriate analytical techniques and optimizing method performance. This review synthesizes current principles and practices to establish a framework for informed decision-making between conventional UV-Vis and UFLC-DAD methodologies, supported by experimental data and technical specifications relevant to pharmaceutical analysis.

The selection of appropriate detection technology is pivotal in analytical method development for pharmaceutical research and quality control. Ultraviolet-visible (UV-Vis) detection remains the workhorse in quality control laboratories due to its reliability, ease of use, and universal response to chromophoric compounds, while diode array detection (DAD) in liquid chromatography systems provides enhanced capabilities for peak identification and purity assessment [12]. The performance of both techniques hinges on three interdependent parameters: spectral bandwidth, which determines wavelength resolution; pathlength, which governs signal intensity according to Beer-Lambert law; and molar absorptivity, an intrinsic molecular property defining absorption strength [12] [22]. This whitepaper examines these critical parameters within the context of selecting between conventional UV-Vis and UFLC-DAD systems, providing technical guidance for method optimization in drug development workflows.

Fundamental Principles and Definitions

Molar Absorptivity (ε)

Molar absorptivity (also known as molar extinction coefficient) is an intrinsic property of a chemical substance that defines how strongly it absorbs light at a specific wavelength [23] [24]. According to the Beer-Lambert law, absorbance (A) is directly proportional to molar absorptivity (ε), pathlength (b), and concentration (c): A = ε × b × c [12] [22]. Compounds with high molar absorptivity (typically >10,000 L·molâ»Â¹Â·cmâ»Â¹) produce strong detection signals even at low concentrations, making them ideal for trace analysis [23]. For drug substances with low native molar absorptivity, analytical sensitivity can be improved through derivatization strategies that create charge-transfer complexes with enhanced absorption properties [23].

Pathlength (b)

Pathlength is the distance light travels through the sample in a flow cell or cuvette, typically measured in millimeters or centimeters [12] [25]. In accordance with Beer-Lambert law, absorbance increases linearly with pathlength, making it a crucial factor for detection sensitivity [25]. HPLC flow cells typically have pathlengths of 10mm, while UHPLC cells are shorter (0.5-1mm) to maintain low dispersion volumes [12]. As a rule of thumb, the flow cell volume should be approximately one-third of the peak volume at half height to minimize band broadening [25].

Spectral Bandwidth (SBW)

Spectral bandwidth is defined as the width of the wavelength of light at half the maximum intensity (Full Width at Half Maximum or FWHM) [26]. This parameter critically influences measurement accuracy, resolution, and ability to distinguish fine spectral features. There are distinct considerations for different instrument types:

- Monochromator-based instruments: SBW is determined by the physical slit width and optical dispersion, with narrower slits providing higher resolution but reduced light throughput [26].

- Diode-array instruments: SBW is often fixed and determined by the design and spacing of the diodes in the array, allowing simultaneous measurement of all wavelengths [26].

The relationship between spectral bandwidth and the natural bandwidth of the sample's absorption band is crucial; for high measurement accuracy (≥99.5%), the ratio of spectral bandwidth to natural bandwidth should be 0.1 or less [26].

Quantitative Comparison of Technical Parameters

Flow Cell Specifications for UV Detection

Table 1: Comparison of HPLC/UFLC flow cell characteristics based on pathlength

| Path Length | Cell Volume | Typical Applications | Linearity Limit (AU) | Sensitivity Consideration |

|---|---|---|---|---|

| 1.0 cm | 1.0 µL | Standard HPLC analysis | ~200 mAU | Balanced sensitivity and dispersion |

| 6.0 cm | 4.0 µL | Trace analysis | ~333 mAU (55.5 mAU/cm) | Higher signal-to-noise ratio; increased band broadening risk |

| 0.5-1.0 mm | 0.5-1.0 µL | UHPLC applications | Instrument-dependent | Minimal dispersion for sharp peaks |

Data adapted from Agilent flow cell specifications and chromatography literature [12] [25].

