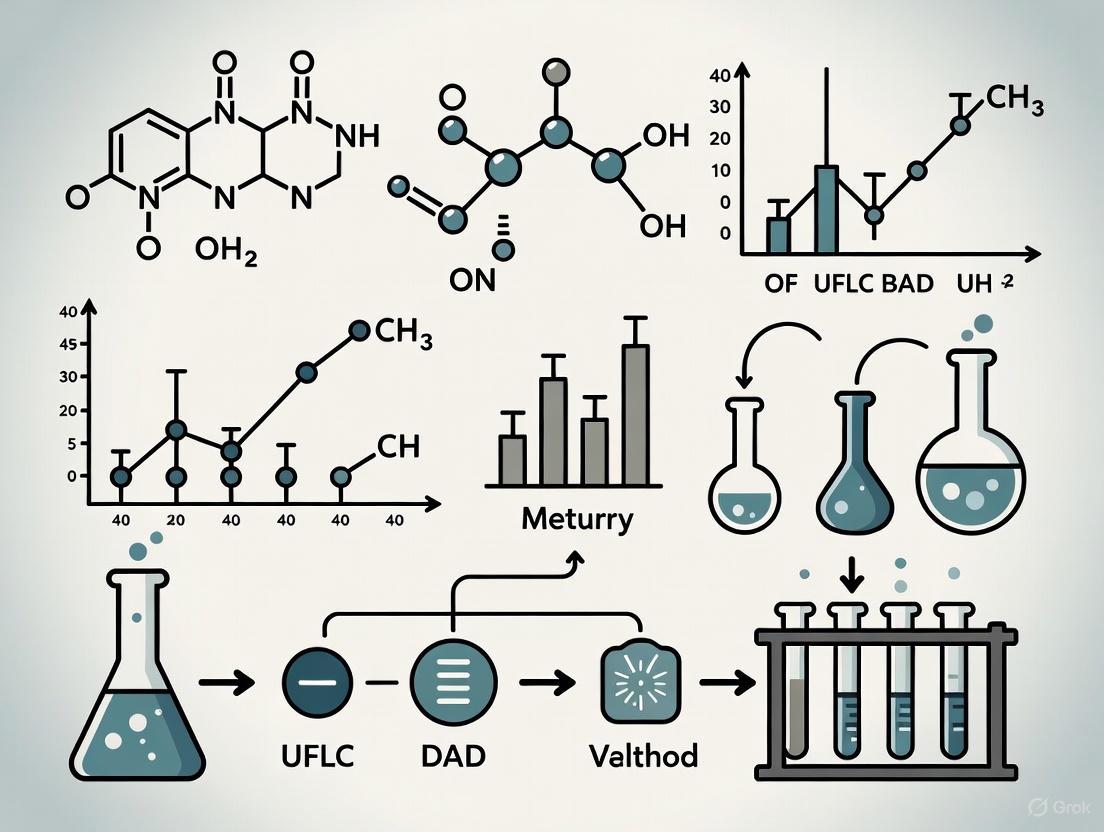

Validating UFLC-DAD Methods for Regulatory Compliance: A Guide to Development, Troubleshooting, and Submission

This article provides a comprehensive guide for researchers and drug development professionals on validating Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) methods to meet stringent global regulatory standards.

Validating UFLC-DAD Methods for Regulatory Compliance: A Guide to Development, Troubleshooting, and Submission

Abstract

This article provides a comprehensive guide for researchers and drug development professionals on validating Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) methods to meet stringent global regulatory standards. It covers foundational principles from ICH Q2(R1), FDA, and EMA guidelines, through method development and optimization, to systematic troubleshooting and comparative analysis with other techniques. The content is designed to help scientists ensure data integrity, avoid common compliance pitfalls highlighted in recent FDA 483 observations, and successfully navigate the regulatory submission process for pharmaceuticals.

UFLC-DAD and Regulatory Compliance: Mastering the Foundational Principles

Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) represents a significant evolution in analytical chromatography, striking an optimal balance between the high performance of UPLC and the practicality of conventional HPLC. This technique delivers substantially faster analysis times and improved resolution over traditional HPLC while maintaining greater method compatibility and cost-effectiveness compared to more demanding UPLC systems. For researchers and drug development professionals, UFLC-DAD offers a compelling platform for method development and validation, especially in regulatory environments that demand robust, reproducible, and efficient analytical methods. The integration of DAD provides additional spectral confirmation capability, enhancing method specificity for compliance with stringent regulatory standards.

UFLC is an advanced liquid chromatography technique that optimizes the conventional HPLC platform to achieve significantly faster analysis and improved resolution without transitioning to the ultra-high-pressure environment of UPLC. The defining characteristic of UFLC systems is their use of standard 3-5 µm particle size columns—identical to HPLC—but with system enhancements that allow operation at moderately elevated pressures up to approximately 600 bar (8,700 psi) [1]. This approach delivers performance improvements while maintaining compatibility with existing HPLC methods, facilitating smoother method transfers and validation processes.

The diode array detector (DAD) enhances the UFLC system by providing comprehensive spectral information for each analyte. Unlike single-wavelength detectors, DAD simultaneously monitors multiple wavelengths across the ultraviolet and visible spectrum, creating a unique spectral fingerprint for each compound. This capability is particularly valuable for peak purity assessment and method specificity—critical parameters in regulatory method validation [2]. When a potential co-eluting impurity is present, DAD can detect spectral inconsistencies within the chromatographic peak, providing a powerful tool for confirming analyte identity and purity in complex pharmaceutical matrices.

Comparative Performance Analysis: UFLC-DAD vs. HPLC and UPLC

Technical Specifications and Operational Parameters

Table 1: System Comparison - UFLC-DAD vs. HPLC vs. UPLC

| Parameter | HPLC | UFLC | UPLC |

|---|---|---|---|

| Full Name | High Performance Liquid Chromatography | Ultra-Fast Liquid Chromatography | Ultra-Performance Liquid Chromatography |

| Column Particle Size | 3–5 µm | 3–5 µm | ≤ 2 µm (typically 1.7 µm) |

| Pressure Limit | Up to ~400 bar (6,000 psi) | Up to ~600 bar (8,700 psi) | Up to ~1000 bar (15,000 psi) |

| Speed of Analysis | Moderate (10–30 min typical run time) | Faster than HPLC (5–15 min) | Very fast (1–10 min) |

| Resolution | Moderate | Improved compared to HPLC | High resolution due to smaller particle size |

| Sensitivity | Moderate | Slightly better than HPLC | High sensitivity |

| Instrument Cost | Lower | Moderate | Higher |

| Column Cost | Lower | Moderate | Higher (due to specialized packing) |

| Method Transfer Compatibility | High | High (uses same particle sizes as HPLC) | Lower (requires method re-development) |

Quantitative Performance Metrics

Table 2: Analytical Performance Comparison

| Performance Metric | HPLC with UV/DAD | UFLC-DAD | UPLC with DAD |

|---|---|---|---|

| Theoretical Plate Count | ~15,000-20,000 | ~20,000-30,000 | ~30,000-50,000 |

| Sample Throughput (samples/day) | 20-40 | 40-80 | 80-150 |

| Solvent Consumption (per analysis) | 5-10 mL | 2-5 mL | 1-3 mL |

| Carryover | <0.1% | <0.05% | <0.01% |

| Detection Wavelength Range | 190-800 nm | 190-800 nm | 190-800 nm |

| Spectral Acquisition Rate | Up to 80 Hz | Up to 100 Hz | Up to 120 Hz |

| Peak Capacity | 100-200 | 150-250 | 200-400 |

UFLC-DAD's performance advantages stem from system optimizations that reduce extra-column band broadening and dwell volume, allowing more efficient separation even with conventional particle sizes [3]. The Van Deemter equation demonstrates that smaller particles provide optimal efficiency at higher linear velocities, but UFLC achieves practical improvements through holistic system design rather than solely relying on particle size reduction [4].

Experimental Validation Protocols for Regulatory Compliance

Method Validation Parameters for UFLC-DAD

For regulatory acceptance, UFLC-DAD methods must undergo comprehensive validation following ICH guidelines (Q2(R1)). The validation protocol should establish method suitability for its intended purpose through the following parameters [2]:

Specificity and Selectivity: Demonstrate accurate analyte measurement in the presence of potential interferents (excipients, impurities, degradation products). DAD enables peak purity assessment through spectral overlay and match factor calculations. A purity match factor >990 indicates no detectable co-elution.

Linearity and Range: Prepare analyte solutions across the analytical method range (typically 50-150% of target concentration). The correlation coefficient (r) should be >0.999, and the y-intercept should not significantly differ from zero.

Accuracy: Assess through recovery studies using spiked samples at three concentration levels (80%, 100%, 120%). Mean recovery should be within 98-102% with RSD <2%.