Molar Absorptivity Values for Selected Compounds

Table 2: Representative molar absorptivity values for pharmaceutical compounds

| Compound/Core Structure | λmax (nm) | Molar Absorptivity (ε, L·molâ»Â¹Â·cmâ»Â¹) | Structural Features |

|---|---|---|---|

| Furo[3,2-e]indolizine (R1=R2=H) | 355 | 1.7 × 10ⴠ| Base heteroaromatic system |

| Furo[3,2-e]indolizine (R1=R2=4-CNPh) | 434 | 3.2 × 10ⴠ| Extended π-system with electron-withdrawing groups |

| Vitamin B1 (after oxidation) | ~375 | Varies with derivatization | Thiochrome formation |

| Vitamin B2 | ~445 | ~1.2 × 10ⴠ| Isoalloxazine ring |

| Vitamin B6 | ~325 | ~8.0 × 10³ | Pyridoxine structure |

Data compiled from multiple sources including furoindolizine studies and vitamin分æžæ–¹æ³• [27] [24].

Experimental Protocols and Methodologies

Determination of Molar Absorptivity

Protocol for Empirical ε Measurement:

Solution Preparation: Prepare a stock solution of accurately known concentration (typically 1-10 mM) using a high-purity standard and appropriate solvent.

Dilution Series: Create a series of 5-8 dilutions covering the expected linear range of Beer-Lambert law (typically yielding absorbances of 0.1-1.0 AU).

Spectroscopic Measurement: Using a spectrophotometer with appropriate SBW setting (≤1 nm recommended), measure absorbance at λmax for each dilution using a cuvette with precisely known pathlength.

Data Analysis: Plot absorbance versus concentration and perform linear regression. The slope of the line (A/c) equals ε × b, allowing calculation of ε using the known pathlength.

Validation: Verify linearity (R² > 0.999) and repeat with at least three independent stock solutions for precision assessment [23] [22].

Simultaneous Vitamin Analysis Using HPLC-DAD/FLD

Chromatographic Conditions:

- Column: Aqua C18 (250 mm × 4.6 mm, 5 μm)

- Temperature: 40°C

- Mobile Phase: Isocratic elution with 70% NaHâ‚‚POâ‚„ buffer (pH 4.95) and 30% methanol

- Flow Rate: 0.9 mL/min

- Detection: DAD for vitamins B2 and B6; FLD for vitamin B1 after pre-column derivatization

Sample Preparation:

- Liquid/Solid Extraction: For pharmaceutical gummies, homogenize and extract with suitable solvent (e.g., acidified methanol)

- Derivatization for B1: Oxidize thiamine to fluorescent thiochrome using alkaline potassium ferricyanide

- Cleanup: For complex matrices (e.g., gastrointestinal fluids), employ Solid Phase Extraction (SPE) with C18 cartridges

- Validation Parameters: Demonstrate linearity (R² > 0.999), accuracy (mean recovery 100 ± 3%), and precision (RSD < 3.23%) [27]

Instrument Selection Guide: UV-Vis vs. UFLC-DAD

Technical Comparison for Pharmaceutical Applications

Table 3: Decision matrix for detector selection based on analytical requirements

| Analytical Requirement | Recommended Detector | Optimal Parameter Settings | Rationale |

|---|---|---|---|

| Routine quantification of chromophoric compounds | Single wavelength UV-Vis | Pathlength: 10 mm; SBW: 4-8 nm | High precision (<0.2% RSD), reliability, simplicity [12] |

| Peak purity/purity assessment | DAD/PDA | SBW: 1-4 nm; full spectrum collection | Spectral comparison across peak (upslope vs. downslope) [12] |

| Method development/unknown identification | DAD/PDA | Full spectrum (190-800 nm); SBW: ≤4 nm | Library matching and multi-wavelength analysis capability [12] |

| Low abundance analytes | Long pathlength UV cell or pre-column derivatization | Pathlength: 30-60 mm; optimized ε | Enhanced sensitivity via Beer-Lambert law [23] [25] |

| Compounds with low molar absorptivity | Derivatization or universal detection | Chemical modification to enhance ε | Complex formation to improve detectability [23] |

| High-resolution separations (UHPLC) | DAD with low-dispersion flow cell | Pathlength: 0.5-1 mm; cell volume: <1 μL | Maintains separation efficiency with minimal peak broadening [12] |

Research Reagent Solutions for Absorption Spectroscopy

Table 4: Essential materials and reagents for method development

| Reagent/ Material | Function/Application | Technical Considerations |

|---|---|---|

| Deuterium Lamp | UV light source for 190-400 nm | Standard in modern UV-Vis and DAD detectors; requires periodic replacement [12] |

| Charge Transfer Complex Reagents (DDQ, TCNQ) | Electron acceptors for enhancing detectability | Improve molar absorptivity of donor compounds; selectivity depends on donor properties [23] |

| C18 SPE Cartridges | Sample cleanup and preconcentration | Essential for complex matrices (biological fluids); improves method sensitivity and column lifetime [27] |

| Buffer Salts (e.g., NaH₂PO₄) | Mobile phase modification | Controls pH for separation and stability; affects chromophore ionization and λmax [27] |

| Pre-column Derivatization Reagents | Convert non-UV-absorbing compounds to detectable forms | Enables detection of vitamins (B1→thiochrome), amines, thiols via fluorescence or enhanced UV absorption [27] |

Visualizing Parameter Relationships

Parameter Interdependence in UV Detection

The strategic selection between UV-Vis and UFLC-DAD detection methodologies requires thorough understanding of three fundamental parameters—spectral bandwidth, pathlength, and molar absorptivity—and their interplay in governing analytical performance. UV-Vis detection remains optimal for routine quantification where high precision and reliability are paramount, while UFLC-DAD provides superior capabilities for method development, peak purity assessment, and analysis of complex mixtures. By applying the technical principles and experimental frameworks presented in this guide, researchers can make informed decisions that optimize detection strategies for specific pharmaceutical applications, ultimately enhancing method performance and analytical confidence in drug development workflows.

The Historical Evolution and Enduring Role of UV Detection in HPLC

The development of High-Performance Liquid Chromatography (HPLC) represents a cornerstone achievement in analytical chemistry, enabling the separation, identification, and quantification of complex mixtures with remarkable precision. While numerous detection methods have emerged over the decades, ultraviolet (UV) detection remains one of the most widely utilized techniques across pharmaceutical, clinical, and environmental laboratories. Its enduring prominence stems from an exceptional balance of reliability, ease of use, and universal response to chromophoric compounds [12].

The evolution of UV detection technology has progressed from simple fixed-wavelength instruments to sophisticated diode array systems capable of full-spectrum monitoring. This progression has occurred within the broader context of HPLC's own development, which traces its modern beginnings to the mid-1960s [28]. Understanding this historical trajectory provides valuable insights for contemporary researchers faced with methodological choices, particularly when deciding between conventional UV-Vis and more advanced diode array detection (DAD) for analytical applications.

This article examines the technical evolution of UV detection, its current applications in modern analytical science, and practical guidance for detector selection within research and development frameworks.

Historical Development of HPLC and UV Detection

The Birth of Modern Liquid Chromatography

The foundational principles of high-performance liquid chromatography were established through pivotal work in the 1960s that transformed traditional liquid chromatography into a powerful analytical technique. The seminal year of 1966 is often cited as a critical starting point, marked by two significant developments: Piel's work using finely ground silica particles in narrow-bore columns under pressure, and Hamilton's application of smaller ion-exchange resins for amino acid analysis [28]. These innovations demonstrated the profound impact of particle size and pressure on separation efficiency, fulfilling the prediction made by Martin and Synge in 1941 that "the smallest HETP should be obtainable by using very small particles and a high pressure difference across the length of the column" [28].

The true revolution in HPLC column technology began with Professor Csaba Horváth's development of pellicular particles (now called superficially porous particles or SPPs) around 1968 [28]. These particles featured an impenetrable solid core (37-50 µm glass beads) coated with a thin, porous outer layer (1-2 µm) of stationary phase. This design provided an order of magnitude improvement in efficiency compared to the larger, fully porous particles used previously, primarily because the thin porous layer restricted diffusion paths for analyte molecules [28].

Evolution of UV Detection Technology

The development of reliable UV detectors was equally crucial to HPLC's success. Early UV detection systems were fixed-wavelength detectors using low-pressure mercury lamps with a strong 254 nm emission line [12]. Introduced in the late 1960s, these detectors represented a significant advancement, with one 1968 model reporting noise of approximately ±0.2 mAU—about 50 times less sensitive than modern detectors [12]. While limited in flexibility, these robust detectors established UV detection as a fundamental HPLC component.