Precision: Includes repeatability (intra-day, n=6) and intermediate precision (inter-day, different analysts/instruments). RSD for peak areas should be <1% for repeatability and <2% for intermediate precision.

Robustness: Deliberately vary method parameters (flow rate ±0.1 mL/min, column temperature ±2°C, mobile phase pH ±0.1 units) to demonstrate method resilience. System suitability criteria must be maintained across all variations.

System Suitability Testing Protocol

System suitability tests verify that the complete UFLC-DAD system performs adequately at the time of analysis. The following protocol should be executed before each analytical run:

Preparation of System Suitability Solution: Prepare a standard solution containing the target analyte and known impurities at specified concentrations.

Chromatographic Conditions:

- Column: C18, 150 × 4.6 mm, 3-5 µm

- Mobile Phase: As per validated method (typically gradient or isocratic)

- Flow Rate: 1.0-2.0 mL/min (UFLC-optimized)

- Column Temperature: 30-40°C

- Detection: DAD at primary and secondary wavelengths

- Injection Volume: 5-20 µL

Acceptance Criteria:

- Theoretical plates: >2000 for the analyte peak

- Tailing factor: <2.0

- Repeatability: RSD of peak areas for 6 replicate injections <1%

- Resolution: >2.0 between analyte and closest eluting impurity

- Spectral Purity: Match factor >990 for analyte peak across multiple wavelengths

Application in Pharmaceutical Analysis and Regulatory Submissions

UFLC-DAD has proven particularly valuable in pharmaceutical analysis where regulatory compliance and method robustness are paramount. The technique successfully balances the need for improved efficiency with the practical requirements of quality control laboratories. Specific applications include:

Stability-Indicating Methods: UFLC-DAD's enhanced resolution enables effective separation of drug substances from degradation products, while DAD spectral analysis confirms peak purity and identifies potential co-elution [2].

Forced Degradation Studies: The rapid analysis time of UFLC (5-15 minutes compared to 10-30 minutes for HPLC) significantly increases throughput for extensive forced degradation studies required in regulatory submissions [1].

Method Transfer to QC Laboratories: UFLC methods transfer more easily to quality control environments than UPLC methods, as they utilize conventional particle sizes and operate at moderate pressures compatible with most HPLC systems [1].

Regulatory agencies including the FDA and EMA recognize the importance of analytical method lifecycle management [5]. UFLC-DAD methods support this approach by providing robust separation that remains stable over the method's lifetime, with DAD serving as a diagnostic tool to detect chromatographic performance issues before they impact data quality.

Essential Research Reagents and Materials

Table 3: Essential Research Reagents for UFLC-DAD Method Development

| Reagent/Material | Function | Specifications for Regulatory Compliance |

|---|---|---|

| Chromatography Column | Stationary phase for compound separation | C18, 150 × 4.6 mm, 3-5 µm particle size; Column efficiency >15,000 plates/meter |

| Mobile Phase Solvents | Carrier for analytes through the system | HPLC-grade water, acetonitrile, or methanol; filtered through 0.45µm membrane |

| Buffer Salts | Mobile phase modifiers for pH control | High-purity ammonium formate/acetate, phosphate buffers; prepared daily for reproducibility |

| Reference Standards | Method calibration and qualification | Certified reference materials with purity >95%; stored under recommended conditions |

| System Suitability Mixture | Verification of instrument performance | Contains analyte and critical impurities at specified levels to test resolution, efficiency |

| Quality Control Samples | Assessment of method accuracy and precision | Prepared in matrix at low, medium, and high concentrations within the calibration range |

Strategic Implementation in Regulatory Environments

The selection of UFLC-DAD for pharmaceutical analysis represents a strategic compromise that addresses both technical and practical considerations in regulatory compliance. While UPLC offers superior performance metrics, UFLC-DAD provides significant improvements over conventional HPLC while maintaining broader accessibility and easier method validation. This balance is particularly valuable in these scenarios:

Regulatory Method Transfer: Methods developed using UFLC-DAD transfer more readily to quality control laboratories that may not have UPLC capability, reducing implementation barriers [1].

Supply Chain Continuity: Columns and consumables for UFLC (using 3-5µm particles) face fewer supply chain constraints than sub-2µm UPLC columns, ensuring consistent method performance over the product lifecycle.

Data Integrity: UFLC-DAD systems provide comprehensive spectral data that supports result verification and enhances data integrity—a key focus in current FDA guidance [5].

For drug development professionals, UFLC-DAD represents a practical platform for method development that can be successfully validated to meet ICH requirements while providing the speed and sensitivity needed for modern pharmaceutical analysis.

This guide provides a comparative analysis of the core regulatory guidelines governing the validation of analytical methods, with a specific focus on Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD). For researchers in drug development, understanding the alignment and nuances between the International Council for Harmonisation (ICH) Q2(R1), the U.S. Food and Drug Administration (FDA), and the European Medicines Agency (EMA) is crucial for ensuring global regulatory compliance [6] [7].

Analytical method validation demonstrates that a laboratory procedure is suitable for its intended purpose, ensuring the reliability, accuracy, and consistency of data used to assess the identity, strength, quality, and purity of drug substances and products [6] [7]. Regulatory bodies worldwide have established guidelines to standardize this process.

The International Council for Harmonisation (ICH) plays a pivotal role in harmonizing technical requirements across the European Union, Japan, the United States, and other regions. The ICH Q2(R1) guideline, titled "Validation of Analytical Procedures: Text and Methodology," is the global benchmark [8] [7]. It defines the core validation parameters and their methodologies. The U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) are key regulatory authorities that adopt and implement these ICH guidelines, making compliance with ICH Q2(R1) a primary path to meeting FDA and EMA requirements for market approval [6] [7]. Recently, the ICH has modernized its approach with the simultaneous release of Q2(R2) on validation and Q14 on analytical procedure development, emphasizing a science- and risk-based lifecycle management model; however, the foundational principles of Q2(R1) remain deeply embedded in current regulatory thinking [7].

For UFLC-DAD methods, which offer high-resolution separation and quantification of analytes in complex matrices, rigorous validation is indispensable. Adhering to these guidelines is not merely a regulatory formality but a fundamental component of pharmaceutical quality control and patient safety [6].

Comparative Analysis of ICH, FDA, and EMA Guidelines

The ICH Q2(R1) guideline establishes the universal definitions and methodologies for validating analytical procedures. The FDA and EMA, as adopting authorities, largely align with its principles. The following table summarizes the core validation parameters as defined by ICH Q2(R1) and their application in a regulatory context.

Table 1: Core Analytical Method Validation Parameters as per ICH Q2(R1)

| Validation Parameter | ICH Q2(R1) Definition | Application in UFLC-DAD Method Validation | FDA & EMA Alignment |

|---|---|---|---|

| Accuracy | The closeness of agreement between the accepted reference value and the value found [8] [7]. | Assessed by spiking a sample matrix with known concentrations of the analyte and measuring recovery percentages (e.g., 95-101%) [9]. | Directly adopted by both agencies as a primary requirement [7] [10]. |

| Precision | The degree of agreement among individual test results when the procedure is applied repeatedly to multiple samplings of a homogeneous sample. Includes repeatability, intermediate precision, and reproducibility [8] [7]. | Measured as repeatability (intra-day) and intermediate precision (inter-day, different analysts) with %RSD of ≤2-4% for retention times and peak areas [9] [11]. | Fully required by FDA and EMA; intermediate precision is critical for demonstrating lab robustness [6] [10]. |

| Specificity | The ability to assess unequivocally the analyte in the presence of components that may be expected to be present (e.g., impurities, matrix) [8] [7]. | Demonstrated by baseline separation of all analytes (resolution >1.5) and no interference from blank matrix at analyte retention times [9] [11]. | A mandatory parameter for all chromatographic methods to prove the method is measuring the intended analyte alone [7]. |

| Linearity | The ability of the method to obtain test results that are directly proportional to the analyte concentration within a given range [8] [7]. | A linear calibration curve (e.g., R² ≥ 0.999) is established over the specified range for each analyte [11] [12]. | Required by all regulatory submissions to prove the method's quantitative capability [10]. |

| Range | The interval between the upper and lower concentrations of analyte for which suitable levels of linearity, accuracy, and precision have been demonstrated [8] [7]. | Defined from the LOQ to 120-150% of the expected sample concentration, ensuring all potential results fall within the validated interval [9]. | The validated range must encompass all possible sample concentrations for release and stability testing [6]. |

| Limit of Detection (LOD) | The lowest amount of analyte in a sample that can be detected, but not necessarily quantified [8] [7]. | Typically determined from a signal-to-noise ratio of 3:1 from chromatographic data [11]. | Required for impurity identification methods; for assays, the LOQ is more critical [10]. |

| Limit of Quantification (LOQ) | The lowest amount of analyte in a sample that can be quantitatively determined with acceptable precision and accuracy [8] [7]. | Typically determined from a signal-to-noise ratio of 10:1 and confirmed by acceptable precision and accuracy at that level [11]. | A key parameter for impurity quantification and trace analysis; must be demonstrated with data [7]. |

| Robustness | A measure of the method's capacity to remain unaffected by small, deliberate variations in method parameters [8] [7]. | Evaluated by testing the impact of small changes in factors like pH of mobile phase (±0.2), flow rate (±0.1 mL/min), and column temperature (±2°C) [9] [11]. | Strongly emphasized by FDA and EMA; a robust method ensures reliability during routine use and transfers between labs [6] [7]. |

Key Alignments and Practical Emphasis

As evidenced in the table, the core parameters defined in ICH Q2(R1) form the basis for both FDA and EMA requirements [7]. The recent modernization with ICH Q2(R2) and Q14 reinforces a science- and risk-based approach, encouraging the use of structured experimentation like Design of Experiments (DoE) during method development to proactively understand method robustness [7].