The next significant advancement came with variable wavelength detectors (VWD), which incorporated deuterium lamps and monochromators to allow user-selectable wavelengths across the UV-Vis spectrum (typically 190-600 nm) [12]. The heart of these systems was a movable diffraction grating that could be rotated to select specific wavelengths through an exit slit, typically with a spectral bandwidth of 5-8 nm [12]. This flexibility enabled method development at the optimal wavelength for specific analytes, greatly enhancing detection selectivity.

The most transformative development in UV detection emerged with the introduction of photodiode array detectors (PDA or DAD) in the 1980s [12]. Unlike variable wavelength detectors that use a monochromator before the flow cell, DADs employ a "reverse optics" design where white light passes through the flow cell first before being dispersed onto an array of photodiodes [29]. This fundamental architectural difference enables simultaneous monitoring of multiple wavelengths and collection of complete spectra for each data point during chromatographic separation [12] [29].

Table 1: Historical Evolution of HPLC UV Detection Technologies

| Time Period | Detector Type | Key Characteristics | Performance Metrics | Applications |

|---|---|---|---|---|

| Late 1960s | Fixed Wavelength | Low-pressure mercury lamps (254 nm); cutoff filters; simple optical design | Noise: ~±0.2 mAU [12] | Basic separations of chromophoric compounds |

| 1980s | Variable Wavelength (VWD) | Deuterium lamps; monochromators; selectable wavelengths (190-600 nm) | Spectral bandwidth: 5-8 nm [12] | Method development; targeted compound analysis |

| 1980s-Present | Diode Array (DAD/PDA) | Reverse optics; full spectrum collection (190-950 nm); photodiode arrays (512-1024 elements) | Simultaneous multi-wavelength monitoring; spectral acquisition [12] [11] | Peak purity; method development; unknown identification |

The timeline of HPLC and UV detection development reveals a pattern of incremental improvements interspersed with revolutionary breakthroughs. The period from 1966 to approximately 1975 established the fundamental principles, while the 1980s brought sophisticated optical designs and electronics that dramatically improved performance. Modern systems continue this evolution with enhanced sensitivity, reduced noise levels, and advanced data processing capabilities.

Fundamental Principles and Technical Evolution

Operating Principles of UV Detection

The fundamental principle underlying all UV detection for HPLC is the Beer-Lambert Law, which mathematically describes the relationship between analyte concentration and light absorption [29]. According to this law, absorbance (A) is proportional to the product of the molar absorptivity (ε), pathlength (b), and analyte concentration (c): A = ε × b × c [12]. This relationship enables quantitative analysis when properly calibrated with standards of known concentration.

UV detectors specifically measure the UV absorbance of HPLC eluent as it passes through a flow cell, providing a continuous signal that correlates with analyte concentration [12]. Key components shared across all UV detector types include:

- Light Source: Typically a deuterium (Dâ‚‚) lamp providing continuous emission in the 190-600 nm range, sometimes augmented with a tungsten lamp for visible light detection (up to 950 nm) [12]

- Flow Cell: A small, flow-through device with quartz windows defining a fixed pathlength (typically 10 mm), with volumes ranging from 8-18 µL for HPLC to 0.5-1 µL for UHPLC applications [12]

- Photodetector: Converts transmitted light intensity into electrical signals for data processing [29]

The essential difference between detector types lies in how they select and process wavelengths. Variable wavelength detectors use a monochromator before the flow cell to select a specific wavelength, while diode array detectors pass polychromatic light through the flow cell first, then disperse it onto a photodiode array for full spectrum capture [29].

Technical Specifications and Performance Metrics

Several key parameters define UV detector performance and suitability for specific applications:

- Pathlength: Typically 10 mm in standard flow cells, directly affecting sensitivity according to Beer's Law [12]

- Spectral Bandwidth: The range of wavelengths passing through the flow cell, typically 5-8 nm for VWD and adjustable for DAD [12]

- Noise: Modern detectors typically exceed the historical benchmark of ±1×10â»âµ AU [12]

- Dispersion: Primarily dependent on flow cell volume and design, contributing to overall system band broadening [12]

Table 2: Comparison of Modern UV Detector Types for HPLC

| Parameter | Variable Wavelength Detector (VWD) | Diode Array Detector (DAD/PDA) |

|---|---|---|

| Optical Design | Pre-cell monochromator with movable diffraction grating [12] | Post-cell fixed diffraction grating with diode array [29] |

| Wavelength Selection | Single or limited wavelengths selected before flow cell [12] | Full spectrum (190-950 nm) captured simultaneously [11] |

| Spectral Data | Limited to preselected wavelengths | Complete UV-Vis spectrum for every time point [12] |

| Primary Applications | Routine quantitative analysis where spectral data is not essential [12] | Peak purity, method development, unknown identification [11] |

| Flow Cell Volume | 8-18 µL (HPLC); 0.5-1 µL (UHPLC) [12] | Similar to VWD, with specialized micro-flow cells available |

| Advantages | Lower cost, sufficient for many routine applications | Spectral information for peak identification and purity assessment [12] [11] |

The evolution of detector technology has progressively addressed limitations while expanding capabilities. Early fixed-wavelength detectors provided limited application range, while variable wavelength detectors introduced method development flexibility. Diode array detectors represented the most significant advancement, enabling retrospective data analysis and peak purity assessment without method redevelopment [11].

UV Detection in Contemporary Analytical Applications

Pharmaceutical Analysis and Therapeutic Drug Monitoring

UV detection remains extensively employed in pharmaceutical analysis and therapeutic drug monitoring (TDM), where its combination of precision, reliability, and cost-effectiveness offers particular advantages. A 2023 study demonstrated the development of a practical HPLC-UV platform for quantifying serum levels of five different drugs (carbamazepine, phenytoin, lamotrigine, vancomycin, and voriconazole) during routine clinical work [30]. The method incorporated solid-phase extraction (SPE) using monolithic C18-silica disk cartridges followed by HPLC-UV analysis on a Chromolith HighResolution RP-18 column [30].

This platform successfully addressed the need for in-hospital TDM without requiring sophisticated MS instrumentation, achieving excellent correlation with both immunoassay (cobas analyzer) and HPLC-MS/MS reference methods [30]. The validation results demonstrated that HPLC-UV methods can deliver the precision required for clinical decision-making, with the authors noting that "the higher precision achievable with UV detection (<0.2% RSD) is pivotal and necessary in regulatory testing because a typical potency specification for drug substances is 98.0 to 102.0%" [12].

Method Comparison and Validation Studies

Comparative studies continue to highlight the appropriate applications and limitations of UV detection. A 2019 study directly compared HPLC-UV with UV-Vis spectrophotometry for quantifying levofloxacin released from mesoporous silica microspheres/nano-hydroxyapatite composite scaffolds [31]. While both methods showed excellent linearity (R²=0.9991 for HPLC-UV vs. R²=0.9999 for UV-Vis), significant differences emerged in recovery rates, particularly at medium concentrations (110.96% for HPLC-UV vs. 99.50% for UV-Vis) [31].

The study concluded that "it is not accurate to measure the concentration of drugs loaded on biodegradable composite composites by UV-Vis" alone, emphasizing that HPLC separation prior to detection is essential for accurate quantification in complex matrices [31]. This distinction highlights the continuing value of HPLC-UV for analyses where sample complexity or interfering substances complicate direct spectrophotometric measurement.

Advanced Applications and Hybrid Techniques

Modern applications increasingly combine HPLC-UV with advanced data processing techniques. A 2025 study on wine aging employed HPLC-DAD alongside chemometric methods to establish correlations between phenolic compound content and wine age [8]. The diode array detection enabled simultaneous quantification of multiple phenolic compounds (catechin, caffeic acid, caftaric acid, gallic acid, protocatechuic acid, and p-coumaric acid) while establishing characteristic spectral fingerprints for quality assessment [8].

Similarly, a 2024 study demonstrated the quantification of active pharmaceutical ingredients (acetylsalicylic acid, caffeine, and paracetamol) in solid formulations using UV-Vis diffuse reflectance spectroscopy with multivariate data processing, validating results against a reference HPLC-DAD method [32]. These applications illustrate how UV detection continues to evolve through integration with advanced data analysis techniques rather than being displaced by more expensive detection methods.