While the parameters are harmonized, the practical emphasis during regulatory inspections can differ. The FDA often emphasizes a lifecycle approach to validation, closely linking it to risk management as outlined in ICH Q9 [6] [7]. The EMA equally stresses the importance of robustness and the scientific justification for the chosen validation strategy [6]. Therefore, the selection of a validation guideline should be primarily dictated by the product's target market, and using a guideline mismatched to the region (e.g., submitting EMA-style data to the FDA) can lead to rejection or requests for revalidation [6].

Experimental Protocols for Validating a UFLC-DAD Method

The following section outlines a detailed experimental protocol for developing and validating a UFLC-DAD method for the simultaneous determination of multiple analytes, incorporating principles from ICH Q2(R1) and modern quality-by-design approaches.

Method Development and Optimization

Objective: To establish optimal chromatographic conditions for the complete separation of all target analytes with a short run time.

Materials:

- UFLC System: Binary pump, auto-sampler, column oven, and Diode Array Detector (DAD).

- Analytical Column: Reversed-phase C18 column (e.g., 150 mm x 4.6 mm, 2.7 µm).

- Reagents: HPLC-grade water, acetonitrile, methanol, and buffer salts (e.g., potassium dihydrogen phosphate).

- Standards: Certified reference standards of all target analytes.

Workflow:

- Sample Preparation: Prepare stock solutions of each analyte and a mixed standard solution in an appropriate solvent (e.g., water-methanol 50:50 v/v) [9].

- Detection Wavelength Selection: Using the DAD, acquire UV-Vis spectra (e.g., 190-350 nm) for each analyte standard. Select a wavelength that offers good sensitivity for all compounds, or use multiple wavelengths for different analytes during the run [9].

- Systematic Optimization with DoE: Instead of a one-factor-at-a-time approach, use an experimental design like a Box-Behnken Design (BBD) to efficiently optimize critical method parameters [9] [11]. Key factors to investigate include:

- Factor A: Initial composition of organic modifier in the mobile phase (e.g., 0-10% methanol).

- Factor B: Final composition of organic modifier in the gradient program (e.g., 60-100% methanol).

- Factor C: pH of the aqueous mobile phase (e.g., 3-7) [9].

- Multi-Response Optimization: The responses (e.g., chromatographic resolution between all peak pairs and total analysis time) are simultaneously optimized using Response Surface Methodology (RSM) and a Desirability Function (DF). This statistical approach identifies a single set of robust conditions that meet all separation goals [9].

Table 2: Research Reagent Solutions for UFLC-DAD Method Validation

| Item | Function in UFLC-DAD Analysis |

|---|---|

| Reverse-Phase C18 Column | The stationary phase for separating analytes based on their hydrophobicity. A core component of the chromatographic system [9] [12]. |

| HPLC-Grade Solvents (Acetonitrile/Methanol) | The organic modifiers in the mobile phase that control the elution strength and separation efficiency [9] [11]. |

| Buffer Salts (e.g., Phosphate, Ammonium Acetate) | Used to prepare the aqueous mobile phase. They control pH and ionic strength, which is critical for achieving peak symmetry and controlling the retention of ionizable analytes [9] [13]. |

| Analytical Reference Standards | Highly purified substances used to confirm the identity and quantity of analytes. They are essential for constructing calibration curves and determining method accuracy [9] [12]. |

| Derivatization Reagent (e.g., Fmoc-Cl) | For compounds like amino acids that lack a strong chromophore, derivatization is used to introduce a UV-absorbing group, enabling their detection by DAD [12]. |

Detailed Validation Experiments

Once the method is developed, a formal validation study is conducted.

1. Specificity Protocol: Inject a blank solvent, individual analyte standards, and a mixture of all standards. The method is specific if the blank shows no interference at the retention times of the analytes, and all analytes are baseline resolved (Resolution > 1.5) [11]. For methods analyzing complex matrices, a placebo sample should also be injected to confirm no matrix interference.

2. Linearity and Range Protocol: Prepare a minimum of five standard solutions at different concentrations spanning the expected range (e.g., from LOQ to 150% of the target concentration). Inject each solution in triplicate. Plot the peak area versus the concentration and perform linear regression analysis. The correlation coefficient (R²) should be ≥ 0.999 [11] [12].

3. Accuracy (Recovery) Protocol: Spike a known amount of analyte into a placebo or sample matrix at three concentration levels (e.g., 80%, 100%, 120% of the target). Analyze these samples and calculate the percentage recovery of the analyte. Mean recovery should be within 95-105% [9] [11].

4. Precision Protocol:

- Repeatability (Intra-day): Analyze six independent samples at 100% of the test concentration on the same day by the same analyst. Calculate the %RSD of the peak areas and retention times. %RSD should be ≤ 2% for retention time and ≤ 4% for area [9] [11].

- Intermediate Precision (Inter-day): Repeat the repeatability experiment on a different day, with a different analyst, and/or on a different instrument. The combined precision data should also meet the predefined criteria [7] [10].

5. LOD and LOQ Protocol: Based on signal-to-noise ratio, inject a series of diluted standards and determine the concentrations that yield an S/N of 3:1 for LOD and 10:1 for LOQ. The LOQ should be confirmed by analyzing six replicates at that level and demonstrating an acceptable precision (e.g., %RSD ≤ 5%) and accuracy [11].

6. Robustness Protocol: Deliberately introduce small, deliberate variations in method parameters according to a predefined plan (e.g., a factorial design). Typical variations include:

- Flow rate: ± 0.1 mL/min

- Mobile phase pH: ± 0.2 units

- Column temperature: ± 2°C

- Gradient program: ± 2% absolute change in organic modifier The system suitability parameters (e.g., resolution, tailing factor) are monitored to ensure they remain within specifications under all conditions [9] [11].

Visualizing the Method Validation Lifecycle

The following diagrams illustrate the interconnected workflow of method development and the modern, lifecycle-oriented validation process.

Diagram 1: Analytical Procedure Lifecycle Workflow. This chart outlines the key stages from initial definition through development, validation, and ongoing lifecycle management, as reinforced by ICH Q14 and Q2(R2).

Diagram 2: Core Validation Parameters defined in ICH Q2(R1). This hierarchy shows the fundamental performance characteristics that must be validated for a quantitative chromatographic method like UFLC-DAD.

The regulatory landscape for analytical method validation is firmly rooted in the harmonized principles of ICH Q2(R1), which are consistently applied by the FDA and EMA. For scientists developing UFLC-DAD methods, a deep understanding of these core parameters—accuracy, precision, specificity, linearity, range, LOD, LOQ, and robustness—is non-negotiable. The trend is moving toward a more proactive, science-based paradigm, as seen with ICH Q2(R2) and Q14, which encourage the use of structured development (e.g., DoE) and a full lifecycle approach. Success in regulatory compliance research hinges on meticulously documented validation that not only checks all the parameter boxes but also demonstrates a deep, scientifically sound understanding of the method's performance and limitations.

The development of Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) methods is a cornerstone of modern pharmaceutical analysis, enabling the precise quantification of active pharmaceutical ingredients (APIs), impurities, and degradation products. However, the mere development of a method is insufficient for regulatory acceptance. Method validation provides the documented evidence that an analytical procedure is suitable for its intended purpose, ensuring the reliability, consistency, and accuracy of data used to make critical decisions about drug safety and quality. For researchers and drug development professionals, adherence to the harmonized guidelines established by the International Council for Harmonisation (ICH) is not merely a best practice but a regulatory necessity for compliance and product approval [14].