Experimental Protocols and Methodologies

HPLC-UV Method Development for Therapeutic Drug Monitoring

The following protocol, adapted from a 2023 clinical study, outlines a standardized approach for developing HPLC-UV methods for therapeutic drug monitoring [30]:

Sample Preparation:

- Solid-Phase Extraction: Use monolithic C18-silica disk centrifugal spin-cartridges (e.g., MonoSpin C18)

- Cartridge Pretreatment: Sequentially pass 500 µL of acetonitrile and 500 µL of water through the cartridge by centrifugation at 5,000 rpm (2,400×g) for 1 minute

- Sample Loading: Filter patient serum through a 0.45 µm syringe filter, load 150 µL onto the pretreated cartridge, and centrifuge for 3 minutes

- Washing: Pass 500 µL of water through the cartridge by centrifugation for 2 minutes

- Elution: Pass 150 µL of elution solution (aqueous 50% acetonitrile for most drugs; 30% for vancomycin) through the cartridge by centrifugation for 1 minute; collect the eluate for analysis

HPLC-UV Analysis:

- Column: Chromolith HighResolution RP-18 (100 mm × 4.6 mm i.d.)

- Mobile Phase: Varies by drug; typically gradient or isocratic mixtures of aqueous buffer and acetonitrile

- Column Temperature: 40°C

- Detection: Diode array detector with monitoring at drug-specific wavelengths (e.g., 220 nm for carbamazepine, 240 nm for voriconazole)

- Validation: Assess linearity, accuracy, precision, recovery, and limit of quantification according to ICH guidelines

Advanced Method Optimization with Experimental Design

A 2024 study on posaconazole quantification demonstrated the application of experimental design and machine learning for HPLC-UV method optimization [33]. The protocol included:

Chromatographic Optimization:

- Factor Evaluation: Assess five critical parameters (total organic phase %, methanol % in organic phase, mobile phase pH, column temperature, and flow rate) using a fractional 2-level factorial design

- Response Monitoring: Measure retention time, peak resolution, and peak symmetry

- Machine Learning Integration: Apply artificial neural networks (ANN) combined with genetic algorithms (GA) to identify optimal conditions

Extraction Optimization:

- Liquid-Liquid Extraction: Evaluate volume of extraction solvent, salt addition, pH, extraction time, and centrifugation time

- Recovery Assessment: Determine extraction efficiency for both drug and internal standard

The optimized method achieved a retention time of 8.2 minutes with recovery above 98%, demonstrating excellent sensitivity (LOQ: 50 ng/mL) using only 150 µL of plasma sample [33]. This approach illustrates how modern method development extends beyond traditional one-factor-at-a-time optimization to more efficient multivariate strategies.

Diagram 1: HPLC-UV Analytical Workflow. This flowchart illustrates the standardized workflow for HPLC-UV analysis, from sample preparation through data analysis.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential Materials for HPLC-UV Analysis in Pharmaceutical Research

| Category | Specific Examples | Function and Application Notes |

|---|---|---|

| SPE Cartridges | Monolithic C18-silica disk cartridges (e.g., MonoSpin C18) [30] | Rapid sample cleanup and concentration; suitable for small sample volumes (150 µL serum) |

| HPLC Columns | Chromolith HighResolution RP-18 (100 mm × 4.6 mm) [30]; Sepax BR-C18 (250 × 4.6 mm, 5 µm) [31] | Fast separations with low backpressure; suitable for pharmaceutical compounds |

| Mobile Phase Components | Acetonitrile (HPLC-grade), methanol, ammonium acetate, phosphate buffers, tetrabutylammonium bromide [30] [31] | Create optimal separation conditions; ion-pairing agents improve peak shape for ionizable compounds |

| Reference Standards | USP/EP certified reference standards for target analytes (e.g., carbamazepine, phenytoin, voriconazole) [30] | Method calibration and quality control; essential for quantitative accuracy |

| Internal Standards | Compound-specific stable isotopes or structural analogs (e.g., ciprofloxacin for levofloxacin analysis) [31] | Monitor extraction efficiency and account for procedural variations |

| STX-0119 | STX-0119, MF:C22H14N4O3, MW:382.4 g/mol | Chemical Reagent |

| Eplerenone-d3 | Eplerenone-d3, MF:C24H30O6, MW:417.5 g/mol | Chemical Reagent |

Guidance for Detector Selection: UV vs. DAD in Research Applications

Decision Framework for Detector Selection

Choosing between variable wavelength UV detectors and diode array detectors requires careful consideration of analytical requirements, budget constraints, and application scope. The following guidelines support informed decision-making:

Select Variable Wavelength UV Detection when:

- Analyzing known compounds with well-characterized absorbance maxima

- Performing routine quantitative analysis with established methods

- Working within budget constraints that preclude DAD acquisition

- Analyzing samples with minimal spectral interference from matrix components [12]

Opt for Diode Array Detection when:

- Developing new methods for unknown or complex samples

- Requiring peak purity assessment for method validation

- Analyzing compounds with potentially co-eluting interferents

- Needing spectral data for confirmatory identification

- Working with compounds having dissimilar absorbance spectra that can be distinguished spectrally [11]

Advanced DAD Applications and Capabilities

Modern diode array detectors offer capabilities extending beyond basic spectral collection. The i-PDeA (intelligent Peak Deconvolution Analysis) function available in some systems enables mathematical resolution of co-eluting peaks based on their spectral differences [11]. This advanced capability provides a powerful alternative to method redevelopment when complete chromatographic separation proves challenging.

For pharmaceutical applications, peak purity assessment represents a critical DAD application. By comparing spectra across different regions of a chromatographic peak, analysts can detect potential co-elution not apparent from the chromatographic profile alone [11]. This capability is particularly valuable for stability-indicating methods and impurity profiling, where the International Council for Harmonisation (ICH) guidelines require demonstrating specificity and the ability to detect degradants [12].

UV detection has maintained its pivotal role in HPLC analysis through continuous technological evolution that has expanded its capabilities while preserving its fundamental advantages of robustness, reproducibility, and accessibility. From its beginnings with fixed-wavelength detectors to contemporary diode array systems, UV detection has adapted to meet the changing demands of analytical science.

The enduring relevance of UV detection is particularly evident in pharmaceutical analysis and therapeutic drug monitoring, where its combination of precision, reliability, and cost-effectiveness continues to support both research and routine applications. While mass spectrometry offers superior sensitivity and specificity for certain applications, UV detection remains the undisputed workhorse for quality control laboratories, especially in regulatory environments where its proven reliability and quantitative precision are essential [12].

For researchers selecting detection strategies, the choice between conventional UV and DAD detection ultimately depends on specific application requirements, with diode array detectors offering clear advantages for method development and verification, while variable wavelength detectors remain sufficient for many routine quantitative applications. As HPLC continues to evolve, UV detection methodologies will likely maintain their central position in the analytical landscape, particularly through integration with advanced data processing techniques and experimental design approaches that maximize their information potential.

Strategic Applications: When to Deploy UV-Vis or UFLC-DAD for Maximum Impact

Within the analytical toolkit available to researchers and drug development professionals, selecting the appropriate technique is fundamental to efficiency and data quality. The choice often hinges on a balance between analytical needs, resource constraints, and time. This guide focuses on the ideal application of standalone UV-Vis spectroscopy for the quantitative analysis of pure compounds, positioning it within a broader methodology that includes more advanced techniques like Ultra-Fast Liquid Chromatography with Diode-Array Detection (UFLC-DAD). While UFLC-DAD offers superior separation for complex mixtures [7], standalone UV-Vis remains a powerful, cost-effective, and straightforward workhorse for specific, well-defined analytical challenges. Its principle, based on measuring the absorption of ultraviolet or visible light by a sample, provides a direct path to quantification when the analyte is known and free of interferents [1] [2]. Understanding its core strengths and limitations allows scientists to make informed decisions, streamlining workflows without compromising data integrity.

Fundamental Principles and Instrumentation of UV-Vis Spectroscopy

Core Mechanism: Electronic Transitions and the Beer-Lambert Law

The fundamental principle of UV-Vis spectroscopy involves the promotion of electrons in a molecule from a ground state to a higher energy, excited state upon absorbing specific wavelengths of light [2]. The energy required for this transition is unique to the molecular structure of the compound, resulting in a characteristic absorption spectrum [1]. This property is harnessed for quantification through the Beer-Lambert Law, which states that the absorbance (A) of a solution is directly proportional to the concentration (c) of the absorbing species and the path length (L) of the light through the sample [1].