The ICH Q2(R1) guideline, "Validation of Analytical Procedures," serves as the primary international standard, defining the key parameters that must be evaluated [14]. Similarly, the United States Pharmacopeia (USP) general chapter <1225>, "Validation of Compendial Procedures," provides a complementary framework, categorizing analytical procedures and specifying validation requirements based on the test's purpose [14]. This article will deconstruct five of these critical validation parameters—Specificity, Linearity, Range, Accuracy, and Precision—within the context of UFLC-DAD analysis. By examining recent, applied research, we will illustrate how these parameters are defined, experimentally determined, and interpreted to demonstrate method robustness for regulatory compliance.

Deconstructing the Core Validation Parameters

Specificity

Specificity is the ability of a method to assess the analyte unequivocally in the presence of other components that may be expected to be present, such as impurities, degradation products, or matrix components [14]. For UFLC-DAD methods, this translates to chromatographic resolution and peak purity.

Experimental Protocol: Specificity is typically demonstrated by injecting blank matrices, placebo formulations, and samples spiked with known impurities and degradation products. The method must show that the analyte peak is free from interference and that any critical peak pairs, such as an impurity eluting near the main compound, are baseline-resolved. Forced degradation studies, where the API is stressed under conditions like acid/base hydrolysis, oxidation, and thermal stress, are a core part of specificity validation [15] [16]. The DAD detector is a powerful tool here, as it can confirm peak purity by comparing spectra across the peak, ensuring it originates from a single compound [17].

Supporting Data: A study on carglumic acid demonstrated specificity by successfully separating the API from its known impurities (e.g., HPA, pyroglutamic acid) and degradation products formed under various stress conditions [15]. Similarly, a UHPLC-DAD method for perindopril l-arginine proved its specificity by resolving the cis and trans isomers of the drug and showing that the peaks of interest were non-interfered with by excipients or degradation products generated from forced degradation [16].

Linearity and Range

Linearity defines the ability of a method to obtain test results that are directly proportional to the concentration of the analyte within a given range. The Range is the interval between the upper and lower concentration levels of the analyte for which suitable levels of precision, accuracy, and linearity have been demonstrated [14].

Experimental Protocol: Linearity is established by preparing and analyzing a series of standard solutions at a minimum of five concentration levels. The peak response (e.g., area) is plotted against the concentration, and the data is evaluated by linear regression analysis. The resulting correlation coefficient (R²) is a key indicator, often required to be greater than 0.999 for assay methods [18]. The range is established from this data, ensuring it encompasses the entire scope of the method's intended use, from the limit of quantitation (LOQ) for impurities to 120% of the test concentration for assay.

Supporting Data: A UHPLC-DAD method for 38 polyphenols in applewood extract exhibited "excellent linearity (R² > 0.999) for all 38 polyphenols" across their respective ranges [18]. In the development of a method for carglumic acid, the linearity was confirmed over a specified range, and the LOD and LOQ were determined to be 0.7 and 0.15 μg/mL, respectively, defining the lower end of the method's capability [15].

Accuracy

Accuracy expresses the closeness of agreement between the value found and the value accepted as a true or reference value. It is typically reported as percent recovery of the known amount of analyte spiked into the sample matrix [14].

Experimental Protocol: Accuracy is determined by spiking the analyte into a blank matrix or placebo formulation at multiple concentration levels (e.g., 80%, 100%, 120% of the target concentration) in replicate (n=3 or more). The recovered amount is calculated using the method's calibration curve and compared to the spiked amount. Recovery percentages are then calculated, with acceptable criteria often set between 98% and 102% for API assays.

Supporting Data: The polyphenol method achieved accuracy with recovery rates "ranging between 95.0 % and 104 %" [18]. Another study validating a UHPLC-DAD method for melatonin in dietary supplements determined accuracy using the "total error approach," which combines systematic and random error to provide a rigorous assessment of method trueness and precision, a requirement for ISO17025 compliance [17].

Precision

Precision refers to the closeness of agreement between a series of measurements obtained from multiple sampling of the same homogeneous sample under prescribed conditions. It is further subdivided into repeatability (intra-day precision), intermediate precision (inter-day, inter-analyst, inter-equipment), and reproducibility [14].

Experimental Protocol:

- Repeatability is assessed by analyzing multiple preparations (n=6) of a homogeneous sample at 100% of the test concentration within the same day and by the same analyst.

- Intermediate Precision is demonstrated by repeating the analysis on a different day, with a different analyst, or on a different instrument within the same laboratory. The results are expressed as the relative standard deviation (RSD %) of the measured concentrations or peak areas.

Supporting Data: The UHPLC-DAD method for polyphenols demonstrated high precision, with "both inter- and intraday precision showing a variation coefficient lower than 5 %" [18]. The carglumic acid method also confirmed precision as part of its ICH Q2(R1) validation, ensuring the method produced consistent results [15].

Table 1: Summary of Key Validation Parameters and Typical Acceptance Criteria for UFLC-DAD Assay Methods

| Validation Parameter | Experimental Approach | Typical Acceptance Criteria | Exemplary Data from Literature |

|---|---|---|---|

| Specificity | Chromatographic resolution (Rs) and peak purity via DAD from forced degradation studies [16]. | No interference; Rs ≥ 2.0 for critical pairs; peak purity angle < threshold [17]. | Baseline separation of cis/trans perindopril isomers and degradation products [16]. |

| Linearity | Minimum of 5 concentration levels, linear regression analysis [14]. | Correlation coefficient (R²) > 0.999 [18]. | R² > 0.999 for 38 polyphenols [18]. |

| Range | Established from linearity data to encompass intended use. | From LOQ to 120% of test concentration for assay. | LOD/LOQ of 0.7/0.15 μg/mL for carglumic acid defining lower range [15]. |

| Accuracy | Spike/recovery at 3 levels (80%, 100%, 120%) in replicate. | Recovery of 98–102% for API assay [14]. | Recovery of 95.0–104% for polyphenols [18]. |

| Precision (Repeatability) | Six replicate injections at 100% concentration. | RSD ≤ 1.0% for API assay [14]. | Inter-/intra-day RSD < 5% for polyphenols [18]. |

Experimental Protocols for UFLC-DAD Method Validation

Workflow for a Validation Study

The following diagram illustrates the logical sequence and key decision points in a typical analytical method validation workflow.

Case Study: Validation of a Stability-Indicating Method

A study on perindopril l-arginine provides a clear protocol for validating a stability-indicating UFLC-DAD method [16].

Chromatographic Conditions:

- Column: Poroshell 120 Hilic (4.6 × 150 mm, 2.7 µm)

- Mobile Phase: Acetonitrile–0.1% formic acid (20:80 v/v)

- Flow Rate: 1.0 mL/min

- Detection: DAD at 230 nm

- Temperature: 25 °C

Specificity Protocol: The specificity was confirmed by subjecting the drug substance to stress conditions including acid and base hydrolysis (1M HCl/NaOH at 80°C), oxidation (10% H₂O₂ at 80°C), and thermal degradation at high humidity (76.4% RH at 80°C) and in dry air (0% RH at 100°C). The method successfully separated the two isomers of perindopril (cis/trans) from degradation products, with peak purity confirmed by the DAD, proving its stability-indicating capability [16].

Accuracy and Precision Protocol: The accuracy was determined by spiking a placebo (talc) with perindopril l-arginine at 80%, 100%, and 120% of the label claim. The recovery was calculated for both the bulk substance and the pharmaceutical dosage form. Precision (repeatability) was assessed by analyzing six replicates at each of the three concentration levels, and the RSD was reported, meeting ICH precision criteria [16].

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table details key materials and reagents commonly used in the development and validation of UFLC-DAD methods, as evidenced in the cited research.

Table 2: Key Research Reagent Solutions for UFLC-DAD Method Development and Validation

| Item | Function & Purpose | Exemplary Use in Literature |

|---|---|---|

| High-Purity Analytical Standards | To create calibration curves for linearity, accuracy, and as a reference for specificity. | Carglumic acid and its impurity standards (HPA, pyrocarglumic acid) from Nuray Chemicals [15]. |

| HPLC/UHPLC Grade Solvents | To prepare mobile phases and sample solutions, ensuring minimal UV background noise and consistent chromatographic performance. | Acetonitrile (LiChrosolv) and ortho-Phosphoric acid (LiChropur) from Merck used for carglumic acid method [15]. |

| Buffering Salts (e.g., KH₂PO₄) | To control mobile phase pH, which is critical for achieving peak symmetry and resolving ionizable compounds. | 10 mM potassium dihydrogen phosphate buffer, pH-adjusted to 2.4, used in carglumic acid separation [15]. |

| Characterized Placebo Formulation | To assess specificity and accuracy by confirming no interference from excipients and determining analyte recovery in the matrix. | Talc used as a placebo to determine accuracy of perindopril l-arginine method [16]. |

| Forced Degradation Reagents | To intentionally degrade the API and demonstrate the method's stability-indicating properties (specificity). | HCl, NaOH, H₂O₂ used for acid/base hydrolysis and oxidative stress studies [16]. |

The rigorous validation of UFLC-DAD methods is a non-negotiable pillar of pharmaceutical development and quality control. As demonstrated through multiple applied studies, the parameters of specificity, linearity, range, accuracy, and precision form an interconnected framework that provides regulatory bodies with the documented evidence required for compliance. The experimental protocols, grounded in ICH Q2(R1) and USP <1225>, are designed to challenge the method and prove its reliability under a variety of conditions. For today's pharmaceutical researcher, a deep and practical understanding of these parameters is not just about passing a regulatory audit—it is about ensuring that every data point generated truly reflects the quality, safety, and efficacy of the medicinal products that reach patients.

The Role of System Suitability in GMP and GLP Environments

System suitability testing (SST) serves as a critical bridge between rigorous regulatory frameworks and reliable analytical data. In both Good Manufacturing Practice (GMP) and Good Laboratory Practice (GLP) environments, it provides documented evidence that a chromatographic system is capable of performing the intended analysis at a specific point in time. This verification is fundamental to ensuring the integrity, accuracy, and reliability of data used in product quality assessment and nonclinical safety studies [19] [20].

For researchers and drug development professionals, establishing a robust system suitability protocol is not merely a regulatory checkbox but a core component of a valid analytical procedure. It confirms that the entire system—from the solvent delivery to the detection—is operating within predefined performance limits before, during, and after a sequence of analytical runs [19]. This is especially crucial for Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) methods, where method robustness and data quality are paramount for regulatory compliance.

System Suitability Parameters and Regulatory Acceptance Criteria

System suitability verifies chromatographic performance through a set of key parameters. Each parameter assesses a different aspect of system performance, and together, they provide a comprehensive picture of system health.

The table below summarizes the core parameters, their definitions, and typical acceptance criteria as required in pharmaceutical analysis [19] [21].

| Parameter | Definition & Purpose | Typical Acceptance Criteria |

|---|---|---|

| Resolution (Rs) | Measures the separation between two adjacent peaks. Critical for ensuring accurate quantitation of individual components. | Rs ≥ 1.5 [21] |

| Tailing Factor (T) | Assesses the symmetry of a chromatographic peak. Peak tailing can affect accuracy and precision. | T ≤ 2.0 [21] |

| Theoretical Plates (N) | Indicates the efficiency of the chromatographic column. A higher number signifies better column performance. | N > 2000 [21] |

| Precision/Repeatability | Evaluates the agreement between replicate injections, typically measured by Relative Standard Deviation (RSD). | RSD ≤ 2% for n=5 or 6 injections [21] |

| Signal-to-Noise Ratio (S/N) | Determines the sensitivity of the system and its ability to detect low-abundance analytes, crucial for impurity testing. | S/N ≥ 10 for quantitation (LOQ) [19] |

The formulas for calculating these parameters are standardized. For instance, resolution is calculated as ( RS=\frac {tRB – tRA}{0.5 (WA + W_B) } ), where ( tR ) is retention time and ( W ) is peak width at baseline [21]. The tailing factor ( T ) is calculated as ( T = \frac {a+b}{2a} ), where 'a' and 'b' are the peak widths at 5% of peak height [21].

Experimental Protocols for System Suitability Testing

A typical system suitability test is integrated into the analytical run sequence. The following workflow outlines a standard protocol for validating a UFLC-DAD method:

Detailed Methodology for a Comparative UHPLC-DAD Study

A published study on the development and validation of methods for guanylhydrazones with anticancer activity provides a concrete example of an experimental protocol incorporating SST [22]. The research directly compared a traditional High-Performance Liquid Chromatography (HPLC) method with an optimized Ultra-High-Performance Liquid Chromatography (UHPLC) method, which is analogous to UFLC.

- Instrumentation and Columns: The HPLC system used a conventional C18 column, while the UHPLC system employed a column with sub-2µm particles capable of withstanding high pressures [22].

- Chromatographic Conditions:

- HPLC: A mobile phase of methanol-water (60:40, v/v) at pH 3.5 (adjusted with acetic acid) was used at a flow rate of 1.0 mL/min.

- UHPLC: The method was optimized using a factorial design of experiments (DoE), evaluating factors like temperature, mobile phase composition, and pH to establish optimal conditions more efficiently and rationally than the traditional empirical approach used for HPLC [22].

- System Suitability and Method Validation: The methods were validated per International Council for Harmonisation (ICH) guidelines. System suitability was confirmed by assessing parameters including specificity, precision, and robustness. The precision for both methods was demonstrated with intra-day and inter-day Relative Standard Deviation (RSD) values below 2.0% for all analytes, meeting standard acceptance criteria [22].

Performance Comparison: HPLC vs. UHPLC/UFLC

The transition from HPLC to UHPLC/UFLC technologies is driven by demonstrable gains in performance, which are reflected in system suitability outcomes. The study on guanylhydrazones provides quantitative data for a direct comparison [22].

The table below summarizes the key performance metrics from the comparative study, illustrating the advantages of UHPLC/UFLC.

| Performance Metric | HPLC Method Performance | UHPLC/UFLC Method Performance | Implication for Analytical Testing |

|---|---|---|---|

| Analysis Speed | Retention times: 2.18 to 5.08 minutes [22] | Significantly shorter run times (data implied) | Higher sample throughput |

| Solvent Consumption | Baseline volume for method | ~4 times less consumption [22] | Reduced cost and environmental impact |

| Injection Volume | Standard volume for method | ~20 times less volume [22] | Preservation of limited samples |

| Signal Quality | Peak areas for 10 µg/mL: ~58,046 to ~101,134 [22] | Comparable or improved precision with lower RSD [22] | Enhanced data quality and confidence |

| Method Development | Empirical (trial-and-error) | Rational (Factorial Design of Experiments) [22] | More robust and optimized methods |

The UHPLC method demonstrated clear economic and performance benefits, including a four-fold reduction in solvent consumption and the ability to use a 20 times smaller injection volume, which is critical for sample-limited analyses [22]. Furthermore, the use of a factorial design for UHPLC method development made the process "faster, more practical and rational" compared to the empirical approach used for HPLC [22].

The Scientist's Toolkit: Essential Reagents and Materials

Conducting reliable system suitability tests requires high-quality materials. The following table lists key research reagent solutions and their functions in the context of UFLC-DAD method validation.

| Item | Function in System Suitability |

|---|---|

| System Suitability Standard | A certified reference material or well-characterized mixture used to verify system performance parameters like resolution, plate count, and tailing [21]. |

| Ultra-Pure Mobile Phase Solvents | High-purity solvents (water, acetonitrile, methanol) are essential to minimize baseline noise and ghost peaks, ensuring an accurate Signal-to-Noise ratio [19]. |

| Certified Reference Standards | Pure analytes of interest used for preparing calibration standards and for accuracy and precision studies during method validation [22]. |

| pH Buffers & Modifiers | High-quality buffers and acids (e.g., acetic acid, formic acid, phosphate buffers) are used to adjust mobile phase pH, critical for achieving optimal peak shape and resolution [22]. |

| Characterized Chromatographic Column | A column with known performance history and specifications (e.g., C18, particle size <2µm for UHPLC) that is qualified for the specific analytical method [23]. |

Navigating Regulatory Challenges in UHPLC/UFLC

The high efficiency of modern UHPLC/UFLC systems introduces unique regulatory considerations. Due to smaller peak widths, a relatively small change in relative retention (~2.5%) can reduce the resolution value by a large amount (~50%) [24]. This heightened sensitivity means that method robustness, particularly control of secondary interactions and instrument precision, must be investigated more rigorously than with traditional HPLC [24].

To mitigate this risk, a Quality by Design (QbD) approach is recommended during method development. Targeting higher resolution values (e.g., Rs ≥ 3.0) during development can build in a safety margin, improving the method's robustness against minor variations in column batches and instrument performance [24]. This proactive strategy is aligned with the principles of current Good Manufacturing Practice (cGMP), which emphasize the use of modern, sound science for continuous improvement [25].

In GMP and GLP environments, system suitability is a non-negotiable pillar of data integrity. It provides the documented assurance that an analytical system, whether HPLC or the more advanced UFLC-DAD, is fit-for-purpose before crucial data is collected. As regulatory scrutiny intensifies and technologies evolve, a deep understanding of SST parameters, coupled with rational method development and a proactive, risk-based approach, is indispensable for any scientist committed to achieving and maintaining regulatory compliance.

For researchers in drug development, ensuring audit readiness and data integrity is a critical component of bringing products to market. With regulatory bodies like the FDA releasing new guidance on analytical procedures, a robust framework for method validation and documentation is more important than ever [26]. This guide focuses on the validation of Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) methods, objectively comparing its performance and documentation needs against other common chromatographic techniques to ensure regulatory compliance.

Performance and Compliance Comparison of Chromatographic Techniques

Liquid chromatography techniques are foundational in pharmaceutical analysis, but they differ significantly in performance and regulatory suitability. The table below compares UFLC-DAD with two common alternatives: traditional High-Performance Liquid Chromatography (HPLC-DAD) and the more advanced Ultra-High-Performance Liquid Chromatography coupled with Mass Spectrometry (UHPLC-MS).

| Feature | UFLC-DAD | HPLC-DAD | UHPLC-MS |

|---|---|---|---|

| Typical Analysis Time | 16 minutes for 21 compounds [27] | 60-100 minutes for similar separations [18] | Under 15 minutes for some applications [28] |

| Key Advantage | Excellent balance of speed, cost, and performance for quantitative analysis of multiple compounds. | Well-established, widely available technology. | Superior sensitivity and compound identification capabilities. |

| Detection Method | Diode Array Detector (DAD) [27] | Diode Array Detector (DAD) [18] | Mass Spectrometer (MS) [28] |

| Detection Specificity | High (based on UV-Vis spectra and retention time) [29] | High (based on UV-Vis spectra and retention time) | Very High (based on mass-to-charge ratio) [28] |

| Instrument Cost | Moderate | Moderate to Low | High [30] |

| Best Suited For | High-throughput, quantitative routine analysis of known compounds with UV chromophores. | Routine analysis where maximum speed is not critical. | Trace analysis, unknown identification, and complex matrices. |

| Regulatory Documentation Focus | Full validation of DAD's specificity and stability-indicating properties; system suitability for speed. | Standard method validation parameters; instrument qualification. | Extensive validation of MS interface and sensitivity; software data integrity. |

Experimental Protocols for Method Validation

For any analytical procedure to be deemed suitable for regulatory submission, it must undergo a rigorous validation process. The International Council for Harmonisation (ICH) guidelines Q2(R2) and Q14 provide the framework for this process, which confirms the method is fit for its intended purpose [26].

Core Validation Parameters and Protocols

The following parameters must be documented to demonstrate method robustness and ensure data integrity:

- Specificity: The protocol must demonstrate that the method can unequivocally assess the analyte in the presence of potential interferences like impurities, degradants, or matrix components [31]. For a UFLC-DAD method, this is typically proven by injecting blank samples, placebo formulations, and stressed samples (e.g., exposed to heat, light, or acid/base) and showing that the analyte peak is pure and free from co-elution. The DAD's ability to provide peak purity assessments is a key documentation output [29].

- Linearity and Range: A series of standard solutions across a defined range (e.g., 50-150% of the target concentration) are prepared and analyzed. The results are plotted as analyte response versus concentration. The method demonstrates linearity if the data fits a linear model with a correlation coefficient (R²) of >0.999, as seen in a UPLC-DAD method for polyphenols [18].

- Accuracy: This measures the closeness of test results to the true value, often established through recovery studies [31]. Samples are spiked with known quantities of the analyte at multiple levels (e.g., 80%, 100%, 120%). The accuracy is calculated as the percentage of the analyte recovered, with acceptable ranges typically between 95-105%, as demonstrated in a UFLC-MS study [27].

- Precision: This includes repeatability (intra-day precision) and intermediate precision (inter-day, analyst-to-analyst, or instrument-to-instrument variation) [31]. Multiple homogenous samples are analyzed under the prescribed conditions. The results are expressed as the percent relative standard deviation (%RSD). An RSD of less than 5% is generally acceptable for intermediate precision, as shown in a UPLC-DAD method validation [18].

- Limits of Detection and Quantification (LOD & LOQ): LOD and LOQ represent the lowest levels an analyte can be reliably detected or quantified, respectively [31]. These can be determined based on the signal-to-noise ratio (typically 3:1 for LOD and 10:1 for LOQ) [32]. For example, an LOD as low as 0.0074 mg/L was achieved for certain polyphenols using UPLC-DAD [18].

- Robustness: This evaluates the method's reliability when small, deliberate changes are made to operational parameters (e.g., mobile phase pH ±0.1, column temperature ±2°C, flow rate ±5%) [33]. The system suitability criteria (e.g., retention time, peak tailing, resolution) must be met throughout these variations to prove the method is robust.

Workflow for Analytical Method Lifecycle

The following diagram illustrates the key stages of the analytical procedure lifecycle, from development to post-approval management, highlighting the documentation required at each phase.

The Scientist's Toolkit: Essential Reagents and Materials

The integrity of analytical results depends on the quality of the materials used. Below is a list of essential items for developing and running a compliant UFLC-DAD method.

| Item | Function | Example from Research |

|---|---|---|

| C18 Reversed-Phase Column | The core of separation; separates compounds based on hydrophobicity. | A Waters XBridge C18 column was used for analyzing Gardenia jasminoides [27]. |

| Reference Standards | Used to identify compounds (via retention time) and create calibration curves for quantification. | High-purity standards are essential, as used for 38 polyphenols [18] and 21 compounds in Gardenia [27]. |

| MS-Grade Solvents & Modifiers | High-purity mobile phase components (e.g., acetonitrile, water, formic acid) ensure low background noise and reproducible results. | MS-grade acetonitrile and 0.1% formic acid were used in UFLC-MS analysis [27]. |

| Syringe Filters | Remove particulate matter from samples to protect the expensive chromatography column and instrument. | 0.22 µm filters were used for sample filtration in a UFLC-MS method [27]. |

| System Suitability Standards | A test mixture used to verify that the entire chromatographic system is performing adequately before analysis begins. | While not explicitly listed, this is a critical GMP requirement for ensuring data validity [31] [33]. |

Documentation for Audit Readiness

A successful audit hinges on demonstrating control over the entire analytical process. Key documentation includes:

- Instrument Qualification Records (DQ/IQ/OQ/PQ): Proof that the UFLC-DAD system was properly designed, installed, and operates according to specifications [34] [33].

- Method Validation Report: The comprehensive report, signed by responsible personnel, summarizing all data and results for each validation parameter as per ICH Q2(R2) [26] [31].

- Electronic Data Integrity: Secure, audit-trailed raw data files from the DAD and chromatography data system (CDS). The FDA emphasizes data integrity in all compliance activities.

- Change Control Documentation: A complete log of any changes to the method or instrumentation, with impact assessments and re-validation data as required by ICH Q12 [26].

- Standard Operating Procedures (SOPs): Approved SOPs for the analytical method itself, instrument operation, and data management ensure consistency and compliance [34].

In summary, selecting UFLC-DAD provides an excellent balance of speed, cost, and data richness for regulatory compliance. Its successful implementation, however, is guaranteed only by a meticulous validation process and unwavering commitment to documentation protocols that ensure data integrity and perpetual audit readiness.

From Theory to Practice: A Step-by-Step Guide to UFLC-DAD Method Development

Method Scoping and Sample Preparation for Complex Matrices

In pharmaceutical development and regulatory compliance research, the analysis of complex biological and formulation matrices presents significant challenges. The journey from a raw sample to a reliable, quantitative result is a multifaceted process, the foundation of which is a well-scoped analytical method and a robust sample preparation protocol. This guide objectively compares the performance of modern chromatographic techniques, with a specific focus on validating Ultra-Fast Liquid Chromatography coupled with Diode Array Detection (UFLC-DAD) methods. The framework is situated within the contemporary regulatory landscape defined by ICH Q2(R2) and ICH Q14 guidelines, which emphasize a science- and risk-based approach to analytical procedure development and validation [7]. The fitness of an analytical method for its intended use is proven through rigorous validation, which provides regulators and scientists with confidence in the generated data for drug approval and quality control [7].

The process, from sample collection to data reporting, involves a series of critical and interconnected steps, as visualized below.

Comparative Performance of Analytical Techniques

Selecting the appropriate analytical technique is a critical decision that balances performance requirements, matrix complexity, and operational constraints. The following table provides a data-driven comparison of several chromatographic methods, based on recent experimental studies.

Table 1: Quantitative Performance Comparison of Chromatographic Techniques for Complex Matrices

| Technique | Application Example | Key Performance Metrics | Analysis Time | Major Advantages | Notable Limitations |

|---|---|---|---|---|---|

| UFLC-DAD | Quantification of 38 polyphenols in applewood extract [18] | Linearity: R² > 0.999 [18]LOD/LOQ: 0.0074-0.1179 / 0.0225-0.3572 mg/L [18]Accuracy: 95.0-104% Recovery [18]Precision: RSD < 5% [18] | 21 minutes [18] | High throughput, cost-effective for routine analysis, provides spectral confirmation with DAD [18]. | Lower specificity for co-eluting peaks compared to MS; may require more sample cleanup. |

| UFLC-MS/MS (MRM) | Multicomponent analysis of 21 bioactive compounds in Gardenia jasminoides [27] | High sensitivity and selectivity for complex herbal matrix; method validated per ICH guidelines [27]. | 16 minutes [27] | Unparalleled specificity and sensitivity; ideal for trace analysis and structural confirmation [27]. | High instrument cost and operational complexity; requires skilled personnel. |

| SFC-ESI-QqQ-MS/MS | Simultaneous analysis of 8 aldehydes in edible oils and foods [35] | Linearity: R² ≥ 0.9995 [35]LOD/LOQ: 0.05-0.60 / 0.15-1.80 μg/kg [35]Accuracy: 85.84-106.71% Recovery [35]Precision: RSD < 7.86% [35] | 16 minutes [35] | Excellent for weakly polar compounds; low solvent consumption; high ionization efficiency [35]. | Limited method history for some analytes; requires optimization of backpressure and modifier. |

| HPLC-DAD | Stability-indicating assay for Ornidazole in polymeric hydrogel [36] | Linearity: R² = 0.9998 [36]LOD/LOQ: 0.23 / 0.70 μg/mL [36]Precision: RSD < 0.879% [36] | >20 minutes (gradient) [36] | Robust and widely available; well-understood; suitable for forced degradation studies [36]. | Slower than UPLC/UFLC; lower peak capacity and resolution. |

As evidenced by the data, UFLC-DAD demonstrates exceptional performance for multi-analyte quantification in complex natural product matrices, offering an optimal balance of speed, precision, and cost-efficiency for quality control laboratories [18]. The UFLC-MS/MS platform, while more expensive, provides definitive identification and superior sensitivity for trace-level analytes or highly complex biological matrices [27]. SFC-MS/MS emerges as a powerful alternative for specific applications, particularly for non-polar analytes, offering impressive green chemistry credentials [35].

Sample Preparation Strategies for Complex Matrices

Effective sample preparation is paramount to mitigating matrix effects and ensuring the accuracy and longevity of the analytical system. The approach must be tailored to the physicochemical properties of the analyte and the nature of the sample matrix [37].

Table 2: Common Sample Preparation Techniques for Complex Matrices

| Technique | Principle & Procedure | Best Suited For | Considerations |

|---|---|---|---|

| Solid-Phase Extraction (SPE) | Sample is passed through a cartridge containing a sorbent. Analytes are retained, interferences are washed off, and analytes are eluted with a strong solvent [37]. | Pre-concentrating trace analytes from large volumes of aqueous samples (e.g., environmental water) [37]; purifying samples for vitamin analysis [38]. | Highly versatile with multiple sorbent chemistries available; can be automated but may add cost and time. |

| Liquid-Liquid Extraction (LLE) | Relies on the differential solubility of an analyte in two immiscible solvents (e.g., organic and aqueous phases) [37]. | Extracting analytes from biological fluids or food homogenates. | Effective for many applications but can be labor-intensive and generate large volumes of organic waste. |

| Derivatization | A chemical reaction is performed to convert the analyte into a derivative with more favorable properties (e.g., higher detectability or volatility) [37]. | Analytes with poor detector response (e.g., pre-column oxidation of non-fluorescent vitamin B1 to fluorescent thiochrome) [38]; stabilizing reactive aldehydes via DNPH derivatization [35]. | Can significantly enhance sensitivity and specificity but adds a reaction step that must be controlled for reproducibility. |

| Protein Precipitation | Adding an organic solvent (e.g., methanol, acetonitrile) to a biological sample (e.g., plasma) to denature and precipitate proteins, which are then removed by centrifugation [39]. | Rapid cleanup of biological samples like plasma or serum prior to analysis [39]. | Simple and fast, but may not remove all interferences and can dilute the sample. |

| QuEChERS | (Quick, Easy, Cheap, Effective, Rugged, and Safe) Involves salting-out extraction with acetonitrile followed by a dispersive-SPE cleanup step. | Multi-residue analysis of pesticides, mycotoxins, and other contaminants in food. | Not explicitly detailed in results, but is a standard high-throughput approach for food and environmental matrices. |

The choice of sample preparation strategy directly impacts the final results. For instance, in the analysis of B vitamins in complex supplements and gastrointestinal fluids, a combination of techniques was employed: a simple liquid/solid extraction for pharmaceutical gummies and a more selective Solid Phase Extraction (SPE) for the complex biological fluids, resulting in excellent recoveries (>99.8% and 100 ± 5%, respectively) [38]. Similarly, the successful SFC-MS/MS analysis of aldehydes in oils relied on a one-step solvent extraction combined with DNPH derivatization, which trapped the reactive analytes and allowed for sensitive detection [35].

Experimental Protocols for UFLC-DAD Method Validation

Detailed Protocol: Validation of a UFLC-DAD Method for Polyphenols

The following protocol is adapted from a study that successfully validated a method for 38 polyphenols, demonstrating compliance with ICH standards [18].

- Instrumentation: UFLC system equipped with a quaternary pump, autosampler, thermostatted column compartment, and Diode Array Detector (DAD). A C18 reverse-phase column (e.g., 100 mm x 2.1 mm, 1.7 μm) is recommended for optimal speed and resolution.

- Chromatographic Conditions:

- Mobile Phase: Solvent A (0.1% formic acid in water) and Solvent B (0.1% formic acid in acetonitrile).

- Gradient Elution: Optimized from an initial 5% B to 95% B over 21 minutes, with a re-equilibration time.

- Flow Rate: 0.4 mL/min.

- Column Temperature: 40 °C.

- Injection Volume: 2 μL.

- DAD Detection: Wavelength range 190-400 nm, with specific quantification at the λ-max for each polyphenol (e.g., 280 nm for flavan-3-ols, 360 nm for flavonols).

- Sample Preparation: Applewood powder was extracted with 70% methanol via ultrasonication. The extract was centrifuged, and the supernatant was filtered through a 0.22 μm membrane prior to injection [18].

- Validation Experiments as per ICH Q2(R2) [7] [18]:

- Linearity & Range: Prepare a minimum of 5 concentrations of standard solutions in duplicate. Plot peak area versus concentration and calculate the regression coefficient (R²). Acceptance criterion: R² > 0.999.

- Accuracy (Recovery): Spike a pre-analyzed sample with known quantities of standard at three levels (e.g., 80%, 100%, 120%). Calculate the percentage recovery of the added analyte. Acceptance criterion: 95-105% recovery.

- Precision:

- Repeatability (Intra-day): Inject six independent preparations of the same sample (100% level) in one day. Calculate the %RSD of the peak areas. Acceptance criterion: RSD < 2%.

- Intermediate Precision (Inter-day): Repeat the repeatability study on a different day, with a different analyst and/or different instrument. Acceptance criterion: RSD < 5% for the combined data.

- Specificity: Inject the blank (extraction solvent), standard, and sample. Demonstrate that the peak for each analyte is pure, with no co-eluting interferences from the matrix. The DAD's spectral overlay capability is critical here to confirm peak purity.

- Limit of Detection (LOD) & Quantification (LOQ): Determine based on signal-to-noise ratio (typically 3:1 for LOD and 10:1 for LOQ) by injecting a series of dilute standard solutions.

- Robustness: Deliberately introduce small variations in method parameters (e.g., flow rate ±0.05 mL/min, column temperature ±2°C, mobile phase pH ±0.1 units) and evaluate the system suitability criteria (retention time, resolution, tailing factor).

Case Study: Overcoming Isomer Co-elution with DAD

A key strength of the DAD detector is its ability to provide spectral information that MS alone may not, which is critical for confirming the identity of co-eluting isomers. In a forensic study, 3-chloromethcathinone (3-CMC) and 4-chloromethcathinone (4-CMC) were indistinguishable by GC-MS and LC-MS/MS alone due to identical mass spectra and similar retention times. However, the LC-DAD/MS method clearly distinguished them by their unique ultraviolet absorption spectra (maxima at 210/250 nm for 3-CMC and 197/262 nm for 4-CMC) [40]. This case underscores that for regulatory compliance, where definitive identification is required, the hyphenation of DAD with MS provides a powerful orthogonal identification tool.

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Key Research Reagent Solutions for UFLC-DAD Analysis

| Item | Function/Application | Example from Literature |

|---|---|---|

| High-Purity Solvents & Additives | Mobile phase components; sample reconstitution. Essential for low baseline noise and avoiding ghost peaks. | MS-grade acetonitrile, methanol, and water; HPLC-grade formic acid [27]. |

| Certified Reference Standards | Method development, calibration, and quantification. Purity is critical for accurate results. | Commercially sourced polyphenol [18], vitamin [38], or drug [36] standards of known purity (>95-99.8%). |

| Stable Isotope-Labeled Internal Standards | Corrects for analyte loss during preparation and matrix effects during ionization (for LC-MS). | Use of ¹³C or ¹⁵N labeled standards is preferred over deuterated ones to avoid chromatographic isotope effects [37]. |

| SPE Cartridges & Sorbents | Selective sample clean-up and pre-concentration. | C18 sorbents for reversed-phase extraction of a wide range of analytes from aqueous samples [38] [37]. |

| Derivatization Reagents | Chemically modify analytes to improve detection (e.g., fluorescence, UV absorption) or stability. | 2,4-dinitrophenylhydrazine (DNPH) for derivatizing aldehydes [35]; oxidizing agents for converting vitamin B1 to thiochrome [38]. |

| Syringe Filters | Removal of particulate matter from samples prior to injection to protect the chromatographic system. | 0.22 μm pore size, nylon or PTFE membrane, compatible with the sample solvent [36]. |

The journey to regulatory compliance for a drug product is underpinned by reliable analytical data. This guide has demonstrated that UFLC-DAD is a highly capable and cost-effective platform for the quantitative analysis of complex matrices, particularly in quality control environments where throughput, operational cost, and method robustness are paramount. Its performance is complemented and extended by mass spectrometric detection for applications requiring ultimate sensitivity and specificity. The successful implementation of any analytical method, however, is inextricably linked to a meticulously planned and executed sample preparation protocol and a rigorous validation process conducted within the modern ICH Q2(R2) and Q14 lifecycle framework. By understanding the comparative strengths of available techniques and adhering to a systematic, science-based approach to method scoping and validation, researchers and drug development professionals can ensure their analytical procedures are fit-for-purpose and meet the stringent demands of global regulators.

In the pharmaceutical industry, the development of robust Ultra-Fast Liquid Chromatography (UFLC) methods is paramount for ensuring drug quality, safety, and efficacy. Method validation demonstrates that an analytical procedure is suitable for its intended purpose and meets regulatory standards set forth by agencies like the U.S. Food and Drug Administration (FDA) and European Medicines Agency (EMA). The optimization of chromatographic conditions—specifically mobile phase composition, column selection, and gradient programming—represents a critical foundation for developing validated methods that provide accurate, precise, and reproducible results. This guide examines the strategic selection of these key parameters within the context of regulatory compliance, providing comparative experimental data to inform method development decisions for researchers and drug development professionals.

The evolution of liquid chromatography from traditional HPLC to UHPLC and UFLC systems has significantly enhanced analytical capabilities. Ultra-High-Performance Liquid Chromatography (UHPLC) utilizes particles smaller than 2µm and operates at pressures up to 1,500 bar, dramatically increasing separation efficiency, speed, and sensitivity compared to conventional HPLC with its 5µm particles and 400-bar pressure limits [41]. These technological advances enable more precise separations but also demand more sophisticated method development and validation approaches to meet stringent regulatory requirements for drug approval and quality control.

Fundamental Principles of Chromatographic Optimization

The Role of the Mobile Phase in Separation Efficiency

The mobile phase serves as the transport medium that carries analytes through the chromatographic system, playing a crucial role in separation efficiency by controlling the differential migration of sample components. Its composition directly governs analyte retention, selectivity, and peak shape by modulating interactions between analytes and the stationary phase [42]. In reversed-phase chromatography, the most common mode for pharmaceutical analysis, the mobile phase typically consists of water (polar solvent) mixed with organic modifiers such as acetonitrile or methanol, which adjust elution strength [42].

Several critical factors must be considered when selecting an optimal mobile phase. Solvent polarity must be balanced to achieve adequate retention and resolution; in reversed-phase systems, less polar organic solvents are mixed with water to elute non-polar compounds while retaining polar ones longer [42]. The pH of the mobile phase profoundly influences the ionization state of ionizable analytes, affecting their retention and separation efficiency; proper pH control is essential for reproducible methods [42]. Buffer systems maintain stable pH levels throughout the analysis, while additives such as formic acid or volatile salts can enhance ionization efficiency in mass spectrometry detection and improve peak shapes [43] [42].

Column Selection Criteria

Chromatographic column selection fundamentally determines the separation mechanism and efficiency. Key parameters include stationary phase chemistry (C18, C8, phenyl, etc.), which defines the primary interaction mechanism with analytes; particle size (conventional 5µm, UHPLC sub-2µm), where smaller particles increase efficiency but require higher pressures; pore size (typically 80-120Å for small molecules), affecting analyte access to the stationary phase; and column dimensions (length and internal diameter), which influence retention time, resolution, and solvent consumption [41].

The evolution from HPLC to UHPLC has driven the adoption of columns packed with smaller particles. HPLC columns traditionally use 5µm particles, providing a balance of efficiency and pressure requirements. In contrast, UHPLC columns employ sub-2µm particles, offering significantly enhanced separation efficiency and faster analyses but requiring instrumentation capable of withstanding much higher operating pressures [41].

Gradient Elution Optimization Strategies

Gradient elution, where mobile phase composition changes systematically during the separation, is essential for analyzing complex mixtures containing components with widely varying polarities. Effective gradient optimization involves balancing analysis time with resolution requirements while ensuring method robustness and transferability [44].

Critical considerations in gradient method development include initial and final solvent strength, determining the retention range of separated compounds; gradient steepness (change in organic modifier per unit time), affecting resolution and analysis time; gradient shape (linear, multi-linear, curved), which can optimize specific difficult separations; and equilibration time between runs, crucial for retention time reproducibility [44]. The gradient delay volume of each instrument must be considered, as differences between systems can cause method transfer challenges unless properly compensated [44].

Table 1: Key Parameters for Chromatographic Condition Optimization

| Parameter | Optimization Considerations | Impact on Separation |

|---|---|---|

| Mobile Phase | Organic modifier type and ratio, pH, buffer concentration, additives | Retention, selectivity, peak shape, detection compatibility |

| Column | Stationary phase chemistry, particle size, dimensions, temperature | Efficiency, resolution, backpressure, analysis time |

| Gradient | Initial/final organic %, slope, time, equilibration | Resolution of complex mixtures, analysis duration, re-equilibration |

Comparative Analysis of Chromatographic Systems and Conditions

HPLC vs. UHPLC: System Performance Comparison

The evolution from HPLC to UHPLC represents a significant advancement in separation technology, with each system offering distinct advantages depending on application requirements. HPLC systems operate at pressures up to 400 bar using columns packed with 5µm particles, providing robust, reliable separations with lower instrumental requirements [41]. UHPLC systems utilize sub-2µm particles and operate at pressures up to 1,500 bar, delivering superior resolution, faster analysis times, and enhanced sensitivity, but requiring more sophisticated instrumentation [41].

Recent advancements in both technologies continue to enhance their capabilities. New HPLC systems introduced in 2024-2025, such as the Shimadzu i-Series, feature improved compact designs, energy efficiency, and detector flexibility while maintaining compatibility with existing methods [45]. Modern UHPLC systems, including the Thermo Fisher Vanquish Neo, incorporate innovative workflows like tandem direct injection for parallel column equilibration, further reducing analysis times in high-throughput environments [45].

Table 2: HPLC vs. UHPLC System Comparison

| Characteristic | HPLC | UHPLC |

|---|---|---|

| Particle Size | 5µm or larger | Typically <2µm |

| Operating Pressure | Up to 400 bar | Up to 1,500 bar |

| Separation Efficiency | Good | Superior |

| Analysis Speed | Standard | 2-3x faster |

| Solvent Consumption | Higher | Reduced |

| Method Transfer | Straightforward | Requires adjustment |

| Instrument Cost | Lower | Higher |

Mobile Phase Composition: Experimental Comparisons

Mobile phase composition significantly impacts chromatographic performance, with different modifiers and additives yielding substantially different separation outcomes. A study validating an HPLC-DAD method for quercitrin quantification in peppers utilized a mobile phase consisting of 0.1% formic acid in water (solvent A) and 100% methanol (solvent B) with a gradient elution program, achieving excellent peak shape and resolution with a correlation coefficient (R²) > 0.9997 [46]. This demonstrates how acidic additives can improve peak shapes for certain compounds while maintaining MS-compatibility.

In contrast, research developing a UHPLC-MS/MS method for almonertinib quantification employed 0.1% formic acid-water and methanol as the mobile phase with a different gradient profile, resulting in sharp peaks and a retention time of 2.08 minutes for the target analyte [43]. The method demonstrated excellent linearity from 0.1–1000 ng/mL (R² = 0.999) and was fully validated for selectivity, accuracy, precision, and stability, making it suitable for pharmacokinetic studies [43]. These comparative examples illustrate how mobile phase selection must be tailored to both the specific analytes and the detection technique employed.

Column Chemistry and Dimensions: Performance Data

Column selection profoundly influences separation outcomes, with different stationary phases and dimensions offering distinct advantages. A method for quercitrin quantification utilized a CAPCELL PAK C18 UG120 column (4.6×250 mm, 5µm) at 40°C, providing sufficient resolution for accurate quantification in a complex plant extract matrix [46]. The longer column contributed to enhanced theoretical plates, critical for separating structurally similar compounds.