The mathematical relationship is expressed as: A = ε * c * L where:

- A is the measured absorbance (unitless)

- ε is the molar absorptivity (L·molâ»Â¹Â·cmâ»Â¹)

- c is the concentration (mol·Lâ»Â¹)

- L is the path length (cm) [1]

This linear relationship is the cornerstone of quantitative UV-Vis analysis, enabling the determination of an unknown concentration from a measured absorbance value once the absorptivity is established using standard solutions [1].

Key Instrument Components

A UV-Vis spectrophotometer is composed of four main components that work in sequence:

- Light Source: Provides broad-spectrum UV and visible light. Common sources include deuterium lamps (UV) and tungsten or halogen lamps (visible light) [1] [2].

- Wavelength Selector: Typically a monochromator, which isolates a specific, narrow band of wavelengths from the broad-spectrum output of the lamp to probe the sample [1].

- Sample Container: A cuvette that holds the solution. For UV studies, quartz cuvettes are essential as they are transparent to UV light, whereas plastic and glass absorb strongly in this region [1].

- Detector: Measures the intensity of light passing through the sample and converts it into an electrical signal. Common detectors include photomultiplier tubes (PMTs), photodiodes, and charge-coupled devices (CCDs) [1].

Table 1: Key Components of a UV-Vis Spectrophotometer and Their Functions

| Component | Function | Common Types |

|---|---|---|

| Light Source | Emits continuous spectrum of UV/Vis light | Deuterium lamp, Tungsten/Halogen lamp |

| Wavelength Selector | Selects a specific wavelength | Monochromator, Absorption/Interference filters |

| Sample Container | Holds the sample solution for analysis | Quartz cuvette (UV), Glass/plastic cuvette (Vis) |

| Detector | Converts light intensity into electrical signal | Photomultiplier Tube (PMT), Photodiode |

Ideal Applications and Method Validation for Pure Compound Analysis

Standalone UV-Vis spectroscopy excels in applications where the target analyte is a single, well-defined pure compound dissolved in a solvent that does not absorb in the spectral region of interest. Its simplicity, speed, and low cost make it an ideal first-choice technique for several key quantitative tasks in research and development.

Exemplary Use Cases

- Pharmaceutical Quality Control: UV-Vis is extensively used for the assay of active pharmaceutical ingredients (APIs) in pure form. For instance, it can be deployed to quantify metoprolol tartrate in bulk substance analysis before formulation, providing a rapid check for content uniformity and potency [7].

- Concentration Verification in Research: In chemical and biochemical labs, it is the go-to method for determining the concentration of purified compounds, such as proteins, DNA, and RNA, based on their intrinsic absorbance (e.g., at 280 nm for proteins, 260 nm for nucleic acids) [1] [2].

- Beverage and Food Industry: It is robustly applied for quantifying specific additives or ingredients, such as caffeine content in beverages, where the matrix is relatively simple or can be easily prepared to isolate the analyte [34] [2].

- Environmental Monitoring: Online UV-Vis sensors are used to monitor parameters like nitrate concentration in drinking water, leveraging the fact that the water matrix is consistent and the target analyte has a distinct absorption profile [35].

Detailed Experimental Protocol: Quantifying a Pure Pharmaceutical Compound

The following protocol, inspired by the validation study for metoprolol tartrate, outlines a standard procedure for quantifying a pure API [7].

1. Instrument Calibration and Setup:

- Power on the UV-Vis spectrophotometer and allow the lamp to warm up for the time specified by the manufacturer (typically 15-30 minutes).

- Select the absorption mode and set the wavelength to the maximum absorbance (λmax) of the target compound. For metoprolol, this is 223 nm [7].

- Using a matched pair of quartz cuvettes (e.g., 1 cm path length), fill one with the pure solvent (water, buffer) to be used as the blank or reference.

2. Preparation of Standard Solutions:

- Accurately weigh a known quantity of the high-purity reference standard of the compound.

- Dissolve in the appropriate solvent to prepare a primary stock solution of known concentration (e.g., 100 µg/mL).

- Serially dilute the stock solution with the same solvent to prepare a calibration curve spanning a concentration range where absorbance is linear (e.g., 5-50 µg/mL). Ensure all solutions are homogeneous.

3. Sample Preparation:

- For a pure API, accurately weigh a portion of the sample and dissolve it in the same solvent used for the standard curve. The sample concentration should fall within the linear range of the calibration curve. If necessary, dilute the sample accordingly.

4. Data Acquisition and Analysis: